3D Phase Field Modeling of Multi-Dendrites Evolution in Solidification and Validation by Synchrotron X-ray Tomography

Abstract

1. Introduction

2. Experiments

2.1. Alloy and Sample Preparation

2.2. Real-Time Synchrotron X-ray Tomography

2.3. Image Processing

3. Phase Field Model and Numerical Scheme

3.1. The 3D Phase Field Model

3.2. Numerical Experiments

4. Results

4.1. Dendrite Evolution Revealed by Synchrotron X-ray Tomography

4.2. Phase Field Modeling

4.2.1. Determining the Locations and Orientations of Dendrite Seeds

4.2.2. Computational Domain, Parameters Used, and Modeling Results

5. Discussions

5.1. Statistical Analyses on the Simulated and Experimental Dendrites

5.2. Coarsening Mechanisms in Different Thermal Conditions

5.3. Comparison with Classical LSW Theory for Dendritic Coarsening

6. Conclusions

- (1)

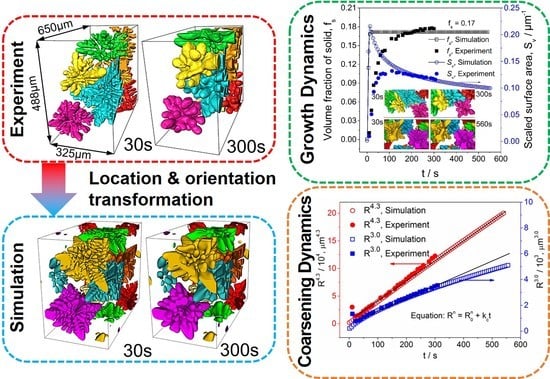

- Using the spatial locations and growth orientations of the real dendrites extracted from the tomography in the planted dendrite seeds at the start of the simulation, high fidelity multi-dendrite simulations have been achieved. The simulated and experimental dendrites showed high similarity in size, hierarchical dendrite branches, orientation, and surface morphology. This study has demonstrated that the phase field modeling is able to provide realistic results in the domain where experiments are very difficult or impossible to reach, such as in a very long time period of coarsening.

- (2)

- The 3D datasets obtained from X-ray tomography experiments and phase field simulations reveal that, in a much more quantitative manner, the relative importance of the dendrite coarsening mechanisms at different stages of solidification. At higher temperatures, small arm melting (SAM) and interdendritic groove advancement (IGA) are the dominant mechanisms for dendritic coarsening, whereas at lower temperatures, i.e., when the solid volume fraction was higher than 0.70, the coalescence between neighboring arms became dominant. Meanwhile, the rate constant kc is highly dependent on the volume fraction of the solid (fs) and increases abruptly as fs approaches unity.

- (3)

- Both phase field simulations and tomography experiments indicated that the coarsening of multi-dendrites indeed obeys the classical Lifshitz-Slyozov-Wagner theory [], but with the exponent n = 4.3. Phase field modeling indicated that this is mainly due to the effect of surface diffusion. This finding for dendrite coarsening has both scientific and technological significance.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rowenhorst, D.J.; Voorhees, P.W. Measurement of interfacial evolution in three dimensions. Annu. Rev. Mater. Sci. 2012, 42, 105–124. [Google Scholar] [CrossRef]

- Bray, A.J. Theory of phase-ordering kinetics. Adv. Phys. 2002, 51, 481–587. [Google Scholar] [CrossRef]

- Fife, J.L.; Gibbs, J.W.; Gulsoy, E.B.; Park, C.-L.; Thornton, K.; Voorhees, P.W. The dynamics of interfaces during coarsening in solid-liquid systems. Acta Mater. 2014, 70, 66–78. [Google Scholar] [CrossRef]

- Limodin, N.; Salvo, L.; Boller, E.; Suery, M.; Felberbaum, M.; Gailliegue, S.; Madi, K. In situ and real-time 3-D microtomography investigation of dendritic solidification in an Al-10 wt.% Cu alloy. Acta Mater. 2009, 57, 2300–2310. [Google Scholar] [CrossRef]

- Kammer, D.; Voorhees, P.W. The morphological evolution of dendritic microstructures during coarsening. Acta Mater. 2006, 54, 1549–1558. [Google Scholar] [CrossRef]

- Chen, M.; Kattamis, T.Z. Dendrite coarsening during directional solidification of Al-Cu-Mn alloys. Mater. Sci. Eng. A 1998, 247, 239–247. [Google Scholar] [CrossRef]

- Terzi, S.; Salvo, L.; Suery, M.; Dahle, A.K.; Boller, E. Coarsening mechanisms in a dendritic Al-10% Cu alloy. Acta Mater. 2010, 58, 20–30. [Google Scholar] [CrossRef]

- Aagesen, L.K.; Johnson, A.E.; Fife, J.L.; Voorhees, P.W.; Miksis, M.J.; Poulsen, S.O.; Lauridsen, E.M.; Marone, F.; Stampanoni, M. Universality and self-similarity in pinch-off of rods by bulk diffusion. Nat. Phys. 2010, 6, 796–800. [Google Scholar] [CrossRef]

- Alkemper, J.; Voorhees, P.W. Three-dimensional characterization of dendritic microstructures. Acta Mater. 2001, 49, 897–902. [Google Scholar] [CrossRef]

- Mendoza, R.; Thornton, K.; Savin, I.; Voorhees, P.W. The evolution of interfacial topology during coarsening. Acta Mater. 2006, 54, 743–750. [Google Scholar] [CrossRef]

- Ardell, A.J.; Ozolins, V. Trans-interface diffusion-controlled coarsening. Nat. Mater. 2005, 4, 309–316. [Google Scholar] [CrossRef] [PubMed]

- Fredriksson, H.; Akerlind, U. Solidification and Crystallization Processing in Metals and Alloys; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Rosam, J.; Jimack, P.K.; Mullis, A.M. An adaptive, fully implicit multigrid phase-field model for the quantitative simulation of non-isothermal binary alloy solidification. Acta Mater. 2008, 56, 4559–4569. [Google Scholar] [CrossRef]

- Provatas, N.; Goldenfeld, N.; Dantzig, J. Efficient Computation of Dendritic Microstructures Using Adaptive Mesh Refinement. Phys. Rev. Lett. 1998, 80, 3308–3311. [Google Scholar] [CrossRef]

- Ofori-Opoku, N.; Provatas, N. A quantitative multi-phase field model of polycrystalline alloy solidification. Acta Mater. 2010, 58, 2155–2164. [Google Scholar] [CrossRef]

- Lan, C.W.; Shih, C.J.; Lee, M.H. Quantitative phase field simulation of deep cells in directional solidification of an alloy. Acta Mater. 2005, 53, 2285–2294. [Google Scholar] [CrossRef]

- Manuwong, T.; Zhang, W.; Kazinczi, P.L.; Bodey, A.J.; Rau, C.; Mi, J. Solidification of Al Alloys Under Electromagnetic Pulses and Characterization of the 3D Microstructures Using Synchrotron X-ray Tomography. Metall. Mater. Trans. A 2015, 46, 2908–2915. [Google Scholar] [CrossRef]

- Yang, M.; Xiong, S.M.; Guo, Z. Characterisation of the 3-D dendrite morphology of magnesium alloys using synchrotron X-ray tomography and 3-D phase-field modelling. Acta Mater. 2015, 92, 8–17. [Google Scholar] [CrossRef]

- Guo, Z.; Xiong, S.M. On solving the 3-D phase field equations by employing a parallel-adaptive mesh refinement (Para-AMR) algorithm. Comp. Phys. Commun. 2015, 190, 89–97. [Google Scholar] [CrossRef]

- PITRE. Available online: http://webint.ts.infn.it/en/research/exp/beats2/pitre.html (accessed on 15 January 2021).

- Avizo Fire. Available online: http://www.fei.com/software/avizo3d/ (accessed on 15 January 2021).

- Echebarria, B.; Folch, R.; Karma, A.; Plapp, M. Quantitative phase-field model of alloy solidification. Phys. Rev. E 2004, 70, 61604. [Google Scholar] [CrossRef]

- Karma, A. Phase-field formulation for quantitative modeling of alloy solidification. Phys. Rev. Lett. 2001, 87, 115701. [Google Scholar] [CrossRef]

- Reeves, J.J.; Kattamis, T.Z. A model for isothermal dendritic coarsening. Scr. Metall. 1971, 5, 223. [Google Scholar] [CrossRef]

- Mortensen, A. On the influence of coarsening on microsegregation. Metall. Trans. A 1989, 20, 247–253. [Google Scholar] [CrossRef]

- Gropp, W.; Lusk, E.; Skjellum, A. Using MPI: Portable parallel programming with the message-passing interface. Sci. Program. 2014, 5, 275–276. [Google Scholar]

- Gropp, W.; Lsk, E.; Skjellum, A. Using MPI: Portable Parallel Programming with the Message-Passing Interface, 2nd ed.; The MIT Press: Cambridge, MA, USA; London, UK, 1999. [Google Scholar]

- Guo, E.; Phillion, A.B.; Cai, B.; Shuai, S.; Kazantsev, D.; Jing, T.; Lee, P.D. Dendritic evolution during coarsening of Mg-Zn alloys via 4D synchrotron tomography. Acta Mater. 2017, 123, 373–382. [Google Scholar] [CrossRef]

- Hardy, S.C.; Vooehees, P.W. Ostwald ripening in a system with a high volume fraction of coarsening phase. Metall. Trans. 1988, 19, 2713–2721. [Google Scholar] [CrossRef]

- Poirier, D.R.; Ganesan, S.; Andrews, M.; Ocansey, P. Isothermal coarsening of dendritic equiaxial grains in Al-15.6 wt.%Cu alloy. Mater. Sci. Eng. A 1991, 148, 289–297. [Google Scholar] [CrossRef]

- Limodin, N.; Salvo, L.; Suéry, M.; DiMichiel, M. In situ investigation by X-ray tomography of the overall and local microstructural changes occurring during partial remelting of an Al-15.8wt.% Cu alloy. Acta Mater. 2007, 55, 3177–3191. [Google Scholar] [CrossRef]

- Wilson, P.W.; Kattamis, T.Z.; Shiohara, Y. Coarsening during solidification of aluminium-copper alloys. J. Mater. Sci. 1988, 23, 2882–2892. [Google Scholar] [CrossRef]

- Mendoza, R.; Alkemper, J.; Voorhees, P.W. Three-dimensional morphological characterization of coarsened microstructures. Z. Met. 2005, 96, 155–160. [Google Scholar] [CrossRef]

- Langer, J.S.; Bar-on, M.; Miller, H.D. New computationalmethod in the theory of spinodaldecomposition. Phys. Rev. A 1975, 11, 1417–1429. [Google Scholar] [CrossRef]

- Kitahara, K.; Imada, M. On the Kinetic Equations for BinaryMixtures. Prog. Theor. Phys. Suppl. 1978, 64, 65–73. [Google Scholar] [CrossRef]

- Lacasta, A.M.; Hernandez-Machado, A.; Sancho, J.M.; Toral, R. Domain growth in binarymixtures at low temperatures. Phys. Rev. B 1992, 45, 5276–5281. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.Z.; Chen, L.Q.; Shen, J.; Tikare, V. Coarsening kinetics from a variable-mobilityCahn-Hilliard equation: Application of a semi-implicit Fourier spectral method. Phys. Rev. E 1999, 60, 3564–3572. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H. A dynamic scaling assumption for phase-separation. Adv. Phys. 1985, 34, 703–750. [Google Scholar] [CrossRef]

| Rotation Axis | Rotation Angle | Before Rotation | After Rotation | Location |

|---|---|---|---|---|

| Y | u | YZ plane | ||

| v | Unknown | |||

| X | Z axis | |||

| Unknown | ||||

| Z | XZ plane |

| Parameter | Value |

|---|---|

| Liquidus slope, m (K/wt.%) | −3.4 |

| Equilibrium partition coefficient, k | 0.15 |

| Anisotropy strength, ε1 | 0.06 |

| Anisotropy strength, ε2 | 0.00 |

| Gibbs-Thomson coefficient, Γ (K m) | 2.4 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Guo, Z.; Kang, J.; Zou, M.; Li, X.; Zhang, A.; Du, W.; Zhang, W.; Lee, T.L.; Xiong, S.; et al. 3D Phase Field Modeling of Multi-Dendrites Evolution in Solidification and Validation by Synchrotron X-ray Tomography. Materials 2021, 14, 520. https://doi.org/10.3390/ma14030520

Wang S, Guo Z, Kang J, Zou M, Li X, Zhang A, Du W, Zhang W, Lee TL, Xiong S, et al. 3D Phase Field Modeling of Multi-Dendrites Evolution in Solidification and Validation by Synchrotron X-ray Tomography. Materials. 2021; 14(3):520. https://doi.org/10.3390/ma14030520

Chicago/Turabian StyleWang, Shuo, Zhipeng Guo, Jinwu Kang, Meishuai Zou, Xiaodong Li, Ang Zhang, Wenjia Du, Wei Zhang, Tung Lik Lee, Shoumei Xiong, and et al. 2021. "3D Phase Field Modeling of Multi-Dendrites Evolution in Solidification and Validation by Synchrotron X-ray Tomography" Materials 14, no. 3: 520. https://doi.org/10.3390/ma14030520

APA StyleWang, S., Guo, Z., Kang, J., Zou, M., Li, X., Zhang, A., Du, W., Zhang, W., Lee, T. L., Xiong, S., & Mi, J. (2021). 3D Phase Field Modeling of Multi-Dendrites Evolution in Solidification and Validation by Synchrotron X-ray Tomography. Materials, 14(3), 520. https://doi.org/10.3390/ma14030520