Precipitate Evolution in 22Cr25NiWCuCo(Nb) Austenitic Heat-Resistant Stainless Steel during Heat Treatment at 1200 °C

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suo, J.; Peng, Z.; Yang, H.; Chai, G.; Yu, M. Formation of laves phase in Sanicro 25 austenitic steel during creep-rupture test at 700 °C. Metallogr. Microstruct. Anal. 2019, 8, 281–286. [Google Scholar] [CrossRef]

- Maziasz, P.J. Development of creep-resistant and oxidation-resistant austenitic stainless steels for high temperature applications. JOM 2018, 70, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Zieliński, A.; Dudziak, T.P.; Golański, G.; Gazdowicz, J.; Kołodziej, A. Effects of long-term ageing at high temperatures on oxide scale development and evolution of austenitic steels microstructure. Steel Res. Int. 2020, 91, 1900595. [Google Scholar] [CrossRef]

- Cempura, G.; Gil, A.; Agüero, A.; Gutiérrez, M.; Kruk, A.; Czyrska-Filemonowicz, A. Microstructural studies of the scale on Sanicro 25 after 25,000h of oxidation in steam using advanced electron microscopy techniques. Surf. Coat. Technol. 2019, 377, 124901. [Google Scholar] [CrossRef]

- Golański, G.; Zieliński, A.; Sroka, M.; Słania, J. The effect of service on microstructure and mechanical properties of HR3C heat-resistant austenitic stainless steel. Materials 2020, 13, 1297. [Google Scholar] [CrossRef] [Green Version]

- Zhou, R.; Zhu, L. Growth behavior and strengthening mechanism of Cu-rich particles in sanicro 25 austenitic heat-resistant steel after aging at 973 K. Mater. Sci. Eng. 2020, A796, 139973. [Google Scholar] [CrossRef]

- Sroka, M.; Zielinski, A.; Golański, G. Analysis of phase precipitation in Sanicro 25 Austenitic steel after ageing. Acta Phys. Pol. 2019, 135, 207–211. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhou, X.; Liu, C.; Yu, J.; Huang, Y.; Li, H.; Li, W. Precipitation and hot deformation behavior of austenitic heat-resistant steels: A review. J. Mater. Sci. Technol. 2017, 33, 1448–1456. [Google Scholar] [CrossRef]

- Viswanathan, R.; Henry, J.F.; Tanzosh, J.; Stanko, G.; Shingledecker, J.; Vitalis, B.; Purgert, R.U.S. program on materials technology for ultra-supercritical coal power plants. J. Mater. Eng. Perform. 2005, 14, 281–292. [Google Scholar] [CrossRef]

- Rutkowski, B.; Gil, A.; Agüero, A.; González, V.; Czyrska-Filemonowicz, A. Microstructure, chemical- and phase composition of Sanicro 25 austenitic steel after oxidation in steam at 700 °C. Oxid. Met. 2018, 89, 183–195. [Google Scholar] [CrossRef]

- Zurek, J.; Yang, S.-M.; Lin, D.-Y.; Hüttel, T.; Singheiser, L.; Quadakkers, W.J. Microstructural stability and oxidation behavior of Sanicro 25 during long-term steam exposure in the temperature range 600–750 °C. Mater. Corros. 2015, 66, 315–327. [Google Scholar] [CrossRef]

- Rana, R.; Bleck, W.; Singh, S.B.; Mohanty, O.N. Development of high strength interstitial free steel by copper precipitation hardening. Mater. Lett. 2007, 61, 2919–2922. [Google Scholar] [CrossRef]

- He, J.; Sandström, R. Application of Fundamental Models for Creep Rupture Prediction of Sanicro 25 (23Cr25NiWCoCu). Crystals 2019, 8, 638. [Google Scholar] [CrossRef] [Green Version]

- Zieliński, A.; Dobrzański, J.; Ppuzyńska, H.; Sikora, R.; Dziuba-Kałuża, M.; Kania, Z. Evaluation of creep strength of heterogeneous welded joint in HR6W alloy and Sanicro 25 steel Arch. Metall. Mater. 2017, 62, 2057–2064. [Google Scholar] [CrossRef] [Green Version]

- Calmunger, M.; Chai, G.; Eriksson, R.; Johansson, S.; Moverare, J.J. Characterization of Austenitic Stainless Steels Deformed at Elevated Temperature. Metall. Mater. Trans. 2017, A48, 4525–4538. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Liu, C.; Li, C.; Li, H. Mechanism for the formation of Z-phase in 25Cr-20Ni-Nb-N austenitic stainless steel. Mater. Lett. 2018, 233, 16–19. [Google Scholar] [CrossRef]

- Zhou, R.; Zhu, L.; Liu, Y.; Lu, Z.; Chen, L. Precipitates and precipitation strengthening of Sanicro 25 welded joint base metal crept at 973 K. Steel Res. Int. 2017, 87, 1600414. [Google Scholar] [CrossRef]

- Merda, A.; Sroka, M.; Klimaszewska, K.; Golański, G. Microstructure and mechanical properties of the Sanicro 25 steel after ageing. J. Achiev. Mater. Manuf. Eng. 2018, 91, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Sourmail, T. Precipitation in creep resistant austenitic stainless steel. J. Mater. Sci. Technol. 2001, 14, 1–14. [Google Scholar] [CrossRef]

- Chai, G.; Bostrom, M.; Olaison, M.; Forsberg, U. Creep and LCF behaviours of newly developed advanced heat resistant austenitic steels for A- USC. Procedia Eng. 2013, 55, 232–239. [Google Scholar] [CrossRef] [Green Version]

- Peng, B.; Zhang, H.; Hong, J.; Gao, J.; Zhang, H.; Li, J.; Wang, Q. The evolution of precipitates of 22Cr-25Ni-Mo-Nb-N heat-resistant austenitic steel in long term creep. Mater. Sci. Eng. 2010, A527, 4424–4430. [Google Scholar] [CrossRef]

- Wei, L.; Hao, W.; Cheng, Y.; Tan, S. Isothermal aging embrittlement in an Fe-22Cr-25Ni alloy. Mater. Sci. Eng. 2018, A737, 40–46. [Google Scholar] [CrossRef]

- Terada, M.; Escriba, D.M.; Costa, I.; Materna-Morris, E.; Padliha, A.F. Investigation on the intergranular corrosion resistance of the AISI 316L(N) stainless steel after long time creep testing. Mater. Charact. 2008, 59, 663–668. [Google Scholar] [CrossRef]

- Kaneko, K.; Futunaga, T.; Yamada, K.; Nakada, N.; Kikuchi, M.; Saghi, Z.; Barnad, J.S.; Midgley, P.A. Formation of M23C6-Type precipitates and chromium–depleted zone in austenite stainless steel. Scr. Mater. 2011, 65, 509–512. [Google Scholar] [CrossRef]

- Raghavan, A.; Klein, C.F.; Marzinsky, C.N. Instabilities in stabilized austenitic stainless steels. Metall. Mater. Trans. 1992, 23A, 2455–2467. [Google Scholar]

- Lula, R.A. New Developments in Stainless Steel Technology; American Society for Metals: Metals Park, OH, USA, 1985; ISBN 978-0-871-70205-0. [Google Scholar]

- Vodárek, V. Morphology and orientation relationship of Z-phase in austenite. Scr. Metall. Mater. 1991, 25, 549–552. [Google Scholar] [CrossRef]

- Heczko, M.; Esser, B.D.; Smith, T.M.; Beran, P.; Mazánová, V.; Kruml, T.; Polák, J.; Mills, M.J. On the origin of extraordinary cyclic strengthening of the austenitic stainless steel Sanicro 25 during fatigue at 700 °C. J. Mater. Res. 2017, 32, 4342–4353. [Google Scholar] [CrossRef] [Green Version]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three Dimensional Surfaces: Basics and Applications; Napoca Star Publishing House: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Hillert, M. On the theory of normal and abnormal grain growth. Acta Metall. 1965, 13, 227–238. [Google Scholar] [CrossRef]

- Ghosh, S. Kinetic study on the coarsening behaviour of equilibrium phases in Nb alloyed ferritic stainless steels at 700 °C. Mater. Chem. Phys. 2010, 124, 13–16. [Google Scholar]

- Zhou, Y.-H.; Liu, C.-X.; Liu, Y.-C.; Guo, Q.-Y.; Li, H.-J. Coarsening behavior of MX carbonitrides in type 347H heat-resistant austenitic steel during thermal aging. Int. J. Miner. Metall. Mater. 2016, 23, 283–293. [Google Scholar] [CrossRef]

- Xia, Z.X.; Zhang, C.; Yang, Z.G. Control of precipitation behavior in reduced activation steels by intermediate heat treatment. Mater. Sci. Eng. 2011, A528, 6764–6768. [Google Scholar]

| Cr | Ni | W | Cu | Co | N | C | Si | Mn | P | S | Nb | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nb-free | 22.20 | 24.40 | 3.39 | 2.90 | 1.47 | 0.23 | 0.07 | 0.19 | 0.49 | 0.009 | 0.005 | - | Bal. |

| Nb-0.3 | 22.10 | 24.30 | 3.40 | 2.90 | 1.49 | 0.23 | 0.07 | 0.19 | 0.49 | 0.010 | 0.005 | 0.29 | Bal. |

| Nb-0.6 | 21.90 | 24.20 | 3.36 | 2.90 | 1.45 | 0.23 | 0.07 | 0.20 | 0.49 | 0.010 | 0.005 | 0.58 | Bal. |

| Nb-0.9 | 21.80 | 24.10 | 3.52 | 2.90 | 1.54 | 0.23 | 0.07 | 0.20 | 0.49 | 0.010 | 0.005 | 0.86 | Bal. |

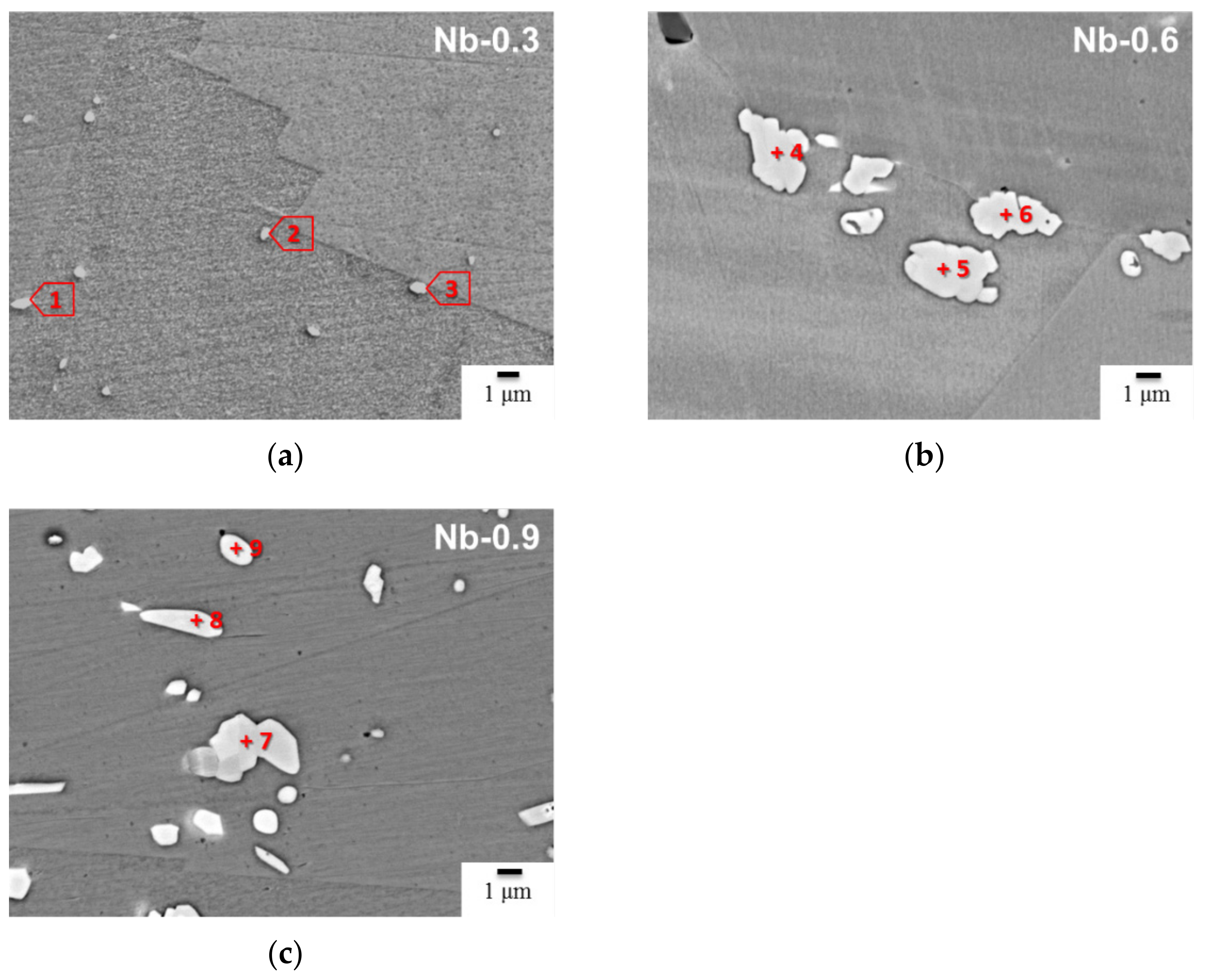

| Cr at.% | Fe at.% | Nb at.% | W at.% | C at.% | N at.% | Si at.% | Phase | |

|---|---|---|---|---|---|---|---|---|

| 1 (Nb-0.3) | 28.5 ± 0.9 | 5.5 ± 0.3 | 31.9 ± 1.6 | 2.5 ± 0.8 | 16.0 ± 0.8 | 15.6 ± 0.5 | - | CrNb(C, N) |

| 2 (Nb-0.3) | 26.2 ± 0.9 | 4.9 ± 0.3 | 29.1 ± 1.6 | 1.9 ± 0.9 | 20.8 ± 0.9 | 17.1 ± 0.6 | - | CrNb(C, N) |

| 3 (Nb-0.3) | 5.6 ± 0.3 | 3.4 ± 0.2 | 47.8 ± 1.4 | - | 27.0 ± 1.0 | 16.2 ± 0.5 | - | MX |

| 4 (Nb-0.3) | 30.5 ± 1.0 | 4.0 ± 0.3 | 33.6 ± 1.6 | 1.3 ± 0.9 | - | 30.6 ± 0.5 | - | CrNbN |

| 5 (Nb-0.6) | 29.8 ± 1.0 | 6.7 ± 0.3 | 30.2 ± 1.5 | 1.6 ± 0.8 | 8.9 ± 0.8 | 22.8 ± 0.6 | - | CrNb(C, N) |

| 6 (Nb-0.6) | 29.3 ± 0.9 | 3.9 ± 0.2 | 30.7 ± 1.4 | 1.7 ± 0.6 | 4.4 ± 0.4 | 30.0 ± 0.5 | - | CrNb(C, N) |

| 7 (Nb-0.6) | 27.1 ± 0.8 | 5.1 ± 0.3 | 34.1 ± 1.6 | 1.8 ± 0.9 | 4.9 ± 0.6 | 27.0 ± 0.5 | - | CrNb(C, N) |

| 8 (Nb-0.9) | 30.1 ± 0.9 | 5.3 ± 0.3 | 30.5 ± 1.6 | 1.3 ± 0.9 | 15.2 ± 0.8 | 17.6 ± 0.6 | - | CrNb(C, N) |

| 9 (Nb-0.9) | 24.9 ± 0.8 | 4.4 ± 0.3 | 30.3 ± 1.5 | 1.4 ± 0.8 | 30.1 ± 1.0 | 8.9 ± 0.5 | CrNb(C, N) | |

| 10 (Nb-0.9) | 28.4 ± 0.9 | 4.5 ± 0.3 | 31.1 ± 1.6 | 1.4 ± 0.9 | 25.6 ± 0.9 | 7.3 ± 0.5 | 1.7 ± 0.6 | CrNb(C, N) |

| 11 (Nb-0.9) | 36.1 ± 1.2 | 17.5 ± 0.6 | 3.0 ± 0.6 | 1.3 ± 0.5 | 22.7 ± 1.0 | 19.4 ± 0.5 | MX | |

| 12 (Nb-0.9) | 33.3 ± 1.1 | 5.3 ± 0.2 | 29.4 ± 1.4 | 1.9 ± 1.0 | 12.6 ± 0.7 | 16.3 ± 0.6 | 1.2 ± 0.6 | CrNb(C, N) |

| 13 (Nb-0.9) | 3.0 ± 0.2 | 1.6 ± 0.3 | 46.7 ± 1.8 | - | 41.9 ± 1.2 | 4.0 ± 0.3 | 2.8 ± 0.8 | MX |

| Cr at.% | Fe at.% | Nb at.% | W at.% | C at.% | N at.% | Cu at.% | Ni at.% | Co at.% | Mn at.% | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 (Nb-0.3) | 29.3 | 27.6 | 14.9 | 1.3 | 3.3 | 7.5 | 1.2 | 13.7 | 0.8 | 0.4 |

| 2 (Nb-0.3) | 25.8 | 36.6 | 5.4 | 1.2 | 1.6 | 6.5 | 1.8 | 19.4 | 1.2 | 0.5 |

| 3 (Nb-0.3) | 23.8 | 34.9 | 5.6 | 1.0 | 2.1 | 11.1 | 1.6 | 18.2 | 1.2 | 0.5 |

| 4 (Nb-0.6) | 29.1 | 4.5 | 29.5 | 1.3 | 4.2 | 30.3 | 0.1 | 0.8 | 0.1 | 0.1 |

| 5 (Nb-0.6) | 28.7 | 4.5 | 30.2 | 1.4 | 4.0 | 30.2 | - | 0.8 | 0.1 | 0.1 |

| 6 (Nb-0.6) | 28.8 | 4.3 | 32.0 | 1.5 | 4.5 | 28.1 | - | 0.6 | 0.1 | 0.1 |

| 7 (Nb-0.9) | 27.3 | 4.5 | 28.6 | 1.3 | 2.9 | 34.2 | - | 0.9 | 0.2 | 0.1 |

| 8 (Nb-0.9) | 28.6 | 5.2 | 29.1 | 1.4 | 2.9 | 31.4 | - | 1.1 | 0.1 | 0.2 |

| 9 (Nb-0.9) | 27.0 | 12.4 | 22.9 | 1.3 | 2.9 | 27.8 | 0.4 | 4.9 | 0.3 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.-M.; Wu, J.-L.; Pan, Y.-T.; Lin, D.-Y. Precipitate Evolution in 22Cr25NiWCuCo(Nb) Austenitic Heat-Resistant Stainless Steel during Heat Treatment at 1200 °C. Materials 2021, 14, 1104. https://doi.org/10.3390/ma14051104

Yang S-M, Wu J-L, Pan Y-T, Lin D-Y. Precipitate Evolution in 22Cr25NiWCuCo(Nb) Austenitic Heat-Resistant Stainless Steel during Heat Treatment at 1200 °C. Materials. 2021; 14(5):1104. https://doi.org/10.3390/ma14051104

Chicago/Turabian StyleYang, Sheng-Min, Jing-Lin Wu, Yeong-Tsuen Pan, and Dong-Yih Lin. 2021. "Precipitate Evolution in 22Cr25NiWCuCo(Nb) Austenitic Heat-Resistant Stainless Steel during Heat Treatment at 1200 °C" Materials 14, no. 5: 1104. https://doi.org/10.3390/ma14051104

APA StyleYang, S.-M., Wu, J.-L., Pan, Y.-T., & Lin, D.-Y. (2021). Precipitate Evolution in 22Cr25NiWCuCo(Nb) Austenitic Heat-Resistant Stainless Steel during Heat Treatment at 1200 °C. Materials, 14(5), 1104. https://doi.org/10.3390/ma14051104