The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect

Abstract

1. Introduction

2. Experiment Details

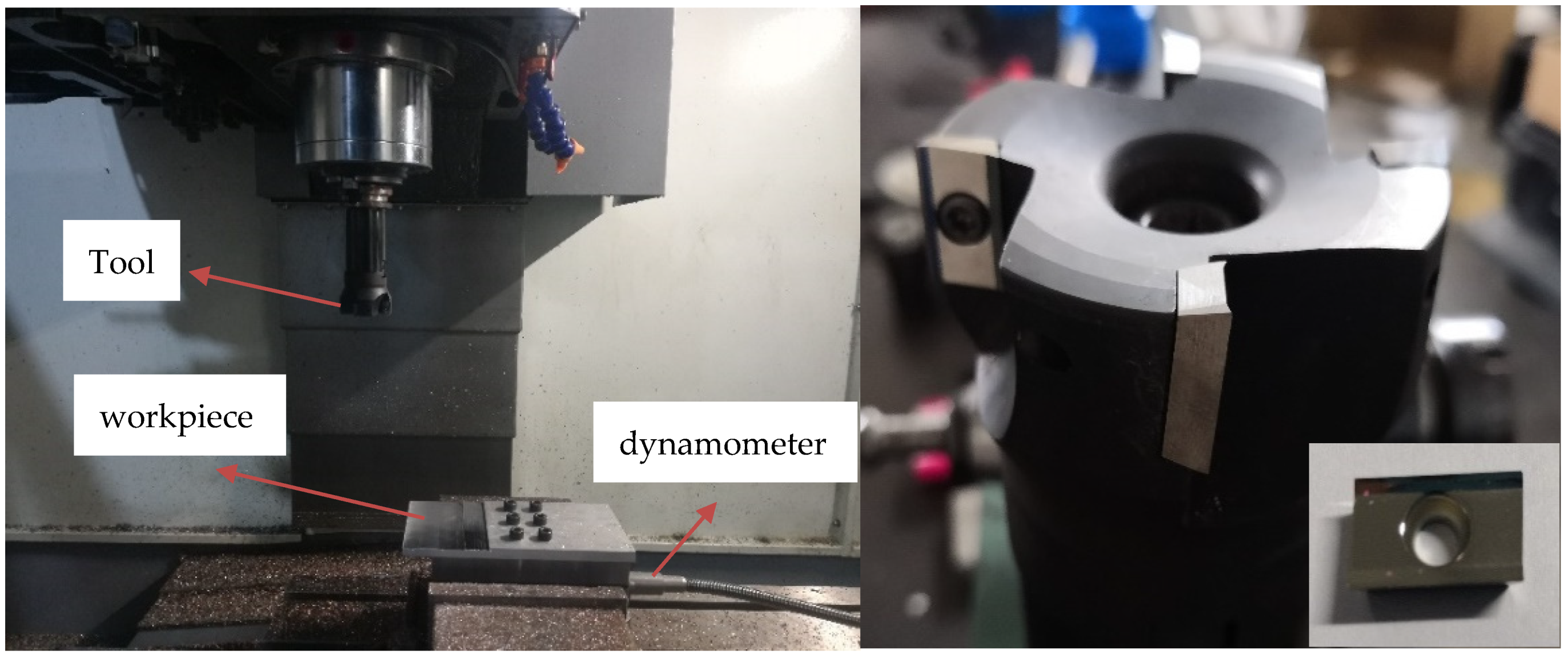

2.1. Experimental Equipment and Carbide Tool

2.2. Detailed Experimental Scheme

3. Results and Discussion

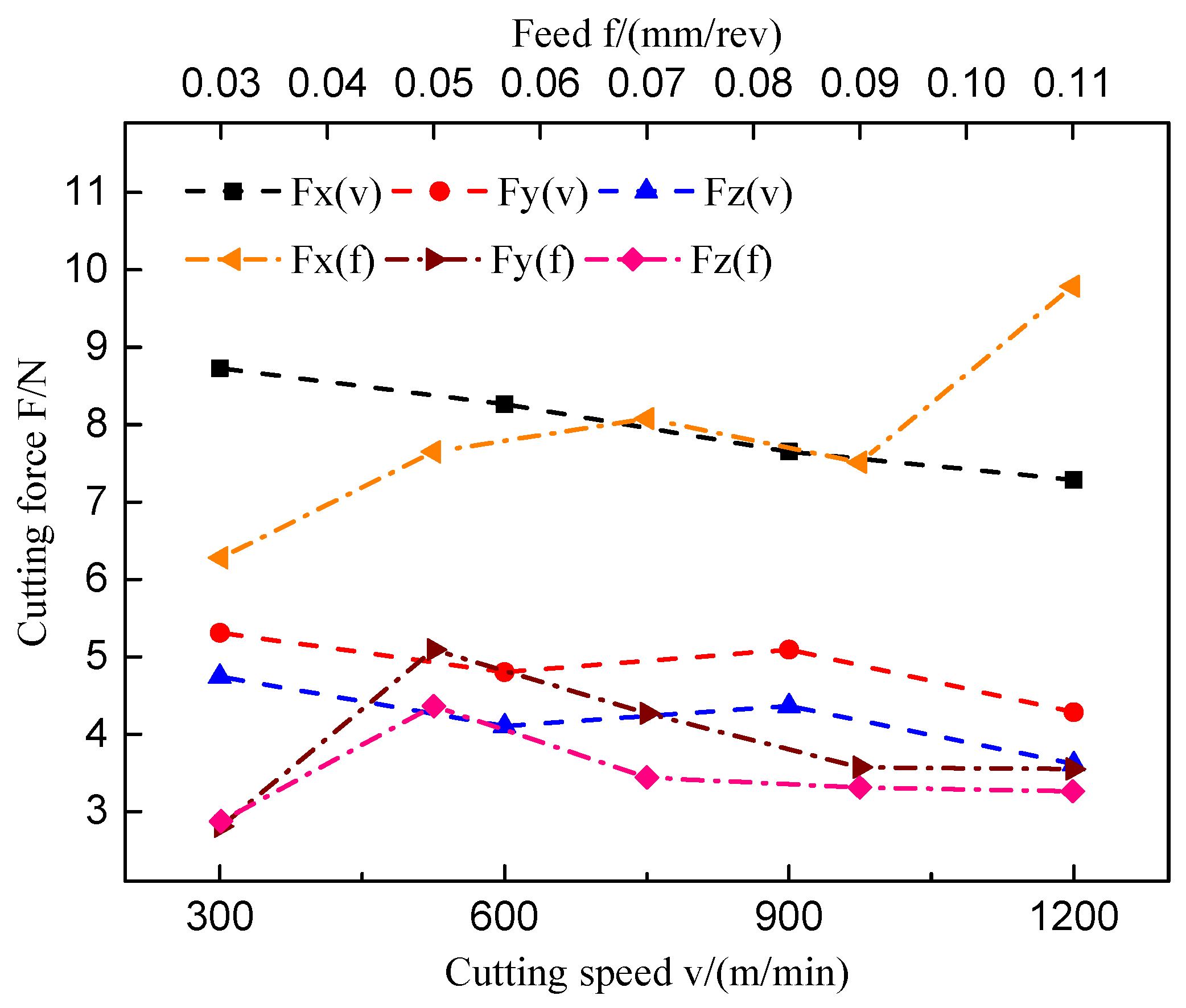

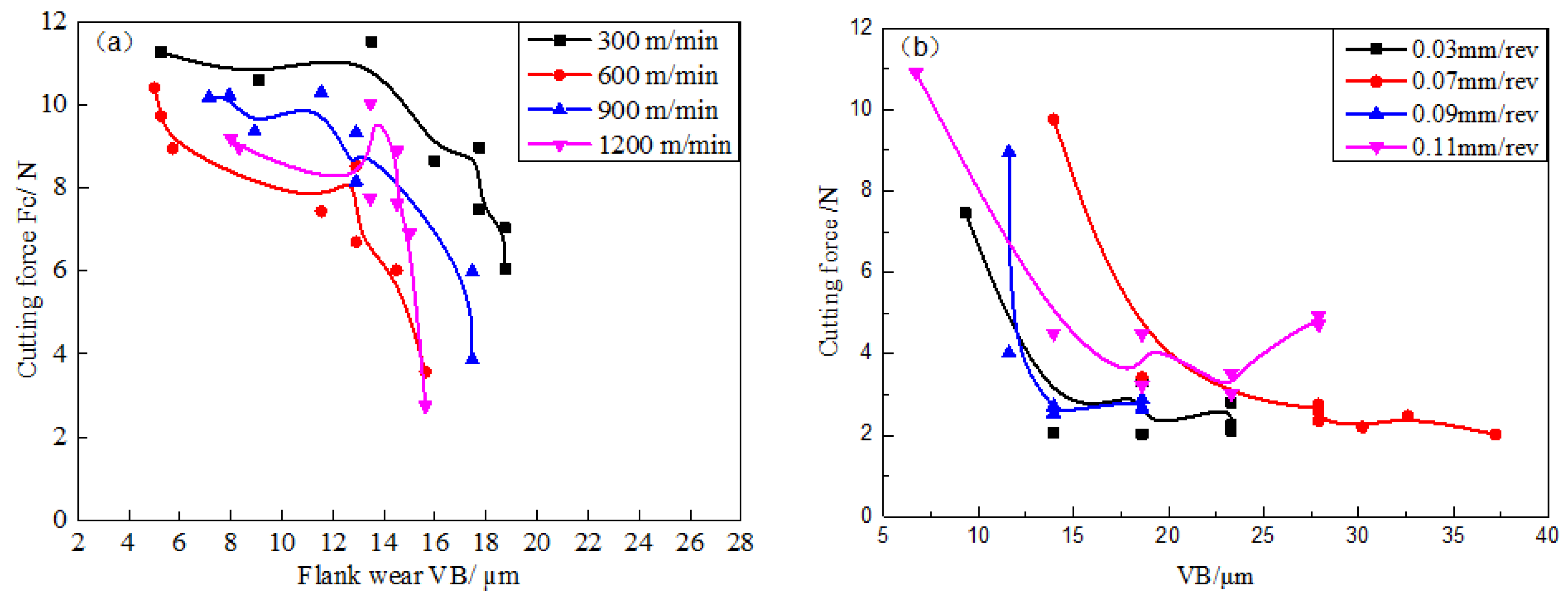

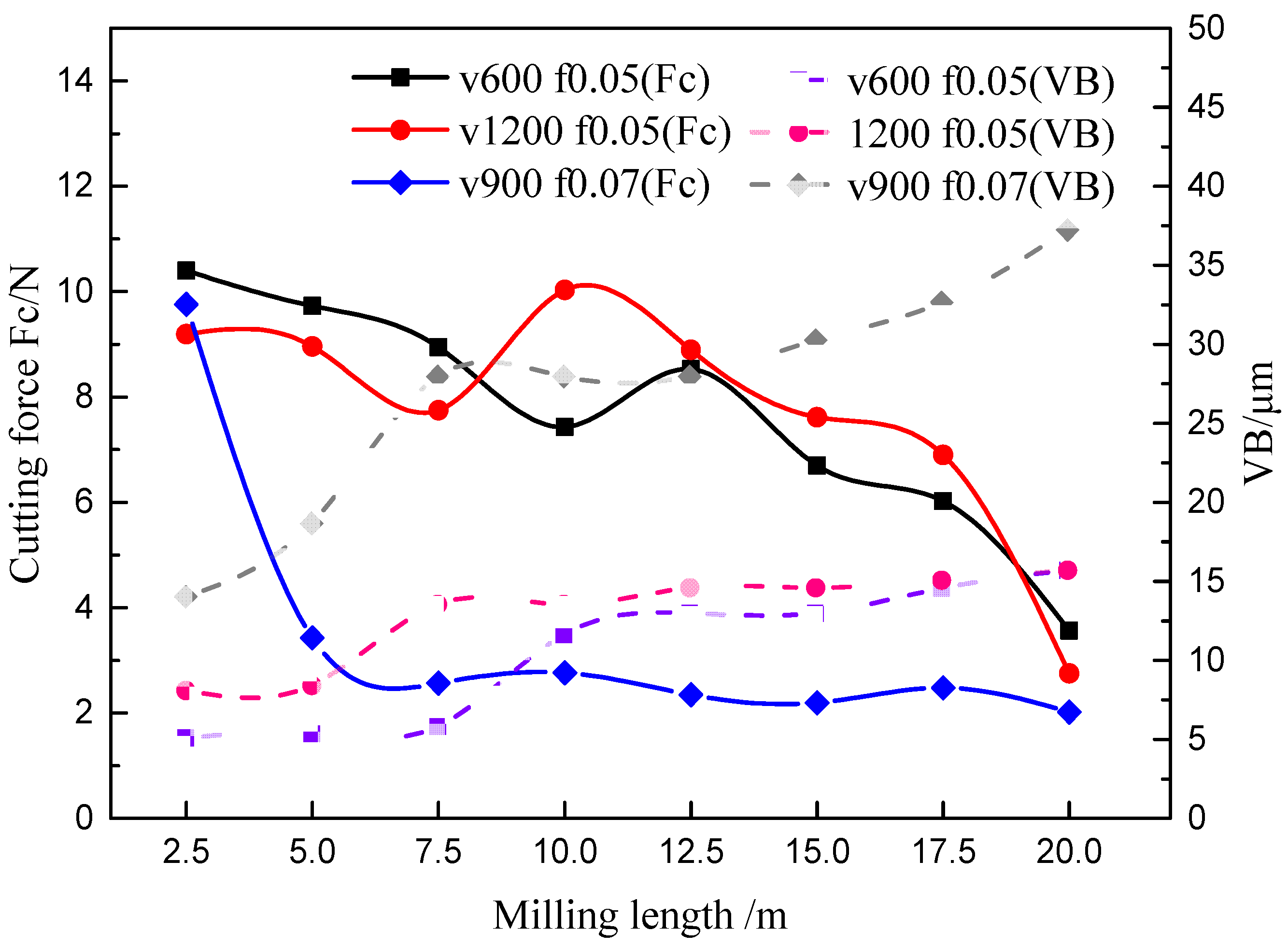

3.1. Variation of the Cutting Force in High-Speed Milling

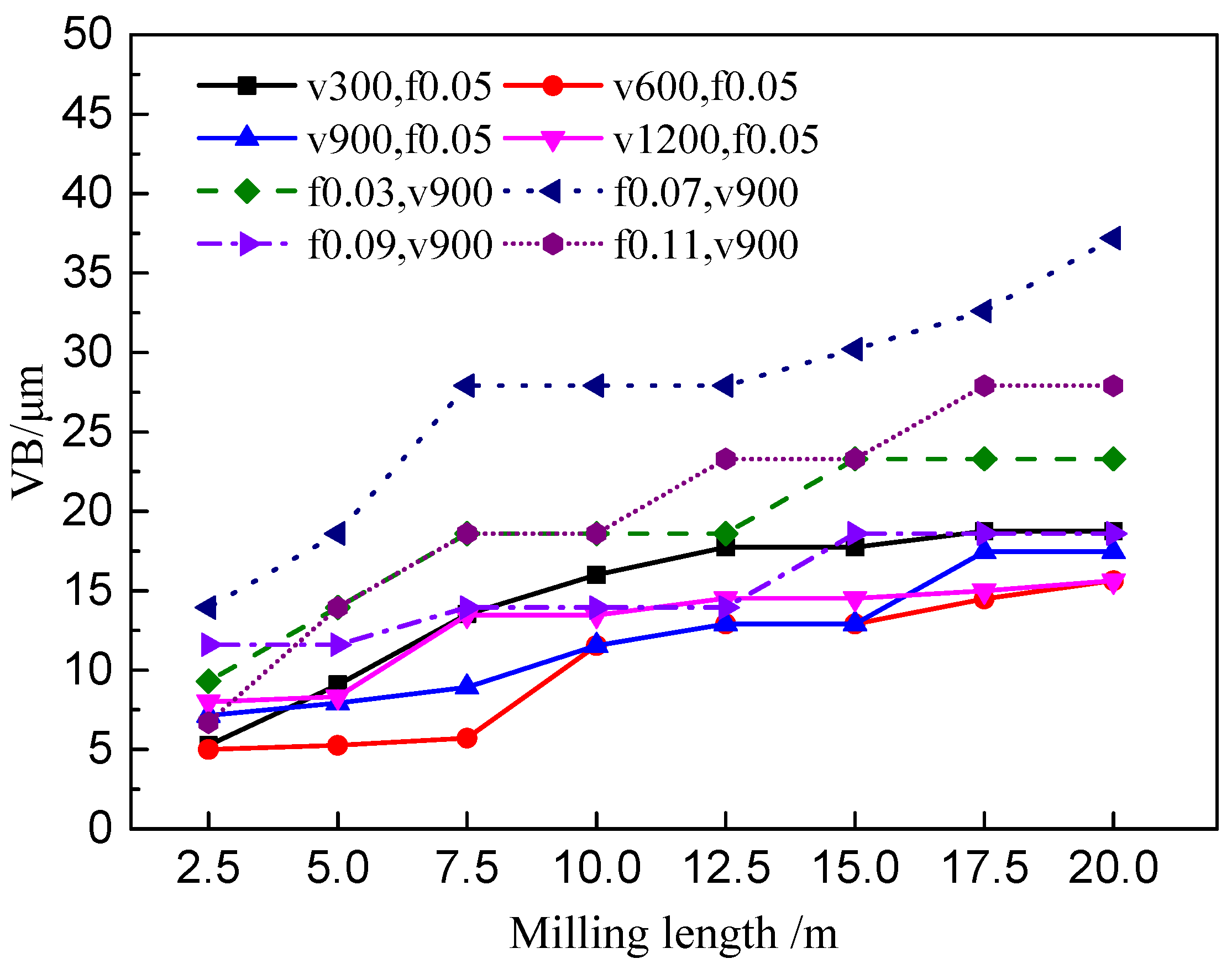

3.2. Variation of the Wear Land Width of Flank Face

3.3. The Tool Wear Morphology

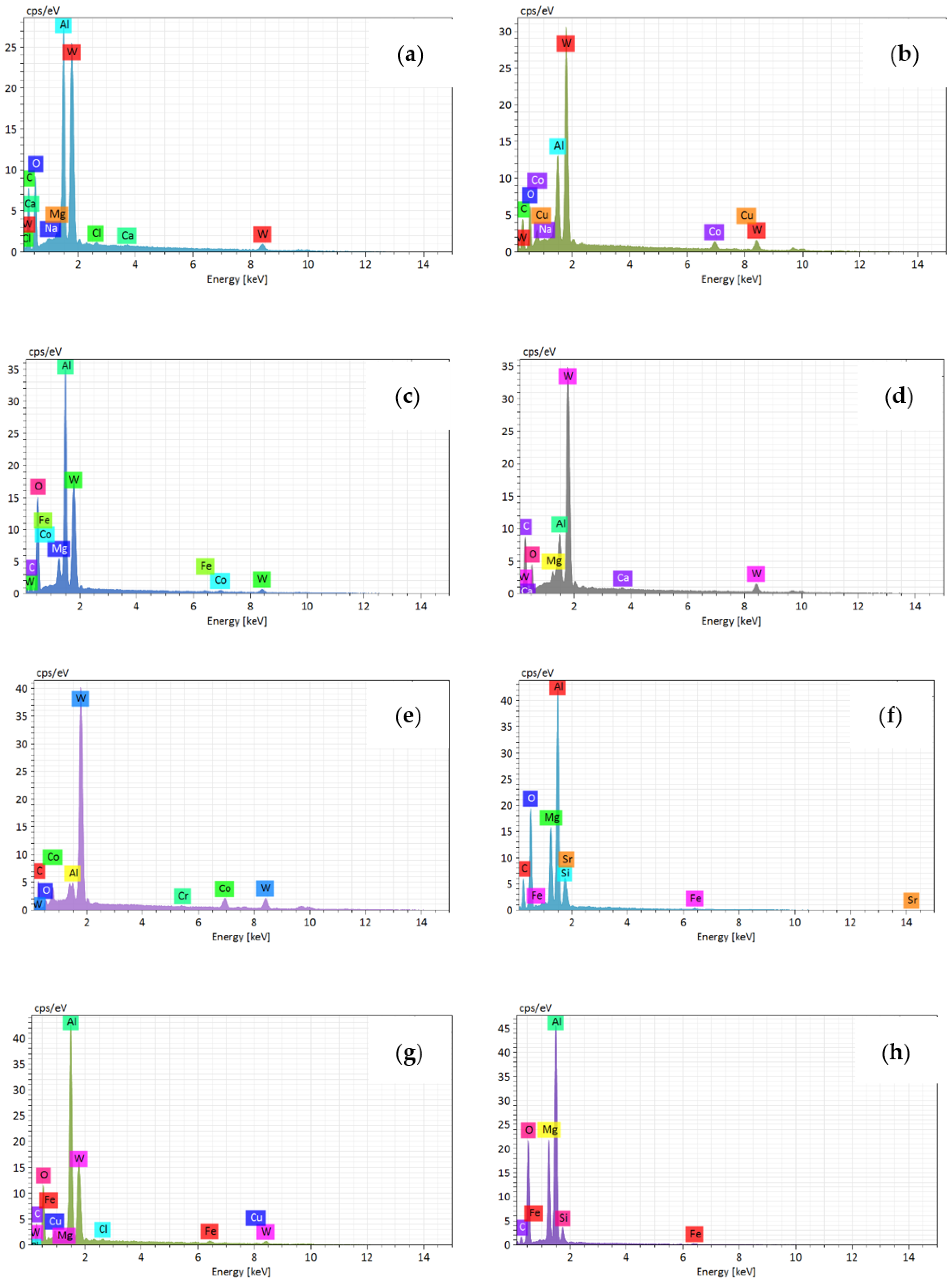

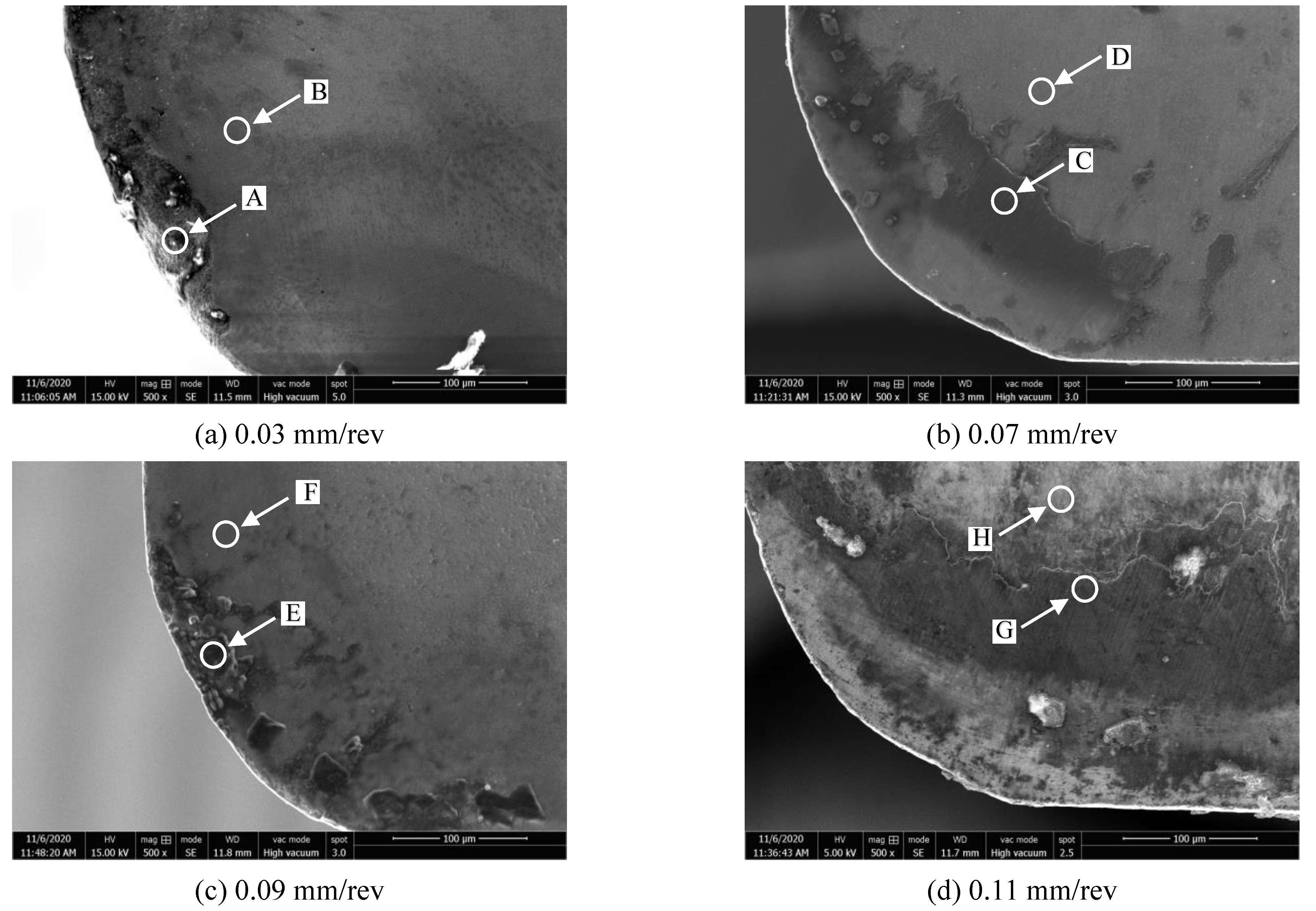

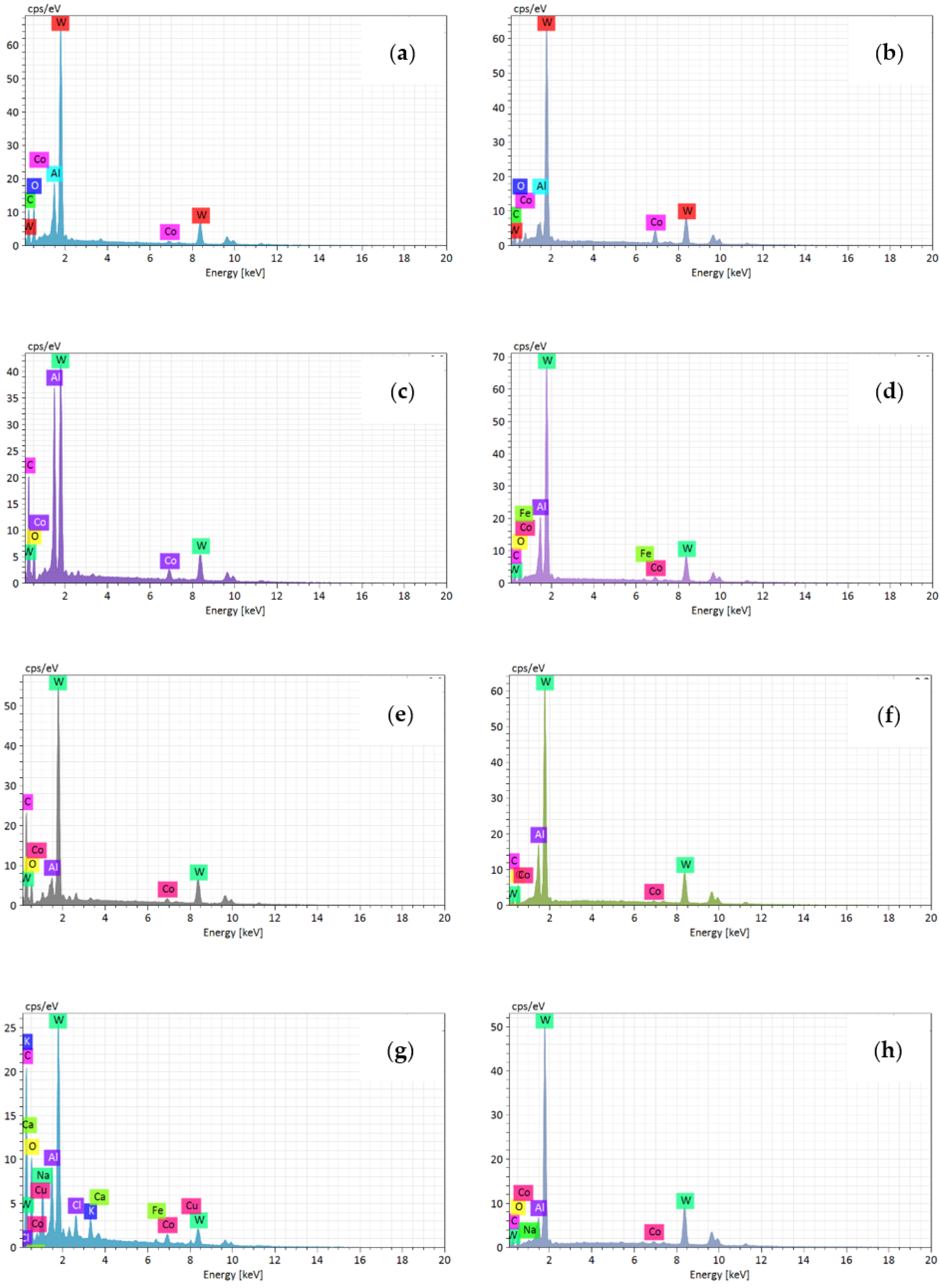

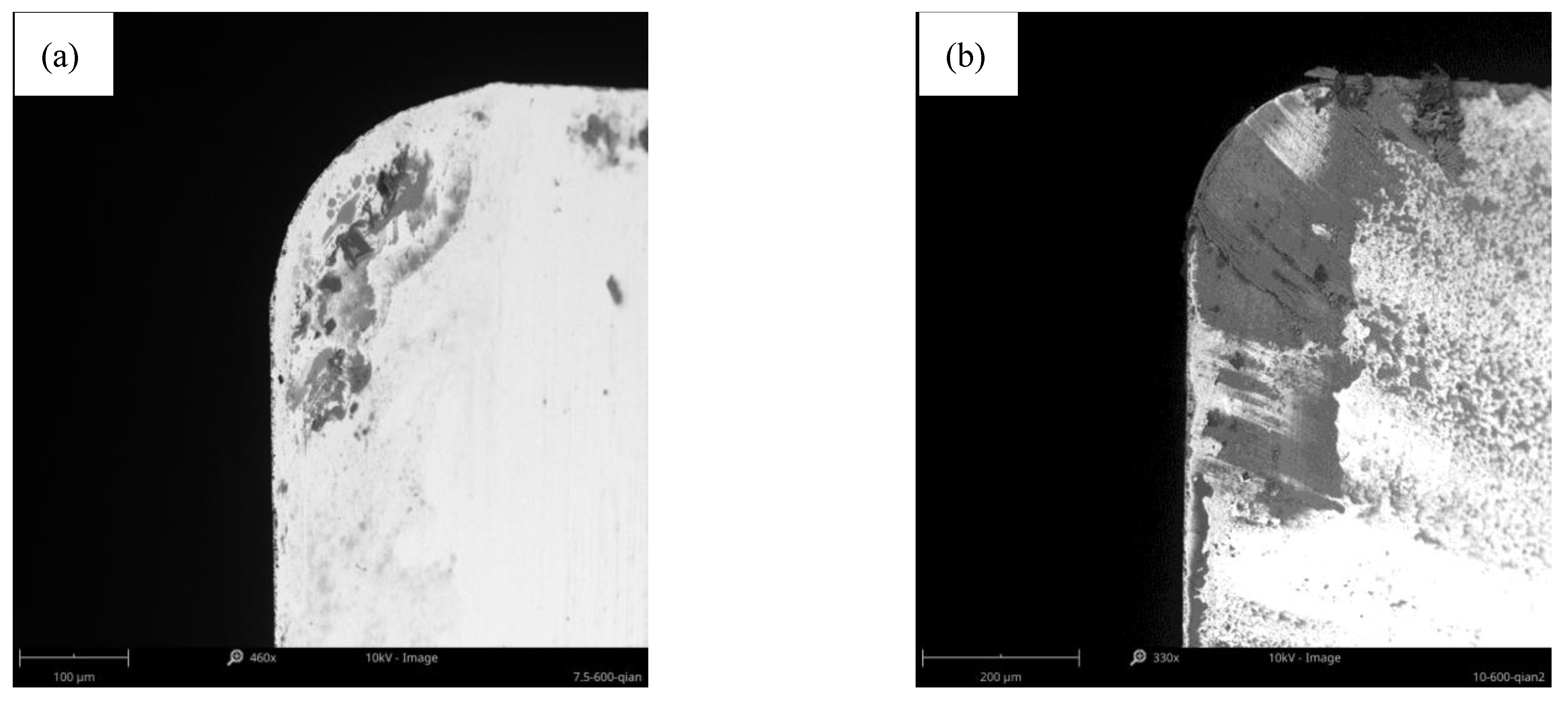

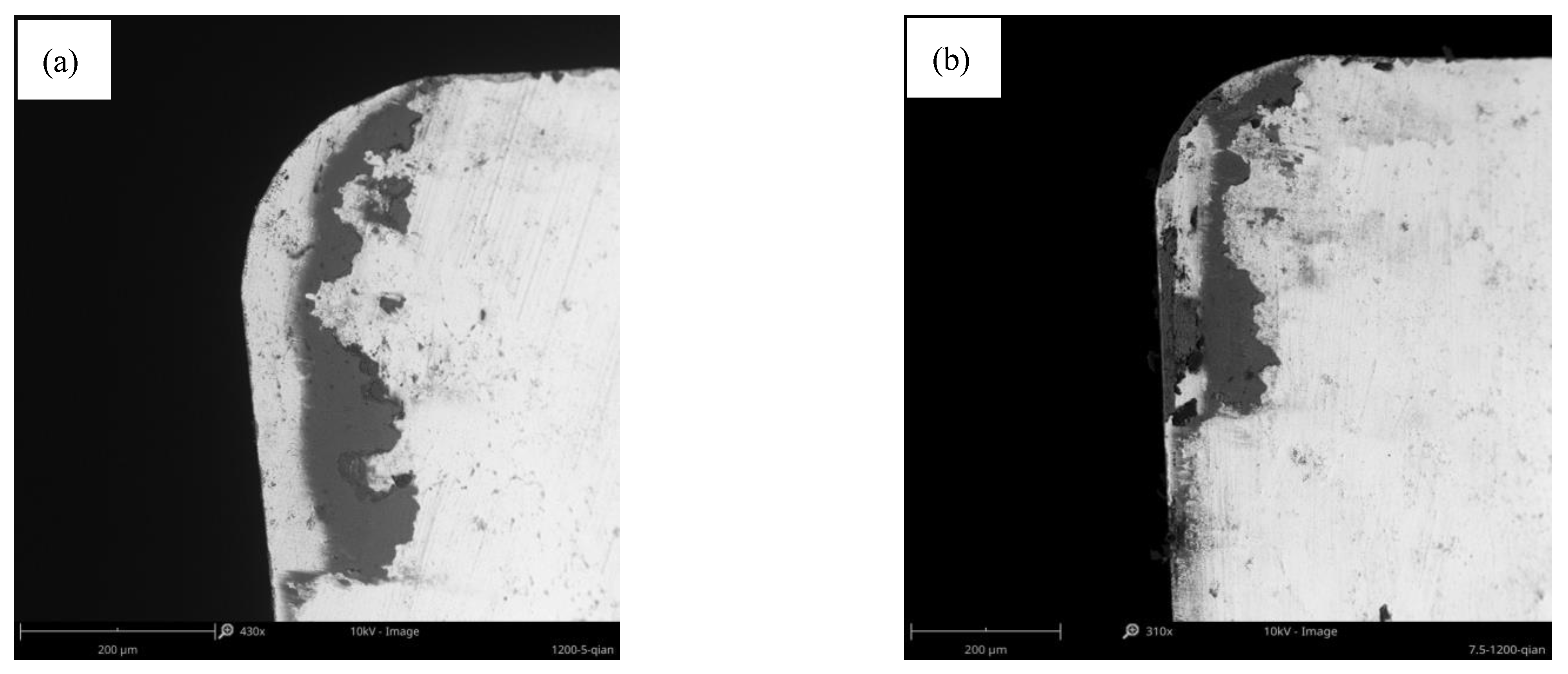

3.3.1. The Tool Wear Morphology of Rake Face

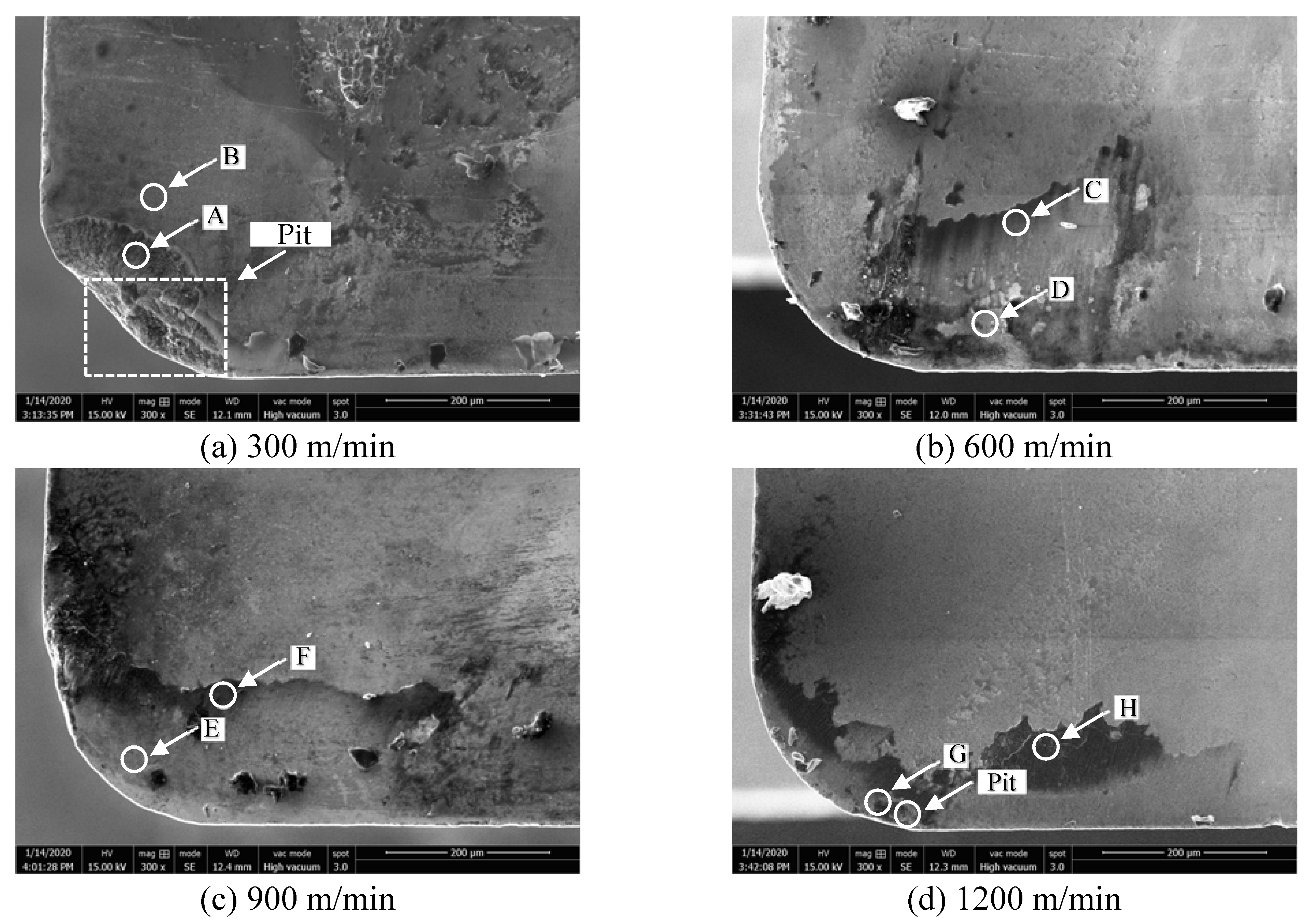

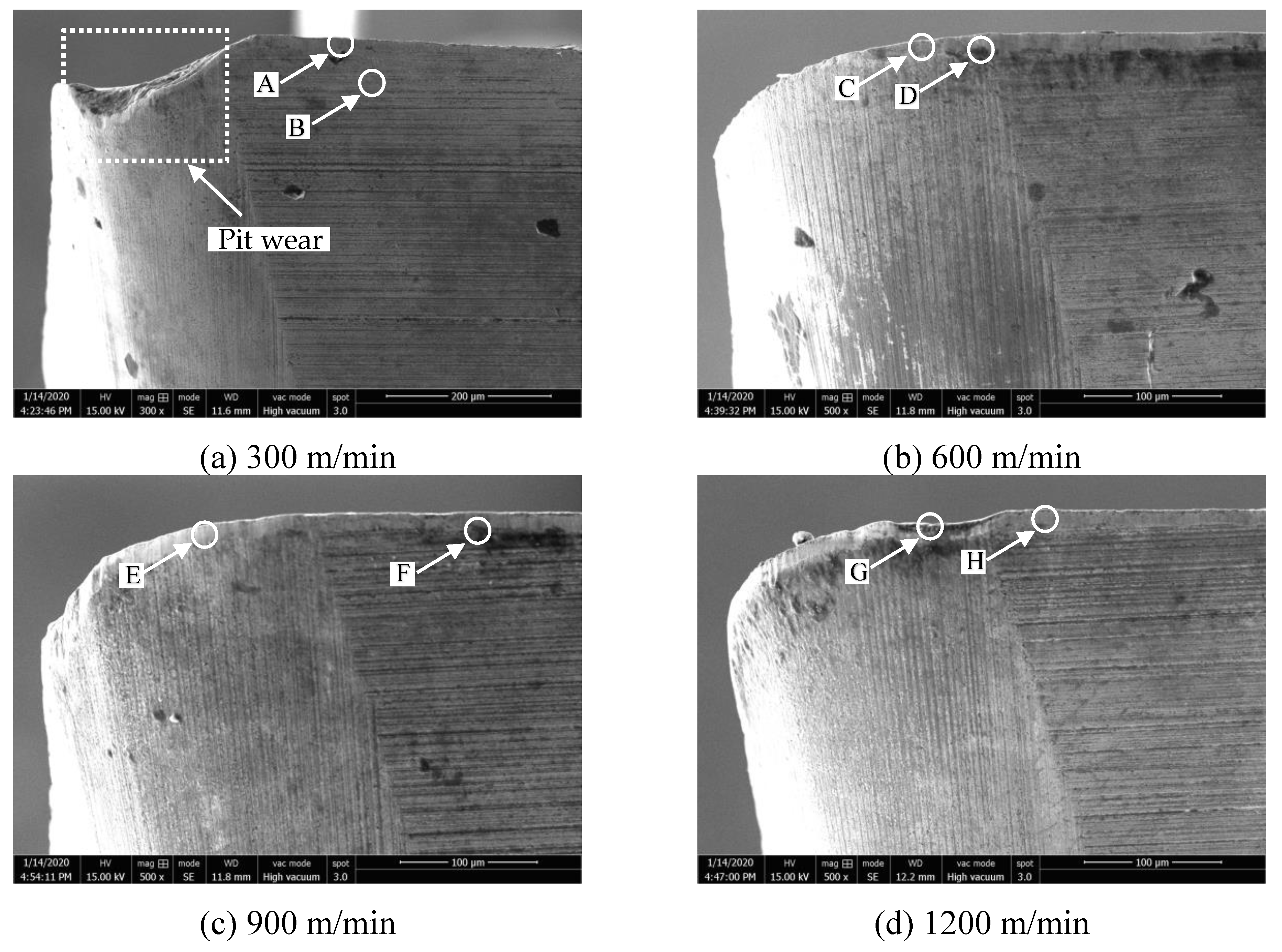

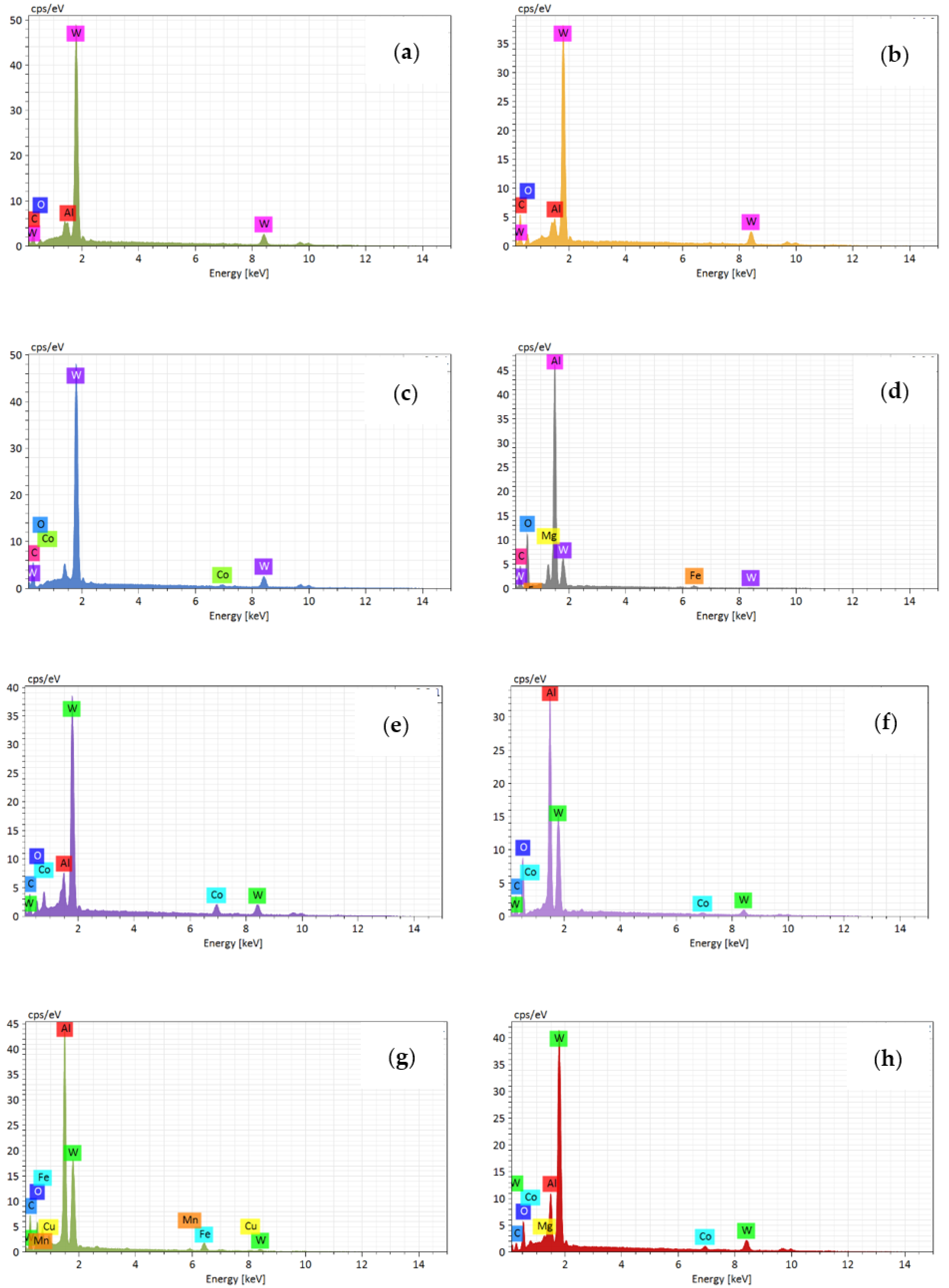

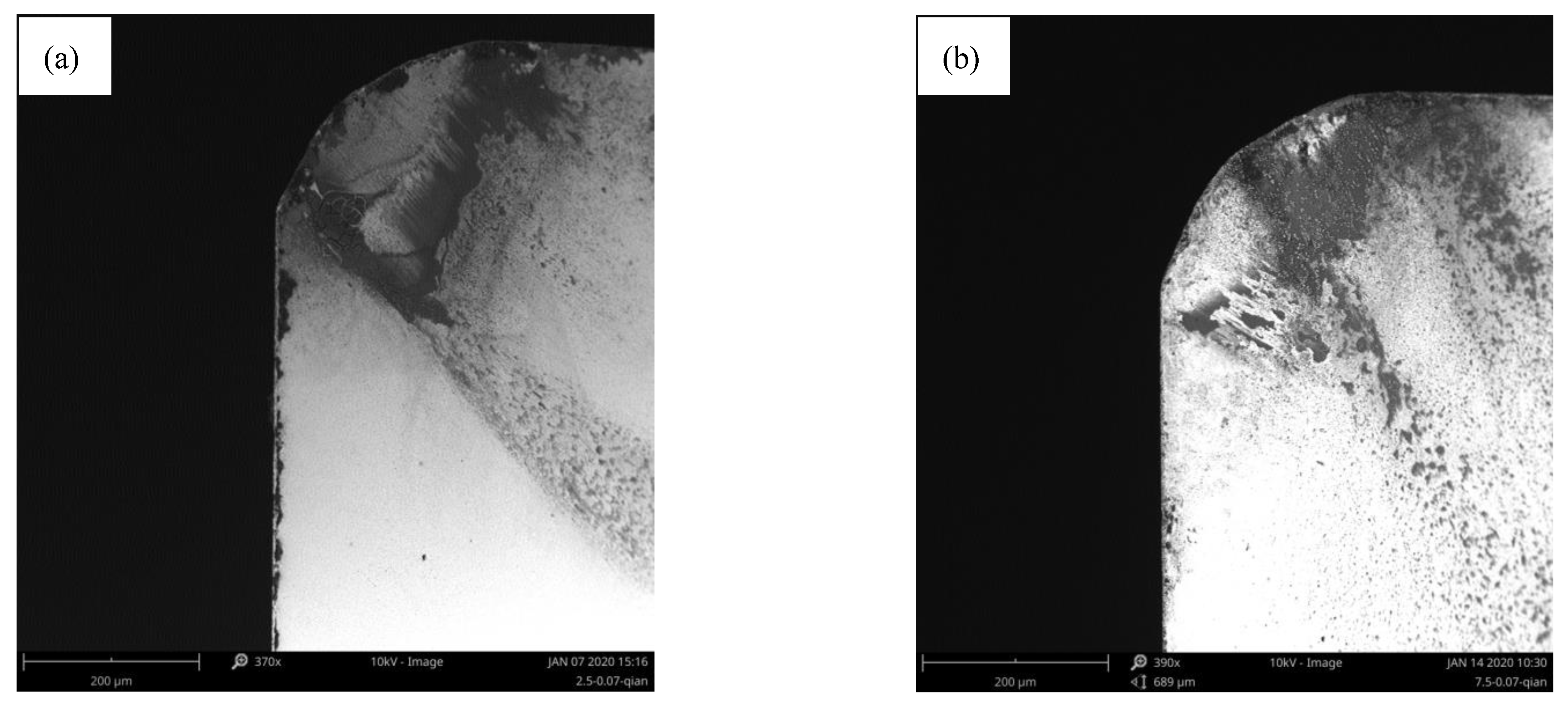

3.3.2. The Wear Morphology of Flank Face

3.4. The Tool Wear Mechanism Considering the Cutting Force Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, D.; Jia, X.; Zhu, X. Research progress of cast aluminum alloy for engine cylinder head. Cast. Tech. 2010, 31, 882–887. [Google Scholar]

- He, Y. Experimental Analysis and Cutting Stability Prediction of ADC12 Al-Si Alloy High Speed Milling; Dalian University of Technology: Dalian, China, 2014. [Google Scholar]

- He, Y.R.; Cong, M.; Bi, J.Y. High Speed Milling Stability Experiment Research on ADC12 Aluminum Alloy. Modul. Mach. Tool Autom. Manuf. Tech. 2014, 12, 10. [Google Scholar]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Karpat, Y.; Özel, T. Predictive Analytical and Thermal Modeling of Orthogonal Cutting Process—Part II: Effect of Tool Flank Wear on Tool Forces, Stresses, and Temperature Distributions. J. Manuf. Sci. Eng. 2006, 128, 33–36. [Google Scholar] [CrossRef]

- Attanasio, A.; Abeni, A.; Özel, T. Finite element simulation of high speed micro milling in the presence of tool run-out with experimental validations. Int. J. Adv. Manuf. Technol. 2019, 100, 25–35. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hua, Y.; Wang, Q. Cutting temperature measurement using an improved two-color infrared thermometer in turning Inconel 718 with whisker-reinforced ceramic tools. Ceram. Int. 2018, 44, 19002–19007. [Google Scholar] [CrossRef]

- Feng, Y.; Pan, Z.; Liang, S.Y. Temperature prediction in Inconel 718 milling with microstructure evolution. Int. J. Adv. Manuf. Technol. 2018, 95, 4607–4621. [Google Scholar] [CrossRef]

- Cui, X.; Guo, J.; Zhao, J.; Yan, Y. Chip temperature and its effects on chip morphology, cutting forces, and surface roughness in high-speed face milling of hardened steel. Int. J. Adv. Manuf. Technol. 2015, 77, 2209–2219. [Google Scholar] [CrossRef]

- Colpani, A.; Fiorentino, A.; Ceretti, E.; Attanasio, A. Tool wear analysis in micromilling of titanium alloy. Precis. Eng. 2019, 57, 83–94. [Google Scholar] [CrossRef]

- Liu, X.; Devor, R.E.; Kapoor, S.G. An Analytical Model for the Prediction of Minimum Chip Thickness in Micromachining. J. Manuf. Sci. Eng. 2006, 128, 474–481. [Google Scholar] [CrossRef]

- Zhu, K.; Zhang, Y. A generic tool wear model and its application to force modeling and wear monitoring in high speed milling. Mech. Syst. Signal Process. 2019, 115, 147–161. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, J.; Li, J. Finite element analysis on prediction of tool wear in milling titanium. J. Manuf. Sci. Eng. 2016, 52, 199–207. [Google Scholar] [CrossRef]

- Kumar, M.P.; Ramakrishna, N.; Amarnath, K.; Kumar, M.S. Study on Tool Life and its Failure Mechanisms. International J. Innov. Res. Sci. Technol. 2015, 2, 126–131. [Google Scholar]

- Liang, X.; Liu, Z.; Yao, G.; Wang, B.; Ren, X. Investigation of surface topography and its deterioration resulting from tool wear evolution when dry turning of titanium alloy Ti-6Al-4V. Tribol. Int. 2019, 135, 130–142. [Google Scholar] [CrossRef]

- Tan, D.; Guo, W.; Wang, H.; Lin, H.; Wang, C. Cutting performance and wear mechanism of TiB2-B4C ceramic cutting tools in high speed turning of Ti6Al4V alloy. Ceram. Int. 2018, 44, 15495–15502. [Google Scholar] [CrossRef]

- An, Q.; Chen, J.; Tao, Z. Experimental investigation on tool wear characteristics of PVD and CVD coatings during face milling of Tie6242S and Ti-555 titanium alloys. Int. J. Refract. Metals Hard Mater. 2019, 86, 105091. [Google Scholar] [CrossRef]

- Kong, X.; Yang, L.; Zhang, H.; Zhou, K.; Wang, Y. Cutting performance and coated tool wear mechanisms in laser-assisted milling K24 nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2015, 77, 2151–2163. [Google Scholar] [CrossRef]

- Wu, S.; Li, Z.; Wang, C.; Li, S.; Ma, W. Tool wear of corner continuous milling in deep machining of hardened steel pocket. Int. J. Adv. Manuf. Technol. 2018, 97, 1315–1333. [Google Scholar]

- Wang, Y.; Zou, B.; Huang, C. Tool wear mechanisms and micro-channels quality in micro-machining of Ti-6Al-4V alloy using the Ti(C7N3)-based cermet micro-mills. Tribol. Int. 2019, 134, 60–76. [Google Scholar] [CrossRef]

- Vipindas, K.; Mathew, J. Wear behavior of TiAlN coated WC tool during micro end milling of Ti-6Al-4V and analysis of surface roughness. Wear 2019, 424, 165–182. [Google Scholar]

- Wang, Y.; Zou, B.; Wang, J.; Wu, Y.; Huang, C. Effect of the progressive tool wear on surface topography and chip formation in micro-milling of Ti–6Al–4V using Ti(C7N3)-based cermet micro-mill. Tribol. Int. 2019, 141, 105900. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Lu, Y.T.; Lin, Y.F.; Huang, T.P.; Hsu, F.C.; Liang, S.Y. Force modeling of Inconel 718 laser-assisted end milling under recrystallization effects. Int. J. Adv. Manuf. Technol. 2017, 92, 1–10. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.P.; Lu, Y.T.; Lin, Y.F.; Hsu, F.C.; Lin, C.F.; Lu, Y.C.; Liang, S.Y. Flank tool wear prediction of laser-assisted milling. J. Manuf. Process. 2019, 43, 292–299. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L.; Yang, Z. Comparative investigation of tool wear mechanism and corresponding machined surface characterization in feed-direction ultrasonic vibration assisted milling of ti-6al-4v from dynamic view. Wear 2019, 436, 203006. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Géhin, D.; Gomez, S.; Manaud, J.P.; Petitcorps, Y.L.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Fernández-Vidal, S.R.; Mayuet, P.; Rivero, A.; Salguero, J.; del Sol, I.; Marcos, M. Analysis of the Effects of Tool Wear on Dry Helical Milling of Ti6Al4V Alloy. Procedia Eng. 2015, 132, 593–599. [Google Scholar] [CrossRef]

- Ramirez, C.; Idhil Ismail, A.; Gendarme, C.; Dehmas, M.; Aeby-Gautier, E.; Poulachon, G.; Rossi, F. Understanding the diffusion wear mechanisms of WC-10%Co carbide tools during dry machining of titanium alloys. Wear 2017, 390, 61–70. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.; Cao, X.; Yu, X.; Wang, Y. Analysis on the tool wear behavior of 7050-T7451 aluminum alloy under ultrasonic elliptical vibration cutting. Wear 2021, 466–467, 203538. [Google Scholar] [CrossRef]

- Zhang, P.; Yue, X.J.; Wang, P.H.; Yu, X. Surface integrity and tool wear mechanism of 7050-T7451 aluminum alloy under dry cutting. Vacuum 2020, 184, 109886. [Google Scholar]

- Belhocine, A.; Ghazaly, N.M. Effects of material properties on generation of brake squeal noise using finite element method. Latin Am. J. Solids Struct. 2015, 12, 1432–1447. [Google Scholar] [CrossRef]

- Junge, T.; Liborius, H.; Mehner, T.; Nestler, A.; Schubert, A.; Lampke, T. Measurement system based on the Seebeck effect for the determination of temperature and tool wear during turning of aluminum alloys. Procedia CIRP 2020, 93, 1435–1441. [Google Scholar] [CrossRef]

- Meng, X.; Lin, Y.; Mi, S. An Improved Johnson–Cook Constitutive Model and Its Experiment Validation on Cutting Force of ADC12 Aluminum Alloy during High-Speed Milling. Met. Open Access Metall. J. 2020, 10, 1038. [Google Scholar] [CrossRef]

| Chemical Compositions (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mg | Mn | Zn | Ni | Sn | Al |

| 9.6–12 | <1.3 | 1.5–3.5 | <0.3 | <0.5 | <1.0 | <0.5 | ≤0.3 | others |

| Material Parameter | Workpiece | Tool |

|---|---|---|

| density/kg·m−3 | 2.67 × 103 | 15 × 103 |

| Young modulus/GPa | 76 | 800 |

| Poisson’s ratio | 0.33 | 0.2 |

| specific heat/J·kg−1·K−1 | 962 | 200 |

| thermal conductivity/W·m−1·K−1 | 92.6 | 46 |

| expansion coefficient/K−1 | 2.06 × 10−5 | 4.7 × 10−6 |

| Cutting Parameters | Value |

|---|---|

| Cutting speed | 300~1200 m/min |

| Feed | 0.03~0.11 mm/rev |

| Cutting depth | 0.5 mm |

| Cutting width | 3 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; Lin, Y.; Mi, S. The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect. Materials 2021, 14, 1054. https://doi.org/10.3390/ma14051054

Meng X, Lin Y, Mi S. The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect. Materials. 2021; 14(5):1054. https://doi.org/10.3390/ma14051054

Chicago/Turabian StyleMeng, Xinxin, Youxi Lin, and Shaowei Mi. 2021. "The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect" Materials 14, no. 5: 1054. https://doi.org/10.3390/ma14051054

APA StyleMeng, X., Lin, Y., & Mi, S. (2021). The Research of Tool Wear Mechanism for High-Speed Milling ADC12 Aluminum Alloy Considering the Cutting Force Effect. Materials, 14(5), 1054. https://doi.org/10.3390/ma14051054