Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS

Abstract

1. Introduction

2. Experimental Details

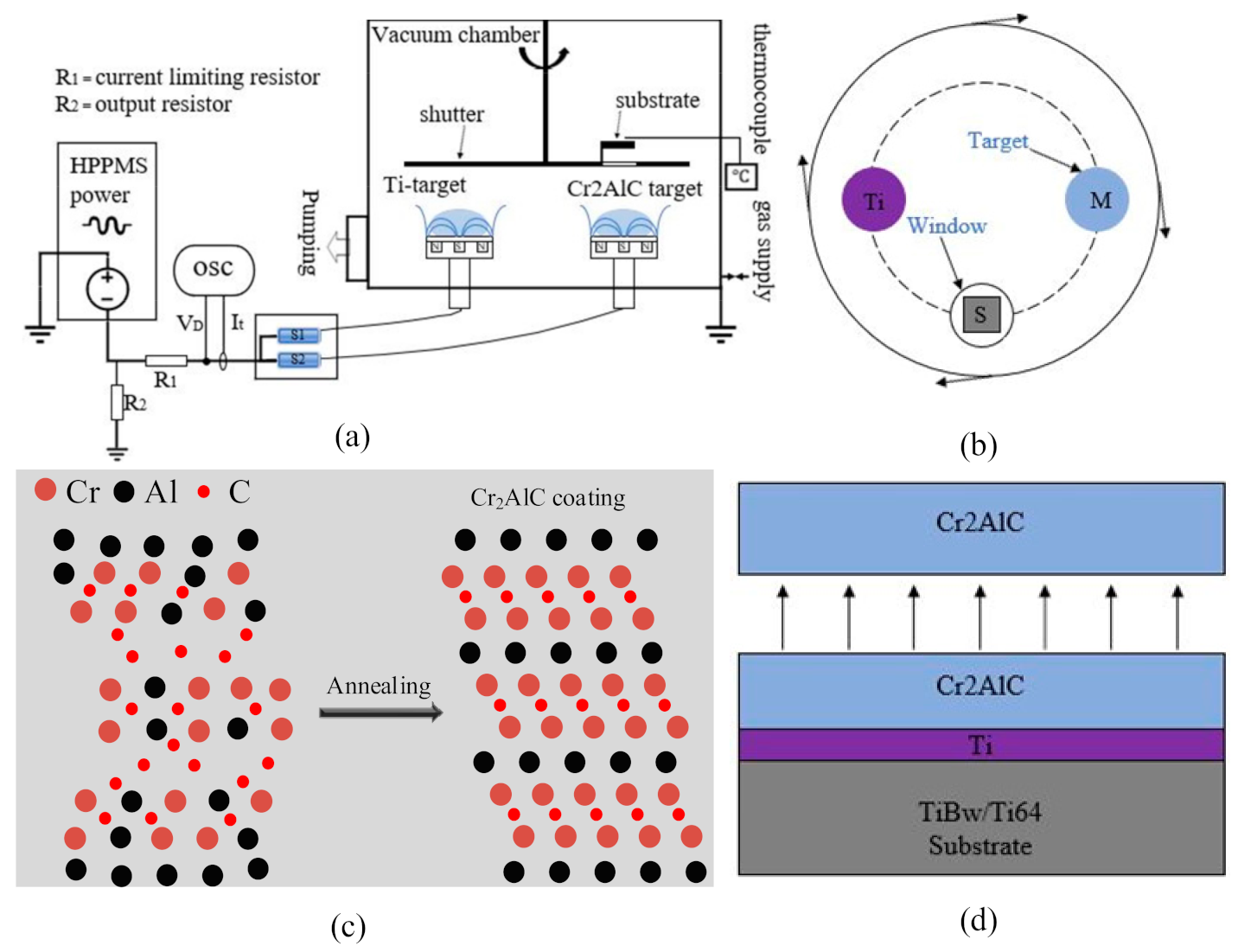

2.1. Coating Deposition

2.2. Characterization Methods

3. Results and Discussion

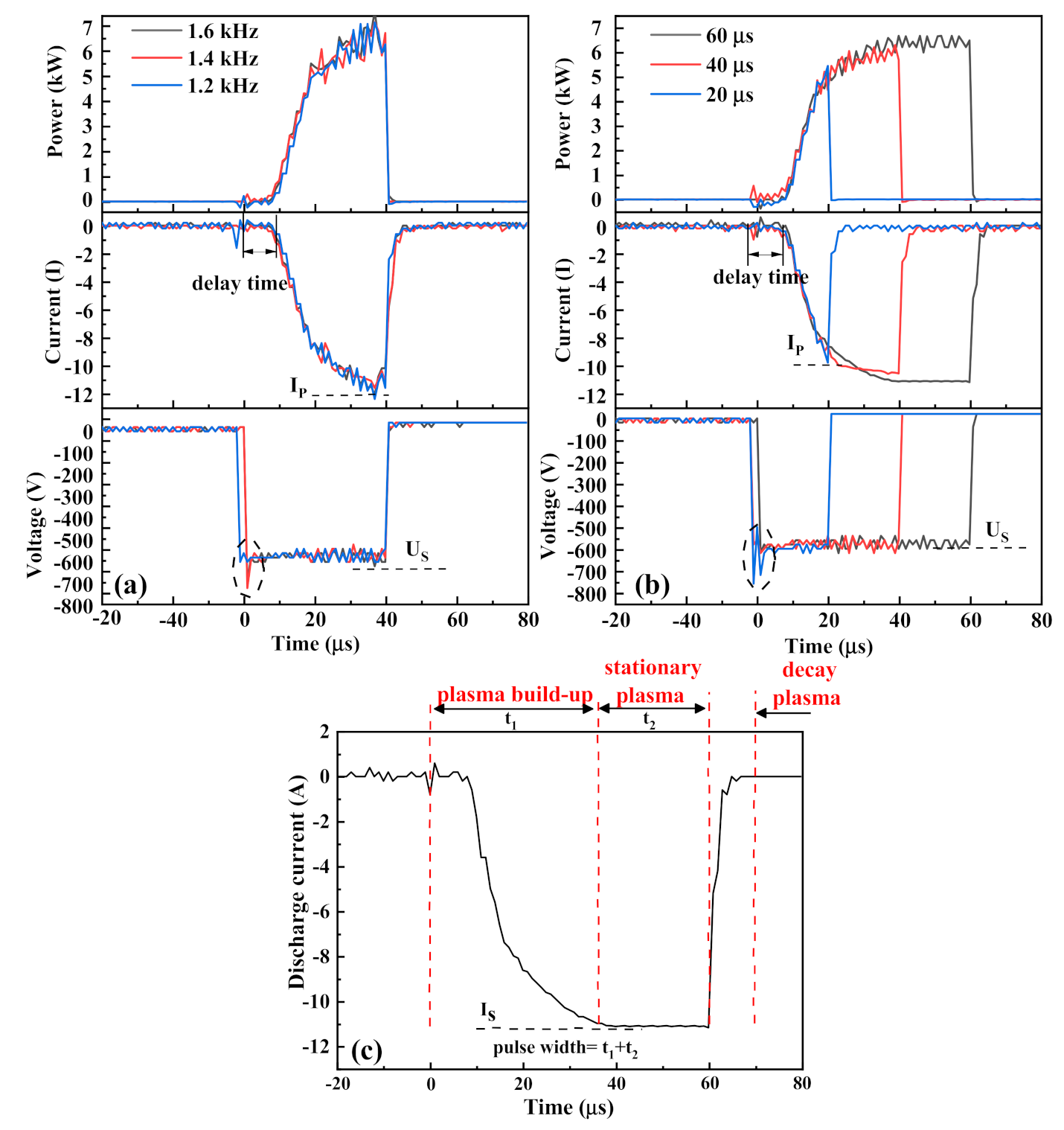

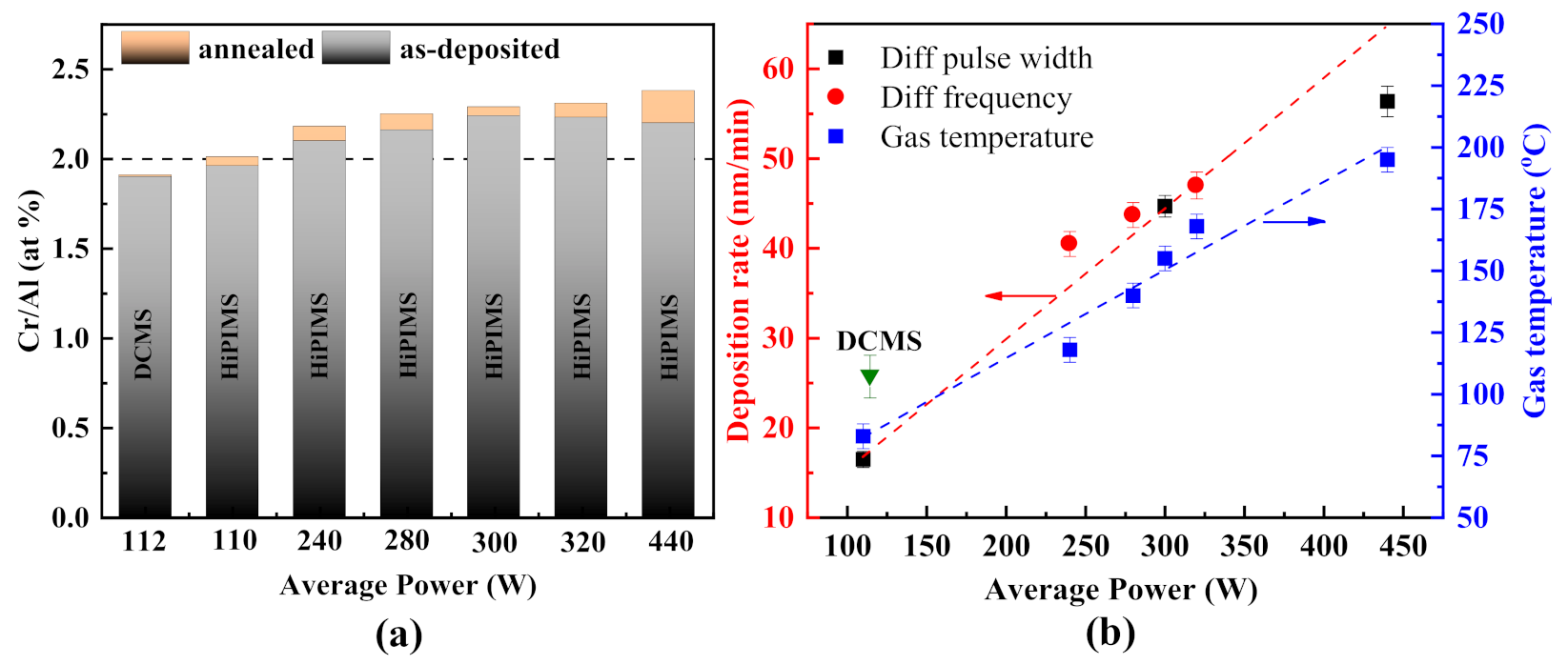

3.1. HiPIMS Discharge Characteristics

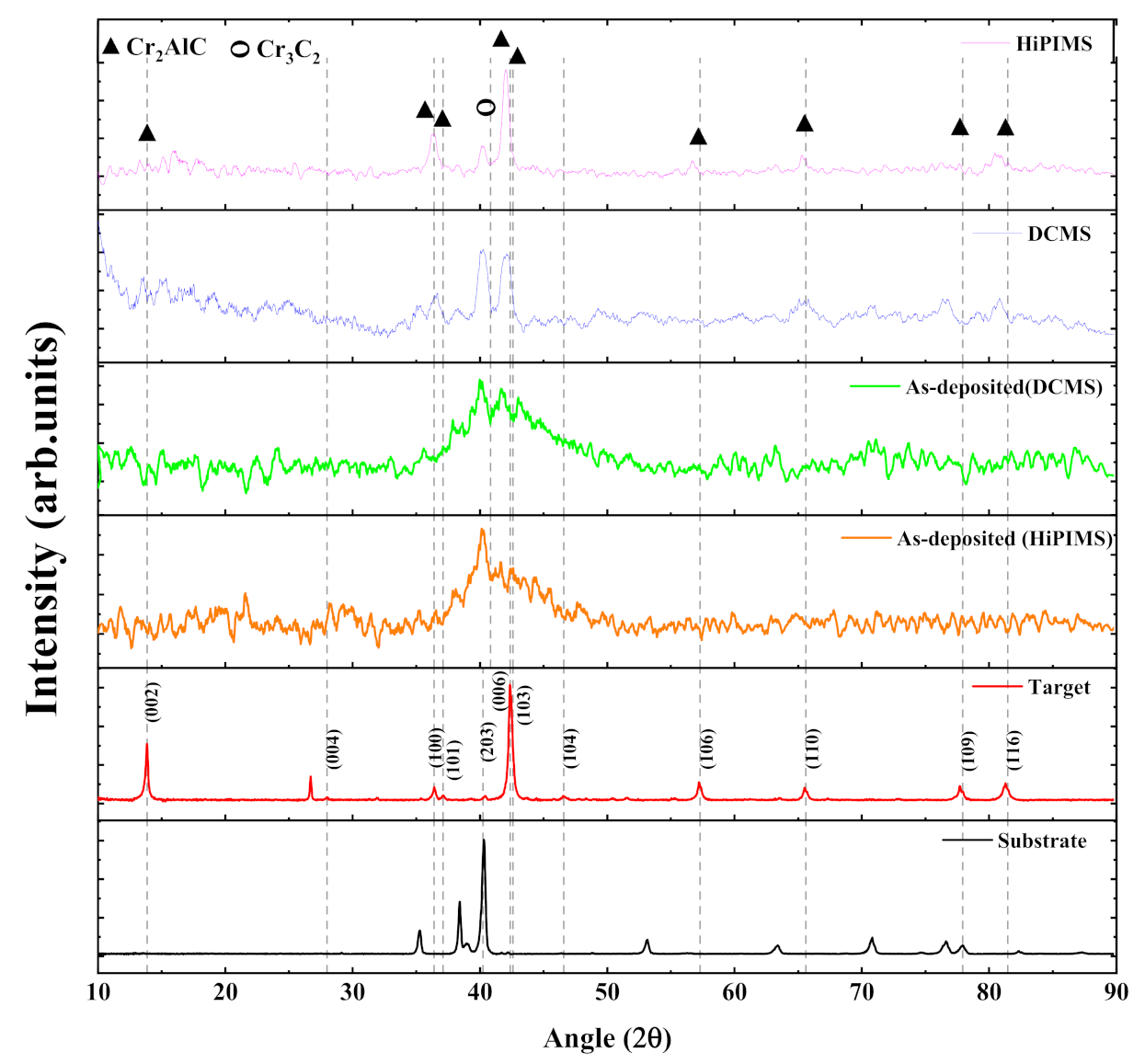

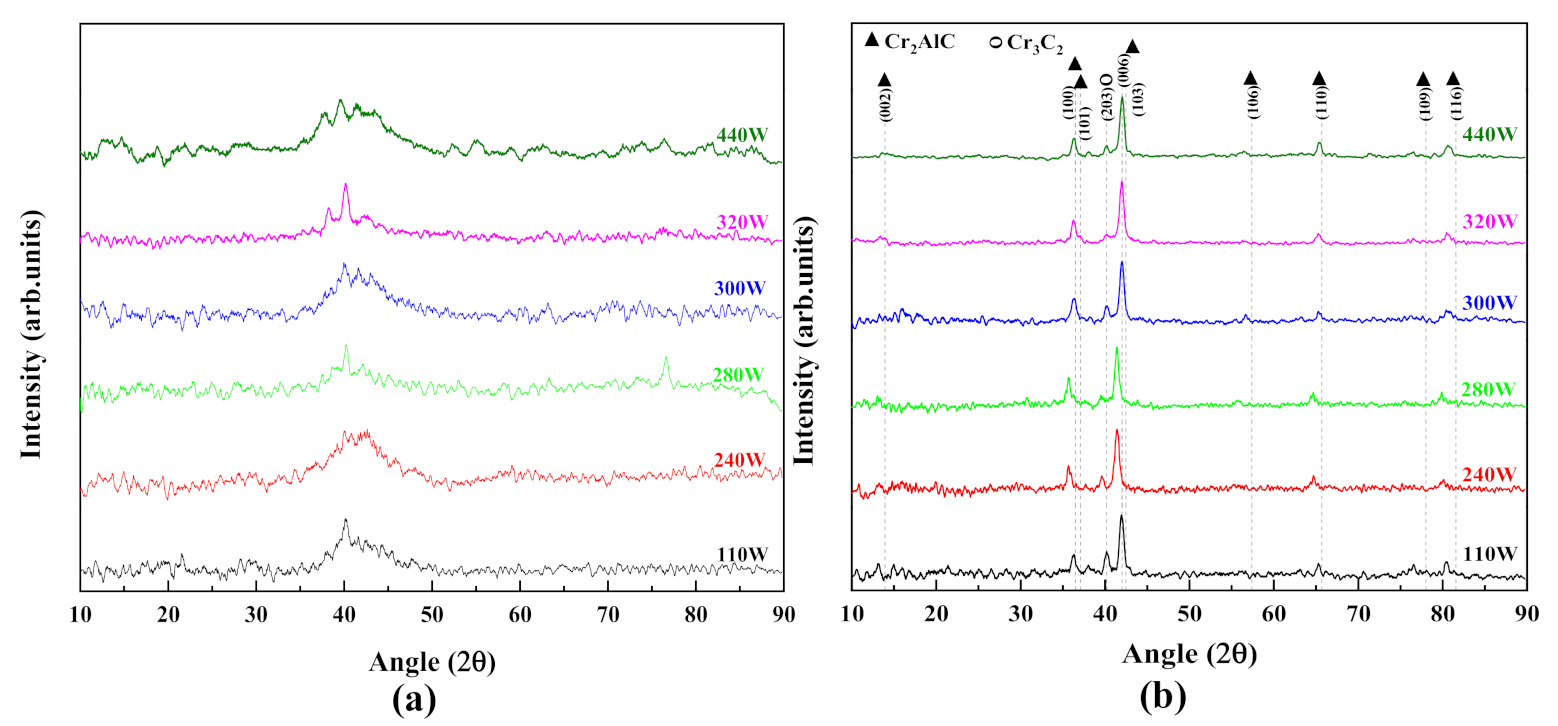

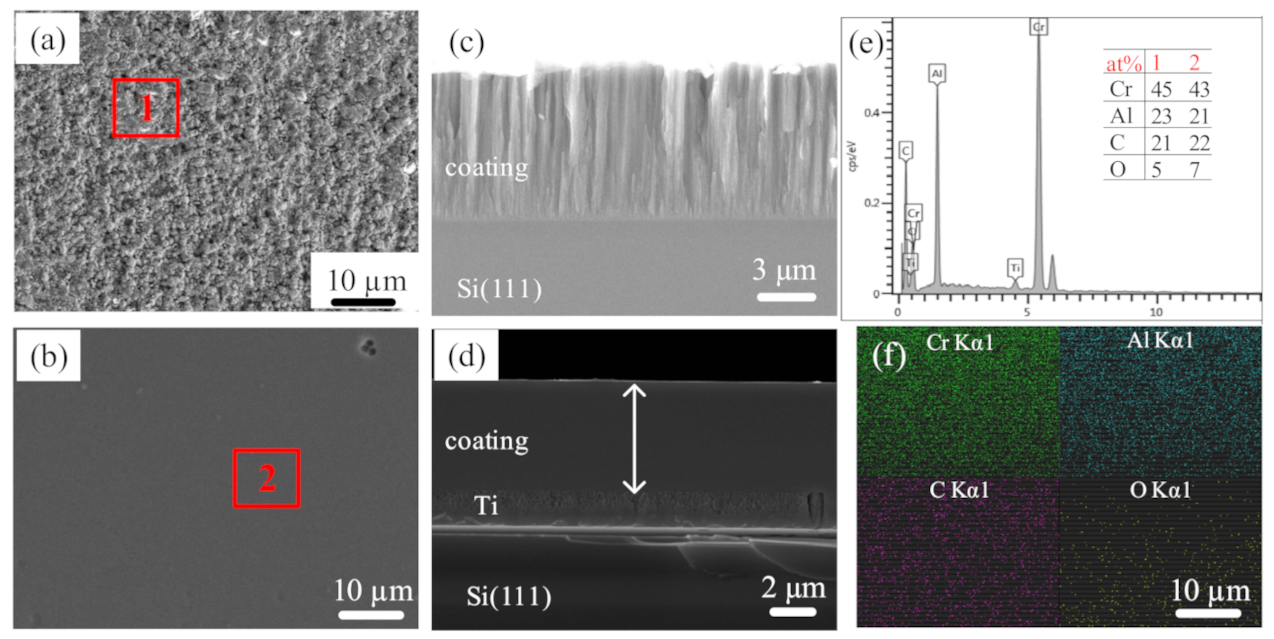

3.2. Microstructure and Phase Composition

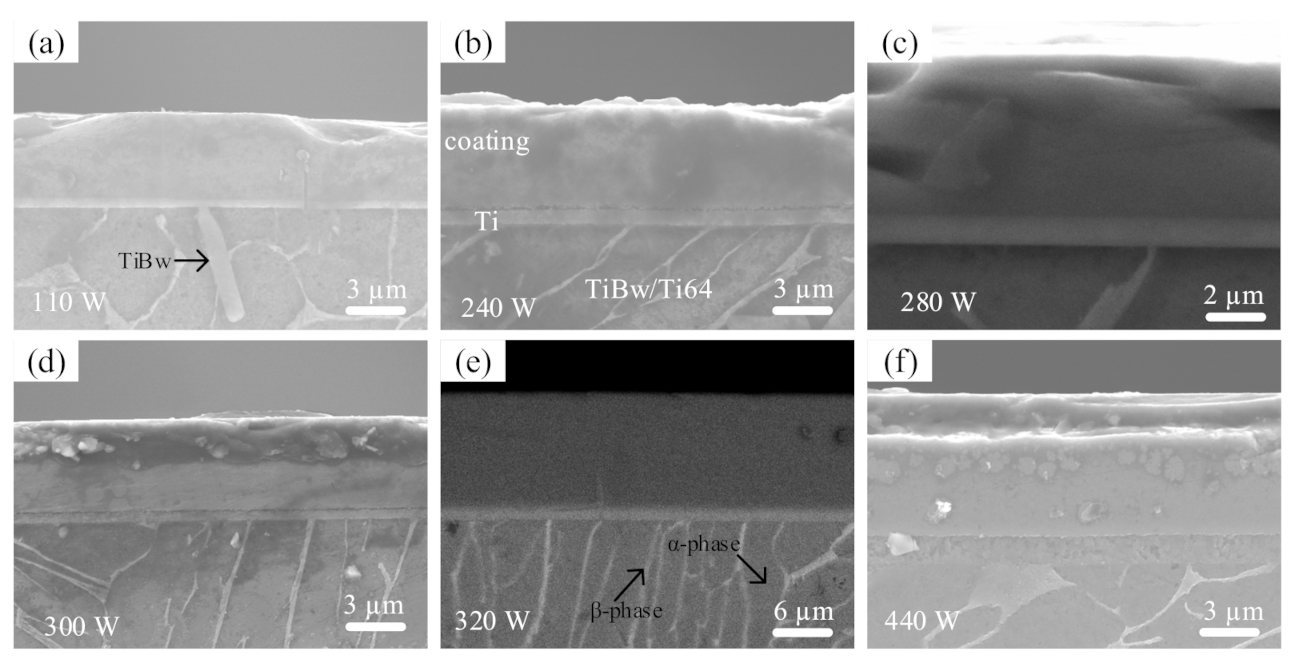

3.3. HiPIMS Surface Defects

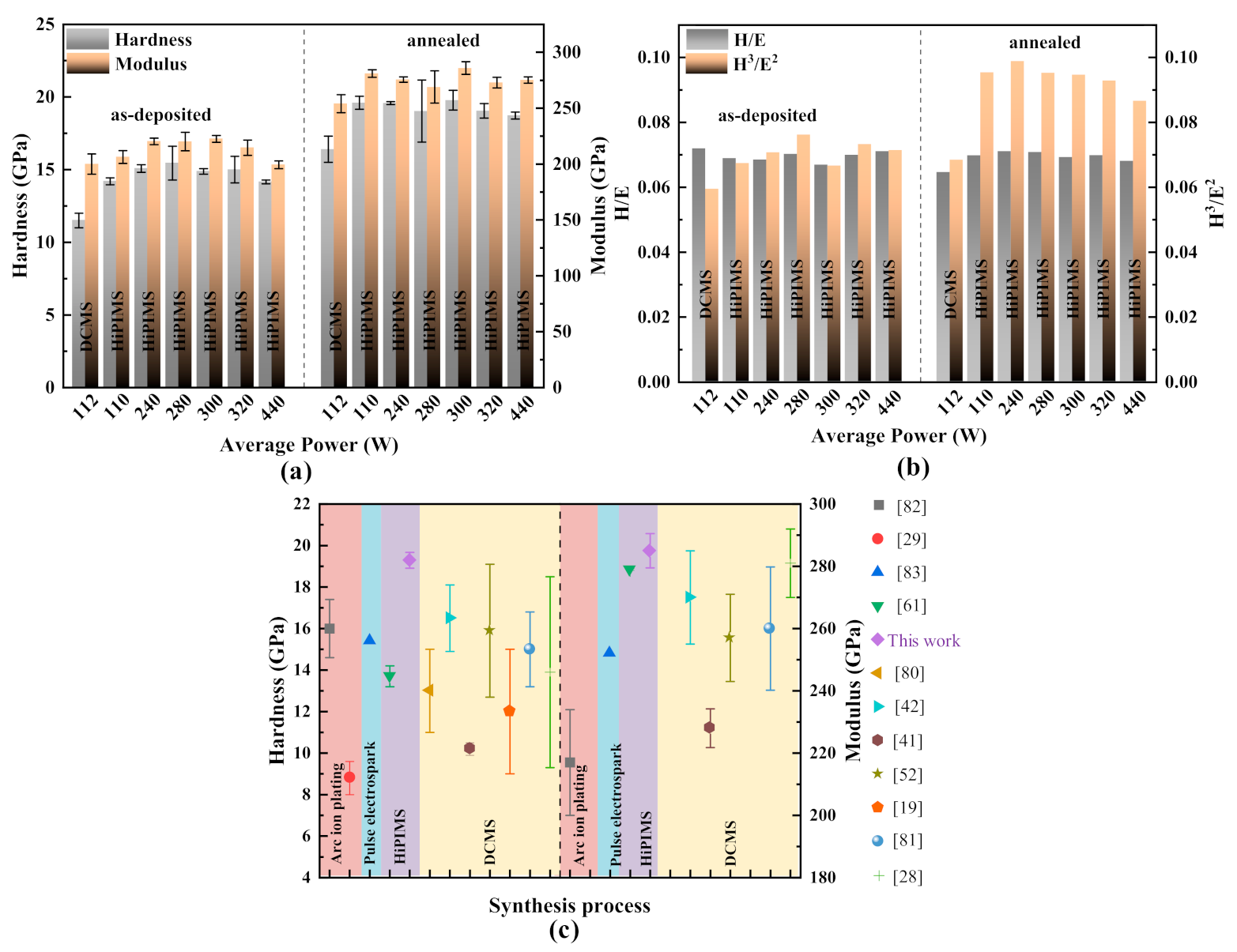

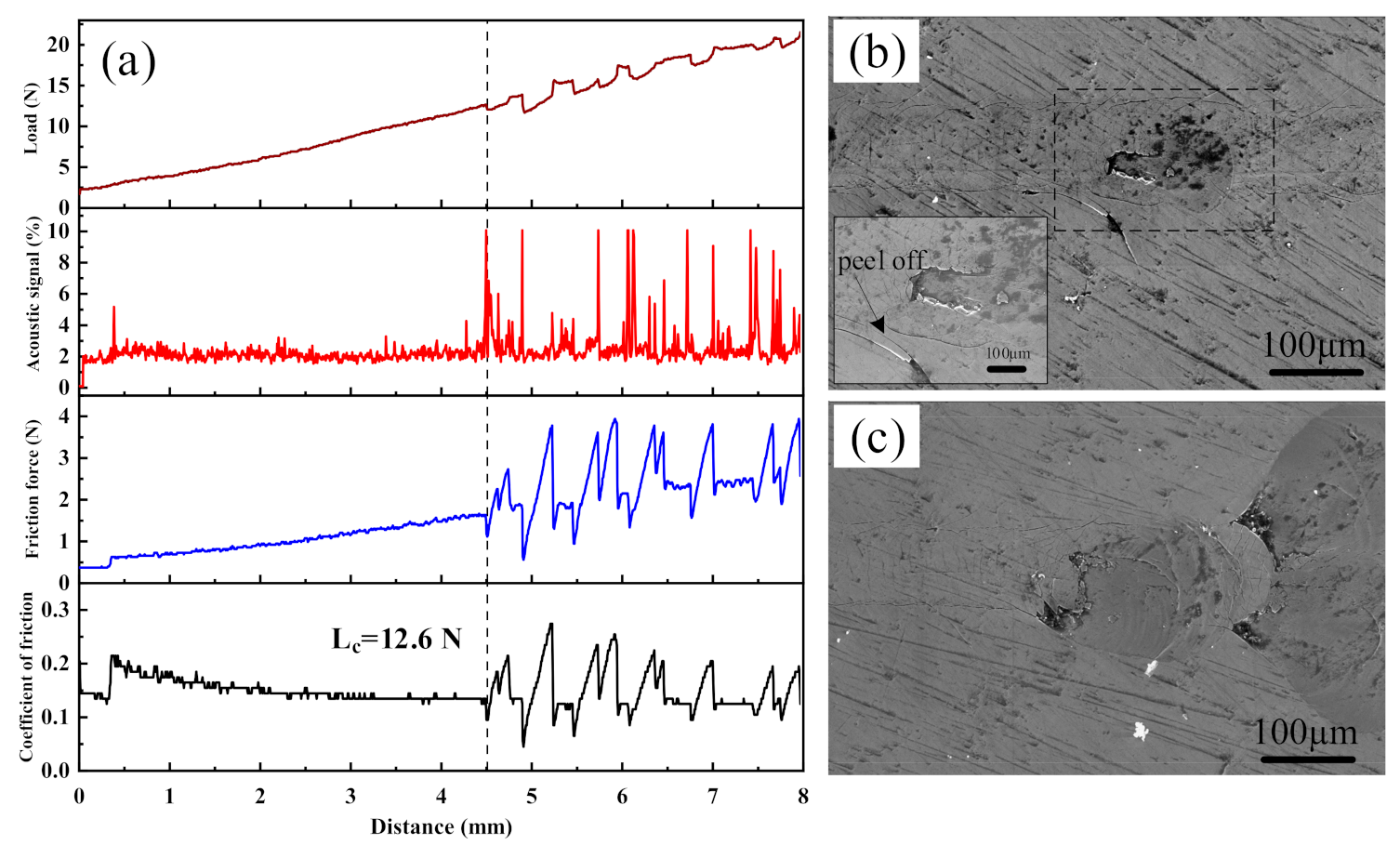

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tjong, S.; Mai, Y. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Huang, L.; Geng, L.; Li, A.; Yang, F.; Peng, H. In situ TiBw/Ti–6Al–4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 60, 996–999. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A: Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Chen, W.; Yang, J.; Zhang, W.; Wang, M.; Du, D.; Cui, G. Influence of TiBw volume fraction on microstructure and high-temperature properties of in situ TiBw/Ti6Al4V composites with TiBw columnar reinforced structure fabricated by pre-sintering and canned extrusion. Adv. Powder Technol. 2017, 28, 2346–2356. [Google Scholar] [CrossRef]

- Huang, L.; Geng, L.; Peng, H.; Balasubramaniam, K.; Wang, G. Effects of sintering parameters on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with a novel network architecture. Mater. Des. 2011, 32, 3347–3353. [Google Scholar] [CrossRef]

- Huang, L.; Geng, L.; Peng, H.; Zhang, J. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture. Scr. Mater. 2011, 64, 844–847. [Google Scholar] [CrossRef]

- Huang, L.; Geng, L.; Peng, H.-X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Huang, L.; Geng, L.; Peng, H.; Kaveendran, B. High temperature tensile properties of in situ TiBw/Ti6Al4V composites with a novel network reinforcement architecture. Mater. Sci. Eng. A 2012, 534, 688–692. [Google Scholar] [CrossRef]

- Li, X.T.; Huang, L.; Wei, S.L.; An, Q.; Cui, X.P.; Geng, L. Cycle oxidation behavior and anti-oxidation mechanism of hot-dipped aluminum coating on TiBw/Ti6Al4V composites with network microstructure. Sci. Rep. 2018, 8, 5790. [Google Scholar] [CrossRef]

- Barsoum, M.W. MAX Phases: Properties of Machinable Ternary Carbides and Nitrides; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar]

- Eklund, P.; Rosen, J.; Persson, P.O.Å. Layered ternary Mn+1AXnphases and their 2D derivative MXene: An overview from a thin-film perspective. J. Phys. D Appl. Phys. 2017, 50, 113001. [Google Scholar] [CrossRef]

- Wang, Q.M.; Renteria, A.F.; Schroeter, O.; Mykhaylonka, R.; Leyens, C.; Garkas, W.; Baben, M.T. Fabrication and oxidation behavior of Cr2AlC coating on Ti6242 alloy. Surf. Coatings Technol. 2010, 204, 2343–2352. [Google Scholar] [CrossRef]

- Hajas, D.E.; Baben, M.T.; Hallstedt, B.; Iskandar, R.; Mayer, J.; Schneider, J. Oxidation of Cr2AlC coatings in the temperature range of 1230 to 1410 °C. Surf. Coatings Technol. 2011, 206, 591–598. [Google Scholar] [CrossRef]

- Rahman, A. Study on Structural, Electronic, Optical and Mechanical Properties of MAX Phase Compounds and Applications Review Article. Am. J. Mod. Phys. 2015, 4, 75. [Google Scholar] [CrossRef]

- Tian, W.; Wang, P.; Zhang, G.; Kan, Y.; Li, Y.; Yan, D. Synthesis and thermal and electrical properties of bulk Cr2AlC. Scr. Mater. 2006, 54, 841–846. [Google Scholar] [CrossRef]

- Schneider, J.M.; Sun, Z.; Mertens, R.; Uestel, F.; Ahuja, R. Ab initio calculations and experimental determination of the structure of Cr2AlC. Solid State Commun. 2004, 130, 445–449. [Google Scholar] [CrossRef]

- Mertens, R.; Sun, Z.; Music, D.; Schneider, J. Effect of the Composition on the Structure of Cr-Al-C Investigated by Combinatorial Thin Film Synthesis and ab Initio Calculations. Adv. Eng. Mater. 2004, 6, 903–907. [Google Scholar] [CrossRef]

- Zamulaeva, E.; Levashov, E.; Skryleva, E.; Sviridova, T.; Kiryukhantsev-Korneev, P. Conditions for formation of MAX phase Cr2AlC in electrospark coatings deposited onto titanium alloy. Surf. Coatings Technol. 2016, 298, 15–23. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, G.; Qian, Y.; Xu, J.; Li, M. Deposition of Phase-pure Cr 2 AlC Coating by DC Magnetron Sputtering and Post Annealing Using Cr-Al-C Targets with Controlled Elemental Composition but Different Phase Compositions. J. Mater. Sci. Technol. 2018, 34, 466–471. [Google Scholar] [CrossRef]

- Liu, J.; Zuo, X.; Wang, Z.; Wang, L.; Wu, X.; Ke, P.; Wang, A. Fabrication and mechanical properties of high purity of Cr2AlC coatings by adjustable Al contents. J. Alloy. Compd. 2018, 753, 11–17. [Google Scholar] [CrossRef]

- Wilhelmsson, J.; Palmquist, E.L.-J.; Lewin, E.; Emmerlich, J.; Eklund, P.; Persson, P.O.Å.; Högberg, H.; Li, S.; Ahuja, R.; Eriksson, O.; et al. Deposition and Characterization of Ternary Thin Films within the Ti–Al–C System by DC Magnetron Sputtering. J. Cryst. Growth 2006, 291, 290–300. Available online: https://www.sciencedirect.com/science/article/pii/S0022024806002508 (accessed on 25 January 2020). [CrossRef]

- Li, J.; Hu, L.; Li, F.; Li, M.-S.; Zhou, Y. Variation of microstructure and composition of the Cr2AlC coating prepared by sputtering at 370 and 500 °C. Surf. Coatings Technol. 2010, 204, 3838–3845. [Google Scholar] [CrossRef]

- Walter, C.; Sigumonrong, D.P.; El-Raghy, T.; Schneider, J.M. Towards large area deposition of Cr2AlC on steel. Thin Solid Films 2006, 515, 389–393. [Google Scholar] [CrossRef]

- Sonoda, T.; Nakao, S.; Ikeyama, M. Deposition and characterization of MAX-phase containing Ti–Si–C thin films by sputtering using elemental targets. Vacuum 2013, 92, 95–99. [Google Scholar] [CrossRef]

- Li, Y.; Qian, Y.; Zhao, G.; Xu, J.; Li, M. Preparation of Nb2AlC coating by DC magnetron sputtering and subsequent annealing. Ceram. Int. 2017, 43, 6622–6625. [Google Scholar] [CrossRef]

- Tang, C.; Klimenkov, M.; Jaentsch, U.; Leiste, H.; Rinke, M.; Ulrich, S.; Steinbrück, M.; Seifert, H.; Stueber, M. Synthesis and characterization of Ti2AlC coatings by magnetron sputtering from three elemental targets and ex-situ annealing. Surf. Coatings Technol. 2017, 309, 445–455. [Google Scholar] [CrossRef]

- Obrosov, A.; Gulyaev, R.V.; Żak, A.; Ratzke, M.; Naveed, M.; Dudziński, W.; Weiß, S. Chemical and Morphological Characterization of Magnetron Sputtered at Different Bias Voltages Cr-Al-C Coatings. Materials 2017, 10, 156. [Google Scholar] [CrossRef]

- Naveed, M.; Obrosov, A.; Żak, A.; Dudziński, W.; Volinsky, A.A.; Weiß, S. Sputtering Power Effects on Growth and Mechanical Properties of Cr2AlC MAX Phase Coatings. Metals 2016, 6, 265. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, G.; Du, B.; Li, M.; Xu, J.; Qian, Y.; Sheng, L.; Zheng, Y. Fabrication of Cr2AlC coating from a cost-efficient Cr–Al–C target by arc ion plating. Surf. Innov. 2018, 7, 4–9. [Google Scholar] [CrossRef]

- Bandorf, R.; Sittinger, V.; Bräuer, G. High Power Impulse Magnetron Sputtering—HIPIMS. Compr. Mater. Process. 2014, 4, 75–99. [Google Scholar] [CrossRef]

- Anders, A. Discharge physics of high power impulse magnetron sputtering. Surf. Coatings Technol. 2011, 205, S1–S9. [Google Scholar] [CrossRef]

- Berger, O.; Leyens, C.; Heinze, S.; Boucher, R.; Ruhnow, M. Characterization of Cr–Al–C and Cr–Al–C–Y films synthesized by High Power Impulse Magnetron Sputtering at a low deposition temperature. Thin Solid Films 2015, 580, 6–11. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, T.; Xia, Q.X.; Lim, S.-H.; Wan, Z.; Lee, T.-W.; Kim, K.H. Oxidation and Corrosion Behavior of Nanolaminated MAX-Phase Ti2AlC Film Synthesized by High-Power Impulse Magnetron Sputtering and Annealing. J. Nanomater. 2015, 2015, 213128. [Google Scholar] [CrossRef]

- Rueß, H.; Baben, M.T.; Mráz, S.; Shang, L.; Polcik, P.; Kolozsvári, S.; Hans, M.; Primetzhofer, D.; Schneider, J.M. HPPMS deposition from composite targets: Effect of two orders of magnitude target power density changes on the composition of sputtered Cr-Al-C thin films. Vacuum 2017, 145, 285–289. [Google Scholar] [CrossRef]

- Field, M.R.; Carlsson, P.; Eklund, P.C.; Partridge, J.G.; McCulloch, D.G.; McKenzie, D.R.; Bilek, M.M.M. A combinatorial comparison of DC and high power impulse magnetron sputtered Cr2AlC. Surf. Coatings Technol. 2014, 259, 746–750. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Q.M.; Lee, J.; Ke, P.; Nowak, R.; Kim, K.H. Nanocrystalline thin films synthesized from a Ti2AlN compound target by high power impulse magnetron sputtering technique. Surf. Coatings Technol. 2012, 212, 199–206. [Google Scholar] [CrossRef]

- Anstis, G.; Chantikul, P.; Lawn, B.; Marshall, D. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Musil, J.; Šícha, J.; Herman, D.; Čerstvý, R. Role of energy in low-temperature high-rate formation of hydrophilic TiO2 thin films using pulsed magnetron sputtering. J. Vac. Sci. Technol. A 2007, 25, 666. [Google Scholar] [CrossRef]

- Musil, J.; Leština, J.; Vlček, J.; Tölg, T. Pulsed dc magnetron discharge for high-rate sputtering of thin films. J. Vac. Sci. Technol. A 2001, 19, 420–424. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Brenning, N.; Lundin, D.; Helmersson, U. High power impulse magnetron sputtering discharge. J. Vac. Sci. Technol. A 2012, 30, 030801. [Google Scholar] [CrossRef]

- Grieseler, R.; Hähnlein, B.; Stubenrauch, M.; Kups, T.; Wilke, M.; Hopfeld, M.; Pezoldt, J.; Schaaf, P. Nanostructured plasma etched, magnetron sputtered nanolaminar Cr2AlC MAX phase thin films. Appl. Surf. Sci. 2014, 292, 997–1001. [Google Scholar] [CrossRef]

- Schuster, J.C.; Nowotny, H.; Vaccaro, C. The ternary systems: Cr-Al-C, V-Al-C, and Ti-Al-C and the behavior of H-phases (M2AlC). J. Solid State Chem. 1980, 32, 213–219. [Google Scholar] [CrossRef]

- Abdulkadhim, A.M.H.; Baben, M.T.; Takahashi, T.; Schnabel, V.; Hans, M.; Polzer, C.; Polcik, P.; Schneider, J.M. Crystallization kinetics of amorphous Cr2AlC thin films. Surf. Coatings Technol. 2011, 206, 599–603. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Zhou, Y. Stable M2AlC(0001) surfaces (M = Ti, V and Cr) by first-principles investigation. J. Physics: Condens. Matter 2008, 20. [Google Scholar] [CrossRef]

- Beckers, M.; Schell, N.; Martins, R.M.S.; Mucklich, A.; Möller, W. Phase stability of epitaxially grown Ti2AlN thin films. Appl. Phys. Lett. 2006, 89, 74101. [Google Scholar] [CrossRef]

- Wilhelmsson, O.; Palmquist, J.-P.; Nyberg, T.; Jansson, U. Deposition of Ti2AlC and Ti3AlC2 epitaxial films by magnetron sputtering. Appl. Phys. Lett. 2004, 85, 1066–1068. [Google Scholar] [CrossRef]

- Ingason, A.S.; Petruhins, A.; Rosen, J. Toward Structural Optimization of MAX Phases as Epitaxial Thin Films. Mater. Res. Lett. 2016, 4, 152–160. [Google Scholar] [CrossRef]

- Qureshi, M.W.; Ma, X.; Tang, G.; Paudel, R. Structural Stability, Electronic, Mechanical, Phonon, and Thermodynamic Properties of the M2GaC (M = Zr, Hf) MAX Phase: An ab Initio Calculation. Materials 2020, 13, 5148. [Google Scholar] [CrossRef]

- Jia, G.; Yang, L. Ab initio calculations for properties of Ti2AlN and Cr2AlC. Phys. B Condens. Matter 2010, 405, 4561–4564. [Google Scholar] [CrossRef]

- Lin, Z.; Zhou, Y.; Li, M.; Wang, J. In-situ hot pressing/solid-liquid reaction synthesis of bulk Cr2AlC. Z. Met. 2005, 96, 291–296. [Google Scholar] [CrossRef]

- Chen, X.; Stelzer, B.; Hans, M.; Iskandar, R.; Mayer, J.; Schneider, J.M. Enhancing the high temperature oxidation behavior of Cr2AlC coatings by reducing grain boundary nanoporosity. Mater. Res. Lett. 2021, 9, 127–133. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, H.; Chen, R.; Ke, P.; Wang, A. Enhanced mechanical and tribological properties of V-Al-C coatings via increasing columnar boundaries. J. Alloy. Compd. 2019, 781, 186–195. [Google Scholar] [CrossRef]

- Macák, K.; Kouznetsov, V.; Schneider, J.; Helmersson, U.; Petrov, I. Ionized sputter deposition using an extremely high plasma density pulsed magnetron discharge. J. Vac. Sci. Technol. A 2000, 18, 1533–1537. [Google Scholar] [CrossRef]

- Anders, A.; Andersson, J.; Ehiasarian, A. High power impulse magnetron sputtering: Current-voltage-time characteristics indicate the onset of sustained self-sputtering. J. Appl. Phys. 2007, 102, 113303. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Wu, J.; Shchelkanov, I.; Ruzic, D.N.; Huang, N.; Leng, Y. Tailoring of titanium thin film properties in high power pulsed magnetron sputtering. Vacuum 2018, 150, 144–154. [Google Scholar] [CrossRef]

- Crisan, O.; Crisan, A.D. Incipient low-temperature formation of MAX phase in Cr–Al–C films. J. Adv. Ceram. 2018, 7, 143–151. [Google Scholar] [CrossRef]

- Ougier, M.; Michau, A.; Lomello, F.; Schuster, F.; Maskrot, H.; Schlegel, M.L. High-temperature oxidation behavior of HiPIMS as-deposited Cr–Al–C and annealed Cr2AlC coatings on Zr-based alloy. J. Nucl. Mater. 2020, 528, 151855. [Google Scholar] [CrossRef]

- Eichner, D.; Schlieter, A.; Leyens, C.; Shang, L.; Shayestehaminzadeh, S.; Schneider, J.M. Solid particle erosion behavior of nanolaminated Cr2AlC films. Wear 2018, 402–403, 187–195. [Google Scholar] [CrossRef]

- Thornton, J.A. High Rate Thick Film Growth. Annu. Rev. Mater. Res. 1977, 7, 239–260. [Google Scholar] [CrossRef]

- Grosse, M.; Steinbrueck, M.; Stueber, M.; Grosse, M.; Yu, X.; Ulrich, S.; Seifert, H.J. Deposition, characterization and high-temperature steam oxidation behavior of single-phase Ti2 AlC-coated Zircaloy-4. Corros. Sci. 2018, 135, 87–98. [Google Scholar] [CrossRef]

- Mráz, S.; Tyra, M.; Baben, M.T.; Hans, M.; Chen, X.; Herrig, F.; Lambrinou, K.; Schneider, J.M. Thermal stability enhancement of Cr2AlC coatings on Zr by utilizing a double layer diffusion barrier. J. Eur. Ceram. Soc. 2020, 40, 1119–1124. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. Peak amplitude of target current determines deposition rate loss during high power pulsed magnetron sputtering. Vacuum 2016, 124, 1–4. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.L.; Vasilovici, O.; Popa, G. Optimization of deposition rate in HiPIMS by controlling the peak target current. J. Phys. D Appl. Phys. 2015, 48, 495204. [Google Scholar] [CrossRef]

- Croll, S. Surface roughness profile and its effect on coating adhesion and corrosion protection: A review. Prog. Org. Coatings 2020, 148, 105847. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P. Understanding the role of surface roughness on the tribological performance and corrosion resistance of WC-Co coating. Surf. Coatings Technol. 2019, 378, 125080. [Google Scholar] [CrossRef]

- Góral, A.; Lityńska-Dobrzyńska, L.; Kot, M. Effect of Surface Roughness and Structure Features on Tribological Properties of Electrodeposited Nanocrystalline Ni and Ni/Al2O3 Coatings. J. Mater. Eng. Perform. 2017, 26, 2118–2128. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Xue, Q. Improving the tribological performances of graphite-like carbon films on Si3N4 and SiC by using Si interlayers. Appl. Surf. Sci. 2011, 257, 10246–10253. [Google Scholar] [CrossRef]

- Ghasemi, S.; Farhadizadeh, A.R.; Ghomi, H. Effect of frequency and pulse-on time of high power impulse magnetron sputtering on deposition rate and morphology of titanium nitride using response surface methodology. Trans. Nonferrous Met. Soc. China 2019, 29, 2577–2590. [Google Scholar] [CrossRef]

- Eichenhofer, G.; Fernandez, I.; Wennberg, A. Industrial use of HiPIMS and the hiP-V hiPlus technology. Vák. Forsch. und Prax. 2017, 29, 40–44. [Google Scholar] [CrossRef]

- Luo, D.; Tang, G.; Ma, X.; Gu, L.; Sun, M.; Wang, L. Various categories of defects after surface alloying induced by high current pulsed electron beam irradiation. Appl. Surf. Sci. 2015, 351, 1069–1074. [Google Scholar] [CrossRef]

- Bräuer, G.; Szyszka, B.; Vergöhl, M.; Bandorf, R. Magnetron sputtering—Milestones of 30 years. Vacuum 2010, 84, 1354–1359. [Google Scholar] [CrossRef]

- Cai, C.; Song, B.; Qiu, C.; Li, L.; Xue, P.; Wei, Q.; Zhou, J.; Nan, H.; Chen, H.; Shi, Y. Hot isostatic pressing of in-situ TiB/Ti-6Al-4V composites with novel reinforcement architecture, enhanced hardness and elevated tribological properties. J. Alloy. Compd. 2017, 710, 364–374. [Google Scholar] [CrossRef]

- Pei, Y.; Huizenga, P.; Galvan, D.; De Hosson, J.T.M. Breakdown of the Coulomb friction law in TiC∕a-C:H nanocomposite coatings. J. Appl. Phys. 2006, 100, 114309. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, Z.; Zhou, F.; Yan, J. Comparison of crack resistance between ternary CrSiC and quaternary CrSiCN coatings via nanoindentation. Mater. Sci. Eng. A 2015, 642, 391–397. [Google Scholar] [CrossRef]

- Kooi, B.J.; Poppen, R.; Carvalho, N.; De Hosson, J.T.M.; Barsoum, M. Ti3SiC2: A damage tolerant ceramic studied with nano-indentations and transmission electron microscopy. Acta Mater. 2003, 51, 2859–2872. [Google Scholar] [CrossRef]

- Emmerlich, J.; Högberg, H.; Sasvári, S.; Persson, P.; Hultman, L.; Palmquist, J.-P.; Jansson, U.; Molina-Aldareguia, J.; Czigány, Z. Growth of Ti3SiC2 thin films by elemental target magnetron sputtering. J. Appl. Phys. 2004, 96, 4817. [Google Scholar] [CrossRef]

- Schneider, J.M.; Sigumonrong, D.P.; Music, D.; Walter, C.; Emmerlich, J.; Iskandar, R.; Mayer, J. Elastic properties of Cr2AlC thin films probed by nanoindentation and ab initio molecular dynamics. Scr. Mater. 2007, 57, 1137–1140. [Google Scholar] [CrossRef]

- Imtyazuddin, M.; Mir, A.H.; Tunes, M.A.; Vishnyakov, V.M. Radiation resistance and mechanical properties of magnetron-sputtered Cr2AlC thin films. J. Nucl. Mater. 2019, 526, 151742. [Google Scholar] [CrossRef]

- Rubshtein, A.P.; Vladimirov, A.B.; Plotnikov, S.A. Composition, Structure and Mechanical Properties of CrAlC Films Deposited by Arc Sputtering Technique. Solid State Phenom. 2018, 279, 160–166. [Google Scholar] [CrossRef]

- Zamulaeva, E.I.; Levashov, E.A.; Sviridova, T.; Shvyndina, N.; Petrzhik, M. Pulsed electrospark deposition of MAX phase Cr2AlC based coatings on titanium alloy. Surf. Coatings Technol. 2013, 235, 454–460. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, Z.; Zhang, H.; Zhang, L.; Wang, J. On the chemical compatibility between Zr-4 substrate and well-bonded Cr2AlC coating. J. Mater. Sci. Technol. 2019, 35, 1–5. [Google Scholar] [CrossRef]

- Sharifi, H.; Aliofkhazraei, M.; Darband, G.B.; Shrestha, S. A Review On Adhesion Strength of Peo Coatings by Scratch Test Method. Surf. Rev. Lett. 2018, 25, 1830004. [Google Scholar] [CrossRef]

| Deposition Method | Voltage (V) | Frequency (kHz) | Pulse Width | Pressure (Pa) | Pave (W) | Ppeak (kW) |

|---|---|---|---|---|---|---|

| HiPIMS | 600 | 1.2 | 40 | 0.5 | 240 | 6.6 |

| 600 | 1.4 | 40 | 280 | 6.6 | ||

| 600 | 1.6 | 40 | 320 | 6.6 | ||

| 600 | 1.5 | 20 | 0.5 | 110 | 5.9 | |

| 600 | 1.5 | 40 | 300 | 6.6 | ||

| 600 | 1.5 | 60 | 440 | 7.1 | ||

| DCMS | 330 | 0.5 | 112 |

| Process | Pave (W) | a (Å) | c (Å) | c/a (Å) | V (A3) | D (nm) | δ × 10−3 (nm−2) | ɛ × 10−3 (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| DCMS | 112 | 2.835 | 12.859 | 4.535 | 89.504 | 13.872 | 7.35 + 1.9 | 7.45 + 2.9 | This work |

| HiPIMS | 110 | 2.851 | 13.037 | 4.572 | 91.798 | 14.870 | 6.99 + 1.3 | 5.10 + 2.2 | |

| 240 | 2.848 | 12.871 | 4.519 | 90.427 | 13.507 | 6.43 + 2.0 | 5.76 + 1.7 | ||

| 280 | 2.847 | 12.863 | 4.518 | 90.310 | 13.358 | 6.81 + 1.2 | 6.80 + 2.1 | ||

| 300 | 2.847 | 12.860 | 4.517 | 90.303 | 13.006 | 3.37 + 1.0 | 6.96 + 1.4 | ||

| 320 | 2.818 | 13.043 | 4.628 | 89.730 | 12.883 | 4.92 + 1.4 | 6.96 + 2.8 | ||

| 440 | 2.808 | 12.875 | 4.585 | 87.908 | 12.575 | 5.33 + 0.8 | 7.05 + 2.4 | ||

| DFT | 2.847 | 12.793 | 4.493 | 89.804 | This work | ||||

| DCMS | 2.85 | 12.93 | 4.536 | Exp [20] | |||||

| DFT | 2.86 | 12.82 | 4.48 | 90.813 | Theo [49] | ||||

| HIP | 2.85 | 12.81 | 4.49 | 90.109 | Exp [50] |

| Average Power (W) | Frequency (kHz) | Pulse Width | Defect Size (µm) | Defect Area (%) | Remarks |

|---|---|---|---|---|---|

| 240 | 1.2 | 3.13 ± 1.51 | 4.94 | pit, pinhole | |

| 280 | 1.4 | 40 | 1.33 ± 0.51 | 4.70 | pinhole |

| 320 | 1.6 | 0.66 ± 0.29 | 2.35 | pinhole | |

| 110 | 20 | None | None | None | |

| 300 | 1.5 | 40 | 3.73 ± 1.47 | 9.30 | craters, pit |

| 440 | 60 | 1.37 ± 0.30 | 5.17 | craters |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qureshi, M.W.; Ma, X.; Tang, G.; Miao, B.; Niu, J. Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS. Materials 2021, 14, 826. https://doi.org/10.3390/ma14040826

Qureshi MW, Ma X, Tang G, Miao B, Niu J. Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS. Materials. 2021; 14(4):826. https://doi.org/10.3390/ma14040826

Chicago/Turabian StyleQureshi, Muhammad Waqas, Xinxin Ma, Guangze Tang, Bin Miao, and Junbo Niu. 2021. "Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS" Materials 14, no. 4: 826. https://doi.org/10.3390/ma14040826

APA StyleQureshi, M. W., Ma, X., Tang, G., Miao, B., & Niu, J. (2021). Fabrication and Mechanical Properties of Cr2AlC MAX Phase Coatings on TiBw/Ti6Al4V Composite Prepared by HiPIMS. Materials, 14(4), 826. https://doi.org/10.3390/ma14040826