Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations

Abstract

1. Introduction

2. Materials and Methods

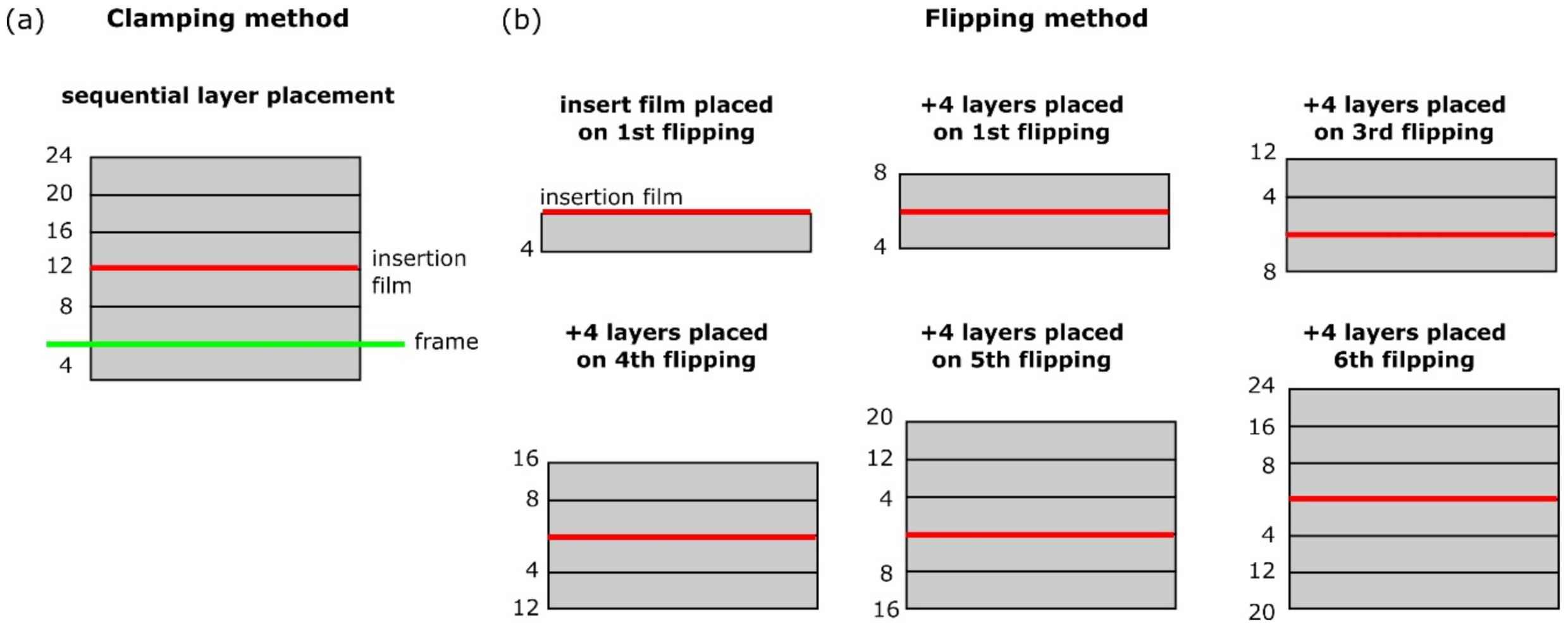

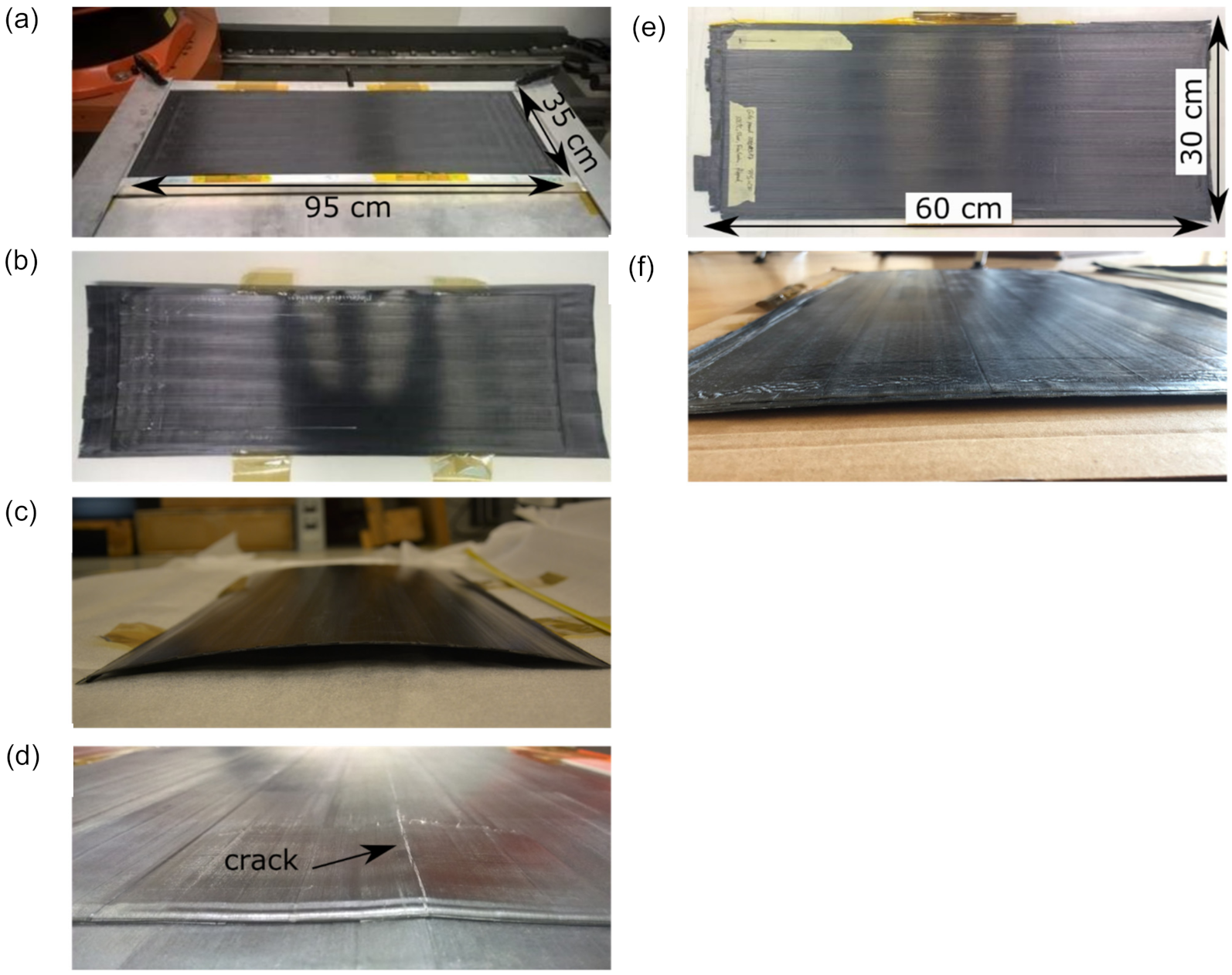

2.1. Materials and Laminate Manufacturing

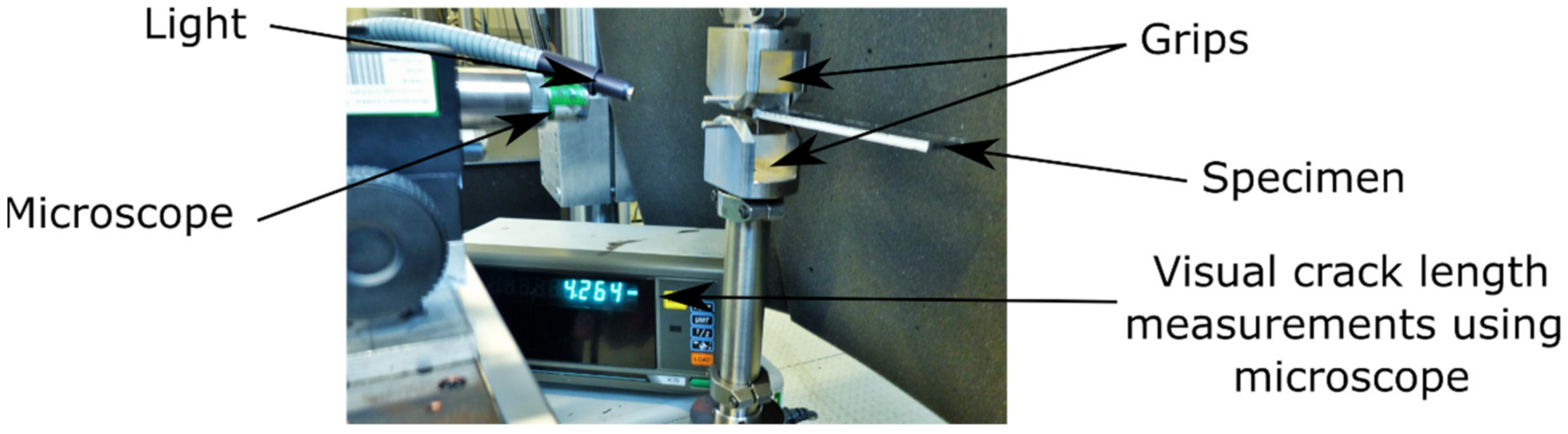

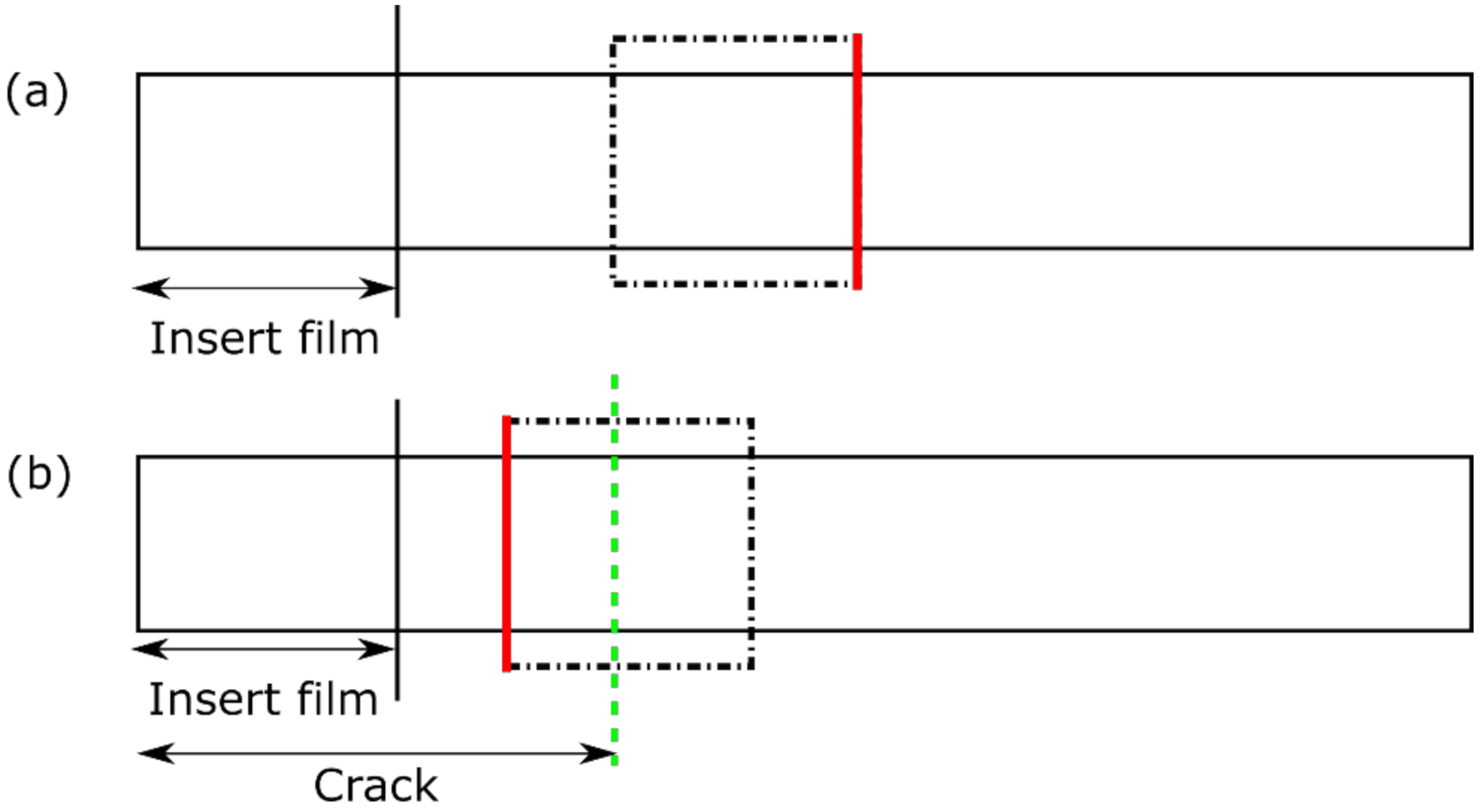

2.2. Fatigue Mode I DCB Testing

2.3. Three-Point Bending

2.4. Optical Analysis

2.5. Data Analysis Techniques

2.5.1. The Paris Relation and the Modified Hartman-Schijve Equation

2.5.2. Calculations of

2.5.3. Damage Parameter

3. Results and Discussion

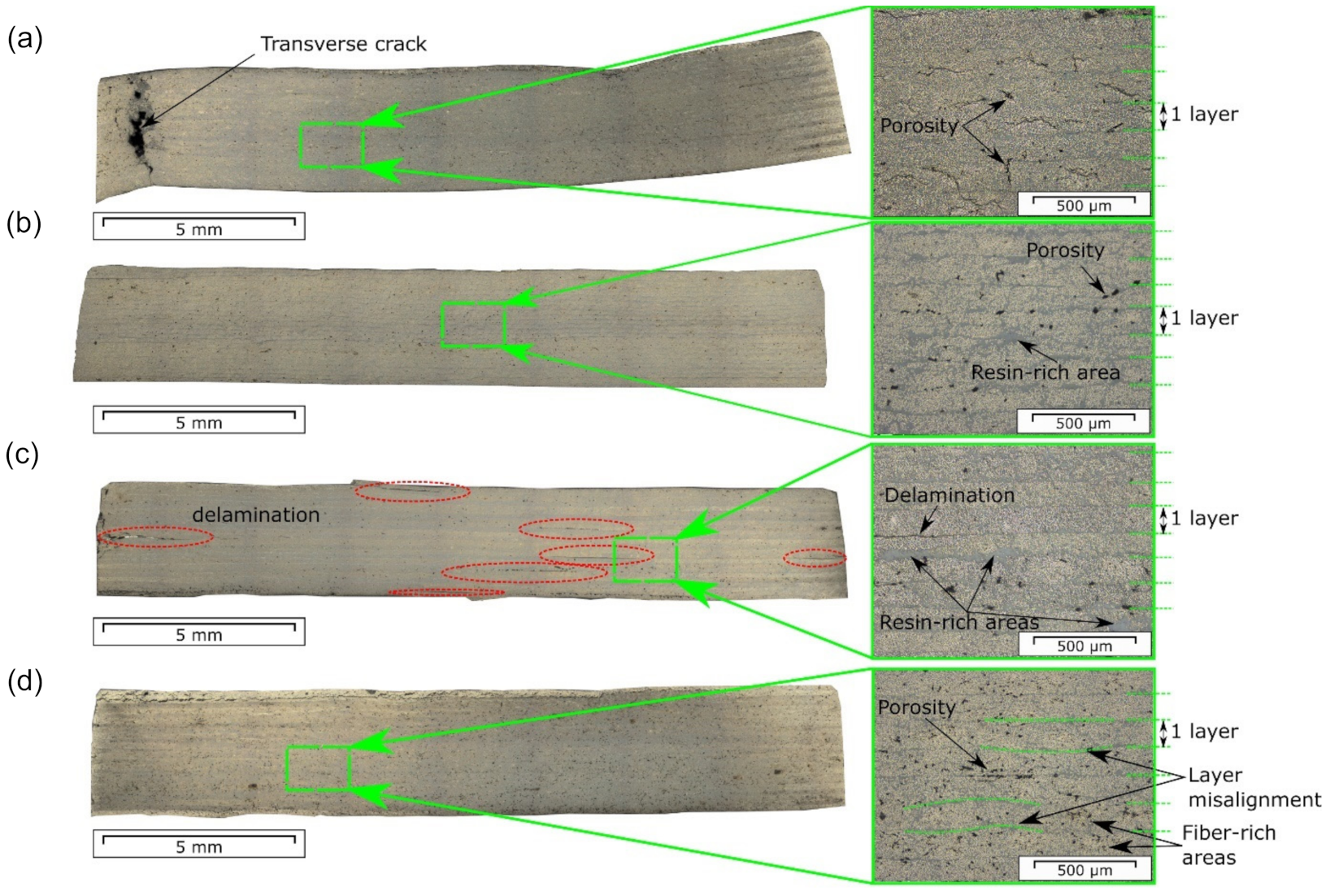

3.1. Laminates After Manufacturing

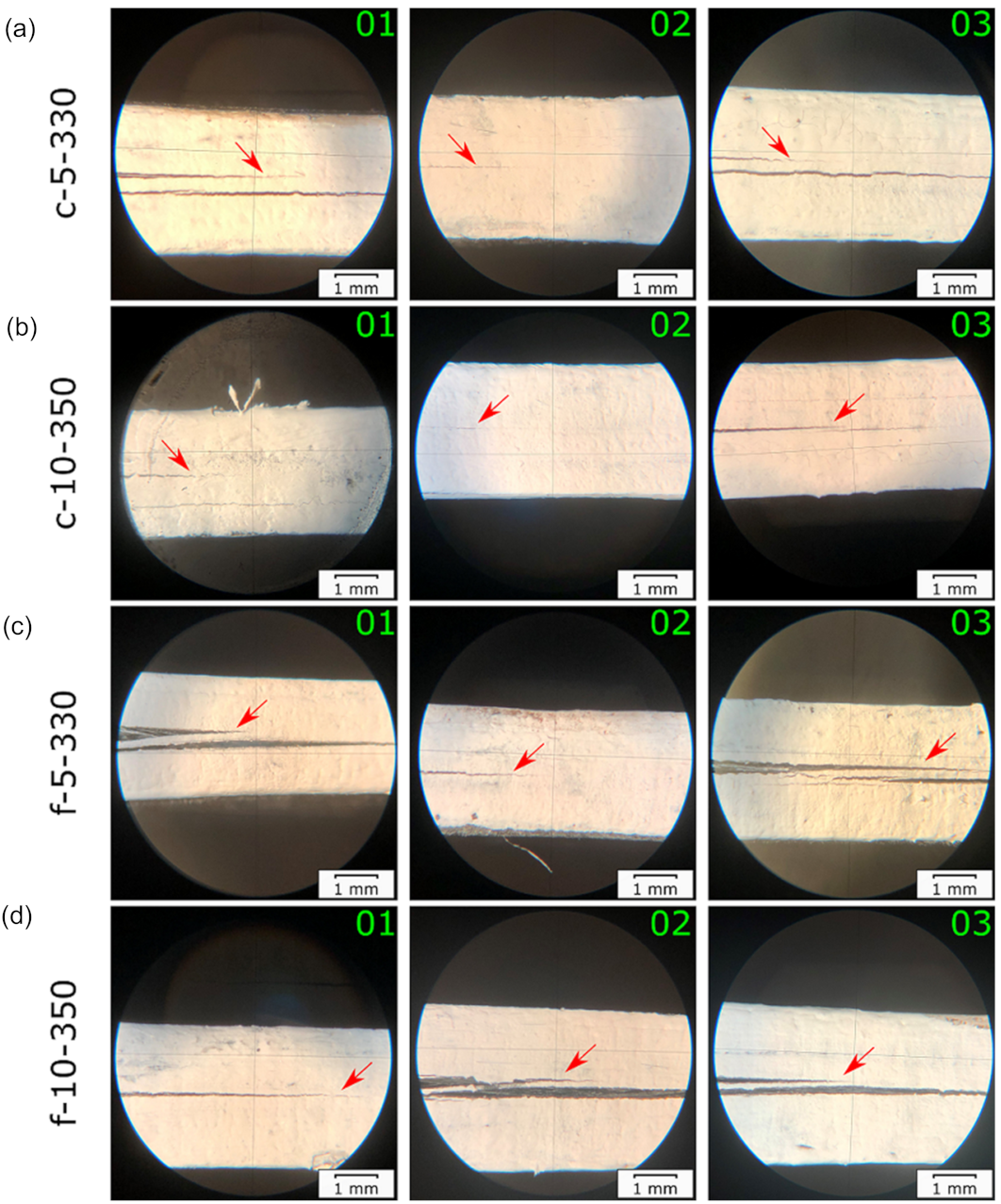

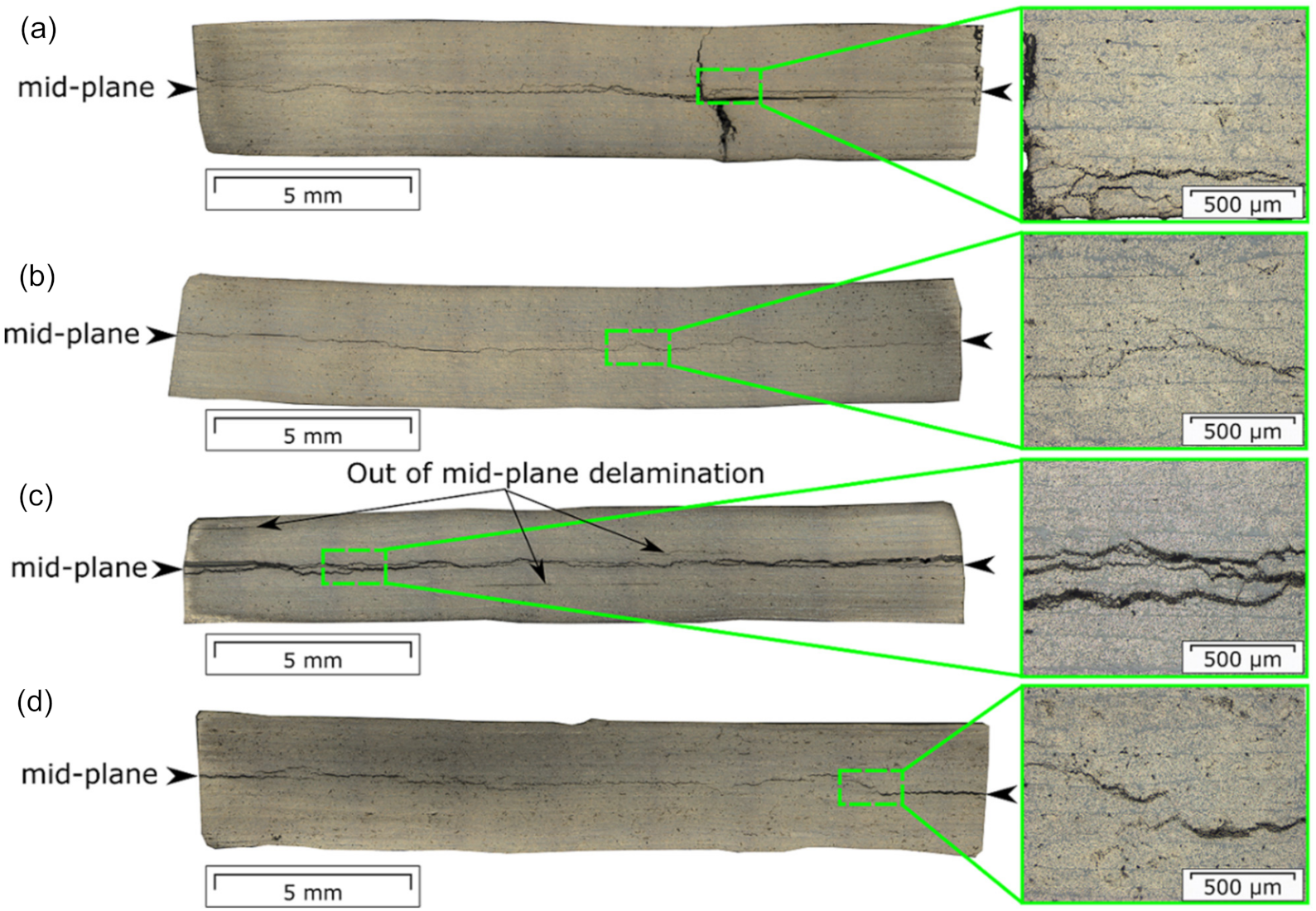

3.2. Damage Processes during Fatigue Testing

3.3. Three-Point Bending Tests

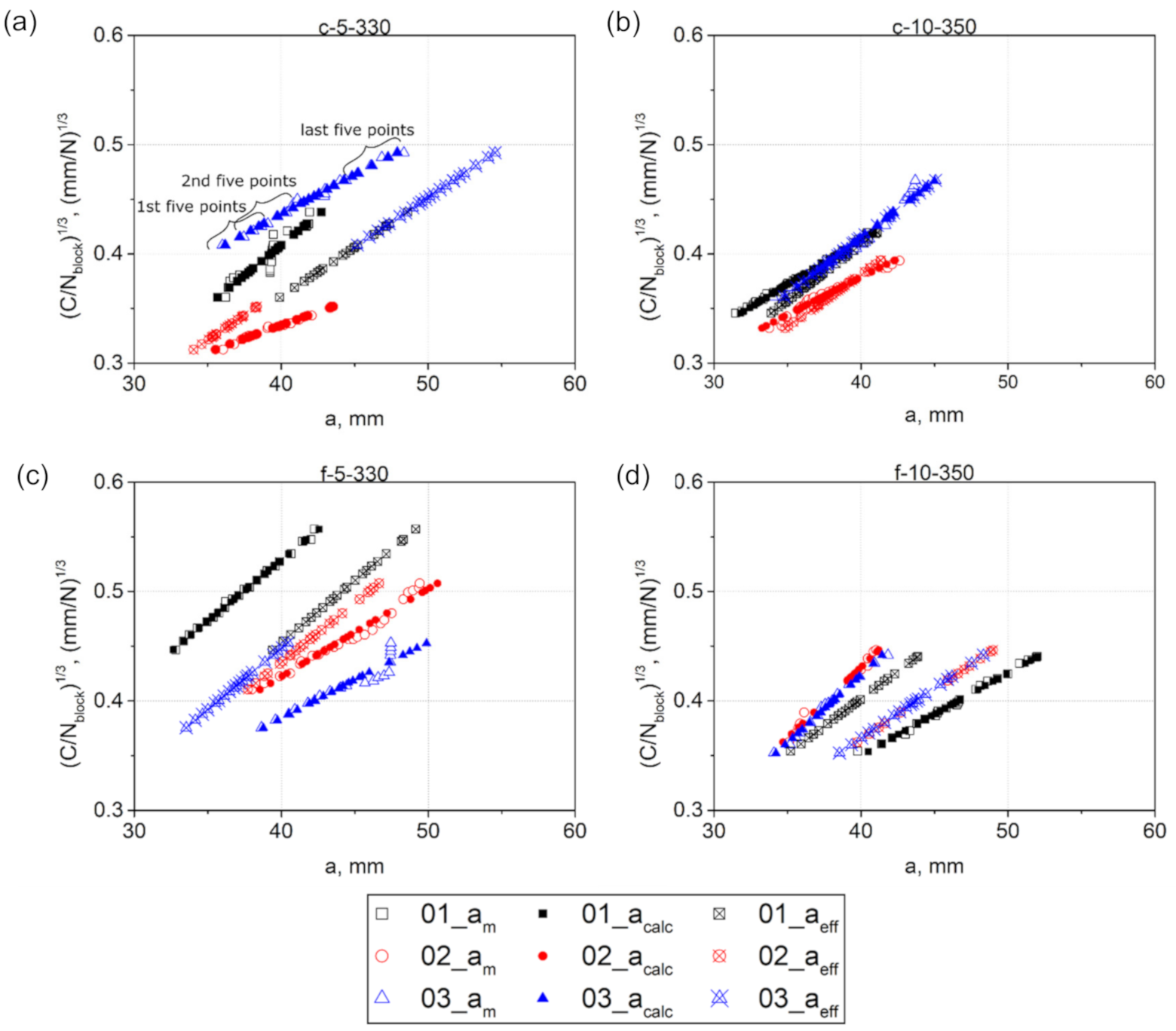

3.4. Crack Length Correction Factor and Effective Flexural Modulus

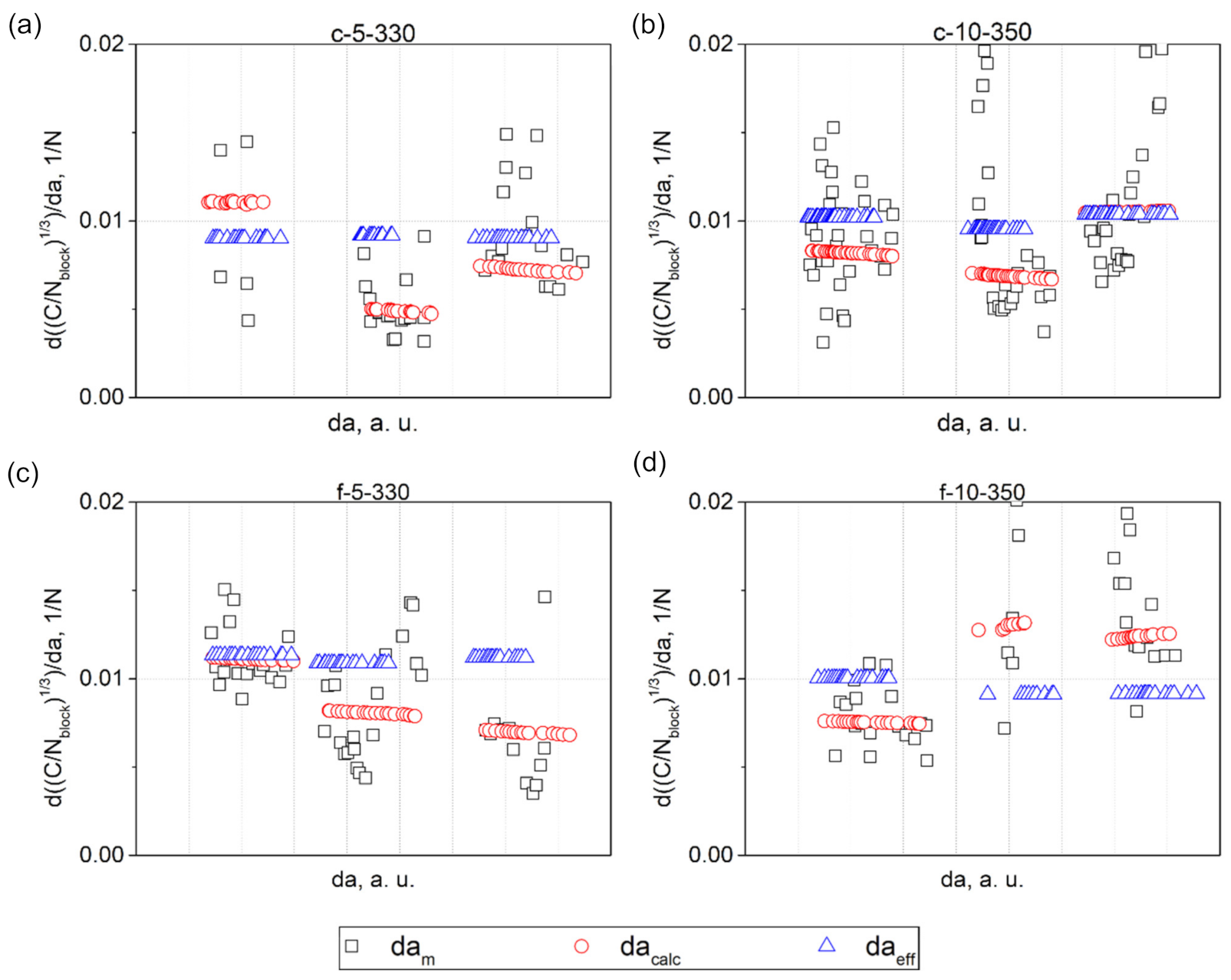

3.5. Damage Parameter

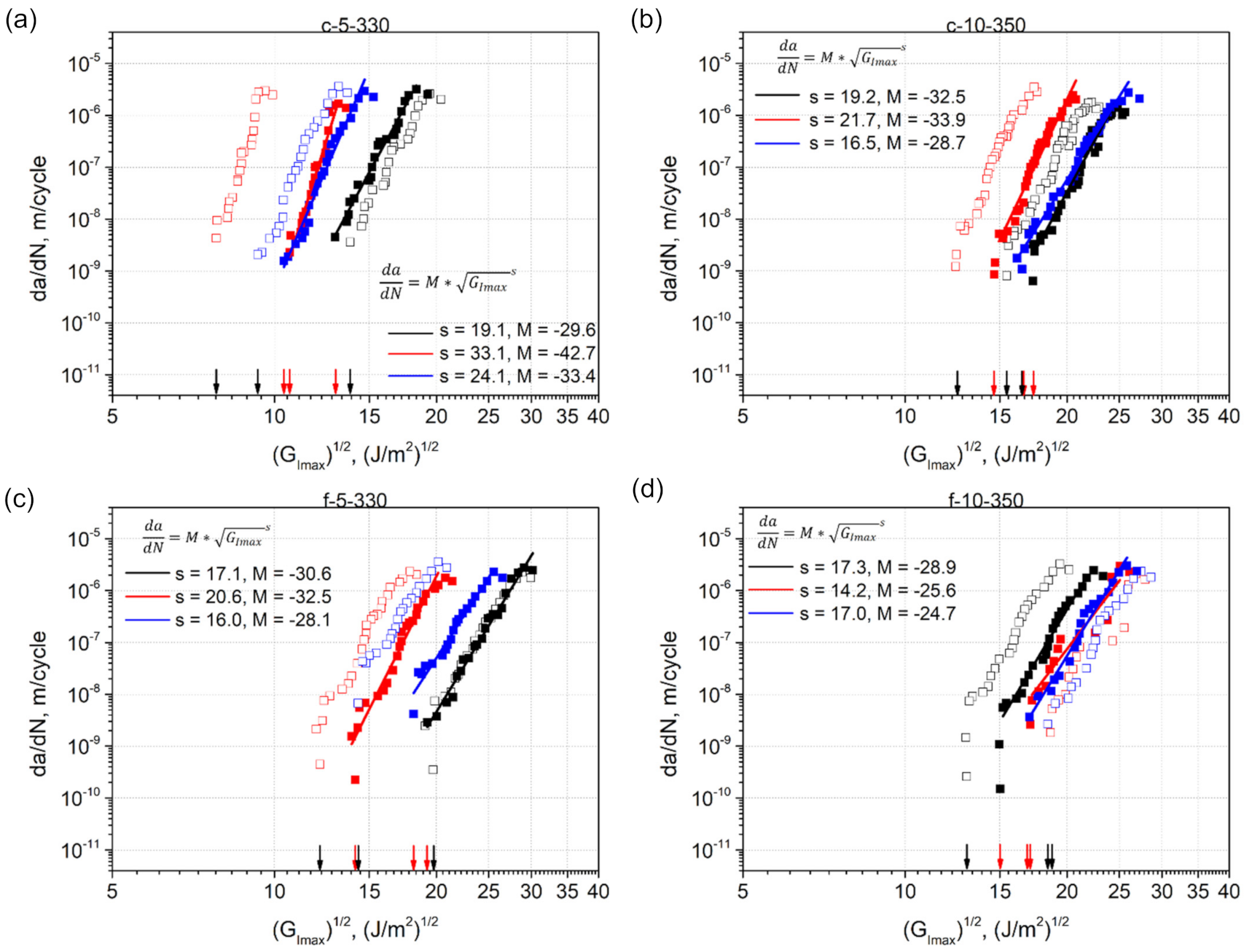

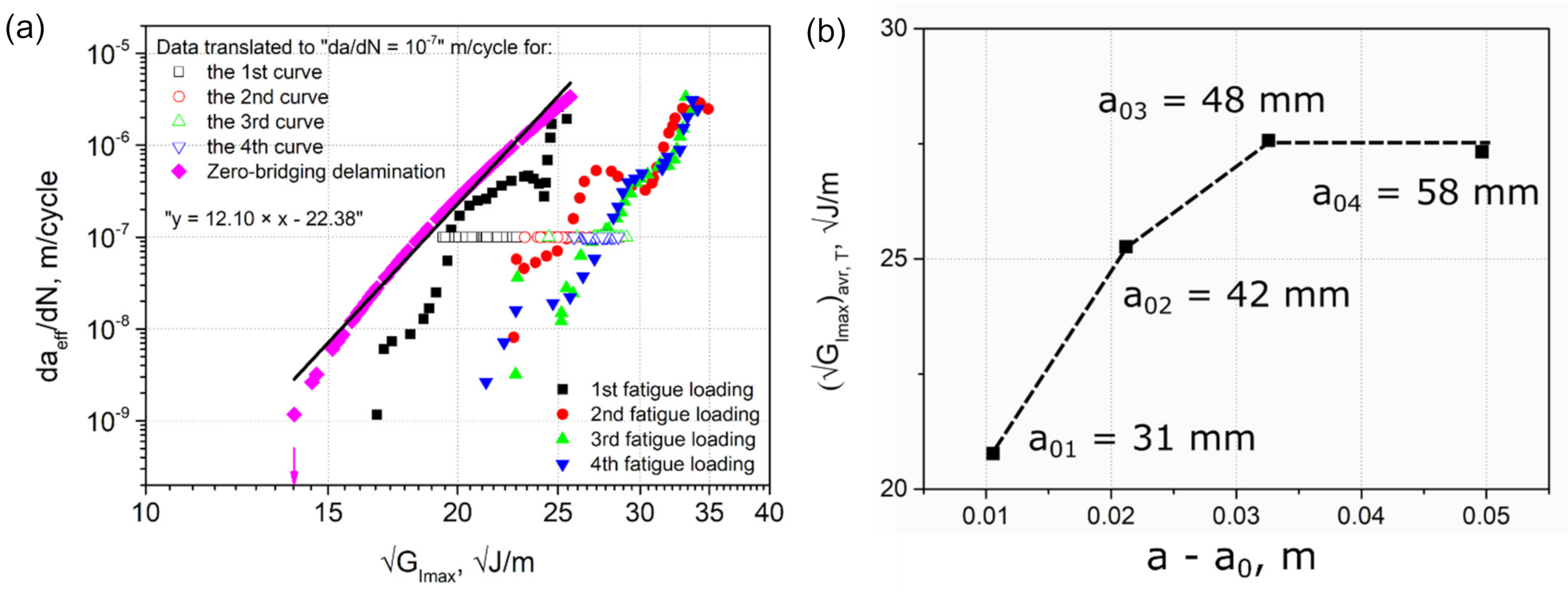

3.6. Fatigue Crack Resistance Curves: The Paris Relation Based Approach

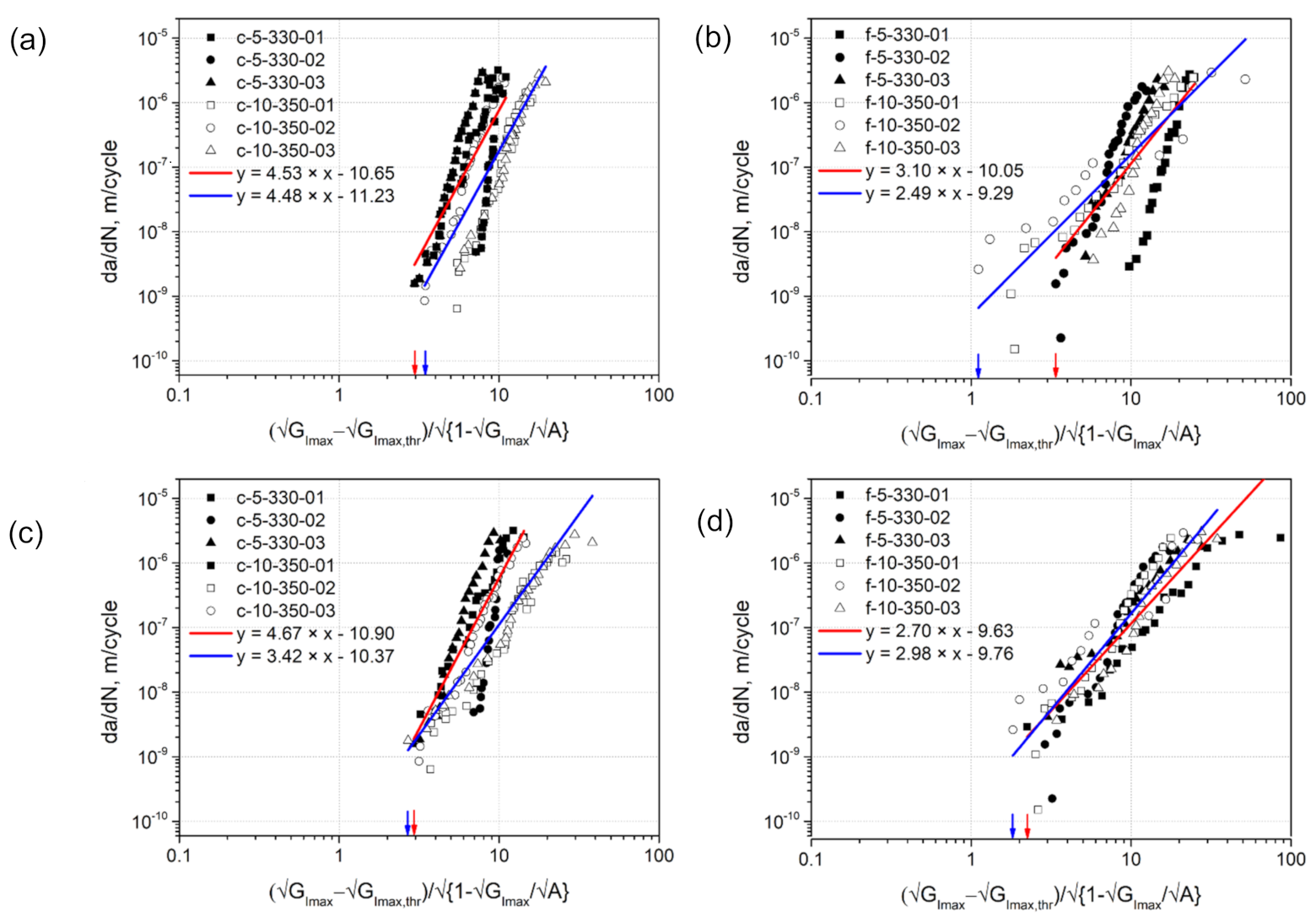

3.7. Fatigue Crack Resistance Curves: The Hartman-Schijve (H-S) Based Approach

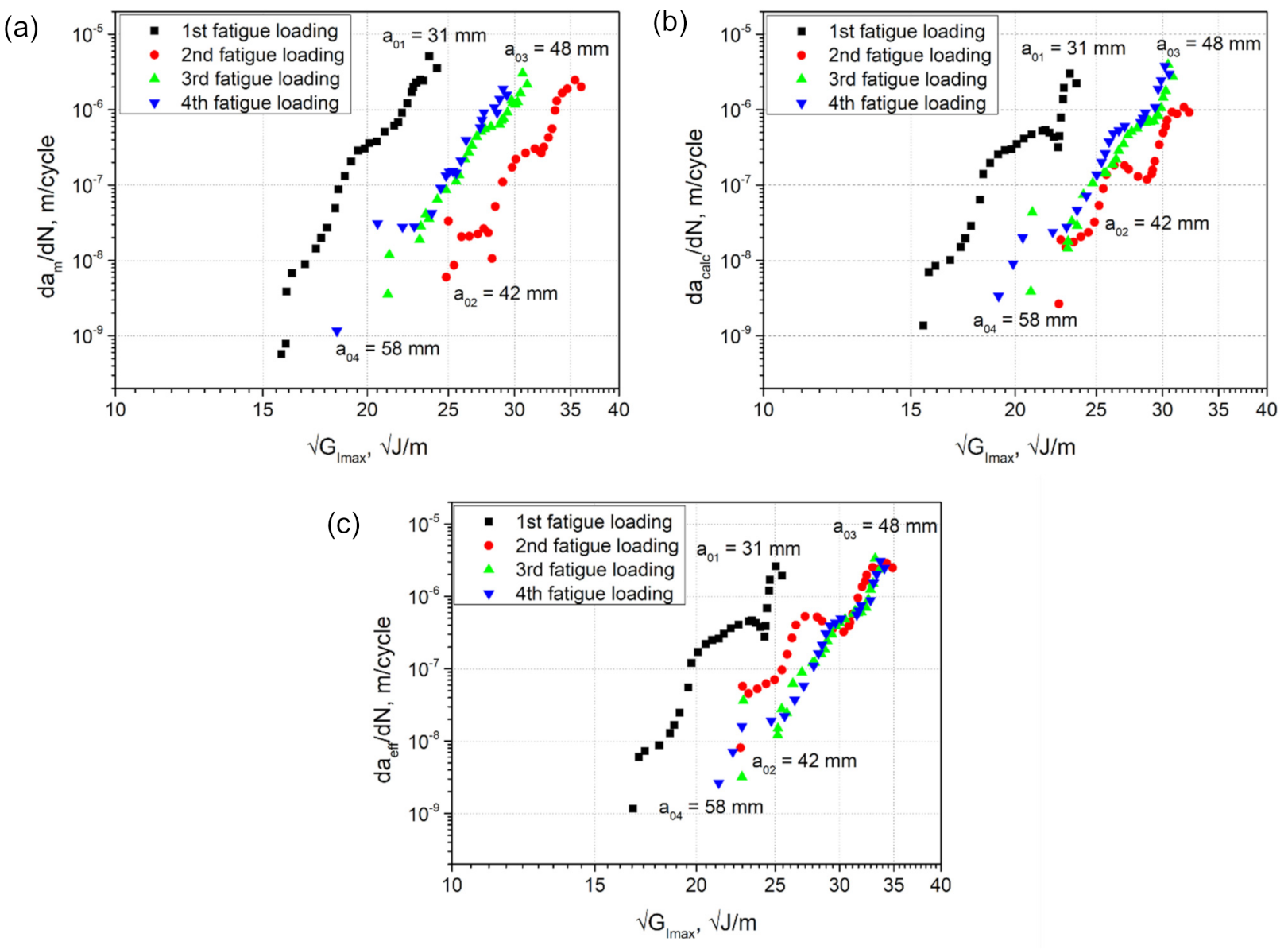

3.8. Zero-Fiber Bridging Approach

4. Summary, Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abrate, S.; Walton, D. Machining of composite materials. Part I: Traditional methods. Compos. Manuf. 1992, 3, 75–83. [Google Scholar] [CrossRef]

- Liao, K.; Schultheisz, C.R.; Hunston, D.L.; Brinson, L.C. Long-term durability of fiber-reinforced polymer-matrix composite materials for infrastructure applications: A review. J. Adv. Mater. Covina 1998, 3–40. [Google Scholar]

- Offringa, A.R. Thermoplastic composites—rapid processing applications. Compos. Part A Appl. Sci. Manuf. 1996, 27, 329–336. [Google Scholar] [CrossRef]

- Costa, A.P.; Botelho, E.C.; Costa, M.L.; Narita, N.E.; Tarpani, J.R. A review of welding technologies for thermoplastic com-posites in aerospace applications. J. Aerosp. Technol. Manag. 2012, 4, 255–265. [Google Scholar] [CrossRef]

- Campbell, F. Structural Composite Materials; ASM International: Materials Park, OH, USA, 2010. [Google Scholar]

- Grouve, W.; Warnet, L.; Rietman, B.; Visser, H.; Akkerman, R. Optimization of the tape placement process parameters for carbon–PPS composites. Compos. Part A: Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Ray, D.; Comer, A.J.; Lyons, J.G.; Obande, W.; Jones, D.J.; Higgins, R.M.O.; McCarthy, M.A. Fracture toughness of carbon fiber/polyether ether ketone composites manufactured by autoclave and laser-assisted automated tape placement. J. Appl. Polym. Sci. 2014, 132, 132. [Google Scholar] [CrossRef]

- Modi, D.; Comer, A.; O’Higgins, R.M.O.; McCarthy, M.A. Thermoplastic composites: In-situ consolidation or in-situ welding. In Proceedings of the 19th International Conference on Composite Materials (ICCM 19), Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Qureshi, Z.; Swait, T.; Scaife, R.J.; El-Dessouky, H. In situ consolidation of thermoplastic prepreg tape using automated tape placement technology: Potential and possibilities. Compos. Part B Eng. 2014, 66, 255–267. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Clancy, G.J.; Peeters, D.; O’Higgins, R.; Weaver, P.M. Interface Characterization of Thermoplastic Skin-Stiffener Composite Manufactured using Laser-Assisted Tape Placement. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018; p. 481. [Google Scholar]

- Sacchetti, F.; Grouve, W.J.; Warnet, L.L.; Villegas, I.F. Effect of cooling rate on the interlaminar fracture toughness of unidirectional Carbon/PPS laminates. Eng. Fract. Mech. 2018, 203, 126–136. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Gamstedt, E.K.; Østergaard, R.C.; Goutianos, S. Micromechanical model of cross-over fibre bridging – Prediction of mixed mode bridging laws. Mech. Mater. 2008, 40, 220–234. [Google Scholar] [CrossRef]

- Yao, L.; Alderliesten, R.; Benedictus, R. The effect of fibre bridging on the Paris relation for mode I fatigue delamination growth in composites. Compos. Struct. 2016, 140, 125–135. [Google Scholar] [CrossRef]

- Goutianos, S.; Sørensen, B.F. Fracture resistance enhancement of layered structures by multiple cracks. Eng. Fract. Mech. 2016, 151, 92–108. [Google Scholar] [CrossRef]

- Pascoe, J.; Rans, C.; Benedictus, R. Characterizing fatigue delamination growth behaviour using specimens with multiple delaminations: The effect of unequal delamination lengths. Eng. Fract. Mech. 2013, 109, 150–160. [Google Scholar] [CrossRef]

- Funari, M.F.; Lonetti, P. Initiation and evolution of debonding phenomena in layered structures. Theor. Appl. Fract. Mech. 2017, 92, 133–145. [Google Scholar] [CrossRef]

- Alfano, G.; Crisfield, M.A. Finite element interface models for the delamination analysis of laminated composites: mechanical and computational issues. Int. J. Numer. Methods Eng. 2001, 50, 1701–1736. [Google Scholar] [CrossRef]

- Mulian, G.; Rabinovitch, O. Debonding dynamics in FRP plated beams: high order cohesive FE formulation and parametric sensitivity. Int. J. Fract. 2015, 195, 53–78. [Google Scholar] [CrossRef]

- Brunner, A.; Blackman, B.; Williams, J. Calculating a damage parameter and bridging stress from GIC delamination tests on fibre composites. Compos. Sci. Technol. 2006, 66, 785–795. [Google Scholar] [CrossRef]

- Jones, R.; Pitt, S.; Bunner, A.; Hui, D. Application of the Hartman–Schijve equation to represent Mode I and Mode II fatigue delamination growth in composites. Compos. Struct. 2012, 94, 1343–1351. [Google Scholar] [CrossRef]

- Alderliesten, R. Fatigue delamination of composite materials—Approach to exclude large scale fibre bridging. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 13–14 August 2018; Volume 388, p. 012002. [Google Scholar] [CrossRef]

- Brunner, A.J.; Stelzer, S.; Pinter, G. Determination of Mode I Fatigue Delamination Propagation in Unidirectionally Reinforced Materials (Version 2, 2009): Test Protocol by ESIS Technical Committee 4 on Fracture of Polymers; Composites and Adhesives; Mon-tanuniversitaet Leoben: Leoben, Austria, 2009; pp. 1–14. [Google Scholar]

- Stelzer, S.; Pinter, G.; Wolfahrt, M.; Brunner, A.J.; Noistnernig, J. Cyclic Interlaminar Crack Growth in Unidirectional and Braided Composites. In Proceedings of the 5th International Conference on Fatigue of Composites, Beijing, China, 27–29 September 2010. [Google Scholar]

- Stelzer, S.; Pinter, G.; Brunner, A.J. Comparison of Quasi-static and Cyclic Fatigue Delamination Resistance of Carbon Fiber Reinforced Polymer-matrix Laminates under Different Mode Loading. Procedia Mater. Sci. 2014, 3, 1087–1092. [Google Scholar] [CrossRef]

- ASTM, International. ASTM D790 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Jones, R.; Hu, W.; Kinloch, A.J. A convenient way to represent fatigue crack growth in structural adhesives. Fatigue Fract. Eng. Mater. Struct. 2014, 38, 379–391. [Google Scholar] [CrossRef]

- Yao, L.; Alderliesten, R.; Jones, R.; Kinloch, A. Delamination fatigue growth in polymer-matrix fibre composites: A methodology for determining the design and lifing allowables. Compos. Struct. 2018, 196, 8–20. [Google Scholar] [CrossRef]

- ASTM E 647. Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Mujtaba, A.; Stelzer, S.; Brunner, A.; Jones, R. Influence of cyclic stress intensity threshold on the scatter seen in cyclic Mode I fatigue delamination growth in DCB tests. Compos. Struct. 2017, 169, 138–143. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.; Hu, W. Cyclic-fatigue crack growth in composite and adhesively-bonded structures: The FAA slow crack growth approach to certification and the problem of similitude. Int. J. Fatigue 2016, 88, 10–18. [Google Scholar] [CrossRef]

- Yao, L.; Sun, Y.; Guo, L.; Lyu, X.; Zhao, M.; Jia, L.; Alderliesten, R.; Benedictus, R. Mode I fatigue delamination growth with fibre bridging in multidirectional composite laminates. Eng. Fract. Mech. 2018, 189, 221–231. [Google Scholar] [CrossRef]

- Brunner, A.; Stelzer, S.; Pinter, G.; Terrasi, G. Cyclic fatigue delamination of carbon fiber-reinforced polymer-matrix composites: Data analysis and design considerations. Int. J. Fatigue 2016, 83, 293–299. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.; Michopoulos, J.; Brunner, A.; Phan, N. Delamination growth in polymer-matrix fibre composites and the use of fracture mechanics data for material characterisation and life prediction. Compos. Struct. 2017, 180, 316–333. [Google Scholar] [CrossRef]

- Brunner, A.J.; Stelzer, S.; Mujtaba, A.; Jones, R. Examining the application of the Hartman-Schijve equation to the analysis of cyclic fatigue fracture of polymer-matrix composites. Theor. Appl. Fract. Mech. 2017, 92, 420–425. [Google Scholar] [CrossRef]

- Brunner, A.J.; Mujtaba, A.; Stelzer, S.; Jones, R. Modified Hartman-Schijve fitting of mode I delamination fatigue data and the resulting variation in threshold values Gthr. Procedia Struct. Integr. 2016, 2, 88–95. [Google Scholar] [CrossRef][Green Version]

- Fibre-Reinforced Plastic Composites: Determination of Mode I Interlaminar Fracture Toughness, GIC, for Unidirection-ally Reinforced Materials; ISO 15024: 2001; International Organization for Standardization: Geneva, Switzerland, 2001.

- Brunner, A.; Murphy, N.; Pinter, G. Development of a standardized procedure for the characterization of interlaminar delamination propagation in advanced composites under fatigue mode I loading conditions. Eng. Fract. Mech. 2009, 76, 2678–2689. [Google Scholar] [CrossRef]

- De Morais, A.; Pereira, A. Application of the effective crack method to mode I and mode II interlaminar fracture of carbon/epoxy unidirectional laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 785–794. [Google Scholar] [CrossRef]

- Brunner, A.; Blackman, B.; Williams, J. Deducing Bridging Stresses and Damage from GIC Tests on Fibre Composites. In European Structural Integrity Society; Elsevier: Amsterdam, The Netherlands, 2003; Volume 32, pp. 479–490. [Google Scholar]

- Younes, R.; Hallal, A.; Fardoun, F.; Hajj, F. Comparative Review Study on Elastic Properties Modeling for Unidirectional Composite Materials. Compos. Prop. 2012, 17, 391–408. [Google Scholar] [CrossRef]

- Barnes, J.; Byerly, G. The formation of residual stresses in laminated thermoplastic composites. Compos. Sci. Technol. 1994, 51, 479–494. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T.; Akbulut, M. Analysis of Process-Induced Residual Stresses in Tape Placement. J. Thermoplast. Compos. Mater. 2002, 15, 525–544. [Google Scholar] [CrossRef]

- Tafreshi, O.A.; Van Hoa, S.; Shadmehri, F.; Hoang, D.M.; Rosca, D. Heat transfer analysis of automated fiber placement of thermoplastic composites using a hot gas torch. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 206–223. [Google Scholar] [CrossRef]

- Kollmannsberger, A.; Lichtinger, R.; Hohenester, F.; Ebel, C.; Drechsler, K. Numerical analysis of the temperature profile during the laser-assisted automated fiber placement of CFRP tapes with thermoplastic matrix. J. Thermoplast. Compos. Mater. 2018, 31, 1563–1586. [Google Scholar] [CrossRef]

- Sisodia, S.; Gamstedt, E.K.; Edgren, F.; Varna, J. Effects of voids on quasi-static and tension fatigue behaviour of carbon-fibre composite laminates. J. Compos. Mater. 2014, 49, 2137–2148. [Google Scholar] [CrossRef]

- Joosten, M.W.; Agius, S.; Hilditch, T.; Wang, C. Effect of residual stress on the matrix fatigue cracking of rapidly cured epoxy/anhydride composites. Compos. Part A Appl. Sci. Manuf. 2017, 101, 521–528. [Google Scholar] [CrossRef]

- Brunner, A.J.; Hack, E.; Neuenschwander, J. Nondestructive Testing of Polymers and Polymer–Matrix Composites. Encycl. Polym. Sci. Technol. 2015, 1–39. [Google Scholar] [CrossRef]

- Brunner, A.J. Fracture mechanics test standards for fiber-reinforced polymer composites: Suggestions for adapting them to Industry 4.0 and the digital age. Procedia Struct. Integr. 2020, 28, 546–554. [Google Scholar] [CrossRef]

- Alderliesten, R.; Brunner, A.; Pascoe, J. Cyclic fatigue fracture of composites: What has testing revealed about the physics of the processes so far? Eng. Fract. Mech. 2018, 203, 186–196. [Google Scholar] [CrossRef]

- Khudiakova, A. Investigation of Mechanical Anisotropy and Interlayer Bonding in Thermoplastic Composites Produced by Additive Manufacturing. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, 2021. [Google Scholar]

| Specimen ID | Manufacturing Method | Number of Plies | Placement Speed, m/min | Process Temperature, °C |

|---|---|---|---|---|

| c-5-330 | clamping | 24 | 5 | 330 |

| c-10-350 | clamping | 24 | 10 | 350 |

| f-5-330 | flipping | 24 | 5 | 330 |

| f-10-350 | flipping | 24 | 10 | 350 |

| Laminate | Pristine Specimens | After Fatigue Mode I DCB Testing |

|---|---|---|

| c-5-330 | 111 ± 6 (6%) | 109 ± 4 (3%) |

| c-10-350 | 96 ± 4 (4%) | 109 ± 20 (18%) |

| f-5-330 | 104 ± 3 (3%) | 90 ± 8 (9%) |

| f-10-350 | 112 ± 8 (7%) | 100 ± 18 (18%) |

| Clamping | |||||||

|---|---|---|---|---|---|---|---|

| 5-330 | 10-350 | ||||||

| Specimen | GPa | Specimen | GPa | ||||

| 01 | 77 ± 1 | 77 ± 1 | 77 ± 1 | 01 | 179 ± 1 | 192 ± 1 | 186 ± 1 |

| 02 * | 639 ± 2 | 754 ± 2 | 697 ± 1 | 02 * | 311 ± 1 | 353 ± 1 | 331 ± 1 |

| 03 | 197 ± 1 | 236 ± 1 | 215 ± 1 | 03 | 96 ± 1 | 96 ± 1 | 95 ± 1 |

| Flipping | |||||||

| 5-330 | 10-350 | ||||||

| Specimen | , GPa | , GPa | , GPa | Specimen | , GPa | , GPa | , GPa |

| 01 | 99 ± 1 | 104 ± 1 | 101 ± 1 | 01 * | 202 ± 1 | 214 ± 1 | 208 ± 1 |

| 02 * | 222 ± 1 | 250 ± 1 | 235 ± 1 | 02 | 70 ± 3 | 70 ± 3 | 70 ± 3 |

| 03 | 330 ± 1 | 377 ± 2 | 352 ± 1 | 03 | 75 ± 2 | 75 ± 2 | 75 ± 2 |

| Clamping | |||||||

|---|---|---|---|---|---|---|---|

| 5-330 | 10-350 | ||||||

| Specimen | Specimen | ||||||

| 01 | 426.171 ** | 426.171 ** | 426.171 ** | 01 | 0.112 | 0.088 | 0.097 |

| 02 * | 0.018 | 0.014 | 0.016 | 02 * | 0.066 | 0.049 | 0.056 |

| 03 | 0.038 | 0.026 | 0.031 | 03 | 391.190 ** | 391.190 ** | 391.190 ** |

| Flipping | |||||||

| 5-330 | 10-350 | ||||||

| Specimen | Specimen | ||||||

| 01 * | 0.175 | 0.143 | 0.158 | 01 * | 0.279 | 0.200 | 0.233 |

| 02 | 0.074 | 0.051 | 0.061 | 02 | 417.974 ** | 417.974 ** | 417.974 ** |

| 03 | 0.044 | 0.031 | 0.037 | 03 | 432.337 ** | 432.337 ** | 432.337 ** |

| Laminate | |||

|---|---|---|---|

| c-5-330 | 80.4 ± 64.8 (81%) | 10.3 ± 3.1 (30%) | 11.4 ± 1.4 (12%) |

| c-10-350 | 205.4 ± 40.7 (20%) | 14.8 ± 2.1 (14%) | 16.1 ± 1.4 (8%) |

| f-5-330 | 366.9 ± 401.1 (109%) | 15.4 ± 3.9 (25%) | 17.2 ± 2.7 (16%) |

| f-10-350 | 195.4 ± 58.6 (30%) | 16.7 ± 3.2 (19%) | 16.4 ± 1.2 (7%) |

| Specimen | |||

|---|---|---|---|

| c-5-330-01 | 5322//950 | 9.8//10.5 | 0.9852//0.9845 |

| c-5-330-02 | 5135//950 | 4.1//5.1 | 0.9700//0.9698 |

| c-5-330-03 | 5183//950 | 7.7//8.0 | 0.9854//0.9849 |

| Average ± st.dev. | 7.2 ± 2.9 (40%)//7.9 ± 2.7 (34%) | ||

| c-10-350-01 | 5606//950 | 12.5//14.8 | 0.9815//0.9792 |

| c-10-350-02 | 5381//950 | 11.9//12.4 | 0.9894//0.9888 |

| c-10-350-03 | 5694//950 | 11.6//14.3 | 0.9904//0.9863 |

| Average ± st.dev. | 12.0 ± 0.5 (4%)//13.8 ± 1.3 (9%) | ||

| f-5-330-01 | 5861//950 | 10.8//17.9 | 0.9907//0.9707 |

| f-5-330-02 | 5408//950 | 10.9//11.8 | 0.9728//0.9719 |

| f-5-330-03 | 5655//950 | 13.6//16.2 | 0.9791//0.9779 |

| Average ± st.dev. | 11.8 ± 1.6 (14%)//15.3 ± 3.1 (21%) | ||

| f-10-350-01 | 652//950 | 13.8//13.2 | 0.9713//0.9709 |

| f-10-350-02 | 731//950 | 16.4//15.9 | 0.9683//0.9663 |

| f-10-350-03 | 5677//950 | 11.9//14.8 | 0.9825//0.9766 |

| Average ± st.dev. | 14.1 ± 2.2 (16%)//14.6 ± 1.4 (9%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khudiakova, A.; Brunner, A.J.; Wolfahrt, M.; Pinter, G. Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations. Materials 2021, 14, 1476. https://doi.org/10.3390/ma14061476

Khudiakova A, Brunner AJ, Wolfahrt M, Pinter G. Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations. Materials. 2021; 14(6):1476. https://doi.org/10.3390/ma14061476

Chicago/Turabian StyleKhudiakova, Anastasiia, Andreas J. Brunner, Markus Wolfahrt, and Gerald Pinter. 2021. "Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations" Materials 14, no. 6: 1476. https://doi.org/10.3390/ma14061476

APA StyleKhudiakova, A., Brunner, A. J., Wolfahrt, M., & Pinter, G. (2021). Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations. Materials, 14(6), 1476. https://doi.org/10.3390/ma14061476