Study on Acoustic Emission Characteristics of Low-Temperature Asphalt Concrete Cracking Damage

Abstract

1. Introduction

- (1)

- Study the variation characteristics and laws of AE parameters during the fracture and damage process of asphalt concrete at −10 °C.

- (2)

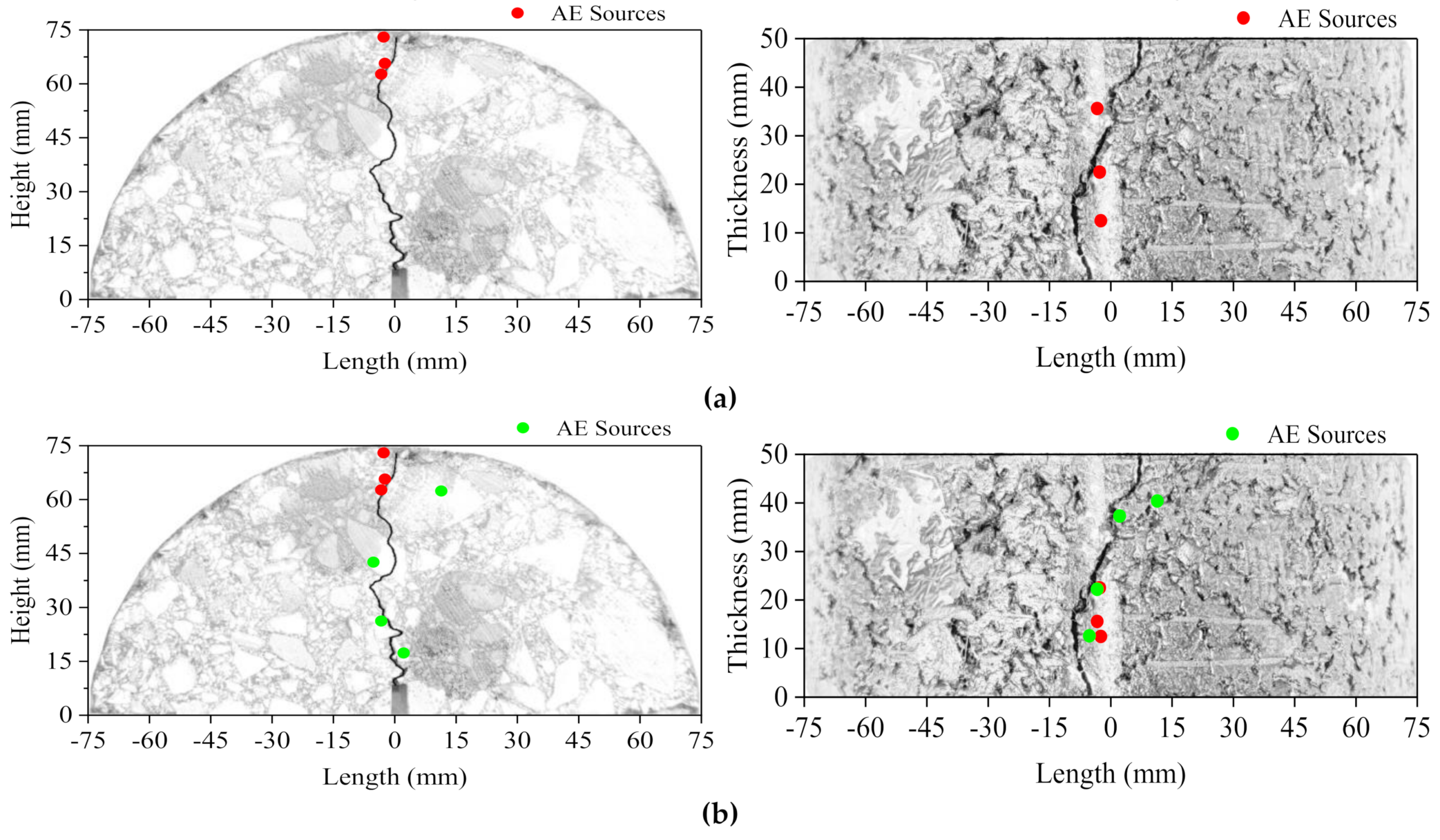

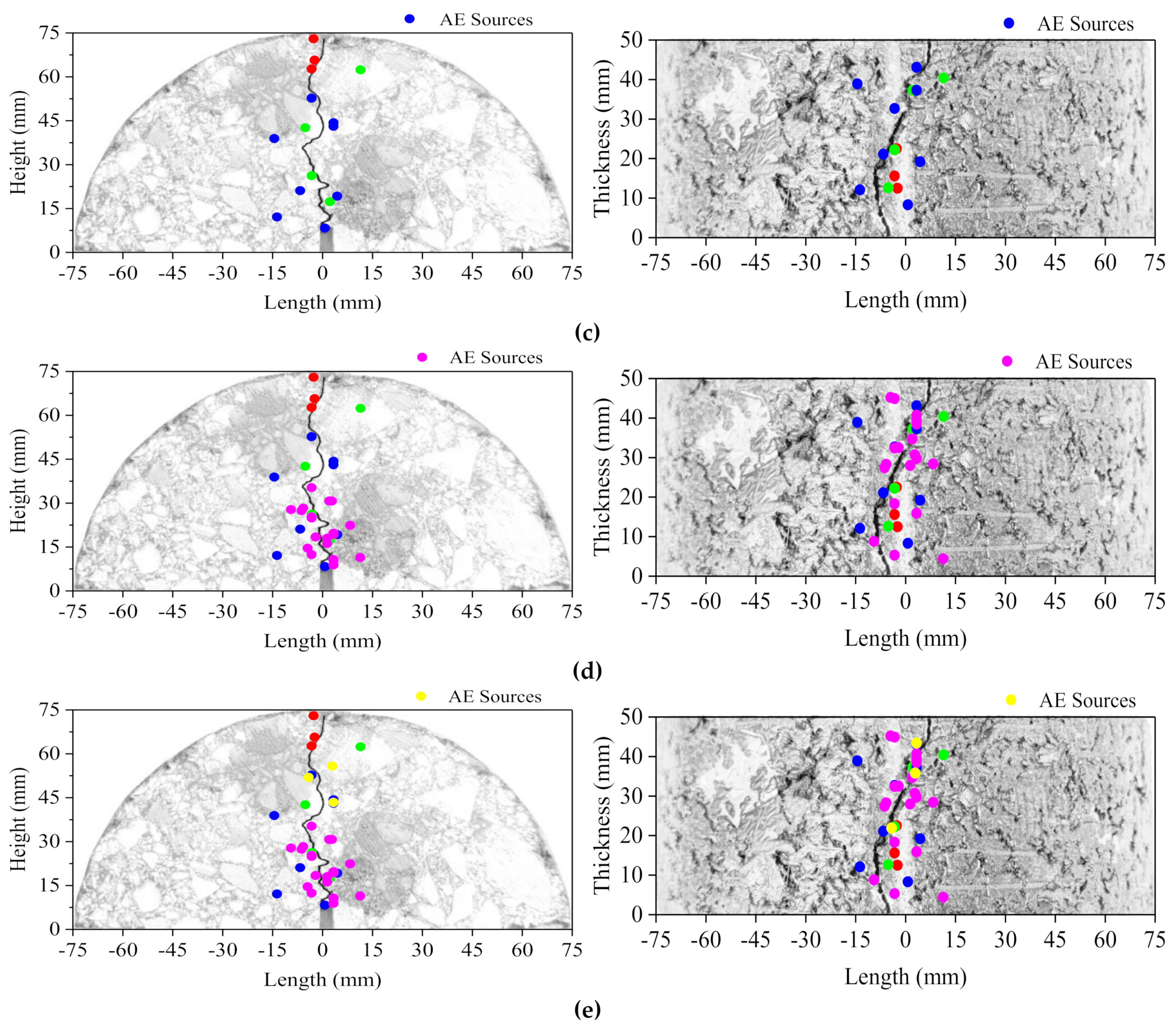

- Track the crack propagation path using AE source localization technology and study the dynamic variation characteristics of AE source spatial distribution during the fracture process of asphalt concrete at −10 °C.

2. Materials and Methods

2.1. Materials

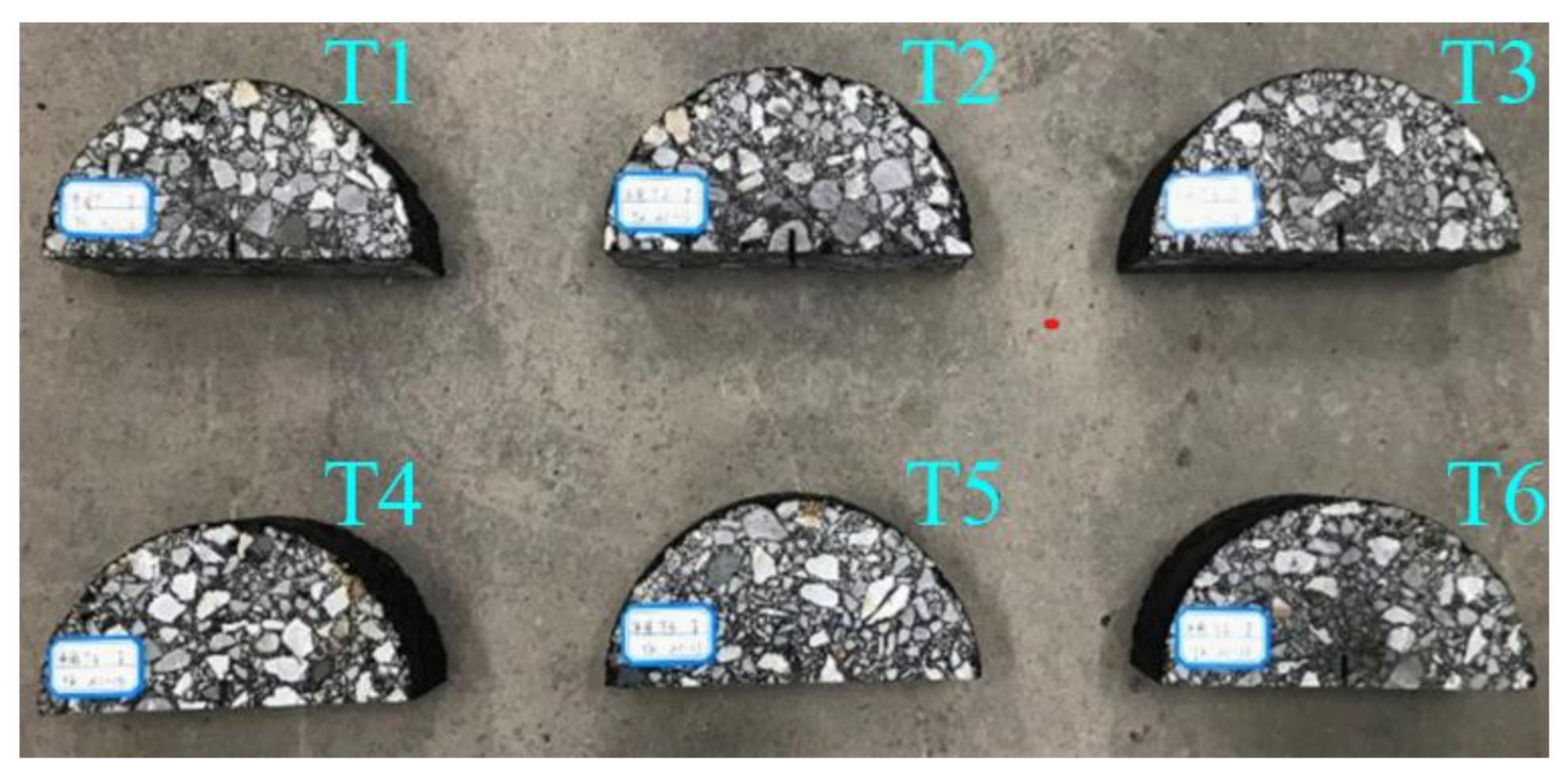

2.2. Test Setup and AE System

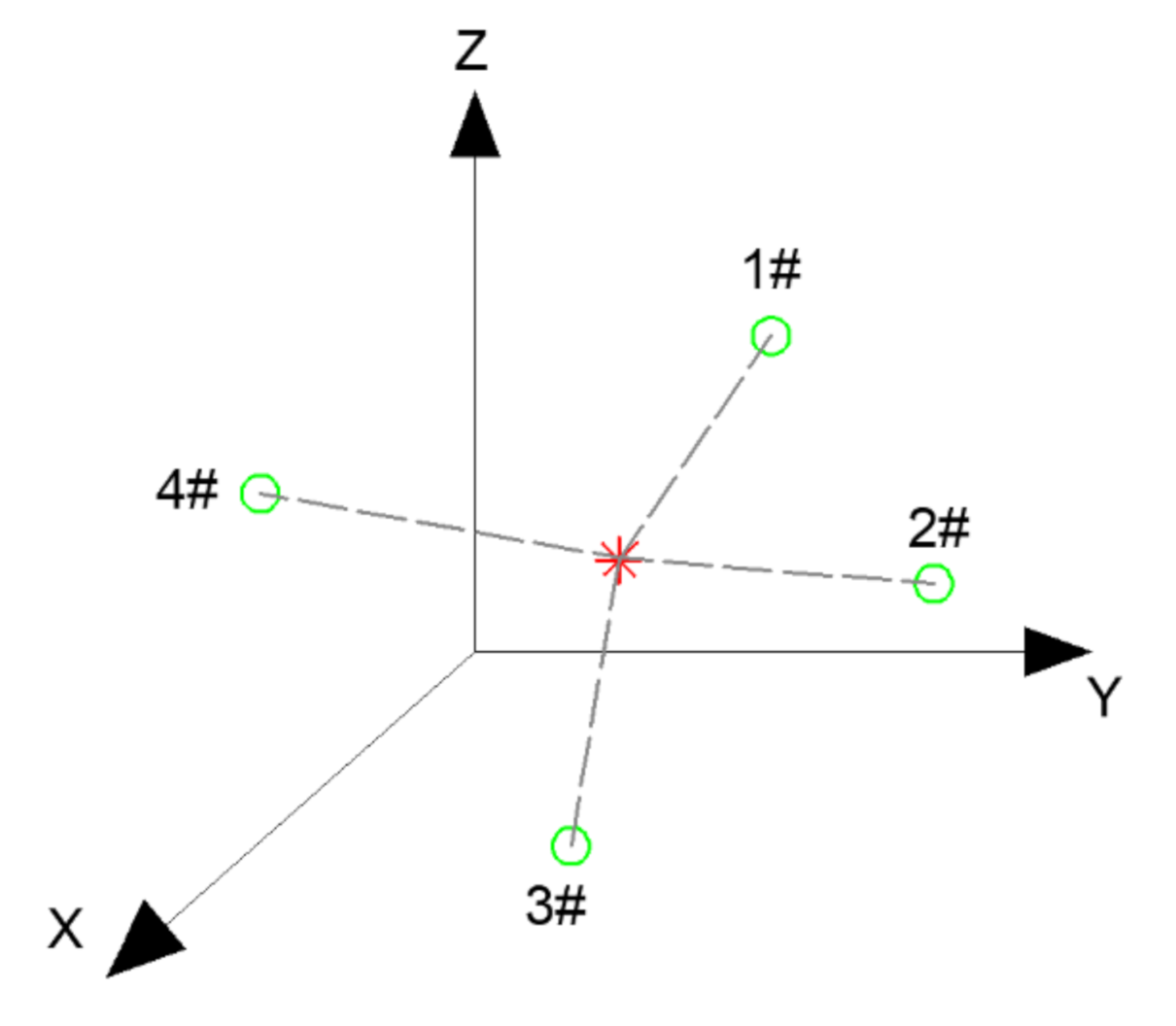

2.3. AE Source Location

3. Results and Discussion

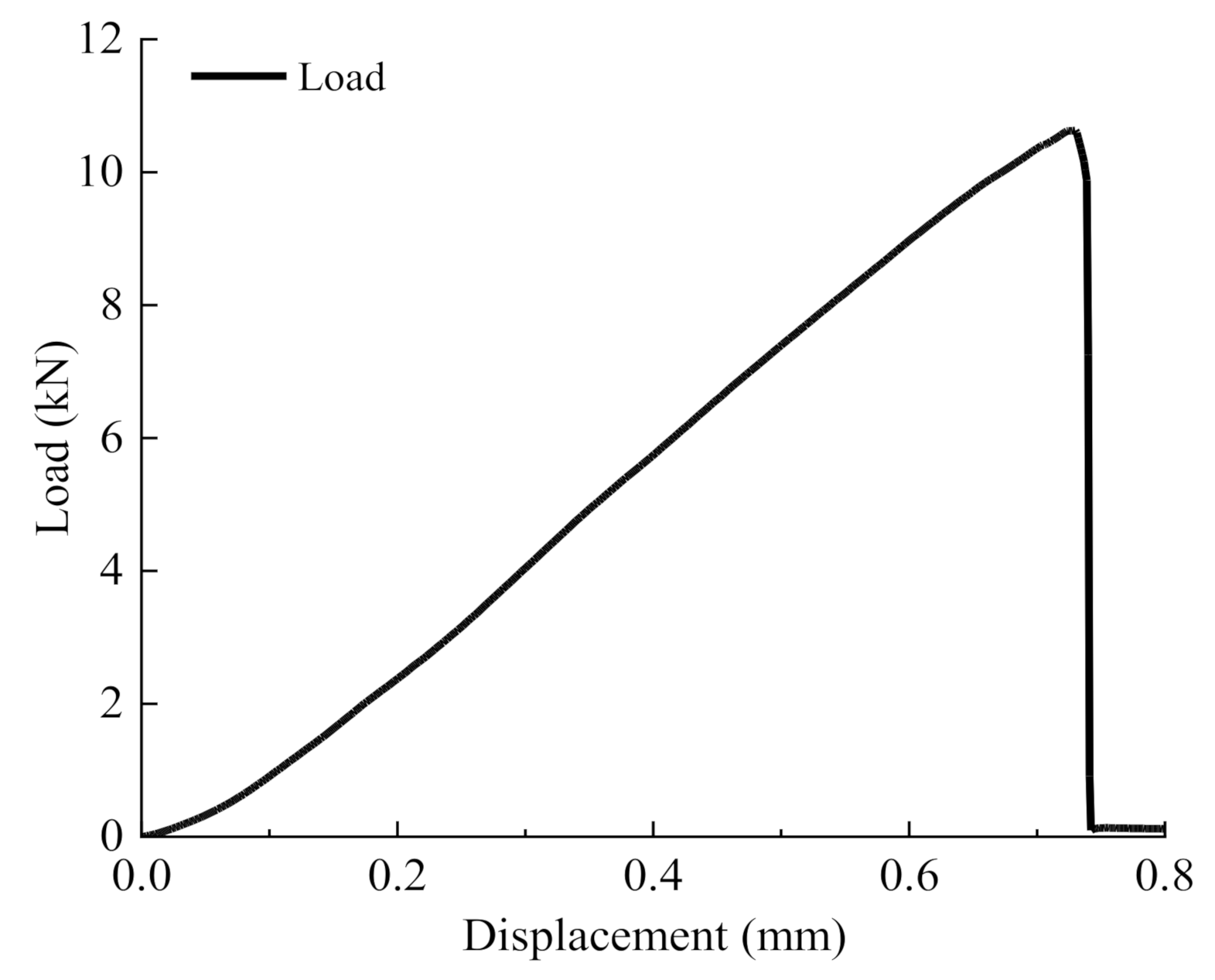

3.1. Deformation Fracture Characteristics

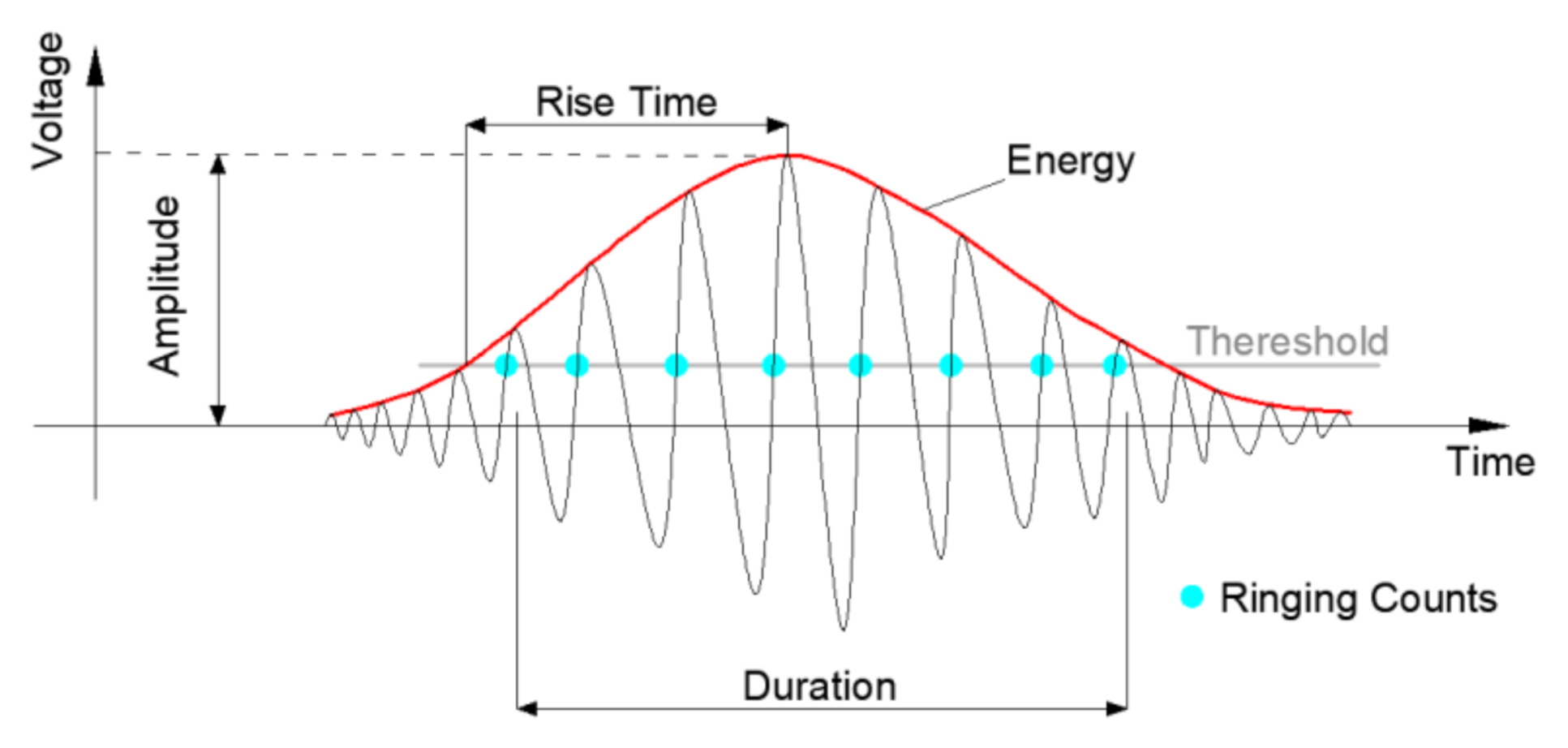

3.2. Characteristics of AE Parameters

3.3. Damage Evaluation

3.4. AE Source Location

4. Conclusions

- (1)

- The fracture process and load–displacement curve of AC-13 asphalt concrete at low temperature showed obvious brittle fracture characteristics; the specimen fractured at the peak load and the corresponding displacement was about 0.75 mm.

- (2)

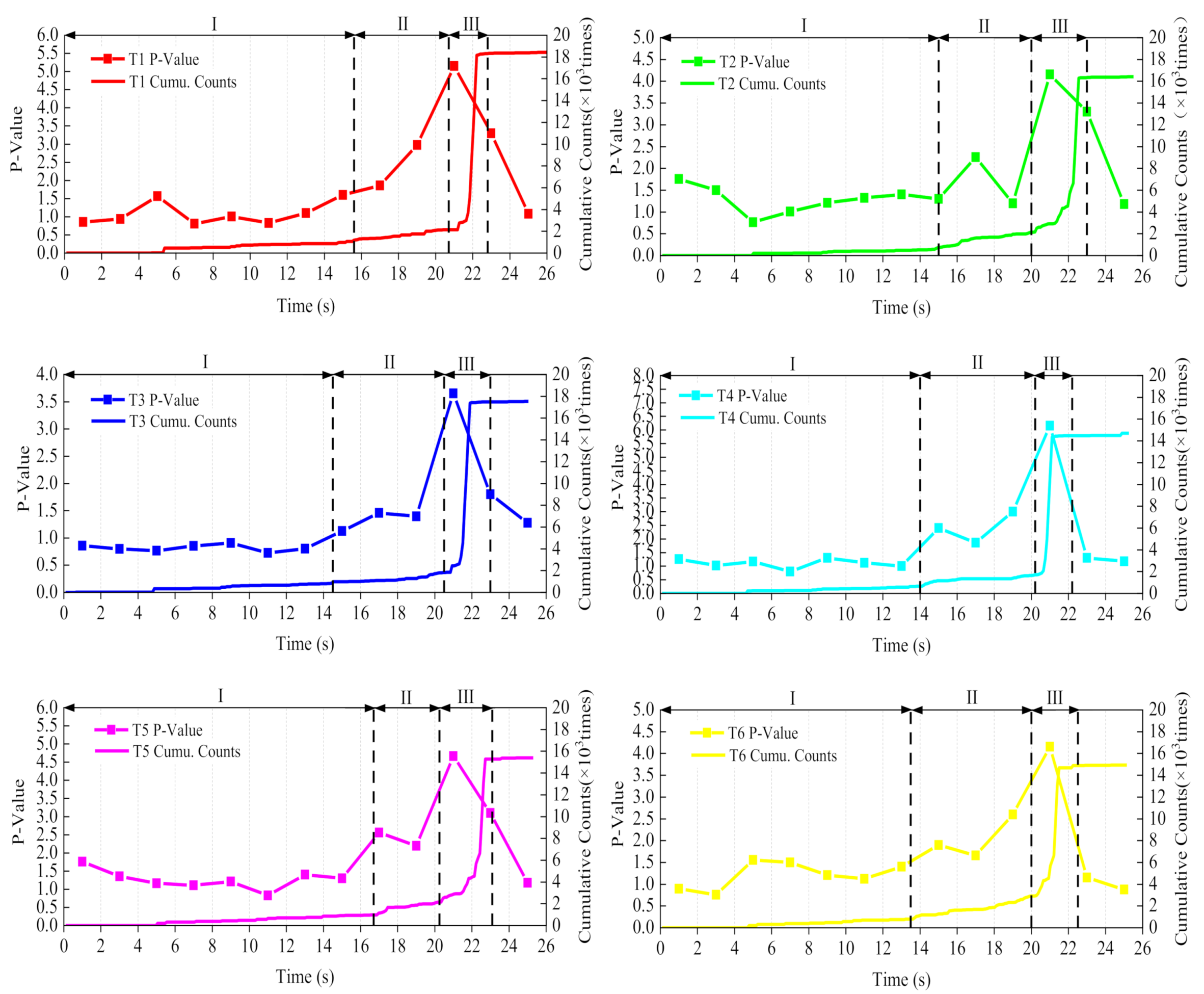

- The variation of AE parameters during the fracture process of low-temperature asphalt concrete could be divided into three periods: a calm period, a stable development period, and a rapid fracture period. During the rapid fracture period, AE energy and ringing count increased gradually, and then suddenly, the cumulative energy and cumulative ringing counts reached a mutation point and then rose in a straight line. This variation characteristic can be regarded as a forewarning of macroscopic cracks. The K value reached its maximum at the rapid fracture period and had a good correspondence with the AE parameters, which could be used to evaluate the damage stability in the process of specimen cracking.

- (3)

- The dynamic evolution of the spatial distribution of AE location points can be used to track the surface path of crack development, reflect the initiation and propagation of micro-cracks, and evaluate the whole process of crack development. It has great potential and prospects in the crack detection of asphalt pavement in cold regions.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, X.; Wang, Y.; Xu, J. Acoustic emission propagation characteristics and damage source localization of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119086. [Google Scholar] [CrossRef]

- Tripathi, R.; Srivastava, M.; Hloch, S. Monitoring of Acoustic Emission During the Disintegration of Rock. Procedia Eng. 2016, 149, 481–488. [Google Scholar] [CrossRef]

- D’Angela, D.; Ercolino, M. Acoustic Emission Entropy as a fracture-sensitive feature for real-time assessment of metal plates under fatigue loading. In Proceedings of the International Conference on Fracture and Structural Integrity, Lviv, Ukraine, 3–6 June 2019. [Google Scholar]

- Xie, C.; Yuan, L.; Zhao, M.; Jia, Y. Study on failure mechanism of porous concrete based on acoustic emission and discrete element method. Constr. Build. Mater. 2020, 235, 117409. [Google Scholar] [CrossRef]

- Fan, Z.; Sun, Y. Detecting and evaluation of fatigue damage in concrete with industrial computed tomography technology. Constr. Build. Mater. 2019, 223, 794–805. [Google Scholar] [CrossRef]

- Dong, L.; Sun, D.; Li, X.; Ma, J.; Zhang, L.; Tong, X. Interval non-probabilistic reliability of surrounding jointed rockmass considering microseismic loads in mining tunnels. Tunn. Undergr. Space Technol. 2018, 81, 326–335. [Google Scholar] [CrossRef]

- Dong, L.; Zou, W.; Li, X.; Shu, W.; Wang, Z. Collaborative localization method using analytical and iterative solutions for microseismic/acoustic emission sources in the rockmass structure for underground mining. Eng. Fract. Mech. 2018, 210, 95–112. [Google Scholar] [CrossRef]

- Jiao, Y.; Fu, L.; Shan, W.; Liu, S. Damage Fracture Characterization of Pervious Asphalt Considering Temperature Effect Based on Acoustic Emission Parameters. Eng. Fract. Mech. 2018, 210, 147–159. [Google Scholar] [CrossRef]

- Jiao, Y.; Liu, S.; Fu, L.; Shan, W. Fracture Monitoring of SBS and Crumb Rubber Modified Porous Asphalt Mixtures under Compression and Splitting Testing Using Acoustic Emission Technique. J. Mater. Civ. Eng. 2019, 31, 04019063. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Zhang, M.; Fu, L.; Zhang, L. Investigation of fracture modes in pervious asphalt under splitting and compression based on acoustic emission monitoring. Eng. Fract. Mech. 2019, 211, 209–220. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xiao, S.; Yang, Q. Acoustic emission parameters and waveforms characteristics of fracture failure process of asphalt mixtures. Constr. Build. Mater. 2019, 215, 135–147. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xu, W.; Xiao, S.; Wang, F.; Yuan, J. Characterization of fatigue damage mechanism of asphalt mixtures with acoustic emission. Constr. Build. Mater. 2020, 240, 117961. [Google Scholar] [CrossRef]

- Behnia, B.; Reis, H. Self-healing of thermal cracks in asphalt pavements. Constr. Build. Mater. 2019, 218, 316–322. [Google Scholar] [CrossRef]

- Geng, J.; Sun, Q.; Zhang, Y.; Cao, L.; Zhang, W. Studying the dynamic damage failure of concrete based on acoustic emission. Constr. Build. Mater. 2017, 149, 9–16. [Google Scholar] [CrossRef]

- Tang, E.L.; Liang, Z.Q.; Wang, L.; Han, Y.F. Experimental investigation on location of debris impact source based on acoustic emission. Adv. Space Res. 2019, 64, 2390–2404. [Google Scholar] [CrossRef]

- Naderloo, M.; Moosavi, M.; Ahmadi, M. Using acoustic emission technique to monitor damage progress around joints in brittle materials. Theor. Appl. Fract. Mech. 2019, 104, 102368. [Google Scholar] [CrossRef]

- Alam, S.Y.; Saliba, J.; Loukili, A. Study of evolution of fracture process zone in concrete by simultaneous application of digital image correlation and acoustic emission. In Proceedings of the Fracture Mechanics of Concrete and Concrete Structures (FraMCoS), University of Castilla La-Mancha, Ciudad Real, Spain, 11–14 March 2013. [Google Scholar]

- Dong, L.; Li, X. Three-dimensional analytical solution of acoustic emission or microseismic source location under cube monitoring network. Trans. Nonferrous Met. Soc. China 2012, 22, 293–302. [Google Scholar] [CrossRef]

- Chen, C.; Fan, X.; Chen, X. Experimental investigation of concrete fracture behavior with different loading rates based on acoustic emission. Constr. Build. Mater. 2020, 237, 117472. [Google Scholar] [CrossRef]

- Liu, Y. Research on Dynamic Response and Fracture Performance of Asphalt Mixture Based on Semi-Circular Bending Test. Ph.D. Thesis, Harbin Institude of Technology, Harbin, China, 2009. [Google Scholar]

- Rasheed, M.A.; Prakash, S.S.; Gangadharan, R. Acoustic Emission Characterization of Hybrid Fiber Reinforced Cellular Concrete Under Direct Shear Loads. J. Nondestruct. Eval. 2019, 38, 17. [Google Scholar] [CrossRef]

- Wu, J.; Chen, Z.; Feng, M.; Wang, Y.; Han, G. The length of pre-existing fissure effects on the dilatancy behavior, acoustic emission, and strength characteristics of cracked sandstone under different confining pressures. Environ. Earth Sci. 2018, 77, 430. [Google Scholar] [CrossRef]

- Mclaskey, G.C.; Glaser, S.D.; Grosse, C.U. Beamforming array techniques for acoustic emission monitoring of large concrete structures. J. Sound Vib. 2010, 329, 2384–2394. [Google Scholar] [CrossRef]

- Lu, Y.; Li, W.; Wang, L.; Meng, X.; Wang, B.; Zhang, K.; Zhang, X. In-situ microscale visualization experiments on microcracking and microdeformation behaviour around a pre-crack tip in a three-point bending sandstone. Int. J. Rock Mech. Min. Sci. 2019, 114, 175–185. [Google Scholar] [CrossRef]

- Antoni, J. The spectral kurtosis: A useful tool for characterising non-stationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Liang, K.; Zhao, M.; Lin, J.; Jiao, J.; Ding, C. Maximum average kurtosis deconvolution and its application for the impulsive fault feature enhancement of rotating machinery. Mech. Syst. Signal Process. 2021, 149, 107323. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Li, D.; He, Z.; Zhou, H.; Li, J. Study on Acoustic Emission Characteristics of Low-Temperature Asphalt Concrete Cracking Damage. Materials 2021, 14, 881. https://doi.org/10.3390/ma14040881

Yang K, Li D, He Z, Zhou H, Li J. Study on Acoustic Emission Characteristics of Low-Temperature Asphalt Concrete Cracking Damage. Materials. 2021; 14(4):881. https://doi.org/10.3390/ma14040881

Chicago/Turabian StyleYang, Kang, Dongxue Li, Zhaoyi He, Hanlin Zhou, and Jiaqi Li. 2021. "Study on Acoustic Emission Characteristics of Low-Temperature Asphalt Concrete Cracking Damage" Materials 14, no. 4: 881. https://doi.org/10.3390/ma14040881

APA StyleYang, K., Li, D., He, Z., Zhou, H., & Li, J. (2021). Study on Acoustic Emission Characteristics of Low-Temperature Asphalt Concrete Cracking Damage. Materials, 14(4), 881. https://doi.org/10.3390/ma14040881