Performance of Epoxy Resin Polymer as Self-Healing Cementitious Materials Agent in Mortar

Abstract

1. Introduction

2. Materials and Experimental Program

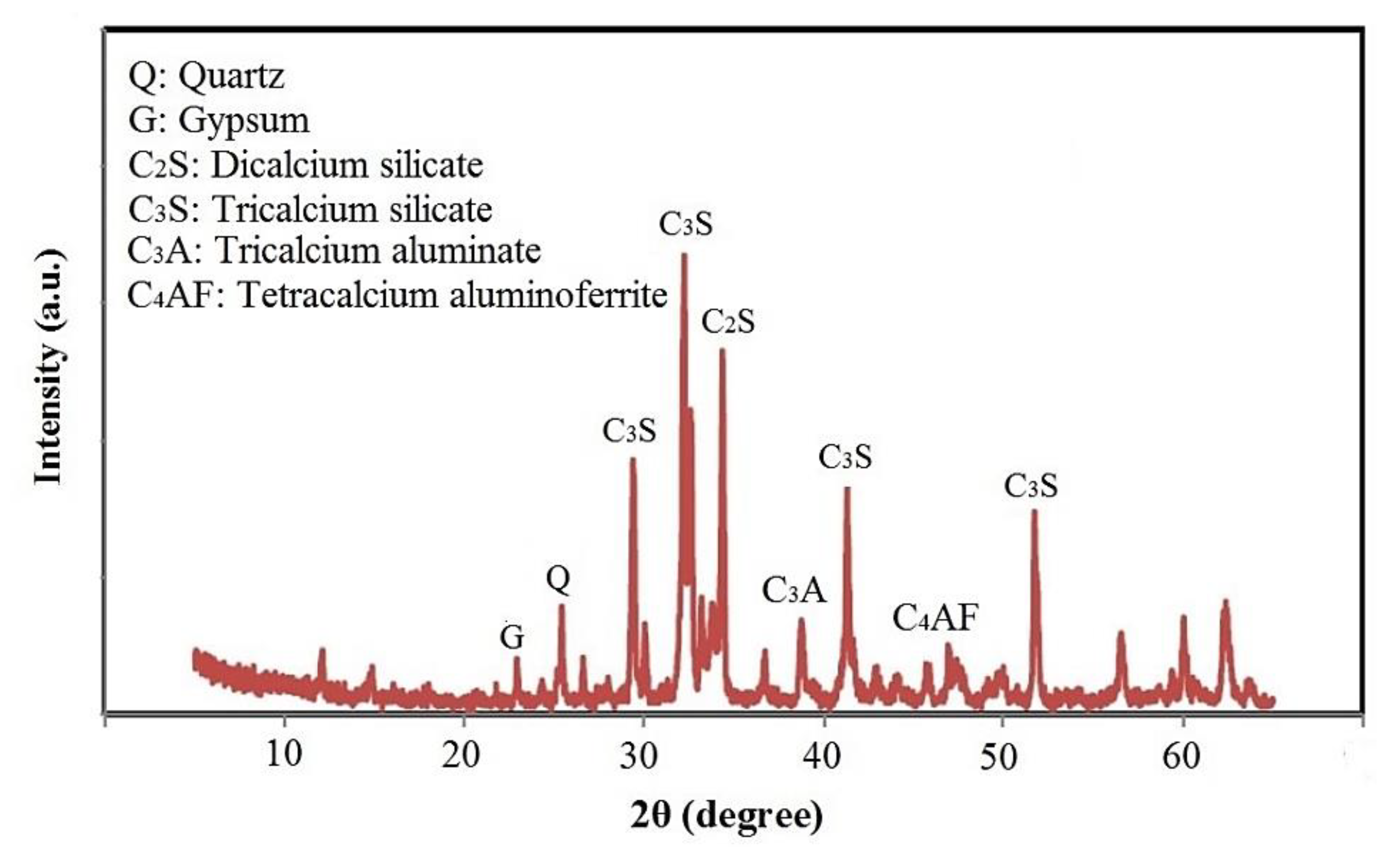

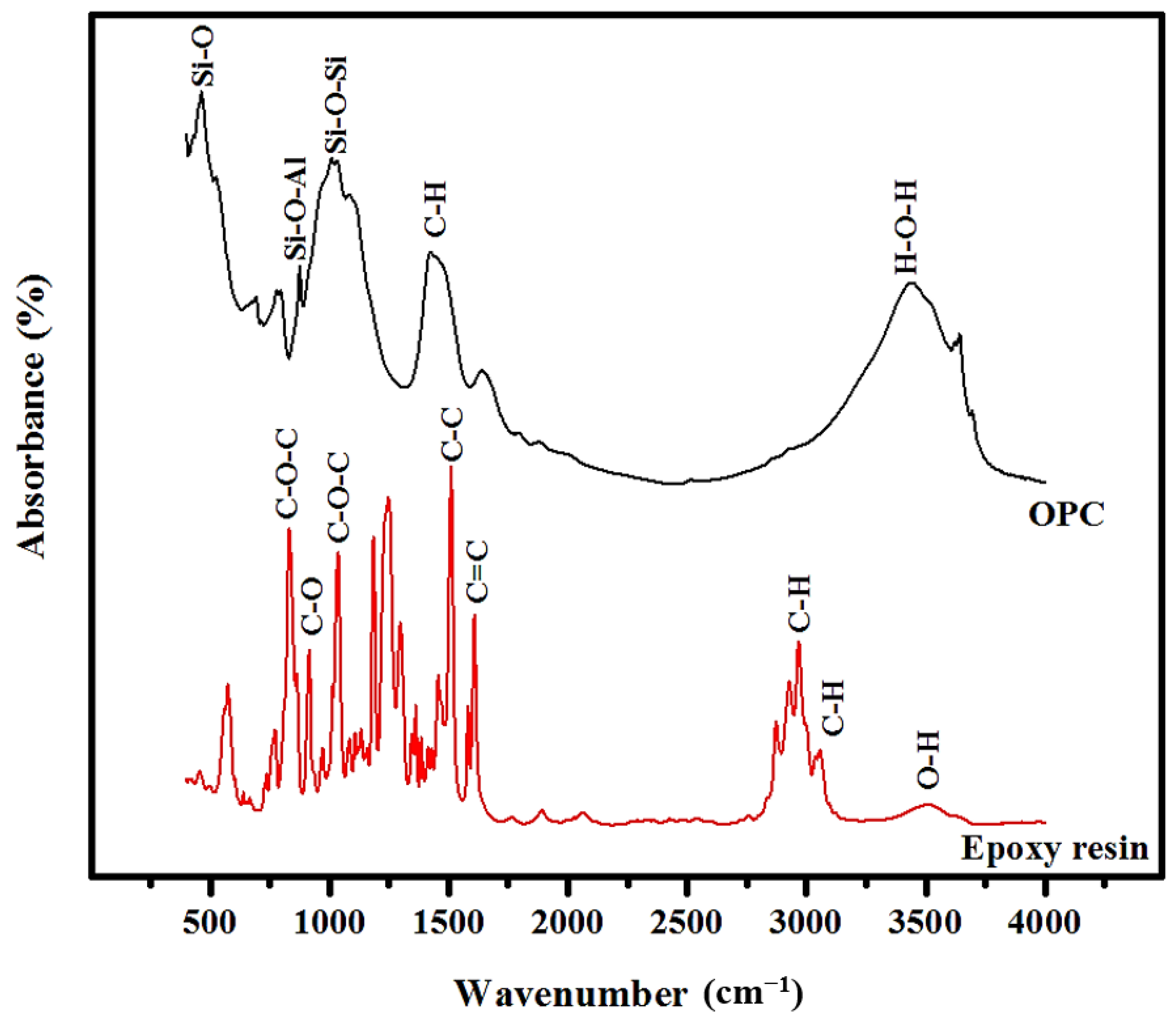

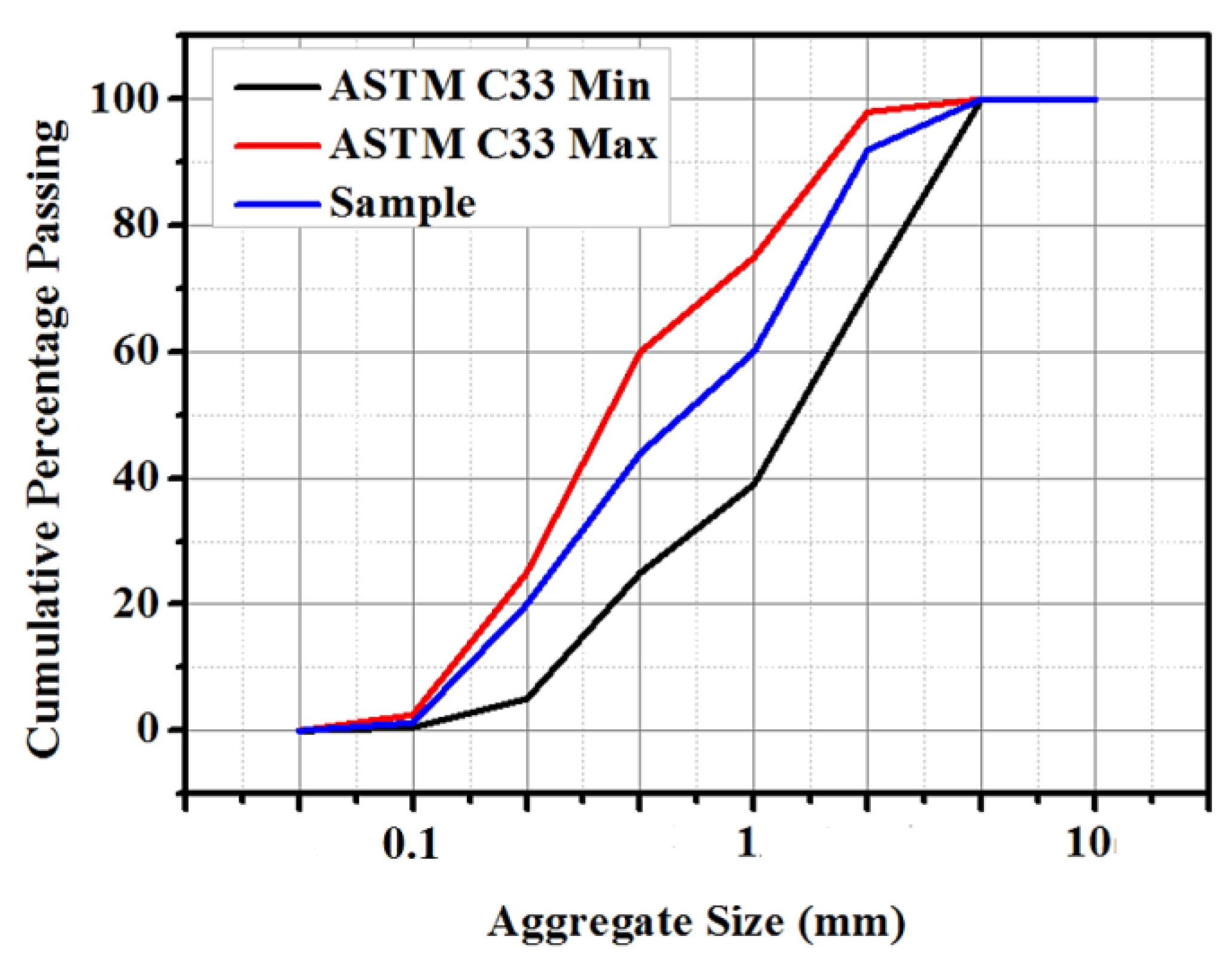

2.1. Materials

2.2. Mix Design, Casting, and Curing Condition

- (1)

- Following to ASTM C1329 and ASTM C109 standards, the ratio of the cement to river sand and water to cement was fixed to 0.33 and 0.48, respectively for all mix designs;

- (2)

- Municipal tap water was added to the concretes during the mixing and curing;

- (3)

- During the preparation stage, a saturated surface dry condition of the river sand was adopted.

2.3. Fresh and Hardened Tests

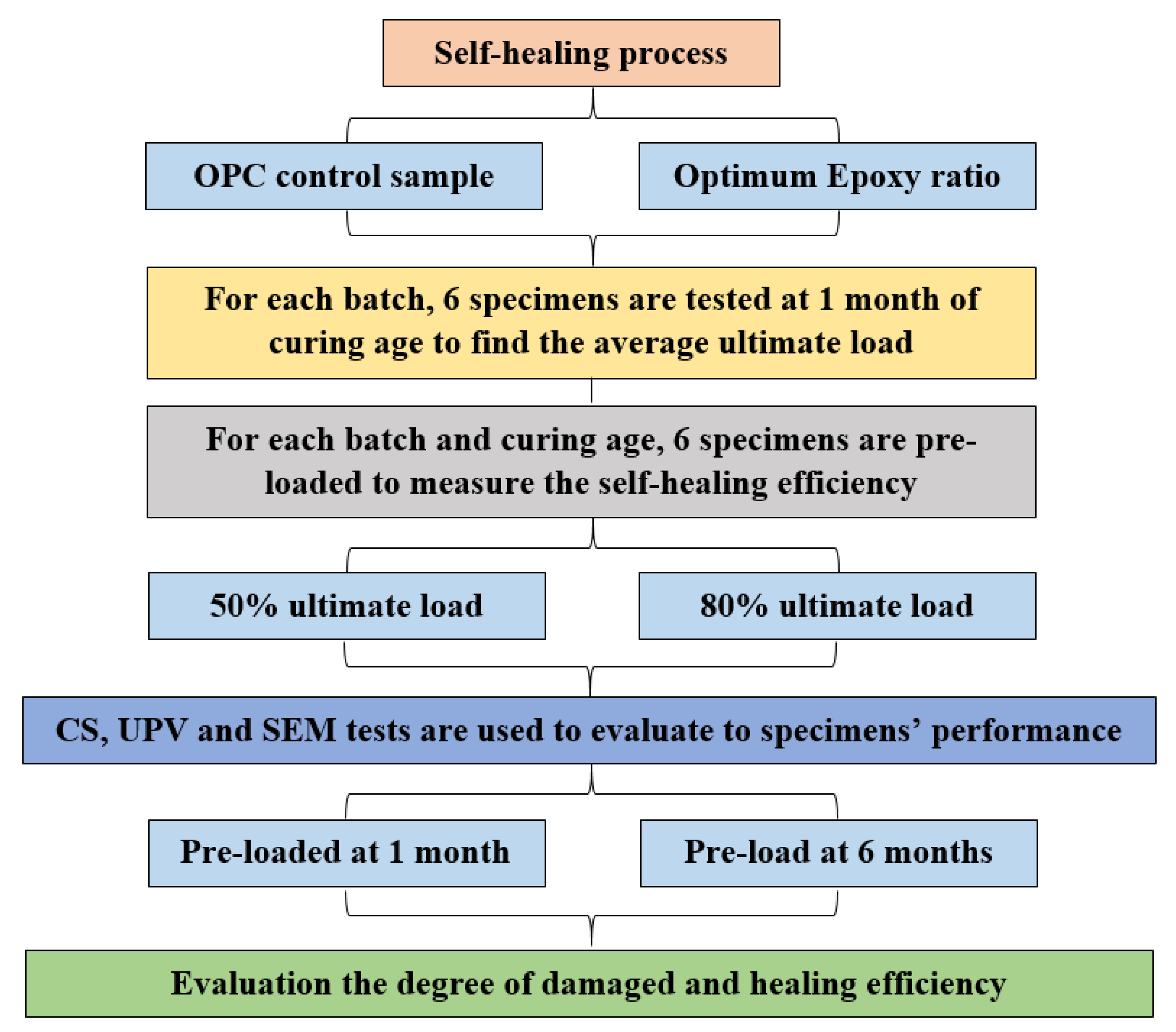

2.4. Self-Healing Evaluation Test

3. Results and Discussion

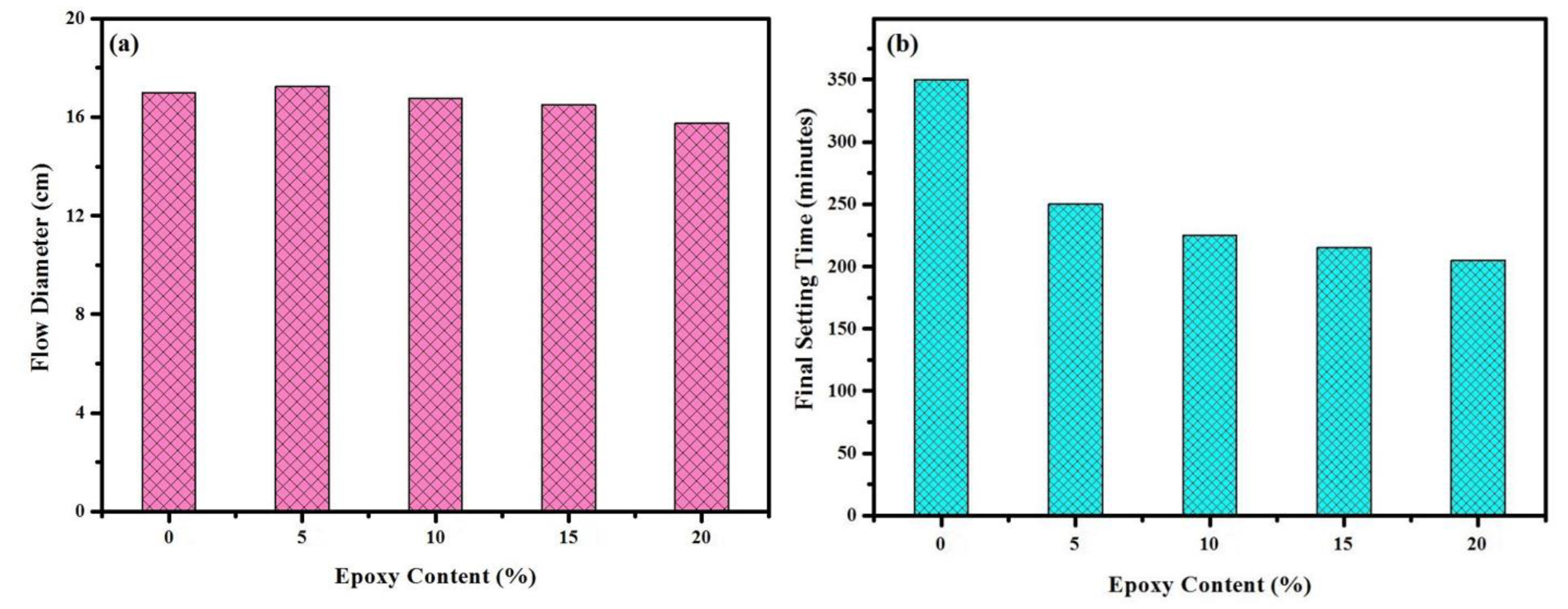

3.1. Fresh Properties

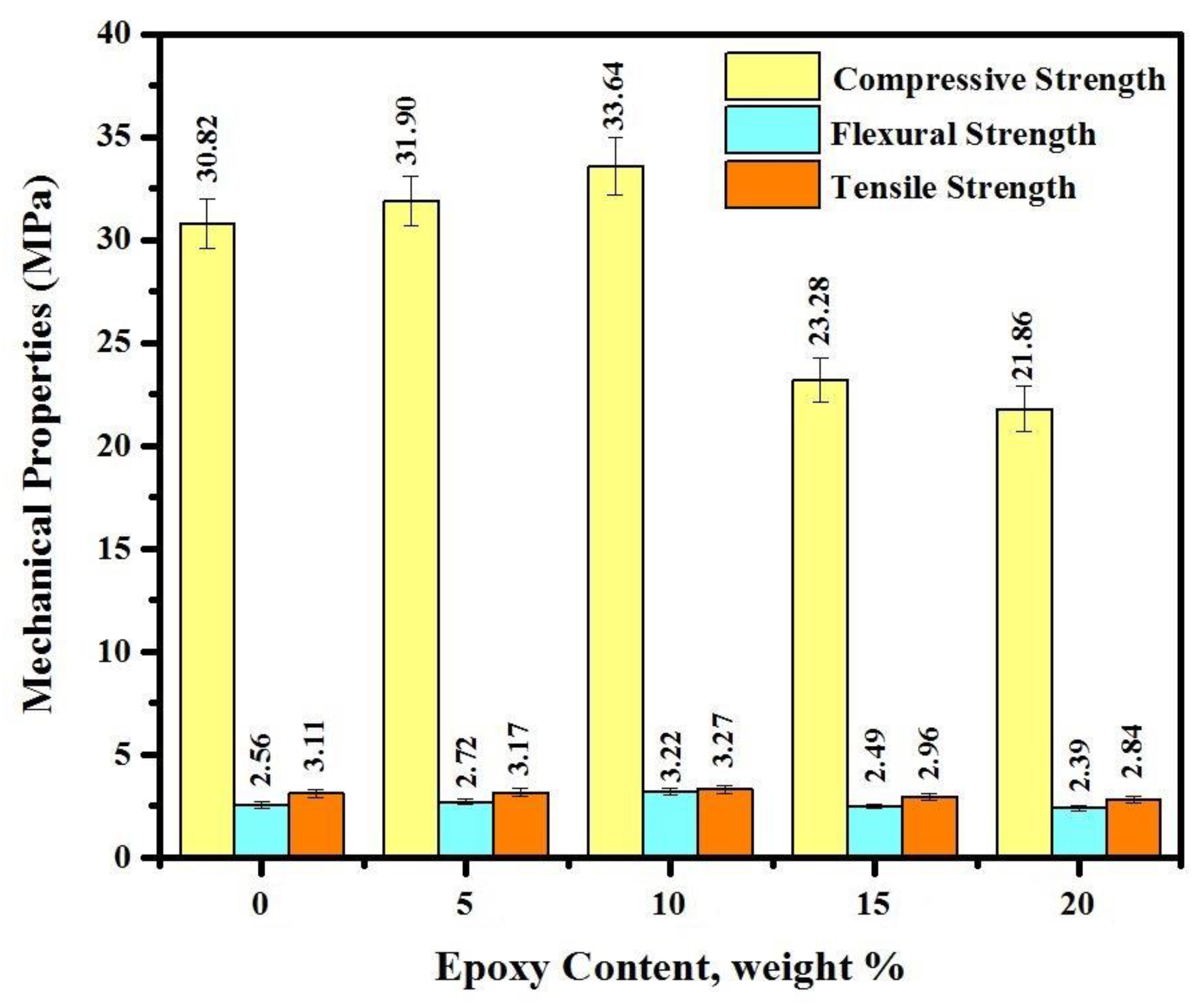

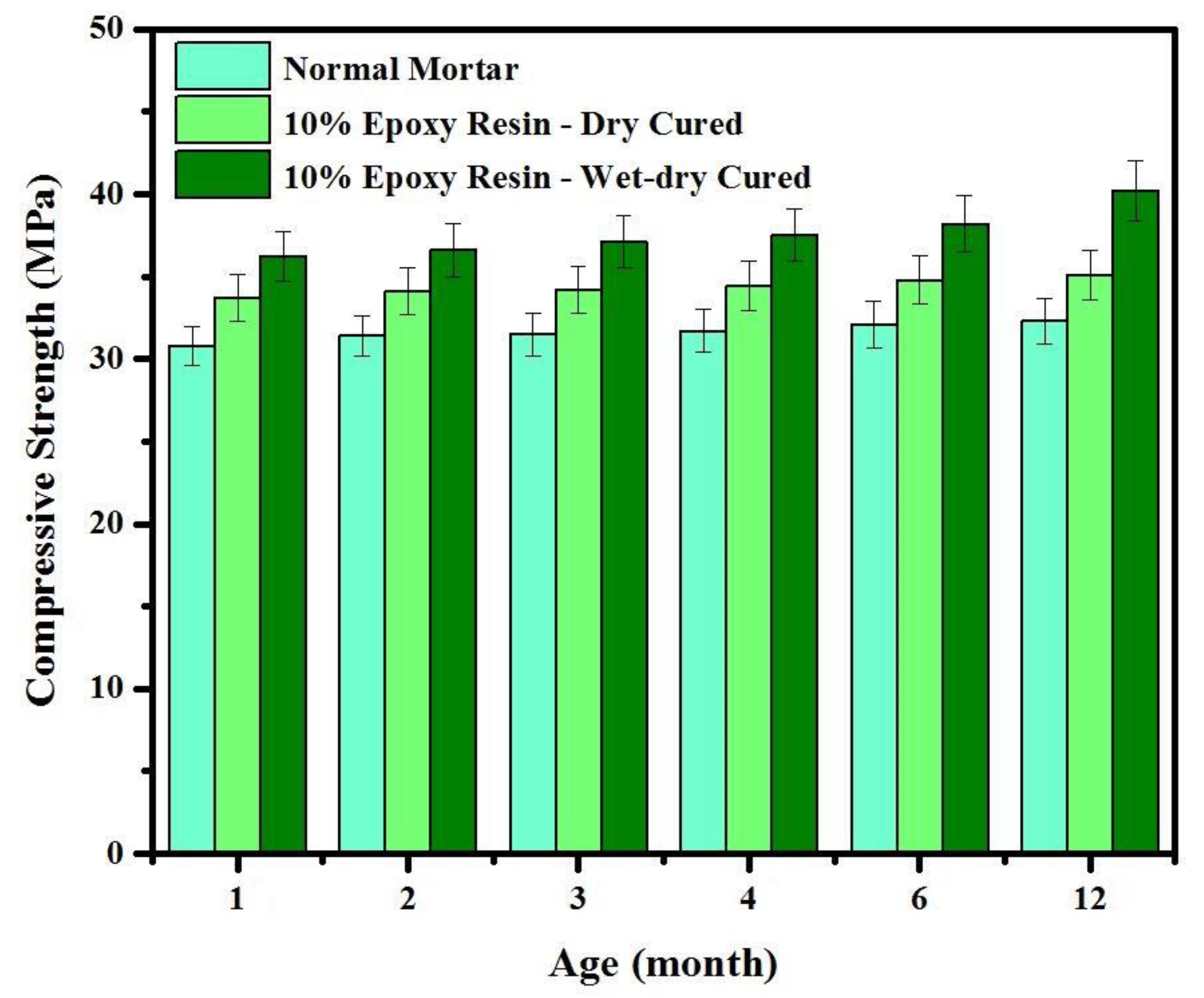

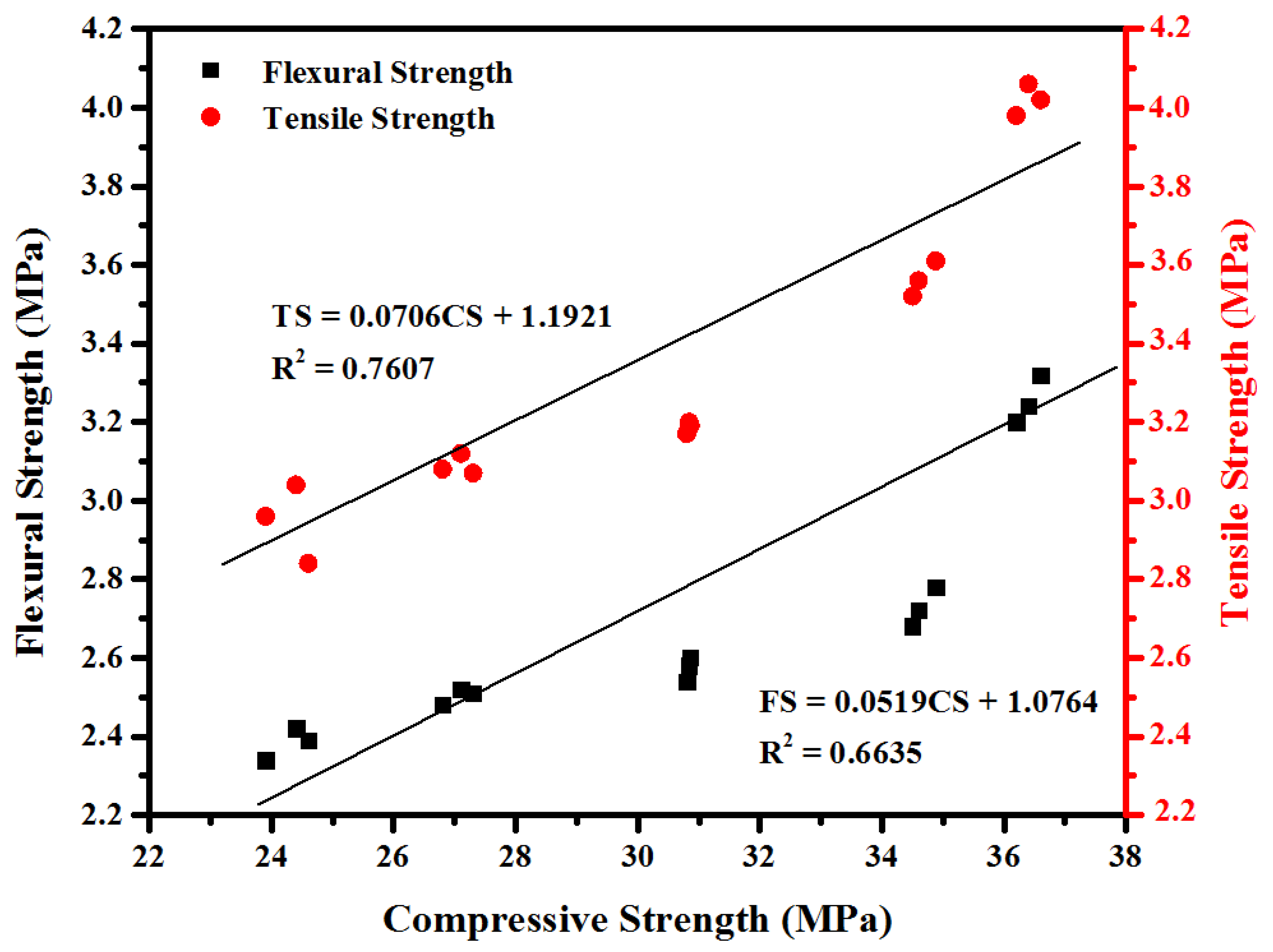

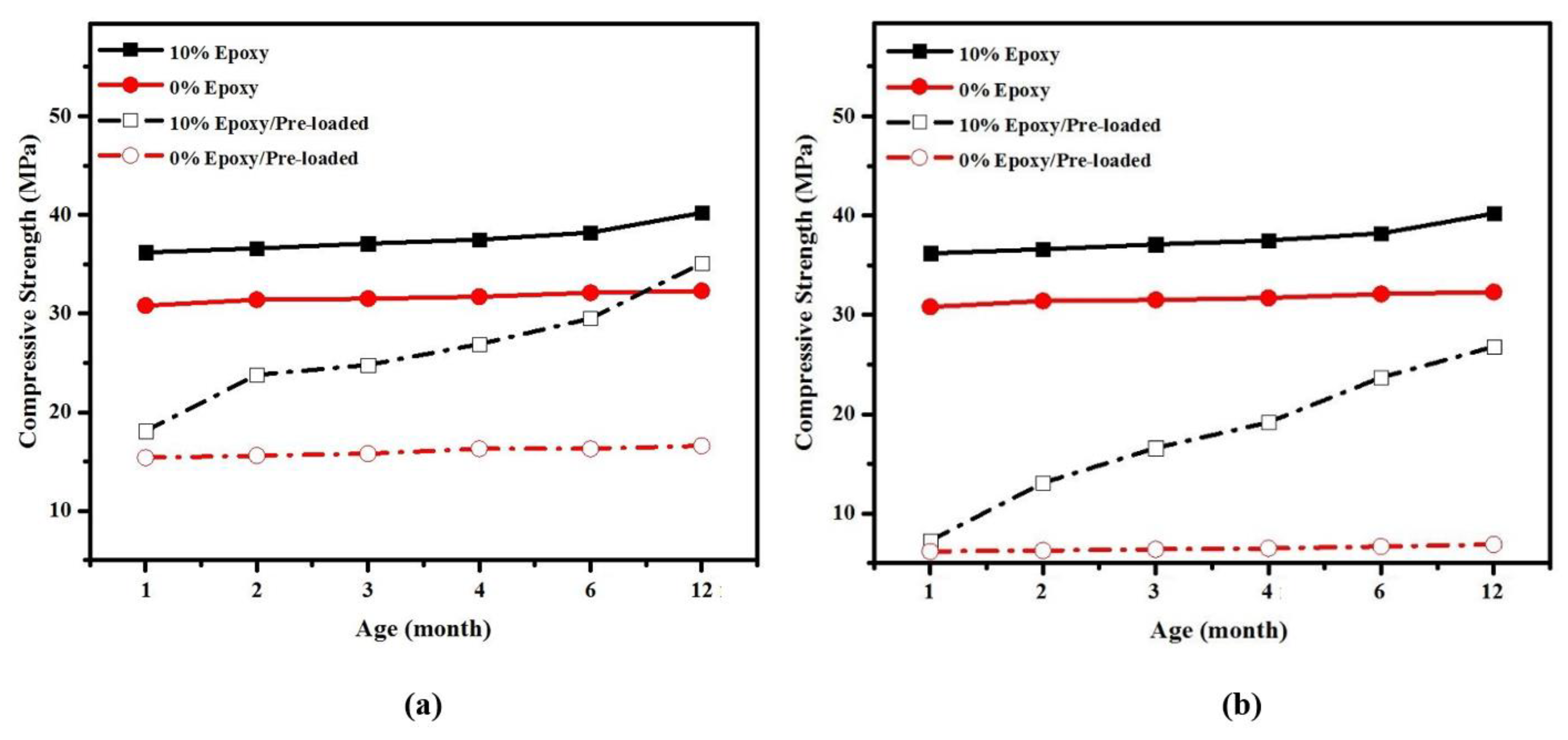

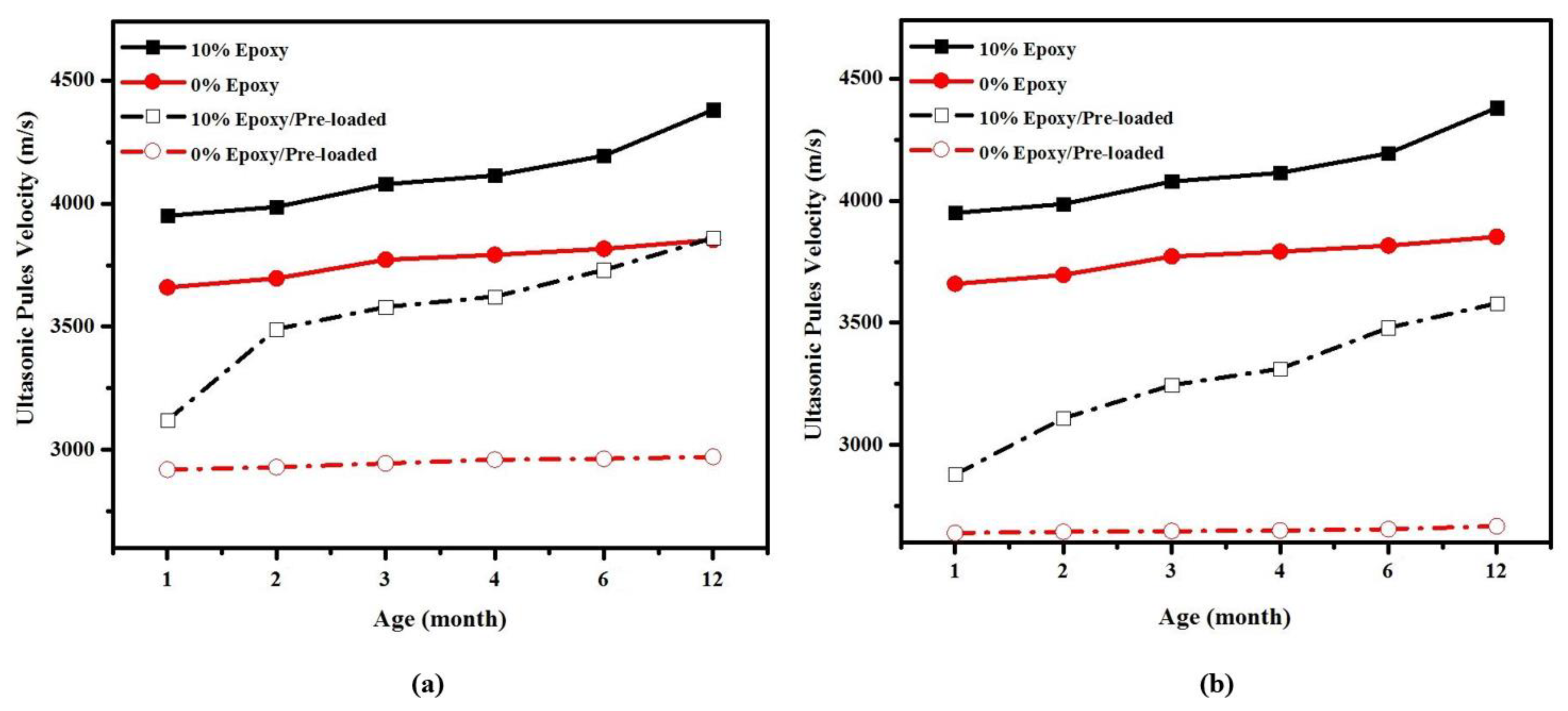

3.2. Mechanical Properties

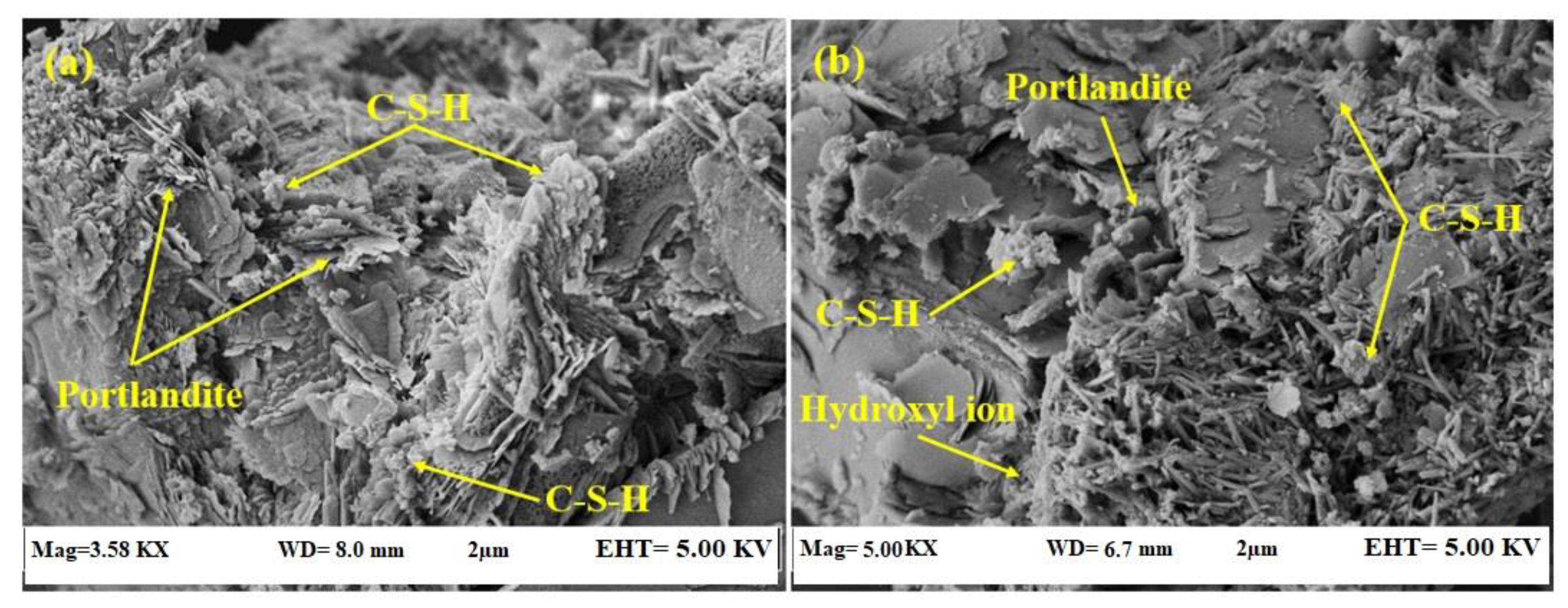

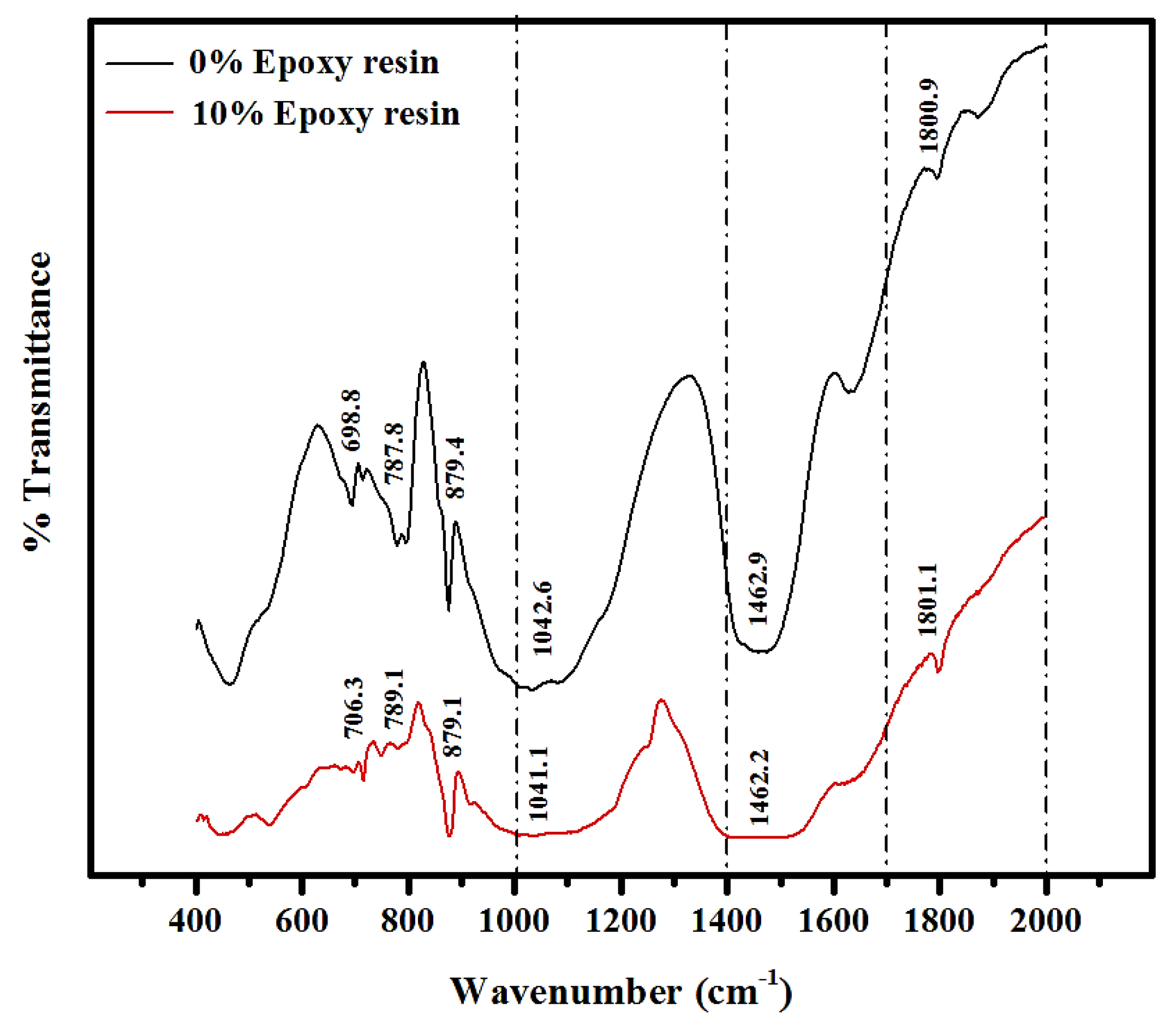

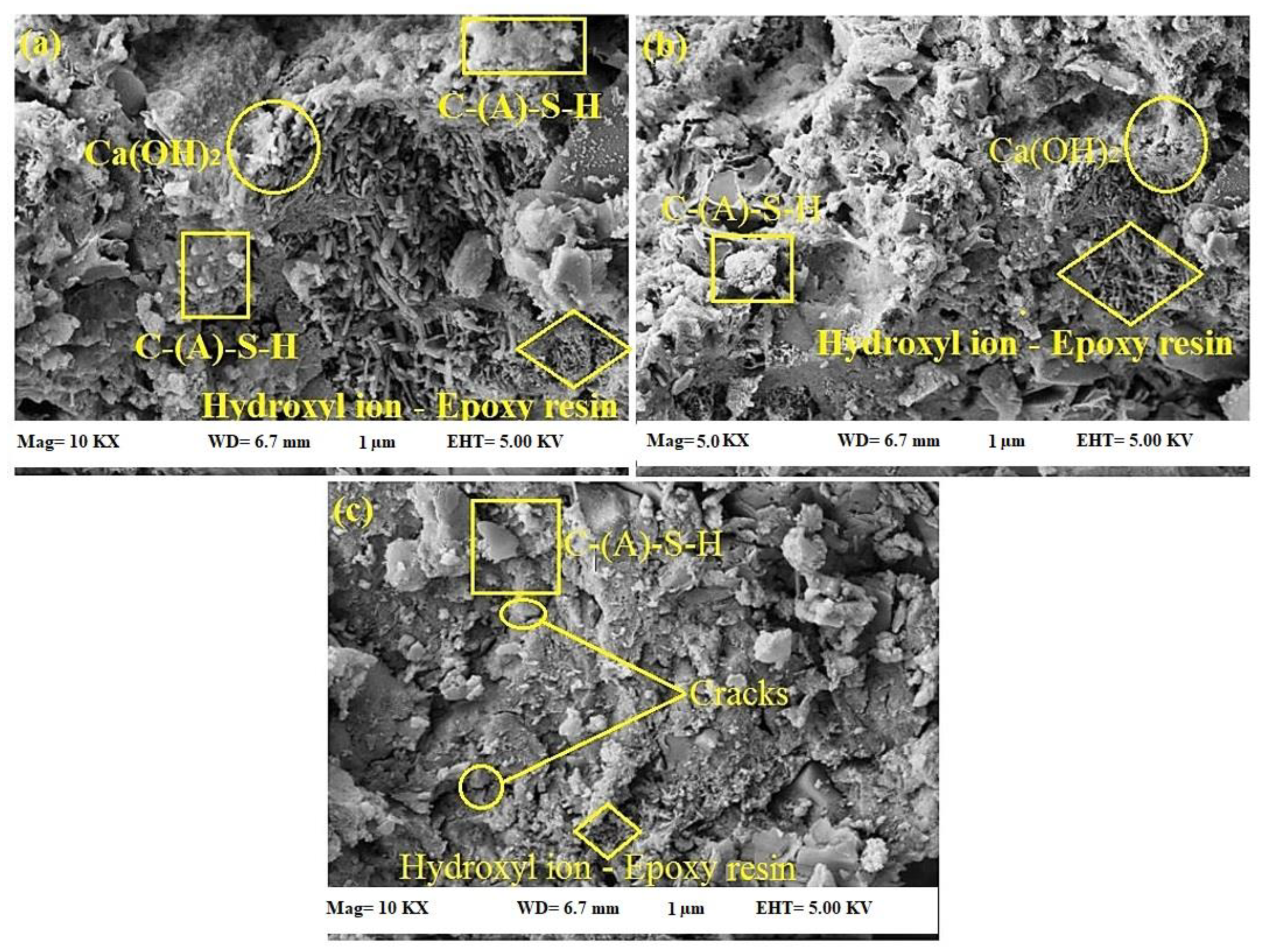

3.3. Microstructural Analysis

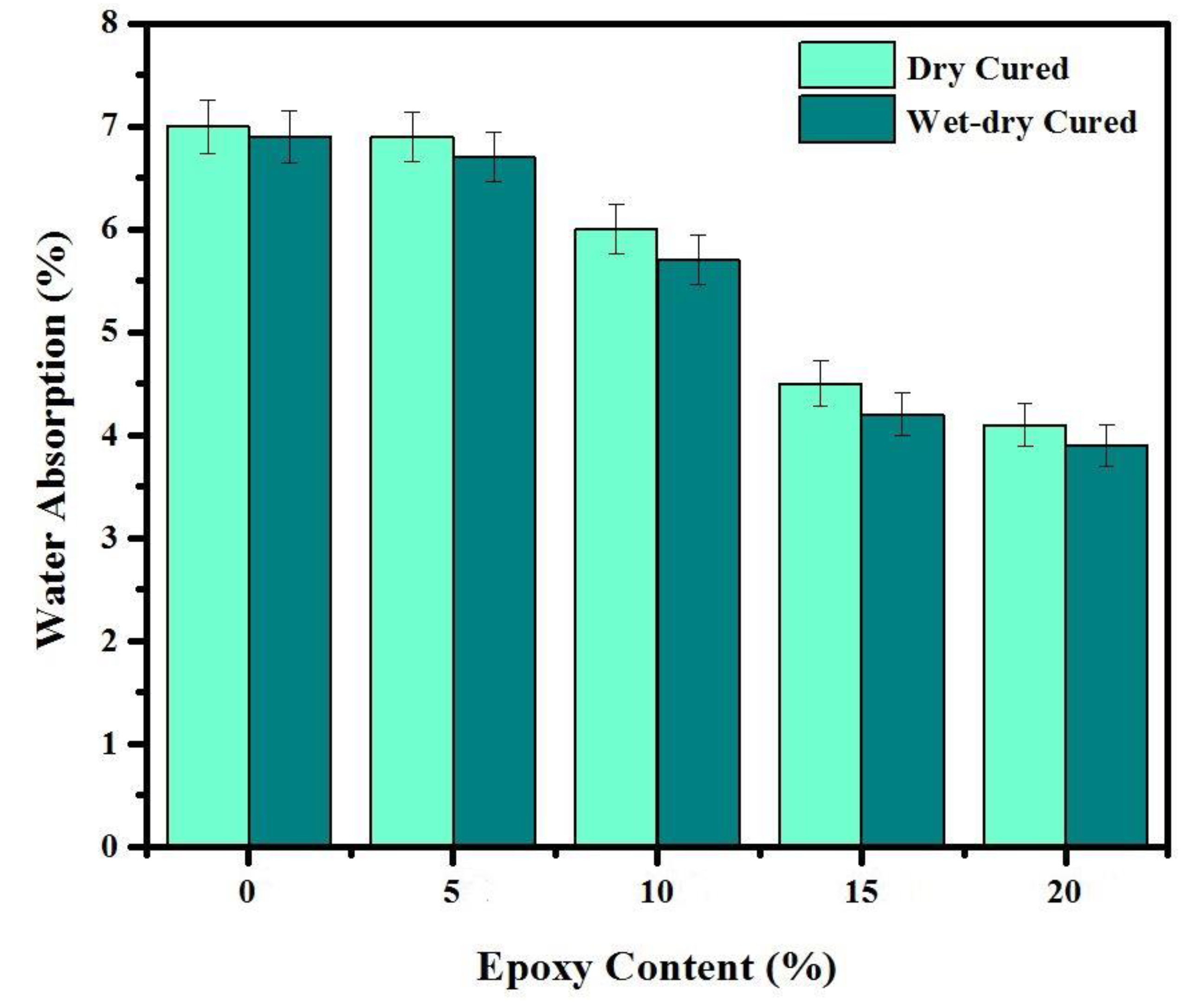

3.4. Water Absorption (WA)

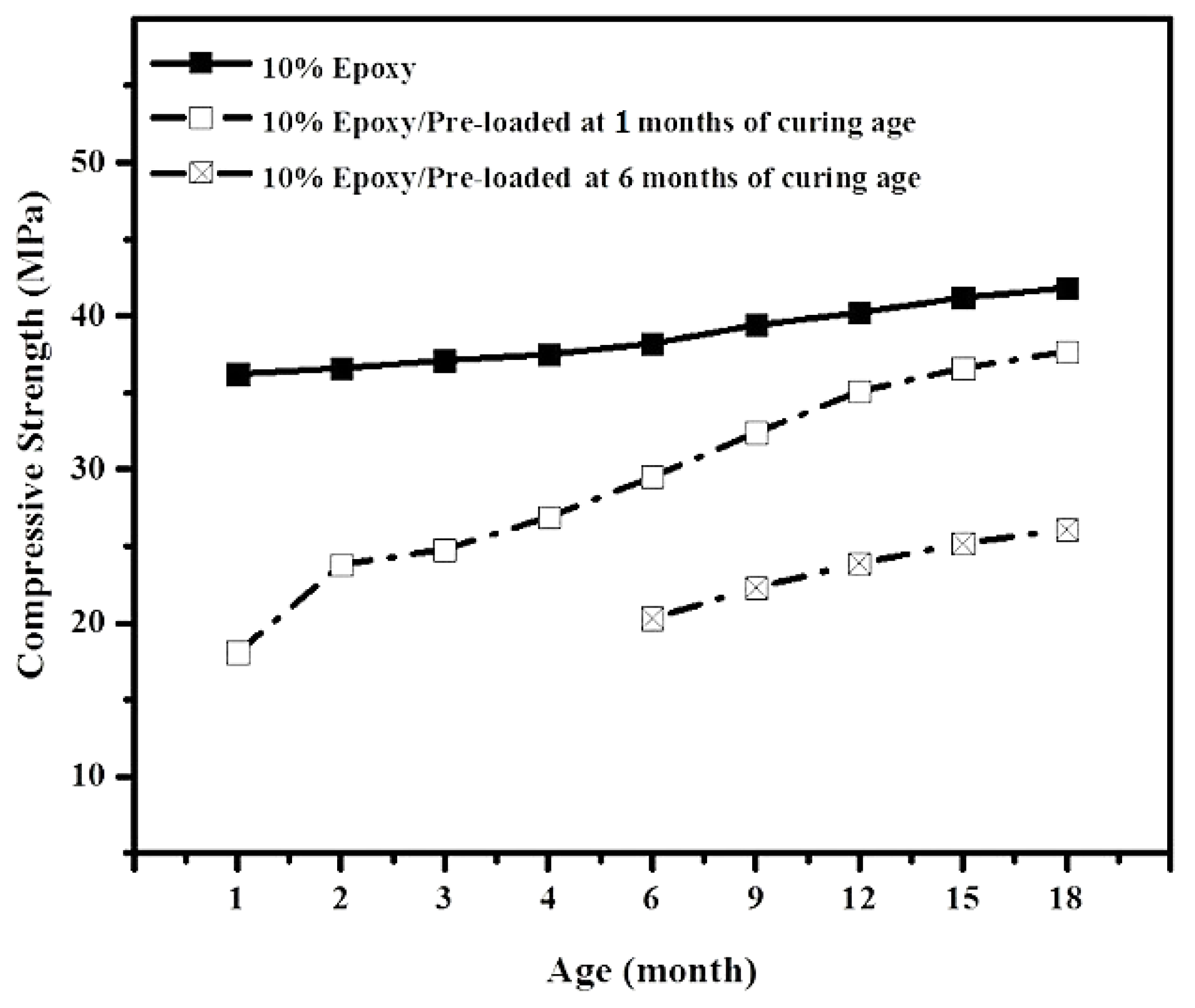

3.5. Self-healing Evaluation

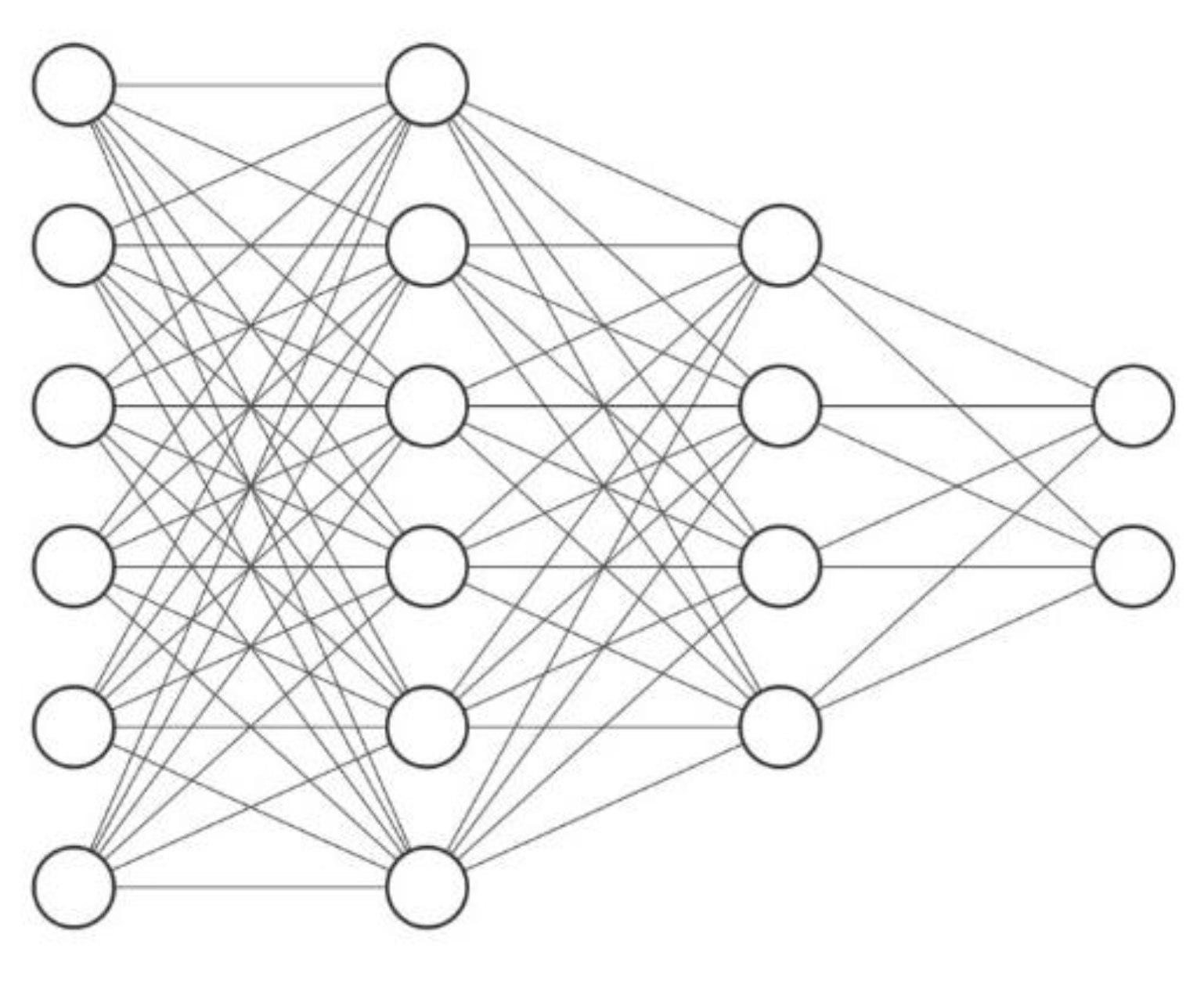

4. Developing ANN to Estimate Degree of Damage and Healing Efficiency

4.1. Firefly Optimization Algorithm (FOA)

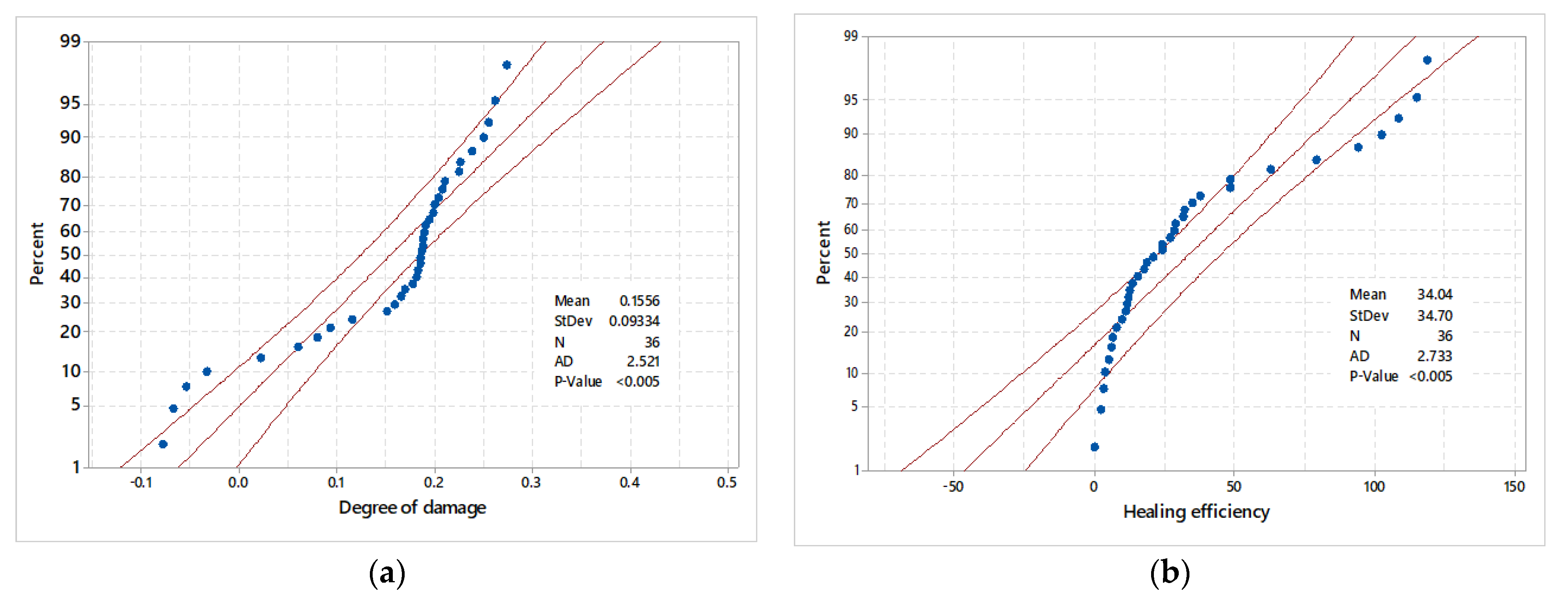

4.2. Generation of Training and Testing Data Sets

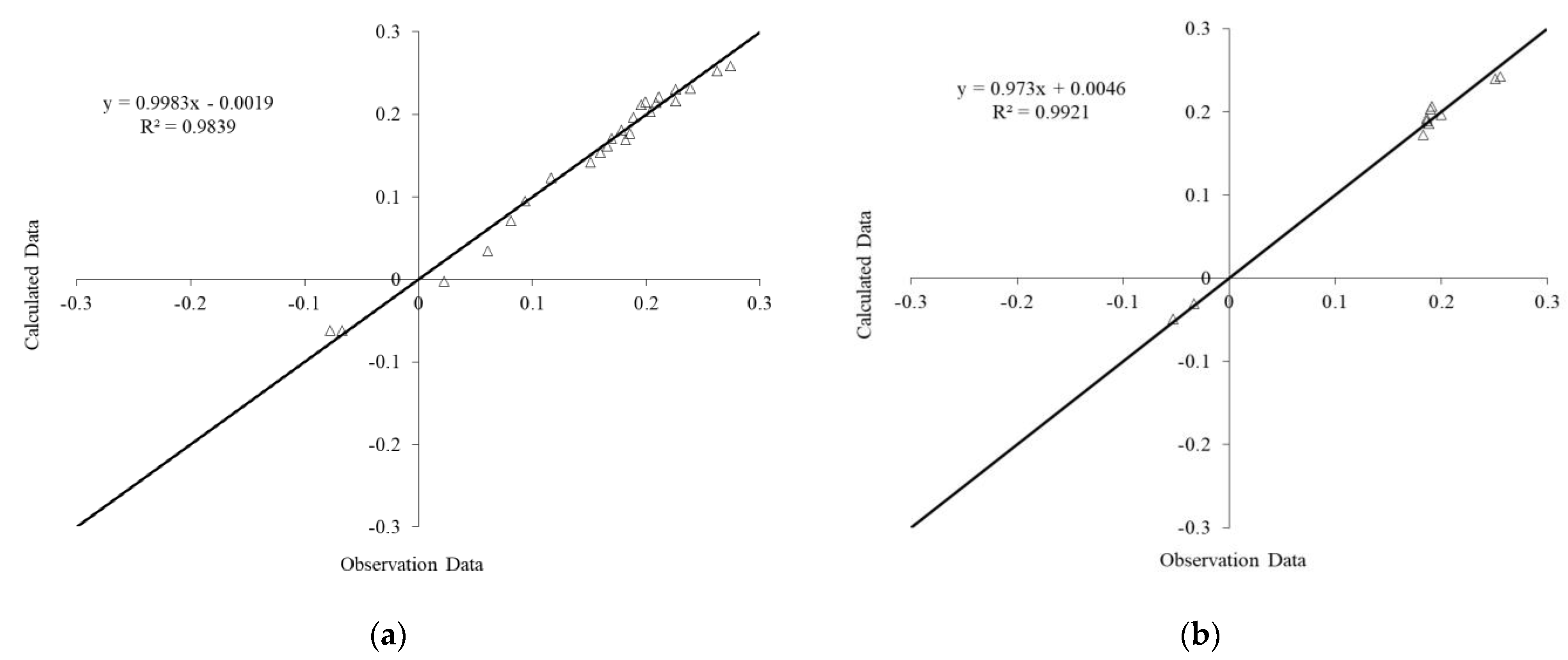

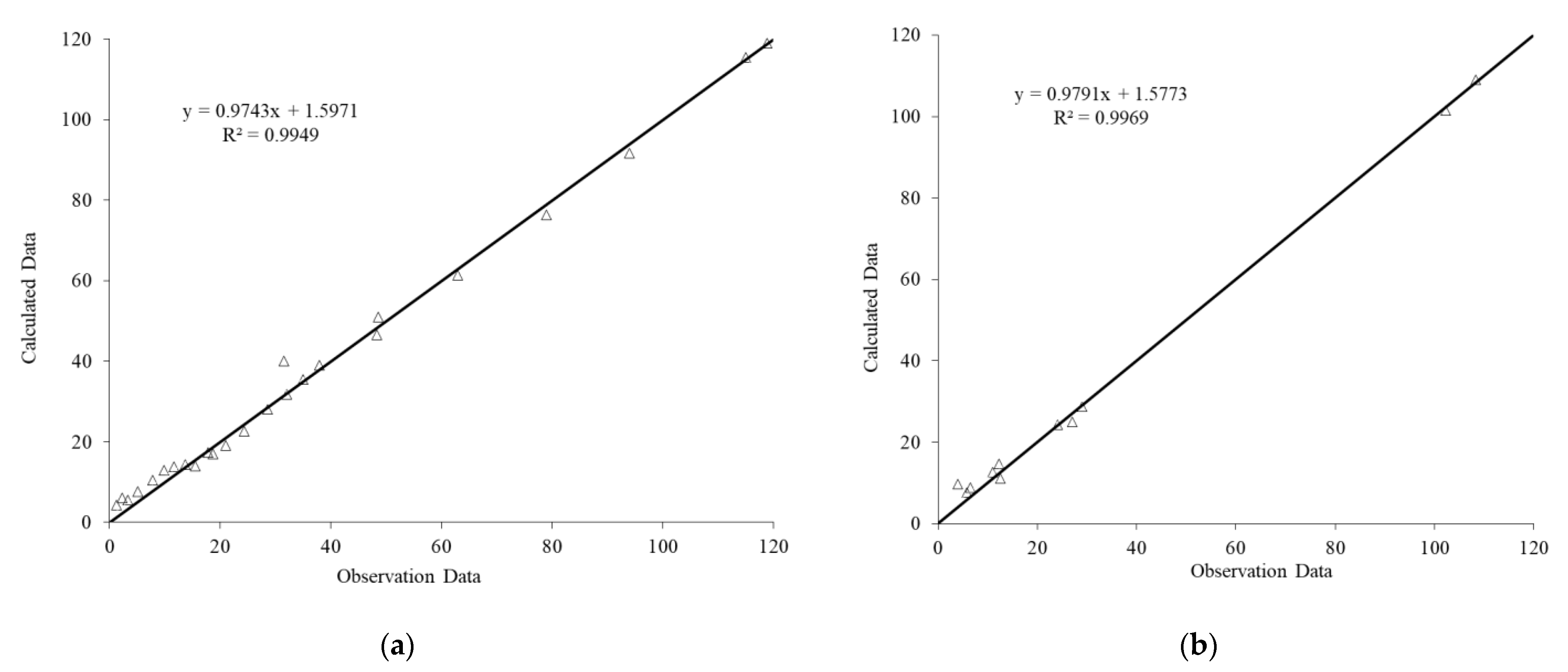

4.3. Results

5. Conclusions

- (1)

- The final setting time and water absorption were significantly decreased by increasing the epoxy resin content in the modified mortar compared to a conventional specimen.

- (2)

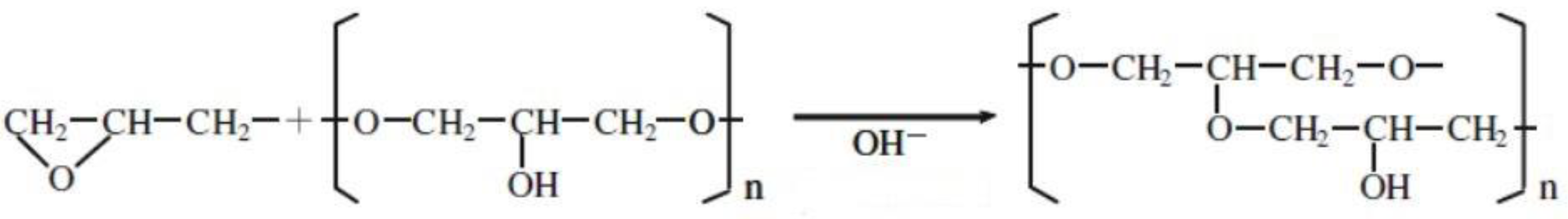

- The best mechanical properties were achieved by a specimen containing 10% epoxy resin, attributed to the presence of OH− ions from the hydration of Ca(OH)2. However, the mechanical properties significantly decreased by increasing epoxy resin content from 10 to 15 and 20%. Such phenomenon can explain by the residual unhardened epoxy within the mortar matrix that may interrupt the hydration and polymerization processes.

- (3)

- The SEM images indicated that the specimen prepared with 10% epoxy resin contain hydroxyl–ion–epoxy resin that led to the microstructure’s improvement, reduced the porosity, and providing high strength performance compared to the control specimen. In addition, in this specimen, the Ca(OH)2 was reacted with the unhardened epoxy resin, creating strong bonds between the hydroxyl ions and epoxy to increase the CS.

- (4)

- The healing efficiency on CS and UPV is much higher for the specimen containing 10% epoxy resin than the conventional mortar. Furthermore, it was concluded that there is a direct relationship between artificial crack age and self-healing efficiency, where a higher healing efficiency was achieved at a younger crack age. Similarly, the degree of damage and healing efficiency were recorded 2.3 and 71.8%, respectively for the epoxy-modified specimen once the artificial cracks were generated at an early age.

- (5)

- The ANN combined with the metaheuristic firefly algorithm provided satisfactorily results to estimate the degree of damage and healing efficiency in epoxy-modified specimens. Furthermore, the firefly algorithm optimization can also be used as a powerful tool in optimizing ANN weights. By using the optimized weight and bias of FOA-ANN, it is possible to design mixes with targeted degree of damage and healing efficiency depending on the particular environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shah, K.W.; Huseien, G.F. Biomimetic Self-Healing Cementitious Construction Materials for Smart Buildings. Biomimetics 2020, 5, 47. [Google Scholar] [CrossRef] [PubMed]

- Batis, G.; Pantazopoulou, P.; Tsivilis, S.; Badogiannis, E. The effect of metakaolin on the corrosion behavior of cement mortars. Cem. Concr. Compos. 2005, 27, 125–130. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G. Shear strengthening of reinforced concrete members with textile reinforced mortar (TRM) jackets. Mater. Struct. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W. Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem. Concr. Res. 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. In Innovation in Concrete Structures: Design and Construction; Thomas Telford Publishing: London, UK, 1999; pp. 473–487. [Google Scholar]

- Ouarabi, M.A.; Antonaci, P.; Boubenider, F.; Gliozzi, A.S.; Scalerandi, M. Ultrasonic Monitoring of the Interaction between Cement Matrix and Alkaline Silicate Solution in Self-Healing Systems. Materials 2017, 10, 46. [Google Scholar] [CrossRef] [PubMed]

- Xue, C.; Li, W.; Castel, A.; Wang, K.; Sheng, D. Effect of incompatibility between healing agent and cement matrix on self-healing performance of intelligent cementitious composite. Smart Mater. Struct. 2020, 29, 115020. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Ryou, J.-S. Crack Healing Performance of PVA-Coated Granules Made of Cement, CSA, and Na2CO3 in the Cement Matrix. Materials 2016, 9, 555. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.; He, S.; Yang, E.-H. Autogenous healing and its enhancement of interface between micro polymeric fiber and hydraulic cement matrix. Cem. Concr. Res. 2019, 124, 105830. [Google Scholar] [CrossRef]

- Yıldırım, G.; KeskinÖzlem, K.; Keskin, S.B.; Şahmaran, M.; Lachemi, M. A review of intrinsic self-healing capability of engineered cementitious composites: Recovery of transport and mechanical properties. Constr. Build. Mater. 2015, 101, 10–21. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Lv, L.-Y.; Zhang, H.; Schlangen, E.; Yang, Z.; Xing, F. Experimental and numerical study of crack behaviour for capsule-based self-healing cementitious materials. Constr. Build. Mater. 2017, 156, 219–229. [Google Scholar] [CrossRef]

- Minnebo, P.; Thierens, G.; De Valck, G.; Van Tittelboom, K.; De Belie, N.; Van Hemelrijck, D.; Tsangouri, E. A Novel Design of Autonomously Healed Concrete: Towards a Vascular Healing Network. Materials 2017, 10, 49. [Google Scholar] [CrossRef] [PubMed]

- Seifan, M.; Samani, A.K.; Hewitt, S.; Berenjian, A. The Effect of Cell Immobilization by Calcium Alginate on Bacterially Induced Calcium Carbonate Precipitation. Fermentation 2017, 3, 57. [Google Scholar] [CrossRef]

- Gollapudi, U.; Knutson, C.; Bang, S.; Islam, M. A new method for controlling leaching through permeable channels. Chemosphere 1995, 30, 695–705. [Google Scholar] [CrossRef]

- Ohama, Y.; Demura, K.; Endo, T. Strength properties of epoxy-modified mortars without hardener. In Proceedings of the 9th International Congress on the Chemistry of Cement, New Delhi, India, 23–28 November 1992. [Google Scholar]

- Ohama, Y.; Ramachandran, V. Polymer-Modified Mortars and Concretes. In Concrete Admixtures Handbook; Elsevier BV: New York, NY, USA, 1996; pp. 558–656. [Google Scholar]

- May, C. Epoxy Resins: Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 1987. [Google Scholar]

- Ariffin, N.F.; Hussin, M.W.; Bhutta, M.A.R.; Lim, N.H.A.S.; Fahim, G. PROPERTIES OF POLYMER-MODIFIED MORTARS. Available online: https://core.ac.uk/download/pdf/83531274.pdf (accessed on 4 March 2021).

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Khalid, N.H.A.; Mirza, J. Strength properties and molecular composition of epoxy-modified mortars. Constr. Build. Mater. 2015, 94, 315–322. [Google Scholar] [CrossRef]

- Ohama, Y.; Demura, K.; Endo, T. Properties of Polymer-Modified Mortars Using Epoxy Resin Without Hardener. In Polymer-Modified Hydraulic-Cement Mixtures; ASTM International: West Conshohocken, PA, USA, 2009; p. 90. [Google Scholar]

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Lim, N.H.A.S.; Khalid, N.H.A. Degree of Hardening of Epoxy-Modified Mortars without Hardener in Tropical Climate Curing Regime. Adv. Mater. Res. 2015, 1113, 28–35. [Google Scholar] [CrossRef]

- Bhutta, M.A.R. Effects of polymer–cement ratio and accelerated curing on flexural behavior of hardener-free epoxy-modified mortar panels. Mater. Struct. 2009, 43, 429–439. [Google Scholar] [CrossRef]

- Jo, Y. Basic properties of epoxy cement mortars without hardener after outdoor exposure. Constr. Build. Mater. 2008, 22, 911–920. [Google Scholar] [CrossRef]

- Łukowski, P.; Adamczewski, G. Self-repairing of polymer-cement concrete. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 195–200. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Portland Cement; ASTM C150; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Sitarz, M.; Mozgawa, W.; Handke, M. Vibrational spectra of complex ring silicate anions—method of recognition. J. Mol. Struct. 1997, 404, 193–197. [Google Scholar] [CrossRef]

- Cabanelas, J.C.; Baselga, J. Applications of FTIR on Epoxy Resins—Identification, Monitoring the Curing Process, Phase Separation and Water Uptake; IntechOpen: Madrid, Spain, 2012; Volume 2, pp. 261–284. [Google Scholar]

- ASTM, C. Standard Specification for Concrete Aggregates; ASTM: Philadelphia, PA, USA, 2003. [Google Scholar]

- Issa, M.A. Effect of Portland Cement (current ASTM C150/AASHTO M85) with Limestone and Process Addition (ASTM C465/AASHTO M327) on the Performance of Concrete for Pavement and Bridge Decks; Illinois Center for Transportation: Rantoul, IL, USA, 2014. [Google Scholar]

- ASTM. Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM; CJAI. Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle; C191-08; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Standard, A.S.T.M. ASTM C109-standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM C109; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM C496/C496M-04e1; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete; ASTM-C496; ASTM: West Conshohocken, PA, USA, 1996. [Google Scholar]

- ASTM. Standard Test Method for Evaluation of the Effect of Clear Water Repellent Treatments on Water Absorption of Hydraulic Cement Mortar Specimens; ASTM D6532; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Suaris, W.; Fernando, V. Ultrasonic Pulse Attenuation as a Measure of Damage Growth during Cyclic Loading of Concrete. ACI Mater. J. 1987, 84, 185–193. [Google Scholar]

- Huseien, G.; Ismail, M.; Tahir, M.; Mirza, J.; Hussein, A.; Khalid, N.; Sarbini, N. Effect of binder to fine aggregate content on performance of sustainable alkali activated mortars incorporating solid waste materials. Chem. Eng. Trans. 2018, 63, 667–672. [Google Scholar]

- Ohama, Y. Handbook of Polymer-Modified Concrete and Mortars: Properties and Process Technology; William Andrew: Norwich, NY, USA, 1995. [Google Scholar]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. of Buil. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Committee, A.; I.O.f. Standardization. Building Code Requirements for Structural Concrete and Commentary; ACI 318-08; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Nikoo, M.; Hadzima-Nyarko, M.; Karlo Nyarko, E.; Nikoo, M. Determining the natural frequency of cantilever beams using ANN and heuristic search. Appl. Artif. Intell. 2018, 32, 309–334. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Prentice-Hall, Inc.: Cambridge, UK, 2007. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Gandomi, A.H.; Yang, X.-S.; Alavi, A.H. Mixed variable structural optimization using Firefly Algorithm. Comput. Struct. 2011, 89, 2325–2336. [Google Scholar] [CrossRef]

- Fister, I.; Yang, X.-S.; Brest, J. A comprehensive review of firefly algorithms. Swarm Evol. Comput. 2013, 13, 34–46. [Google Scholar] [CrossRef]

- Bui, D.-K.; Nguyen, T.; Chou, J.-S.; Nguyen-Xuan, H.; Ngo, T.D. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Sheikholeslami, R.; Khalili, B.G.; Sadollah, A.; Kim, J.H. Optimization of reinforced concrete retaining walls via hybrid firefly algorithm with upper bound strategy. KSCE J. Civ. Eng. 2015, 20, 2428–2438. [Google Scholar] [CrossRef]

- Nigdeli, S.M.; Bekdaş, G.; Yang, X.-S. Metaheuristic Optimization of Reinforced Concrete Footings. KSCE J. Civ. Eng. 2018, 22, 4555–4563. [Google Scholar] [CrossRef]

| Epoxy equivalent | 184 |

| Molecular weight | 380 |

| Flash point (°C) | 264 |

| Viscosity (cPs, 20 °C) | 10,000 |

| Density (g/cm3, 20 °C) | 1.16 |

| Mix | Cement (kg/m3) | Water (kg/m3) | River Sand (kg/m3) | Epoxy/Cement (%) |

|---|---|---|---|---|

| 1 (control sample) | 506 | 243 | 1518 | 0 |

| 2 | 506 | 243 | 1518 | 5 |

| 3 | 506 | 243 | 1518 | 10 |

| 4 | 506 | 243 | 1518 | 15 |

| 5 | 506 | 243 | 1518 | 20 |

| Healing Efficiency of Modified Mortar Prepared with 10% Epoxy and 50% Pre-Loaded | ||||||

|---|---|---|---|---|---|---|

| A-Specimens pre-loaded at 1 month of curing age. | ||||||

| Concrete curing age, month | 1 | 2 | 3 | 4 | 6 | 12 |

| CS of non-loaded concrete, MPa | 36.2 | 36.6 | 37.1 | 37.5 | 38.2 | 40.2 |

| CS of pre-loaded concrete, MPa | 18.1 | 23.8 | 24.8 | 26.9 | 29.5 | 35.1 |

| Healing period, month | - | 1 | 2 | 3 | 5 | 11 |

| Degree of damage, % | 21 | 11.6 | 9.4 | 8.9 | 8.1 | 2.3 |

| Healing efficiency, % | - | 29.3 | 32 | 41.4 | 51.9 | 71.8 |

| B-Specimens pre-loaded at 6 months of curing age. | ||||||

| Concrete curing age, month | 6 | 7 | 8 | 9 | 12 | 18 |

| CS of non-loaded concrete, MPa | 38.2 | 38.9 | 39.2 | 39.8 | 40.2 | 41.8 |

| CS of pre-loaded concrete, MPa | 19.1 | 21.1 | 22.3 | 23.9 | 24.8 | 26.7 |

| Healing period, month | - | 1 | 2 | 3 | 5 | 11 |

| Degree of damage, % | 26 | 25.6 | 23.8 | 23.1 | 22.5 | 17.8 |

| Healing efficiency, % | - | 6.8 | 11.5 | 16.7 | 19.4 | 20.9 |

| Number | Parameter | Type | Unit | Max | Min | Average | STD |

|---|---|---|---|---|---|---|---|

| 1 | Epoxy | Input | kg/m3 | 50.6 | 0 | 37.95 | 22.22 |

| 2 | Pre-Load at Age | Input | (Day) | 360 | 28 | 149 | 138.65 |

| 3 | Healing Duration | Input | (Month) | 36 | 1 | 14 | 10.71 |

| 4 | CS | Input | (MPa) | 39.6 | 15.6 | 25.2 | 6.79 |

| 5 | UPV | Input | (km/s) | 4.26 | 2.93 | 3.45 | 0.37 |

| 6 | Water Absorption | Input | (%) | 14.8 | 5.5 | 9.57 | 3.08 |

| 7 | Observation Degree of damage | Output | (%) | 0.27 | −0.08 | 0.16 | 0.09 |

| 8 | Observation Healing efficiency | Output | (%) | 118.78 | 0 | 34.04 | 34.7 |

| Training | Testing | ||||||

|---|---|---|---|---|---|---|---|

| MSE | ME | MAE | RMSE | MSE | ME | MAE | RMSE |

| 2.94 | 0.26 | 0.92 | 1.71 | 3.72 | 0.89 | 1.11 | 1.93 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Population size | 100 | Attraction coefficient base value | 2 |

| Mutation coefficient | 0.25 | Mutation coefficient damping ratio | 0.99 |

| Light absorption coefficient | 1 | M (exponent of distance term) | 2 |

| IW | b1 | |||||

| −0.2226 | 0.6913 | 0.7234 | 0.4921 | −0.2198 | 0.7664 | 0.3660 |

| 0.5876 | 0.2296 | 0.0543 | −0.9068 | −0.8038 | 0.7919 | −0.4297 |

| 0.8156 | 0.8708 | 0.2050 | −0.7444 | −0.4160 | −0.3075 | 0.9485 |

| 0.3177 | −0.3422 | −0.9205 | −0.8923 | 0.5018 | −0.0903 | −0.4386 |

| 0.0142 | −0.9034 | −0.3105 | 0.9778 | 0.5866 | 0.3670 | −0.0370 |

| −0.7485 | −0.0284 | −0.7803 | −0.2927 | 0.7430 | −0.8874 | −0.8910 |

| LW1 | b2 | |||||

| 0.1391 | −0.6483 | −0.9244 | −0.2580 | 0.3317 | −0.2730 | −0.5625 |

| 0.1451 | −0.9574 | 0.9974 | 0.7265 | −0.0867 | −0.6183 | 0.5001 |

| −0.0218 | 0.1769 | −0.2386 | 0.5438 | −0.2493 | −0.0382 | −0.8893 |

| 0.3847 | −0.1255 | −0.1702 | 0.4274 | −0.7884 | −0.6989 | 0.2426 |

| LW2 | b3 | |||||

| −0.4282 | 0.0805 | 0.6376 | 0.7041 | - | - | 0.0395 |

| 0.7643 | 0.4558 | −0.4930 | −0.4541 | - | - | −0.3842 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huseien, G.F.; Sam, A.R.M.; Faridmehr, I.; Baghban, M.H. Performance of Epoxy Resin Polymer as Self-Healing Cementitious Materials Agent in Mortar. Materials 2021, 14, 1255. https://doi.org/10.3390/ma14051255

Huseien GF, Sam ARM, Faridmehr I, Baghban MH. Performance of Epoxy Resin Polymer as Self-Healing Cementitious Materials Agent in Mortar. Materials. 2021; 14(5):1255. https://doi.org/10.3390/ma14051255

Chicago/Turabian StyleHuseien, Ghasan Fahim, Abdul Rahman Mohd Sam, Iman Faridmehr, and Mohammad Hajmohammadian Baghban. 2021. "Performance of Epoxy Resin Polymer as Self-Healing Cementitious Materials Agent in Mortar" Materials 14, no. 5: 1255. https://doi.org/10.3390/ma14051255

APA StyleHuseien, G. F., Sam, A. R. M., Faridmehr, I., & Baghban, M. H. (2021). Performance of Epoxy Resin Polymer as Self-Healing Cementitious Materials Agent in Mortar. Materials, 14(5), 1255. https://doi.org/10.3390/ma14051255