2. Critical Analysis of the Present Knowledge

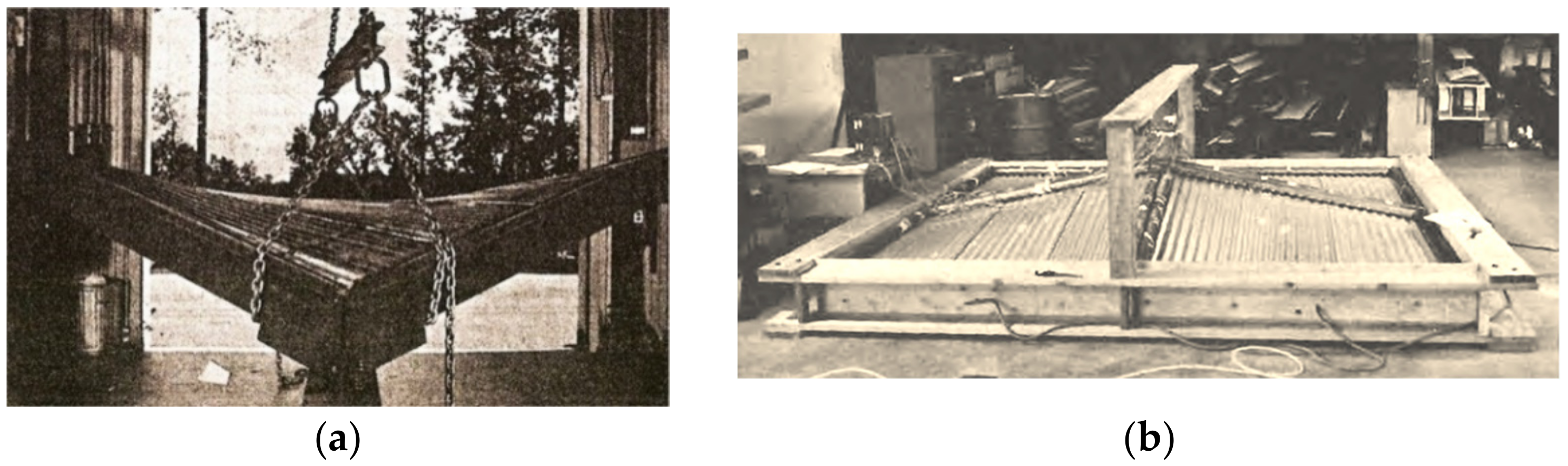

Nominally, plane thin-walled folded steel sheets of open profiles are transformed into shell shapes to obtain doubly-curved covers. They are most often modeled with two-dimensional regular ruled surfaces. The behavior of a central sector of a folded steel hyperbolic paraboloid stiffened with a circumferential frame was studied by McDermott [

2], Experimental studies of umbrella roofs composed of transformed hyperbolic parabolic quarters were first undertaken by Nilson [

3] (

Figure 3a). He proved that two-layer fold sheeting transformed elastically into a central sector of a hyperbolic paraboloid is more economical than the corresponding reinforced concrete hyperbolic paraboloid shell.

The most comprehensive research on two-layer transformed hyperbolic parabolic shells was carried out by Winter [

4] at Cornell University. He studied a greater variety of the sheet profiles and dimensions of two-layer central sectors and compositions of quarters of hyperbolic paraboloid roofs. The obtained results were consistent with those presented by Nilsen. Various types and methods of determining ruled surfaces, including hyperbolic paraboloids, are described by Carmo [

5] and Grey [

6].

These shells were subjected to forced shape transformations, causing relatively big initial stresses. The negative impact of the forced transformations was enhanced by the bolt joints between two orthogonal layers arranged over the whole area of each transformed shell unit and the frame stiffened the entire complex shell. As a result, only shallow hyperbolic paraboloid shells called hypars could be created in that way [

7].

Parker examined roof structures composed of four folded hyperbolic paraboloid quarters (

Figure 3b). These units are also made up of two layers of sheets located orthogonally in two directions. He studied the changes in stiffness and stresses of the units [

8]. Muscat primarily focused on the critical loads and stability of the corrugated shell sheeting [

9]. Banavalkar performed an analysis related to static-strength work of the hypars [

10].

Gioncu and Petcu [

11] studied the principle of the work of the hyperbolic paraboloid shells using the traditional analytical analysis of strength and critical load. They invented a novel HYPBUCK computer program. They analyzed umbrella shell sheeting composed of four symmetrical hyperbolic paraboloid units in various configurations (

Figure 4a,b).

Analogous studies related to the static strength work of single and complex hyperbolic paraboloid shells made up of flat folded sheets of different profiles were carried out by Egger et al. [

12]. They performed tests, a conventional analysis, and analytical calculations of strength and critical loads.

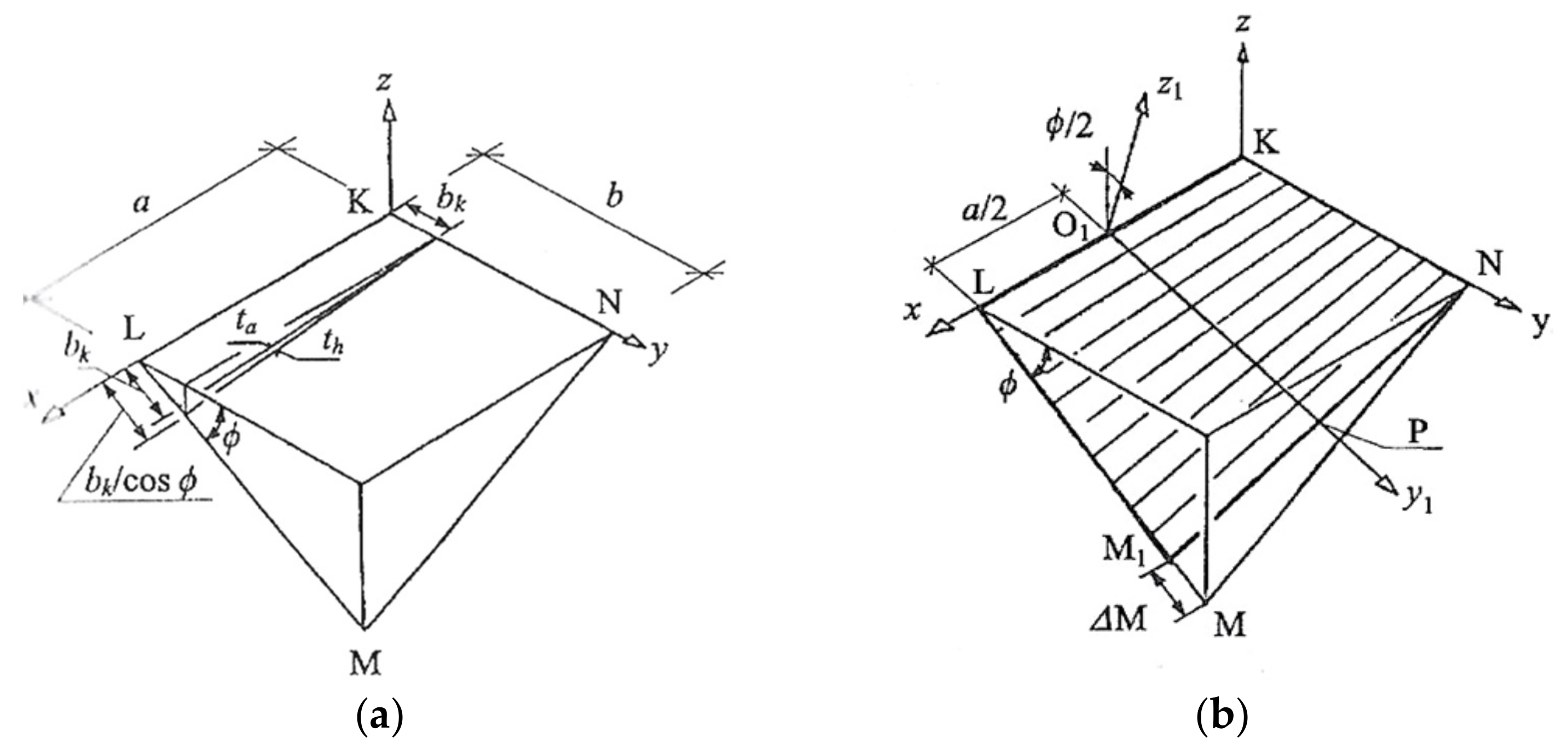

The above-mentioned researchers adopted the following traditional concept of geometric shaping of the transformed shells. At the beginning, they assumed the shape of a spatial quadrangle modeling the edge line of the designed transformed shell. Then they adopted two opposite lines; for example, LM and KL (see

Figure 5a,b), as the directrices of the transformed sheeting. These directrices are linear elements of the roof construction supporting the designed shell along its edge line passing transversely to the fold’s direction. The segments KL and MN model the longitudinal edges of the border folds of the sheeting. After unfolding the subsequent sheets on the skew directrices, all folds try to adjust their shape to the mutual position of the directrices. Thus, the folds change the shape of their cross-sections, including the width, along their length depending on the supporting conditions that change along the length of each directrix.

Since the directrix LM is longer than the directrix KN in each right hyperbolic paraboloid quarter, the subsequent sheets are spread only over the section LM1 of the directrix LM. To cover the empty triangle MM1N with the transformed sheeting, its transverse ends passing along the directrices must be stretched, which causes additional stresses in relation to the ones caused by the free unfolding of the sheets on the skew directrices.

If b

k is the length of one transverse end of a sheet supported by the directrix KN (

Figure 5a), the opposite end must be extended to the length b

k/cos (ϕ) so that the entire directrix LM could be covered with the transverse ends of all subsequent sheets of the designed roof shell. The angle f between the directrices KN and LM is the total twist angle of the outside sheet containing the edge KL, if the directrices are rulings of a quadrant right hyperbolic-paraboloid sector.

The ϕ total twist angles of all subsequent folds of the shell modeled with the sector are different from themselves, which results from the changes in the inclination angles of the longitudinal edges of these folds to the directrices. The angle between the edges KL and KN is always right for the case of a quadrant sector of a right hyperbolic-paraboloid. The same is true for the angle between KL and LM. On the other hand, the angle between KN and NM or between NL and ML is different from right. Thus, the total twist angle of each shell fold, denoted in

Figure 5 as ϕ, is congruent with the angle of the inclination of two planes defined by each of the directrices and a longitudinal edge of the fold.

The unit twist angle of this sheet is the quotient of the ϕ total twist angle and the a length of the sheet expressed in meters. The length of each transverse end of a transformed sheet depends on the profile type, length and degree of twisting of its subsequent folds.

The adjustment of all longitudinal shell fold’s longitudinal edges to the adopted finite number of rulings of the designed hyperbolic paraboloid quarters imposes a significant change in the width Δ

M of the transverse fold’s ends passing along each roof directrix

LM and important initial stresses [

13] (

Figure 5b). Therefore, the conventional methods drastically limit the variety of the designed transformed folded shell forms to central sectors of right hyperbolic paraboloids [

13] and their quarters [

14,

15]. Therefore, the shells designed by means of these methods enforce unjustified additional stresses resulting from the need for the adjustment of the shell fold’s longitudinal axes to the locations of a selected few rulings and the length

LM of the adopted directrix. The additional forces cause a reduction of the searched shell forms to shallow hypars.

Davis and Bryan [

16] described the most important geometrical and mechanical characteristics of thin-walled flat and transformed shell folds. They showed a complete way of analyzing and designing various shells and structures made up of two-layer corrugated sheets located in two orthogonal directions. Two most important general conclusions given by these authors, and regarding the transformed roof shells, are as follows. They found that, theoretically, it is possible to shape many different configurations of the transformed folded shell sheeting. Practically, it is possible to build only cylindrical and a few hyperbolic paraboloid types of the transformed roof shells due to the available technology and the technique of the assembly of the nominally plane folded sheets.

Therefore, the use of the conventional design methods [

1,

7,

11,

17] in shaping such transformed two-layer shell roofs is ineffective. The methods usually result in high levels of transverse tensile normal stresses, local buckling and distortion of thin-walled walls. On the basis of the results achieved by the above-mentioned researchers, it can be stated that the assembly of each designed shell sheeting onto skew roof directrices is often impossible because of the plasticity of the fold’s edges between the flanges and webs or transverse ends of the flanges of the most transformed shell folds.

In the 1990s, Reichhart elaborated a new method for shaping deformed corrugated steel shells [

13]. The algorithm of this method results from the specific orthotropic geometric and mechanical properties of elastically transformed folded sheeting [

18]. Its main advantage is that the initial stresses are the smallest possible and the freedom of the transversal width increments of all shell folds is assured. His method relies on modeling the subsequent folds by means of sectors of right hyperbolic paraboloids, which enables one to reduce the initial effort of all shell folds belonging to deep, medium or even shallow right ruled surfaces. However, the Reichhart’s method is only accurate if the fold’s directions are perpendicular to the contraction of the designed transformed shell or very close to those. This is caused by the fact that he did not introduce a condition related to the location of the contraction of the transformed shell folds.

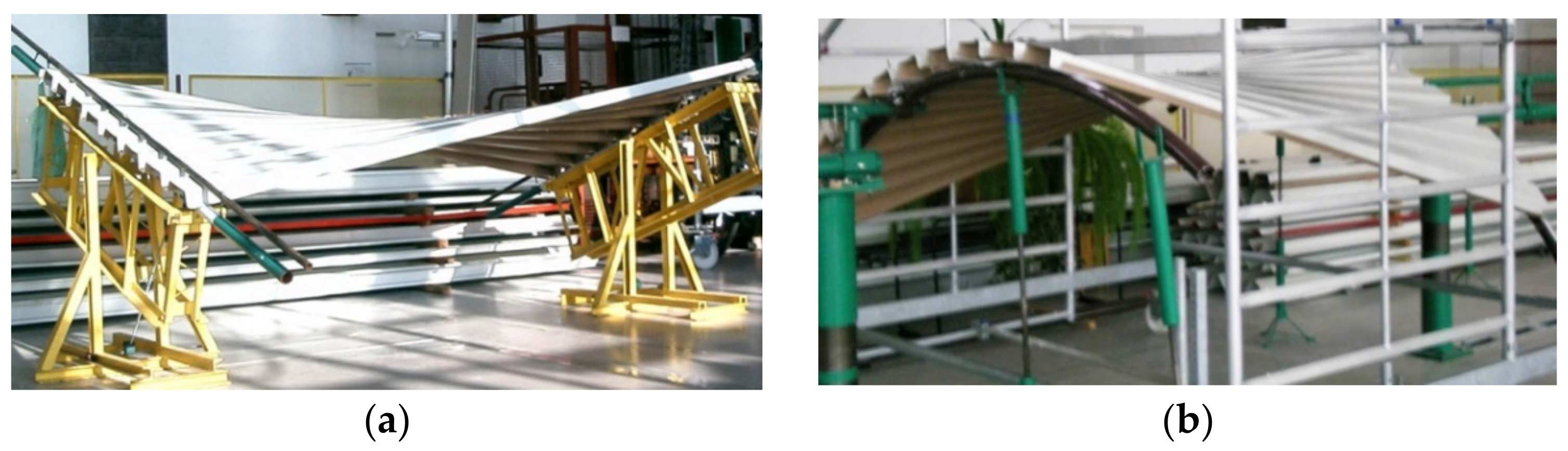

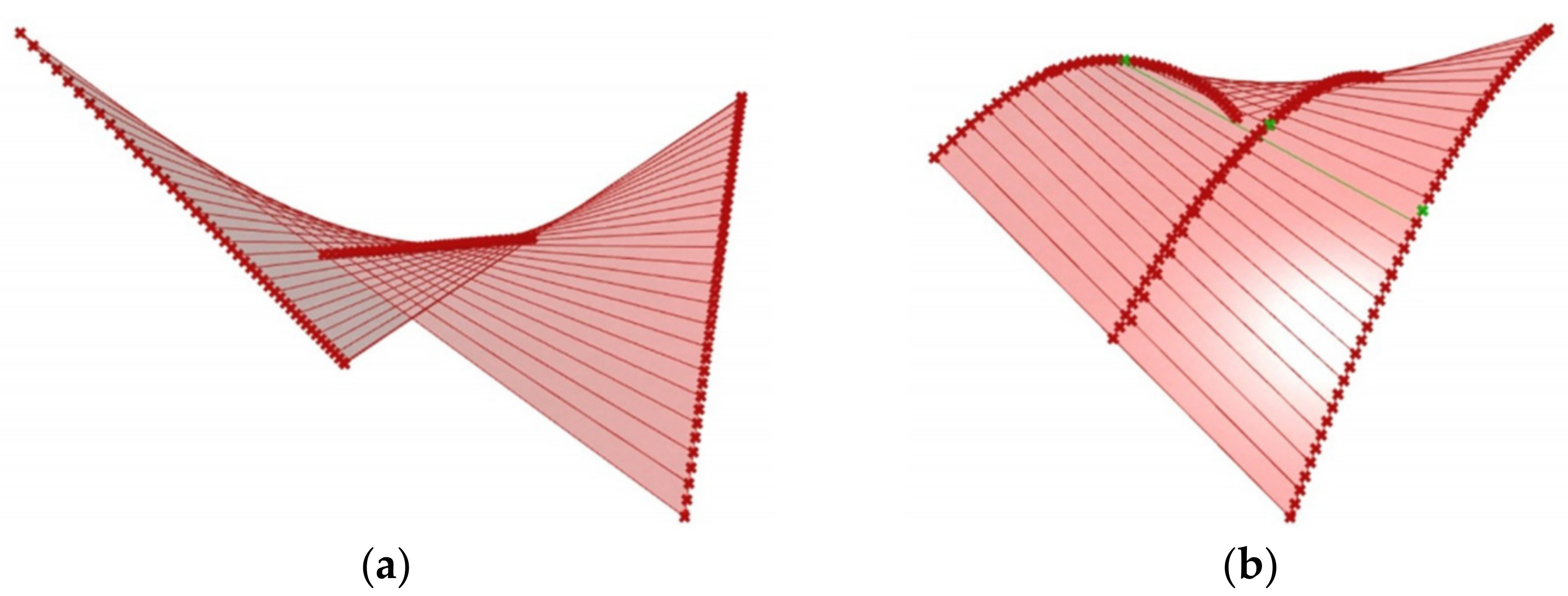

Abramczyk [

19] invented a condition requiring the contraction of the entire corrugated shell sheeting to pass halfway along the length of each its fold (

Figure 6a,b). He utilized the lines of striction of various warped surfaces (

Figure 7a,b) to obtain smooth models of shell folds characterized by the effectiveness of their shape transformations [

20]. The Abramczyk’s method also relates to calculations of the respective surface areas modeling compressing and stretching zones on the transformed folds [

21]. The condition was defined on the basis of his analysis related to the results of the experimental tests [

22] and computer simulations [

21,

23].

Samyn [

24] elaborated a method of shaping two-layer transformed folded aluminum shells and their structures. He has also explored the possibility of using PVC trapezoidal plastic sheets for transformed coverings [

25].

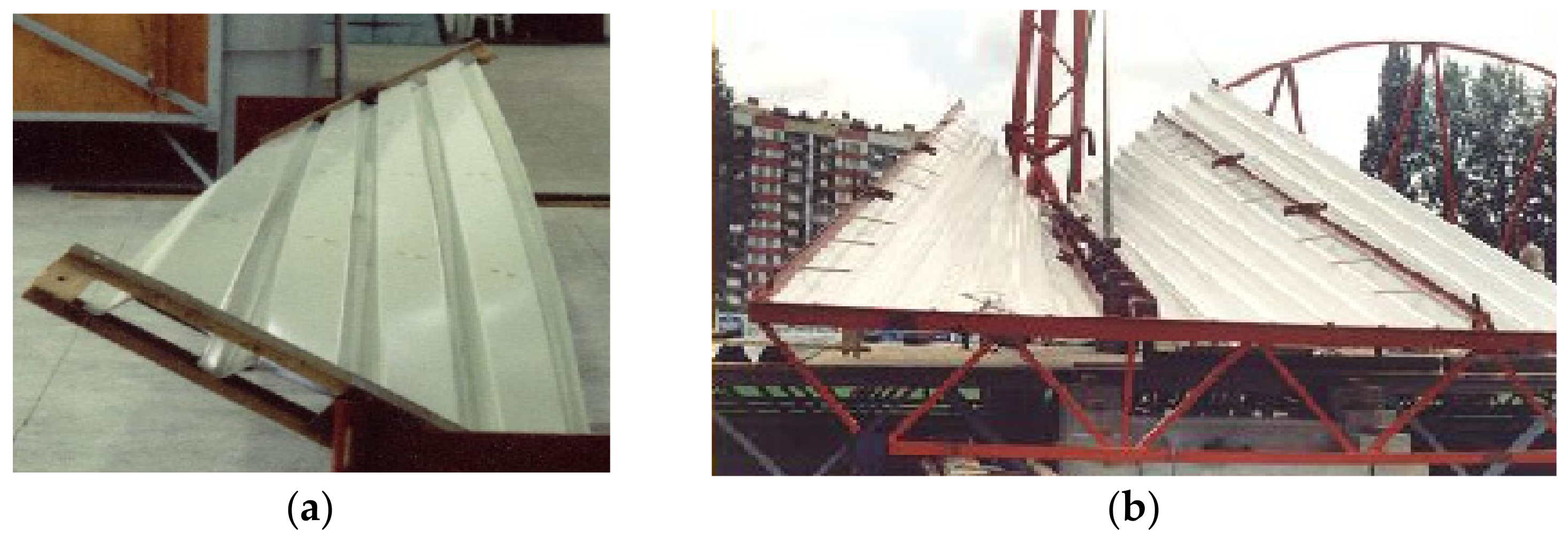

Transformed folded sheets can increase the visual attractiveness of the roof when viewed from the outside (

Figure 1) or the inside (

Figure 2b). Most often, however, in order to increase the durability of the roof, the sheeting is used as a bottom load-bearing layer supporting thermal insulation and insulating foil (

Figure 2a).

As a result of joining the sheets with their longitudinal edges and supporting them on different skew directrices, unconventional coatings are formed [

18,

19]. They have a rather small span equal to the length of the shell folds and a contraction passing transversally in relation to the fold’s directions. Transformed shells of medium and large spans may be considered at a relatively small level of accuracy, where many individual shells with similar geometric properties are regularly distributed in the three-dimensional Euclidean space [

26].

Reichhart also elaborated a method for arranging many complete corrugated shells on a horizontal or oblique plane [

18] to achieve various continuous ribbed shell roof structures (

Figure 8). Each corrugated shell sheeting designed by Reichhart is stiffened with a spatial framework, intermediate girders and oblique bracings [

19].

A method for shaping regular ribbed roof structures composed of many identical ruled sectors made up of transformed folded steel sheets and arranged on one sphere was defined by Biswas and Iffland [

27]. In the first concept, shown in

Figure 9a,b, they proposed triangular revolved hyperboloid sectors. The important feature of this concept is the proposed system of a few planes, dividing the roof structure into shell segments. This concept requires significant oblique cuts and a big transformation degree of all folded sheets.

In the second concept, quadrilateral hyperbolic paraboloid sectors divided by the spherical system of planes are used (

Figure 10a,b). The twist degree of all complete hyperbolic paraboloid sectors is rather small compared to the previous structure.

Prokopska proposed various ways to increase the attractiveness of the ribbed shell structures. These are as follows: (1) areas of discontinuity between the adjacent steel segments, filled with, for example, glass panels (

Figure 11); (2) green plant gardens placed on the transformed segments; and (3) communication routes between the segments [

28]. To create attractive regular complex structures composed of many complete roof shells, he developed a geometric method [

26] of creating a spatial polyhedral reference net arranged on various regular smooth surfaces of positive, negative or zero Gaussian curvature. The division of the network into spatial tetrahedral meshes allows one to easily locate single transformed folded shells and bar constructions supporting these segments in the three-dimensional space.

The above-mentioned problems show the wide possibilities of using the specific orthotropic geometric and mechanical properties of folded sheets in rational shaping of the transformed roof coatings [

29,

30]. A respective analysis should be carried out at different levels: single points, walls or folds, smooth shell models, and ribbed structures composed of many smooth transformed shell segments [

31,

32]. The presented issues indicate many unexplored areas in the field of effective elastic transformations of thin-walled folded roof shells and great possibilities of geometric and mechanical analysis at many different levels of accuracy.

Parameterization of the transformed shapes enables one to computationally search for attractive unconventional building free forms [

22,

26,

33] and innovative structural systems intended for the investigated building free forms. Obrębski [

34] developed a few methods for shaping very diversified shell rod structures. Rebielak [

35] developed steel rod structural systems supporting flat roof covers composed of corrugated sheets. Abel and Mungan [

36] present many examples of the construction systems associated with shaping many diversified roof shells and building free forms. Nominally plane folded steel sheets transformed plastically into shell shapes are used as curved supports for shell panels of entire roof covers [

37]. In this way, convex roof shells characterized by a positive Gaussian curvature are created. Nominally plane folded steel sheets transformed elastically into shell shapes are used as suspended roof structures [

38,

39].

4. The Concept of the Research

The essential step of the research is the analysis of the orthotropic geometric and mechanical properties of the thin-walled folded sheets in order to select those properties that have a decisive influence on the form and work of the sheets in the transformed roof shells. The next step concerns the parameters describing these properties, so that they allow one to shape rational transformed sheet forms as (a) structural rod elements (for example, thin-walled beams), and (b) filling shell elements as, for example, an outside roof cover or a lost shell roof formwork. The presented analysis is based on the results of the laboratory tests related to the different transformation degrees and types of the profiles used for the transformed experimental shells.

The obtained results related to the geometric analysis of the shape properties of the transformed folded sheets treated as a two-dimensional orthotropic material are the basis for deriving the geometric stiffness matrix [

40] and elasticity constants of various transformed shell sheeting. Thus, the shell shapes defined in a three-dimensional space by means of this material are described by two curvilinear coordinates.

From the above assumption, it follows that the transformed shell coverings are to be modeled by means of various smooth sectors and characteristic lines of regular warped surfaces [

33]. The analyzed basic geometric elements are contracting lines, edge lines, supporting lines and central sectors of warped surfaces. The standardized variables are the lengths of the above-mentioned lines and the areas of warped surfaces modeling the entire transformed shells or their individual folds. In order to define the zones of compression and tensile stresses appearing in each shell fold of a transformed roof, the width changes along the length of the fold are determined by means of the above variables.

The level of the accuracy of the analysis related to the geometric properties of the entire transformed folded shells or their complete folds does not have to be great. It may be limited to central sectors and lines distinguished on two-dimensional warped surfaces [

19]. On the other hand, the level of the analysis related to a stress state of each shell fold must refer to the selected points characterizing all individual walls of the fold and their common edges [

41]. Therefore, the level of the detailed mechanical analysis associated with the transformed shells is significantly greater than the previous one.

In order to elaborate a quantitative description of the effective shape transformations of the corrugated shells, such parameters related to the mechanical properties of the folded sheets as shear or normal stresses and strains are examined [

42,

43]. The effect of these transformations is to be such a state of equilibrium in which the effort of each shell fold is going to be the smallest possible and the work of the internal forces is balanced out [

44]. Therefore, the following are considered: (a) the type of the stress state, e.g., whether it is pure shear or complex stress state [

45], (b) loading conditions, and (c) supporting conditions adopted for the entire cover and its complete folds. As a result, the interdependences between the parameters describing the form and the stress state of each folded shell, the transformation degree and the adopted supporting conditions of the shell are sought.

The invented dependencies should describe the subsequent momentary states of equilibrium of all shell folds, obtained as the result of the effective subsequent transformations corresponding to the increase in the transformation degree. A quantitative description of these configurations should allow one to derive displacement equations of each transformed shell using smooth sectors of regular warped surfaces. On the basis of the above equations, it becomes simple to calculate the strains, stresses and the form of the designed transformed shell, including the length of its directrices, edge lines and line of striction.

The big variety of the employed sheet types, ways of joining these sheets in the roof shells, methods of modeling, loading and supporting of the designed shells induces the development of a universal accurate thin-walled FEM computer model [

41]. Such a model was developed and then initially configured based on the results of the experimental research [

23]. This model is used in the presented research. It is planned to be used in further studies, too.

5. Geometric Characteristics of the Transformed Folded Roof Shells

The nominally flat folded sheets are subject to the initial transformations to achieve their shell shapes. The unstiffened longitudinal edges of the transformed sheets become convex arcs (

Figure 12a). If the longitudinal edges are stiffened with special rigid profiles or other profiled sheets,

Figure 12b, then the edges and longitudinal axes of the subsequent folds can be regarded as straight. It is necessary to provide all transformed shell folds with appropriate boundary conditions. In particular, the technique of unfolding the sheets onto the roof directrices, joining the sheets longitudinally and fixing the folds to the roof directrices should assume the pre-stresses and pre-strains of each shell fold to be the smallest possible regardless of the transformation degree. In addition, the longitudinal edges of all shell folds ought to stay straight.

Uncontrolled shape transformations of the sheets lead to large deformations of their walls: flanges and webs resulting from the small transverse bending stiffness and the twist stiffness around the longitudinal axis of each fold. On the other hand, the relatively high deformations of the walls and high transformation degree of each shell fold are necessary to obtain deep, medium and even some shallow shells. They cause non-linear relationships between different dimensions characterizing the shell form of each transformed folded sheeting. It is advisable to reduce the level of the initial effort of the fold by limiting the value of its twist degree or using a method assuring the freedom of the transversal width increments of each shell fold. In this case, the shape transformation is called effective.

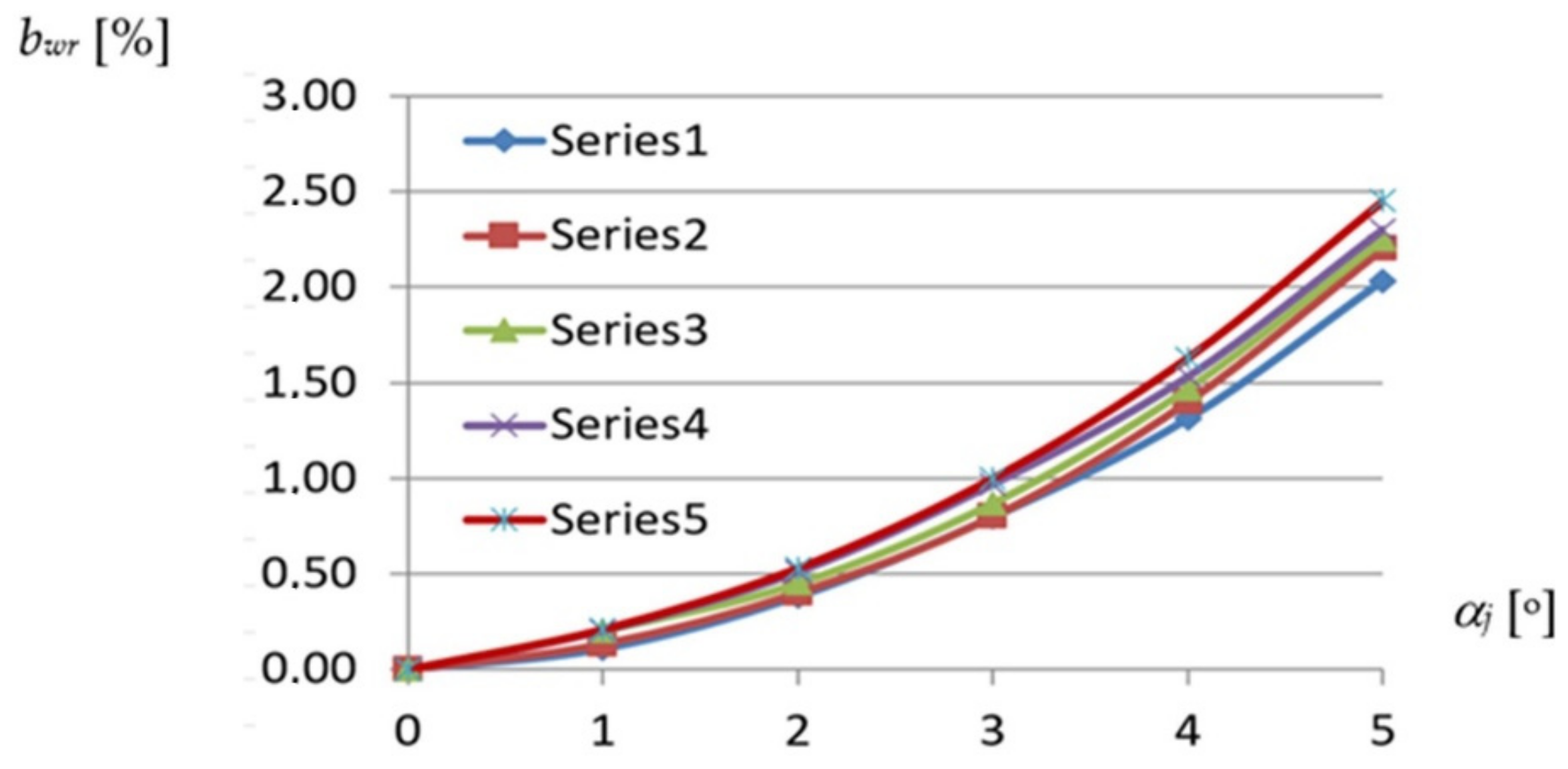

The most important dependence used in the description of the geometrical properties of each effectively transformed shell fold is defined between the width of the fold along the roof directrix and its transformation degree (

Figure 13) adopted as the unit twist angle of the fold resulting from the inclination of two skew directrices supporting the fold at its crosswise ends (

Figure 12). The denotation TR 50 mm × 0.75 mm × 8.0 m means that the folds of the examined sheets are trapezial—TR and the height, thickness and length of these sheets are respectively equal to 50 mm, 0.75 mm and 8.0 m.

Total twist angle

αc of a shell fold or sheet, shown in

Figure 5 as ϕ, is defined as the angle of twist of the opposite transverse fold or sheet’s ends passing compatibility with the directrices of a shell. The unit twist angle

αj is defined as the total twist angle

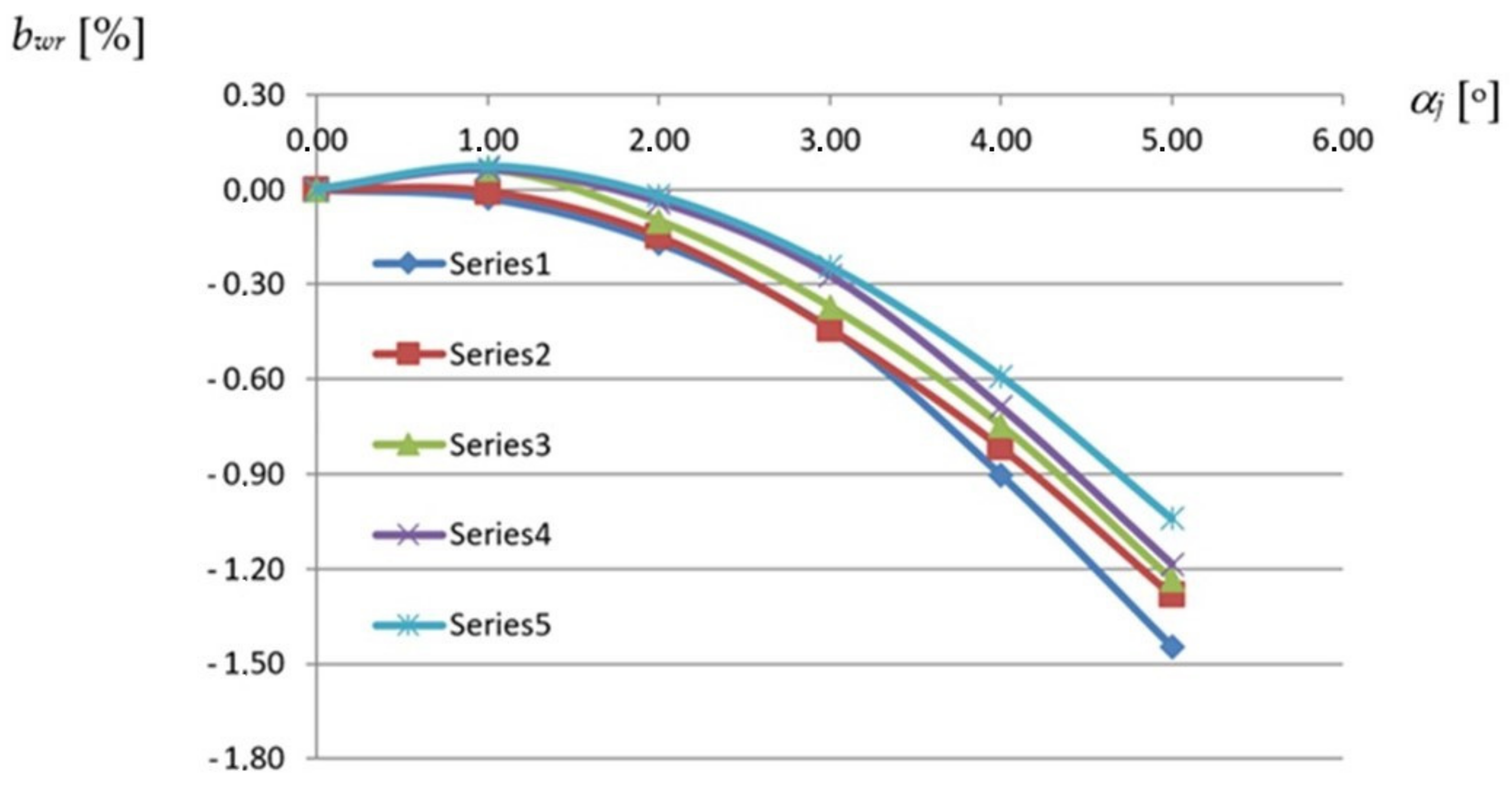

αc divided by the length of the fold or sheet measured in meters. On the basis of the observations made, the unit twist angle defining the transformation degree is assumed to be constant along the fold’s length. To precisely study the obtained relationships and make the analysis independent of the number and width of the folds in the considered sheets, the relative width increments are considered. The relative

bwr width increments of any shell fold are defined as the quotient of its absolute

bw width after transformation to the width

b0 of the fold before the transformation as follows:

Each of the lines, Series1 to Series5, introduces a relationship obtained for the reference fold of the experimental folded shell of a strictly defined profile. For example, the Series1 line represents the relationship between bwr and αj of the reference fold defined for the TR 50 m × 0.75 mm × 8.0 m profile. This line was determined on the basis of six points whose coordinates are the values of the unit twist angles and the values of the relative width increments of the above-mentioned fold. These values were obtained for the successive configurations of each experimental shell generated by means of an increase in the transformation degree of this shell. Therefore, for five different shells being characterized by a different profile, five reference folds were determined. The presented characteristics of these folds were examined in six subsequent configurations of each respective transformed experimental shell, where each configuration was generated by increasing the transformation degree of the shell. Each quantity describing the respective property of the reference fold was calculated on the basis of the corresponding quantities measured during the tests for several adjacent folds of the examined experimental shell.

The above diagram, shown in

Figure 13, shows a relatively small variation in the influence of the profile type on the fold’s shell form in the range of the unit twist angle of up to 3.5°. In this case, the variation causes an insignificant differentiation of the fold’s width increments comparable with the measurement accuracy of about ± 0.5 mm, which corresponds to the value of

bwr = ± 0.2%.

The above dependencies were obtained by means of the experimental tests on the experimental stand [

14,

20,

42] (see

Figure 6). They made it possible to configurate the elaborated thin-walled FEM computer models [

23] (

Figure 14 and

Figure 15) used in computer simulations whose results are presented in the next section.

On the basis of the analysis made to date, it should be stated that the folded sheets with (a) free longitudinal edges (

Figure 12a), and (b) stiffened longitudinal edges (

Figure 12b) are characterized by mutually different geometrical relationships [

14]. Both types of the sheets can be modeled with the same type of ruled surface, but the sectors of this surface corresponding to the above sheets must be different [

20]. In the first case, the free longitudinal arcuate edges are modeled with curved lines. In the second case, the longitudinal edges are straight. The above two types of folded sheets cause different lengths of their contracting lines, and different lengths of their supporting lines passing along their crosswise roof edges. Therefore, the sheets with free longitudinal edges should be converted to sheets with straight longitudinal edges by means of the same type of smooth surface.

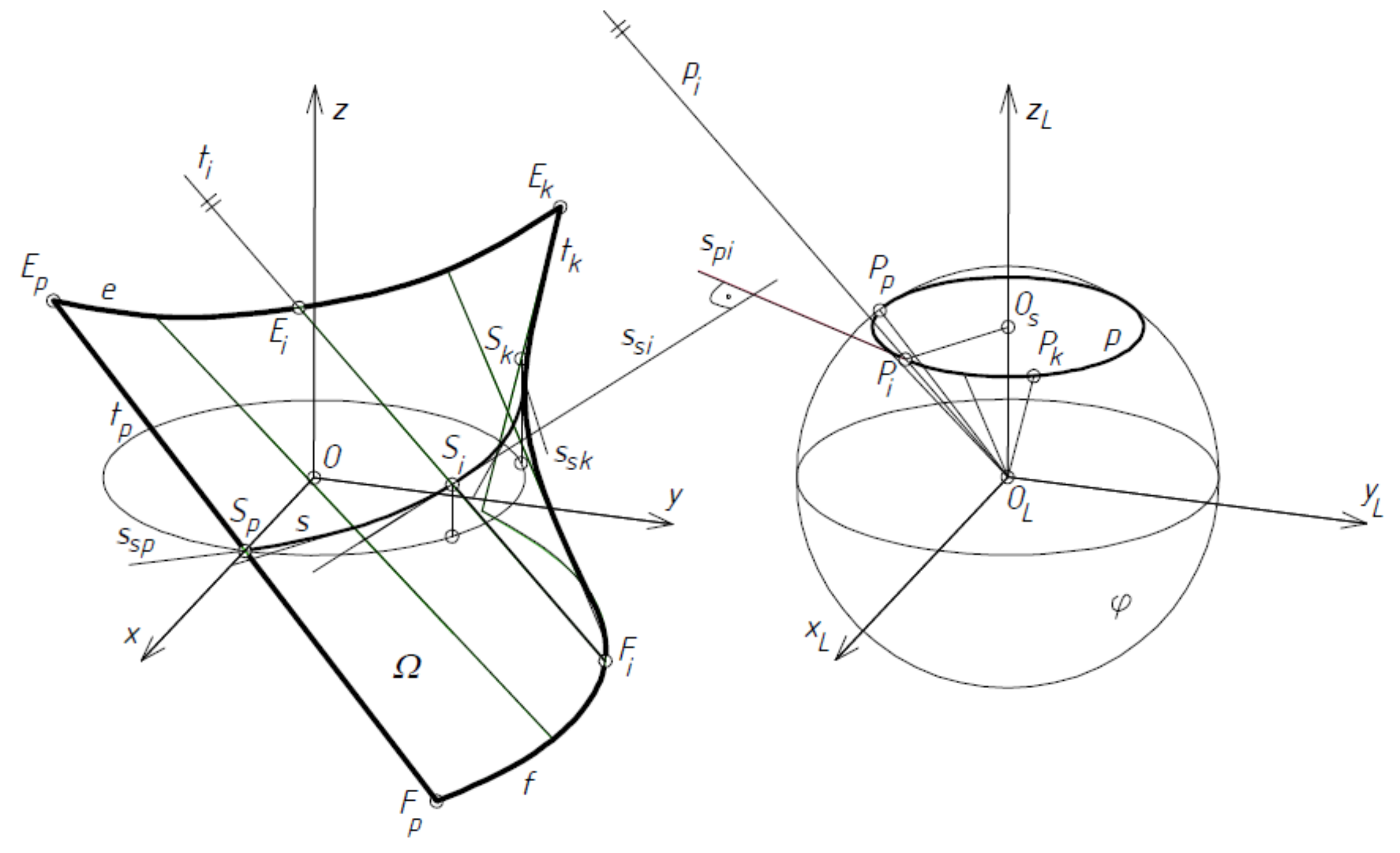

In a general case, the equation of ruled surface

Ω modeling one fold, sheet or whole transformed shell is as follows:

where

r(

u,

v) = [

x(

u,

v),

y(

u,

v),

z(

u,

v)] is the vector of the position of any point on a ruled surface

Ω,

e(

u) is the vector of the position of any point on directrix

e (

Figure 16), and

p(

u) is the unit director vector of ruling

ti. All vectors

p(

u) can have one common origin at point

OL and determine that spherical indicatrix

p(u) contained in sphere

φ of the unit radius and center

OL, and

u,

v are curvilinear coordinates of

Ω.

The location of any point on the line of striction

s(

u) of

Ω in relation to directrix

e(

u) of

Ω, can be determined by the following formula:

where

s(

u) is the line of striction composed of the central points of all rulings

ti of

Ω, and

v is the parameter describing the position of any point of

s(u) on the respective ruling

ti in relation to the adopted directrix

e(

u). If

s(u) is adopted as directrix

e(

u), the following condition must be satisfied:

which results from comparing Equation (3) to zero. From Equation (4), it follows that the

s′(

u) straight line tangent to

s(

u) and the straight line

p′(

u) tangent to the spherical indicatrix

p(

u) of

Ω have to be perpendicular to each other, so

If Equation (5) is preserved, the function e(u) in Equation (2) should be replaced by representing a line of striction modeling the contraction of the designed folded shell.

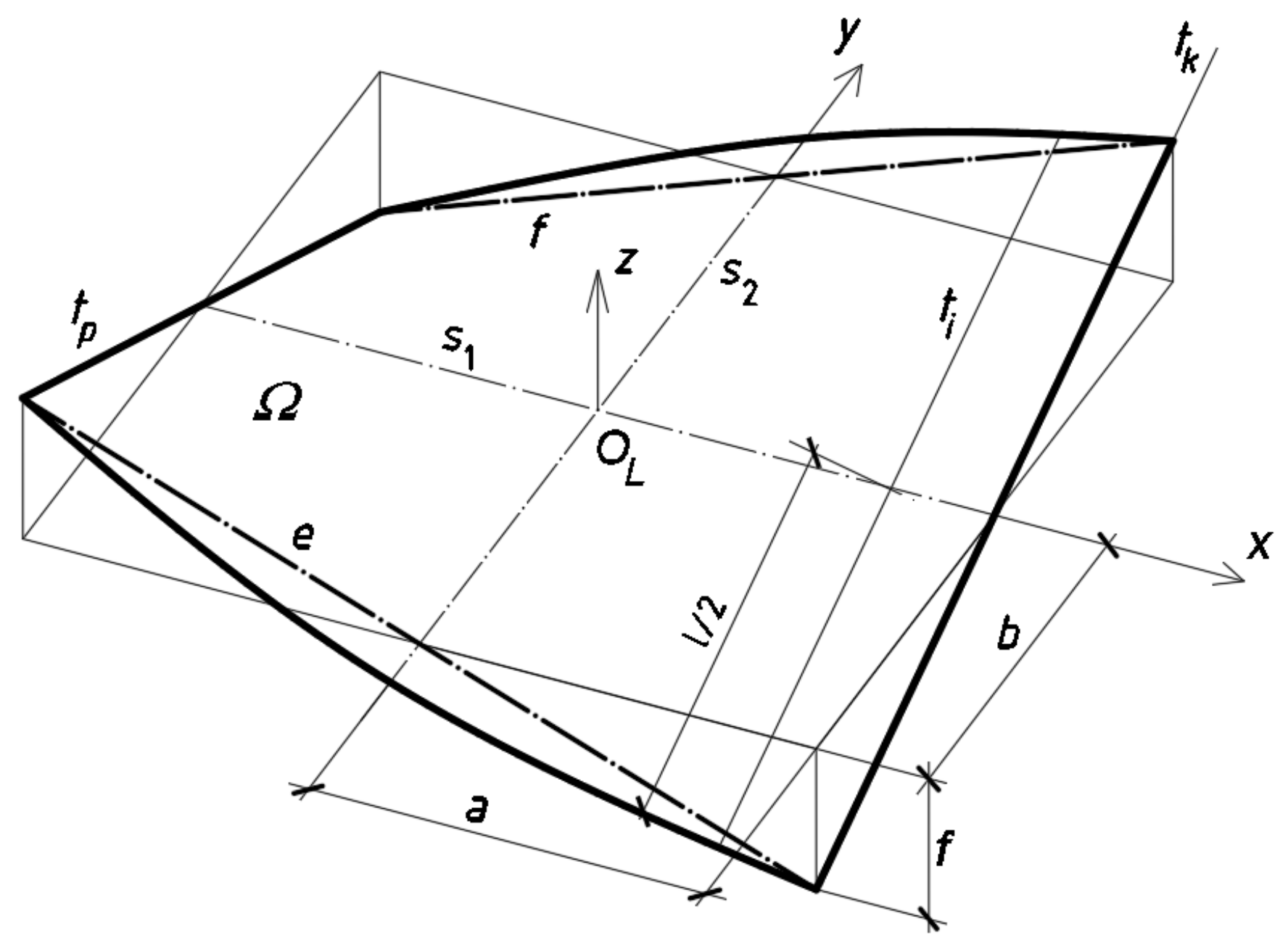

A special type of ruled surfaces is used in the further considerations. This is right hyperbolic paraboloid,

Figure 17, whose mathematical equation is as follows:

where

f,

a and

b are the constants determining the right hyperbolic paraboloid

ω, its sector

Ω and line of striction

s1.

A parametric equation of right hyperbolic paraboloid can be created by means of Equation (2) as follows:

where

a,

b, and

f are the constants characterizing the right hyperbolic paraboloid sector

Ω,

Figure 18. The following parametric equations of its line of striction

s1 are used in the modeling shell folds

The second line of striction of the paraboloid is a straight line s2 perpendicular to s1 and contained in the plane (x,y). The line s2 is not employed in the further analysis. The above parametric equations are convenient for defining some quantitative geometrical relationships describing the basic properties of right hyperbolic paraboloids because, for example, the parameter v expresses the position of a point along the length of each ruling, so it changes from −l/2 to l/2 for all subsequent folds of each transformed shell.

On the basis of the relative width increments

bwr presented in

Figure 13 and referring to the transverse edges of the transformed folds of different profiles, the minimum widths

bwr of these folds at a half along their length were calculated assuming that each fold is modeled by a central sector of a right hyperbolic paraboloid given by Equation (7) and its line of striction by Equation (8). The diagram (see

Figure 19) presents relations between the relative width increments

bwr measured at a half along the fold’s length and the unit twist angle of the reference shell folds assigned to various types of profiles. The relative width increments

bwr of these folds were calculated using Equation (1).

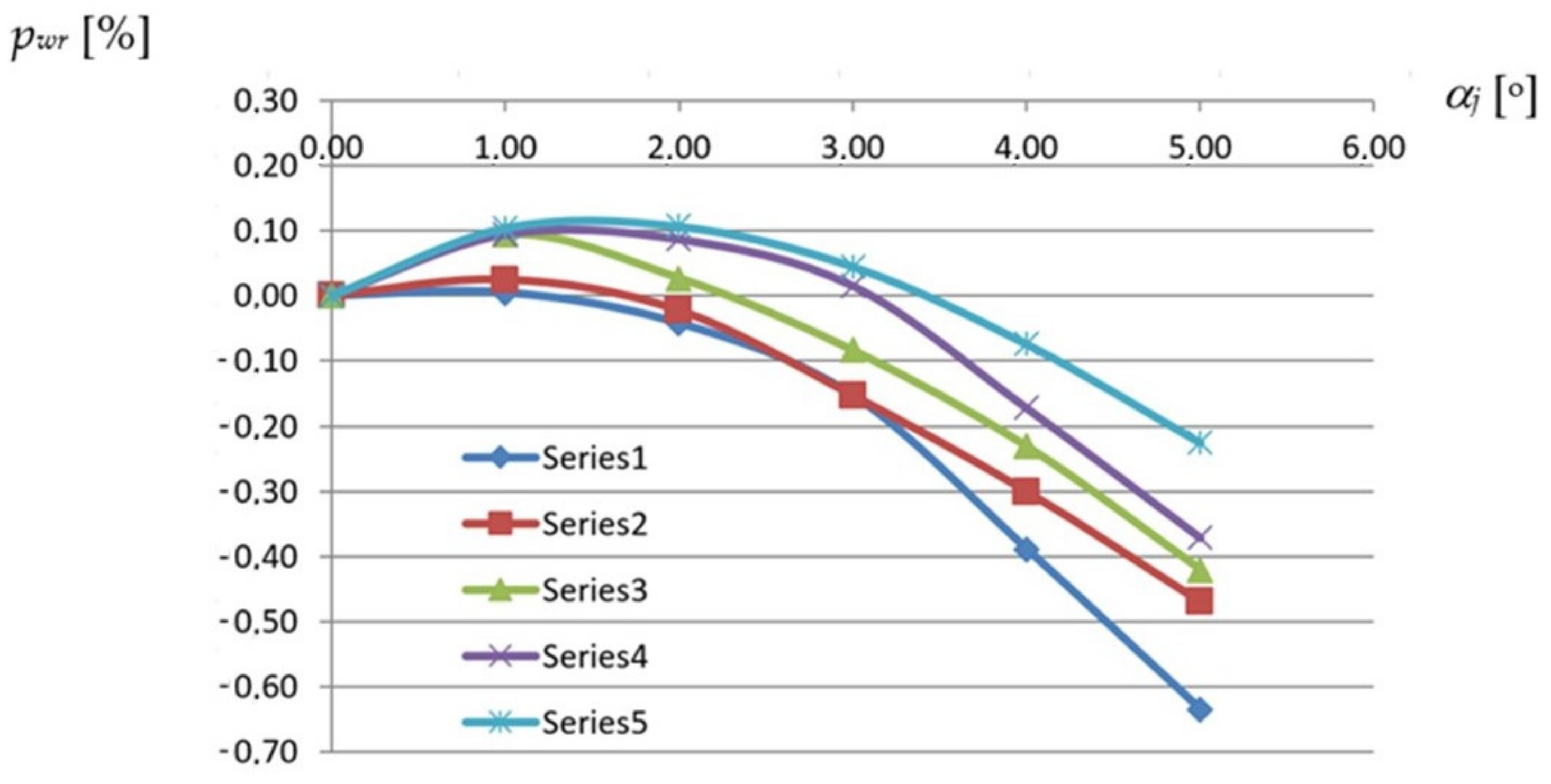

The relative

pwr neutral surface increments of any shell fold are defined as the quotient of its absolute

pw neutral surface area after the transformation to the plane neutral surface area

b0 of the fold before the transformation as follows:

The Series1 line corresponds to the same TR50 × 0.75 mm × 8.0 m reference fold for which the same-named line was created in

Figure 13. The difference between these lines is that the values shown in

Figure 13 are the width increments measured along the transverse ends of the reference fold while the values presented in

Figure 19 are the width increments measured at a half along the length of this fold. The above increases are one of the basic variables on which the designed displacement method of shaping the considered shells is planned to be based.

Since all effectively transformed folds contract in a half along the fold’s length in a way dependent on the type of the fold’s profile, the achieved relations assist in determining the smooth shell models of each shell fold by means of the line of striction, especially its shape and length. The absolute values of these increments are approximately halves of the positive width increment values at the stretched crosswise ends of the shell folds. Although the relations obtained between these increments and the degree of twist of the folds are non-linear, some disturbances in the course of the complete curves corresponding to the folds of the higher profiles and the smaller transformation degrees can be noticed. Such anomalies appear due to the significant influence of the weight on the width increments of each fold at a half along its length.

The areas of central sectors

Ω of right hyperbolic paraboloids defined by means of the above-mentioned relationships play a significant role in further geometric and strength analyses. The area surface of the sectors can be calculated as follows:

where the following Jacobi functions must be calculated:

where

l is the length of each fold, and

ukp is the function describing the position of the edge ruling

tk of

Ω defined on the hyperbolic paraboloid. Thus, the function describes the width of the entire transformed shell sheeting.

Centers of gravity of some selected cross-sections of each shell fold are calculated to determine the longitudinal axis of the fold. The longitudinal axes of all folds define a smooth neutral surface of the entire shell and each complete fold. The neutral surface can be taken as a simplified smooth model of the entire transformed shell and treated as a sum of the complete fold’s models. The surface area of this model can be calculated using Equations (10) and (11). This model of the transformed shell can be used together with another smooth model that is created on the basis of the longitudinal straight edges of all subsequent shell folds, see

Figure 5. A rectangle is a simplified smooth model of the flat fold before its transformation. The area of the rectangle is denoted as

p0. The neutral surface area of the fold after its transformation is denoted as

pw. The relative neutral surface area increments

pwr of the fold can be calculated using Equation (9).

The graph presented in

Figure 20 shows that the

pwr relative increments of the neutral surface area of each transformed shell fold nonlinearly decrease with the increase in the fold’s transformation degree. The obtained results depend on the size of the fold. The

pwr relative increment of the neutral surface of each shell fold is defined as the quotient of the

pw absolute neutral surface increment of the fold to its area

p0 before the transformation.

Each of the curves shown in

Figure 20 corresponds to a reference fold designated for a different type of profile. For example, the Series1 line corresponds to the same reference fold to which the Series1 lines, shown in

Figure 13 and

Figure 19, were previously assigned. Each curve from

Figure 20 was derived on the basis of five points whose coordinates are different values of the unit twist angle and the relative increase in the neutral surface area of the fold. These points correspond to the selected subsequent configurations of the appropriate experimental transformed shell characterized by a strictly defined profile. These configurations were generated by gradually increasing the twist degree of the experimental shell.

Some disturbances in the course of the above curves corresponding to the folds of the higher profiles can be noticed for smaller twist degrees. This fact results from the influence of the weight of the transformed folds on the size of the surface areas and that the twist of each hyperbolic paraboloid fold nonlinearly varies along its length. The variability can accurately be expressed by the dependence of the

αi rotation angle of the successive cross-sections along the fold’s length according to the following formula:

calculated on the basis of the geometrical properties of central sector

Ω of right ruled paraboloid, where

f,

a and

b are the constants of

Ω used in (6).

An additional increase in the width of the fold’s transverse end induced by, for example, adjusting this end to the length of the directrix may cause an important change in the position of the contraction line on Ω. The inclination of the contraction line to the ruling ti may also change. As a result, the ruled surface is no longer a right hyperbolic paraboloid. In this way, we obtain the possibility of increasing the variety of the unconventional transformed folded shells forms. The models of such transformed shell sheeting can be adopted in the form of warped surfaces of various types, including conoids or cylindroids. The models can be defined using Equation (2) and their rulings can be determined by means of Equation (12).

The neutral surface areas of the transformed folds and their compressed and stretched sectors are important when calculating the work of the internal forces occurring in each folded shell. The compressed area is related to the line of contraction. The tensile areas refer to the supporting directrices.

The location of the contraction of a transformed shell at the length of all transformed folds must be determined by means of a proper calculation method based on the specific orthotropic properties of the corrugated shells. In addition, respective supporting conditions and ways of loading must be adopted. Each shell fold is in an optimal state of equilibrium if it can freely deform in its transverse directions and its contraction appears halfway along the fold’s length. In the case of straight directrices, the initial stress level is reduced to the smallest possible and the considered central sectors of hyperbolic paraboloids are characterized by straight lines of striction perpendicular to all shell folds.

6. Mechanical Properties of the Transformed Folded Roof Shells

Since the transformed folds are characterized by small transverse bending stiffness and small torsional stiffness around the longitudinal axis, nonlinear geometric relationships are observed. A few basic geometric relationships were presented in the previous section. In the present section, some nonlinear interdependences occurring between the mechanical properties and the unit twist angle of the twisted folded sheets are presented.

Based on the experimental studies carried out in the Rzeszow University of Technology hall [

19,

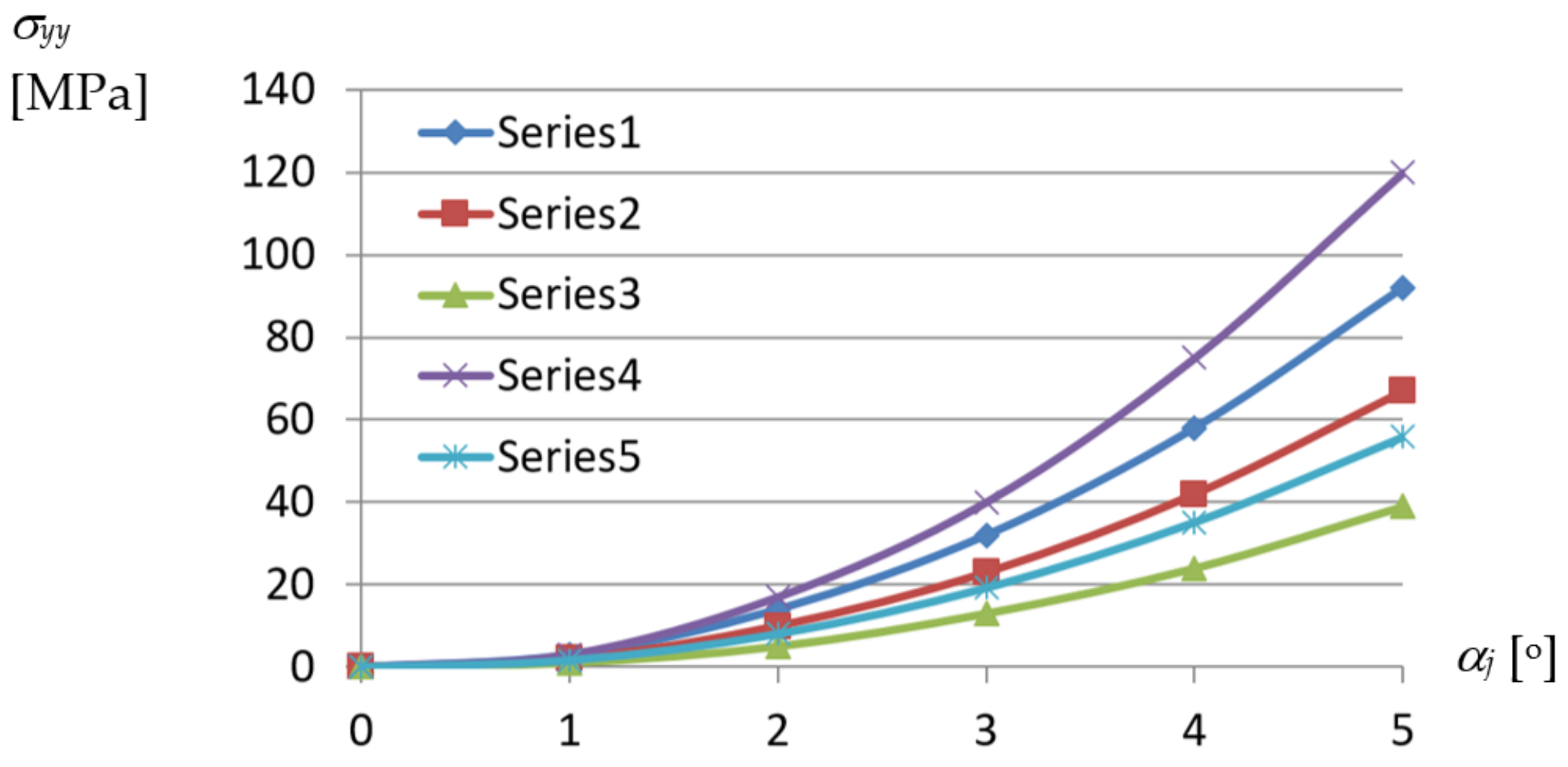

42], there was elaborated a diagram composed of curves corresponding to various profiles, representing relations between the normal stresses acting orthogonally to the directions of the longitudinal axes and

αj unit twist angle of a shell fold (

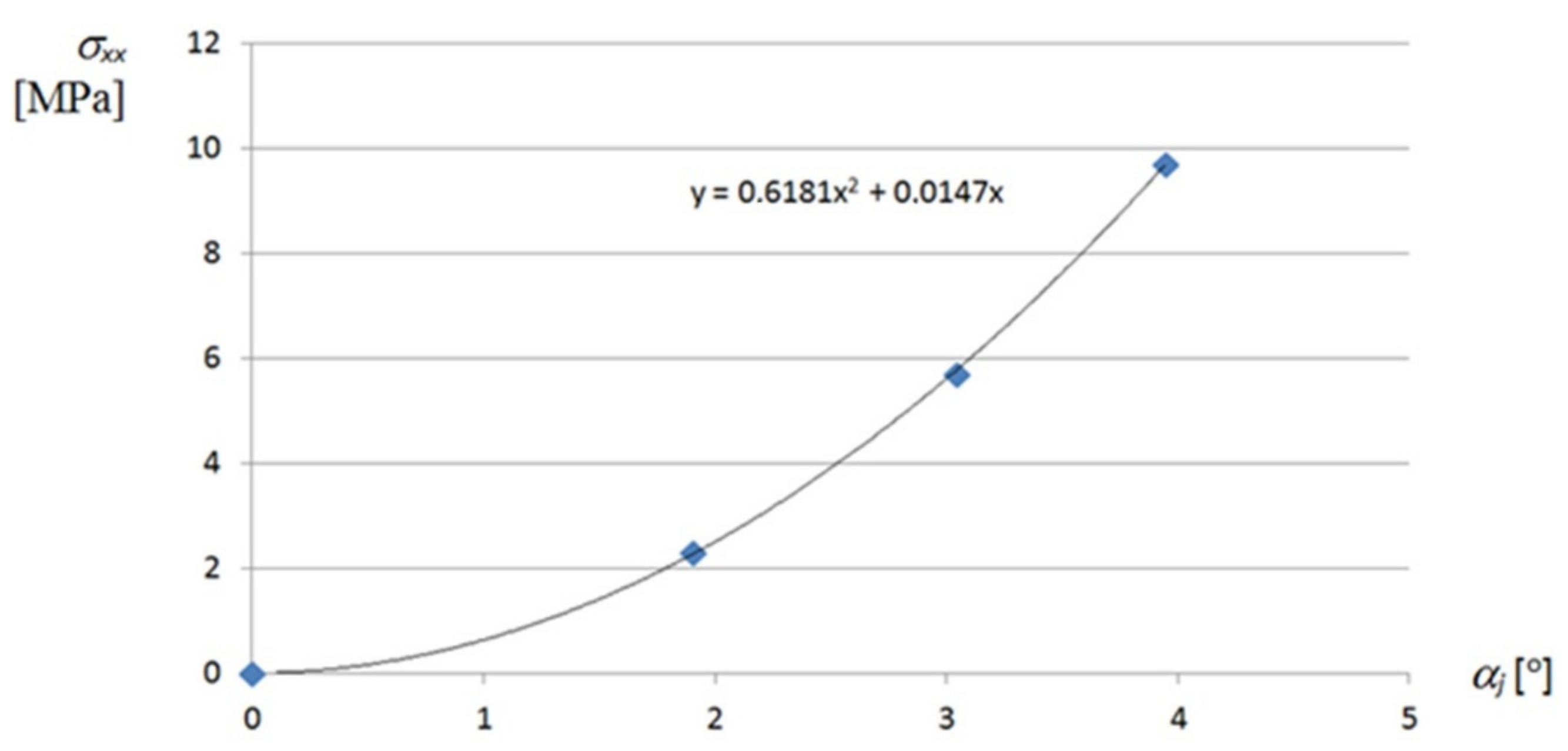

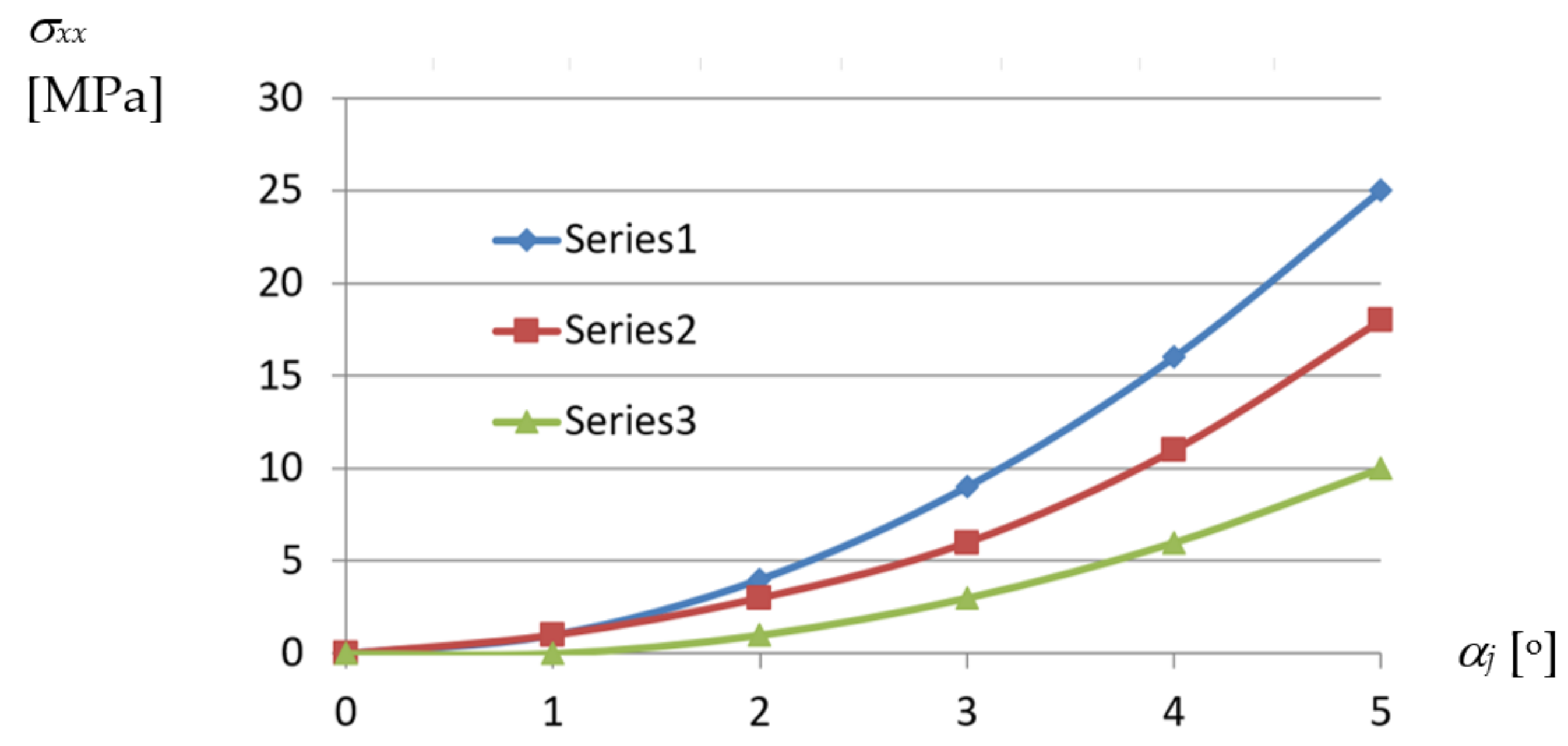

Figure 21).

The curves presented in

Figure 22 and corresponding to various profiles express the relations between the

σxx normal stresses acting along the longitudinal axes of the shell folds and

αj unit angle of these folds.

Similarly, the curves presented in

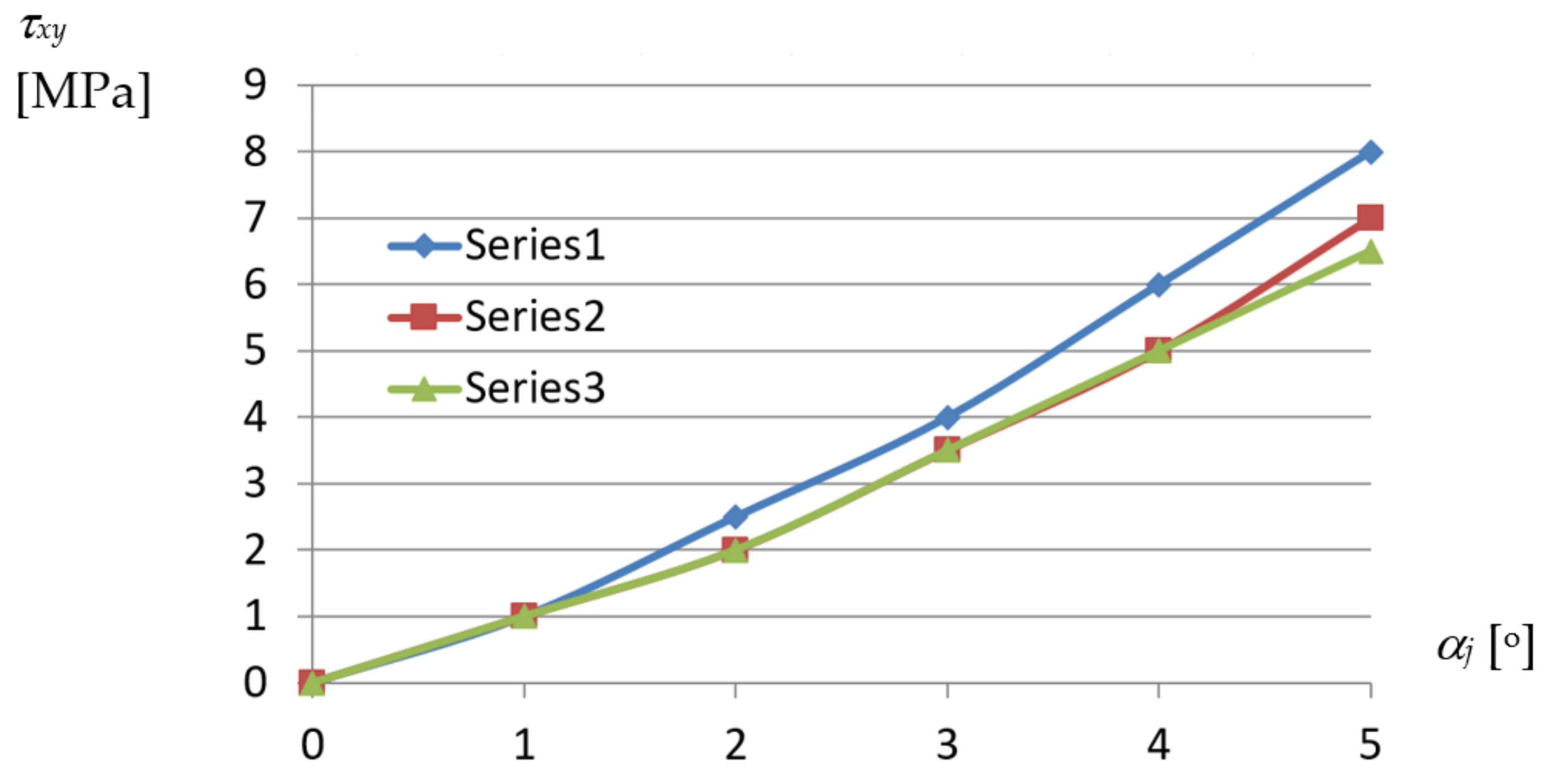

Figure 23 represent the relations achieved between the shear stresses

τxy and the

αj unit twist angle of the examined fold.

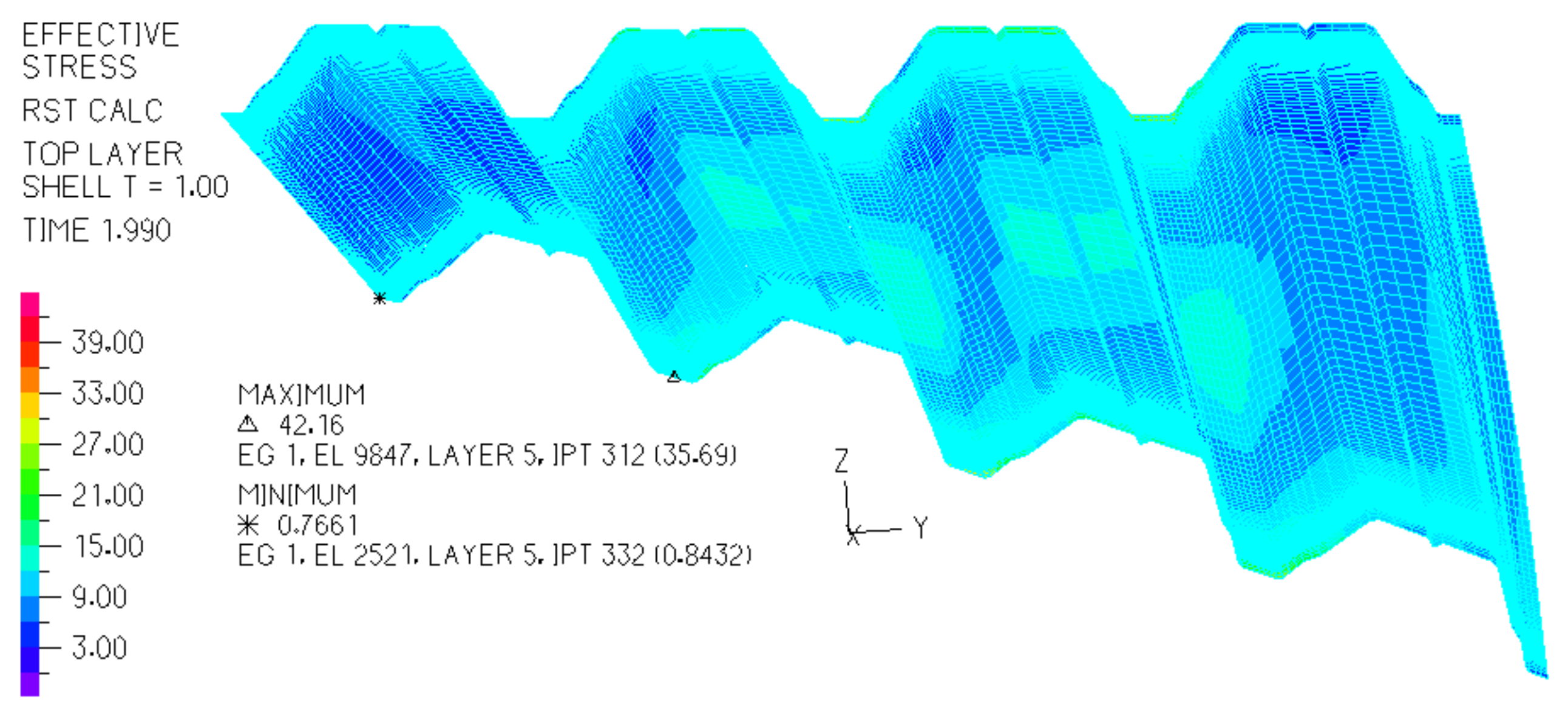

From the above diagrams, the following conclusion can be drawn. The unit twist angle of 3° induces important initial normal stresses of about 10 to 40 MPa in the directions passing transversally toward the fold’s longitudinal axes. Thus, the stresses have to be taken into account during the design process, for the unit angle higher than or equal to 3°. The observed shear τxy and normal σxx stresses, the latter acting along the fold’s longitudinal axes, are of little importance compared to σyy. The big differences in stresses obtained for different profiles, referring to the same measure of the fold’s unit twist angle, are noticed. The stresses non-linearly decrease with the increase in the profiles’ height.

On the basis of the determined dependencies, an elaborated exact thin-walled mechanical model of a transformed fold of the examined TR 85 m × 0.75 mm × 5.0 m profile was configured. The model is used to describe the changes in the geometric and mechanical properties of various effectively transformed shell folds. A relationship obtained between the normal stresses acting transversely to the direction of an effectively twisted fold of the TR 85 m × 0.75 mm × 5.0 m type and the unit twist angle of the fold was achieved by means of this model (

Figure 24). The relationship is represented by the curve labeled Series5. Other curves shown in this figure enable one to compare the achieved results of the experimental tests and computer simulations. All examined shell folds are fastened to the directrices with their lower flanges, only.

The highest normal stresses σyy are assigned to the crosswise fold’s ends and directions passing transversally to the longitudinal axes of the shell folds. The nonlinear tendencies related to the increase in the unit twist angle and height of the examined folds are obvious. However, in the case of Series4 and Series5 referring to the same type of profiles employed, the results are too divergent, most likely because of the actual supporting conditions obtained at the shell fold’s ends fastened to the directrices. In the case represented by the Series4 line, the way of fixing the fold’s end was too stiff, so the freedom of the fold’s width increments was not ensured. In contrast, the relation represented by the Serie5 curve is convergent with the other ones.

Since the results obtained by means of the thin-walled computer model were integrated and standardized by the results of the experimental tests, the mechanical properties of the variously transformed subsequent shell folds can be analyzed using this model to define an orthotropic material employed for shaping unconventional folded roof shell forms. It was assumed that the examined steel sheets modeled by means of the thin-walled computer model are of the T85 × 0.75 profile, see

Figure 25, and 5.00 m length. The modulus of elasticity E = 2.05 GPa.

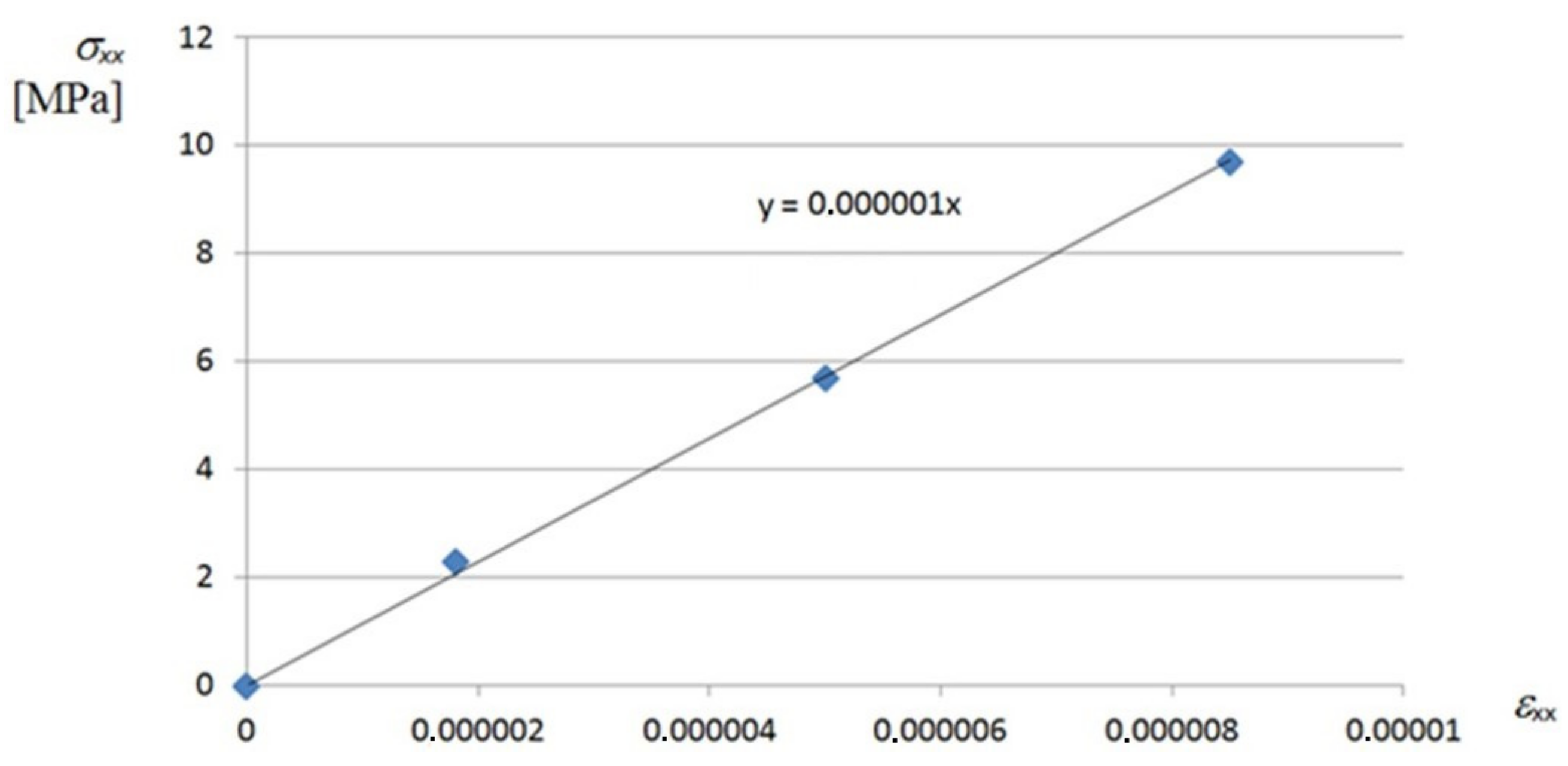

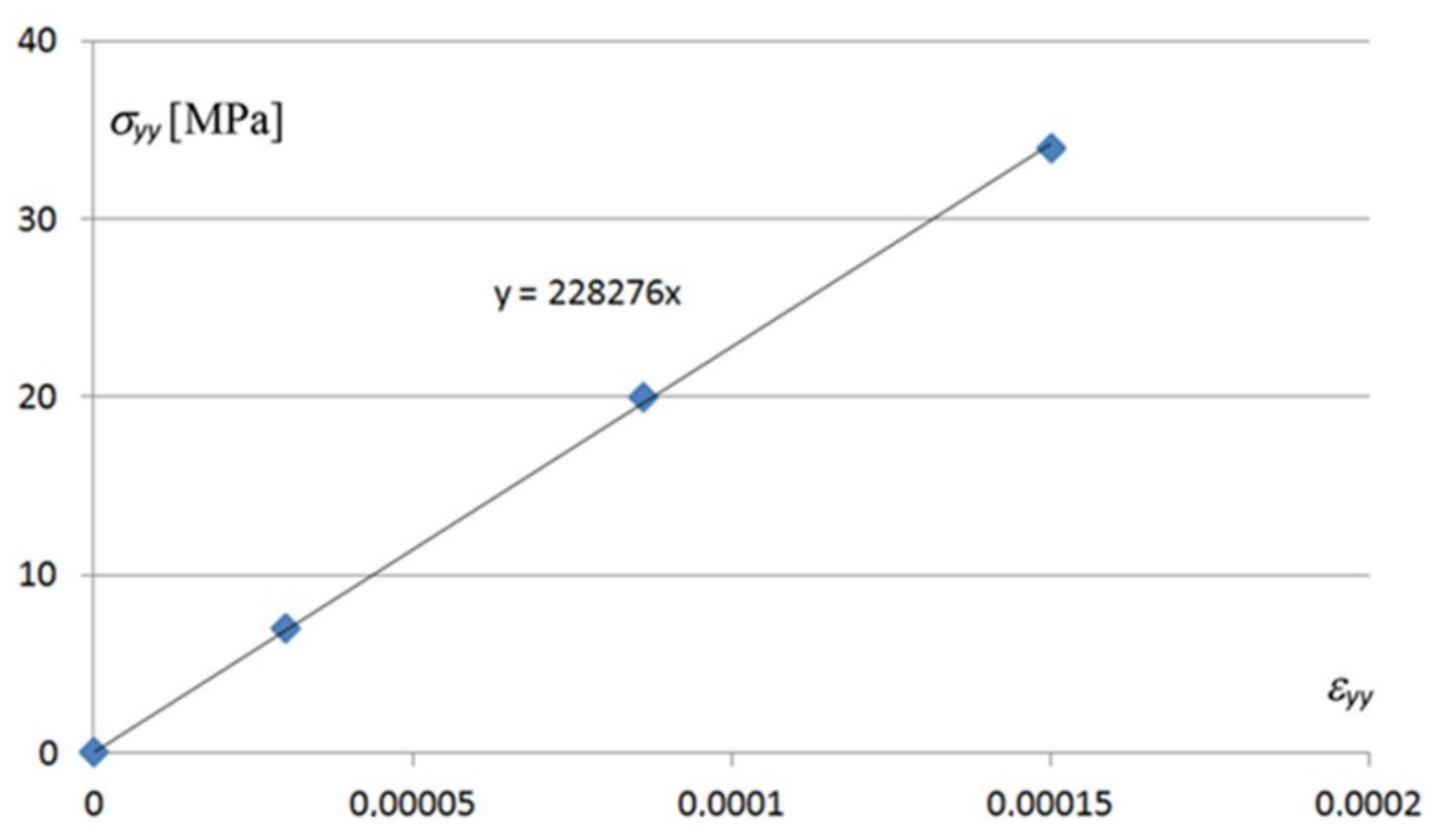

Despite the highly non-linear relationships presented in the above diagrams, the constitutive relations

between stresses {

σ} and corresponding strains {

ε} appearing in the examined profile TR 85 are linear. Variable [

E] is the stiffness matrix of the sheets and {

σ0} is the vector of the initial stresses resulting, for example, from the folding of a smooth thin-walled sheet into corrugated plate. The main linear relation between normal stresses

σyy and corresponding strains

εyy appearing in the areas of the biggest values of these stresses is shown in

Figure 26.

The methods based on small strains and big deformations, referring to cross-sections of the 4th code class [

46], can be used for strength shaping of the transformed shells in the tested range of the shape twist transformation degree of up to 5°. Other linear constitutive relations, including the ones for the

σxx normal stresses and

τxy shear stresses are presented in the figures included in

Appendix A.

A detail of the graphical representation of the normal stresses

σyy acting in the upper surface of the transformed accurate computational model of the TR 85 × 0.75 shell fold at its crosswise end is shown in

Figure 27 in the form of a map. We can see how quickly the values of the

σyy normal stresses increase when we approach the fold’s crosswise end.

A non-linear dependence of the normal stresses

σxx appearing at the transverse ends of the examined effectively twisted fold and acting along the direction of the fold on its unit twist angle

αj is shown in

Figure A1 included in

Appendix A. From this diagram, it follows that the stresses reach much smaller values than

σyy.

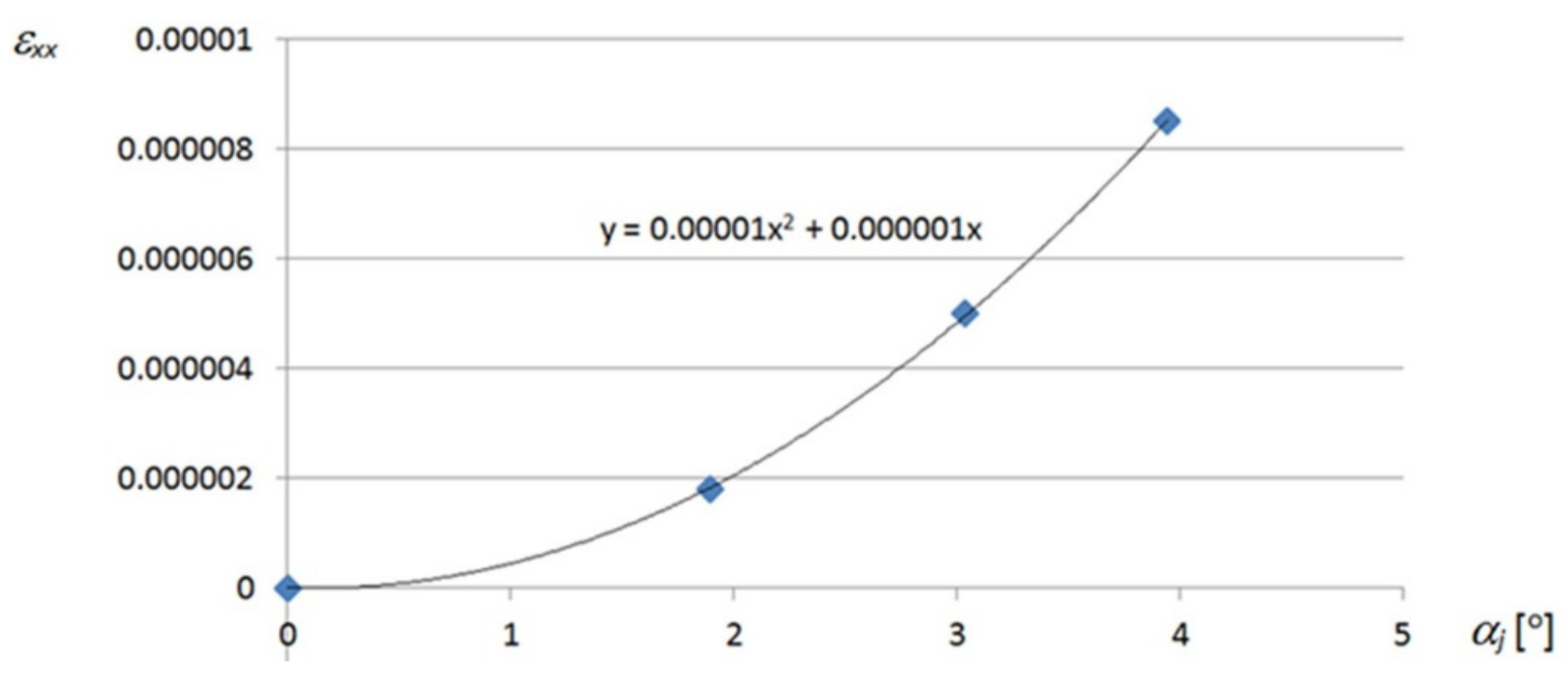

An analogous non-linear dependence of the strains

εxx corresponding to

σxx on the unit twist angle

αj of the effectively transformed fold is shown in

Figure A2. In turn, a linear relation between the

σxx normal stresses and corresponding

εxx strains, for the most deformed walls located at the crosswise ends of the shell fold, can be observed in

Figure A3.

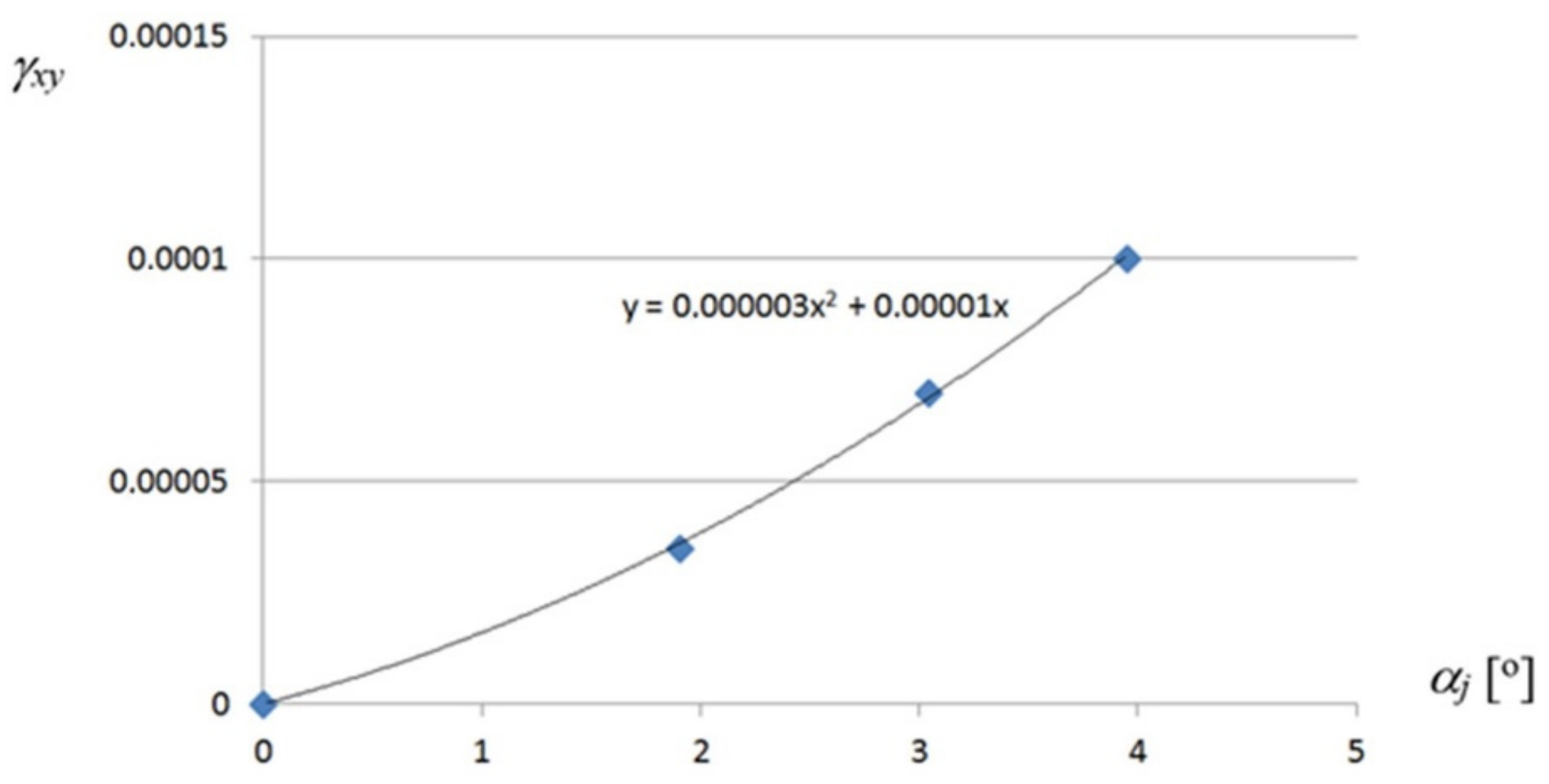

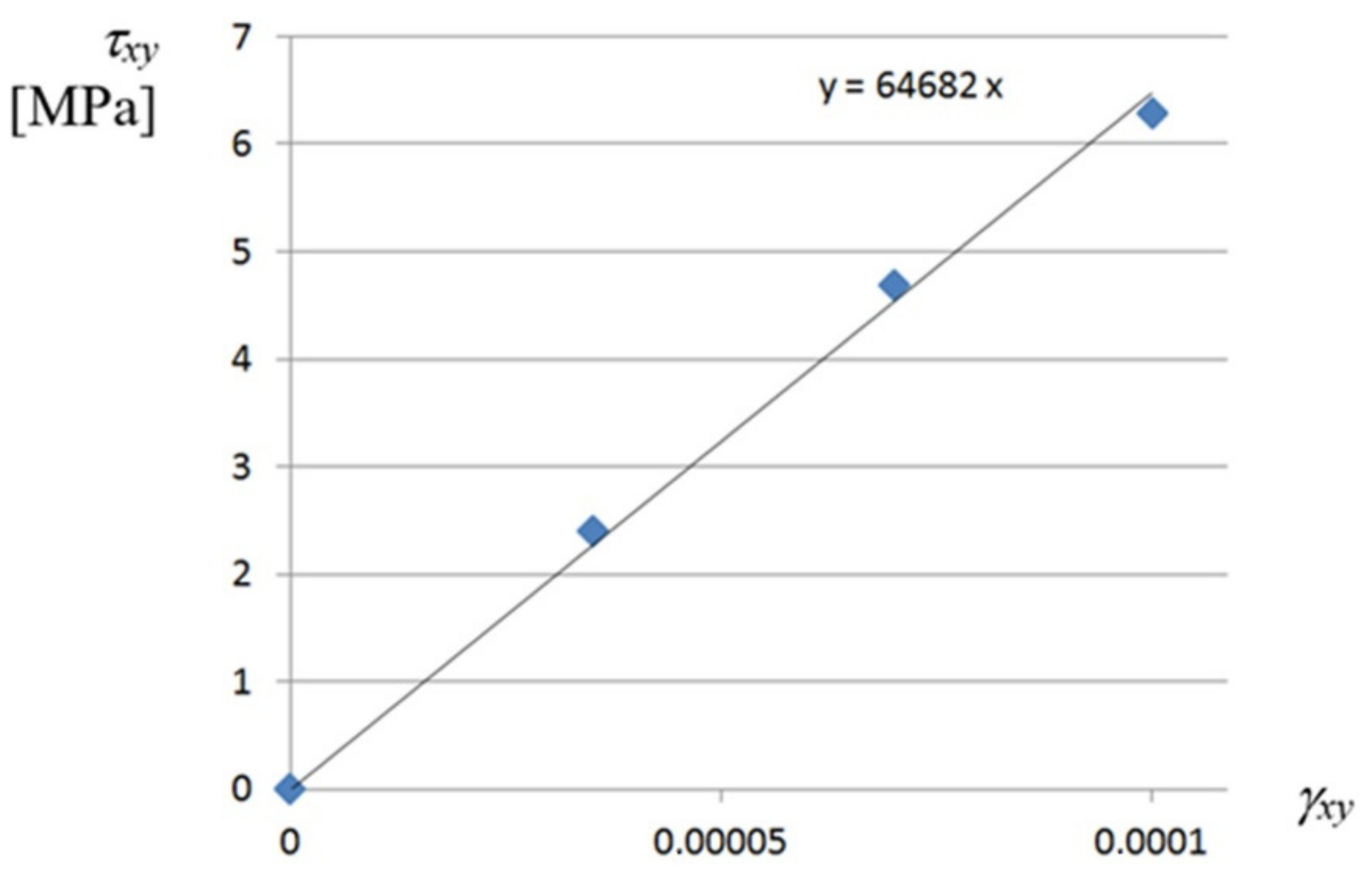

The shear stresses

τxy and corresponding strains

γxy of the most deformed fold’s walls also take small values,

Figure A4 and

Figure A5. They reach the maximum values of 6.0 MPa and 0.000072 for

αj = 3.94°, which allows one to assume that these values are negligible for the calculation of the stress–strain state of the transformed folds. The relationship obtained between

τxy and

γxy is linear, too (

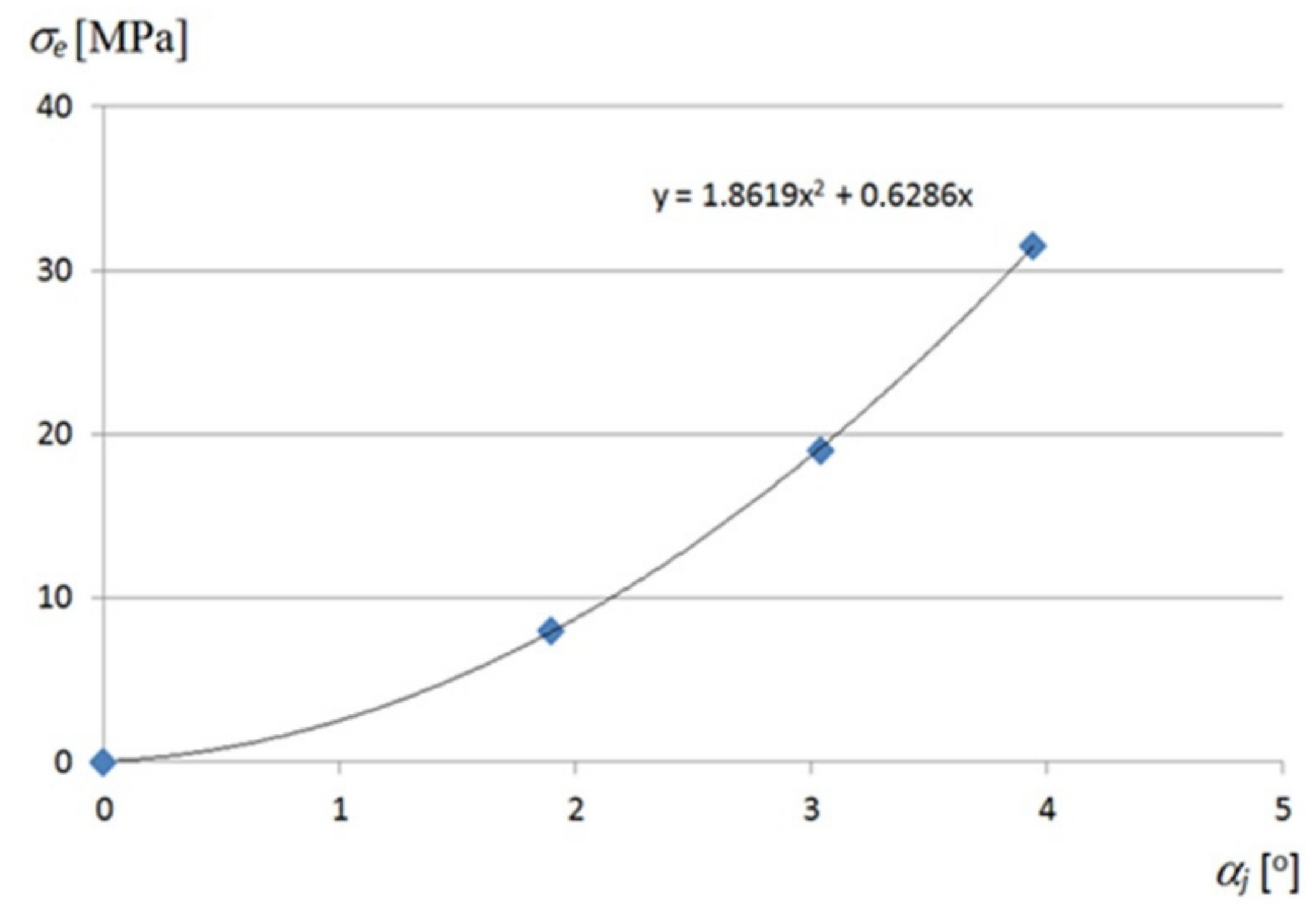

Figure A6). A nonlinear relation between the “effective” Huber–Mises–Hencky stresses

σe and the unit twist angle

αj achieved for the walls located at the crosswise fold’s ends is shown in

Figure 28.

On the basis of all aforementioned diagrams, it can be concluded that the twist of each shell fold by the unit angle of 3° to 5° induces its significant effort, affecting the mechanical properties of the fold. Such values of the transformation degree allow quite significant differences in the shapes, curvatures and contractions of the designed variously transformed shell roofs. Similarly, the initial strains of such deformed folds are relatively small compared with these referring to the yield point or even the elastic limit of steel. The presented examples allow the designer to use linear constitutive relationships in the analyzed ranges of the transformation degree.

The conducted analysis shows that it is advisable to search for such effective transformations that the level of the normal stresses σyy would be reduced to the minimum. For this purpose, it is necessary to assure the freedom of the fold’s width increments determining the linear constitutive relationships between the stresses and strains. The respective calculation methods, loading conditions and supporting conditions are needed.

From the relationships presented in this section, some additional, important conclusions can be drawn. The complex states of stresses archived for the examined twisted folded shell sheeting supported by straight directrices cannot be reduced to pure shear. The σyy normal stresses acting perpendicularly to the old’s directions play the most important role in this state. The state causes a precisely defined position and length of the contraction line on the transformed shell. The aim is to calculate the length and such a position of the contraction that the contraction passes through the middle of each shell fold. In this case, it is only possible to use interdependences between the form of the effectively transformed fold and its supporting conditions.

7. Conclusions

The presented dependencies describing the properties of the transformed folded sheets are very useful in the process of the rational shaping of attractive roof shell sheeting. They were derived on the basis of the analysis performed at various levels of accuracy. At the most detailed level related to single walls, flanges and webs of the transformed folds, the complex states of stresses appearing at particular points of these walls were analyzed. The highest values are achieved by the normal stresses acting transversely to the fold’s directions. These are tensile stresses acting in the flanges along the transverse ends of the shell folds. The values of these stresses are distributed in the range from 20 to 80 MPa for the unit twist angle αj = 4° and in the range of 40 to 120 MPa for αj = 5° depending on the type of the examined fold’s profiles.

The results of the performed analysis are consistent with the visible shape changes observed for adjacent folds in each transformed sheeting at the experimental stand. The longitudinal axes of two adjacent folds are mutual skew straight lines, so they approach each other halfway along their length, and move away from each other if they approach the transverse ends. Thus, the crosswise fold’s ends tend to expand. The compress stresses appear at a half along the length of each transformed fold, and the tensile stresses occur at the crosswise ends of the fold.

The presented analysis shows the usefulness of each transformed fold as a structural element, the mechanical properties of which are only slightly deteriorated by the initial transformations if the control and reduction of the level of the fold’s effort is applied in the manner proposed in this article. In this case, despite the large transformations of all folds and deformations of their walls, it is possible to obtain small values of the strains and the linear constitutive relationships resulting from the open profiles, small transverse bending stiffness and small torsional stiffness of the shell folds.

The conditions leading to the reduction of the initial stresses of each fold in a transformed shell are imposed in the analysis carried out at the second level of detail, lower than the previously mentioned one. At this level, smooth models of all single folds are shaped in the form of regular ruled surfaces whose properties preserve the relationships obtained on the basis of the experimental tests and computer simulations. The variable width increments appearing along the length of each transformed fold are modeled by means of a central sector of a smooth hyperbolic paraboloid characterized by (a) straight longitudinal edges, (b) variable width along its length, and (c) a straight line of striction perpendicular to these longitudinal edges and passing through the halves of all shell folds.

The limitations reducing the effort of the transformed fold are imposed by means of the appropriate position of its contracting line and the appropriate value of its surface area calculated in the process of shaping a transformed folded shell. The conducted analysis shows strongly non-linear relationships appearing between the essential geometric properties of the transformed shell sheeting and the degree of twist of each of its fold. These relationships significantly depend on the profile type of the examined folds.

A central sector of a right hyperbolic paraboloid is used as a simplified model of each fold after its transformation. In order to describe the relationships appearing between many specific properties of the shell fold in its various configurations, surface areas of the hyperbolic paraboloid models are used.

If we know the variation of the surface areas of the successive fold’s configurations, we are able to calculate the widths of the transformed fold in its subsequent configurations and the length of the contraction line of the entire transformed shell. Then, we can calculate the positions of the lines modeling the longitudinal and transverse edges of each shell fold and its state of stresses using the geometric properties of the central sector of a right hyperbolic paraboloid. These interdependences are going to be analyzed in the further publications. Based on the obtained relationships and smooth hyperbolic paraboloid models, it is possible to obtain displacement equations of all points of the entire transformed folded shell. The derivation of these equations is beyond the scope of the present article.