Numerical Study on the Dependency of Microstructure Morphologies of Pulsed Laser Deposited TiN Thin Films and the Strain Heterogeneities during Mechanical Testing

Abstract

1. Introduction

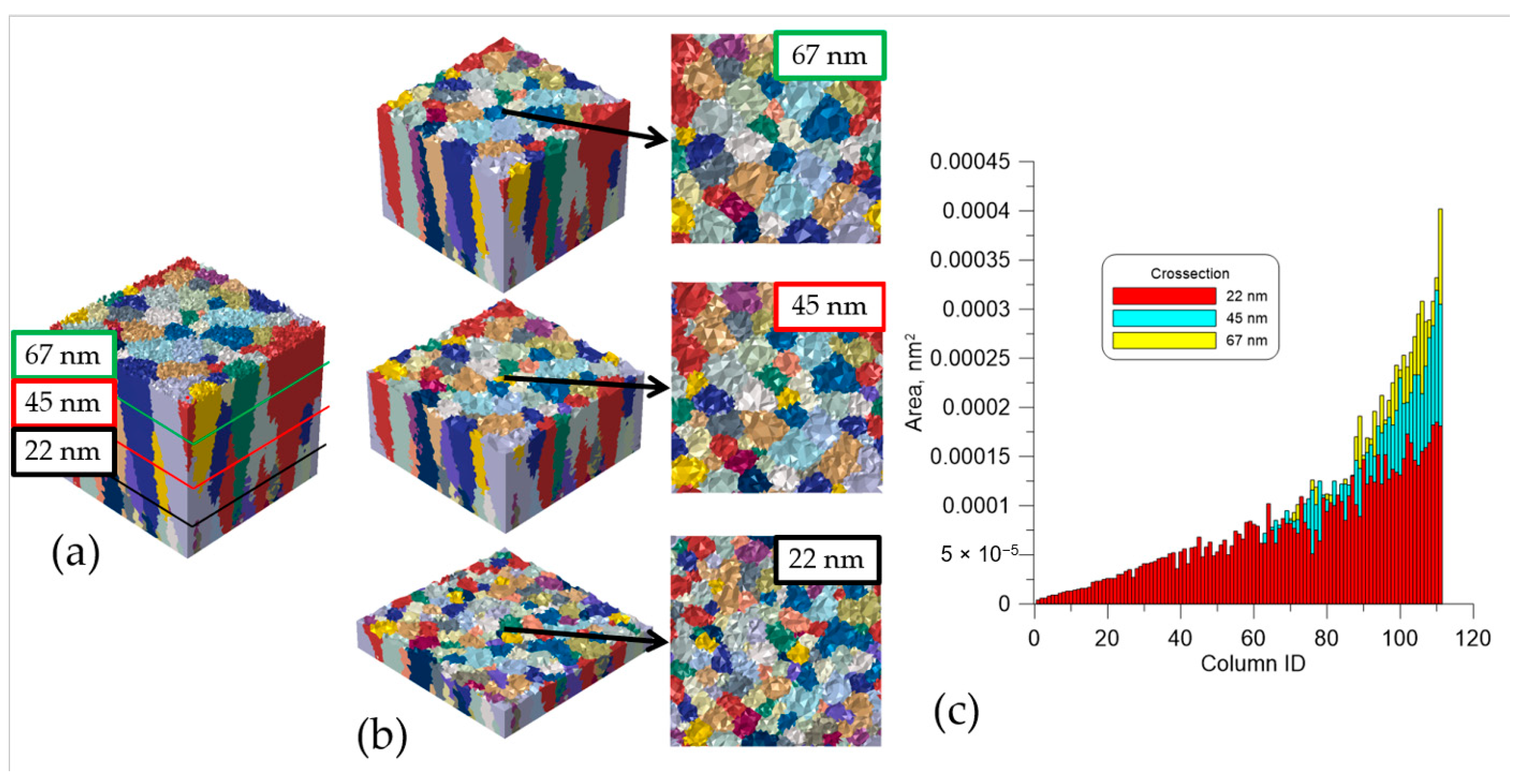

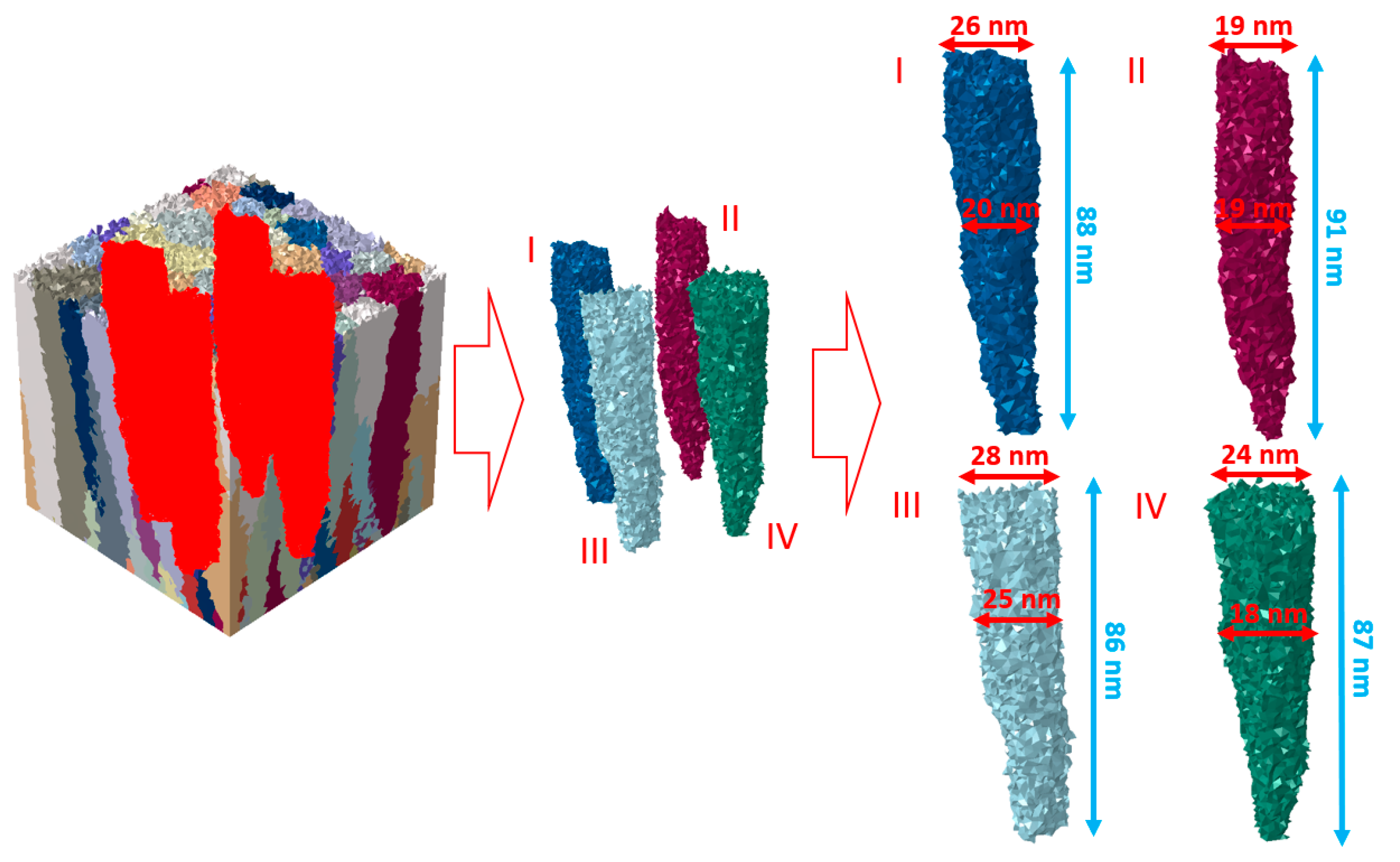

2. Numerical Modelling of the PLD Process

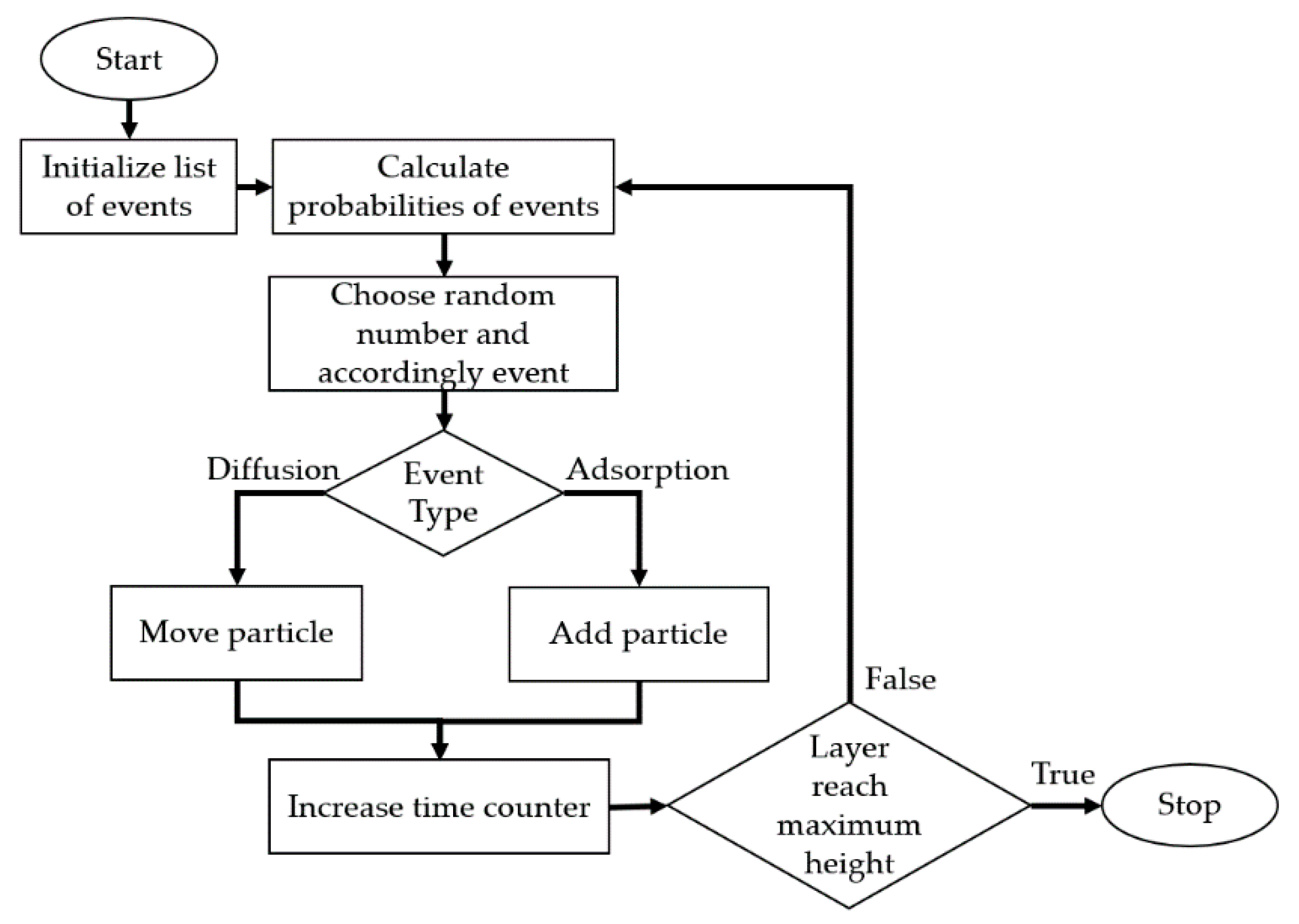

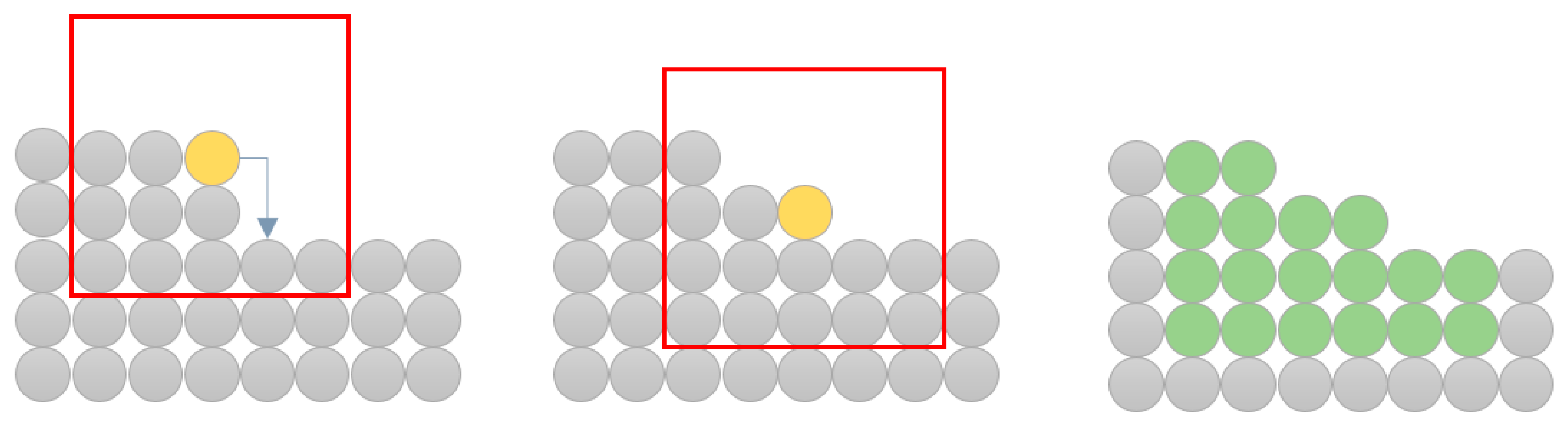

Formulation of the kMC PLD Deposition Model

- (1)

- Creation of a list of all possible events in the system and calculation of a likelihood of their occurrence .

- (2)

- Calculation of the sum of probabilities of all events .

- (3)

- Random selection of a number in a range 〈).

- (4)

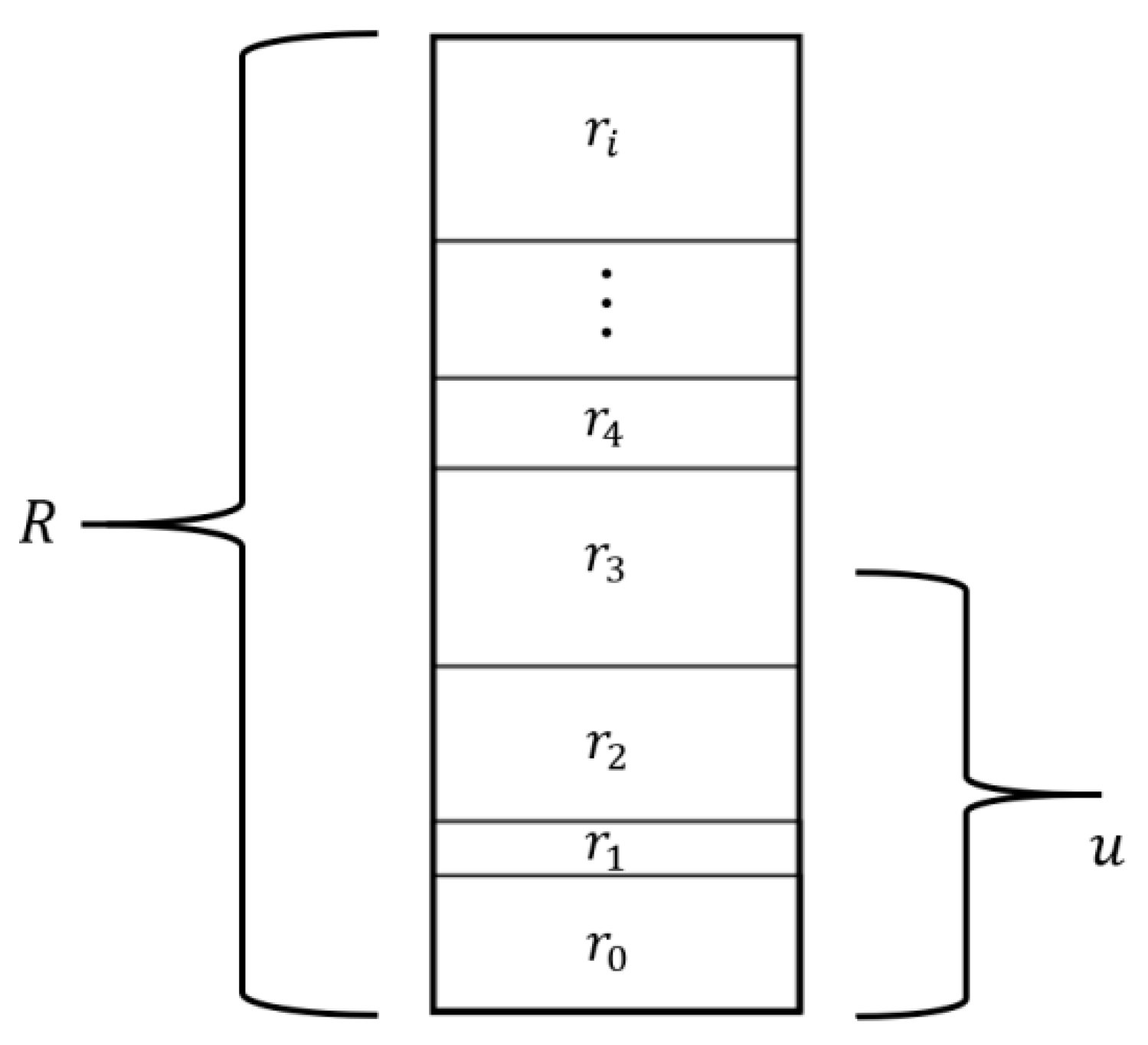

- Each event is placed on a stack. Graphically (Figure 3), the height of a particular event represents its probability of occurrence. An overall height stack is thus equal to a cumulated probability of all considered events—. A randomly chosen number unambiguously indicates the event, which will be applied to the system. Selection of the event is shown in Figure 3.

- (5)

- Transposition of the system to a new state by applying the selected event.

- (6)

- Updating the time counter by .

- Adding events, which become possible;

- Removing obsolete events;

- Updating probabilities of all events, which could be affected by a previous change in the system.

3. Kinetic Monte Carlo Simulations of the PLD Process

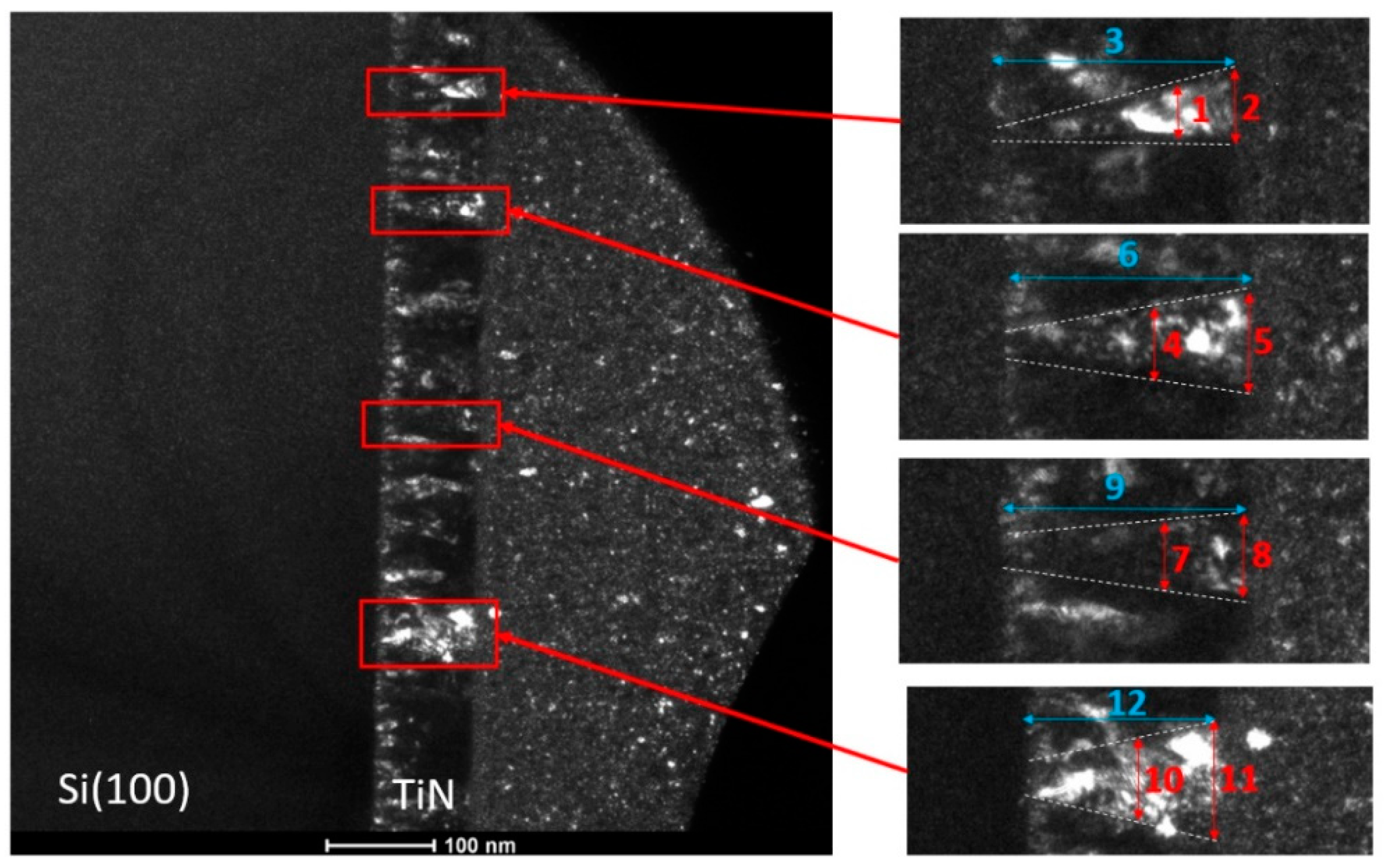

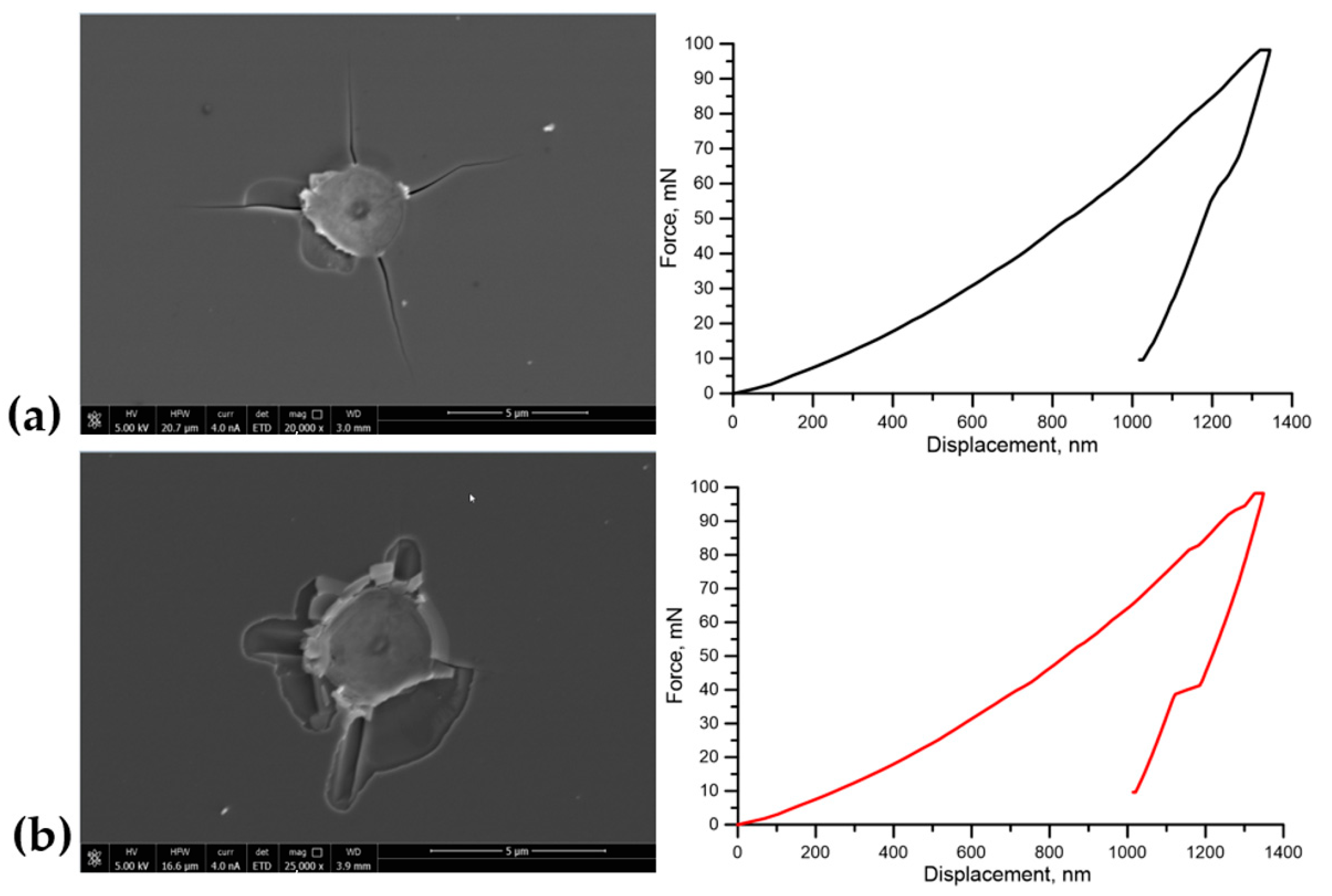

4. Experimental Investigation

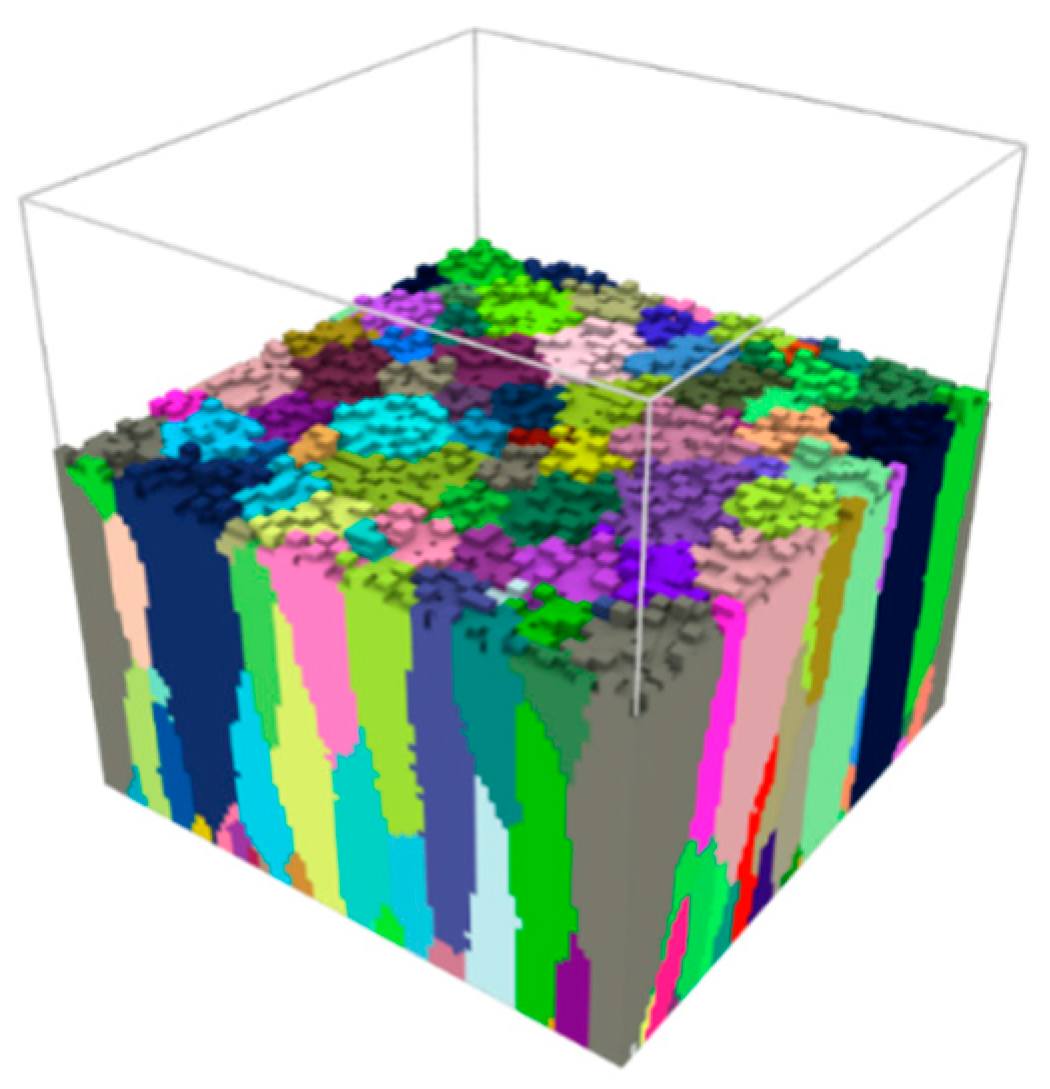

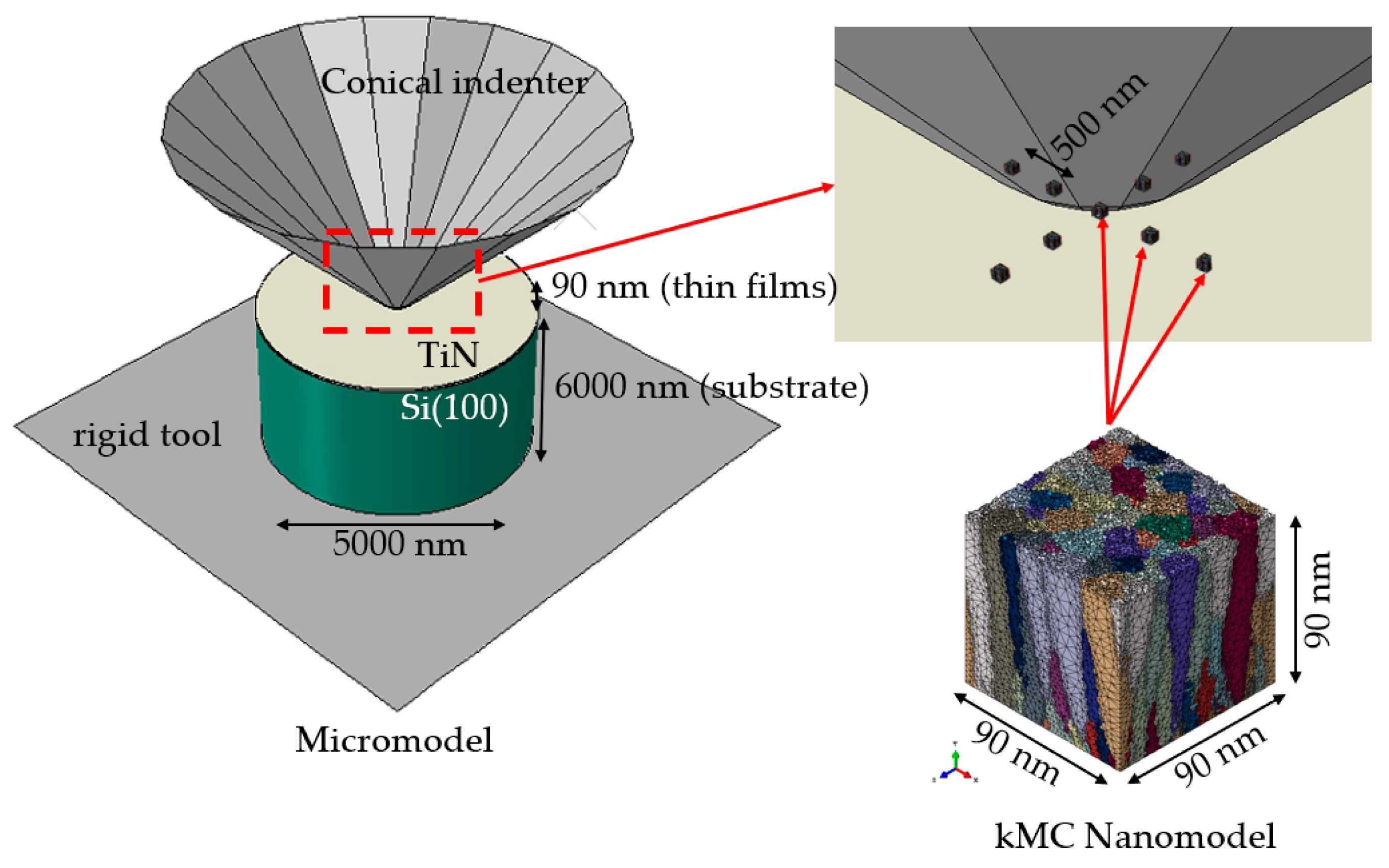

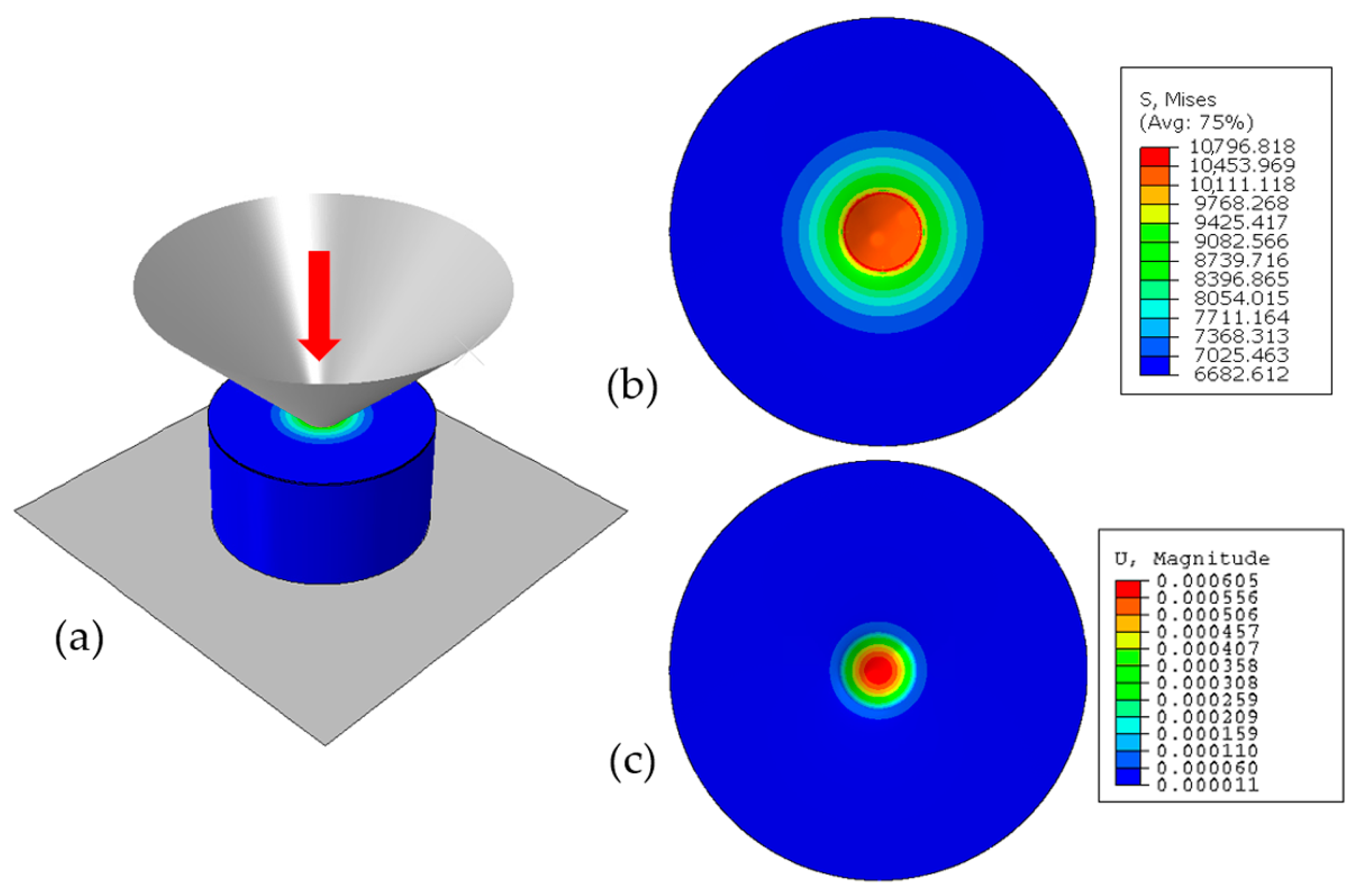

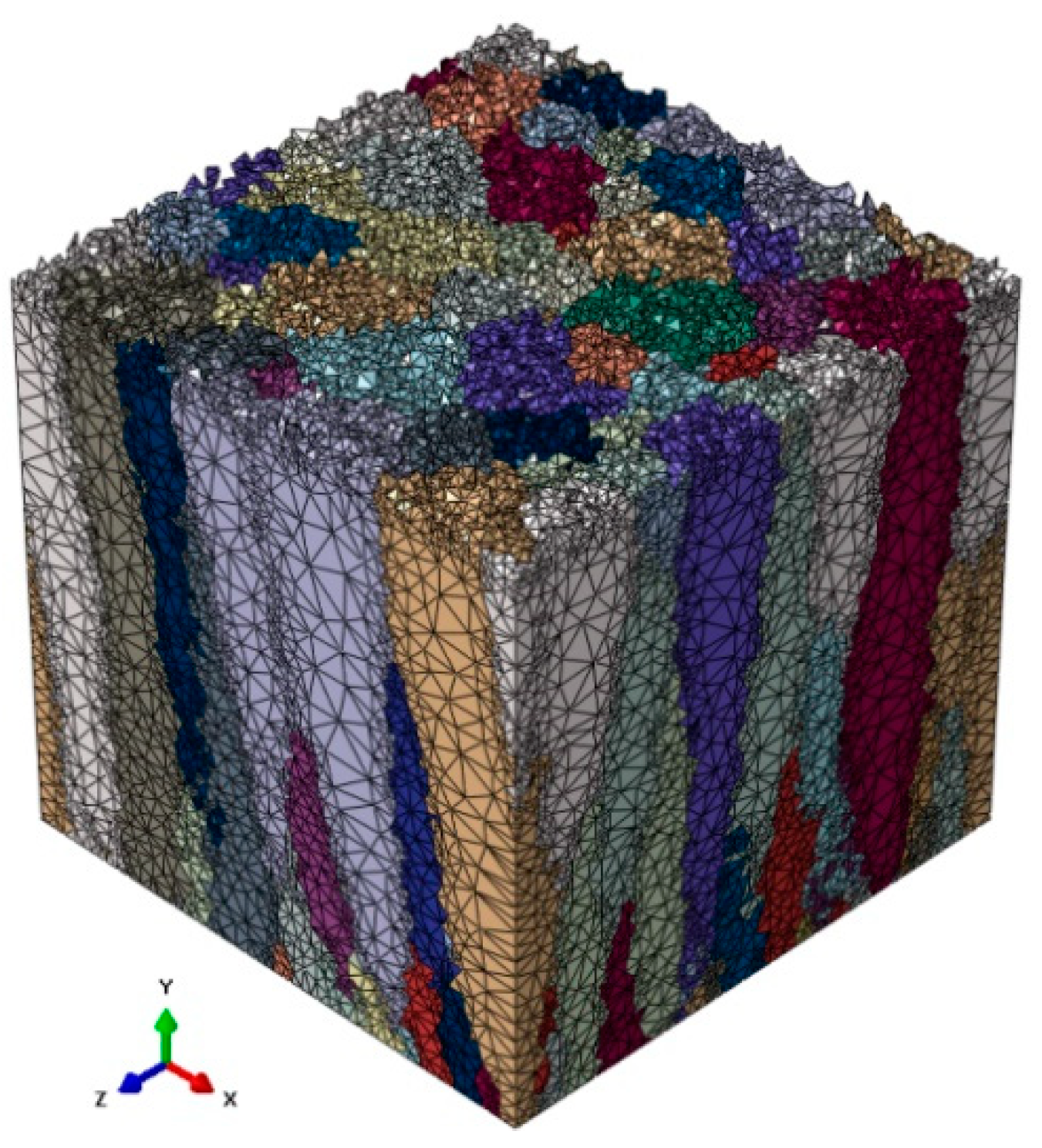

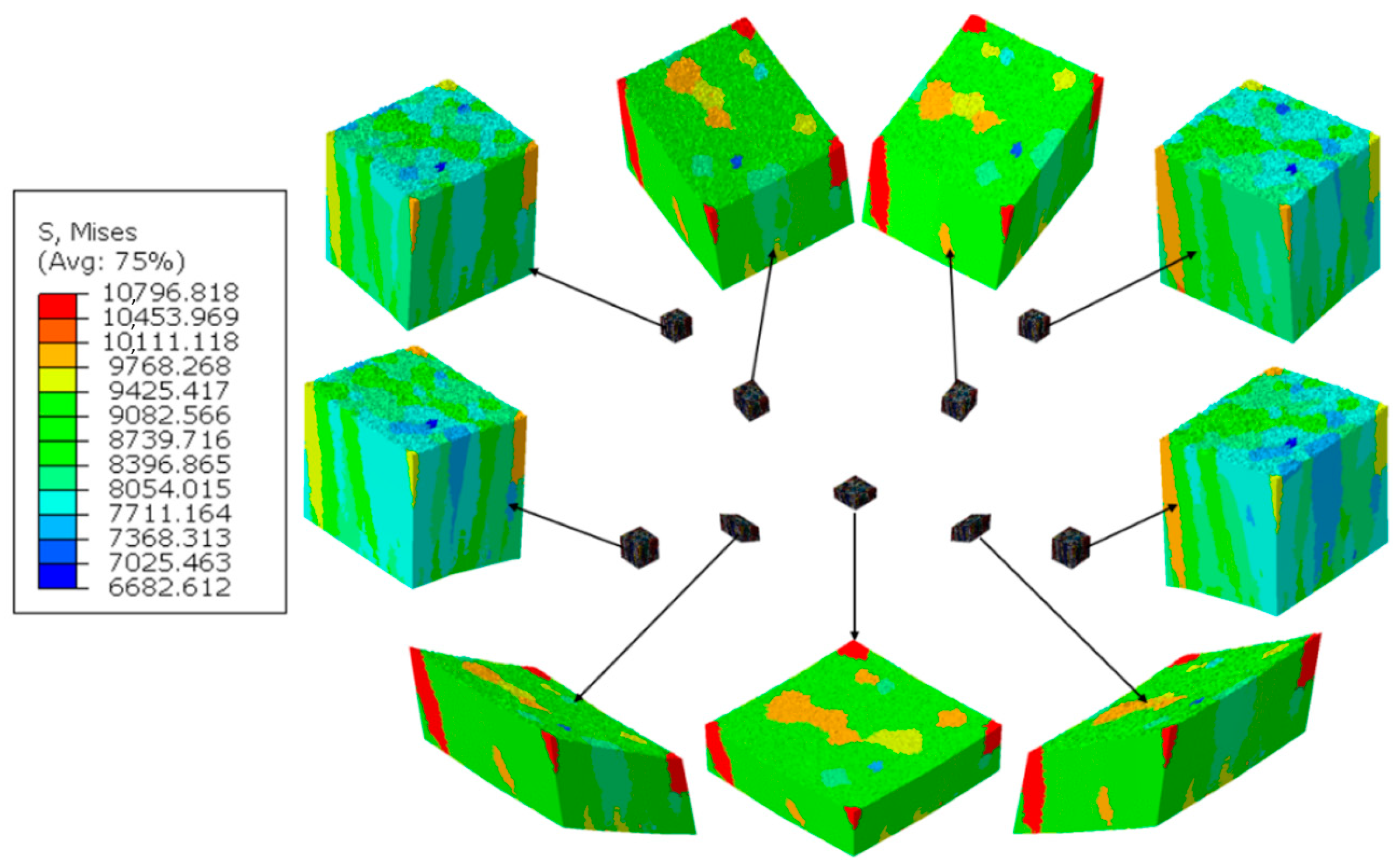

5. Numerical Nanoindentation Test Based on the Explicit Representation of Thin Films Morphologies

6. Discussion

7. Conclusions

- The kinetic Monte Carlo method is an adequate and feasible technique for numerical simulation of the PLD process and provides a reliable digital representation of microstructure morphology;

- The presented kMC PLD model can be adjusted to design the deposition processes of different nanolayered structures;

- The digital material representation model of the deposited thin films allows predicting of inhomogeneities in stress/strain fields under deformation conditions;

- Predicted local heterogeneities, especially in the interface area and along columns boundaries, can be further used to study fracture initiation and propagation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Greer, J.A. History and current status of commercial pulsed laser deposition equipment. J. Phys. D Appl. Phys. 2014, 47, 1–10. [Google Scholar] [CrossRef]

- Major, R.; Bonarski, J.; Morgiel, J.; Major, B.; Czarnowska, E.; Kustosz, R.; Lackner, J.M.; Waldhauser, W. Elastic TiN coating deposited on polyurethane by pulsed laser. Surf. Coat. Technol. 2006, 200, 6340–6345. [Google Scholar] [CrossRef]

- Kot, M.; Major, Ł.; Lackner, J. The tribological phenomena of a new type of TiN/a-C:H multilayer coatings. Mater. Des. 2013, 51, 280–286. [Google Scholar] [CrossRef]

- Galinski, H.; Ryll, T.; Reibisch, P.; Schlagenhauf, L.; Schenker, I.; Gauckler, L.J. Temperature-dependent 2-D to 3-D growth transition of ultra-thin Pt films deposited by PLD. Acta Mater. 2013, 61, 3297–3303. [Google Scholar] [CrossRef]

- Xu, X.H.; Zhang, R.Q.; Dong, X.Z.; Gehring, G.A. A study of the optimization of parameters for pulsed laser deposition using Monte Carlo simulation. Thin Solid Film. 2006, 515, 2754–2759. [Google Scholar] [CrossRef]

- Tekaya, A.; Ghulman, H.A.; Benameur, T.; Labdi, S. Cyclic Nanoindentation and Finite Element Analysis of Ti/TiN and CrN Nanocoatings on Zr-Based Metallic Glasses Mechanical Performance. J. Mater. Eng. Perform. 2014, 23, 4259–4270. [Google Scholar] [CrossRef]

- Kopernik, M.; Milenin, A. Numerical modeling of substrate effect on determination of elastic and plastic properties of TiN nanocoating in nanoindentation test. Arch. Civ. Mech. Eng. 2014, 14, 269–277. [Google Scholar] [CrossRef]

- Hajder, L.; Madej, Ł. Sphere packing algorithm for the generation of digital models of polycrystalline microstructures with heterogeneous grain sizes. Comput. Methods Mater. Sci. 2020, 20, 22–30. [Google Scholar]

- Perzynski, K.; Cios, G.; Szwachta, G.; Zych, D.; Setty, M.; Bala, P.; Madej, L. Numerical modelling of a compression test based on the 3D digital material representation of pulsed laser deposited TiN thin films. Thin Solid Film. 2019, 673, 34–43. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Brabazon, D. X-ray Tomography, AFM and Nanoindentation Measurements for Recyclability Analysis of 316L Powders in 3D Printing Process. Procedia Manuf. 2020, 47, 1113–1116. [Google Scholar] [CrossRef]

- Feber, R.C.; Allen, L.D.F.; Grimmer, D. Monte carlo simulation of the nucleation of thin films. J. Vac. Sci. Technol. 1971, 8, 397–402. [Google Scholar] [CrossRef]

- Huang, H.; Gilmer, G.H.; Díaz de la Rubia, T. An atomistic simulator for thin film deposition in three dimensions. J. Appl. Phys. 1998, 84, 3636–3649. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Shu, Y.; Fan, J. Growth and properties of Cu thin film deposited on Si(001) substrate: A molecular dynamics simulation study. Appl. Surf. Sci. 2012, 261, 690–696. [Google Scholar] [CrossRef]

- Divi, S.; Chatterjee, A. Study of silicon thin film growth at high deposition rates using parallel replica molecular dynamics simulations. Energy Procedia 2014, 54, 270–280. [Google Scholar] [CrossRef]

- Kosturek, R.; Malarz, K. New cellular automaton designed to simulate epitaxial films growth. Phys. A Stat. Mech. Its Appl. 2005, 345, 538–546. [Google Scholar] [CrossRef]

- Perzynski, K.; Major, L.; Madej, L.; Pietrzyk, M. Analysis of the stress concentration in the nanomultilayer coatings based on digital representation of the structure. Arch. Metall. Mater. 2011, 56, 393–399. [Google Scholar] [CrossRef]

- El-Nashar, H.F.; Cerdeira, H.A. Random deposition-like model for two species in (2+1) dimensions. Surf. Sci. 1998, 415, 1–10. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, J.M. A model of random deposition with relaxation on fractal substrates. J. Stat. Mech. 2010, 2010, P08008. [Google Scholar] [CrossRef]

- Kwak, W.; Kim, J.M. Random deposition model with surface relaxation in higher dimensions. Phys. A Stat. Mech. Its Appl. 2019, 520, 87–92. [Google Scholar] [CrossRef]

- Wei, W.; Cerdeira, H.A. Random-Like Deposition Model of Surface Growth Kinetics. Chin. Phys. Lett. 1995, 12, 755–758. [Google Scholar] [CrossRef]

- Ahn, J.-H.; Kwon, S.-H.; Kim, J.-H.; Kim, J.-Y.; Kang, S.-W. Theoretical Simulation of Surface Evolution Using the Random Deposition and Surface Relaxation for Metal Oxide Film in Atomic Layer Deposition. J. Mater. Sci. Technol. 2010, 24, 371–374. [Google Scholar] [CrossRef]

- Landau, D.P.; Pal, S. Monte Carlo simulation of simple models for thin film growth by MBE. Thin Solid Film. 1996, 272, 184–194. [Google Scholar] [CrossRef]

- Goswami, J.; Ananthakrishna, G.; Shivashankar, S.A. Monte Carlo simulation of nucleation and growth of thin films. Bull. Mater. Sci. 1997, 20, 823–843. [Google Scholar] [CrossRef]

- Helin, W.; Zuli, L.; Kailun, Y. Monte Carlo simulation of thin-film growth on a surface with a triangular lattice. Vacuum 1999, 52, 435–440. [Google Scholar] [CrossRef]

- Mirabella, D.A.; Aldao, C.M. Surface growth by random deposition of rigid and wetting clusters. Surf. Sci. 2016, 646, 282–287. [Google Scholar] [CrossRef]

- Gall, D.; Kodambaka, S.; Wall, M.A.; Petrov, I.; Greene, J.E. Pathways of atomistic processes on TiN(001) and (111) surfaces during film growth: An ab initio study. J. Appl. Phys. 2003, 93, 9086. [Google Scholar] [CrossRef]

- Tholander, C.; Alling, B.; Tasnádi, F.; Greene, J.E.; Hultman, L. Effect of Al substitution on Ti, Al, and N adatom dynamics on TiN(001), (011), and (111) surfaces. Surf. Sci. 2014, 630, 28–40. [Google Scholar] [CrossRef]

- Sangiovanni, D.G.; Tasnádi, F.; Hultman, L.; Petrov, I.; Greene, J.E.; Chirita, V. N and Ti adatom dynamics on stoichiometric polar TiN(111) surfaces. Surf. Sci. 2016, 649, 72–79. [Google Scholar] [CrossRef]

- Perzynski, K.; Cios, G.; Szwachta, G.; Zych, D.; Setty, M.; Bala, P.; Madej, L. Evaluation of pulsed laser deposited thin films properties on the basis of the nanoindentation test. Procedia Eng. 2017, 207, 2191–2196. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation; Mechanical Engineering Series; Springer: New York, NY, USA, 2011. [Google Scholar]

- Madej, L.; Sieradzki, L.; Sitko, M.; Perzynski, K.; Radwanski, K.; Kuziak, R. Multi scale cellular automata and finite element based model for cold deformation and annealing of a ferritic–pearlitic microstructure. Comp. Mater. Sci. 2013, 77, 172–181. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Cairney, J.M.; Harris, S.G.; Ma, L.W.; Munroe, P.R.; Doyle, E.D. Characterisation of TiN and TiAlN thin films deposited on ground surfaces using focused ion beam milling. J. Mater. Sci. 2004, 39, 3569–3575. [Google Scholar] [CrossRef]

- Bhowmick, S.; Jayaram, V.; Biswas, S. Deconvolution of fracture properties of TiN films on steels from nanoindentation load-displacement curves. Acta Mater. 2005, 53, 2459–2467. [Google Scholar] [CrossRef]

- Tilbrook, M.T.; Paton, D.J.; Xie, Z.; Hoffman, M. Microstructural effects on indentation failure mechanisms in TiN coatings: Finite element simulations. Acta Mater. 2007, 55, 2489–2501. [Google Scholar] [CrossRef]

- Xie, Z.H.; Hoffman, M.; Munroe, P.; Bendavid, A.; Martin, P.J. Deformation mechanisms of TiN multilayer coatings alternated by ductile or stiff interlayers. Acta Mater. 2008, 56, 852–861. [Google Scholar] [CrossRef]

- Peng, S.; Xu, J.; Munroe, P.; Xie, Z. Sandwich-structured, damage-resistant TiN/graded TiSiN/TiSiN film. Results Phys. 2019, 12, 543–554. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Domain edge length | 90 nm |

| Elementary cell size | 1 nm |

| Substrate melting temperature | 1414 °C |

| Substrate temperature | 200 °C |

| Binding energy | 0.8 eV |

| Deposition rate | 0.05 nm/s |

| Vibration frequency | 1 × 1013 Hz |

| Dimension Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size (nm) | 15.1 | 25.9 | 89.1 | 24.8 | 33.1 | 94.4 | 23.6 | 30.5 | 87.6 | 30.8 | 53 | 93.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perzynski, K.; Cios, G.; Szwachta, G.; Bała, P.; Madej, L. Numerical Study on the Dependency of Microstructure Morphologies of Pulsed Laser Deposited TiN Thin Films and the Strain Heterogeneities during Mechanical Testing. Materials 2021, 14, 1705. https://doi.org/10.3390/ma14071705

Perzynski K, Cios G, Szwachta G, Bała P, Madej L. Numerical Study on the Dependency of Microstructure Morphologies of Pulsed Laser Deposited TiN Thin Films and the Strain Heterogeneities during Mechanical Testing. Materials. 2021; 14(7):1705. https://doi.org/10.3390/ma14071705

Chicago/Turabian StylePerzynski, Konrad, Grzegorz Cios, Grzegorz Szwachta, Piotr Bała, and Lukasz Madej. 2021. "Numerical Study on the Dependency of Microstructure Morphologies of Pulsed Laser Deposited TiN Thin Films and the Strain Heterogeneities during Mechanical Testing" Materials 14, no. 7: 1705. https://doi.org/10.3390/ma14071705

APA StylePerzynski, K., Cios, G., Szwachta, G., Bała, P., & Madej, L. (2021). Numerical Study on the Dependency of Microstructure Morphologies of Pulsed Laser Deposited TiN Thin Films and the Strain Heterogeneities during Mechanical Testing. Materials, 14(7), 1705. https://doi.org/10.3390/ma14071705