Environmental Impact on VOCs Emission of a Recycled Asphalt Mixture with a High Percentage of RAP

Abstract

1. Introduction

2. Materials and Methods

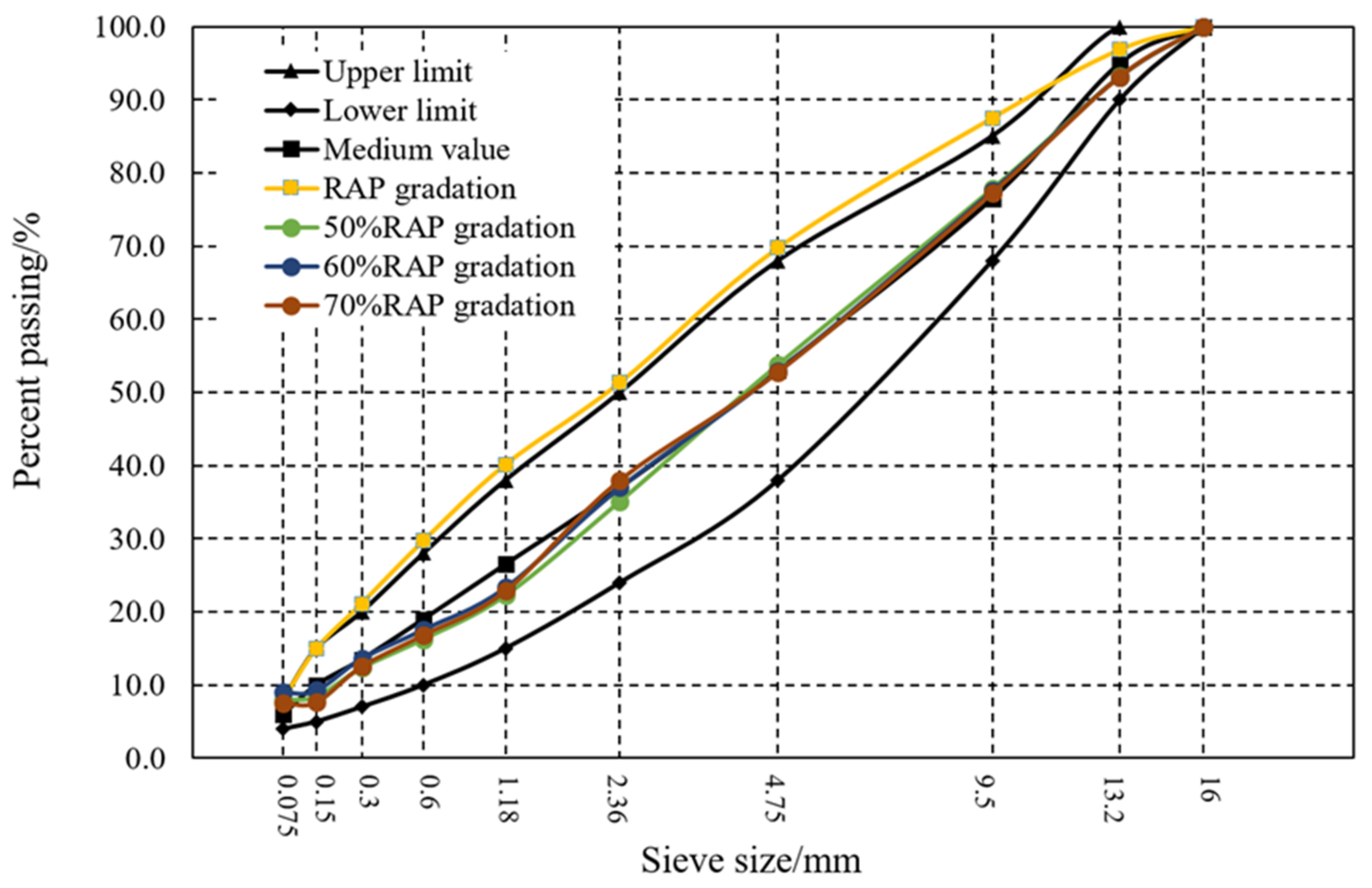

2.1. Materials

2.2. Sample Collection

2.3. Rheological Properties Test

2.4. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.5. Servicing Performance Test

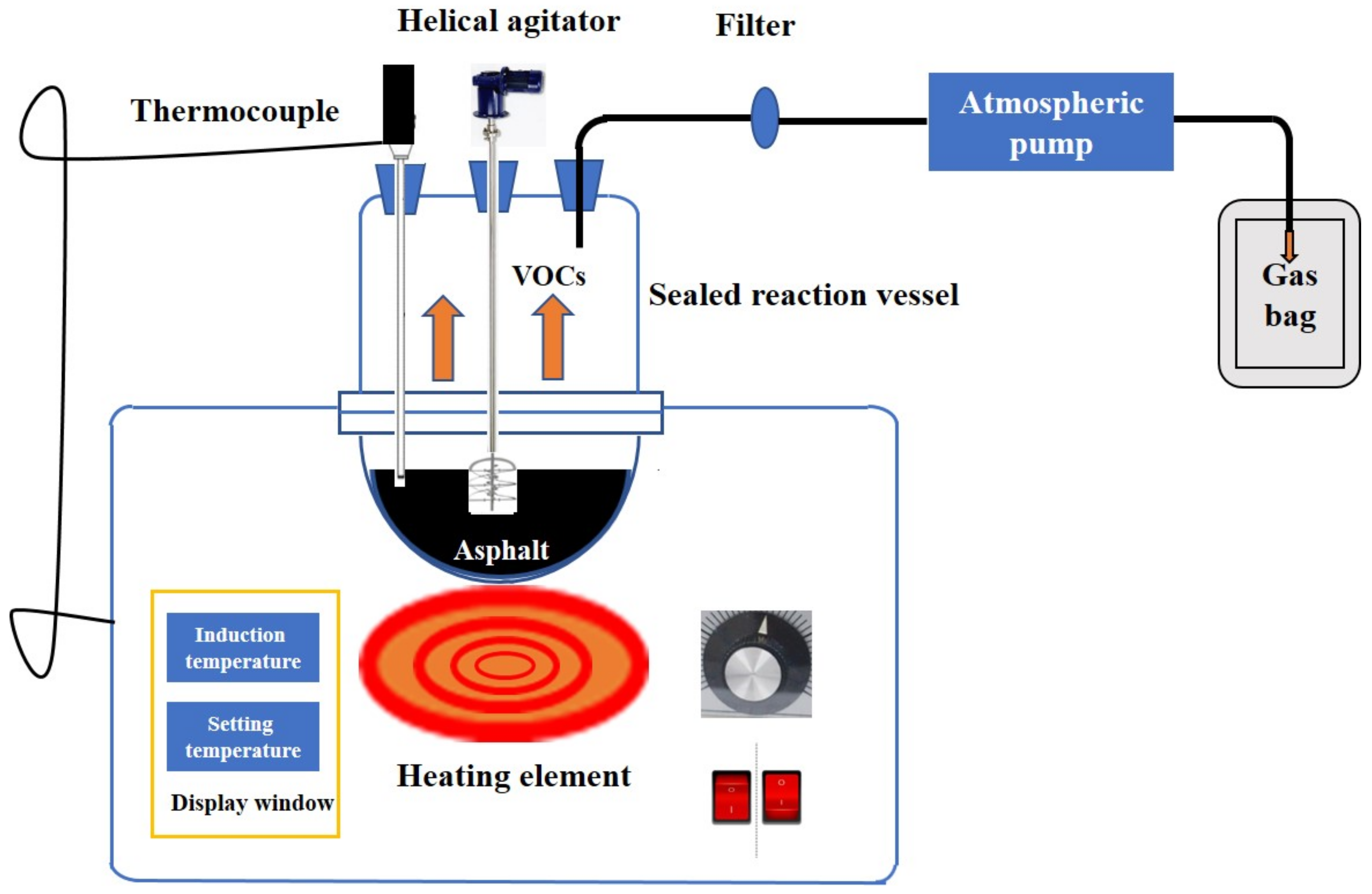

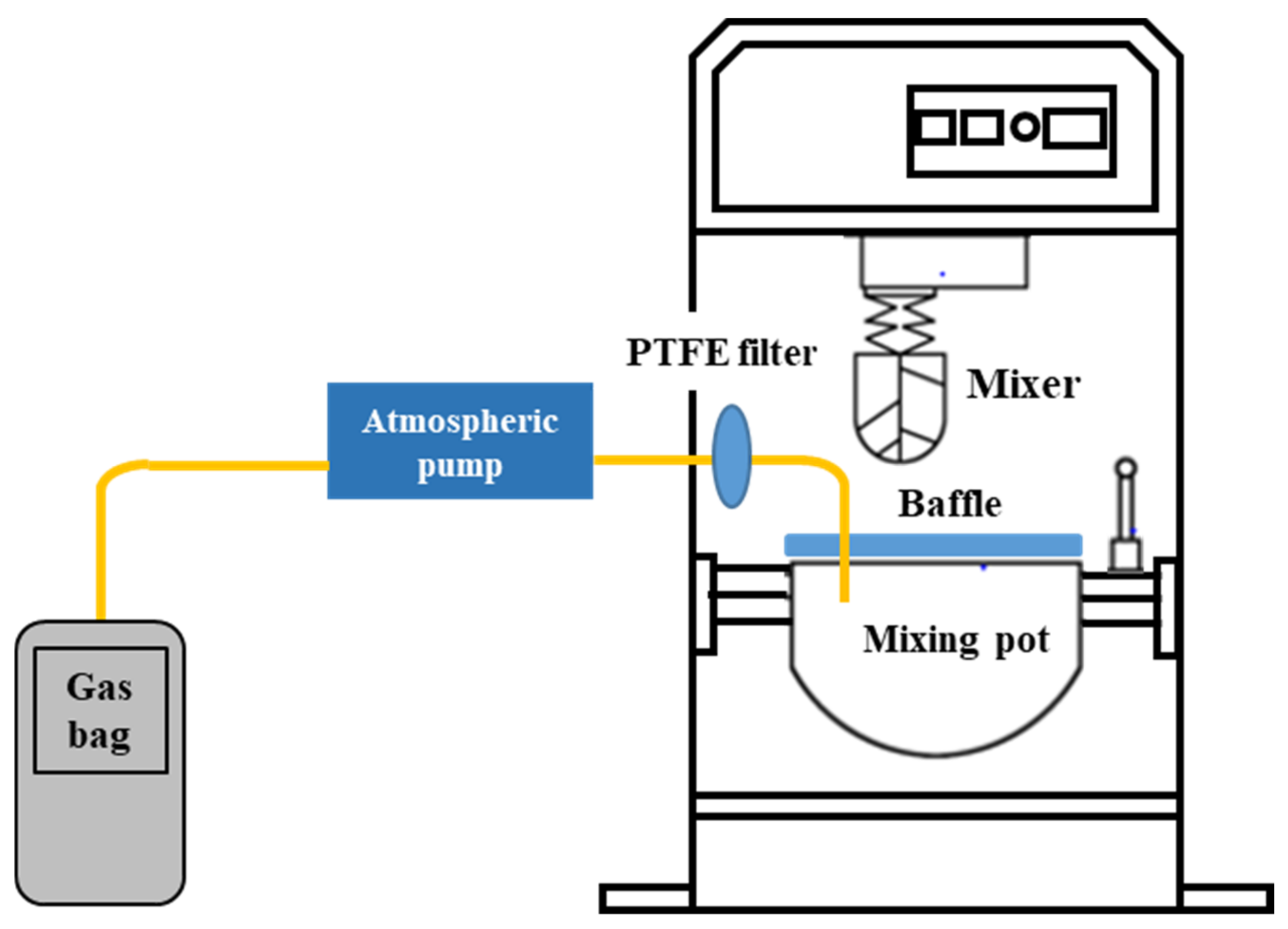

2.6. Asphalt VOCs Test

3. Results and Discussion

3.1. Effect of Mixed Recycled Asphalt Binder

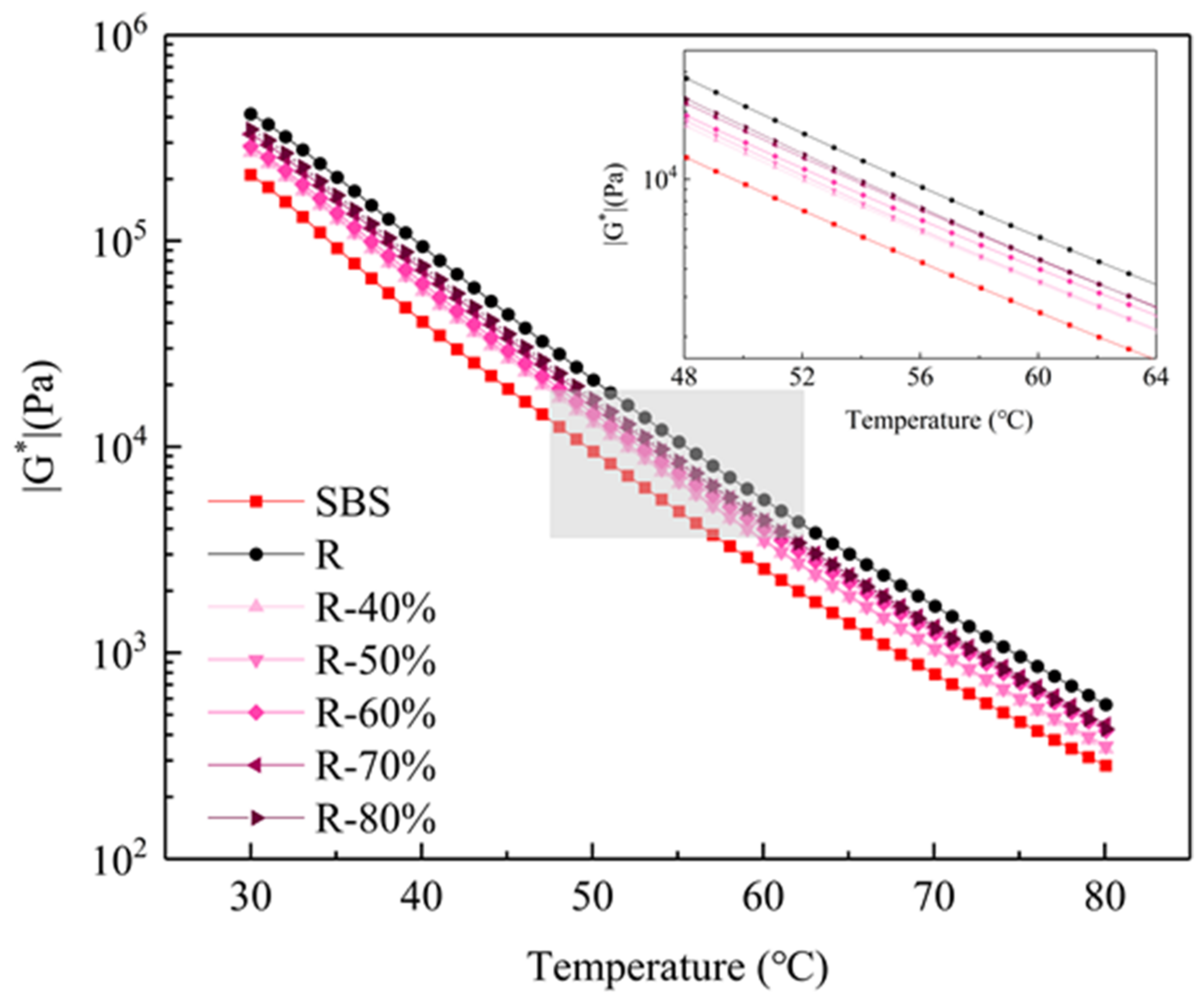

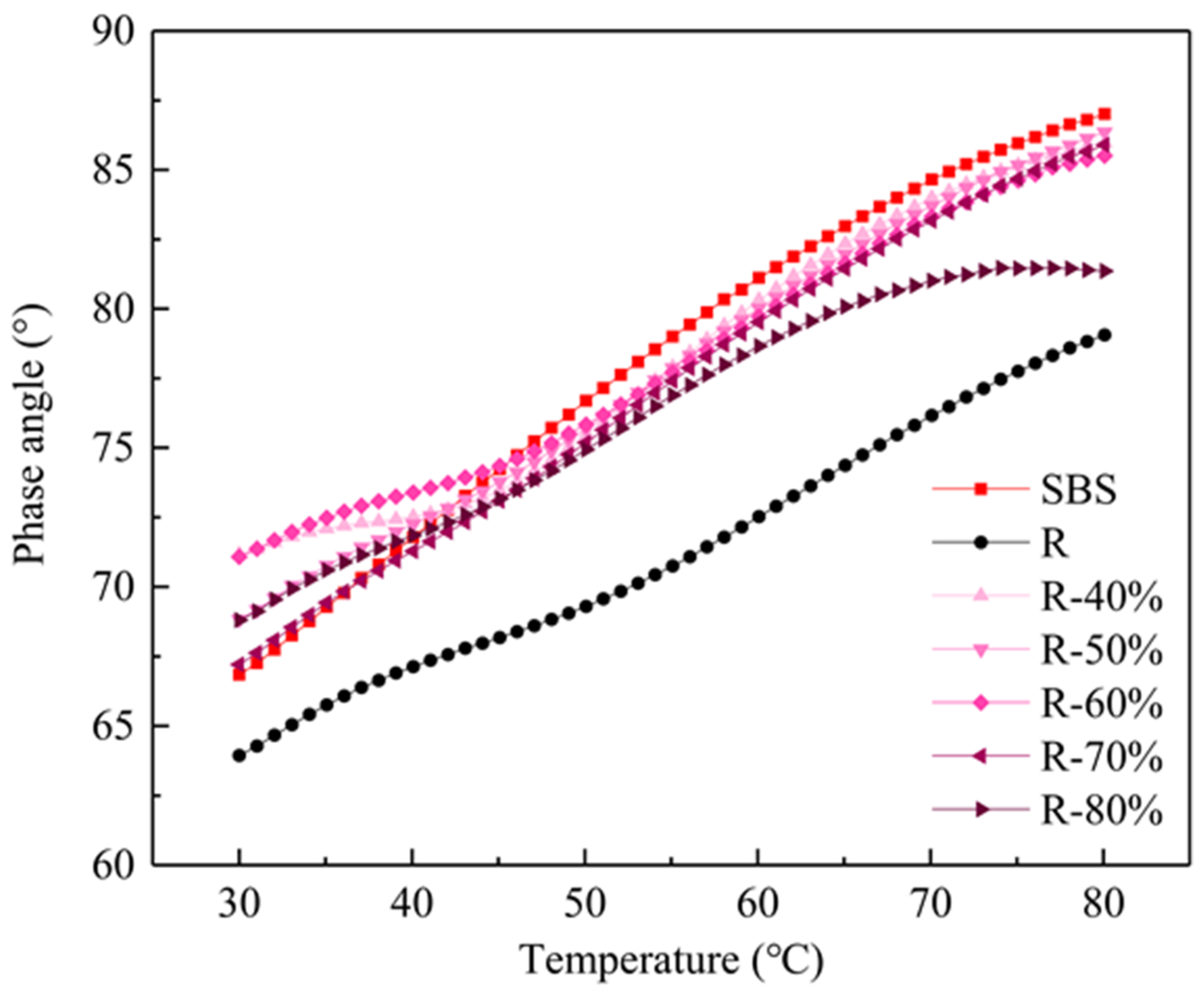

3.1.1. Performance Evaluation

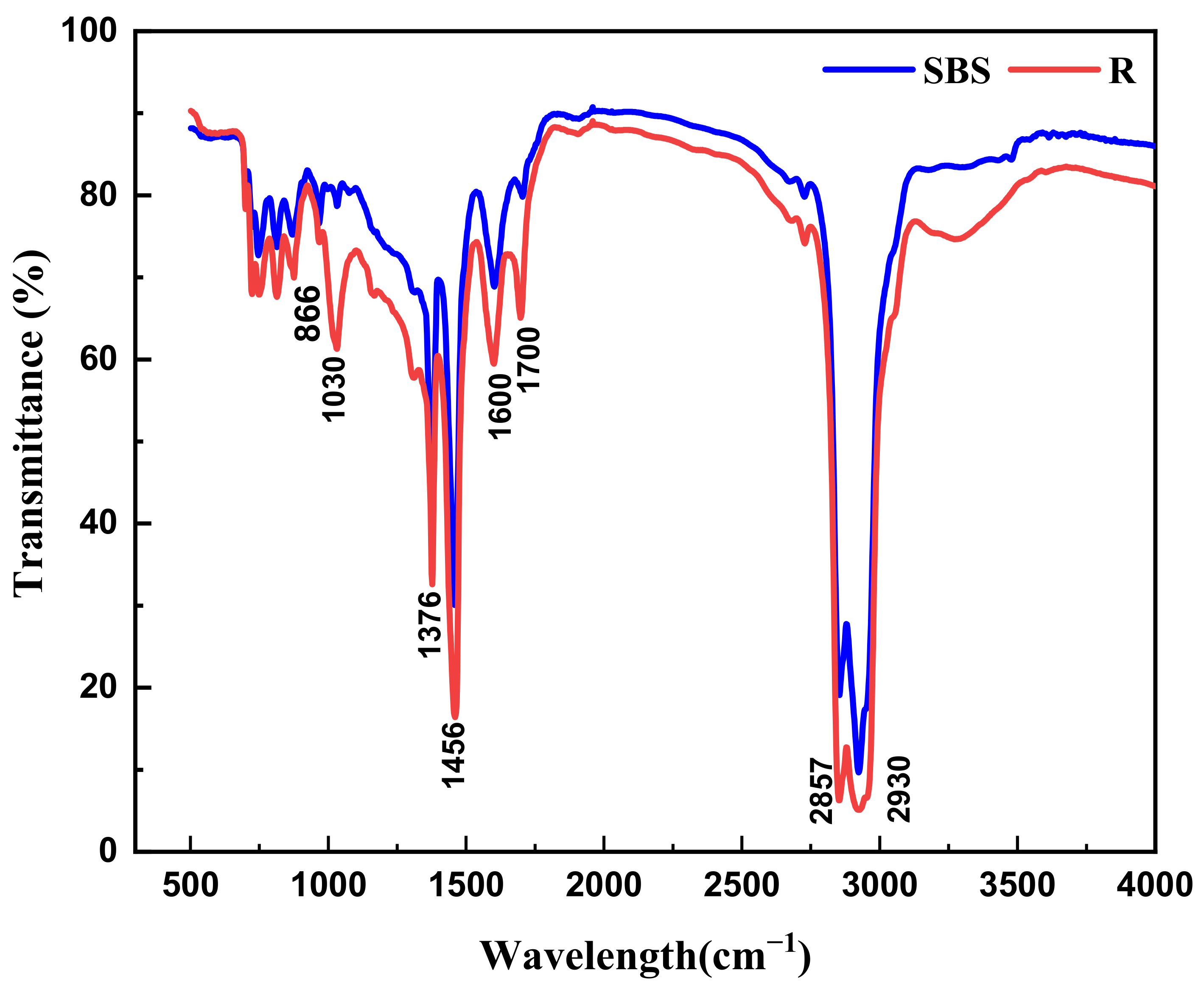

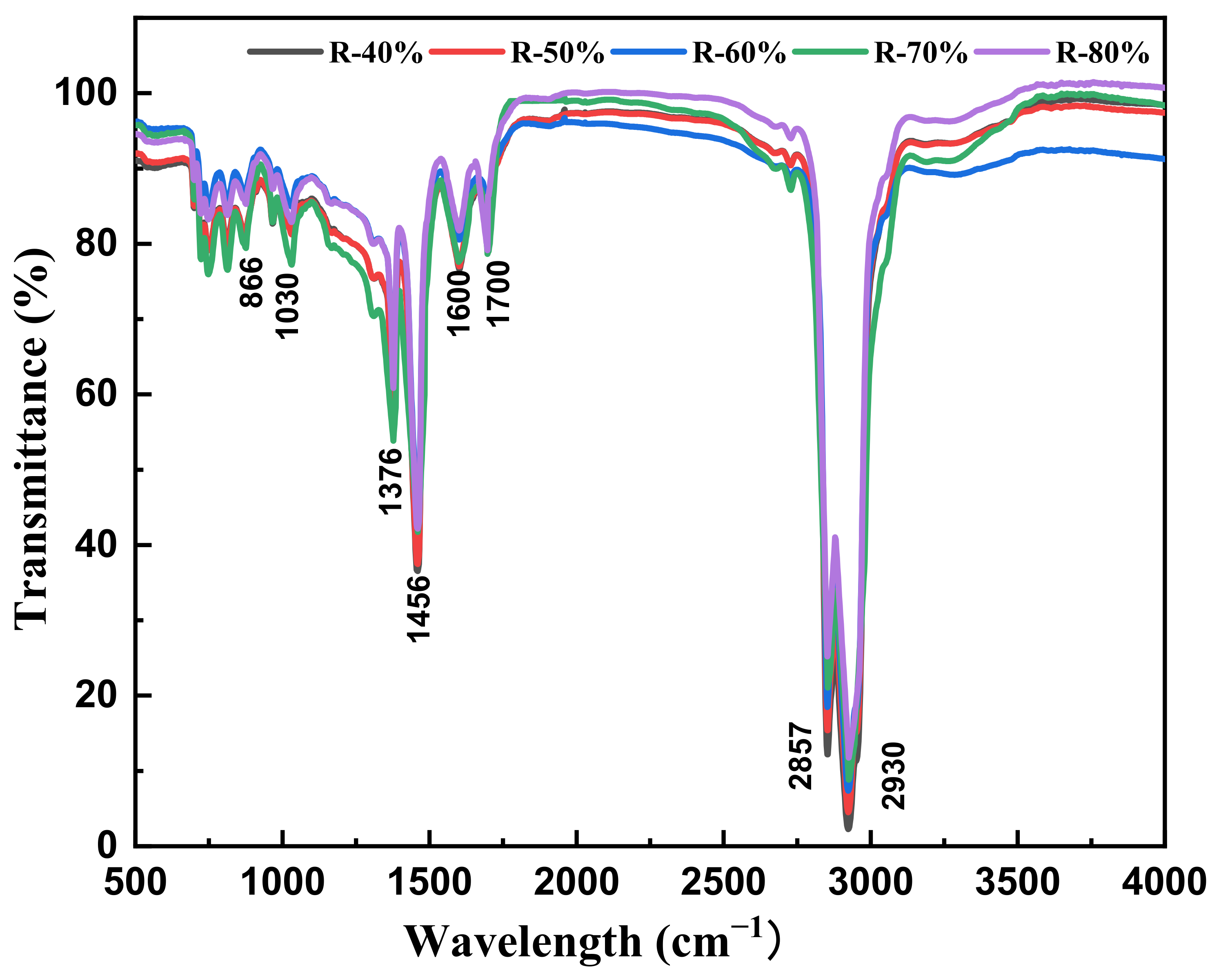

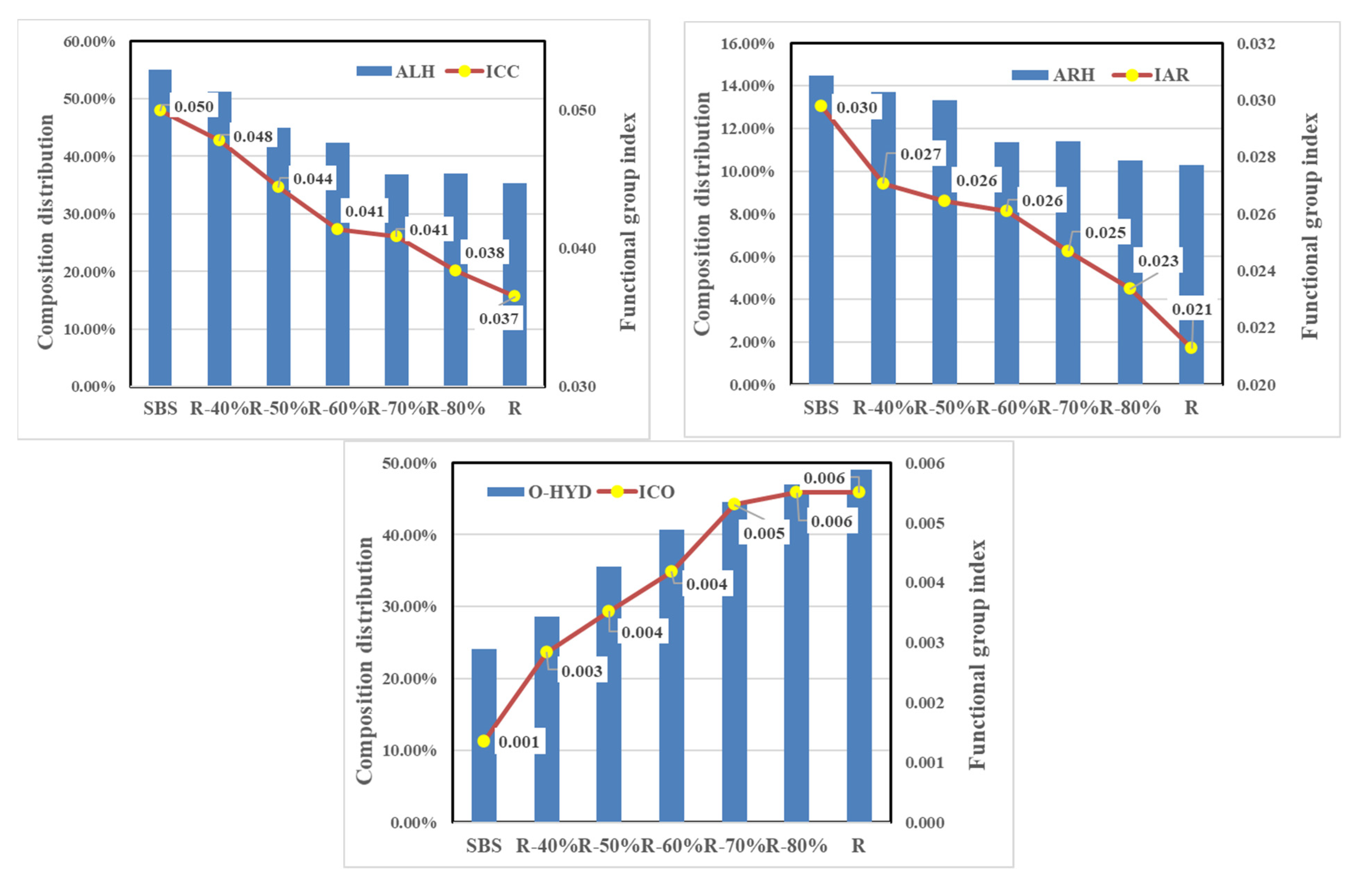

3.1.2. Chemical Structure Analysis

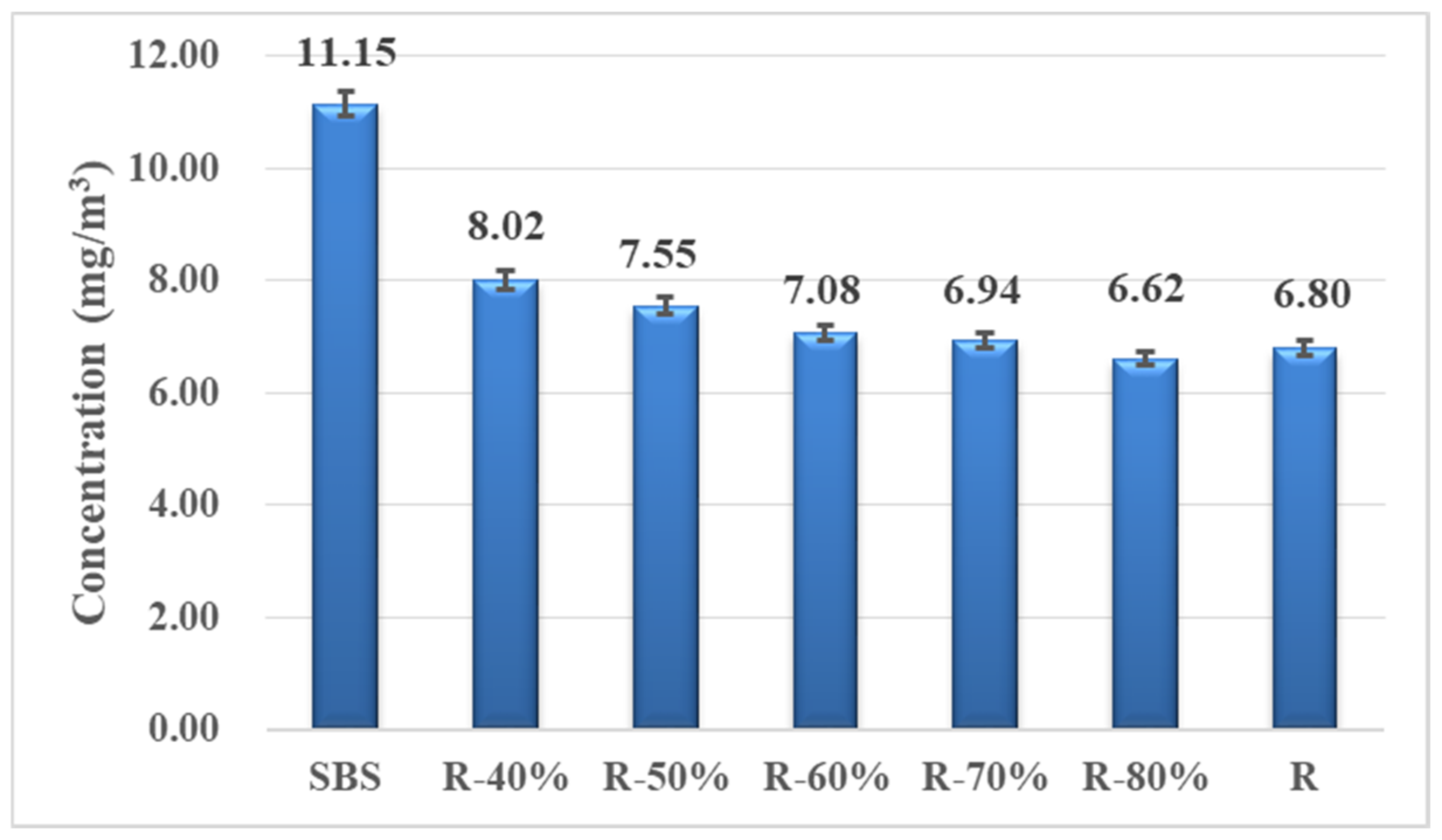

3.1.3. VOCs Emission Assessment

3.2. Effect of Recycled Asphalt Mixture with High Percentage of RAP

3.2.1. Performance Evaluation

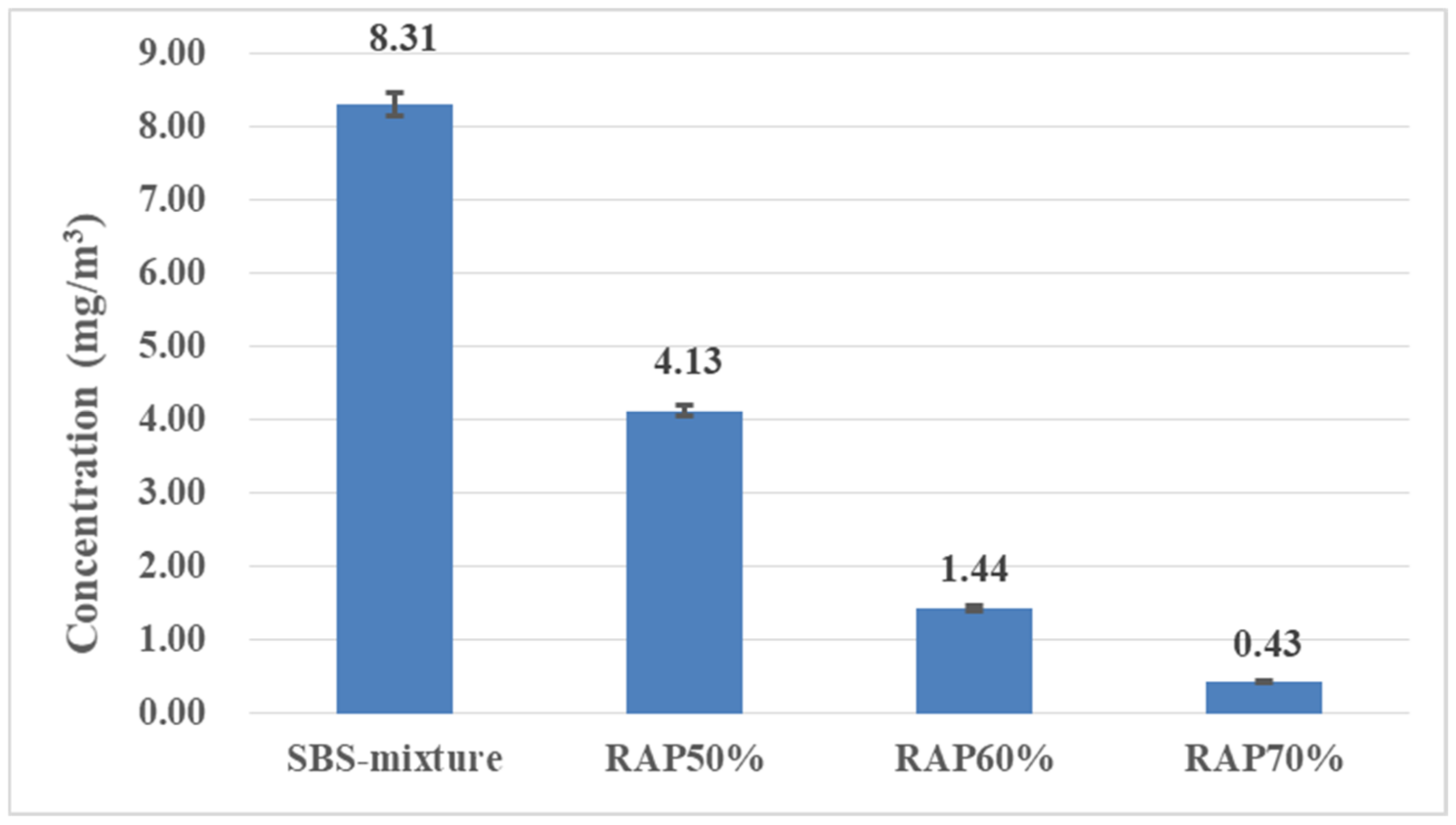

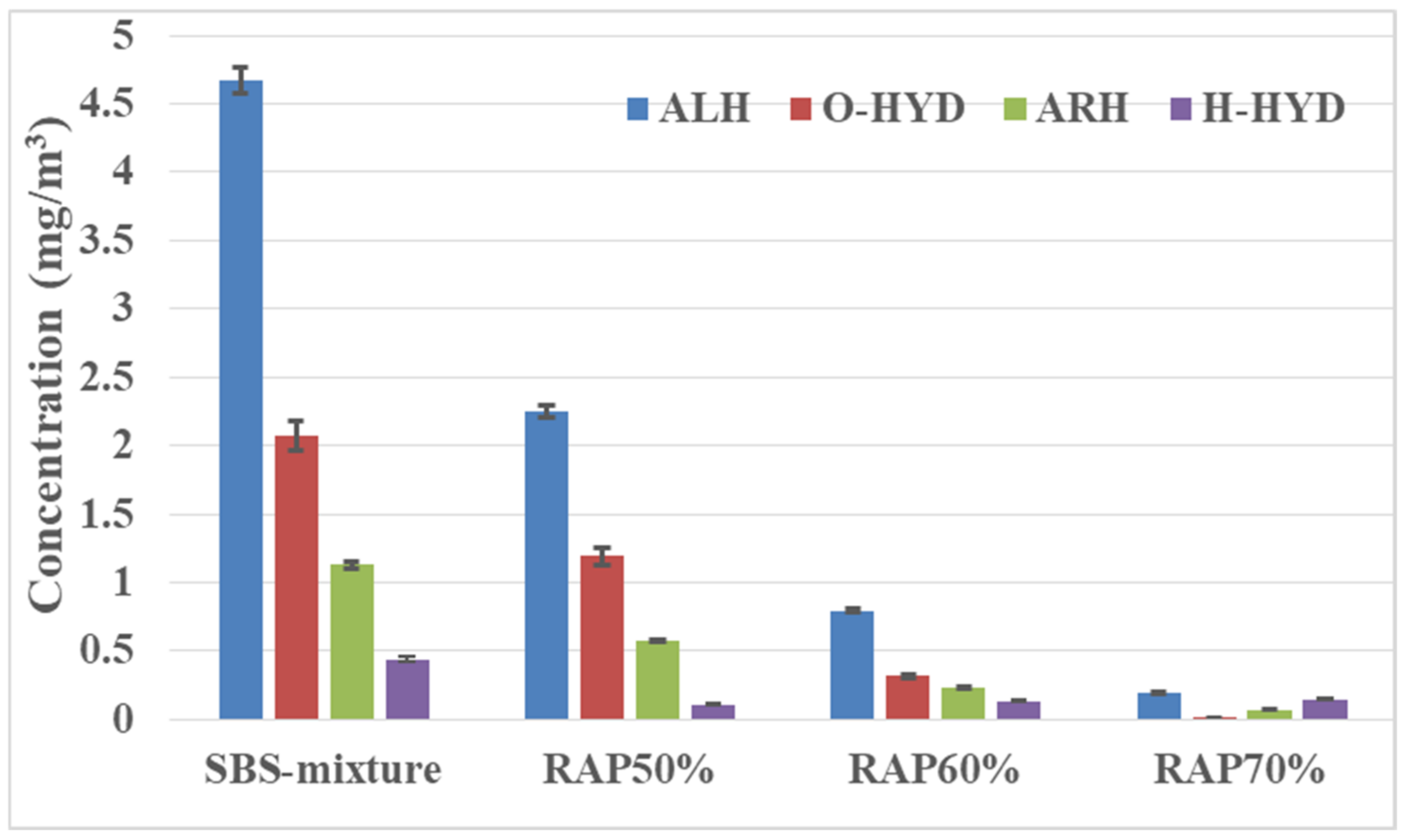

3.2.2. VOCs Emission Assessment

4. Conclusions

- (1)

- The rheological properties of the mixed recycled asphalt binder are found to be between those of the virgin SBS asphalt and RAP binder and they gradually deteriorated with the increase of content of the RAP binder. Especially when the RAP binder content reaches 80%, the relative performance approaches that of the extracted RAP binder.

- (2)

- The addition of a high percentage of RAP aggregate will not affect the volume performance of recycled asphalt mixture. Although the water damage resistance, high temperature stability, low temperature cracking resistance and fatigue cracking resistance demonstrate a downward trend with the increase of RAP aggregate, the road performance still meets the construction requirements.

- (3)

- In addition to the change of the relative content of specific functional groups, the addition of RAP will not introduce new substances. There exists an internal relationship between chemical composition and VOCs release behavior with the variation of recycled asphalt binder content. The increase of the RAP binder mainly affects the release of ALH and O-HYD, which account for more than 80% of the total VOCs release.

- (4)

- The recycled asphalt mixture with a high RAP content has an obvious emission reduction effect on VOCs. When the content of RAP aggregate is 50%, the VOCs emission can be decreased by 50.30% during the mixing stage compared with the asphalt mixture without RAP. The VOCs emission reduction can be up to 94.82% if the content of RAP aggregates increases to 70%. Maximizing the utilization of RAP can not only make the use of raw materials sustainable, but also is an effective method to enhance environmental protection.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Transport of the People’s Republic of China. Statistical Bulletin of Transport Industry Development in 2019; Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- Devulapalli, L.; Kothandaraman, S.; Sarang, G. Effect of rejuvenating agents on stone matrix asphalt mixtures incorporating RAP. Constr. Build. Mater. 2020, 254, 119298. [Google Scholar] [CrossRef]

- Rathore, M.; Zaumanis, M. Impact of laboratory mixing procedure on the properties of reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 264, 120709. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef]

- Hidalgo, A.E.; Moreno-Navarro, F.; Tauste, R.M.C.R.-G.J.; Rubio-Gámez, M.C. The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale. Sustainability 2020, 12, 8343. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis, Resources. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Izaks, R.; Haritonovs, V.; Klasa, I.; Zaumanis, M. Hot Mix Asphalt with High RAP Content. Procedia Eng. 2015, 114, 676–684. [Google Scholar] [CrossRef]

- Widyatmoko, I. Mechanistic-empirical mixture design for hot mix asphalt pavement recycling. Constr. Build. Mater. 2008, 22, 77–87. [Google Scholar] [CrossRef]

- Pradyumna, T.A.; Mittal, A.; Jain, P.K. Characterization of Reclaimed Asphalt Pavement (RAP) for Use in Bituminous Road Construction. Procedia Soc. Behav. Sci. 2013, 104, 1149–1157. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Sahoo, U.C. Influence of softer binder and rejuvenator on bituminous mixtures containing reclaimed asphalt pavement (RAP) material. Int. J. Transp. Sci. Technol. 2020, in press. [Google Scholar]

- Shen, J.; Amirkhanian, S.; Aune Miller, J. Effects of Rejuvenating Agents on Superpave Mixtures Containing Reclaimed Asphalt Pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Wistuba, M.P.; Marasteanu, M.O. Rheological Investigation of Asphalt Mixtures Containing RAP and RAS; Springer: Dodrecht, The Netherlands, 2016. [Google Scholar]

- Arshad, H.; Qiu, Y.J. Materials Evaluation of Asphalt Mixes Containing Reclaimed Asphalt Pavement. Appl. Mech. Mater. 2012, 178–181, 1522–1525. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the mechanical performance of recycled asphalt mixtures incorporated with high percentage of RAP and self-developed rejuvenators. Constr. Build. Mater. 2020, 269, 121337. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Yu, B.; Gu, X.; Zhang, L.; Ni, F. Performance Evaluation of Aged Asphalt Mix for Hot In-Place Recycling. J. Test Eval. 2016, 44, 770–780. [Google Scholar] [CrossRef]

- Lee, K.W.; Brayton, T.E.; Mueller, M.; Singh, A. Rational Mix-Design Procedure for Cold In-Place Recycling Asphalt Mixtures and Performance Prediction. J. Mater. Civil Eng. 2016, 28, 04016008. [Google Scholar] [CrossRef]

- Cong, P.; Luo, W.; Xu, P.; Zhao, H. Investigation on recycling of SBS modified asphalt binders containing fresh asphalt and rejuvenating agents. Constr. Build. Mater. 2015, 91, 225–231. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Liang, M.; Jiang, H.; Wei, J.; Yao, Z. Influence of different rejuvenating agents on rheological behavior and dynamic response of recycled asphalt mixtures incorporating 60% RAP dosage. Constr. Build. Mater. 2020, 238, 117778. [Google Scholar] [CrossRef]

- Xiao, F.; Putman, B.; Amirkhanian, S. Amirkhanian, Plant and Laboratory Compaction Effects on Performance Properties of Plant-Foamed Asphalt Mixtures Containing RAP. J. Mater. Civil Eng. 2014, 27, 04014240. [Google Scholar] [CrossRef]

- Loria, L.; Hajj, E.; Sebaaly, P.; Barton, M.; Kass, S.; Liske, T. Performance Evaluation of Asphalt Mixtures with High Recycled Asphalt Pavement Content. Transp. Res. Rec. J. Transp. Res. Board 2011, 2208, 72–81. [Google Scholar] [CrossRef]

- Diefenderfer, G.W.; Gillespie, J.S. Virginia’s Higher Specification for Reclaimed Asphalt Pavement: Performance and Economic Evaluation. Transp. Res. Rec. J. Transp. Res. Board 2009, 2126, 142–150. [Google Scholar]

- Anderson, E.; Daniel, J. Long-Term Performance of Pavement with High Recycled Asphalt Content: Case Studies. Transp. Res. Rec. 2013, 2371, 1–12. [Google Scholar] [CrossRef]

- Autelitano, F.; Bianchi, F.; Giuliani, F. Airborne emissions of asphalt/wax blends for warm mix asphalt production. J. Clean. Prod. 2017, 164, 749–756. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Q.; Wang, F.; Xie, J.; Li, Y.; Li, J.; Wu, S. Emission behavior, environmental impact and priority-controlled pollutants assessment of volatile organic compounds (VOCs) during asphalt pavement construction based on laboratory experiment. J. Hazard. Mater. 2020, 398, 122904. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Q.; Wang, F.; Cui, P.; Xie, J.; Li, Y.; Li, J.; Wu, S. Comparative Assessment of Asphalt Volatile Organic Compounds Emission from field to laboratory. J. Clean. Prod. 2020, 278, 123479. [Google Scholar] [CrossRef]

- Lamontagnea, J.; Dumasb, P.; Mouillet, V.; Kistera, J. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: Application to road bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Liu, Q.; Dai, Y.; Li, C.; Li, H.; Nie, S.; Song, W. Aging degradation of asphalt binder by narrow-band UV radiations with a range of dominant wavelengths. Constr. Build. Mater. 2019, 220, 637–650. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S.; Wang, Q.; Yao, H. Rheological and structural evolution of SBS modified asphalts under natural weathering. Fuel 2016, 184, 242–247. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; JTG-E20; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

| Binder Type | Penetration 25 °C (0.1 mm) | Softening Point (°C) | Ductility 50 mm/min, 5 °C (cm) |

|---|---|---|---|

| SBS asphalt | 68 | 56 | 48.6 |

| RAP binder | 45 | 73 | 18.7 |

| Test Method | ASTM D5 | ASTM D36 | ASTM D113 |

| RAP Ratio (%) | Porosity (%) | Residual Stability (%) | Tensile Strength Ratio (%) | Dynamic Stability (Frequency/mm) | Bending Strength (MPa) |

|---|---|---|---|---|---|

| 50 | 4.01 | 94.6 | 93.4 | 4228 | 15.5 |

| 60 | 4.08 | 93.2 | 89.3 | 4437 | 13.4 |

| 70 | 3.91 | 89.4 | 84.2 | 4701 | 11.2 |

| Specification requirements | ≤5% | ≥85 | ≥80 | ≥2400 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, M.; Wu, S.; Zhu, L.; Li, N.; Yang, C. Environmental Impact on VOCs Emission of a Recycled Asphalt Mixture with a High Percentage of RAP. Materials 2021, 14, 947. https://doi.org/10.3390/ma14040947

Wei M, Wu S, Zhu L, Li N, Yang C. Environmental Impact on VOCs Emission of a Recycled Asphalt Mixture with a High Percentage of RAP. Materials. 2021; 14(4):947. https://doi.org/10.3390/ma14040947

Chicago/Turabian StyleWei, Minghua, Shaopeng Wu, Lei Zhu, Na Li, and Chao Yang. 2021. "Environmental Impact on VOCs Emission of a Recycled Asphalt Mixture with a High Percentage of RAP" Materials 14, no. 4: 947. https://doi.org/10.3390/ma14040947

APA StyleWei, M., Wu, S., Zhu, L., Li, N., & Yang, C. (2021). Environmental Impact on VOCs Emission of a Recycled Asphalt Mixture with a High Percentage of RAP. Materials, 14(4), 947. https://doi.org/10.3390/ma14040947