Wire-Feeding Laser Welding of Copper/Stainless Steel Using Different Filler Metals

Abstract

1. Introduction

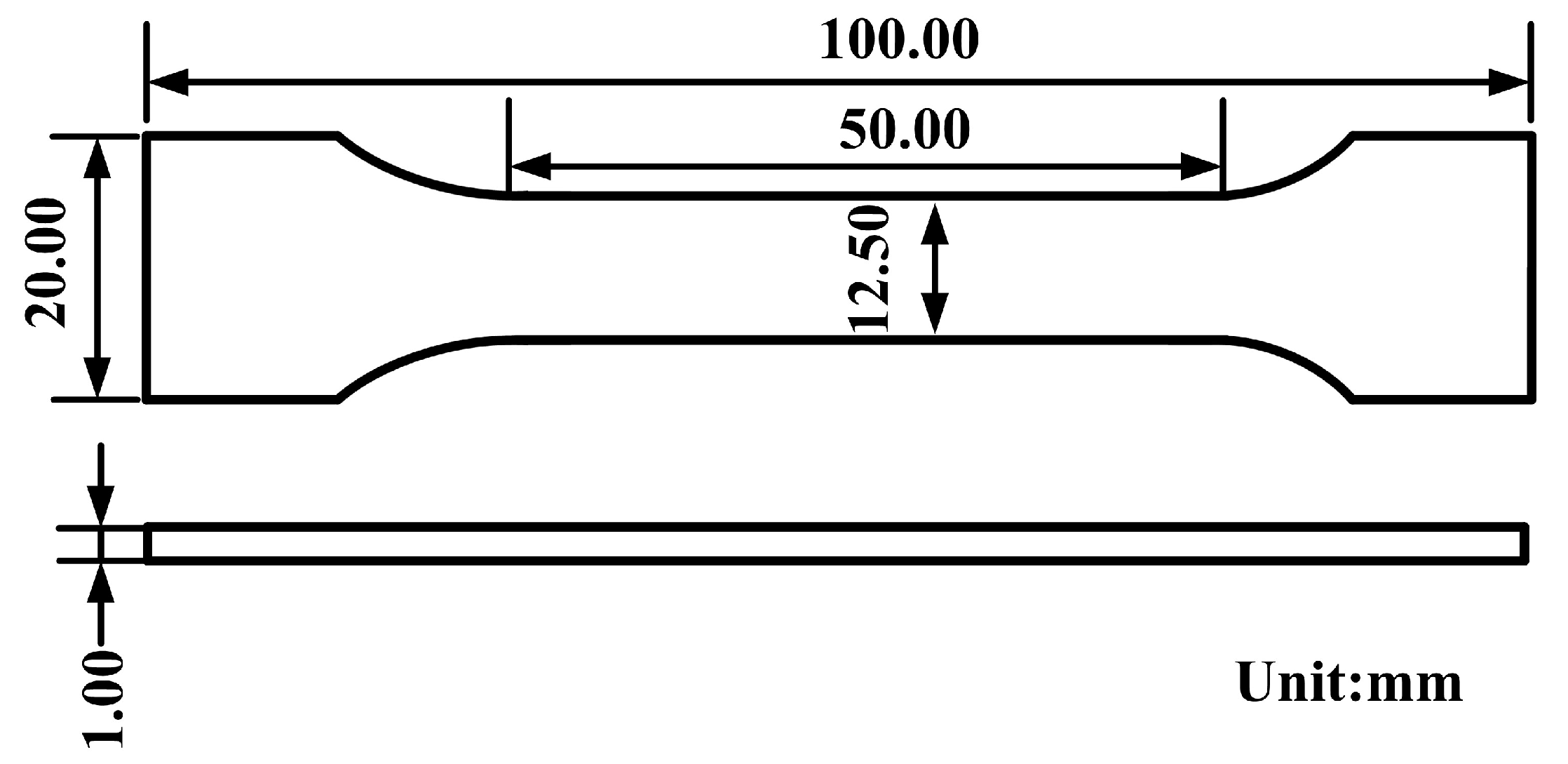

2. Materials and Experimental Methods

2.1. Materials

2.2. Welding Process

2.3. Characterization of the Welds

3. Results

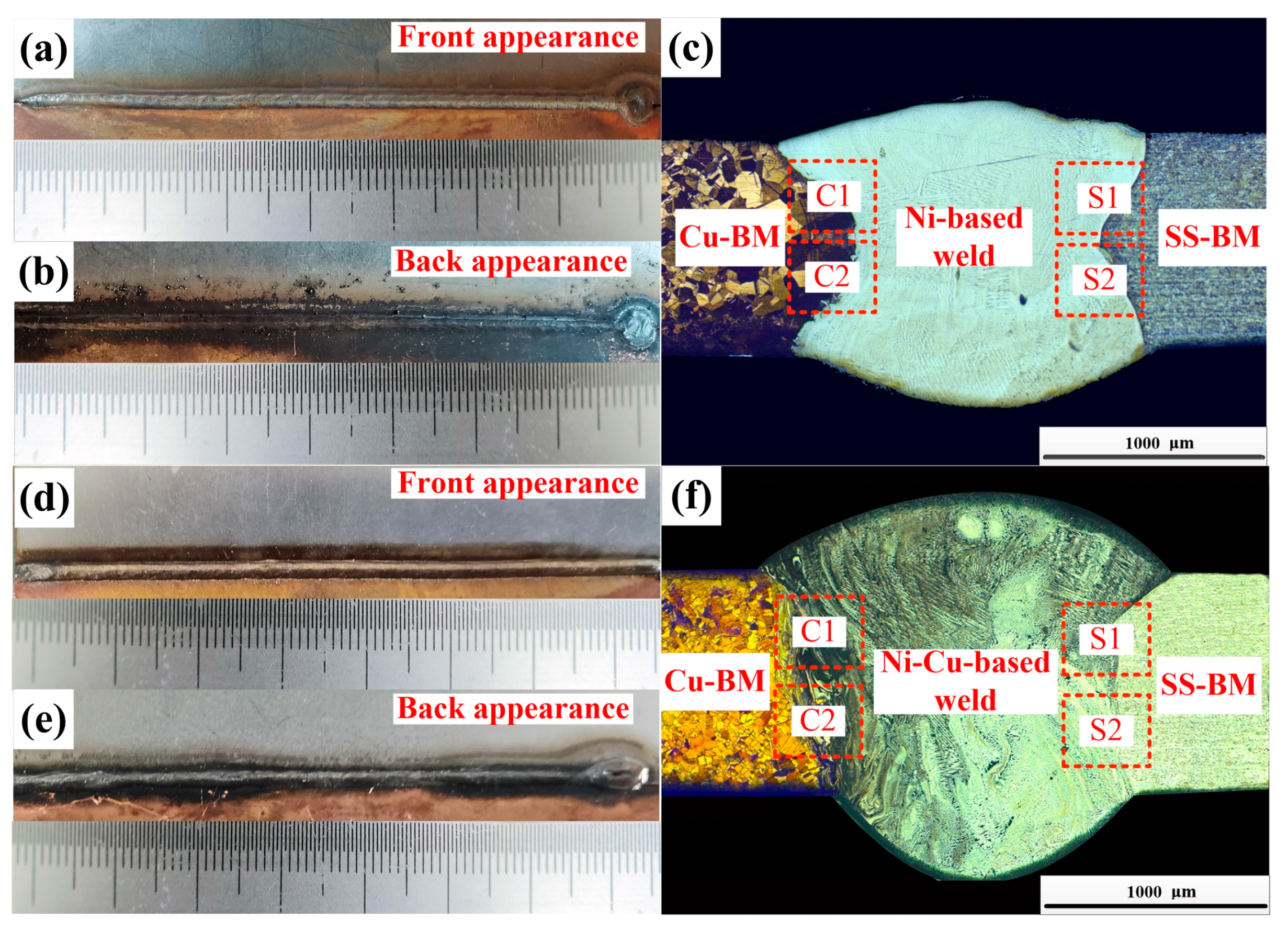

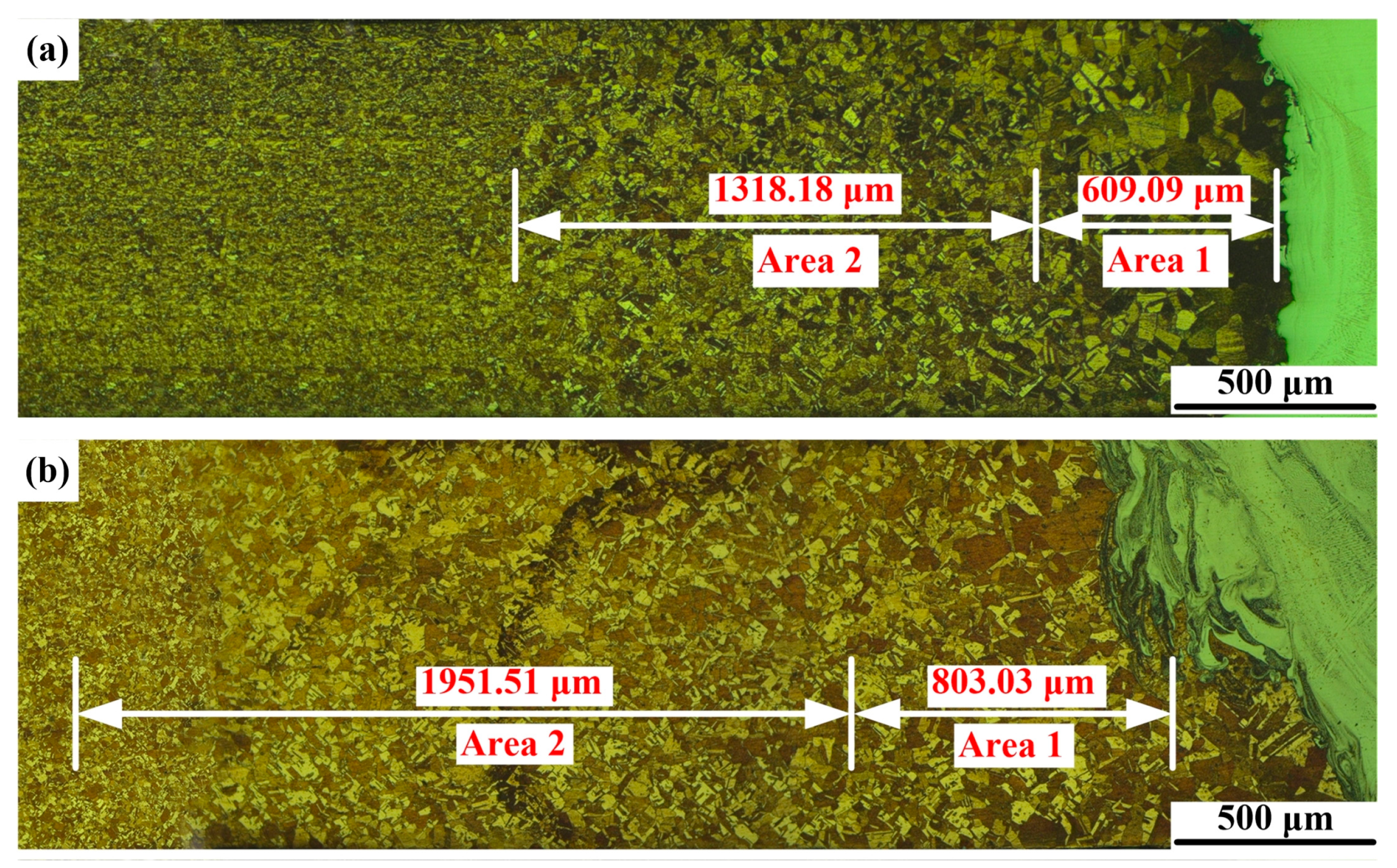

3.1. Macrostructure

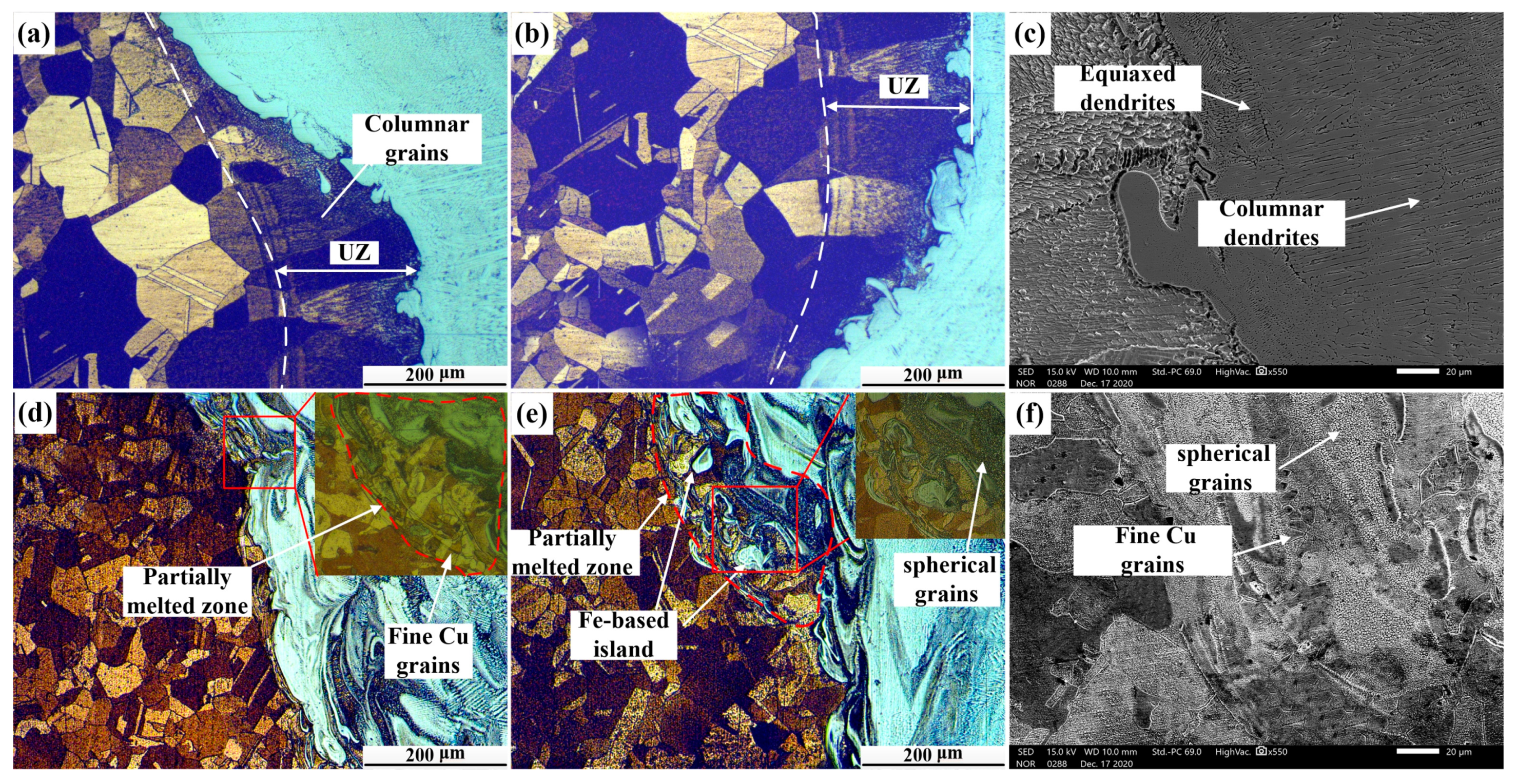

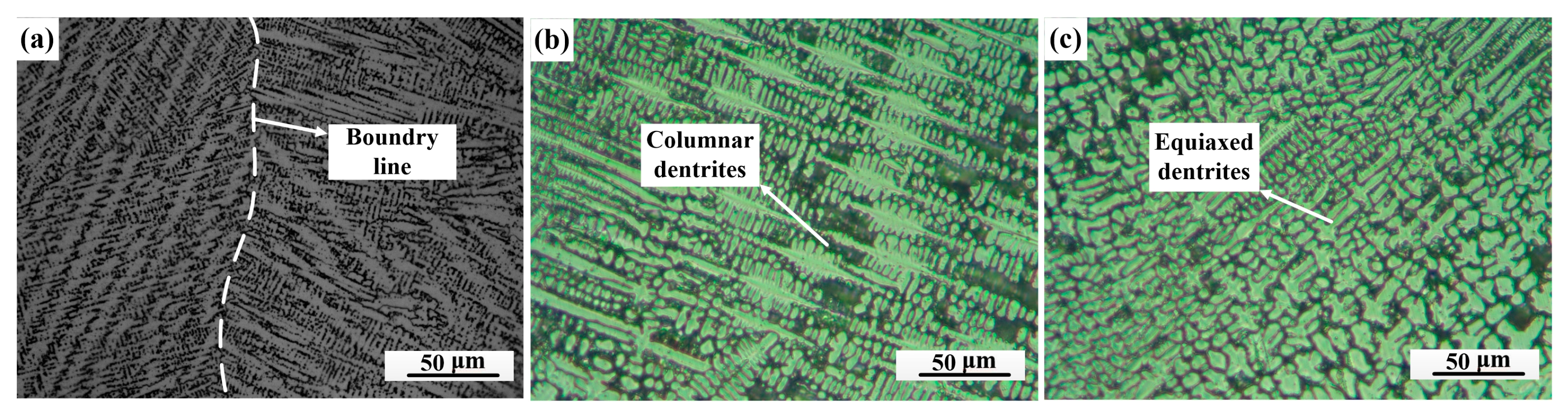

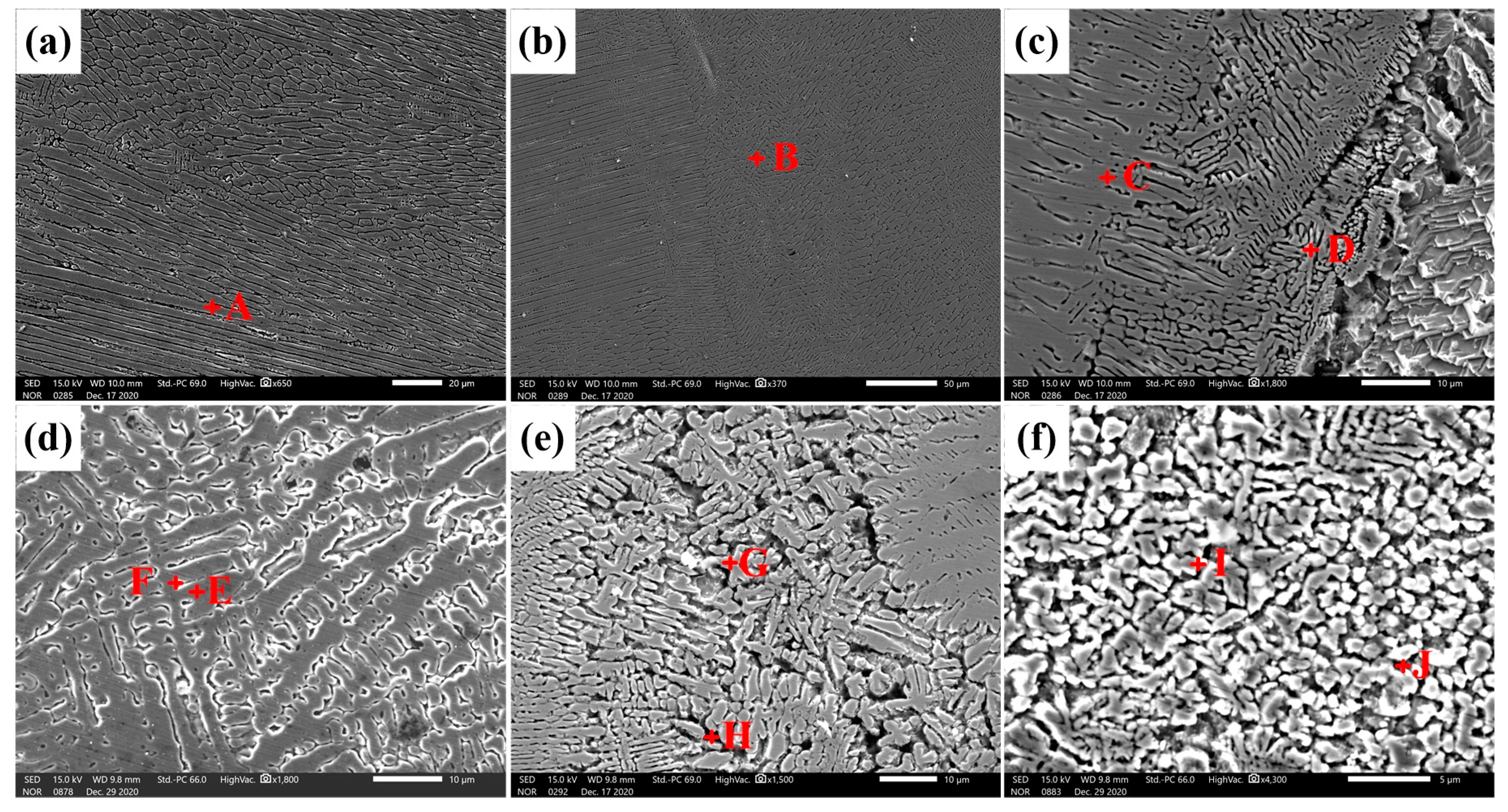

3.2. Microstructures

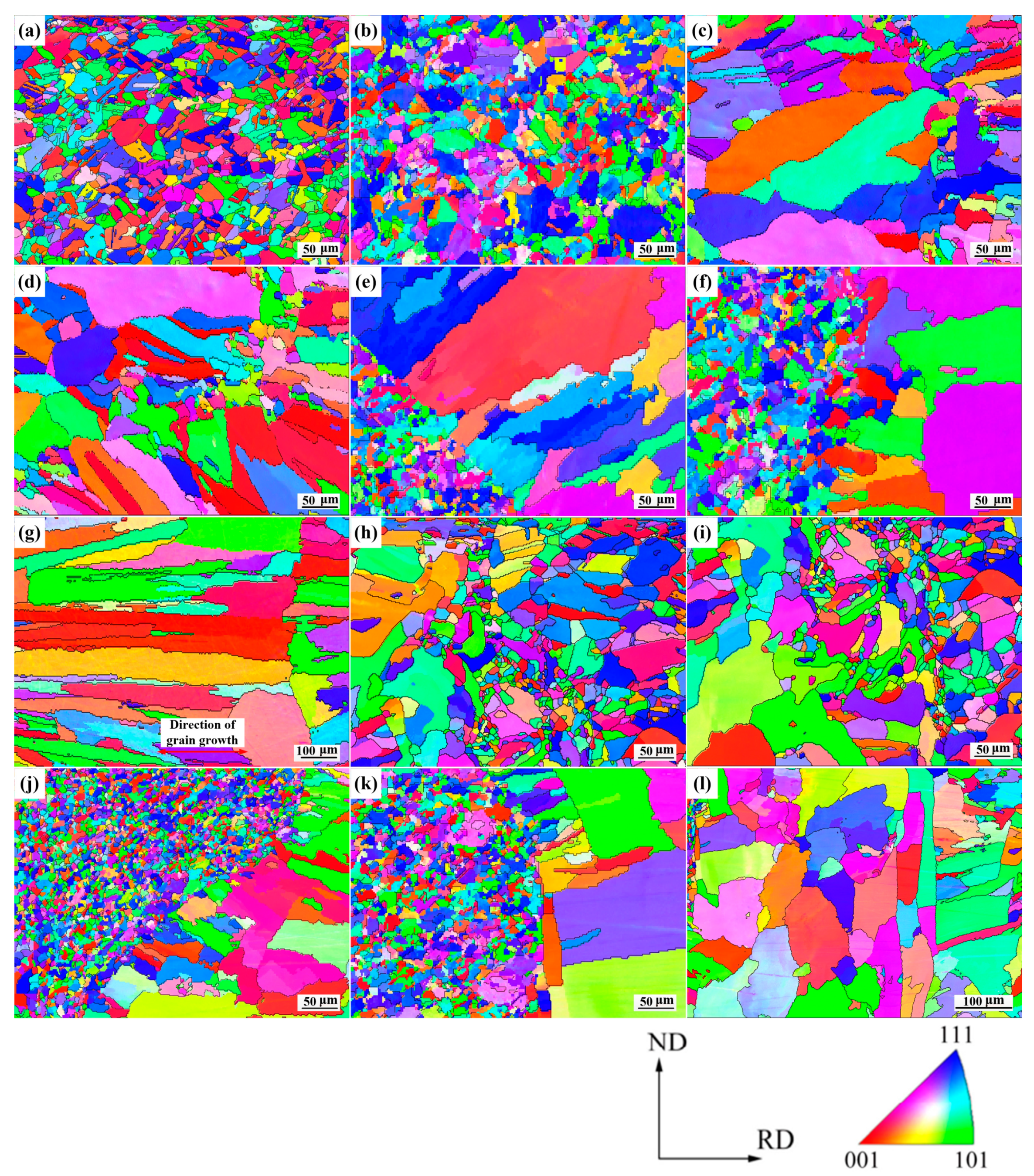

3.3. EBSD Microstructural Analysis

3.3.1. Grain Orientations

3.3.2. Grain Misorientations

3.3.3. Grain Size Statistics

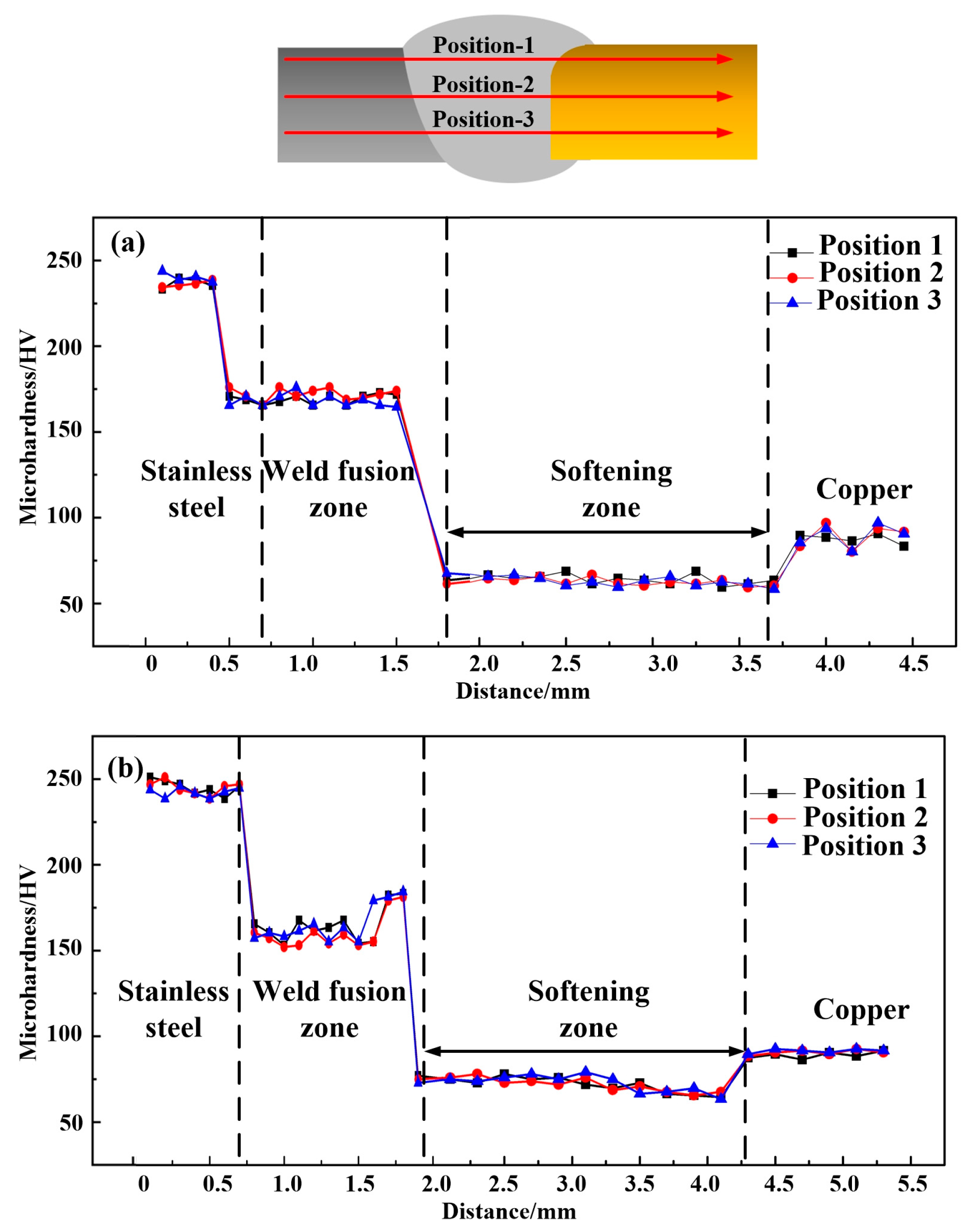

3.4. Microhardness

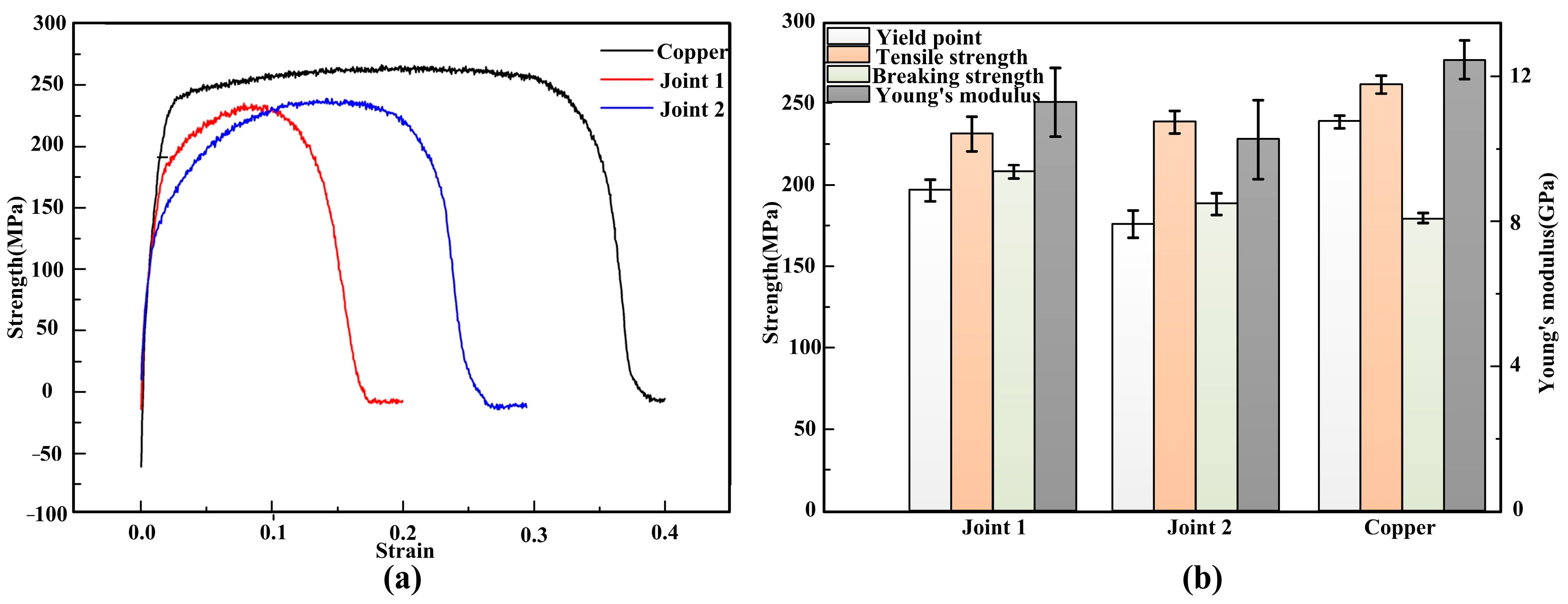

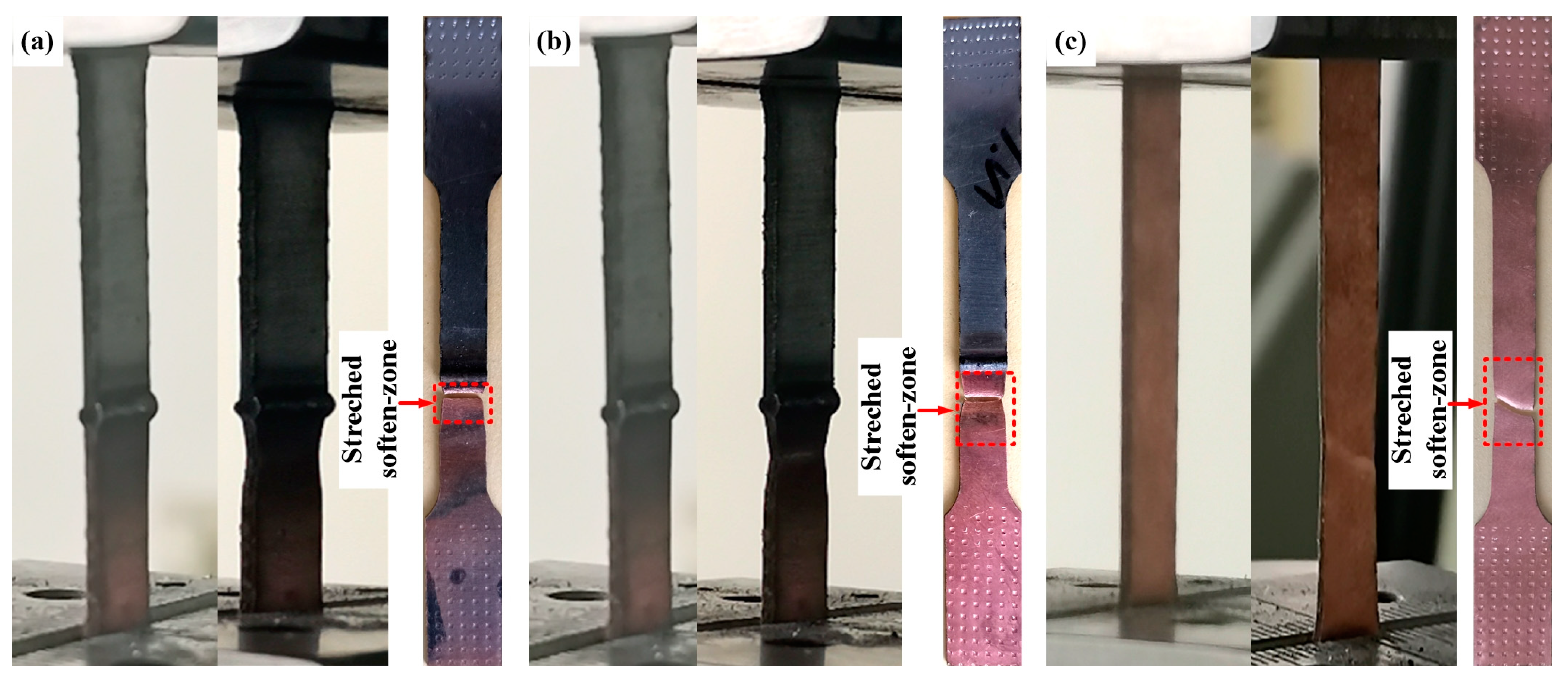

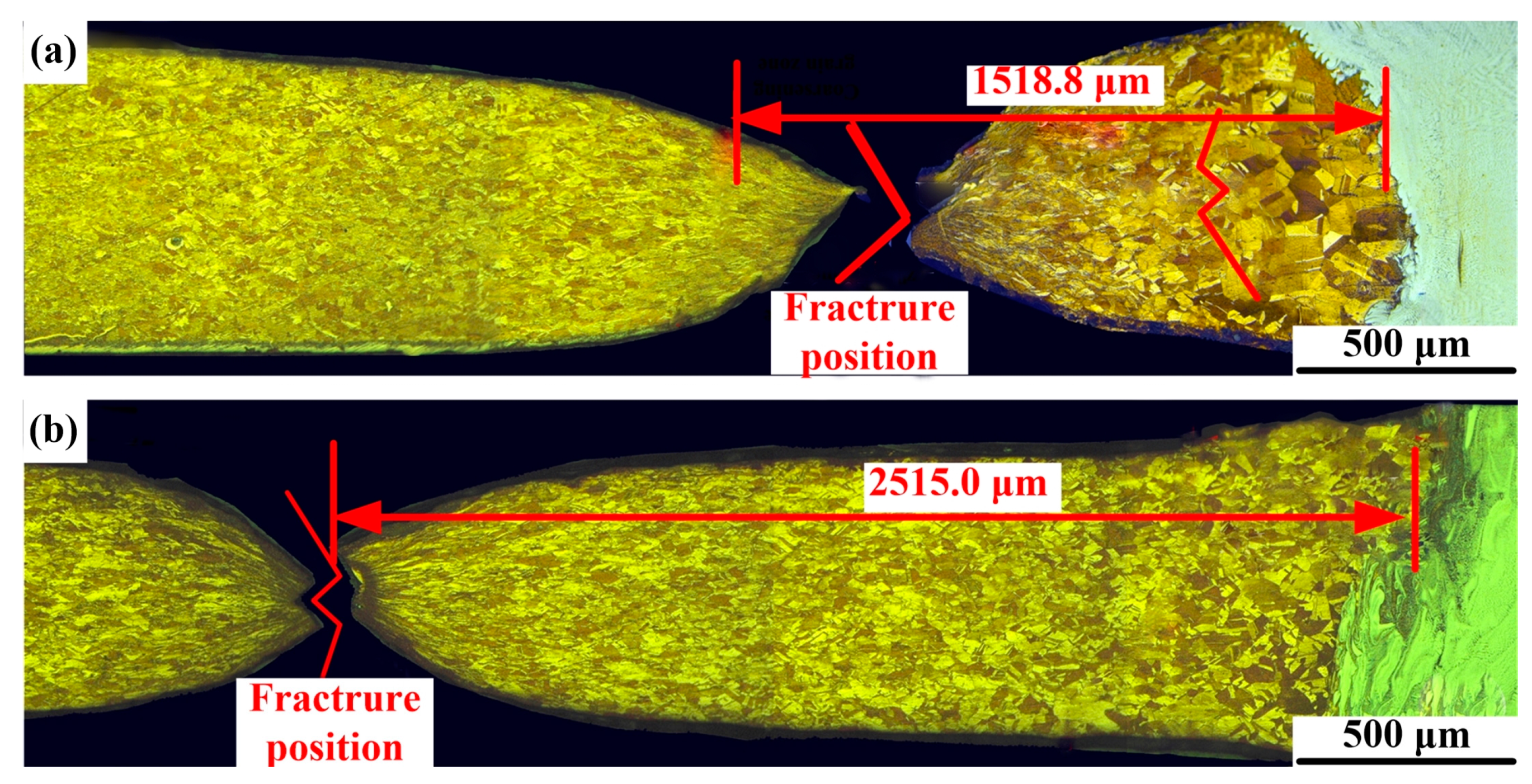

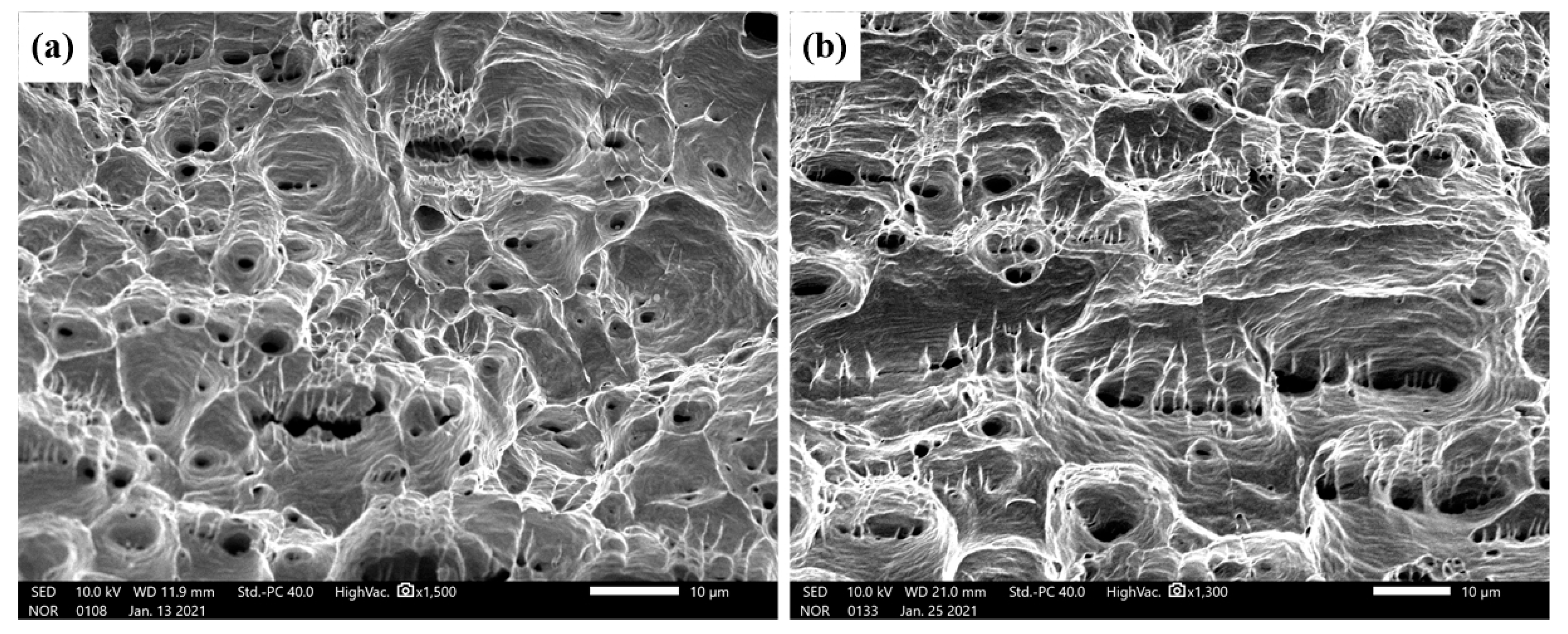

3.5. Tensile Strength

4. Conclusions

- The results showed that there were no obvious weld defects in the fusion zone and the welding interface of the wire-fed laser welded joint with 600 alloy filler metal and ERNiCu 7 filler metal. All the optical and SEM micrographs agree with these findings. In conclusion, 600 alloy filler and ERNiCu-7 filler were appropriate filler materials for the welding of copper to stainless steel.

- Cu-HAZ consists of two areas with different grain sizes and the sizes of grains in Cu-HAZ of the Ni-Cu-based filled joint was smaller than that of the Ni-based filled joint. Our results showed that the composition distribution in the weld zone of both joints was uniform and the weld zone was composed of a mixture of columnar and equiaxed dendrites. Epitaxial grain growth was identified along the SS/weld interface.

- EBSD analysis of SS/weld interfaces and the fusion zone indicated that all these regions have a distinct grain morphology and the grain refinement zone was spotted in the Cu/weld interface of the Ni-Cu-based filled joint.

- Results of the microhardness measurements indicated that the highest hardness was observed at SS-BM (nearly 240 HV), among all the weld zones. Additionally, the hardness in the weld zone of the Ni-based filled joint was more homogeneous than that of the Ni-Cu-based filled joint, and there was an elevation in hardness at the Cu/weld interface of the Ni-Cu-based filled joint due to the grain refinements located in the weld of Cu.

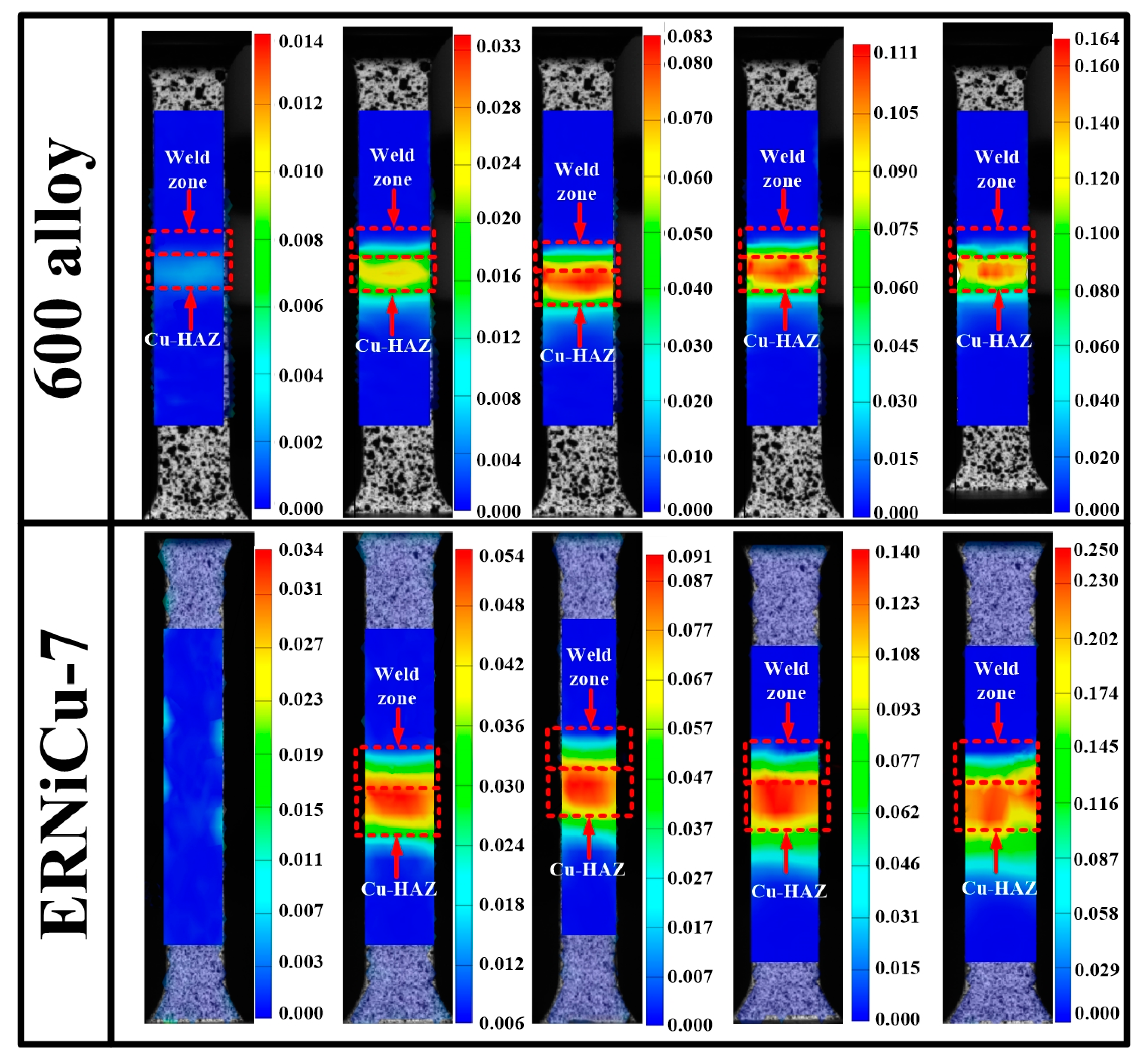

- A 91.2% tensile strength of Cu was obtained in the Ni-Cu base filled joint. Among these joints, most of the strain was distributed to the Cu-HAZ and fractured in a ductile pattern. Analysis of the 2D-DIC showed that the deformation of the Ni-Cu-based filled joint was higher than that of the Ni-based filled joint, which was caused by the high deformation in the weld zone and less stress concentration at Cu/weld interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Z.; Huang, J.; Ye, Z.; Chen, Y.; Yang, J.; Chen, S. Microstructures and mechanical properties of copper-stainless steel butt-welded joints by MIG-TIG double-sided arc welding. J. Mater. Process. Technol. 2019, 265, 87–98. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel-kovar, copper-steel and copper-aluminium. Mater. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Vyskoč, M.; Sahul, M.; Dománková, M.; Jurči, P.; Sahul, M.; Vyskočová, M.; Martinkovič, M. The Effect of Process Parameters on the Microstructure and Mechanical Properties of AW5083 Aluminum Laser Weld Joints. Metals 2020, 10, 1443. [Google Scholar] [CrossRef]

- Meng, Y.; Li, X.; Gao, M.; Zeng, X. Microstructures and mechanical properties of laser-arc hybrid welded dissimilar pure copper to stainless steel. Opt. Laser Technol. 2019, 111, 140–145. [Google Scholar] [CrossRef]

- Guo, S.; Zhou, Q.; Kong, J.; Peng, Y.; Xiang, Y.; Luo, T.; Wang, K.; Zhu, J. Effect of beam offset on the characteristics of copper/304stainless steel electron beam welding. Vacuum 2016, 128, 205–212. [Google Scholar] [CrossRef]

- Kuryntsev, S.; Morushkin, A.; Gilmutdinov, A.K. Fiber laser welding of austenitic steel and commercially pure copper butt joint. Opt. Lasers Eng. 2017, 90, 101–109. [Google Scholar] [CrossRef]

- Yao, C.; Xu, B.; Zhang, X.; Huang, J.; Fu, J.; Wu, Y. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint. Opt. Lasers Eng. 2009, 47, 807–814. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xia, J.; Zhao, X.; Lin, S. Influence of processing parameters on the characteristics of stainless steel/copper laser welding. J. Mater. Process. Technol 2015, 222, 43–51. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xia, J.; Zhao, X. Microstructural characteristics of a stainless steel/copper dissimilar joint made by laser welding. Metall. Mater. Trans. A 2013, 44, 3690–3696. [Google Scholar] [CrossRef]

- Kar, J.; Roy, S.K.; Roy, G.G. Effect of beam oscillation on electron beam welding of copper with AISI-304 stainless steel. J. Mater. Process. Technol. 2016, 233, 174–185. [Google Scholar] [CrossRef]

- Magnabosco, I.; Ferro, P.; Bonollo, F.; Arnberg, L. An investigation of fusion zone microstructures in electron beam welding of copper–stainless steel. Mater. Sci. Eng. A 2006, 424, 163–173. [Google Scholar] [CrossRef]

- Salminen, A.S.; Kujanpää, V.P. Effect of wire feed position on laser welding with filler wire. J. Laser Appl. 2003, 15, 2–10. [Google Scholar] [CrossRef]

- Kong, X.; Li, F.; Lu, J.; Wu, S.; Xiao, R. Fiber Laser Welding of 5083 Aluminum Alloy with Filler Wire. Chin. J. Lasers 2014, 41, 81–86. [Google Scholar]

- An, N.; Zhang, X.; Wang, Q.; Yang, W.; Xiao, R. Fiber Laser Welding of 2060 Aluminum-Lithium Alloy with Filler Wire. Chin. J. lasers 2014, 41, 94–99. [Google Scholar]

- Chai, D.; Wu, D.; Ma, G.; Zhou, S.; Jin, Z.; Wu, D. The Effects of Pulse Parameters on Weld Geometry and Microstructure of a Pulsed Laser Welding Ni-Base Alloy Thin Sheet with Filler Wire. Metals 2016, 6, 237. [Google Scholar] [CrossRef]

- Cheng, Z.; Liu, H.; Huang, J.; Ye, Z.; Yang, J.; Chen, S. MIG-TIG double-sided arc welding of copper-stainless steel using different filler metals. J. Manuf. Process. 2020, 55, 208–219. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Zhou, J.; Sun, D.; Gu, X. Forming mechanism and mechanical property of pulsed laser welded Ti alloy and stainless steel joint using copper as interlayer. J. Mater. Res. Technol. 2020, 9, 1425–1433. [Google Scholar] [CrossRef]

- Ramachandran, S.; Lakshminarayanan, A.K. An insight into microstructural heterogeneities formation between weld subre-gions of laser welded copper to stainless steel joints. Trans. Nonferr. Metal. Soc. 2020, 30, 727–745. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, C.; Han, Q. Effect of ultrasonic vibration on unmixed zone formation. Scr. Mater. 2006, 55, 975–978. [Google Scholar] [CrossRef]

- Xin, J.; Song, Y.; Fang, C.; Wei, J.; Huang, C.; Wang, S. Evaluation of inter-granular corrosion susceptibility in 316LN austenitic stainless steel weldments. Fusion Eng. Des. 2018, 133, 70–76. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Naren, S.V.; Paga, V.R.K.; Tiwari, A.; Arivazhagan, N. Development of pulsed current gas tungsten arc welding technique for dissimilar joints of marine grade alloys. J. Manuf. Process. 2016, 21, 201–213. [Google Scholar] [CrossRef]

- Switzner, N.; Queiroz, H.; Duerst, J.; Yu, Z. Si-bronze to 304 stainless steel GTA weld fusion zone microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 709, 55–64. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Ning, J.; Zhang, X.-J.; Zhang, G.-F.; Zhang, J.-X. Single pass hybrid laser–MIG welding of 4-mm thick copper without preheating. Mater. Des. 2015, 74, 1–18. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.; Zhang, Q.; Ma, Z. Achieving friction stir welded pure copper joints with nearly equal strength to the parent metal via additional rapid cooling. Scr. Mater. 2011, 64, 1051–1054. [Google Scholar] [CrossRef]

- Misseroni, D.; Corso, F.D.; Shahzad, S.; Bigoni, D. Stress concentration near stiff inclusions: Validation of rigid inclusion model and boundary layers by means of photoelasticity. Eng. Fract. Mech. 2014, 121–122, 87–97. [Google Scholar] [CrossRef]

| Name | C | Mn | Si | Cr | Ni | P | S | Fe |

| 301SS | 0.053 | 1.300 | 0.703 | 18.000 | 8.220 | 0.033 | 0.002 | Bal |

| Name | O | S | Zn | Fe | As | Sb | Bi | Cu |

| T2 copper | 0.060 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.001 | Bal |

| Name | Ni | Fe | Cu | Cr | Mn | Nb |

| 600 alloy | 67 | 3 | - | 20 | 3 | 3 |

| Name | Ni | Fe | Cu | Si | Mn | P |

| ERNiCu-7 | 69 | 2.5 | 23.215 | 1.25 | 4 | 0.02 |

| Filler Metal | Samples | Welding Power (W) | Welding Speed (m/s) | Wire Feed Speed (mm/min) | Heat Input (KJ/m) |

|---|---|---|---|---|---|

| 600 Alloy | Joint 1 | 1400 | 0.018 | 1.5 | 77.78 |

| ERNiCu-7 | Joint 2 | 1500 | 0.020 | 1.3 | 75.00 |

| Fe | Ni | Cu | Cr | |

|---|---|---|---|---|

| A | 31.50 | 38.27 | 15.10 | 14.26 |

| B | 29.01 | 34.57 | 16.10 | 13.61 |

| C | 20.00 | 31.62 | 22.68 | 10.48 |

| D | 18.16 | 28.54 | 31.68 | 11.42 |

| E | 35.66 | 27.88 | 20.29 | 14.87 |

| F | 16.71 | 16.61 | 61.81 | 10.25 |

| G | 28.03 | 31.33 | 16.66 | 12.87 |

| H | 12.12 | 10.26 | 65.92 | 11.7 |

| I | 21.66 | 32.02 | 34.18 | 11.05 |

| J | 15.11 | 15.72 | 68.86 | 10.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, X.; Cui, Z.; Gu, X.; Shao, J. Wire-Feeding Laser Welding of Copper/Stainless Steel Using Different Filler Metals. Materials 2021, 14, 2122. https://doi.org/10.3390/ma14092122

Gu X, Cui Z, Gu X, Shao J. Wire-Feeding Laser Welding of Copper/Stainless Steel Using Different Filler Metals. Materials. 2021; 14(9):2122. https://doi.org/10.3390/ma14092122

Chicago/Turabian StyleGu, Xiaoyan, Ziwei Cui, Xiaopeng Gu, and Jiaxu Shao. 2021. "Wire-Feeding Laser Welding of Copper/Stainless Steel Using Different Filler Metals" Materials 14, no. 9: 2122. https://doi.org/10.3390/ma14092122

APA StyleGu, X., Cui, Z., Gu, X., & Shao, J. (2021). Wire-Feeding Laser Welding of Copper/Stainless Steel Using Different Filler Metals. Materials, 14(9), 2122. https://doi.org/10.3390/ma14092122