Energy Utilization of Torrefied Residue from Wine Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Preparation of Torrefied Samples

2.3. Sample Analysis

3. Results and Discussion

3.1. Elemental Analysis and Calorific Value

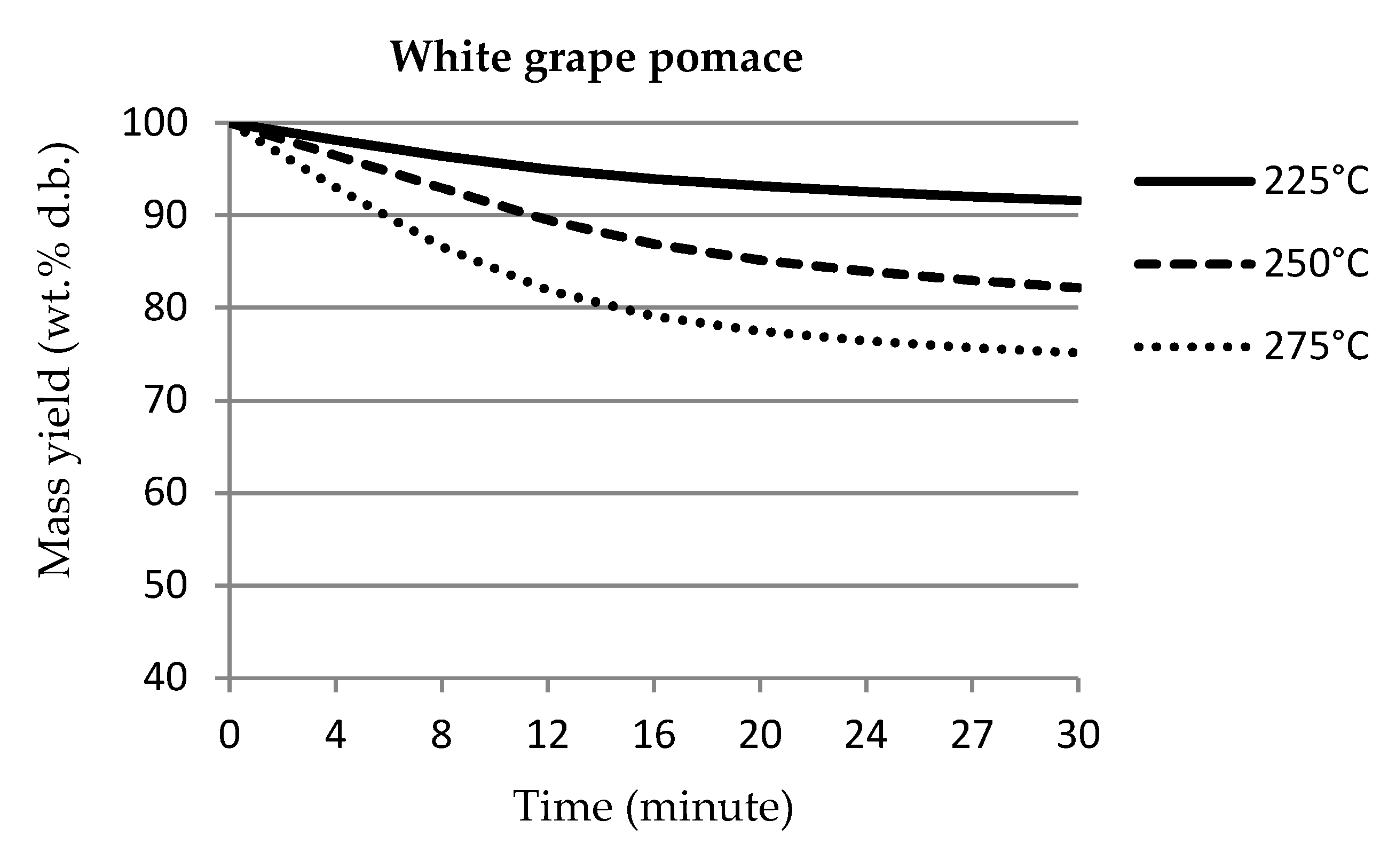

3.2. Sample Weight Loss Depending on Torrefaction Temperature

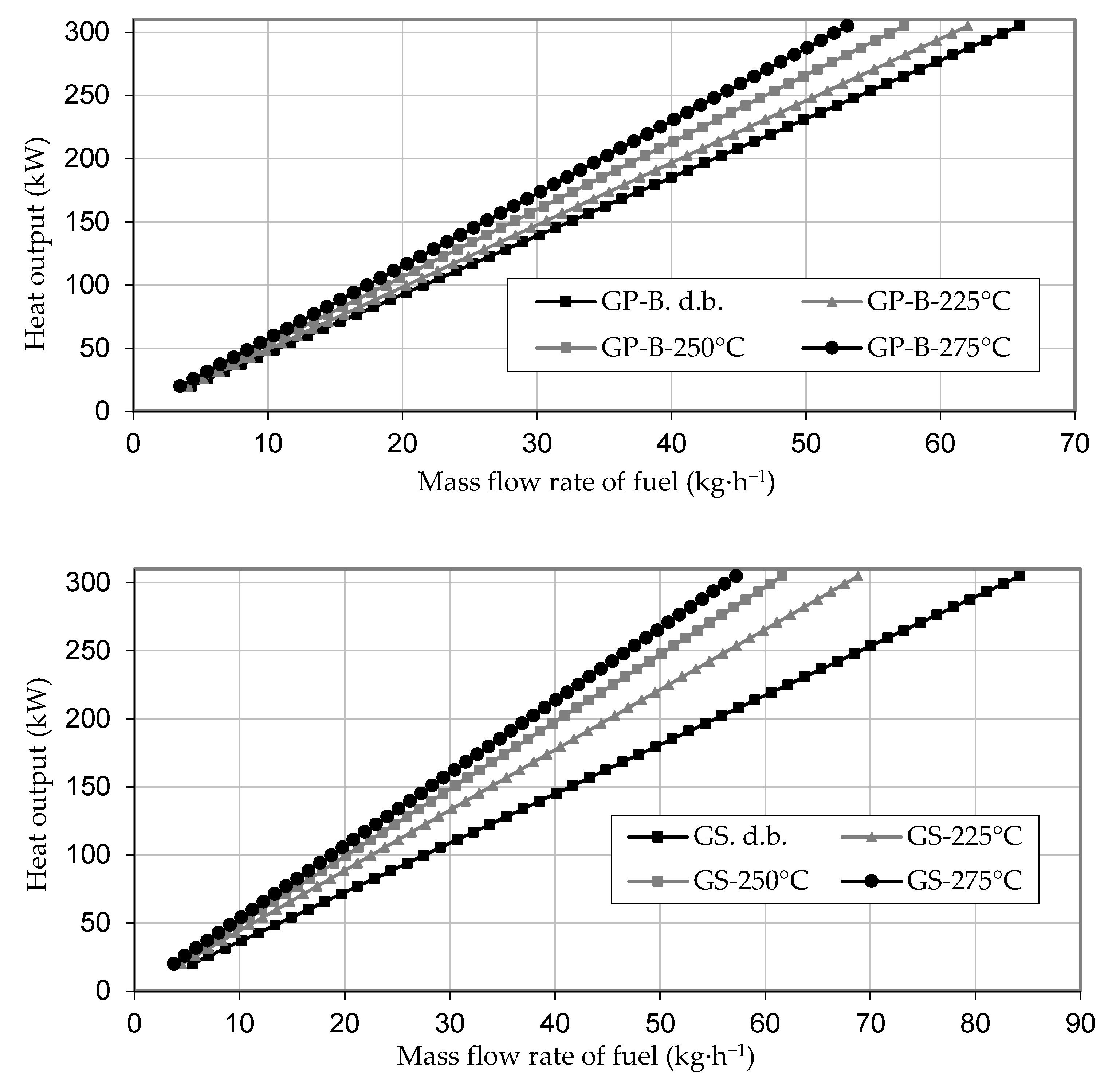

3.3. Stoichiometric Combustion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alburquerque, J.A.; Sánchez, M.E.; Mora, M.; Barrón, V. Slow pyrolysis of relevant biomasses in the Mediterranean basin. Part 2. Char characterisation for carbon sequestration and agricultural uses. J. Clean. Prod. 2016, 120, 191–197. [Google Scholar] [CrossRef]

- Beres, C.; Costa, G.N.S.; Cabezudo, I.; da Silva-James, N.K.; Teles, A.S.C.; Cruz, A.P.G.; Mellinger Silva, C.; Tonon, R.V.; Cabral, L.M.C.; Freitas, S.P. Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef]

- Scoma, A.; Rebecchi, S.; Bertin, L.; Fava, F. High impact biowastes from South European agro-industries as feedstock for second-generation biorefineries. Crit. Rev. Biotechnol. 2014, 36, 175–189. [Google Scholar] [CrossRef]

- Spigno, G.; Maggi, L.; Amendola, D.; Dragoni, M.; De Faveri, D.M. Influence of cultivar on the lignocellulosic fractionation of grape stalks. Ind. Crop. Prod. 2013, 46, 283–289. [Google Scholar] [CrossRef]

- Beres, C.; Simas-Tosin, F.F.; Cabezudo, I.; Freitas, S.P.; Iacomini, M.; Mellinger-Silva, C.; Cabral, L.M.C. Antioxidant dietary fibre recovery from Brazilian Pinot noir grape pomace. Food Chem. 2016, 201, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal carbonization and torrefaction of grape pomace: A comparative evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Riazi, F.; Zeynali, F.; Hoseini, E.; Behmadi, H.; Savadkoohi, S. Oxidation phenomena and color properties of grape pomace on nitrite-reduced meat emulsion systems. Meat Sci. 2016, 121, 350–358. [Google Scholar] [CrossRef]

- Yu, J.; Ahmedna, M. Functional components of grape pomace: Their composition, biological properties and potential applications. Int. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Dwyer, K.; Hosseinian, F.; Rod, M. The market potential of grape waste alternatives. J. Food Res. 2014, 3, 91–106. [Google Scholar] [CrossRef]

- Fontana, A.R.; Antoniolli, A.; Bottini, R. Grape pomace as a sustainable source of bioactive compounds: Extraction characterization, and biotechnological applications of phenolics. J. Agric. Food Chem. 2013, 61, 8987–9003. [Google Scholar] [CrossRef]

- Muhlack, R.A.; Potumarthi, R.; Jeffery, D.W. Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag. 2018, 72, 99–118. [Google Scholar] [CrossRef]

- Mayr Marangon, C.; De Rosso, M.; Carraro, R.; Flamini, R. Changes in volatile compounds of grape pomace distillate (Italian grappa) during one-year ageing in oak and cherry barrels. Food Chem. 2021, 344, 128658. [Google Scholar] [CrossRef]

- Da Porto, C. Grappa: Production, sensory properties and market development. Alcohol. Beverages: Sens. Eval. Consum. Res. 2011, 299–314. [Google Scholar] [CrossRef]

- Hixson, J.L.; Jacobs, J.L.; Wilkes, E.N.; Smith, P.A. Survey of the Variation in Grape Marc Condensed Tannin Composition and Concentration and Analysis of Key Compositional Factors. J. Agric. Food Chem. 2016, 64, 7076–7086. [Google Scholar] [CrossRef]

- Pinelo, M.; Arnous, A.; Meyer, A.S. Upgrading of grape skins: Significance of plant cell-wall structural components and extraction techniques for phenol release. Trends Food Sci. Technol. 2006, 17, 579–590. [Google Scholar] [CrossRef]

- Paradelo, R.; Moldes, A.B.; Barral, M.T. Evolution of organic matter during the mesophilic composting of lignocellulosic winery wastes. J. Environ. Manag. 2013, 116, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Greenwood, S.L.; Edwards, G.R.; Harrison, R. Short communication: Supplementing grape marc to cows fed a pasture-based diet as a method to alter nitrogen partitioning and excretion. J. Dairy Sci. 2012, 95, 755–758. [Google Scholar] [CrossRef] [PubMed]

- Botelho, T.; Costa, M.; Wilk, M.; Magdziarz, A. Evaluation of the combustion characteristics of raw and torrefied grape pomace in a thermogravimetric analyzer and in a drop tube furnace. Fuel 2018, 12, 95–100. [Google Scholar] [CrossRef]

- Encinar, J.M.; Beltrán, F.J.; Bernalte, A.; Ramiro, A.; González, J.F. Pyrolysis of two agricultural residues: Olive and grape bagasse. Influence of particle size and temperature. Biomass Bioenergy 1996, 11, 397–409. [Google Scholar] [CrossRef]

- Lapuerta, M.; Hernández, J.J.; Pazo, A.; López, J. Gasification and co-gasification of biomass wastes: Effect of the biomass origin and the gasifier operating conditions. Fuel Process. Technol. 2008, 89, 828–837. [Google Scholar] [CrossRef]

- Miranda, M.T.; Arranz, J.I.; Román, S.; Montero, I.; López, M.; Cruz, J.A. Characterization of grape pomace and pyrenean oak pellets. Fuel Process. Technol. 2011, 92, 278–283. [Google Scholar] [CrossRef]

- Czech Statistical Office (2021). Trends Areas, Per Hectare Yields Harvest. Crop.—1.1.; 2021; Available online: https://vdb.czso.cz/vdbvo2/faces/en/index.jsf?page=vystup-objekt&pvo=ZEM02G&z=T&f=TABULKA&skupId=386&katalog=30840&pvo=ZEM02G&evo=v1442_!_ZEM02G-celek_1 (accessed on 7 March 2021).

- García-Pérez, J.V.; Blasco, M.; Cárcel, J.A.; Clemente, G.; Mulet, A. Drying kinetics of grape stalk. Defect Diffus. Forum 2006, 258–260, 225–230. [Google Scholar] [CrossRef]

- Deiana, A.C.; Sardella, M.F.; Silva, H.; Amaya, A.; Tancredi, N. Use of grape stalk, a waste of the viticulture industry, to obtain activated carbon. J. Hazard. Mater. 2009, 172, 13–19. [Google Scholar] [CrossRef] [PubMed]

- Ping, L.; Brosse, N.; Sannigrahi, P.; Ragauskas, A. Evaluation of grape stalks as a bioresource. Ind. Crop. Prod. 2011, 33, 200–204. [Google Scholar] [CrossRef]

- Pujol, D.; Liu, C.; Fiol, N.; Olivella, À.M.; Gominho, J.; Villaescusa, I.; Pereira, H. Chemical characterization of different granulometric fractions of grape stalks waste. Ind. Crop. Prod. 2013, 50, 494–500. [Google Scholar] [CrossRef]

- Malaťak, J.; Gürdil, G.A.K.; Jevic, P.; Selvi, K.Ç. Biomass heat-emission characteristics of energy plants. Ama-Agric. Mech. Asia Afr. Lat. Am. 2009, 39, 9–13. [Google Scholar]

- Nguyen, T.L.T.; Hermansen, J.E.; Nielsen, R.G. Environmental assessment of gasification technology for biomass conversion to energy in comparison with other alternatives: The case of wheat straw. J. Clean. Prod. 2013, 53, 138–148. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Gürdil, G.A.K.; Demirel, B. Effect of particle size on surface smoothness of bio-briquettes produced from agricultural residues. Manuf. Technol. 2018, 18, 742–747. [Google Scholar] [CrossRef]

- Ivanova, T.; Mendoza Hernández, A.H.; Bradna, J.; Fernández Cusimamani, E.; García Montoya, J.C.; Armas Espinel, D.A. Assessment of Guava (Psidium guajava L.) Wood Biomass for Briquettes’ Production. Forests 2018, 9, 613. [Google Scholar] [CrossRef]

- Wróbel, M.; Jewiarz, M.; Mudryk, K.; Knapczyk, A. Influence of Raw Material Drying Temperature on the Scots Pine (Pinus sylvestris L.) Biomass Agglomeration Process-A Preliminary Study. Energies 2020, 13, 1809. [Google Scholar] [CrossRef]

- Kučerová, V.; Vybohova, E.; Honig, V.; Cabalova, i. Chemical Changes within Solids during Liquid Hot Water Pretreatment of Wood. Bioresources 2020, 15, 38–48. [Google Scholar] [CrossRef]

- Correia, R.; Gonçalves, M.; Nobre, C.; Mendes, B. Impact of torrefaction and low-temperature carbonization on the properties of biomass wastes from Arundo donax L. and Phoenix canariensis. Bioresour. Technol. 2017, 223, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Keipi, T.; Tolvanen, H.; Kokko, L.; Raiko, R. The effect of torrefaction on the chlorine content and heating value of eight woody biomass samples. Biomass Bioenergy 2014, 66, 232–239. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, J.-W. Optimization of biomass torrefaction conditions by the Gain and Loss method and regression model analysis. Bioresour. Technol. 2014, 172, 438–443. [Google Scholar] [CrossRef] [PubMed]

- Wannapeera, J.; Worasuwannarak, N. Upgrading of woody biomass by torrefaction under pressure. J. Anal. Appl. Pyrolysis 2012, 96, 173–180. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Kikas, T. Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements. Bioresour. Technol. 2020, 301, 122737. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Mikušová, L.; Očkajová, A.; Dado, M.; Kučera, M.; Danihelová, Z. Thermal treatment’s effect on dust emission during sanding of meranti wood. BioResources 2019, 14, 5316–5326. [Google Scholar]

- Novák, V.; Křížová, K.; Šařec, P. Biochar dosage impact on physical soil properties and crop status. Agron. Res. 2020, 18, 2501–2511. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Preparation, modification and environmental application of biochar: A review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Kalemba, I. Characterisation of renewable fuels’ torrefaction process with different instrumental techniques. Energy 2015, 87, 259–269. [Google Scholar] [CrossRef]

- Zhao, B.; O’Connor, D.; Zhang, J.; Peng, T.; Sheng, Z.; Tsang, D.C.W.; Hou, D. Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 2018, 174, 977–987. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lu, K.-M.; Tsai, C.-M. An experimental analysis on property and structure variations of agricultural wastes undergoing torrefaction. Appl. Energy 2012, 100, 318–325. [Google Scholar] [CrossRef]

- Tamelová, B.; Malaťák, J.; Velebil, J. Hydrothermal carbonization and torrefaction of cabbage waste. Agron. Res. 2019, 17, 862–871. [Google Scholar] [CrossRef]

- González-Centeno, M.R.; Rosselló, C.; Simal, S.; Garau, M.C.; López, F.; Femenia, A. Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: Grape pomaces and stems. LWT Food Sci. Technol. 2010, 43, 1580–1586. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood. Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Chiou, B.S.; Valenzuela-Medina, D.; Bilbao-Sainz, C.; Klamczynski, A.K.; Avena-Bustillos, R.J.; Milczarek, R.R.; Du, W.X.; Glenn, G.M.; Orts, W.J. Torrefaction of pomaces and nut shells. Bioresour. Technol. 2015, 177, 58–65. [Google Scholar] [CrossRef] [PubMed]

- Burg, P.; Ludín, D.; Rutkowski, K.; Krakowiak-Bal, A.; Trávníček, P.; Zemánek, P.; Turan, J.; Višacki, V. Calorific evaluation and energy potential of grape pomace. Int. Agrophysics 2016, 30, 261–265. [Google Scholar] [CrossRef]

- Chen, D.; Zheng, Z.; Fu, K.; Zeng, Z.; Wang, J.; Lu, M. Torrefaction of biomass stalk and its effect on the yield and quality of pyrolysis products. Fuel 2015, 159, 27–32. [Google Scholar] [CrossRef]

- Tamelová, B.; Malaťák, J.; Velebil, J. Energy valorisation of citrus peel waste by torrefaction treatment. Agron. Res. 2018, 16, 276–285. [Google Scholar] [CrossRef]

- Díaz-Ramiréz, M.; Sebastián, F.; Royo, J.; Rezeau, A. Influencing factors on NOX emission level during grate conversion of three pelletized energy crops. Appl. Energy 2014, 115, 360–373. [Google Scholar] [CrossRef]

- Kažimírová, V.; Opáth, R. Biomass combustion emissions. Res. Agric. Eng. 2016, 62, 61–65. [Google Scholar] [CrossRef]

- Malaťák, J.; Gendek, A.; Aniszewska, M.; Velebil, J. Emissions from combustion of renewable solid biofuels from coniferous tree cones. Fuel 2020, 276, 118001. [Google Scholar] [CrossRef]

- Abelha, P.; Kiel, J. Techno-economic assessment of biomass upgrading by washing and torrefaction. Biomass Bioenergy 2020, 142, 105751. [Google Scholar] [CrossRef]

- Sermyagina, E.; Saari, J.; Kaikko, J.; Vakkilainen, E. Integration of torrefaction and CHP plant: Operational and economic analysis. Appl. Energy 2016, 183, 88–99. [Google Scholar] [CrossRef]

- Akbari, M.; Oyedun, A.O.; Kumar, A. Techno-economic assessment of wet and dry torrefaction of biomass feedstock. Energy 2020, 207, 118287. [Google Scholar] [CrossRef]

| Temp. | C | H | N | S | O | Ash | GCV | NCV |

|---|---|---|---|---|---|---|---|---|

| °C | % | MJ·kg−1 | ||||||

| GP-White | ||||||||

| Dry basis | 53.29 ± 0.03 | 6.03 ± 0.02 | 1.64 ± 0.06 | <0.02 | 32.88 | 6.13 ± 0.01 | 21.65 ± 0.03 | 20.33 |

| 225 | 56.54 ± 0.03 | 5.85 ± 0.01 | 1.75 ± 0.02 | <0.02 | 29.95 | 5.88 ± 0.01 | 23.05 ± 0.06 | 21.78 |

| 250 | 60.67 ± 0.09 | 5.71 ± 0.02 | 1.86 ± 0.03 | <0.02 | 25.11 | 6.62 ± 0.04 | 24.95 ± 0.04 | 23.71 |

| 275 | 64.96 ± 0.02 | 5.57 ± 0.03 | 1.96 ± 0.01 | <0.02 | 20.22 | 7.25 ± 0.03 | 26.82 ± 0.02 | 25.61 |

| GP-Blue | ||||||||

| Dry Basis | 54.04 ± 0.09 | 6.13 ± 0.05 | 2.13 ± 0.06 | <0.02 | 32.67 | 5.00 ± 0.03 | 22.17 ± 0.04 | 20.83 |

| 225 | 56.64 ± 0.08 | 6.03 ± 0.03 | 2.22 ± 0.03 | <0.02 | 29.62 | 5.46 ± 0.05 | 23.44 ± 0.08 | 22.13 |

| 250 | 69.60 ± 0.10 | 5.93 ± 0.02 | 2.40 ± 0.03 | <0.02 | 25.17 | 5.87 ± 0.04 | 25.24 ± 0.05 | 23.94 |

| 275 | 64.92 ± 0.02 | 5.84 ± 0.03 | 2.52 ± 0.06 | <0.02 | 19.86 | 6.83 ± 0.03 | 27.12 ± 0.10 | 25.84 |

| GS | ||||||||

| Dry Basis | 46.40 ± 0.13 | 5.47 ± 0.01 | 0.69 ± 0.01 | <0.02 | 39.18 | 8.23 ± 0.03 | 17.49 ± 0.03 | 16.30 |

| 225 | 54.56 ± 0.08 | 4.83 ± 0.03 | 1.03 ± 0.03 | <0.02 | 28.93 | 10.61 ± 0.02 | 20.99 ± 0.08 | 19.94 |

| 250 | 59.92 ± 0.10 | 4.46 ± 0.01 | 1.25 ± 0.02 | <0.02 | 21.96 | 12.38 ± 0.03 | 23.24 ± 0.09 | 22.27 |

| 275 | 63.45 ± 0.02 | 4.32 ± 0.03 | 1.28 ± 0.06 | <0.02 | 17.32 | 13.60 ± 0.05 | 24.93 ± 0.04 | 23.98 |

| Sample | Temperature | Polynomial Equation | Reliability Value |

|---|---|---|---|

| GP-W | 225 °C | y = 0.1153x2 − 2.1784x + 102.01 | R2 = 0.9988 |

| 250 °C | y = 0.2546x2 − 4.781x + 104.74 | R2 = 0.9987 | |

| 275 °C | y = 0.5295x2 − 8.2311x + 107.22 | R2 = 0.9940 | |

| GP-B | 225 °C | y = 0.0726x2 − 1.5408x + 101.54 | R2 = 0.9993 |

| 250 °C | y = 0.1427x2 − 3.4018x + 103.59 | R2 = 0.9984 | |

| 275 °C | y = 0.4115x2 − 7.2972x + 107.47 | R2 = 0.9974 | |

| GS | 225 °C | y = 0.3314x2 − 5.4592x + 104.03 | R2 = 0.9839 |

| 250 °C | y = 0.6584x2 − 10.501x + 108.69 | R2 = 0.9947 | |

| 275 °C | y = 0.9073x2 − 13.17x + 110.61 | R2 = 0.9819 |

| Parameter | Parameter | Unit | GP-W d.b. | GP-W 225 °C | GP-W 250 °C | GP-W 275 °C |

|---|---|---|---|---|---|---|

| L min | Stoichiometric Volume of Air for Complete Combustion | (m3·kg−1) | 5.23 | 5.57 | 6.06 | 6.57 |

| vssp min | Stoichiometric Volume of Dry Flue Gas | (m3 kg−1) | 5.08 | 5.41 | 5.87 | 6.35 |

| vCO2 | Stoichiometric Volume of CO2 | (m3·kg−1) | 0.99 | 1.05 | 1.13 | 1.21 |

| vH2O | Stoichiometric Volume of H2O | (m3 kg−1) | 1.11 | 1.12 | 1.14 | 1.17 |

| vN2 | Stoichiometric Volume of N2 | (m3·kg−1) | 8.59 | 9.14 | 9.95 | 10.78 |

| CO2max | Concentration of Carbon Dioxide in Dry Flue Gas after Stoichiometric Combustion | (% vol.) | 19.44 | 19.38 | 19.17 | 18.98 |

| Parameter | Parameter | Unit | GP-B d.b. | GP-B 225 °C | GP-B 250 °C | GP-B 275 °C |

|---|---|---|---|---|---|---|

| L min | Stoichiometric Volume of Air for Complete Combustion | (m3·kg−1) | 5.33 | 5.64 | 6.11 | 6.65 |

| vssp min | Stoichiometric Volume of Dry Flue Gas | (m3 kg−1) | 5.18 | 5.47 | 5.91 | 6.41 |

| vCO2 | Stoichiometric Volume of CO2 | (m3 kg−1) | 1.01 | 1.05 | 1.13 | 1.21 |

| vH2O | Stoichiometric Volume of H2O | (m3 kg−1) | 1.13 | 1.14 | 1.17 | 1.21 |

| vN2 | Stoichiometric Volume of N2 | (m3 kg−1) | 8.75 | 9.26 | 10.03 | 10.91 |

| CO2max | Concentration of Carbon Dioxide in Dry Flue Gas After Stoichiometric Combustion | (% vol.) | 19.35 | 19.21 | 19.01 | 18.78 |

| Parameter | Parameter | Units | GS d.b. | GS 225 °C | GS 250 °C | GS 275 °C |

|---|---|---|---|---|---|---|

| L min | Stoichiometric Volume of Air for Complete Combustion | (m3 kg−1) | 4.26 | 5.16 | 5.77 | 6.20 |

| vssp min | Stoichiometric Volume of Dry Flue Gas | (m3 kg−1) | 4.19 | 5.04 | 5.62 | 6.02 |

| vCO2 | Stoichiometric Volume of CO2 | (m3 kg−1) | 0.86 | 1.01 | 1.11 | 1.18 |

| vH2O | Stoichiometric Volume of H2O | (m3 kg−1) | 0.97 | 0.97 | 0.98 | 1.00 |

| vN2 | Stoichiometric Volume of N2 | (m3·kg−1) | 6.99 | 8.46 | 9.46 | 10.17 |

| CO2max | Concentration of Carbon Dioxide in Dry Flue Gas After Stoichiometric Combustion | (% vol.) | 20.53 | 20.05 | 19.76 | 19.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamelová, B.; Malaťák, J.; Velebil, J.; Gendek, A.; Aniszewska, M. Energy Utilization of Torrefied Residue from Wine Production. Materials 2021, 14, 1610. https://doi.org/10.3390/ma14071610

Tamelová B, Malaťák J, Velebil J, Gendek A, Aniszewska M. Energy Utilization of Torrefied Residue from Wine Production. Materials. 2021; 14(7):1610. https://doi.org/10.3390/ma14071610

Chicago/Turabian StyleTamelová, Barbora, Jan Malaťák, Jan Velebil, Arkadiusz Gendek, and Monika Aniszewska. 2021. "Energy Utilization of Torrefied Residue from Wine Production" Materials 14, no. 7: 1610. https://doi.org/10.3390/ma14071610

APA StyleTamelová, B., Malaťák, J., Velebil, J., Gendek, A., & Aniszewska, M. (2021). Energy Utilization of Torrefied Residue from Wine Production. Materials, 14(7), 1610. https://doi.org/10.3390/ma14071610