3.3. Micromechanical Analysis

It is a known fact that the properties of composites may vary depending on the literature source given the particular processing conditions that the matrix, fiber, and composite were subjected to in each singular study [

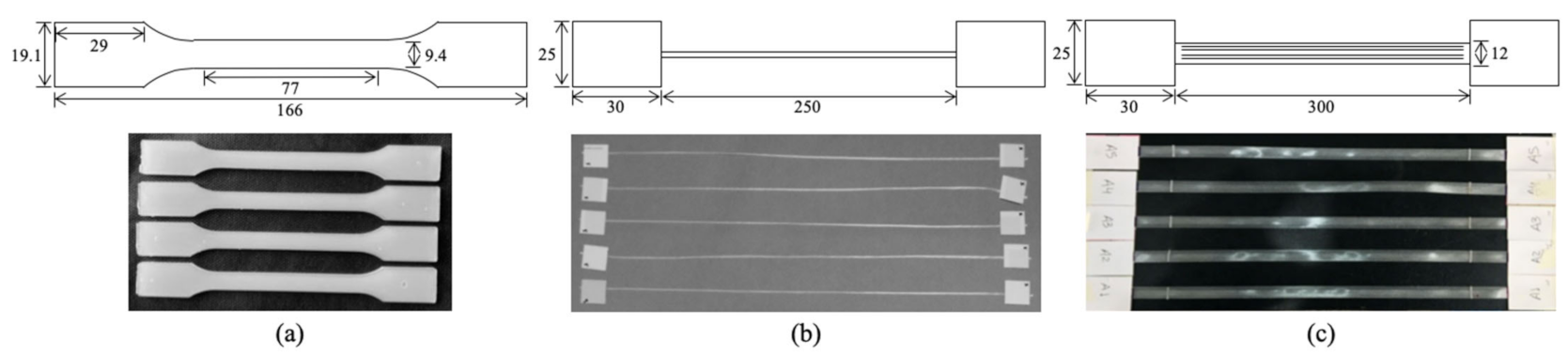

85], whereby extra/interpolations of properties from state-of-the-art reviews are often the most reliable approach to estimate the mechanical behavior of composites. Furthermore, micromechanical-oriented studies on composite materials are rare in the literature, whereas most authors perform macromechanical tests and rely on the commercial properties of the constituents as provided by the manufacturers for a more thorough analysis. For this reason, taking advantage of the fact that the present work individually studies the components of the composite, an analytical determination of important properties is hereby provided. These include the area of the transversal section of the multifilament yarn, which is not possible to measure using regular metrology instruments beyond the costly procedure of measuring the diameter of a single fiber through SEM and multiplying the result by the number of fibers, as well as the yarn ultimate tensile stress and the yarn modulus. These properties are rarely available in the literature and could contribute to future studies, either for designing composites or for applications where there is no matrix (e.g., ropes for cargo-lifting and station-keeping of vessels). An isostrain condition and the rule of mixture approach were used for these calculations, due to the simplicity and yet extremely elevated accuracy of this method in this specific case of unidirectional thin composites [

86].

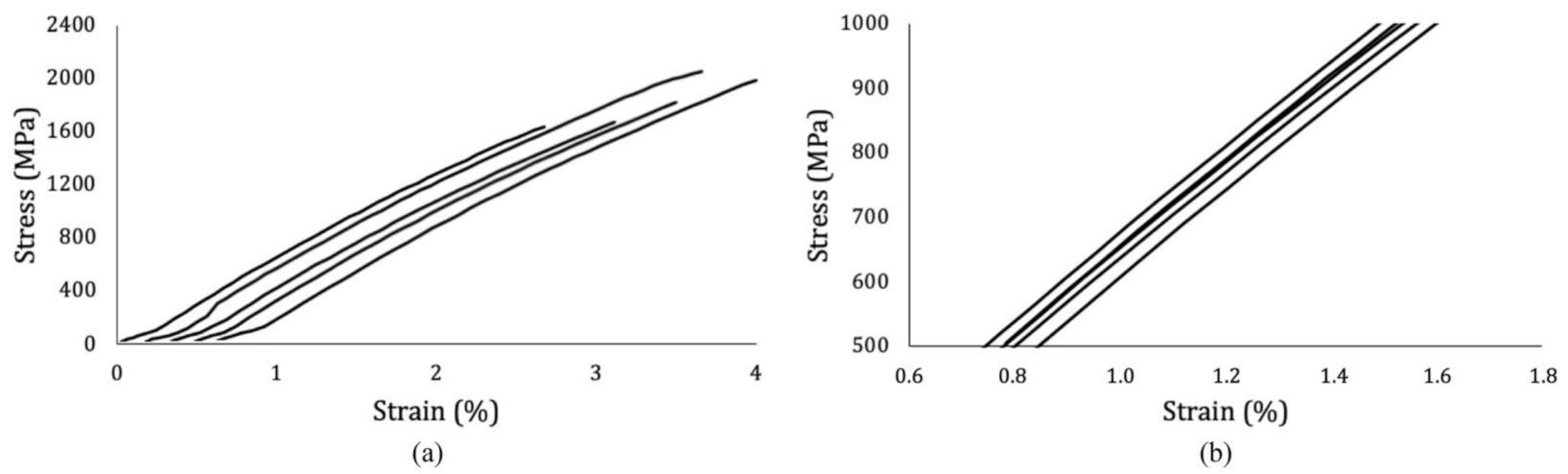

With the values of ultimate tensile strength of the composite (

) and the matrix (

) of 1830 MPa and 10.6 MPa, respectively, found in the experiments above, and the fiber volume (

) of 65.6% provided by the composite manufacturer, it was then possible to calculate the ultimate tensile stress of the fibers (

) according to Equation (2), resulting in 2785 MPa. The Hookean product of the maximum yarn tensile load of 540.8 N shown in

Table 4 through the ultimate tensile stress of fibers yielded an individual transversal area of 0.194 mm

2 for each yarn that was tested solely.

It is worth noting that the ultimate fiber breakage force in the composite, a product of

and 65.6% of the transversal area (i.e., 0.732 mm

2), was 2038 N; this value can be considered equal to the ultimate tensile force of the composite itself of 2043 ± 203 N, demonstrating numerically that the composite fails as soon as fiber failure occurs.

The same rule of mixture approach could be used to calculate the longitudinal tensile modulus of the fiber () from the moduli of the composite () and matrix () found experimentally (Equation (3)), resulting in a value of 101 GPa.

3.4. Shear Characterization of Single-Lap Cured Joints

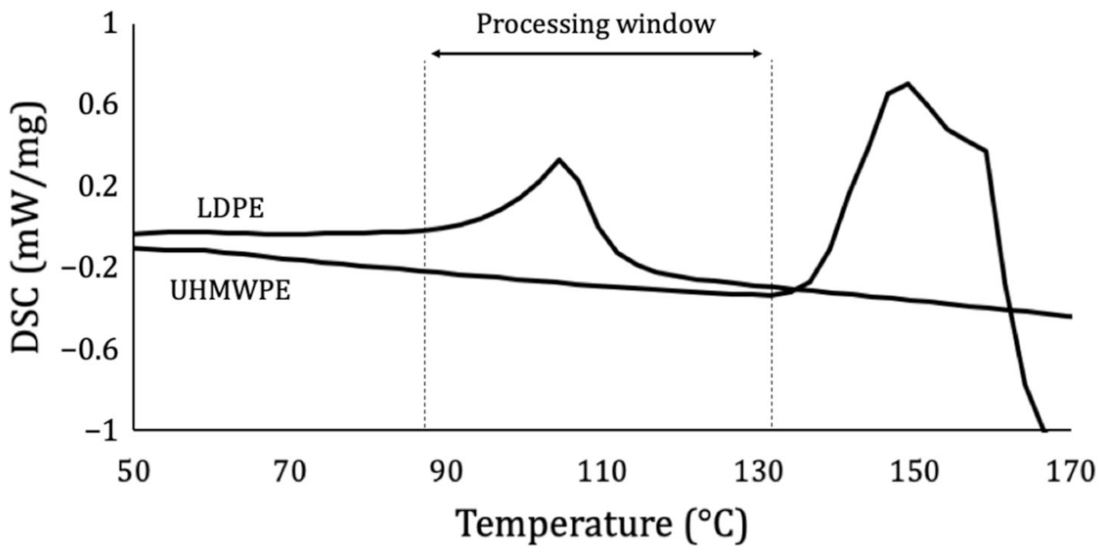

First, the cure of joints was carried out according to

Table 2 in the specified order.

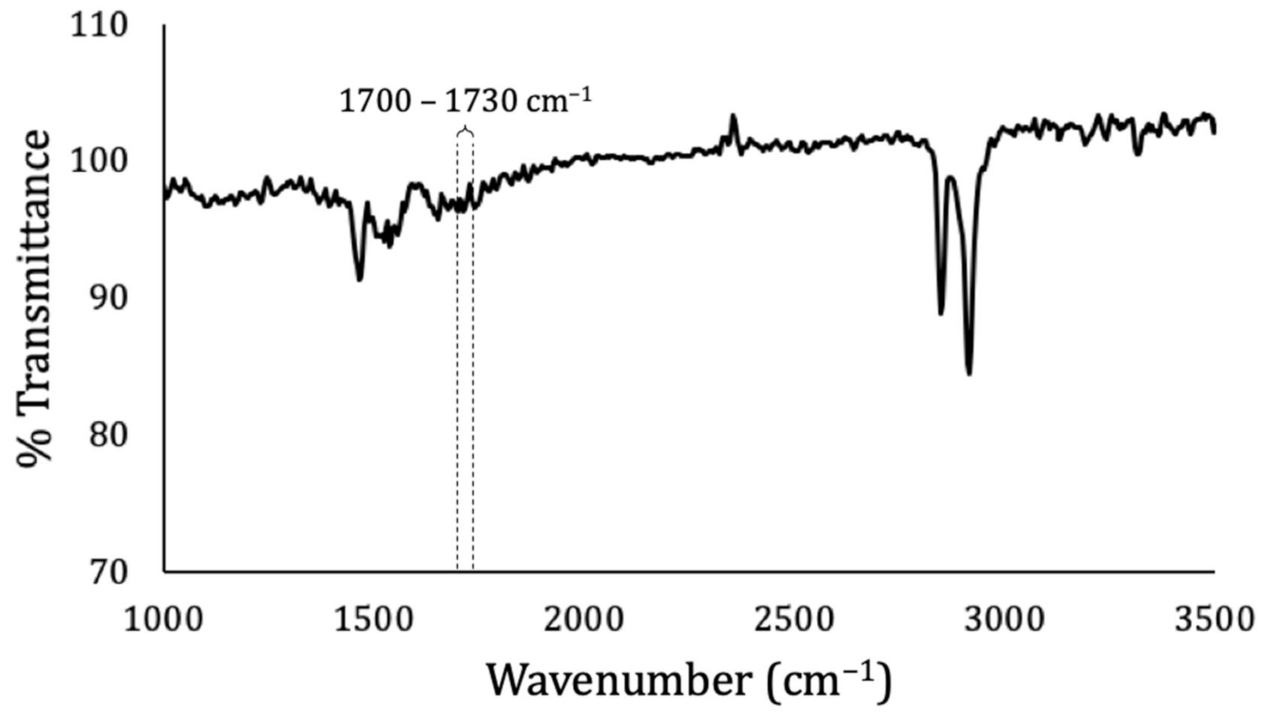

Figure 2 shows that the temperatures selected were adequate, as they were all higher than the T

m of the matrix, allowing it to at least partially melt and bond the two adherends. Also, they were all lower than the T

m of the reinforcement, preserving its structural integrity. The triple-peak curve of UHMWPE after T

m, as explained by Lacroix et al. [

33], is due to its crystallinity and refers to the melting of a part of the orthorhombic phase, a lattice transition from orthorhombic to hexagonal, and a melting of the hexagonal phase, in that order.

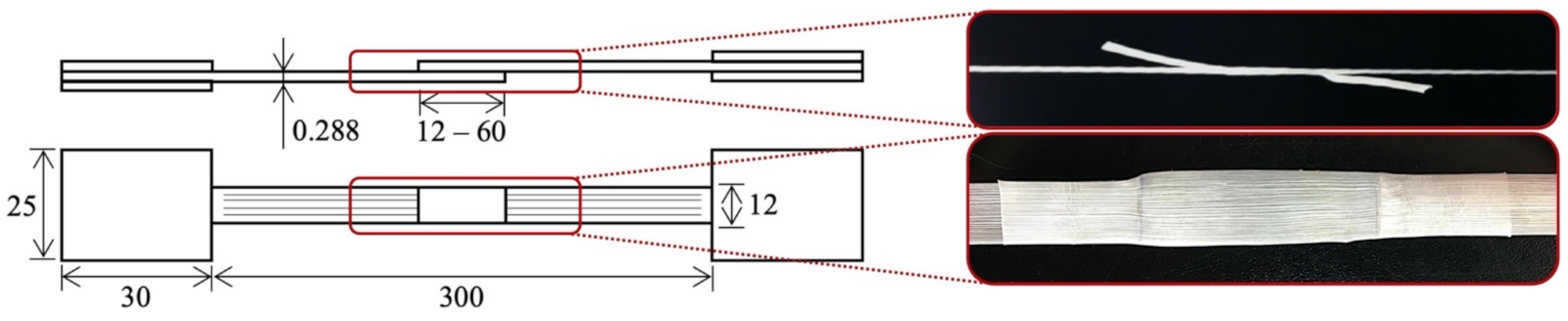

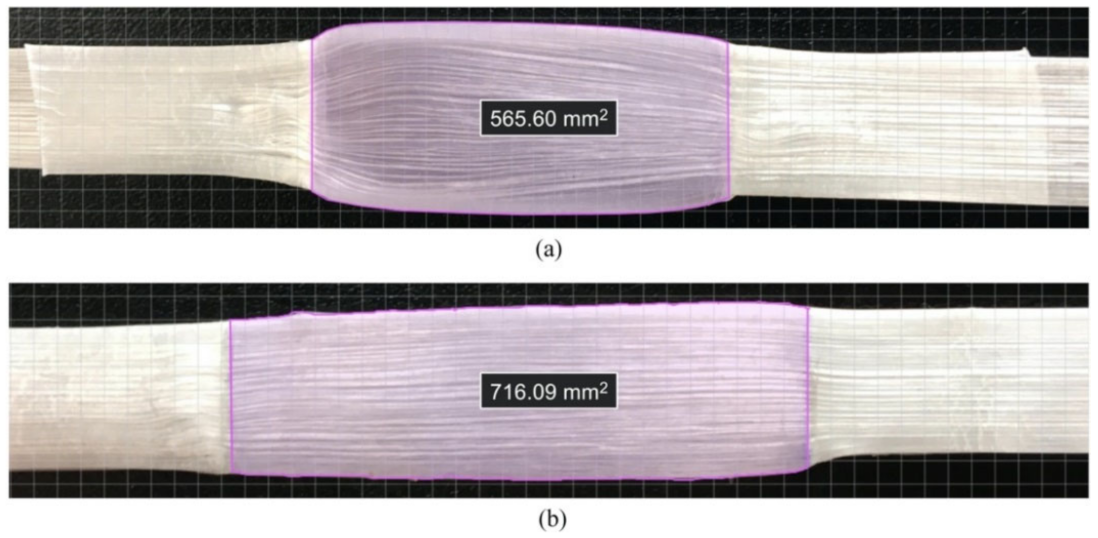

After the cure, the total gage length of all specimens (

LT) was measured to make sure no undesired longitudinal deformations occurred due to any potential shrinking of the cured regions. An average value of 299.6 ± 0.65 was found, concluding that any longitudinal deformation that might have taken place was negligible. Each individual joint thickness (

tJ) was measured in three different portions, with the aim of understanding how the processing parameters, mainly pressure and temperature, affect the out-of-plane compression of the joint (

ΔtJ), which became thinner than two overlapped tapes after curing. The cured area was always higher than merely the product of the tape width and the designed length of the joint (

AJ), as the matrix flowed beyond the original 12 mm width when heat and pressure were applied. Since this area must be the one adopted for stress calculations to provide a precise analysis, each individual joint area after cure was measured (

AJ,real), and the consequent in-plane expansions (

ΔAJ) were determined. Examples of measurements of the actual joint area are displayed in

Figure 8, which displays a more prominent flattening of specimen #26 that was cured at 3 bar, 110 °C, and 3 min than specimen #9 that was cured at 2 bar, 100 °C and 2 min. All of these dimensions are given in detail for all specimens in

Table 6.

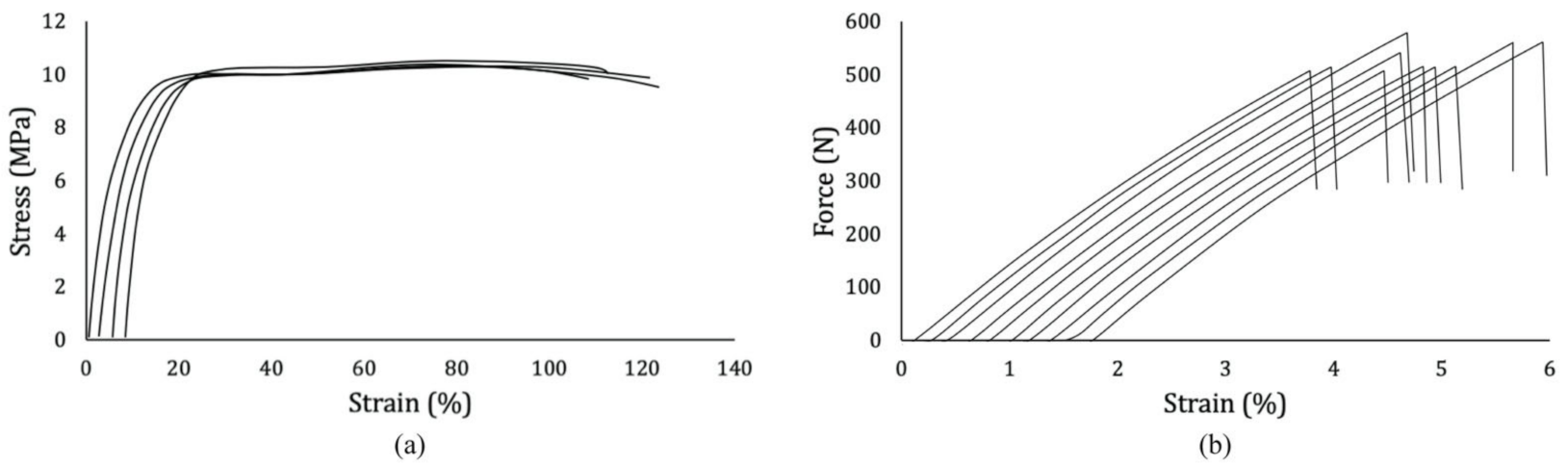

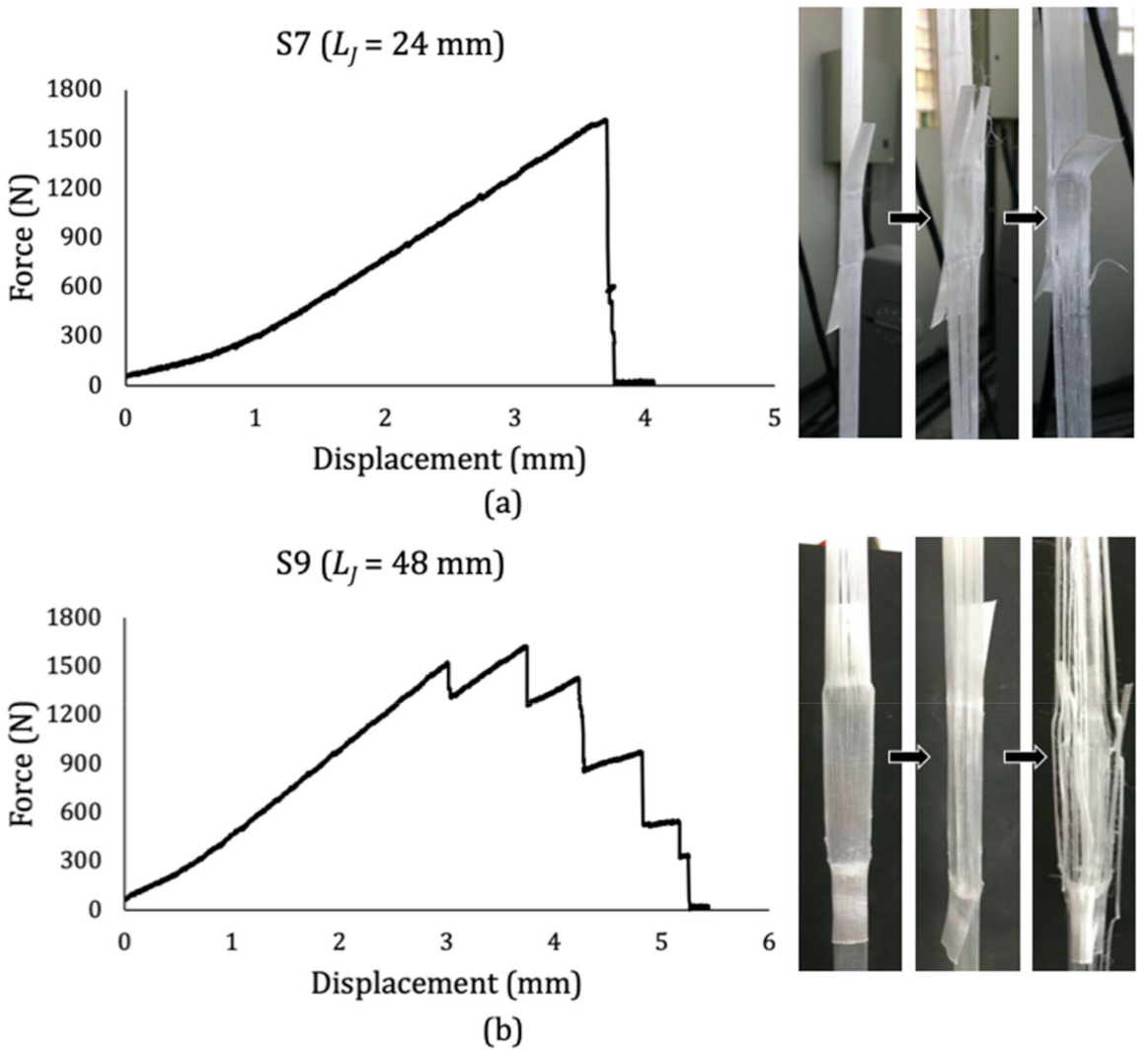

Two main damage progression mechanisms were identified. For shorter joints (

LJ = 12 or 24 mm), linear loadings until failure were more common, where the joint remained mostly flat during the test while longitudinal cracks progressively appeared out of the joint. For longer joints (

LJ = 36, 48 and 60 mm), generally, the load rose to a point in which they became transversally wavy, which increased the local stress on the joint and allowed longitudinal cracks to take place within it. This effect could be explained by thinking of the specimens as a body constituted by three springs in series, where the portions out of the joint have a particular modulus defined by the tensile tests on the tape, and the joint in the middle has different properties, mainly due to twice the number of fibers in it. As the test goes on, the joint tends to deform less than the outer portions, and the stress concentration inferred to it causes this wavy-like deformation and consequent longitudinal cracks. Given the significantly weaker resistance of the material in the transversal axis, it leads to multiple subsequent longitudinal fractures along the length of the specimen, causing the load to drop several times before terminal failure.

Figure 9 illustrates these mechanisms for specimen #7 (S7,

Figure 9a) and specimen #9 (S9,

Figure 9b), with

LJ = 24 mm and 48 mm, respectively.

Naturally, this phenomenon was more pronounced in specimens with longer joints due to their lower ability to longitudinally deform and their enhanced flattening during curing, where a higher amount of resin was displaced to the borders of the tape, leaving a larger central area with impaired transversal stiffness. No joint deflection was noted in the tests, probably because the specimens were quite thin.

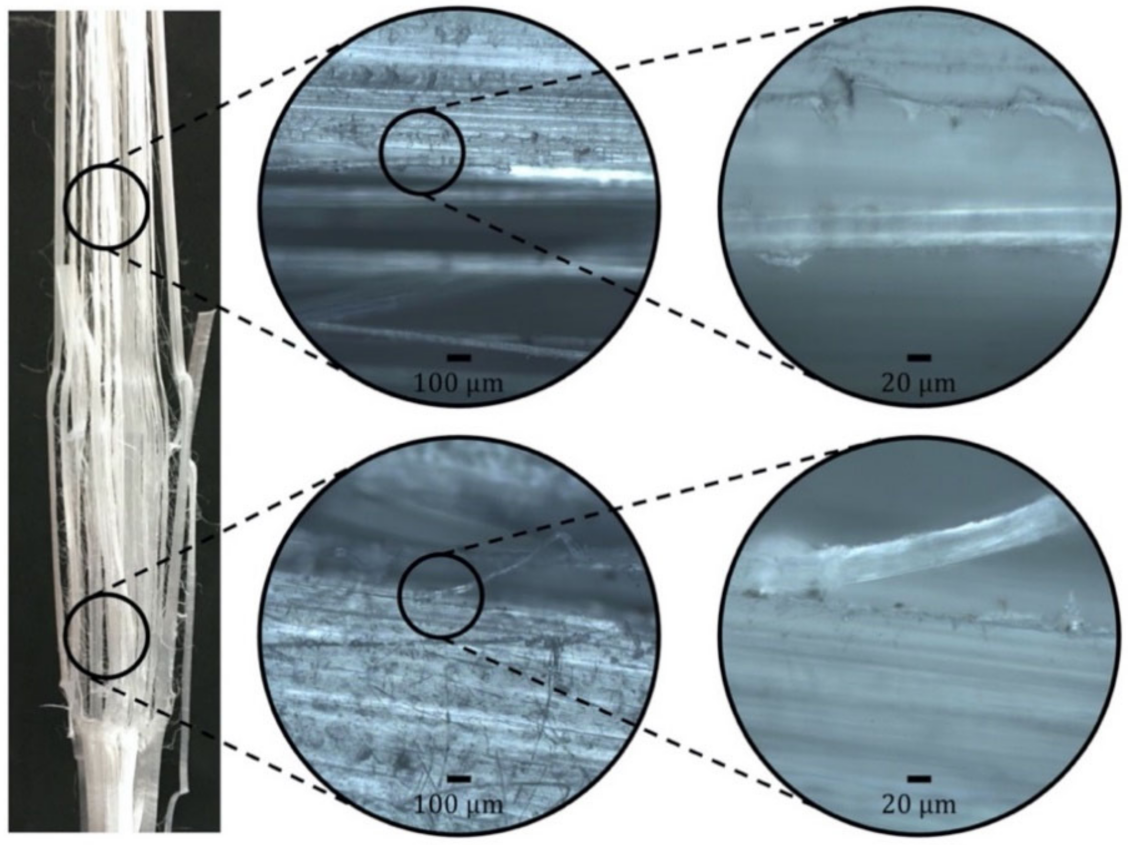

With the aim of further investigating the fracture mechanics of this unidirectional composite, LM images revealed that the longitudinal cracks that preceded joint failure due to shear, which were more present in larger joint lengths due to the higher force levels and consequent enhanced transversal stress, were caused by debonding. As can be seen in

Figure 10, this failure was typical of regions inside and outside the joint, meaning that processing was not a determinant factor. This finding makes sense, as, given the intrinsic low adhesion of UHMWPE, it is only logical that the stress level required to provoke debonding is smaller than that for a cohesive failure. This is understood as a positive feature of the composite, providing visually clear progressive failures before the terminal breakage of the joint rather than a catastrophic failure, which is an important advantage for structural composites by pointing out the eventual need for corrective maintenance.

From the experiment designed, the influence of processing parameters was calculated for average shear stress (τ) as an output variable. This assessment is important to fill the gap on co-cured thermoplastic tapes left by the single-lap shear technical standards, in an effort to identify the optimal processing conditions to generate a specimen that most accurately reproduces the behavior of the material when subjected to such loading and to study the fracture phenomena involved. Secondly, the optimization of shear is interesting for the actual performance of the joint (e.g., for industrial purposes), where load-bearing is the most practical and important feature of the material to be analyzed for potential applications.

Knowing that the maximum shear stress may coincide with the first load drop in the test (

Figure 9a) or with a peak found several load drops after that (

Figure 9b), for conservative purposes, the processing parameters optimization was made for the first failure stresses. This stress might be the actual breaking load or an early debonding-induced failure typical of joints with larger areas, from which the composite structural integrity is already compromised. Moreover, the optimization considering all maximum stresses provided the same optimal curing parameters and same correlation coefficient for the regression equation as that with the first failure stresses. The experimental stress and force results are shown in

Table 7. These stresses were calculated considering the actual joint area (

Table 6) to provide higher accuracy.

A first regression equation of shear was then determined using the OLS method by embracing all possible linear and quadratic combinations of the processing parameters in pairs, with a correlation coefficient of

R2 = 87.43%. However, it was possible to narrow down the influence of these parameters on shear stress by selecting only the interactions among them with

p-values lower than 5%, namely,

LJ,

T2,

P·

t,

T·

LJ, and

t·

LJ, thereby generating Equation (4), where τ is the shear stress (MPa),

P is the pressure (bar),

T is the temperature (°C),

t is the time (s), and

LJ is the joint length (mm). Even though the new correlation coefficient became 81.99%, narrowing down the regression model to its significant terms is the advised approach to make the model simpler but reliable [

67].

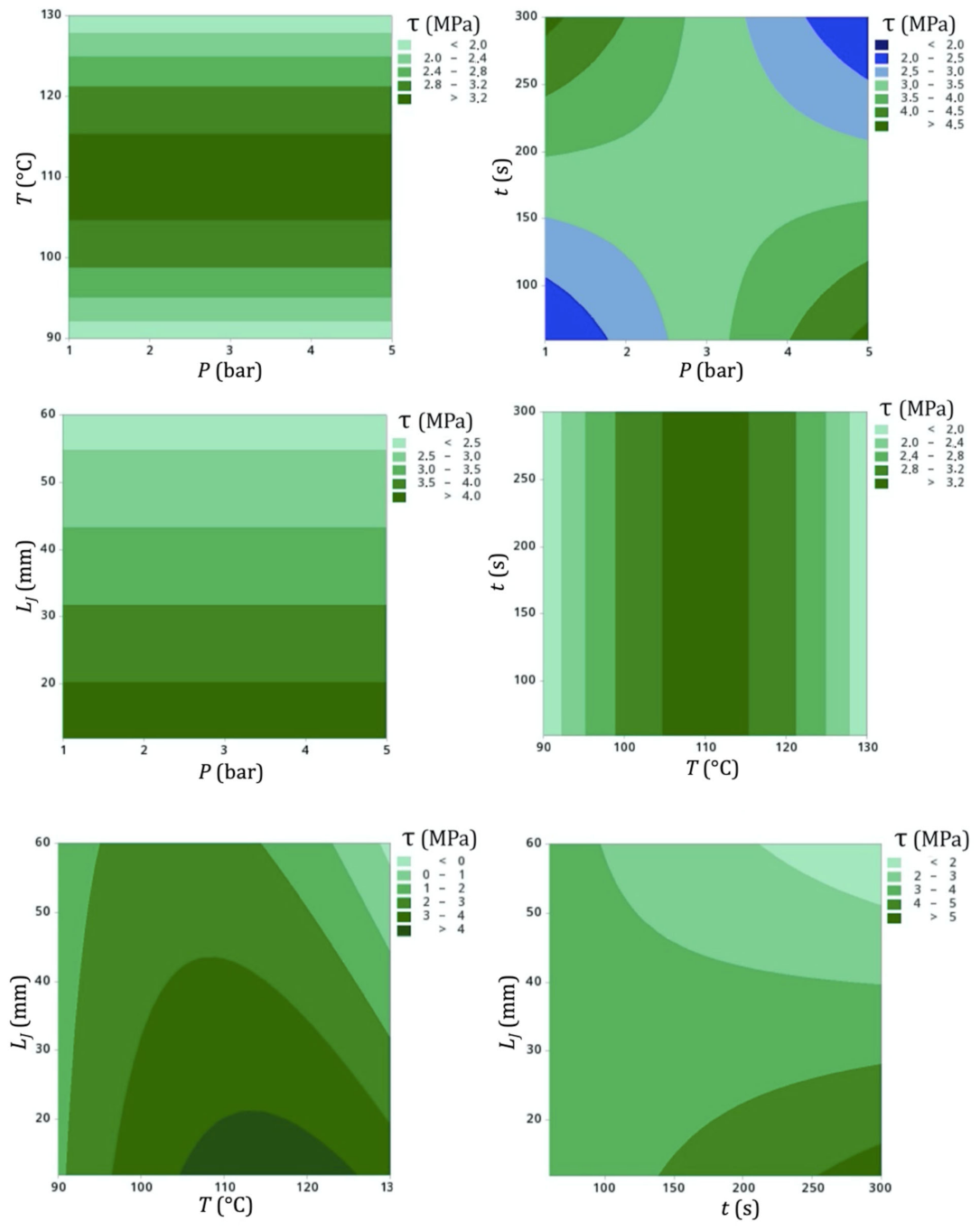

Figure 11 shows the contour plots of the model.

Upon analyzing the influence of processing parameters in pairs, it is interesting to highlight the major relevance of temperature with respect to other variables. When confronted with pressure and time, these parameters became practically indifferent for the outcome stress, an effect which was noticeably higher when the temperature was closer to 110 °C and lower when it drifted toward 90 °C or 130 °C. The key role of temperature in defining the final stress strength can be seen in Equation (4), where it is squared and linked to a relatively high 0.4 constant.

When pressure and time were compared, it was found that an average stress of 3.0 to 3.5 MPa could be achieved in most combinations, but it could be maximized if high pressures (4 to 5 bar) were applied for a time small enough to not allow the joint to suffer from exaggerated flattening (under 100 s) or if the cure adopted a low pressure (under 2 bar) for a time high enough for a successful bond between the adherend tapes.

The increase in joint length was linked to a decrease in shear stress in all related contour plots. Considering the Hookean perspective in Equation (1), this means that, although the force increased with higher joint areas (

Table 7), this increase was not proportional. In other words, a constant increase in joint length led to a progressively smaller increase in force, resulting in decreasing stresses. This aspect can be explained by the fact that the stress concentration and structural imperfections inherent of the joint (such as the higher amount of material pushed outward the longitudinal centerline, with spread and less aligned fibers) became more prominent with larger joint areas, thus decreasing the stress despite increasing the force. The

LJ parameter takes into account all of these structural flaws and represents them quantitatively in the DoE. Hence, values of

LJ approximately equal or smaller than two times the adherend width were ideal for yielding higher shear stresses (which may be an interesting basis for the design of a proper technical standard test in the future). The aforementioned inversely proportional relationship for force and stress was also observed for joints on carbon-reinforced composites co-cured with steel [

81].

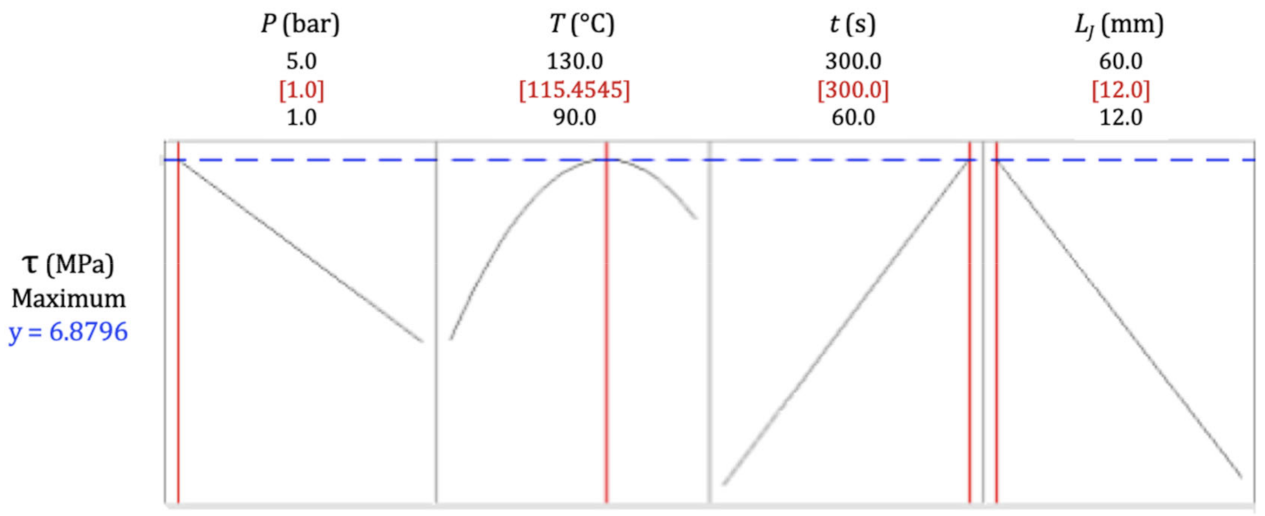

Taking the regression equation into account (Equation (4)), a multiple response prediction approach was used to optimize all combinations of input variables in order to estimate the maximum possible shear stress in an ideal case (represented by a composite desirability of 1.0) [

67]. As shown in

Figure 12, it is estimated that a shear force of 6.88 MPa could be achieved with a 12 mm long joint cured at 1 bar, 115.45 °C, and 300 s. More precisely, the optimal shear presented an averaged value of 6.88 ± 0.58 MPa within a fairly narrow 95% confidence interval between 5.68 and 8.08 MPa. This value is considered to be approximate to the ultimate tensile strength of the matrix alone (

Table 3). Hence, knowing that the single-lap shear strength is mostly dependent on the matrix, this result can be seen as adequate.

Beyond the phenomenological aspect of this study, it is important to adopt these ultimate resistance values with caution when designing a structural application for the composite; not only may its resistance vary within the aforementioned statistical confidence interval, but applications involving constant loading may also infer an enhanced degradation to UHMWPE, which is known to degrade faster under creep.

The input values revealed by this optimization were very meaningful, evidencing that an ideal joint must be cured right after the endothermic transformation of LDPE, as seen in the DSC analysis (

Figure 2), which took place between the T

m of the polymer and 115 °C, suggesting that the material was melted in its entirely. In other words, this temperature was the exact value to simultaneously provide the full melting of the matrix and cause less possible damage to the reinforcement, and it had to be applied for a time long enough to make sure the bond was well achieved, under a pressure sufficiently small to avoid excessive joint deformation and fiber misalignment.

An optimal lap joint processing at 115 °C was previously reported in the literature when co-curing PE with aluminum [

56], where time was also reported to have a low influence on the resulting strength of the joint. A low effect of pressure in manufacturing thermoplastic UHMWPE-reinforced composites was reported by Hazzard et al. [

87], who stated that higher pressures lead only to a small increase in shear strength and to a negligible effect on the laminate stiffness. It is important to underline that a low effect of pressure was present in the current study of thin PE SRCs, whereas it may be important when co-curing PP [

30] or when joining PE to aluminum [

56].

It is interesting to note that the shear resistance found both in the DoE optimization and in some of the unoptimized experiments carried out was superior even to the single-lap shear strength of UHMWPE/UHMWPE SRCs [

88], which varied from 1.1 to 3.8 MPa depending on the processing parameters, demonstrating the extremely high performance of the reprocessed matrix SRC studied herein.