Microstructures and Macrosegregation of Al–Zn–Mg–Cu Alloy Billet Prepared by Uniform Direct Chill Casting

Abstract

1. Introduction

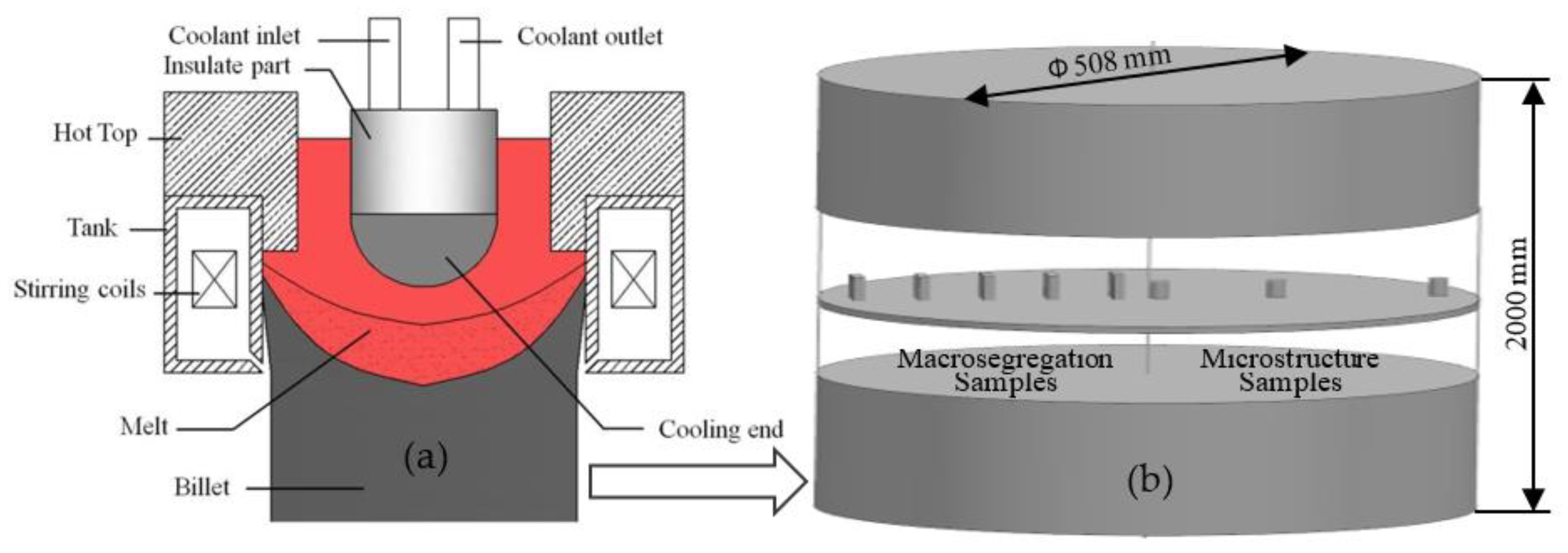

2. Experimental

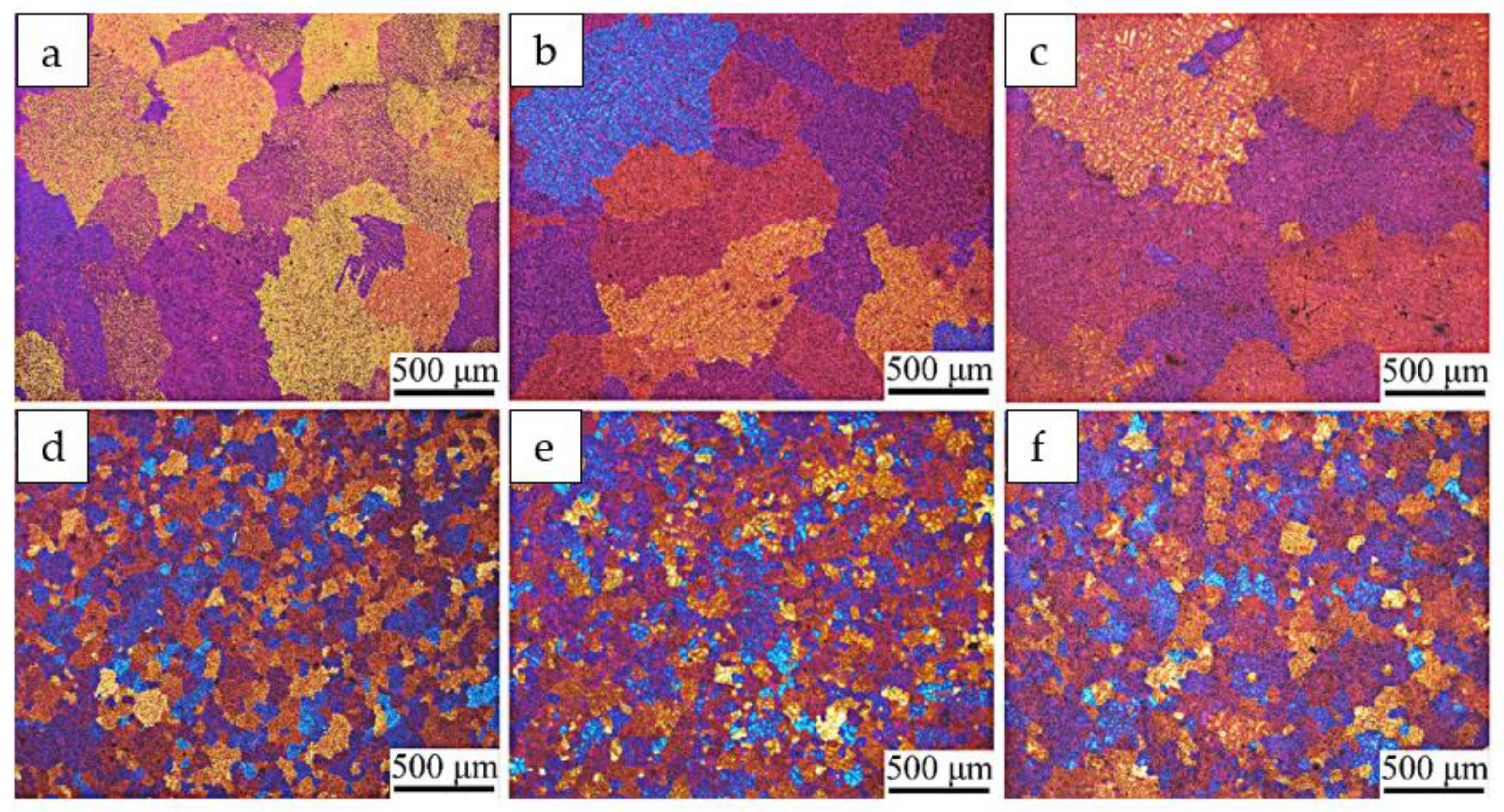

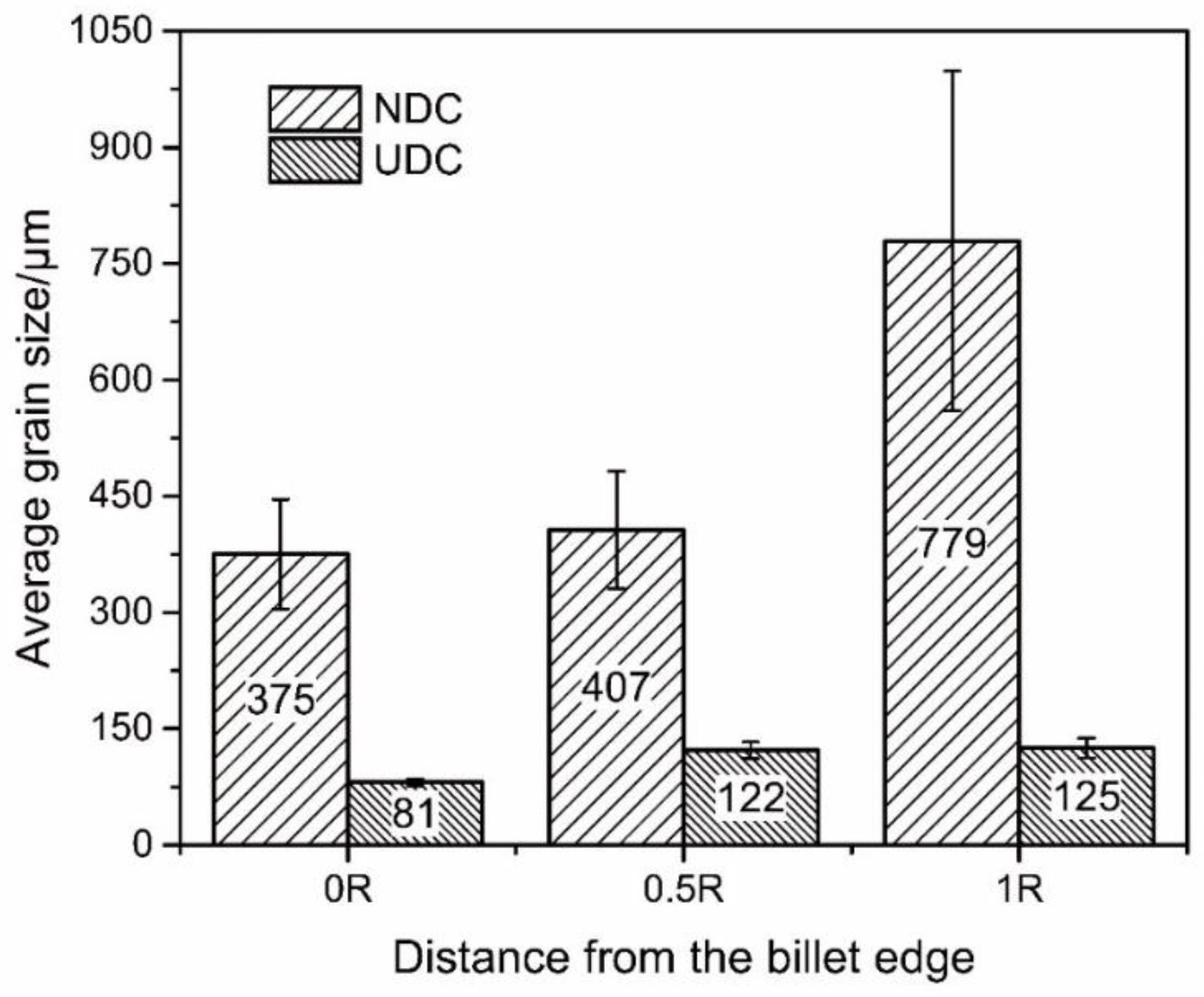

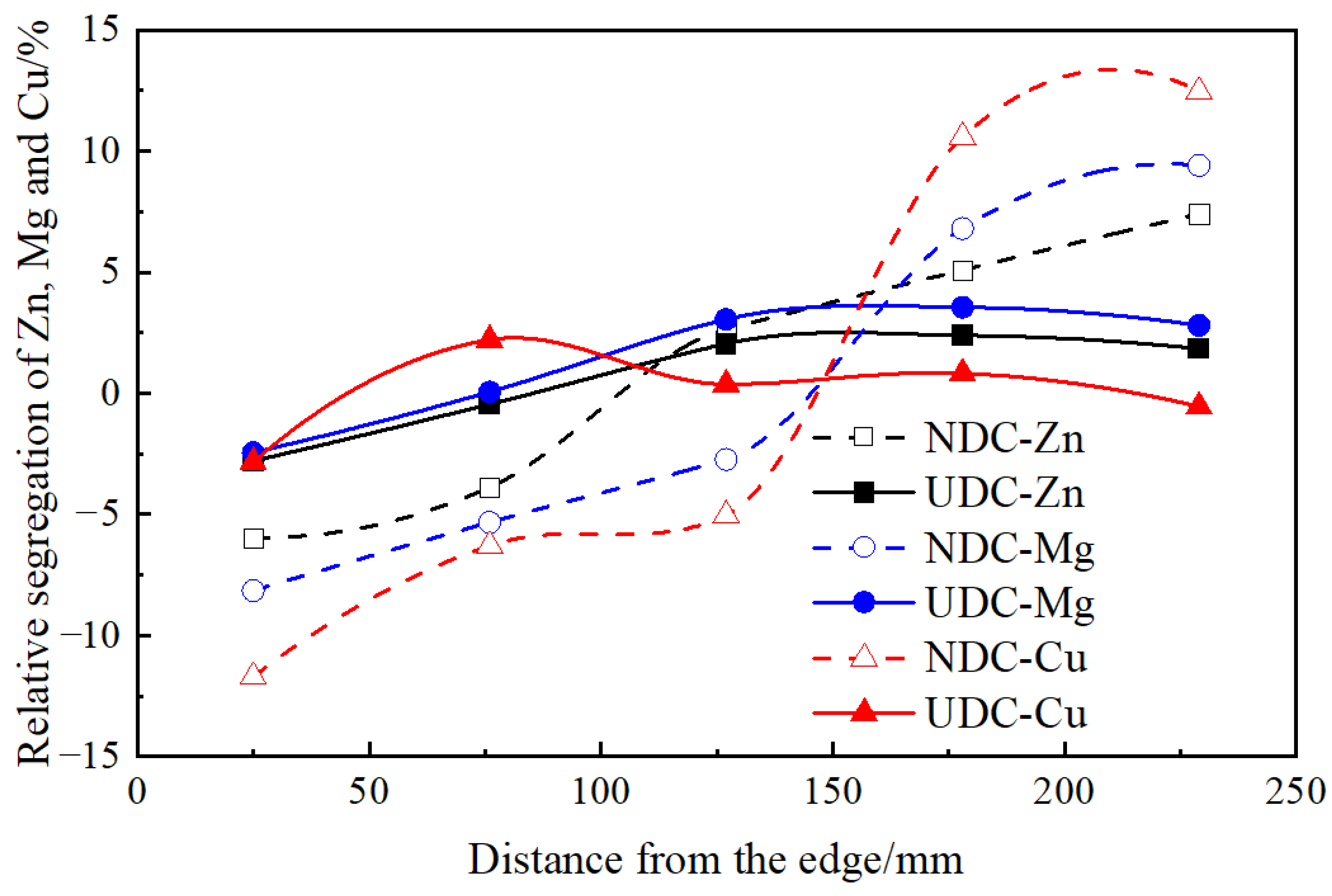

3. Results

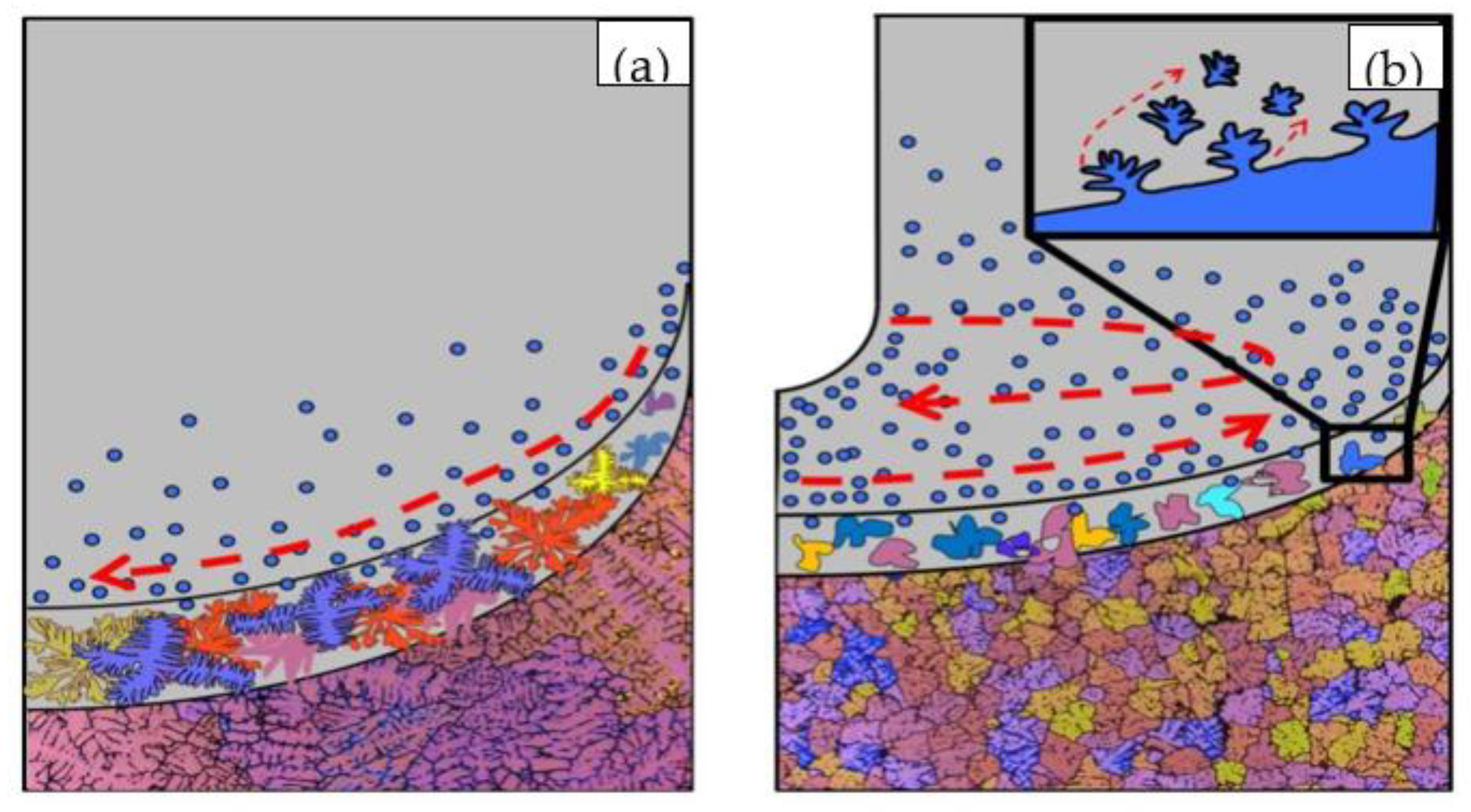

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shih, T.-S.; Kwang, E.-T.; Huang, Y.-S. The Optimum Process to Produce High-Strength Cast/Forged Al–8%Zn–2.5%Mg–1%Cu Alloy. Metals 2019, 9, 970. [Google Scholar] [CrossRef]

- Ferguson, J.; Schultz, B.F.; Mantas, J.C.; Shokouhi, H.; Rohatgi, P.K. Effect of Cu, Zn, and Mg Concentration on Heat Treating Behavior of Squeeze Cast Al-(10 to 12)Zn-(3.0 to 3.4)Mg-(0.8 to 1)Cu. Metals 2014, 4, 314–321. [Google Scholar] [CrossRef]

- Gong, H.; Cao, X.; Liu, Y.; Wu, Y.; Jiang, F.; Zhang, M. Simulation and Experimental Study on the Inhomogeneity of Mechanical Properties of Aluminum Alloy 7050 Plate. Metals 2020, 10, 515. [Google Scholar] [CrossRef]

- Ye, S.; Chen, K.; Liu, L.; Chen, S.; Zhu, C. Prediction and Experimental of Yield Strengths of As-Quenched 7050 Aluminum Alloy Thick Plates after Continuous Quench Cooling. Metals 2020, 10, 26. [Google Scholar] [CrossRef]

- Cao, J.; Li, F.; Ma, W.; Wang, K.; Ren, J.; Nie, H.; Dang, W. A Strain Rate Dependent Fracture Model of 7050 Aluminum Alloy. Metals 2020, 10, 3. [Google Scholar] [CrossRef]

- Ye, S.; Chen, K.; Zhu, C.; Chen, S. A New Path of Quench-Induced Residual Stress Control in Thick 7050 Aluminum Alloy Plates. Metals 2019, 9, 393. [Google Scholar] [CrossRef]

- Fezi, K.; Plotkowski, A.; Krane, M.J.M. Macrosegregation modeling during direct-chill casting of aluminum alloy 7050. Numer. Heat Transf. Part A Appl. 2016, 70, 939–963. [Google Scholar] [CrossRef]

- Liu, X.D.; Zhu, Q.F.; Kang, Y.L.; Zuo, Y.B.; Wang, R.; Li, Z.M. An investigation of direct-chill cast 2024 aluminum alloy under the influence of high shearing with regards to different shear positions. J. Mater. Process. Technol. 2020, 279, 116547. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Z.; Zhou, L.; He, M.; Zhang, Z.; Peng, X.; Zhang, Z. Effect of Electromagnetic Stirring Position on Uniform Direct Chill Casting of Large-sized 7005 Alloy Billet. JOM 2020, 72, 4665–4673. [Google Scholar] [CrossRef]

- Li, H.X.; Bai, Q.L.; Li, Y.; Du, Q.; Katgerman, L.; Zhang, J.S.; Zhuang, L.Z. Mechanical properties and cold cracking evaluations of four 7××× series aluminum alloys using a newly developed index. Mater. Sci. Eng. A 2017, 698, 230–237. [Google Scholar] [CrossRef]

- Yue, L.; Zhang, Z.R.; Zhao, Z.Y.; Li, H.X.; Katgerman, L.; Zhang, J.S.; Zhuang, L.Z. Effect of Main Elements (Zn, Mg, and Cu) on Hot Tearing Susceptibility During Direct-Chill Casting of 7xxx Aluminum Alloys. Metall. Mater. Trans. A 2019, 50, 3603–3616. [Google Scholar]

- Fezi, K.; Krane, M.J.M. Influence of a wiper on transport phenomena in direct chill casting of aluminium alloy 7050. Int. J. Cast Met. Res. 2017, 30, 191–200. [Google Scholar] [CrossRef]

- Al-Helal, K.; Patel, J.; Fan, Z. Melt Conditioning Twin Roll Casting with Thermo-Mechanical Treatment of Recycled AA6111 Alloy. JOM 2019, 71, 1714–1721. [Google Scholar] [CrossRef]

- Haghayeghi, R.; de Paula, L.C.; Zoqui, E.J. Comparison of Si Refinement Efficiency of Electromagnetic Stirring and Ultrasonic Treatment for a Hypereutectic Al-Si Alloy. J. Mater. Eng. Perform. 2017, 26, 1900–1907. [Google Scholar] [CrossRef]

- Li, L.; Zhu, Q.; Zhao, Z.; Zhang, H.; Zuo, Y.; Cui, J. Structural and crystallographic study on 3004 aluminum alloy ingot by horizontal direct chill casting under combined electromagnetic fields. J. Mater. Res. 2015, 30, 745–752. [Google Scholar] [CrossRef]

- Zou, Q.; Jie, J.; Wang, T.; Li, T. An efficient method to purify metallurgical grade Si by electromagnetic semi-continuous casting of Al-30Si melt. Mater. Lett. 2016, 185, 59–62. [Google Scholar] [CrossRef]

- Wan, Y.; Li, M.; Chen, L.; Wu, Y.; Li, J.; Pan, H.; Zhong, W. Effect of final electromagnetic stirring parameters on central cross-sectional carbon concentration distribution of high-carbon square billet. Metals 2019, 9, 665–680. [Google Scholar] [CrossRef]

- Mehr, N.F.; Aashuri, H. The effects of annular electromagnetic stirring parameters on microstructure evolution of rheocast AZ91 magnesium alloy. J. Mater. Res. Technol. 2019, 8, 2300–2308. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, J.; Zhang, Z.; Bai, Y.; Shi, L. Annular electromagnetic stirring-a new method for the production of semi-solid A357 aluminum alloy slurry. Acta Metall. Sin. 2009, 22, 408–414. [Google Scholar] [CrossRef][Green Version]

- Luo, Y.; Zhang, Z. Numerical modeling of annular electromagnetic stirring with intercooling in direct chill casting of 7005 aluminum alloy billet. Prog. Nat. Sci. Mater. Int. 2019, 29, 81–87. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Li, B.; Gao, M.; Qiu, Y.; He, M. Effects of Annular Electromagnetic Stirring Coupled with Intercooling on Grain Refinement and Homogeneity During Direct Chill Casting of Large-Sized 7005 Alloy Billet. JOM 2017, 69, 2640–2643. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Gao, M.; Li, B.; Chen, C. Control of microstructure and macrosegregation of large-sized aluminium alloy billet by uniform direct chill casting. Int. J. Cast Met. Res. 2019, 32, 31–35. [Google Scholar] [CrossRef]

- Campanella, T.; Charbon, C.; Rappaz, M. Grain refinement induced by electromagnetic stirring: A dendrite fragmentation criterion. Metall. Mater. Trans. A 2004, 35A, 3201–3210. [Google Scholar] [CrossRef]

- Liotti, E.; Lui, A.; Vincent, R.; Kumar, S.; Guo, Z.; Connolley, T.; Dolbnya, I.P.; Hart, M.; Arnberg, L.; Mathiesen, R.H.; et al. A synchrotron X-ray radiography study of dendrite fragmentation induced by a pulsed electromagnetic field in an Al-15Cu alloy. Acta Mater. 2014, 70, 228–239. [Google Scholar] [CrossRef]

- Li, M.; Tamura, T.; Omura, N.; Murakami, Y.; Tada, S. Grain refinement of AZCa912 alloys solidified by an optimized electromagnetic stirring technique. J. Mater. Process. Technol. 2016, 235, 114–120. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. Metall. Trans. A 1991, 22, 957–981. [Google Scholar] [CrossRef]

- Hellawell, A.; Liu, S.; Lu, S.Z. Dendrite fragmentation and the effects of fluid flow in castings. JOM 1997, 49, 18–20. [Google Scholar] [CrossRef]

- Hatič, V.; Mavrič, B.; Šarler, B. Simulation of macrosegregation in direct-chill casting—A model based on meshless diffuse approximate method. Eng. Anal. Bound. Elem. 2020, 113, 191–203. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, Z.; Luo, Y.; Gao, M.; Li, B.; Chen, C. Effect of coupled annular electromagnetic stirring and intercooling on the microstructures, macrosegregation and properties of large-sized 2219 aluminum alloy billets. Int. J. Mater. Res. 2018, 109, 469–475. [Google Scholar] [CrossRef]

- Yao, Q.; Luo, Z.; Li, Y.; Yan, F.Y.; Duan, R. Effect of electromagnetic stirring on the microstructures and mechanical properties of magnesium alloy resistance spot weld. Mater. Des. 2014, 63, 200–207. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

| Parameters | NDC | UDC |

|---|---|---|

| Pouring temperature (K) | 1023 | 1023 |

| Casting speed (mm min−1) | 27 | 27 |

| Cooling water (m3 h−1) | 9 | 9 |

| Electromagnetic current (A) | - | 100 |

| Electromagnetic frequency (Hz) | - | 5 |

| Cooler diameter (mm) | - | 200 |

| Cooling rate (W m−2 K−1) | - | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Luo, Y.; Zhang, Z.; He, M.; Xu, Y.; Zhao, Y.; Liu, S.; Dong, L.; Zhang, Z. Microstructures and Macrosegregation of Al–Zn–Mg–Cu Alloy Billet Prepared by Uniform Direct Chill Casting. Materials 2021, 14, 708. https://doi.org/10.3390/ma14040708

Zhou L, Luo Y, Zhang Z, He M, Xu Y, Zhao Y, Liu S, Dong L, Zhang Z. Microstructures and Macrosegregation of Al–Zn–Mg–Cu Alloy Billet Prepared by Uniform Direct Chill Casting. Materials. 2021; 14(4):708. https://doi.org/10.3390/ma14040708

Chicago/Turabian StyleZhou, Li, Yajun Luo, Zhenlin Zhang, Min He, Yinao Xu, Yulei Zhao, Sheng Liu, Lijun Dong, and Zhifeng Zhang. 2021. "Microstructures and Macrosegregation of Al–Zn–Mg–Cu Alloy Billet Prepared by Uniform Direct Chill Casting" Materials 14, no. 4: 708. https://doi.org/10.3390/ma14040708

APA StyleZhou, L., Luo, Y., Zhang, Z., He, M., Xu, Y., Zhao, Y., Liu, S., Dong, L., & Zhang, Z. (2021). Microstructures and Macrosegregation of Al–Zn–Mg–Cu Alloy Billet Prepared by Uniform Direct Chill Casting. Materials, 14(4), 708. https://doi.org/10.3390/ma14040708