Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature

Abstract

1. Introduction

2. Materials and Methods

3. Results

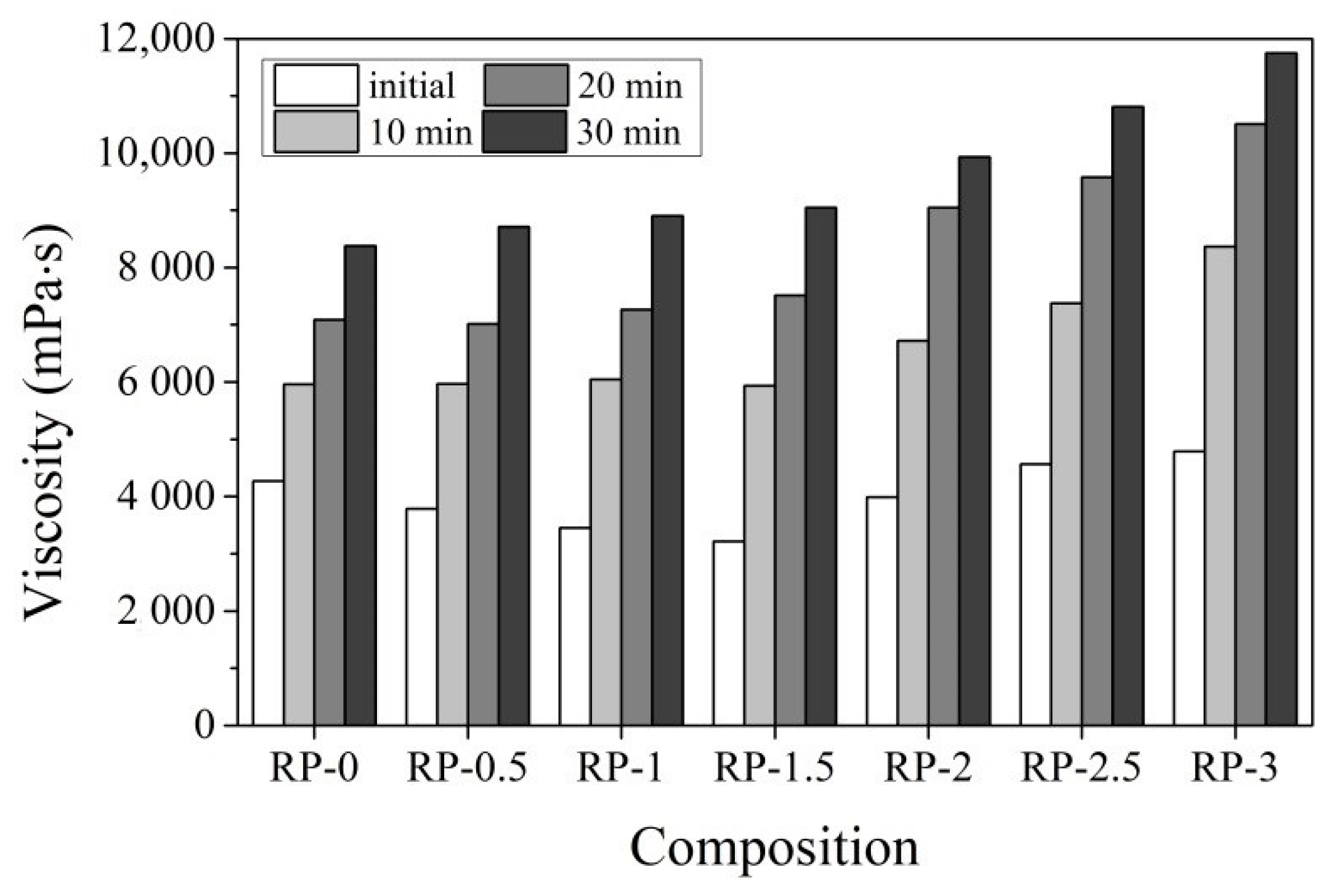

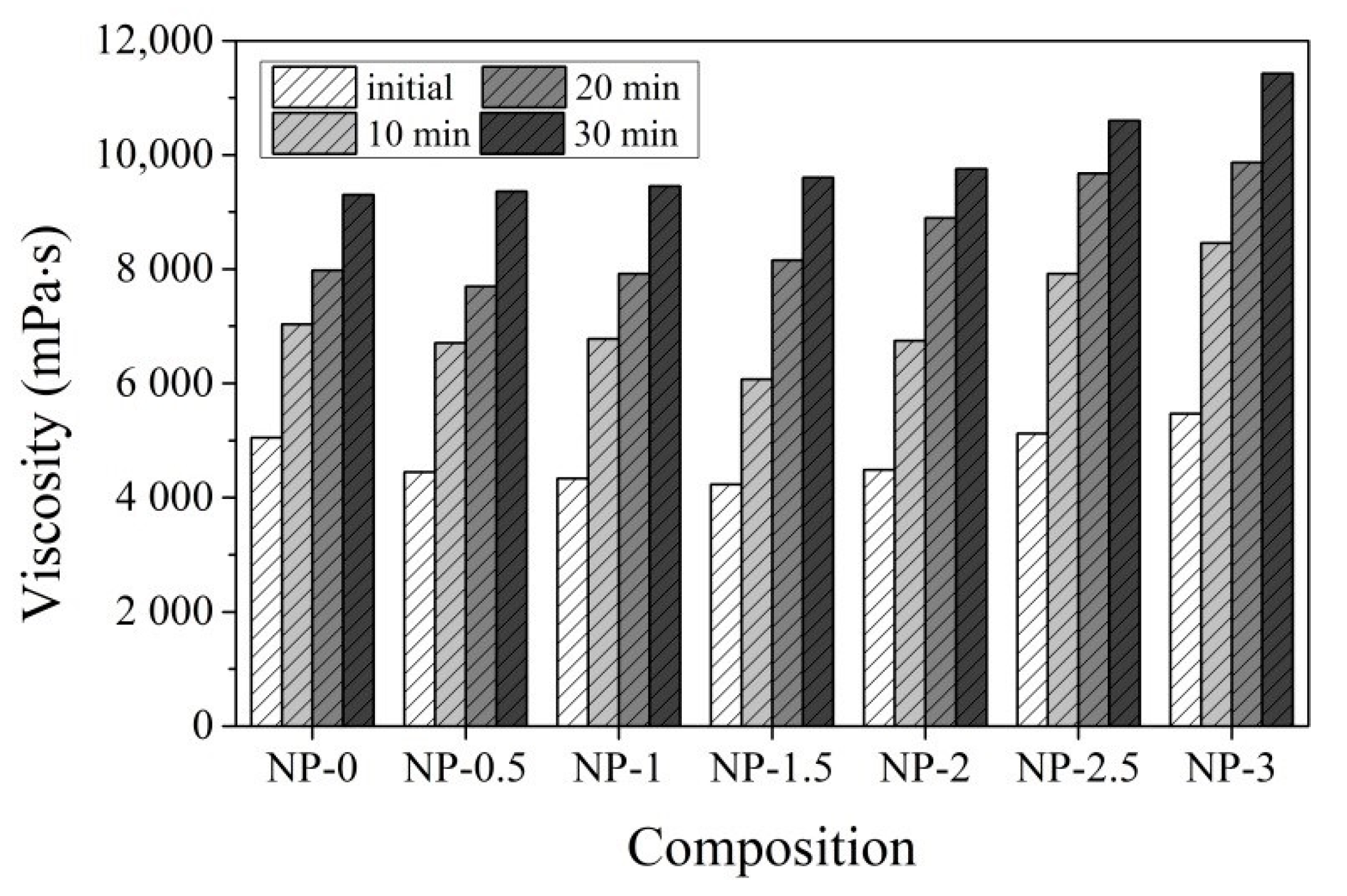

3.1. Cement Paste Viscosity Test

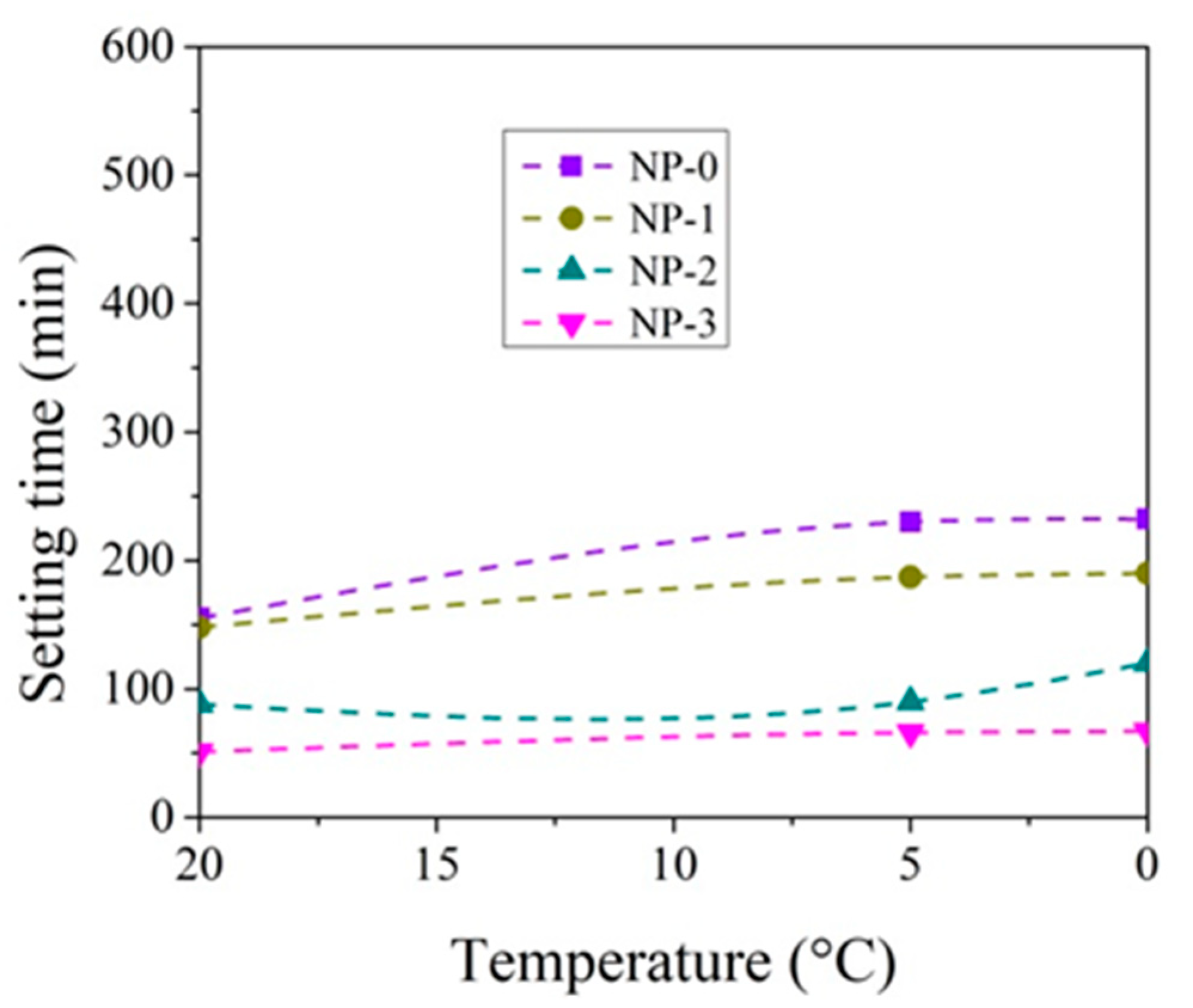

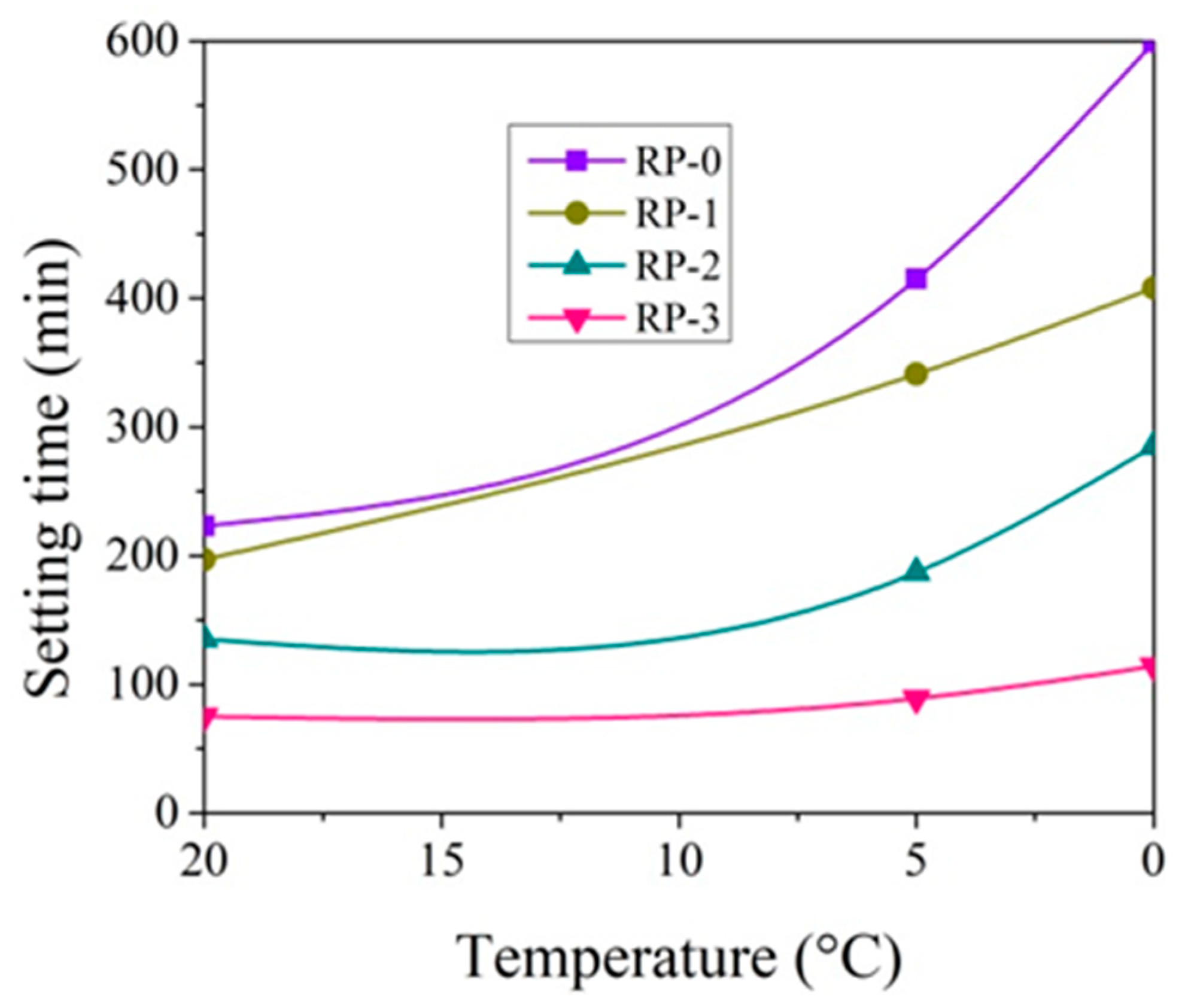

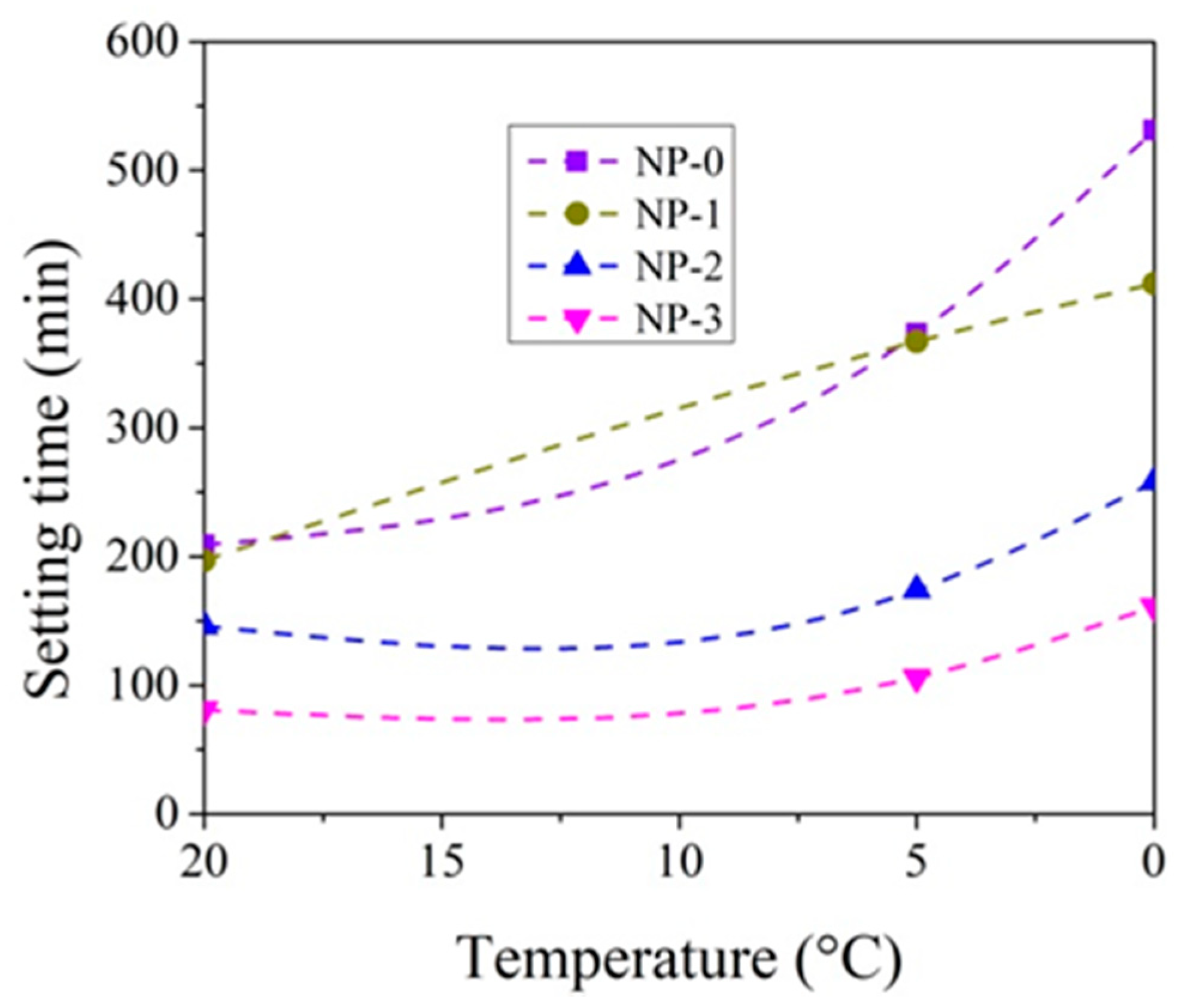

3.2. Setting Time of Cement Paste with CN at Different Temperatures

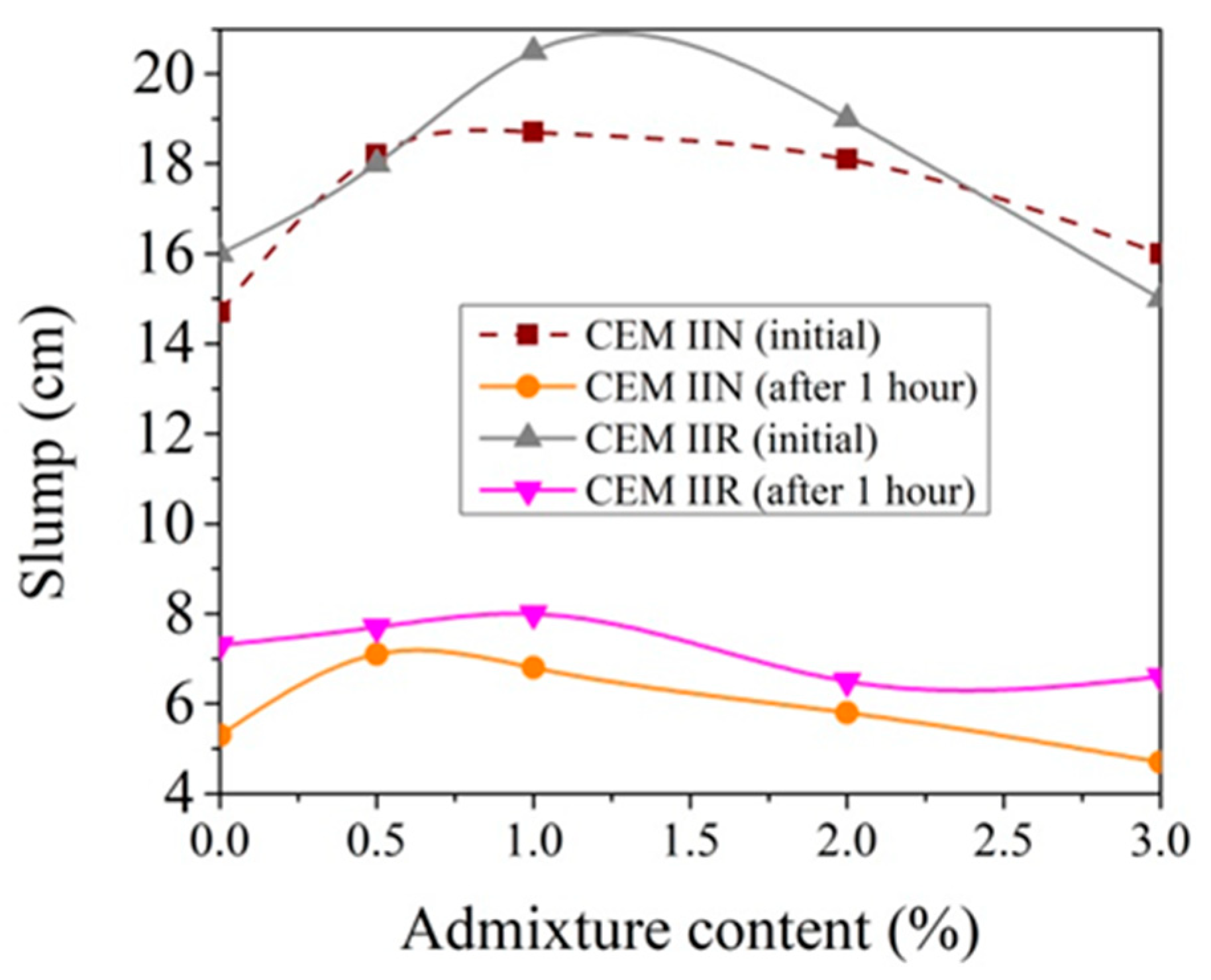

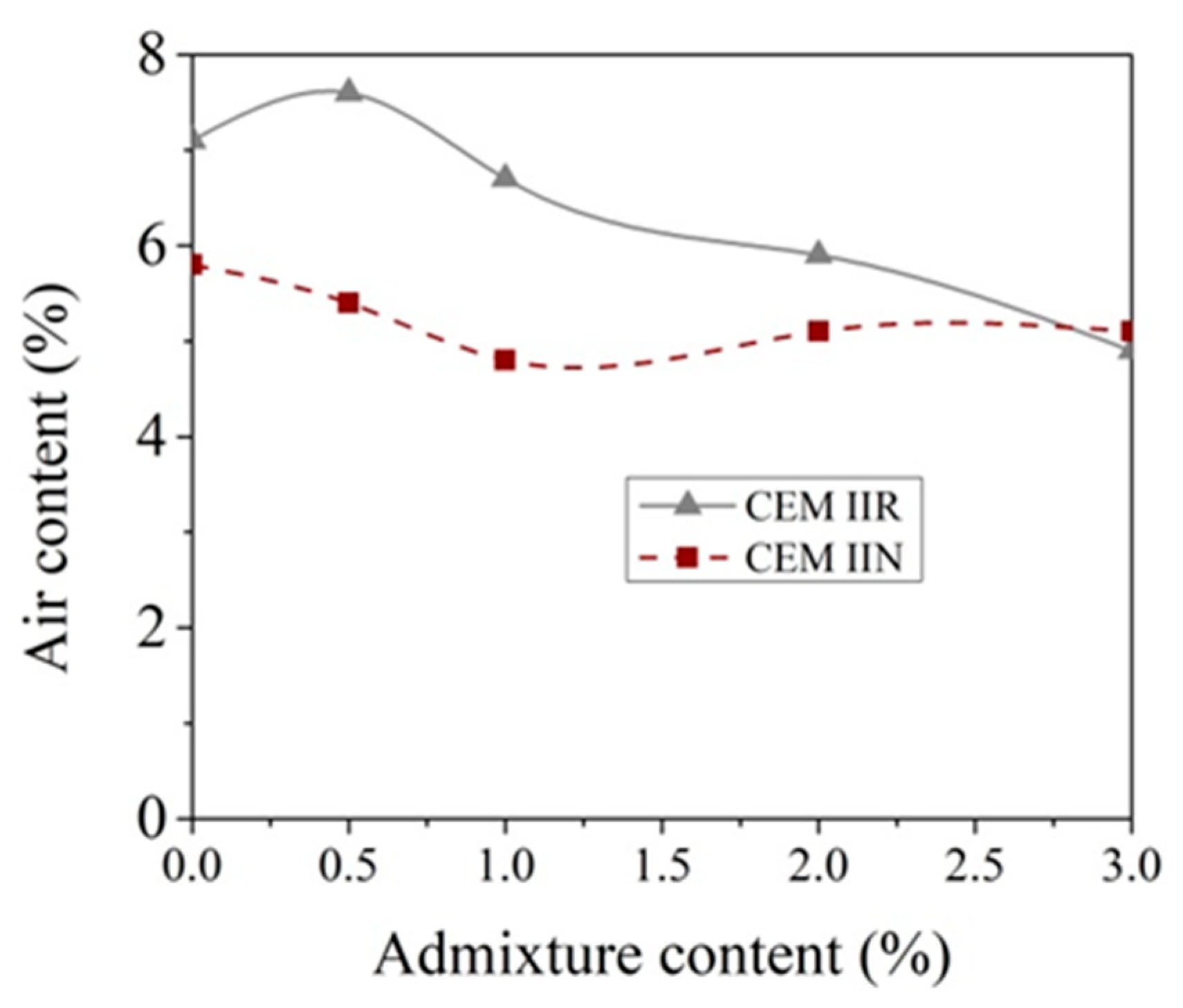

3.3. Technological Properties of Concrete Mixture with CN

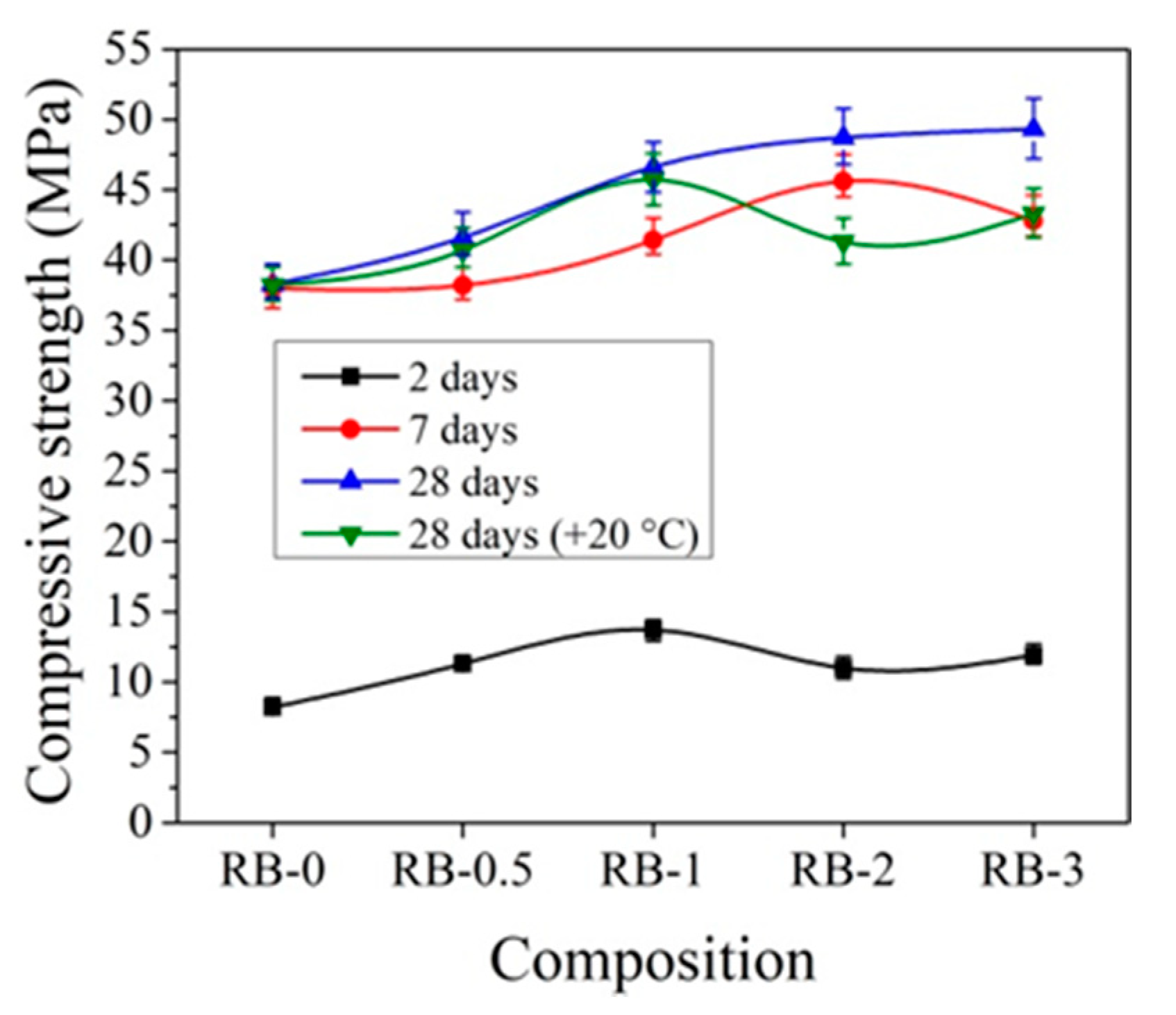

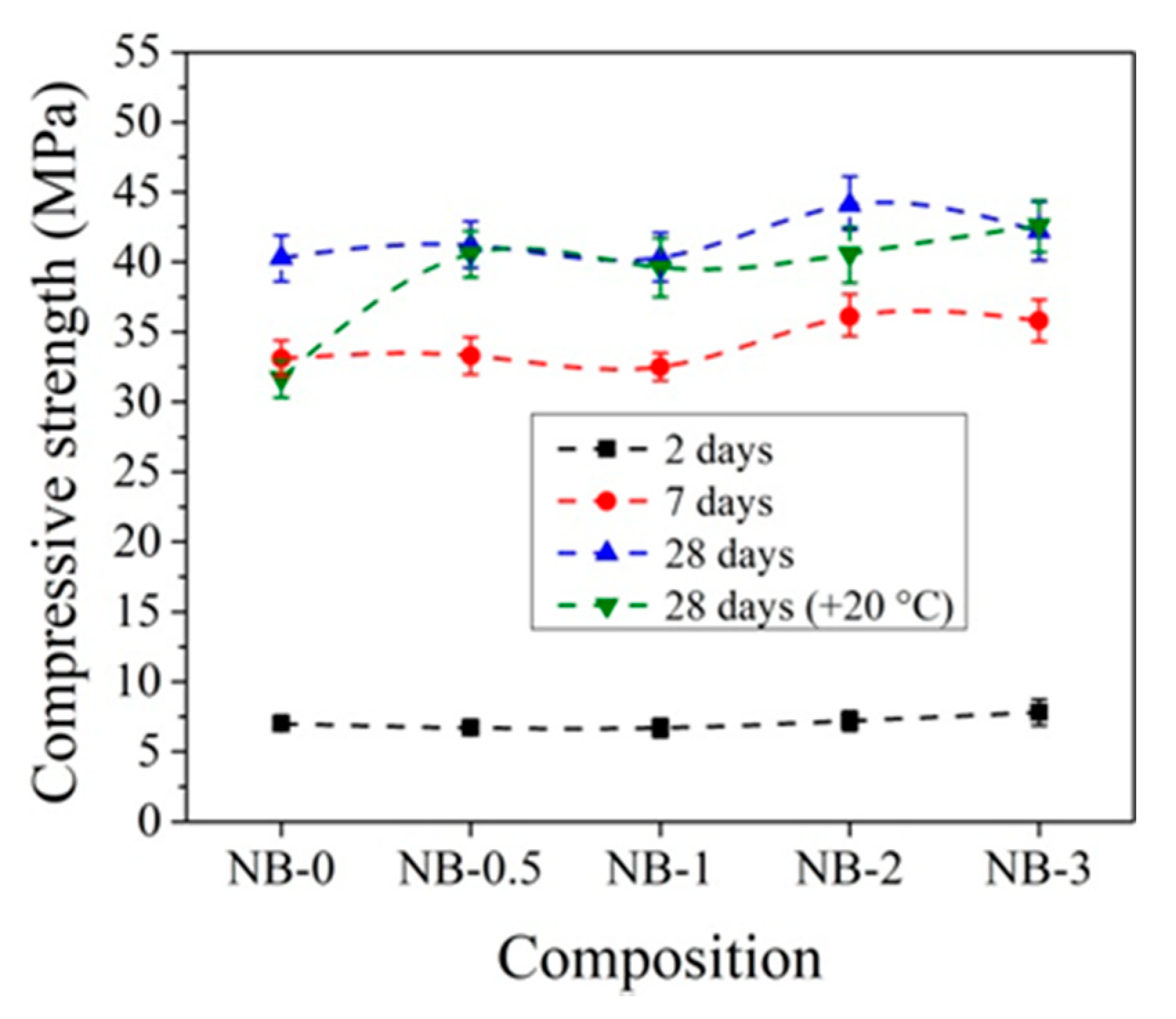

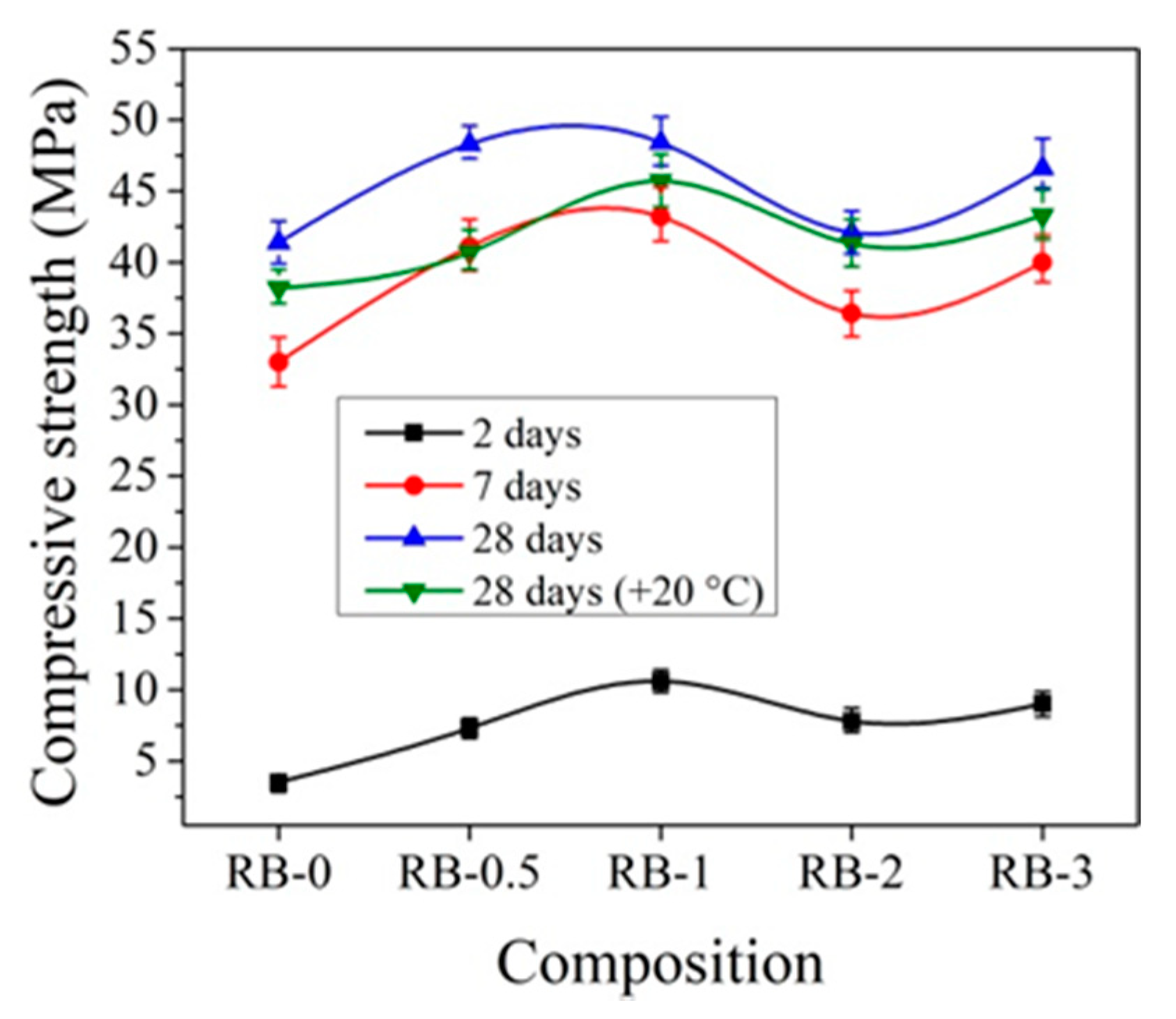

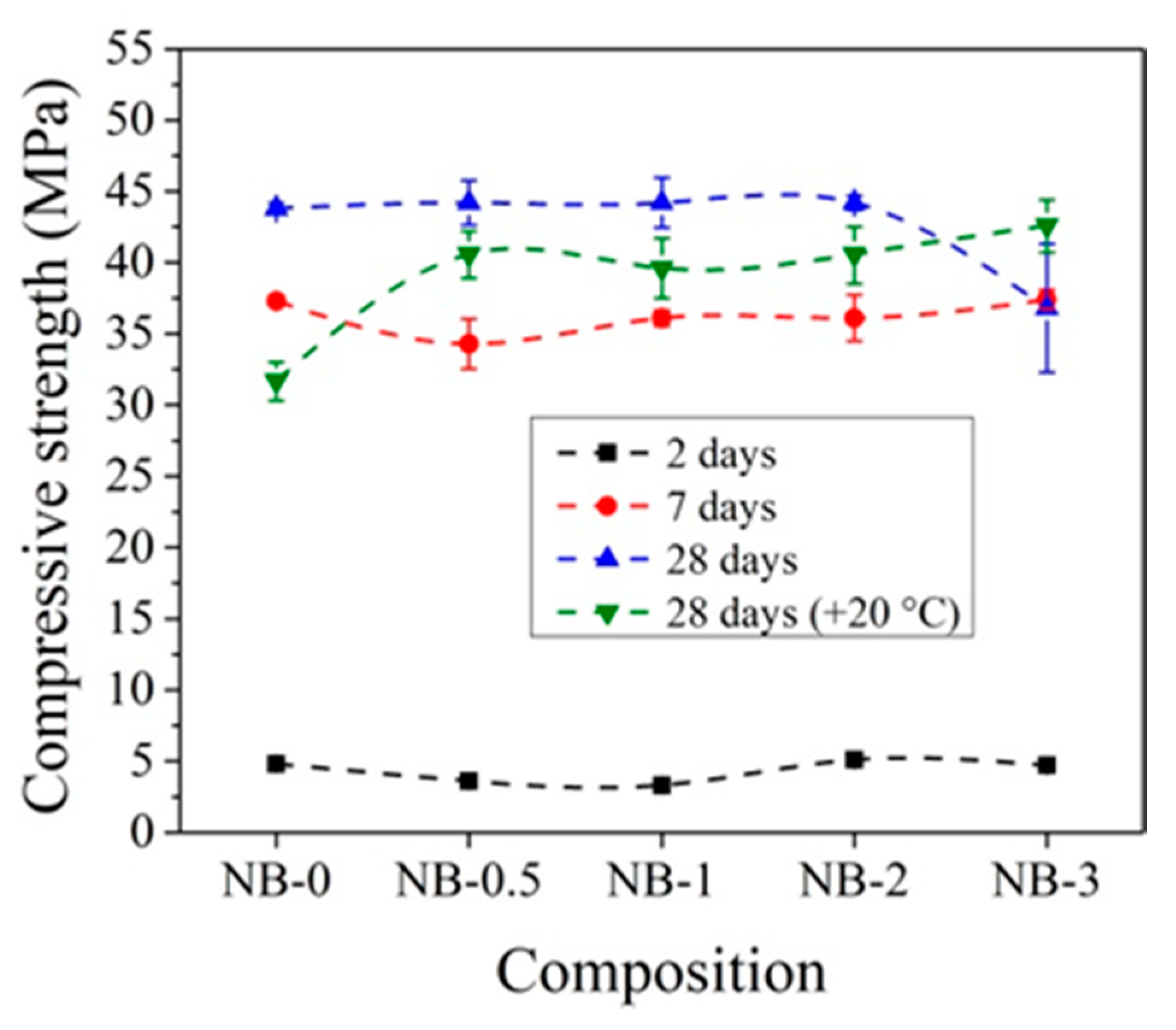

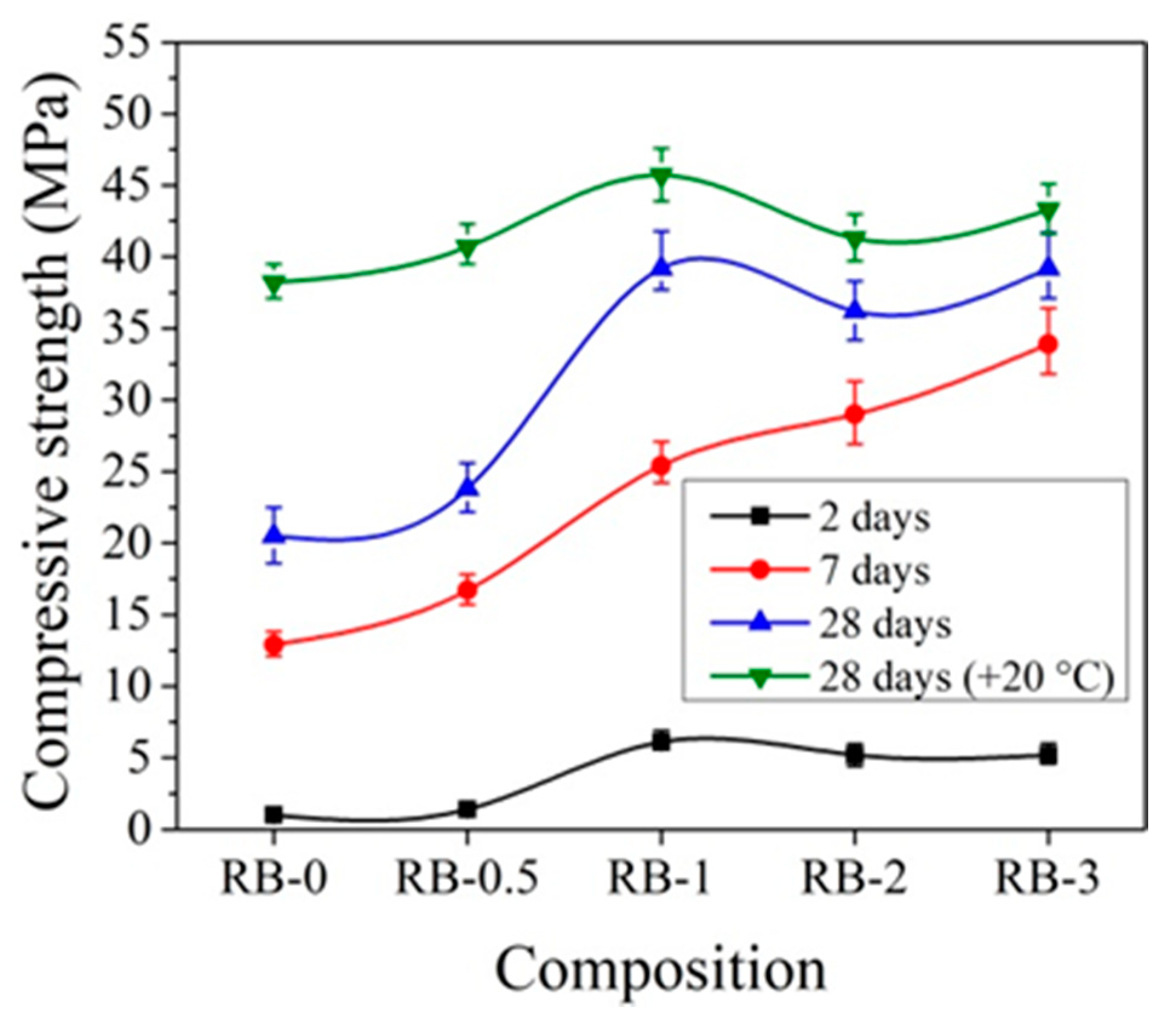

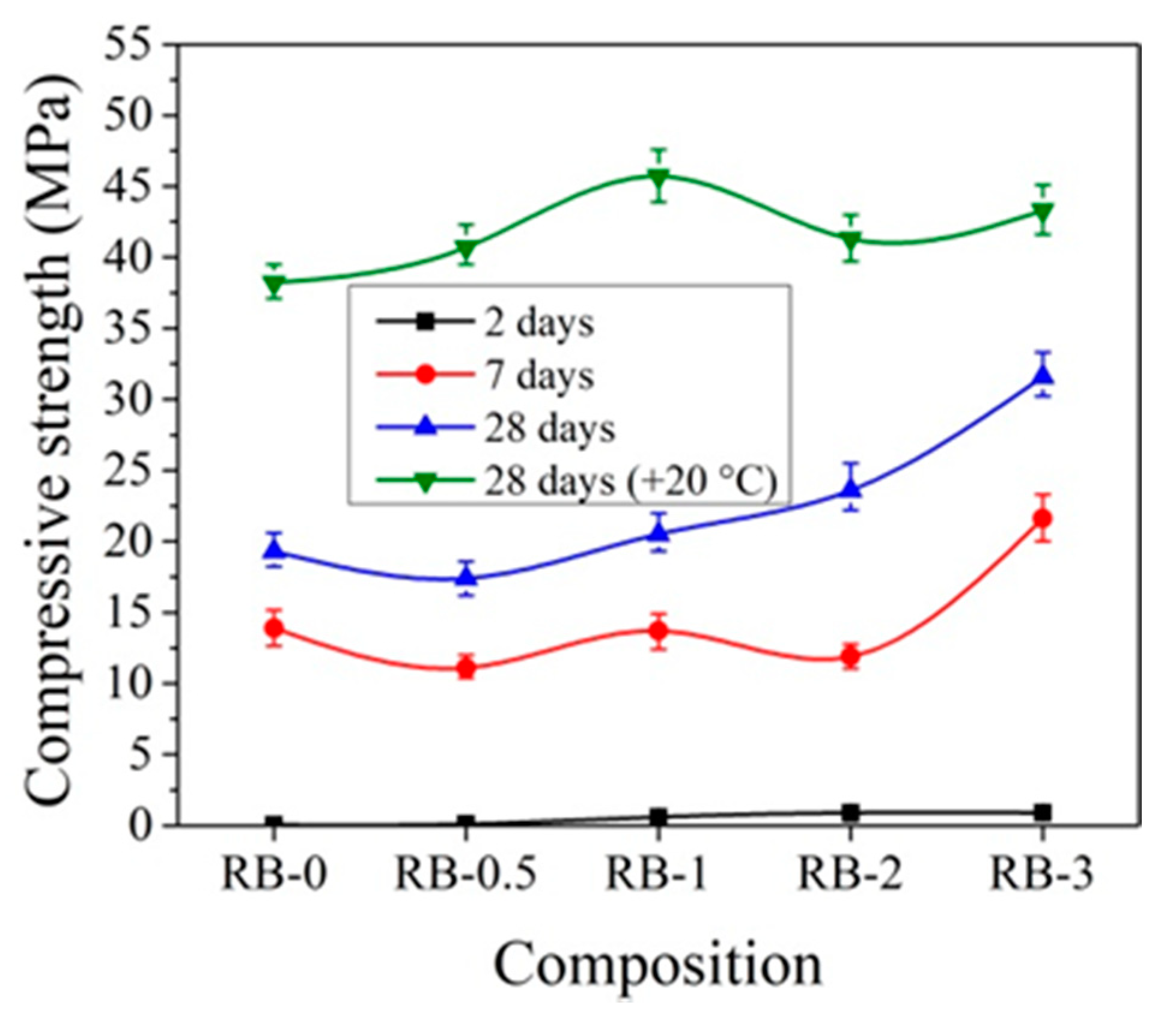

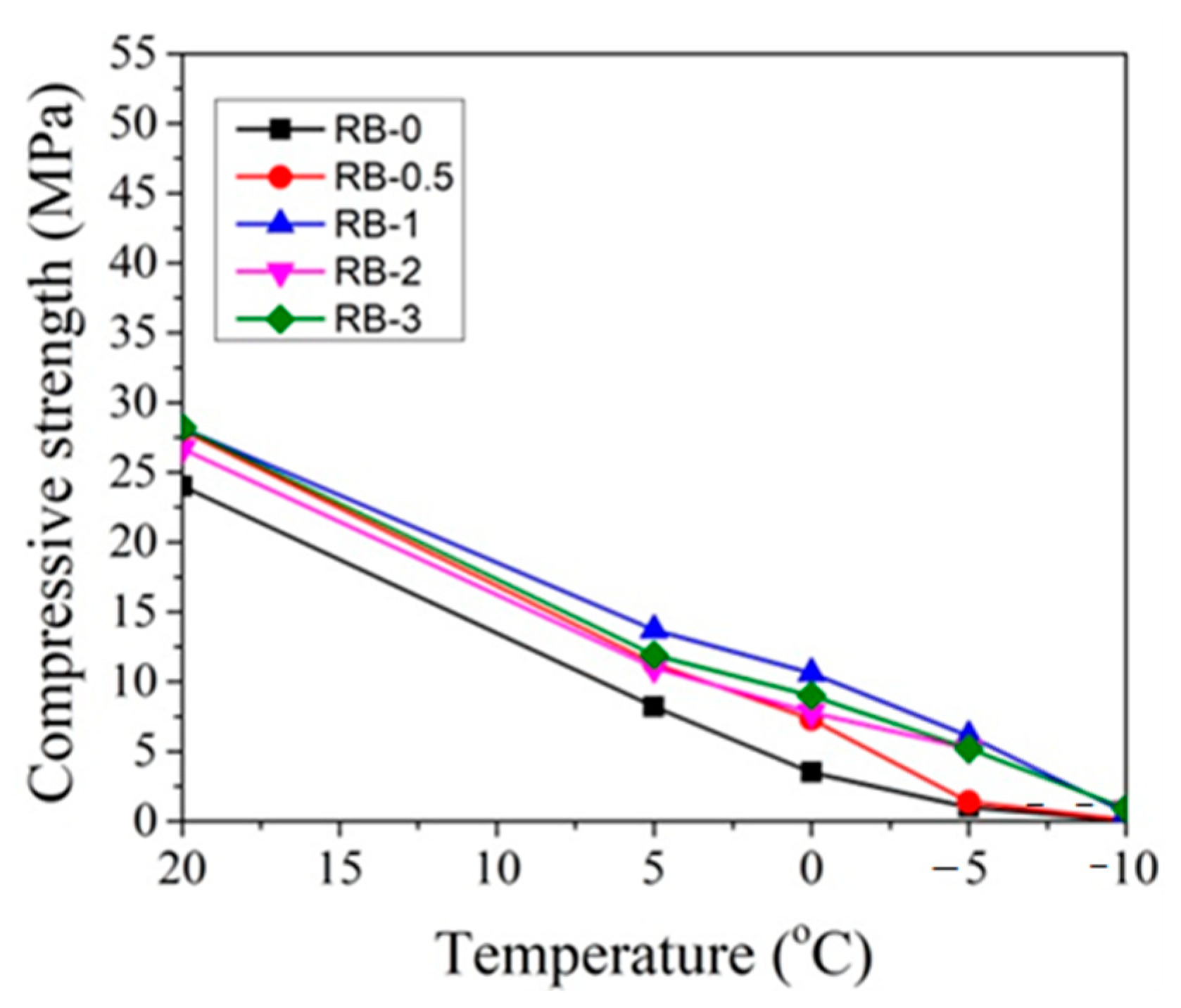

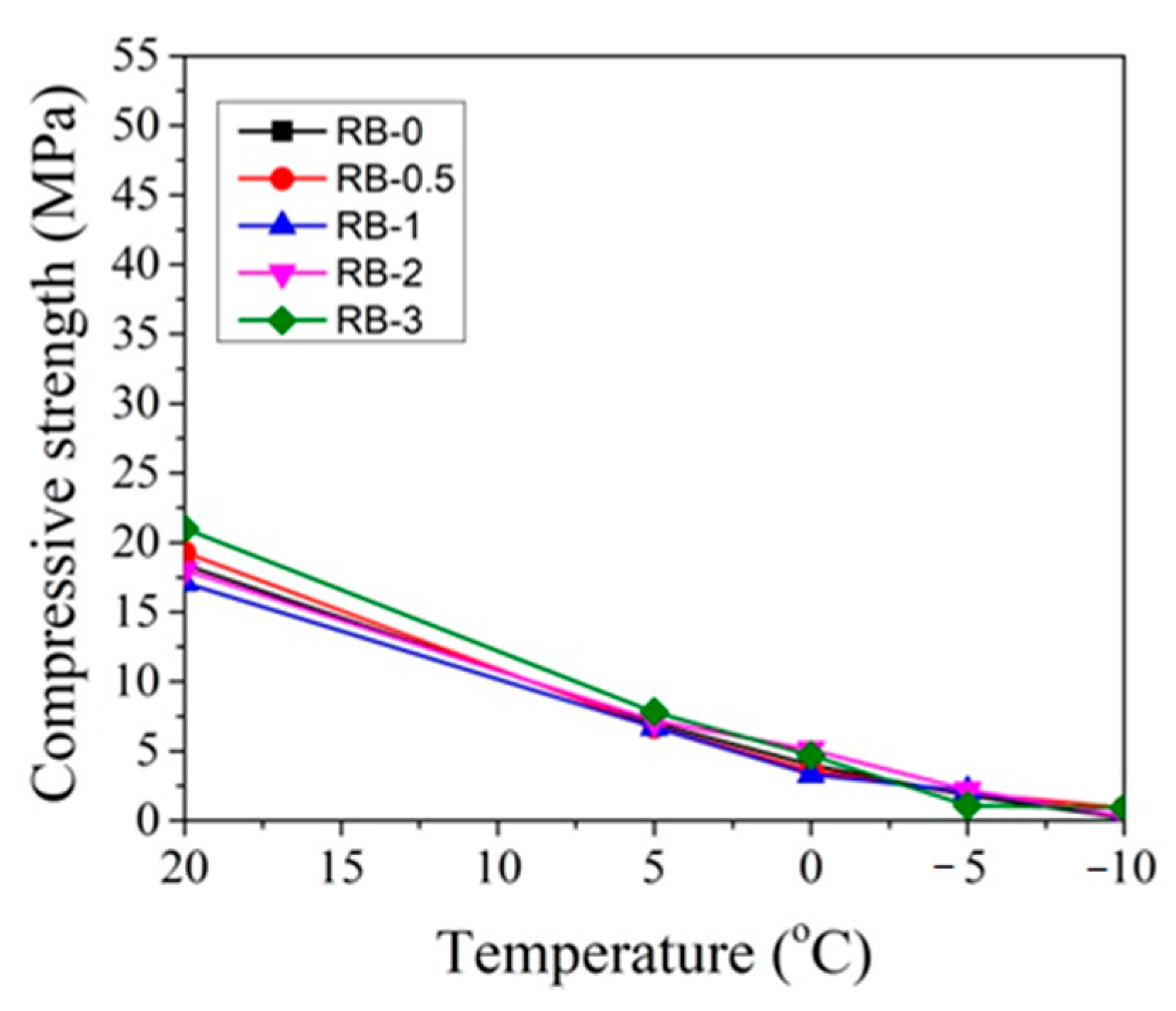

3.4. Compressive Strength of Concrete with CN in Ordinary at Low Temperature

4. Discussion

5. Conclusions

- Larger amounts of CN (2 and 3%) increase the viscosity of both CEM IIR and CEM IIN cement pastes. The effect is more pronounced for CEM IIR cement paste. A CEM IIN paste with 3% CN exhibiting lower viscosity than an analogous CEM IIR paste with the same CN amount. The CEM IIR cement granulometry and higher w/c required to achieve normal consistency caused by smaller cement particles of CEM IIR compared to CEM IIN can explain the more rapid increase in viscosity.

- CN contents at 0.5% and 1% in the cement pastes increases the slump of concrete. This tendency does not change during the first hour. The slump of concrete mix, regardless of the type of cement, decreases when the CN amount increase above 1.5%. These slump results for concrete correlates well with viscosity studies on pastes.

- The accelerator efficiency of CN increases with deceasing temperature from +20 °C to 0 °C. CN is the most effective as an accelerator at +5 °C and 0 °C. At these temperatures, the use of 3% CN reduces the initial setting times for CEM IIR paste by 7.4 and 5.4 times, respectively, and for CEM IIN paste by 3.5 and 3.4 times when compared to a CN-free control paste.

- Reductions in the compressive strength of concrete with CN were lower than that of the control without CN when initially cured at temperatures lower than +20 °C. The early strength of samples with CEM IIR cured for 2 days at +20 °C, +5 °C, and 0 °C when 1% dosage of CN was used in the concrete, while 3% dosage of CN was required for CEM IIN. The most efficient use of CN is achieved at −5 °C, where 1% CN ensures the compressive strength of samples with a CEM IIR higher than 3.5 MPa but less than the required 3.5 MPa in the samples with CEM IIN. The samples with both cement and 0.5–3% CN after hardening for 2 days at −10 °C did not reach the required value of 3.5 MPa.

- According to the procedure where concrete samples are hardened for 2 days in cold conditions and further hardened at +20 °C for 26 days, the compressive strength of the concrete samples is higher than that of the samples hardened in water at +20 °C continuously for 28 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scivener, K.L. Options for the future cement. Indian Conc. J. 2014, 88, 11–21. [Google Scholar]

- US Geological Survey. Mineral Commodity Summaries; US Geological Survey: Reston, VI, USA, 2013; p. 198. [CrossRef]

- Scivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tsudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Wang, L.; Gao, X.; Huang, Y.; Song, Q.; Liu, K. Alumina-rich pozzolan modification on Portland-limestone cement concrete: Hydration kinetics, formation of hydrates and long-term performance evolution. Constr. Build. Mater. 2020, 258, 119712. [Google Scholar] [CrossRef]

- CSA. Cementitious Materials Compendium; Canadian Standard Association: Toronto, ON, USA, 1983. [Google Scholar]

- BS-EN-197-1. Composition Specifications and Conformity Criteria for Common Cements; British Standard Institution: London, UK, 2000. [Google Scholar]

- ASTM-C150-18. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Palm, S.; Proske, T.; Rezvani, M.; Hainer, S.; Müller, C.; Graubner, C.-A. Cements with a high limestone content—Mechanical properties, durability and ecological characteristics of the concrete. Constr. Build. Mater. 2016, 119, 308–318. [Google Scholar] [CrossRef]

- Proske, T.; Hainer, S.; Rezvani, M.; Graubner, C.-A. Eco-friendly concretes with reduced water and cement contents—Mix design principles and laboratory tests. Cem. Concr. Res. 2013, 51, 38–46. [Google Scholar] [CrossRef]

- Panesar, D.K.; Zhang, R. Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials—A review. Constr. Build. Mater. 2020, 251, 118866. [Google Scholar] [CrossRef]

- Shaker, F.; Rashad, A.; Allam, M. Properties of concrete incorporating locally produced Portland limestone cement. ASEJ 2018, 9, 2301–2309. [Google Scholar] [CrossRef]

- Rezvani, M.; Proske, T. Influence of chemical-mineralogical properties of limestone on the shrinkage behavior of cement paste and concrete made of limestone-rich cements. Constr. Build. Mater. 2017, 157, 818–828. [Google Scholar] [CrossRef]

- Hawkins, P.; Tennis, P.; Detwiler, R. The Use of Limestone in Portland Cement: A State-of-the-Art Review; EB 227; Portland Cement Association: Skokie, IL, USA, 1996; p. 36. [Google Scholar]

- Jambor, J. Influence of 3CaO.Al2O3·CaCO3.nH2O on the structure of cement paste. In Proceedings of the 7th International Conference on Computational Creativity, Paris, France, 30 June–4 July 1980; ICCC: Paris, France, 1980; pp. 449–487. [Google Scholar]

- Polat, R. The effect of antifreeze additives on fresh concrete subjected to freezing and thawing cycles. Cold Reg. Sci. Technol. 2016, 127, 10–17. [Google Scholar] [CrossRef]

- Chang, H.; Wu, S.; Li, H.; Zhang, X. Influence of time and temperature on rheology and flow performance of cemented paste backfill. Constr. Build. Mater. 2020, 231, 117117. [Google Scholar] [CrossRef]

- Krylov, B.A. Cold Weather Concreting; Book Review; J. Cold Reg. Eng.; CRC Press: Boca Raton, FL, USA, 1999; pp. 213–214. [Google Scholar]

- Rixom, M.R.; Mailvaganam, N. Chemical Admixture for Concrete; E&FN Spon: London, UK, 1999; Chapter 5. [Google Scholar]

- Nmai, C.K. Cold weather concreting admixtures. Cem. Concr. Compos. 1998, 20, 121–128. [Google Scholar] [CrossRef]

- Demirboğa, R.; Karagöl, F.; Polat, R.; Kaygusuz, M.A. The effects of urea on strength gaining of fresh concrete under the cold weather conditions. Constr. Build. Mater. 2014, 64, 114–120. [Google Scholar] [CrossRef]

- Karagöl, F.; Demirboğa, R.; Kaygusuz, M.A.; Yadollahi, M.M.; Polat, R. The influence of calcium nitrate as antifreeze admixture on the compressive strength of concrete exposed to low temperatures. Cold Reg. Sci. Technol. 2013, 89, 30–35. [Google Scholar] [CrossRef]

- Korhonen, C.J. Antifreeze Admixtures for Cold Regions Concreting: A Literature Review; Special Report 90–32; U.S. Army Corps of Engineers Cold Regions Research & Engineering Laboratory: Hanover, NH, USA, 1990. [Google Scholar]

- Ramachandran, V.S. Concrete Admixtures Handbook. Properties, Science and Technology, 2nd ed.; Printed in the United States; Noyes Publications: Park Ridge, NJ, USA, 1995; p. 1153. [Google Scholar]

- Mydral, R. Accelerating Admixtures for Concrete; State of art. SINTEF REPORT; SINTEF: Trondheim, Norway, 2007; p. 35. [Google Scholar]

- Brook, J.W.; Factor, D.F.; Kinney Frederick, D.; Sarkar, A.K. Cold weather admixture. Concr. Int. 1988, 10, 44–49. [Google Scholar]

- EN 934-2:2009 Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labeling; iTeh Standards: Washington, DC, USA, 2009.

- Justness, H.; Nygaard, E.C. Technical calcium nitrate as set accelerator for cement at low temperatures. Cem. Concr. Res. 1995, 25, 1766–1774. [Google Scholar] [CrossRef]

- Rosskopf, P.; Linton, F.; Peppler, R. Effect of Various Accelerating Chemical Admixtures on Setting and Strength Development of Concrete. JTE 1975, 3, 322–330. [Google Scholar] [CrossRef]

- Ramachandran, V.S. Elucidation of the role of chemical admixtures in hydrating cements by DTA technique. Therm. Acta 1972, 4, 343–366. [Google Scholar] [CrossRef]

- Justnes, H. Report STF70 F93138. In SINTEF Structures and Concrete; SINTEF: Trondheim, Norway, 1993; p. 40. [Google Scholar]

- Justness, H. Calcium nitrate as multifunctional concrete admixture. In Proceedings of the Slovenian 14th Colloquium on Concrete, Ljubljana, Slovenia, 29 May 2007; pp. 21–28. [Google Scholar]

- Angtad, R.L.; Hurley, F.R. Accelerator for Portland Cement. US Patent No. 3,427,175, 11 February 1969. [Google Scholar]

- Justnes, H.; Clemmens, F.; Depuydt, P.; Van Gemert, D.; Sellevolt, E.J. Setting Accelerators for Portland Cement. In Proceedings of the Supplementary Paper of the Sixth International Conference on Superplasticizers and Other Chemical Admixtures in Concrete, Nice, France, 11–13 October 2000. CANMET/ACI SP-195. [Google Scholar]

- Justnes, H. Calcium Nitrate as a Multifunctional Concrete Admixture; SINTEF Technology and Society: Trondheim, Norway, 2005. [Google Scholar]

- Popovics, S. Concrete Materials, Properties, Specifications and Testing, 2nd ed.; William Andrew Publishing Noyes: Park Ridge, NJ, USA, 1992; Chapter 6; pp. 236–246. [Google Scholar]

- El-Didamony, H.E.; Sharara, A.M.; Helmy, I.M.; Abd El-Aleem, S. Hydration characteristics of β-C2S in the presence of some accelerators. Cem. Concr. Res. 1996, 26, 1179–1187. [Google Scholar] [CrossRef]

- Dong, S.; Feng, D.; Jiang, S.; Zhu, W. Effect of a new type antifreeze agent on the mechanical behavior of negative temperature concrete. In Proceedings of the ICTE 2013—4th International Conference on Transportation Engineering, Chengdu, China, 19–20 October 2013; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 3027–3032. [Google Scholar]

- Korhonen, C.J.; Orchino, S.A. Off-the Shelf Antifreeze Admixture for Concrete; Technical Report ERDC/CRREL TR-01-2; US Army Corps of Engineers, Engineer Research and Development Center: Vicksburg, MS, USA, 2001. [Google Scholar]

- Pundienė, I.; Kičaitė, A.; Pranckevičienė, J. Impact of different types of plasticizing admixtures on the rheological properties and hydration of blended cements. J. Therm. Anal. Calorim. 2016, 123, 1099–1109. [Google Scholar] [CrossRef]

- Kičaitė, A.; Skripkiūnas, G.; Pundienė, I. The effect of calcium nitrate on the properties of Portland cement pastes and concrete hardening at low temperatures. Ceram. Silikáty 2020, 64, 263–270. [Google Scholar] [CrossRef]

- International Society for Rock Mechanics Commission on Rock Grouting. Int. J. Rock Mech. Min Sci. Geomech. Abstr. 1996, 33, 803–847. [CrossRef]

- Elkhadiri, I.; Palacios, M.; Puertas, F. Effect of curing temperature on cement hydration. Ceram. Silik. 2009, 53, 65–75. [Google Scholar]

- Ogunbode, E.B.; Hassan, I.O. Effect of Calcium Nitrate on Selected Properties of Concrete Containing Volcanic Ash. Leonard Electron. J. Pract. Technol. 2011, 19, 29–38. [Google Scholar]

- Chikh, N.; Cheikh-Zouaoui, M.; Aggoun, S. Effect of calcium nitrate and triisopropanolamine on the setting and strength evolution on Portland cement pastes. Mater. Struct. 2008, 41, 31–36. [Google Scholar] [CrossRef]

- Franke, W.; Weger, D.; Skarabis, J.; Gehlen, C. Study on Calcium Nitrate impact on Carbonation of Concrete. In Proceedings of the 1st International Conference on Grand Challenges in Construction Materials, Los Angeles, CA, USA, 17–18 March 2016. [Google Scholar]

- Justnes, H.; Thys, A.; Vanparijs, F. Reasons for Increase in Long Term Compressive Strength of Concrete by the Set Accelerator Calcium Nitrate. In Proceedings of the Kurdowski Symposium “Science of Cement and Concrete”, Kraków, Poland, 20–21 June 2001; pp. 265–278. [Google Scholar]

- Mirza, J.; Saleh, K.; Langevin, M.A.; Mirza, S.; Rafique Bhutta, M.A.; Tahir, M.M. Properties of microfine cement grouts at 4 °C, 10 °C and 20 °C. Constr. Build. Mater. 2013, 47, 1145–1153. [Google Scholar] [CrossRef]

- Korhonen, C.J.; Cortez, E.R. Antifreeze Admixtures for Cold Weather Concreting; Concrete International: Detroit, MI, USA, 1991; Volume 13, pp. 38–41. [Google Scholar]

- Suprenant, B.A. Designing cold weather concrete mixes. Aberd. Concr. Constr. 1990, 35, 882–884. [Google Scholar]

- Kumar, A.; Bishnoi, S.; Scrivener, K.L. Modelling early age hydration kinetics of alite. Cem. Concr. Res. 2012, 42, 903–918. [Google Scholar] [CrossRef]

- Karagöl, F.; Demirboğa, R.; Kaygusuz, M.A.; Yadollahi, M.M. The Influence of Calcium Nitrate on The Compressive Strength of Concrete Exposed to Freezing Weather, Proceedings of the International Balkans Conference on Challenges of Civil Engineering, BCCCE, Tirana, Albania, 19–21 May 2011; EPOKA University: Tirana, Albania, 2011. [Google Scholar]

- Karagöl, F.; Demirboga, R.; Khushefati, W.H. Behaviour of fresh and hardened concretes with antifreeze admixtures in deep-freeze low temperatures and exterior winter conditions. Contr. Build. Mater. 2015, 76, 388–395. [Google Scholar] [CrossRef]

- Bohloli, B.; Skjølsvos, O.; Justnes, H.; Olsson, R.; Grøv, E.; Aarset, A. Cement for tunnel grouting—Rheology and flow properties tested at different temperatures. Tunnel. Undergr. Space Technol. 2019, 91, 103011. [Google Scholar] [CrossRef]

- Xu, L.; Wang, P.; Zhang, G. Formation of ettringite in Portland cement/calcium aluminate cement/calcium sulfate ternary system hydrates at lower temperatures. Constr. Build. Mater. 2012, 31, 347–352. [Google Scholar] [CrossRef]

| Cement Type | Marking | Compressive Strength, MPa 7 Days 28 Days | Fineness Blaine, cm2·g−1 | |

|---|---|---|---|---|

| CEM II A-LL 42.5R | CEM IIR | 29.9 | 51.1 | 4400 |

| CEM II A-LL 42.5N | CEM IIN | 23.7 | 51.2 | 4080 |

| Cement Type | Marking | C3S, % | C2S, % | C3A, % | C4AF, % |

|---|---|---|---|---|---|

| CEM II A-LL 42.5R | CEM IIR | 58.7 | 12.9 | 6.3 | 10.79 |

| CEM II A-LL 42.5N | CEM IIN | 61.8 | 8.57 | 7.1 | 11.9 |

| Batch | Materials (in Mass%) | |||

|---|---|---|---|---|

| - | CEM IIR | CEM IIN | CN * | W/C |

| RP-0 | 100 | – | 0 | 0.267 |

| RP-0.5 | 100 | – | 0.5 | 0.267 |

| RP-1 | 100 | – | 1 | 0.267 |

| RP-1.5 | 100 | – | 1.5 | 0.267 |

| RP-2 | 100 | – | 2 | 0.267 |

| RP-2.5 | 100 | – | 2.5 | 0.267 |

| RP-3 | 100 | – | 3 | 0.267 |

| NP-0 | – | 100 | 0 | 0.240 |

| NP-0.5 | – | 100 | 0.5 | 0.240 |

| NP-1 | – | 100 | 1 | 0.240 |

| NP-1.5 | – | 100 | 1.5 | 0.240 |

| NP-2 | – | 100 | 2 | 0.240 |

| NP-2.5 | – | 100 | 2.5 | 0.240 |

| NP-3 | – | 100 | 3 | 0.240 |

| Batch | CEM IIR | CEM IIN | Sand | Gravel | CN | Superplasticizer | Water |

|---|---|---|---|---|---|---|---|

| RB-0 | 310 | – | 925 | 1005 | 0 | 1.55 | 170 |

| RB-0.5 | 310 | – | 925 | 1005 | 1.55 | 1.55 | 170 |

| RB-1 | 310 | – | 925 | 1005 | 3.1 | 1.55 | 170 |

| RB-2 | 310 | – | 925 | 1005 | 6.2 | 1.55 | 170 |

| RB-3 | 310 | – | 925 | 1005 | 9.3 | 1.55 | 170 |

| NB-0 | – | 310 | 925 | 1005 | 0 | 1.55 | 170 |

| NB-0.5 | – | 310 | 925 | 1005 | 1.55 | 1.55 | 170 |

| NB-1 | – | 310 | 925 | 1005 | 3.1 | 1.55 | 170 |

| NB-2 | – | 310 | 925 | 1005 | 6.2 | 1.55 | 170 |

| NB-3 | – | 310 | 925 | 1005 | 9.3 | 1.55 | 170 |

| Dosage of CN | Initial Solidification Time at Temperature | Final Solidification Time at Temperature | ||

|---|---|---|---|---|

| −5 °C | –10 °C | –5 °C | –10 °C | |

| 0% | 154 | 137 | 214 | 163 |

| 1% | 138 | 107 | 198 | 150 |

| 2% | 124 | 95 | 190 | 170 |

| 3% | 100 | 100 | 193 | 160 |

| Dosage of CN | Initial Solidification Time at Temperature | Final Solidification Time at Temperature | ||

|---|---|---|---|---|

| −5 °C | −10 °C | −5 °C | −10 °C | |

| 0% | 110 | 122 | 180 | 150 |

| 1% | 132 | 80 | 187 | 123 |

| 2% | 125 | 99 | 180 | 165 |

| 3% | 105 | 100 | 210 | 156 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skripkiūnas, G.; Kičaitė, A.; Justnes, H.; Pundienė, I. Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature. Materials 2021, 14, 1611. https://doi.org/10.3390/ma14071611

Skripkiūnas G, Kičaitė A, Justnes H, Pundienė I. Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature. Materials. 2021; 14(7):1611. https://doi.org/10.3390/ma14071611

Chicago/Turabian StyleSkripkiūnas, Gintautas, Asta Kičaitė, Harald Justnes, and Ina Pundienė. 2021. "Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature" Materials 14, no. 7: 1611. https://doi.org/10.3390/ma14071611

APA StyleSkripkiūnas, G., Kičaitė, A., Justnes, H., & Pundienė, I. (2021). Effect of Calcium Nitrate on the Properties of Portland–Limestone Cement-Based Concrete Cured at Low Temperature. Materials, 14(7), 1611. https://doi.org/10.3390/ma14071611