The Green Approach to the Synthesis of Bio-Based Thermoplastic Polyurethane Elastomers with Partially Bio-Based Hard Blocks

Abstract

1. Introduction

2. Materials and Methods

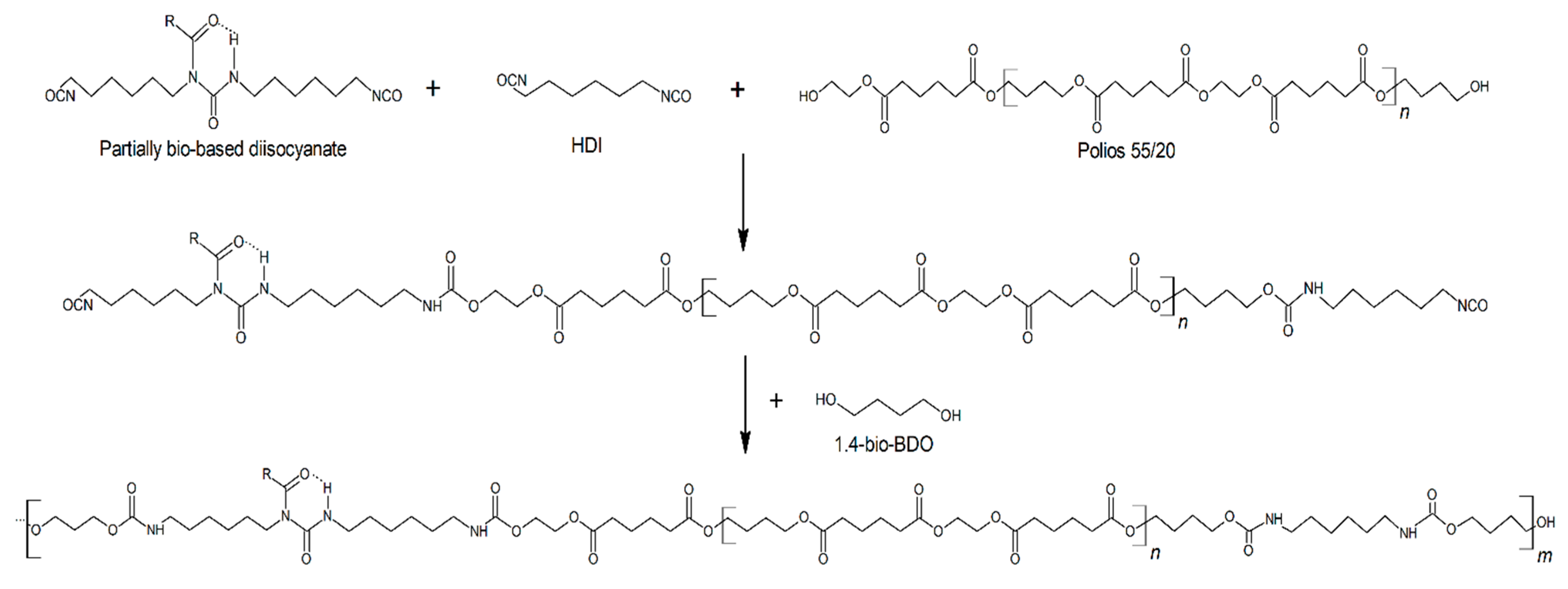

2.1. Samples Preparation

2.2. Measurement

2.2.1. Fourier Transform Infrared Spectroscopy—FTIR

2.2.2. Differential Scanning Calorimetry—DSC

2.2.3. Dynamic Mechanical Analysis—DMA

2.2.4. Thermogravimetric Analysis—TGA

2.2.5. X-ray Diffraction (XRD)

2.2.6. Tensile Test

2.2.7. Hardness

3. Results and Discussion

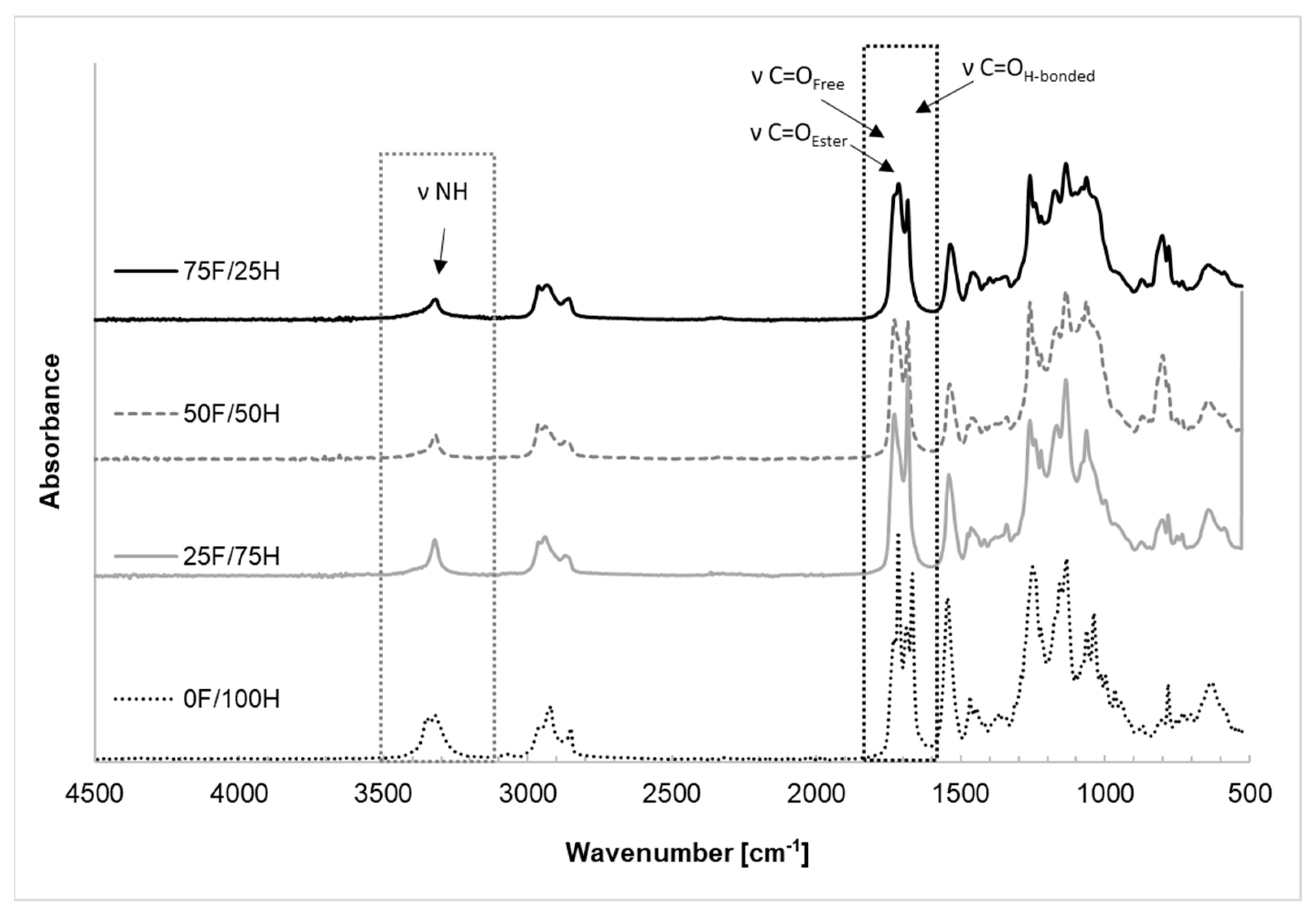

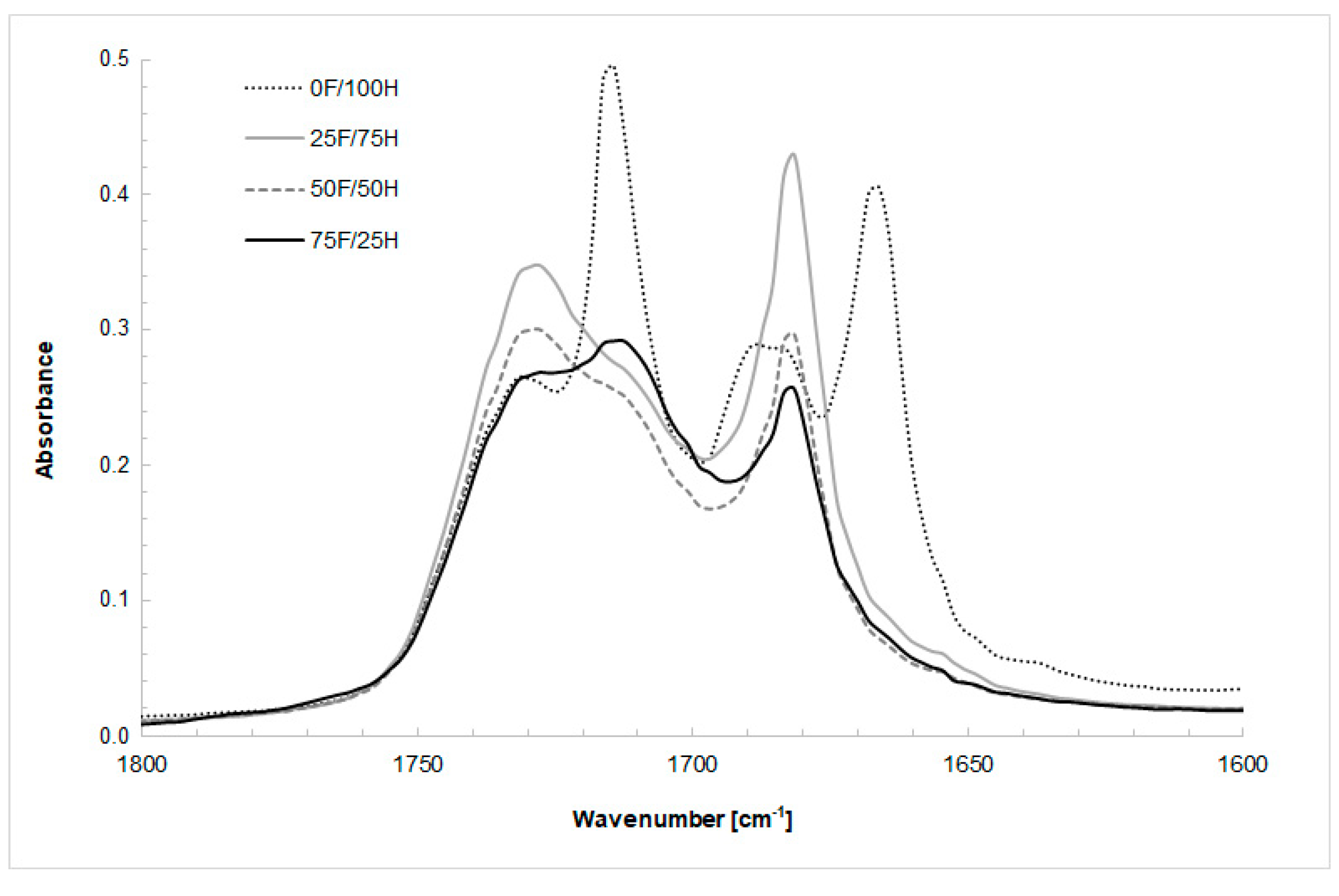

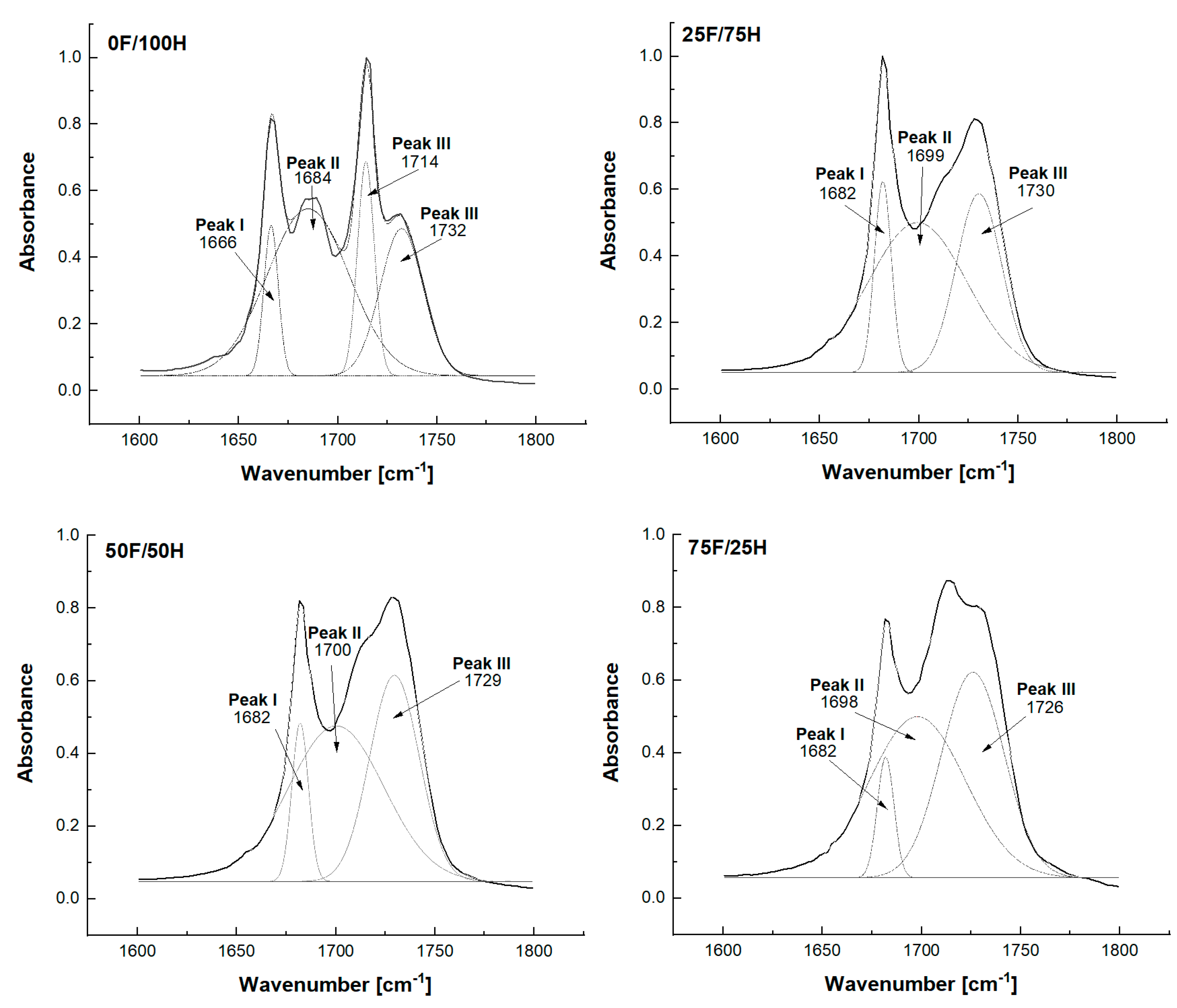

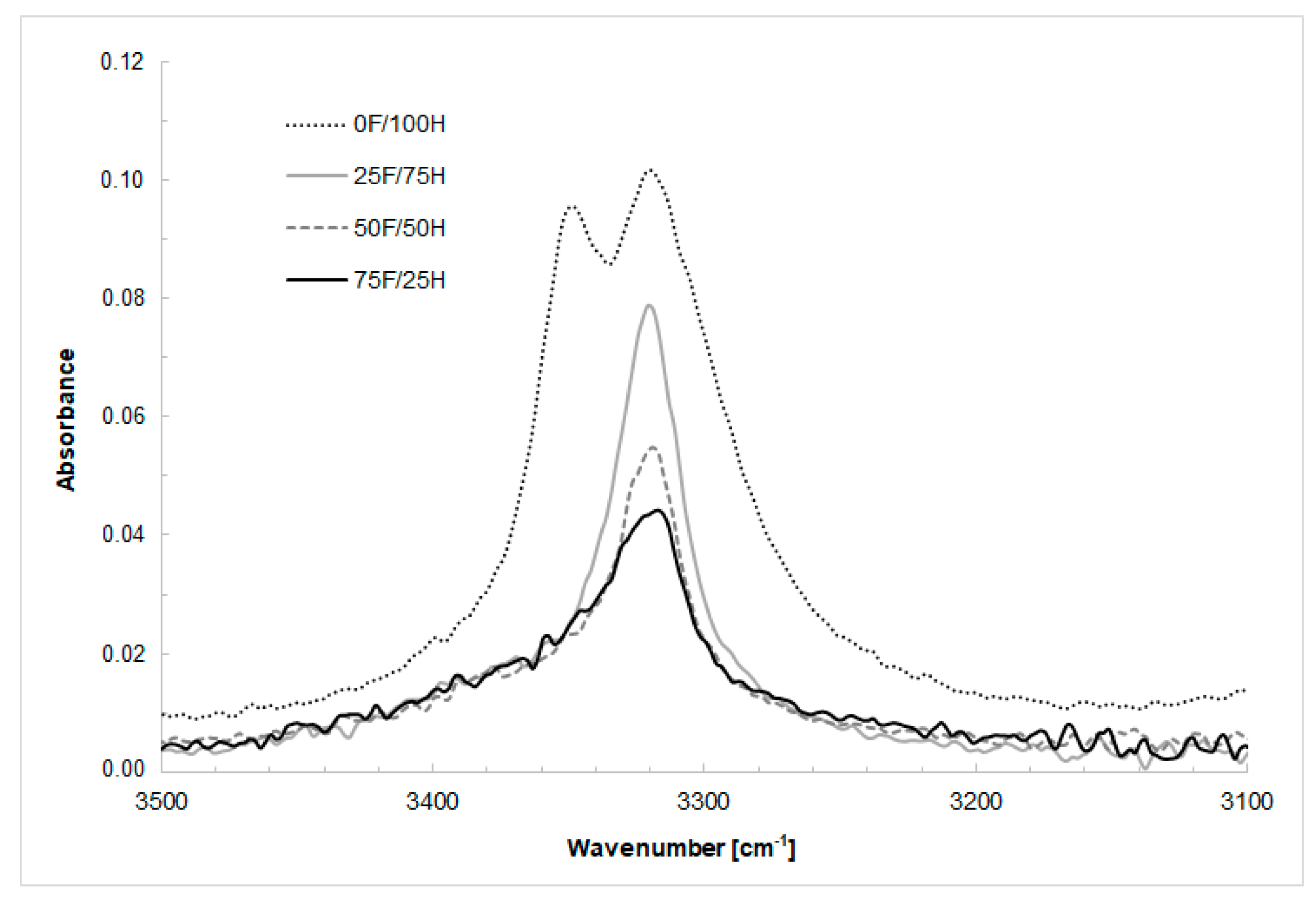

3.1. FT-IR Spectroscopy Analysis

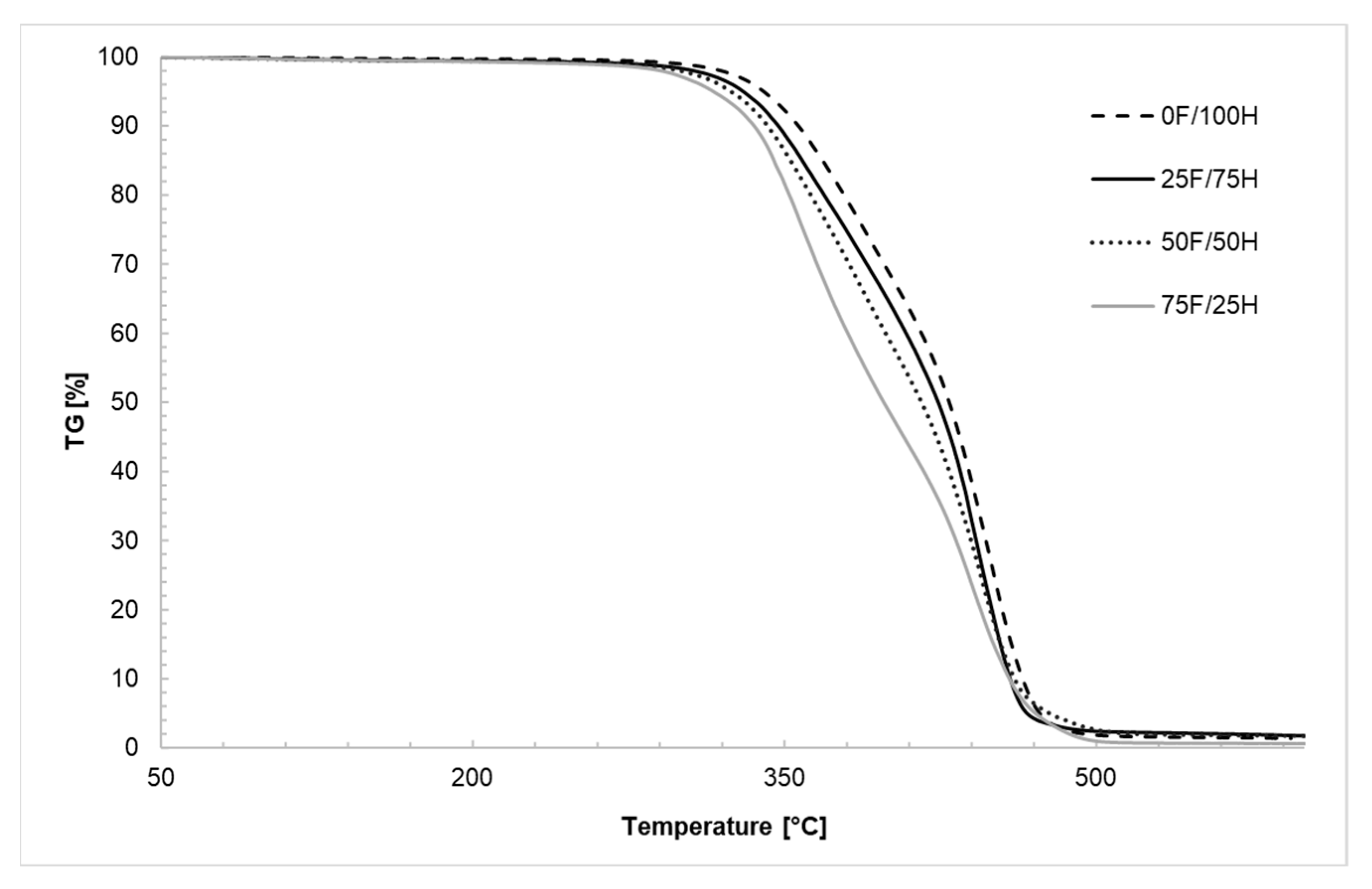

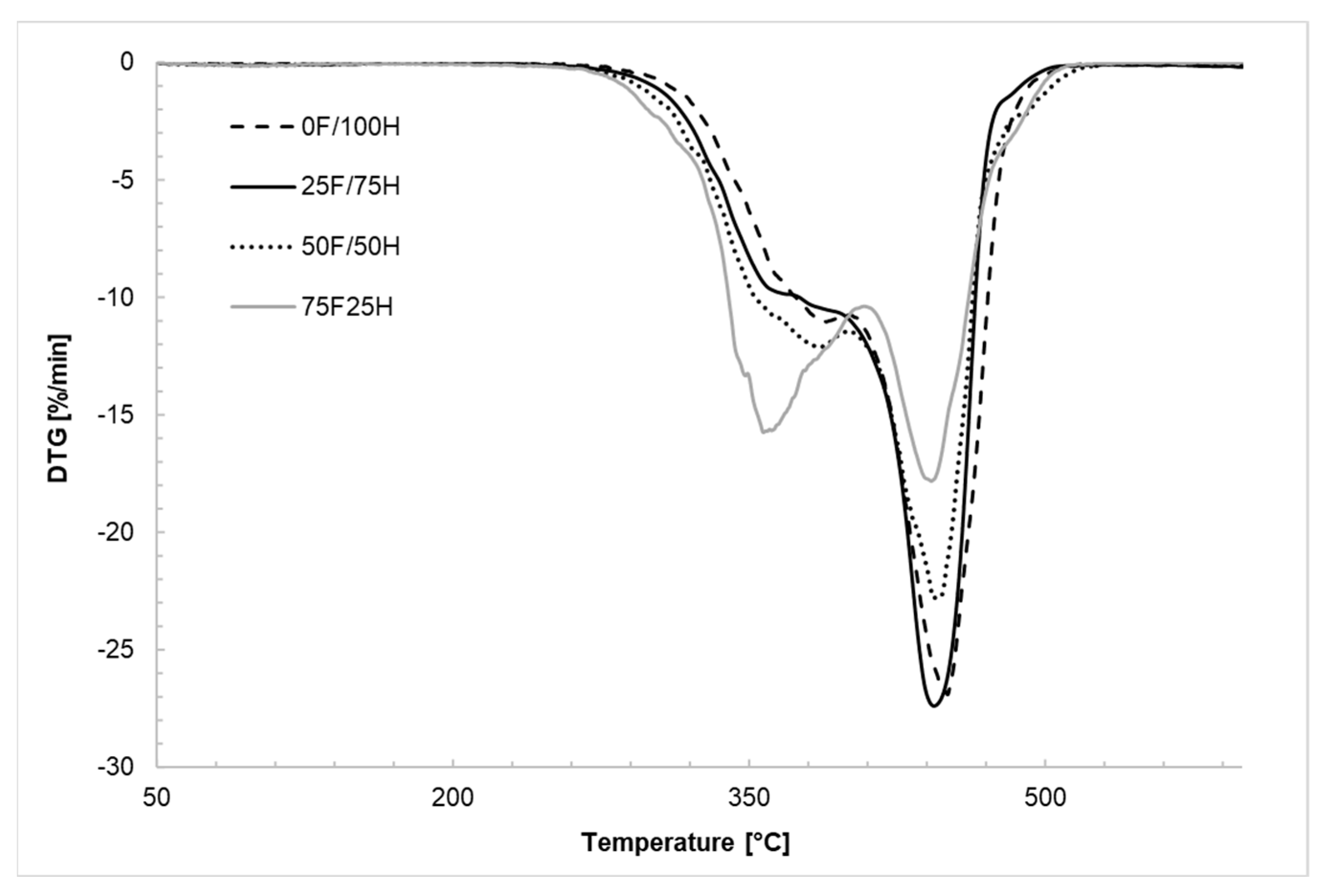

3.2. Thermogravimetric Analysis

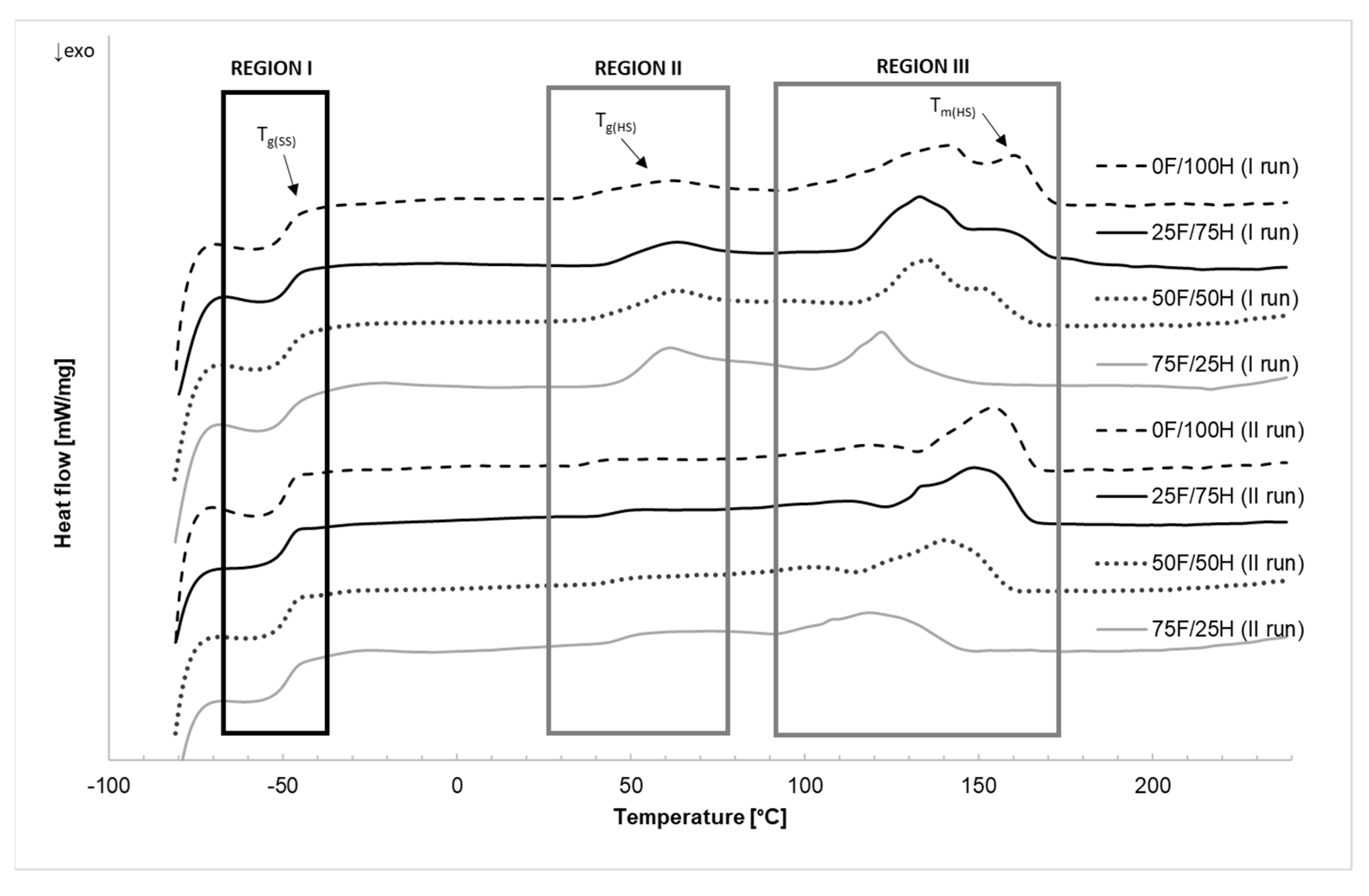

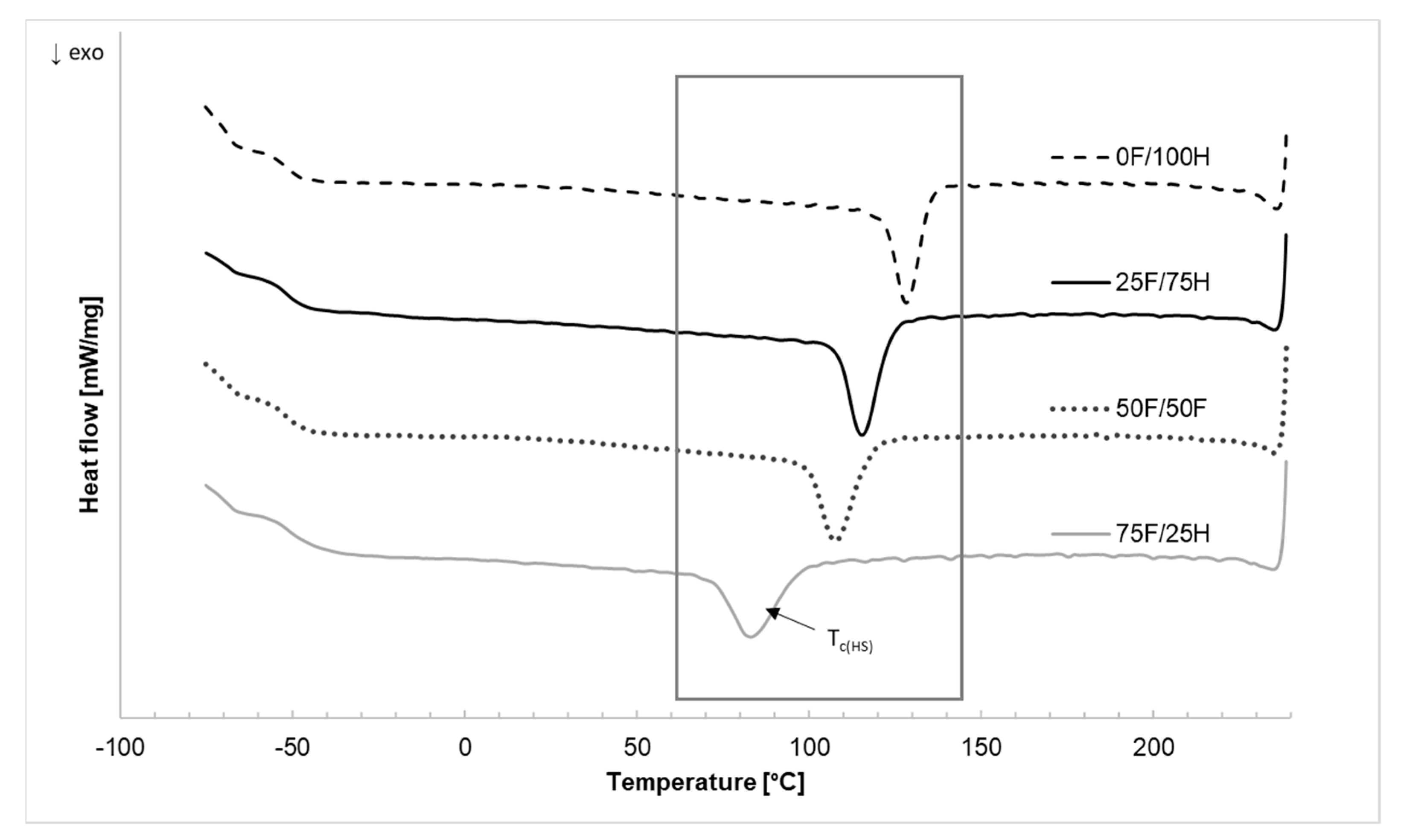

3.3. Differential Scanning Calorimetry

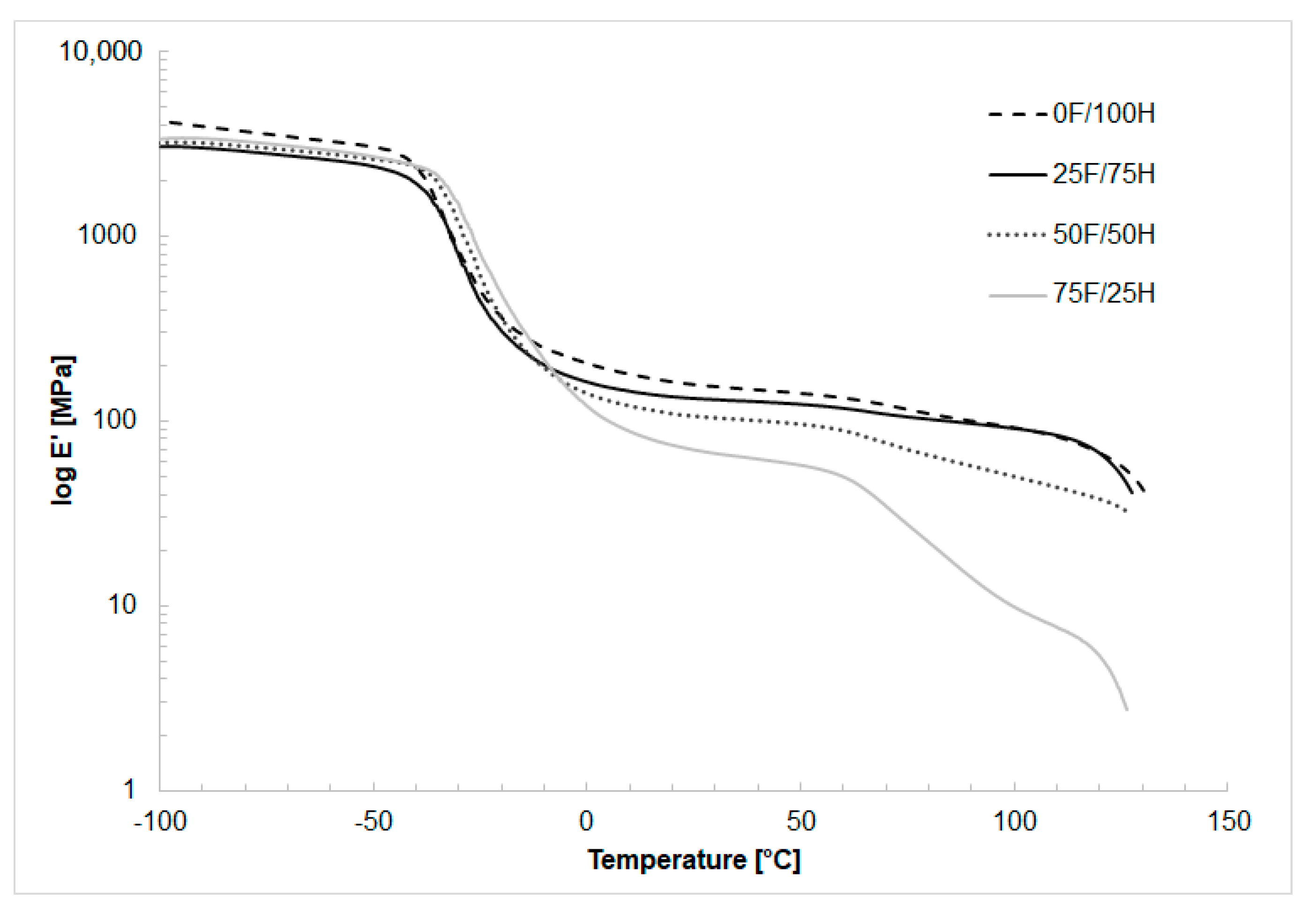

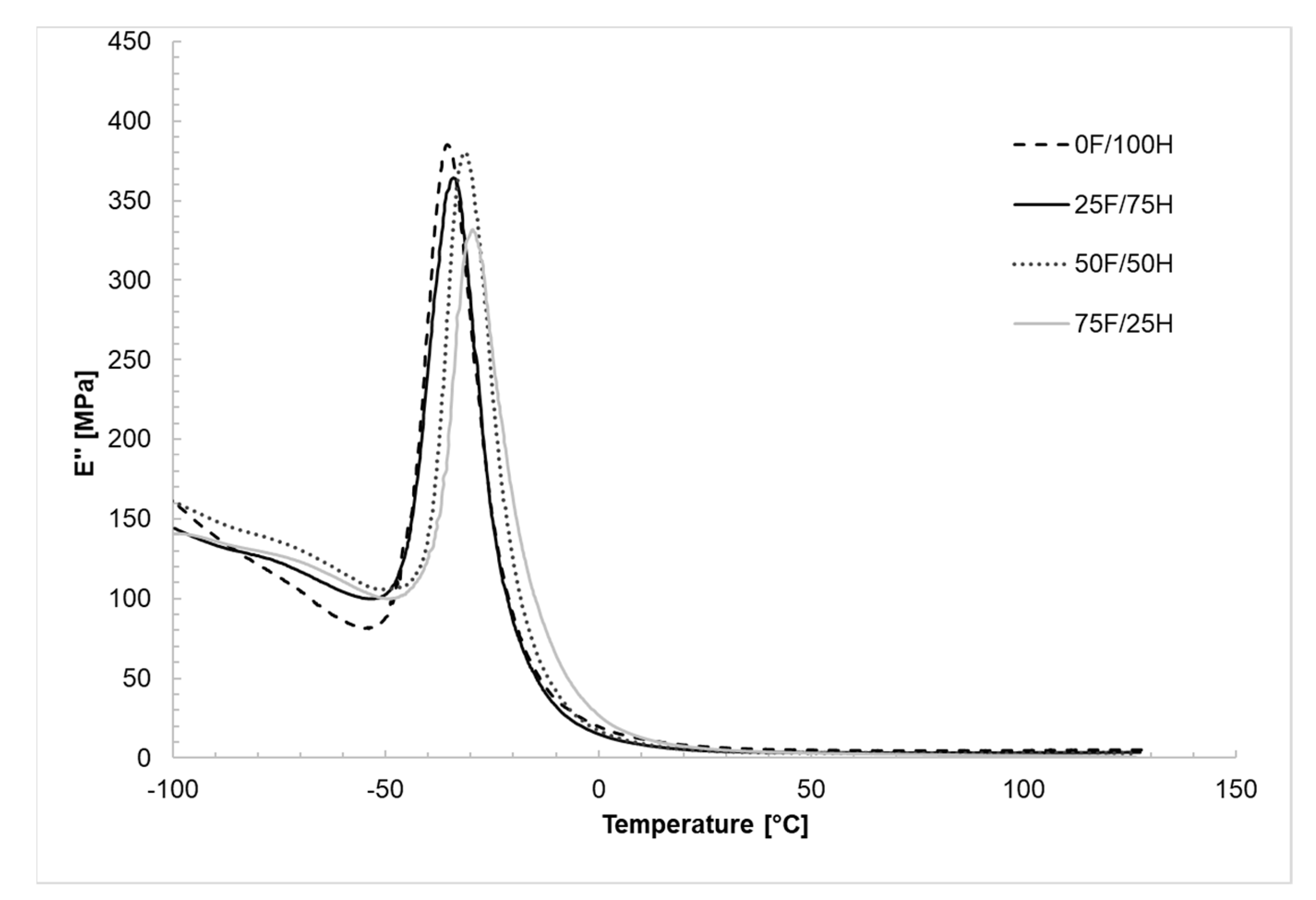

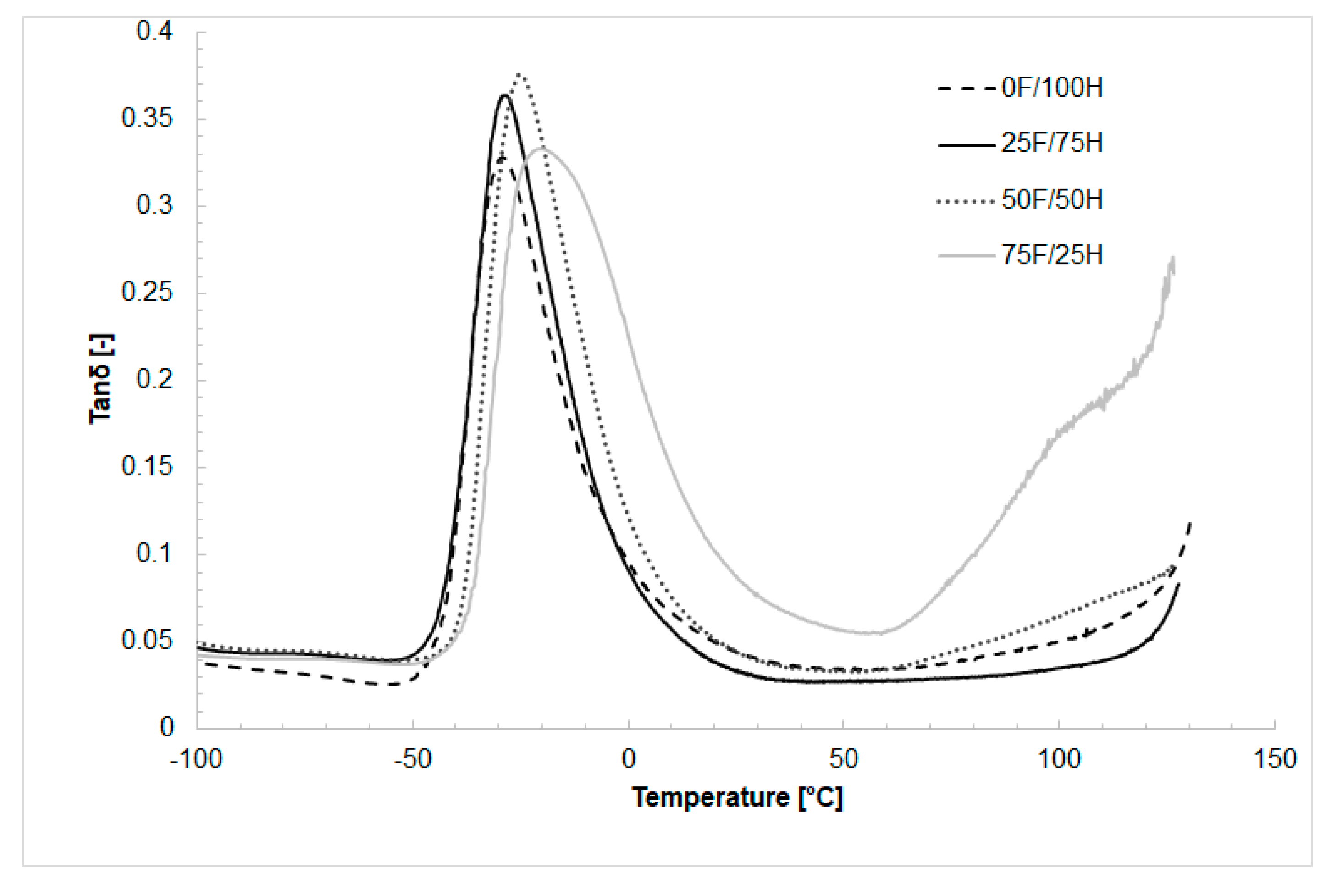

3.4. Dynamic Mechanical Analysis

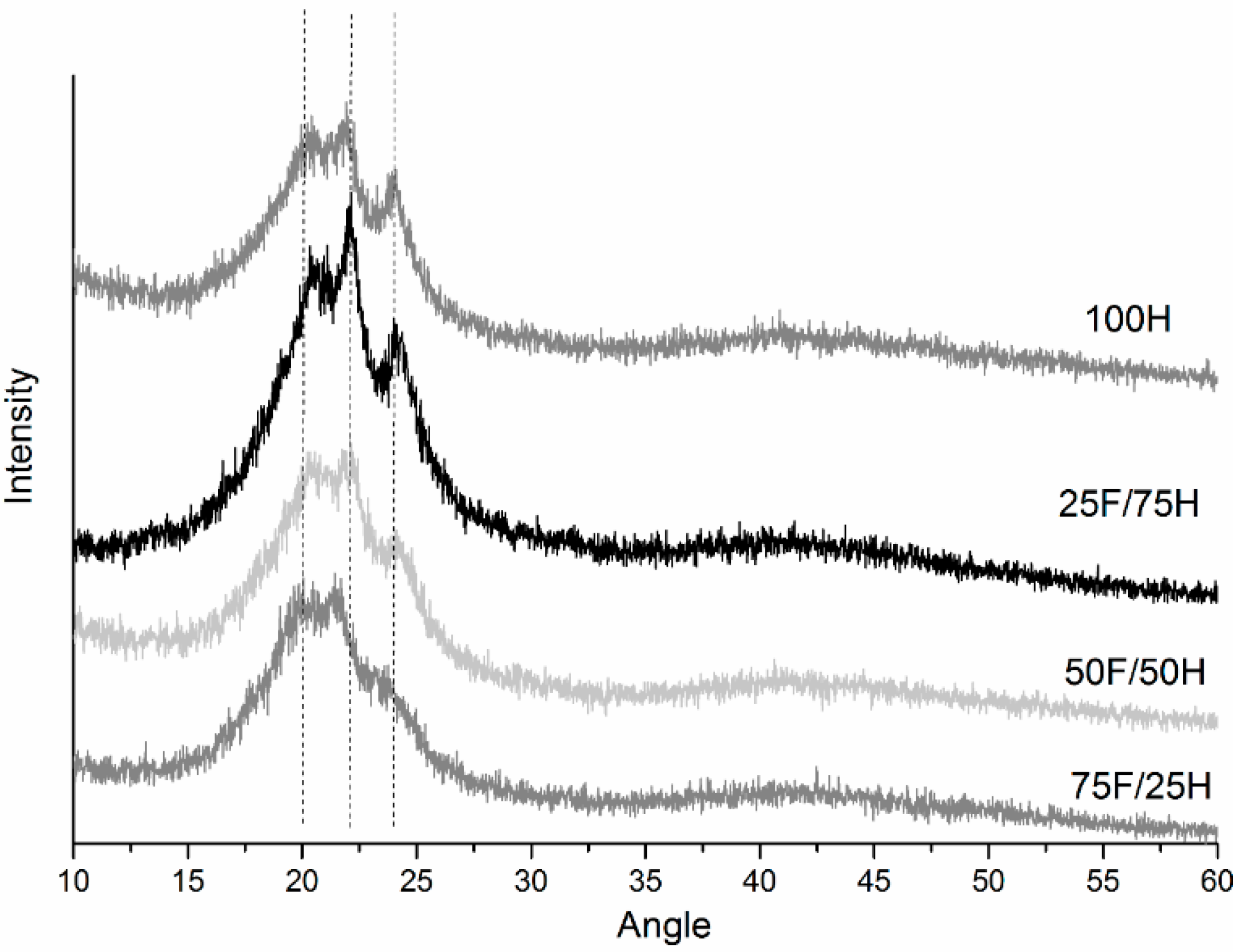

3.5. X-ray Diffraction (XRD)

3.6. Tensile Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beneš, H.; Vlček, T.; Černá, R.; Hromádková, J.; Walterová, Z.; Svitáková, R. Polyurethanes with bio-based and recycled components. Eur. J. Lipid Sci. Technol. 2012, 114, 71–83. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Santamaria-Echart, A.; Saralegi, A.; Martin, L.; Valea, Á.; Corcuera, M.A.; Eceiza, A. Thermally-responsive biopolyurethanes from a biobased diisocyanate. Eur. Polym. J. 2015, 70, 173–185. [Google Scholar] [CrossRef]

- Charlon, M.; Heinrich, B.; Matter, Y.; Couzigné, E.; Donnio, B.; Avérous, L. Synthesis, structure and properties of fully biobased thermoplastic polyurethanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur. Polym. J. 2014, 61, 197–205. [Google Scholar] [CrossRef]

- Calle, M.; Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Non-isocyanate route to biobased polyurethanes and polyureas. Eur. Polym. J. 2016, 84, 837–848. [Google Scholar] [CrossRef]

- Abdolhosseini, F.; Kazem, M.; Givi, B. Characterization of a biodegradable polyurethane elastomer derived from castor oil. Am. J. Polym. Sci. 2016, 6, 18–27. [Google Scholar] [CrossRef]

- Karami, Z.; Zohuriaan-Mehr, M.; Rostami, A. Bio-based thermo-healable non-isocyanate polyurethane DA network in comparison with its epoxy counterpart. J. CO2 Util. 2017, 18, 294–302. [Google Scholar] [CrossRef]

- Maisonneuve, L.; Lebarbé, T.; Grau, E.; Cramail, H. Structure–properties relationship of fatty acid-based thermoplastics as synthetic polymer mimics. Polym. Chem. 2013, 4, 5472–5517. [Google Scholar] [CrossRef]

- Bueno-Ferrer, C.; Hablot, E.; Garrigós, M.D.C.; Bocchini, S.; Averous, L.; Jiménez, A. Relationship between morphology, properties and degradation parameters of novative biobased thermoplastic polyurethanes obtained from dimer fatty acids. Polym. Degrad. Stab. 2012, 97, 1964–1969. [Google Scholar] [CrossRef]

- Kasprzyk, P.; Datta, J. New plant-derived monomers in the synthesis of thermoplastic polyurethane elastomers. Elastomery 2018, 22, 200–213. [Google Scholar]

- Głowińska, E.; Datta, J. Possibilities for using modified soya and palm oils in synthesis of biopolyurethanes. Przem. Chem. 2012, 91, 1234–1236. [Google Scholar]

- Datta, J.; Głowińska, E. Chemical modifications of natural oils and examples of their usage for polyurethane synthesis. J. Elastomers Plast. 2012, 46, 33–42. [Google Scholar] [CrossRef]

- Głowińska, E.; Datta, J. Structure, morphology and mechanical behaviour of novel bio-based polyurethane composites with microcrystalline cellulose. Cellulose 2015, 22, 2471–2481. [Google Scholar] [CrossRef]

- Głowińska, E.; Datta, J. Bio polyetherurethane composites with high content of natural ingredients: Hydroxylated soybean oil based polyol, bio glycol and microcrystalline cellulose. Cellulose 2016, 23, 581–592. [Google Scholar] [CrossRef]

- Corcuera, M.A.; Rueda, L.; Saralegui, A.; Martín, M.D.; Fernández-D’Arlas, B.; Mondragon, I.; Eceiza, A. Effect of diisocyanate structure on the properties and microstructure of polyurethanes based on polyols derived from renewable resources. J. Appl. Polym. Sci. 2011, 122, 3677–3685. [Google Scholar] [CrossRef]

- Kaur, R.; Kumar, M. Function of silicon oil in the castor oil based rigid polyurethane foams. J. Polym. Eng. 2013, 33, 875–880. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Błażek, K.; Datta, J. Renewable natural resources as green alternative substrates to obtain bio-based non-isocyanate polyurethanes-review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 173–211. [Google Scholar] [CrossRef]

- Trzebiatowska, P.J.; Deuter, I.; Datta, J. Cast polyurethanes obtained from reactive recovered polyol intermediates via crude glycerine decomposition process. React. Funct. Polym. 2017, 119, 20–25. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit. Rev. Environ. Sci. Technol. 2016, 46, 905–946. [Google Scholar] [CrossRef]

- Simón, D.; De Lucas, A.; Rodríguez, J.F.; Borreguero, A.M. Flexible polyurethane foams synthesized employing recovered polyols from glycolysis: Physical and structural properties. J. Appl. Polym. Sci. 2017, 134, 45087. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.; de Lucas, A.; Rodríguez, J. Glycolysis of viscoelastic flexible polyurethane foam wastes. Polym. Degrad. Stab. 2015, 116, 23–35. [Google Scholar] [CrossRef]

- McCarthy, P.; Rasul, M.; Moazzem, S. Comparison of the performance and emissions of different biodiesel blends against petroleum diesel. Int. J. Low-Carbon Technol. 2011, 6, 255–260. [Google Scholar] [CrossRef]

- Zain, N.M.; Ahmad, S.H.; Ahad, N.A.; Ali, E.S. Influence of isocyanate structures on mechanical performance of aluminum bonded with green polyurethane adhesive. Adv. Mater. Res. 2015, 879, 119–127. [Google Scholar] [CrossRef]

- Javni, I.; Zhang, W.; Petrović, Z.S. Effect of different isocyanates on the properties of soy-based polyurethanes. J. Appl. Polym. Sci. 2002, 88, 2912–2916. [Google Scholar] [CrossRef]

- AqilahHamuzan, H.; Badri, K.H. The role of isocyanates in determining the viscoelastic properties of polyurethane. AIP Conf. Proc. 2016. [Google Scholar] [CrossRef]

- Rahmawati, R.; Nozaki, S.; Kojio, K.; Takahara, A.; Shinohara, N.; Yamasaki, S. Microphase-separated structure and mechanical properties of cycloaliphatic diisocyanate-based thiourethane elastomers. Polym. J. 2019, 51, 265–273. [Google Scholar] [CrossRef]

- Terban, M.W.; Dabbous, R.; Debellis, A.D.; Pöselt, E.; Billinge, S.J.L. Structures of Hard Phases in Thermoplastic Polyurethanes. Macromolecules 2016, 49, 7350–7358. [Google Scholar] [CrossRef]

- Leung, L.M.; Koberstein, J.T. DSC annealing study of microphase separation and multiple endothermic behavior in polyether-based polyurethane block copolymers. Macromolecules 1986, 19, 706–713. [Google Scholar] [CrossRef]

- Rueda, L.; D’Arlas, B.F.; Corcuera, M.; Eceiza, A. Biostability of polyurethanes. Study from the viewpoint of microphase separated structure. Polym. Degrad. Stab. 2014, 108, 195–200. [Google Scholar] [CrossRef]

- Bhausaheb, T.; Shingte Rahul, D.; Sachin, K.; Prakash, W.; Sadavarte, N.V.; Garg, K.; Maher, D.; Ichake, A.; More, A. Bio-based di/ polyisocyanates for polyurethanes: An overview. Polyureth. Today 2017, 41–46. [Google Scholar] [CrossRef]

- Konieczny, J.; Loos, K. Green polyurethanes from renewable isocyanates and biobased white dextrins. Polymers 2019, 11, 256. [Google Scholar] [CrossRef]

- More, A.S.; Lebarbé, T.; Maisonneuve, L.; Gadenne, B.; Alfos, C.; Cramail, H. Novel fatty acid based di-isocyanates towards the synthesis of thermoplastic polyurethanes. Eur. Polym. J. 2013, 49, 823–833. [Google Scholar] [CrossRef]

- Reddy, C.S.; Connor, K.O. The influence of biobased olegomeric diisocyanate on thermal and mechanical properties of poly(3-hydroxybutyrate). Macromol. Symp. 2016, 365, 223–229. [Google Scholar] [CrossRef]

- Schemmer, B.; Kronenbitter, C.; Mecking, S. Thermoplastic polyurethane elastomers with aliphatic hard segments based on plant-oil-derived long-chain diisocyanates. Macromol. Mater. Eng. 2018, 303, 1–8. [Google Scholar] [CrossRef]

- Li, S.; Jose, J.; Bouzidi, L.; Leao, A.L.; Narine, S.S. Maximizing the utility of bio-based diisocyanate and chain extenders in crystalline segmented thermoplastic polyester urethanes: Effect of polymerization protocol. Polymer 2014, 55, 6764–6775. [Google Scholar] [CrossRef]

- Głowińska, E.; Wolak, W.; Datta, J. Eco-friendly route for thermoplastic polyurethane elastomers with bio-based hard segments composed of bio-glycol and mixtures of aromatic–aliphatic and aliphatic–aliphatic diisocyanate. J. Polym. Environ. 2021, 1–10. [Google Scholar] [CrossRef]

- Teo, L.-S.; Chen, A.C.-Y.; Kuo, J.-F. Fourier transform infrared spectroscopy study on effects of temperature on hydrogen bonding in amine-containing polyurethanes and poly(urethane−urea)s. Macromolecules 1997, 30, 1793–1799. [Google Scholar] [CrossRef]

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Niemczyk, A.; Piegat, A.; Olalla, Á.S.; El Fray, M. New approach to evaluate microphase separation in segmented polyurethanes containing carbonate macrodiol. Eur. Polym. J. 2017, 93, 182–191. [Google Scholar] [CrossRef]

- Oliaie, H.; Haddadi-Asl, V.; Mirhosseini, M.M.; Jouibari, I.S.; Mohebi, S.; Shams, A. Role of sequence of feeding on the properties of polyurethane nanocomposite containing halloysite nanotubes. Des. Monomers Polym. 2019, 22, 199–212. [Google Scholar] [CrossRef] [PubMed]

- Parcheta, P.; Głowińska, E.; Datta, J. Effect of bio-based components on the chemical structure, thermal stability and mechanical properties of green thermoplastic polyurethane elastomers. Eur. Polym. J. 2020, 123, 109422. [Google Scholar] [CrossRef]

- Głowińska, E.; Datta, J.; Parcheta, P. Effect of sisal fiber filler on thermal properties of bio-based polyurethane composites. J. Therm. Anal. Calorim. 2017, 130, 113–122. [Google Scholar] [CrossRef]

- Datta, J.; Kasprzyk, P. Thermoplastic polyurethanes derived from petrochemical or renewable resources: A comprehensive review. Polym. Eng. Sci. 2018, 58, E14–E35. [Google Scholar] [CrossRef]

- Saralegi, A.; Rueda, L.; Fernández-D’Arlas, B.; Mondragon, I.; Eceiza, A.; Corcuera, M.A. Thermoplastic polyurethanes from renewable resources: Effect of soft segment chemical structure and molecular weight on morphology and final properties. Polym. Int. 2013, 62, 106–115. [Google Scholar] [CrossRef]

- Wirpsza, Z. Poliuretany: Chemia, Technologia, Zastosowanie; Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 1991. [Google Scholar]

| Parameter | Bio-Based Diisocyanate Content (wt %) | |||

|---|---|---|---|---|

| 0 | 25 | 50 | 75 | |

| R | 3.56 | 1.92 | 1.56 | 1.43 |

| R2 | 0.9931 | 0.9976 | 0.9963 | 0.9943 |

| DPS | 0.780 | 0.657 | 0.609 | 0.588 |

| DPM | 0.220 | 0.343 | 0.391 | 0.412 |

| HS [%] | 29.6 | 34.0 | 40.2 | 53.4 |

| Properties | Bio-Based Diisocyanate Content (wt %) | |||

|---|---|---|---|---|

| 0 | 25 | 50 | 75 | |

| T5% [°C] | 339 | 330 | 324 | 316 |

| T10% [°C] | 357 | 347 | 341 | 335 |

| T50% [°C] | 429 | 424 | 415 | 398 |

| Ash residue at 600 °C [%] | 1.4 | 1.7 | 1.7 | 0.6 |

| Properties | Bio-Based Diisocyanate Content (wt %) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | |||||

| I Run | II Run | I Run | II Run | I Run | II Run | I Run | II Run | |

| TgSS [°C] | −49.5 | −49.1 | −48.9 | −49.1 | −49.2 | −48.9 | −49.7 | −49.1 |

| TgHS [°C] | 43.9 | 38.0 | 51.8 | 44.2 | 54.0 | 44.7 | 54.2 | 47.1 |

| TmHS [°C] | 160.2 | 154.1 | 161.2 | 148.7 | 150.7 | 140.3 | 122.1 | 118.4 |

| ΔHmHS [J/g] | 16.67 | 12.34 | 20.68 | 13.27 | 16.19 | 11.92 | 5.34 | 10.01 |

| TcHS [°C] | 128.2 | - | 115.4 | - | 107.7 | - | 83.1 | - |

| ΔHc [J/g] | −11.39 | - | −14.82 | - | −13.78 | - | −14.62 | - |

| Properties | The Diisocyanate Mixture Type | |||

|---|---|---|---|---|

| 0F/100H | ||||

| [NCO]/[OH] | 0.95 | 1.0 | 1.05 | 1.1 |

| TSb (MPa) | 9.2 ± 0.6 | 16.8 ± 2.8 | 17.9 ± 2.6 | 25.8 ±4.5 |

| εb (%) | 218 ± 67 | 706 ± 139 | 613 ± 82 | 803 ± 86 |

| 25F/75H | ||||

| [NCO]/[OH] | 0.95 | 1.0 | 1.05 | 1.1 |

| TSb (MPa) | 10.8 ± 0.8 | 25.7 ± 1.9 | 29.8 ± 1.9 | 31.7 ± 2.2 |

| εb (%) | 449 ± 98 | 883 ± 52 | 890 ± 16 | 874 ± 29 |

| 50F/50H | ||||

| [NCO]/[OH] | 0.95 | 1.0 | 1.05 | 1.1 |

| TSb (MPa) | 8.7 ± 0.5 | 27.5 ± 3.1 | 24.9 ± 8.3 | 33.3 ± 1.8 |

| εb (%) | 449 ± 102 | 895 ± 16 | 809 ± 91 | 904 ± 15 |

| 75F/25H | ||||

| [NCO]/[OH] | 0.95 | 1.0 | 1.05 | 1.1 |

| TSb (MPa) | 6.5 ± 0.6 | 16.1 ± 0.9 | 18.9 ± 0.9 | 18.4 ± 1.2 |

| εb (%) | 421 ± 4 | 818 ± 41 | 845 ± 40 | 883 ± 43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głowińska, E.; Kasprzyk, P.; Datta, J. The Green Approach to the Synthesis of Bio-Based Thermoplastic Polyurethane Elastomers with Partially Bio-Based Hard Blocks. Materials 2021, 14, 2334. https://doi.org/10.3390/ma14092334

Głowińska E, Kasprzyk P, Datta J. The Green Approach to the Synthesis of Bio-Based Thermoplastic Polyurethane Elastomers with Partially Bio-Based Hard Blocks. Materials. 2021; 14(9):2334. https://doi.org/10.3390/ma14092334

Chicago/Turabian StyleGłowińska, Ewa, Paulina Kasprzyk, and Janusz Datta. 2021. "The Green Approach to the Synthesis of Bio-Based Thermoplastic Polyurethane Elastomers with Partially Bio-Based Hard Blocks" Materials 14, no. 9: 2334. https://doi.org/10.3390/ma14092334

APA StyleGłowińska, E., Kasprzyk, P., & Datta, J. (2021). The Green Approach to the Synthesis of Bio-Based Thermoplastic Polyurethane Elastomers with Partially Bio-Based Hard Blocks. Materials, 14(9), 2334. https://doi.org/10.3390/ma14092334