1. Introduction

Composite structures with sensors and actuators, which are called smart structures, are used in a wide range of engineering applications [

1,

2,

3]. Among the various available smart materials, the piezoelectric material is one of the most commonly used materials that can be used as both actuators and sensors. Macro-fiber composites (MFCs) are a new type of piezoelectric intelligent materials that were developed by NASA. The rectangular cross-section of the piezoelectric fibers in the MFC increases the contact area between the interdigitated electrodes and piezoceramic fibers in order to improve the transfer of electricity [

4,

5,

6]. With a higher electro-mechanical conversion efficiency and better flexibility, the MFC has broad application prospects and research value.

In order to achieve the vibration control and shape simulation of smart structures with MFC patches, Zhang et al. [

7] studied the active shape and vibration control of laminated plates with MFCs. Guo et al. [

8] analyzed the nonlinear dynamics of MFC piezoelectric plates with graphene skins. Dong et al. [

9] proposed an equivalent-force-modeling approach to investigate plate-type structures that were integrated with MFC actuators. Rao et al. [

10] carried out the large-deflection electro-mechanical analysis of laminated composite structures that were bonded with MFC actuators under thermo-electro-mechanical loads. Gawryluk et al. [

11] studied the dynamic behavior of a composite beam that was rotating at a constant angular velocity and excited by an MFC actuator. In addition, Gawryluk et al. [

12] analyzed the problem of vibration reduction in a cantilever beam with an embedded MFC actuator under kinematic excitation. Zhou et al. [

13] investigated the aeroelastic stability of curved composite panels with embedded MFC actuators in a supersonic airflow.

Recently, functionally graded composites that are reinforced with carbon nanotubes and graphene have emerged as the new generation of advanced composite materials with greater improvements of physical [

14], chemical [

15] and mechanical properties [

16] compared to composites without reinforcement. Due to the outstanding mechanical properties of graphene, the investigations into the FG-GRC-laminated structures that are integrated with piezoelectric actuators are significant in a wide range of engineering applications. For reliable and safe designs, effective models are required in order to study the mechanical behaviors of smart FG-GRC-laminated structures. Due to the limitations of the existing manufacturing techniques, it is extremely difficult to fabricate graphene-reinforced composites with continuous material-characteristic distributions through the thickness [

17]. In addition, the multilayer configuration of nanocomposites composed of stacked layers was introduced. Graphene was uniformly dispersed in each layer, and the graphene volume fraction gradually changed layer by layer. Based on the first-order shear-deformation theory (FSDT), Song et al. [

17] studied the free and forced vibration behaviors of FG-GRC plates. Then, investigations into the bending [

18], buckling and postbuckling [

19], nonlinear free vibration [

20], and dynamic instability [

21,

22] of FG-GRC structures were reported by Yang et al. Kiani et al. [

23,

24,

25,

26,

27,

28] carried out the buckling and postbuckling analysis of FG-GRC structures in a thermal environment. Reddy et al. [

29] investigated the free vibration of GRC plates via the finite-element method. Guo et al. [

30] proposed an element-free IMLS-Ritz method for the vibration analysis of GRC-laminated plates. Zhang et al. [

31] proposed the DSC-regularized Dirac-delta method for the vibration analysis of porous FG-GRC beams that were resting on an elastic foundation under a moving load. Liu et al. [

32] investigated the dynamic behaviors of porous FG-GRC plates that were resting on an elastic foundation. By using the spectral-Chebyshev approach, free vibration and buckling responses of porous FG-GRC plates were conducted by Anamagh and Bediz [

33]. In a review of the aforementioned works, FSDT was used to analyze the FG-GRC structures. However, the accuracy of FSDT was impacted by the shear correction factor. In order to avoid using the shear correction factor, various higher-order shear-deformation theories (HSDT) with nonlinear shear strains were used for the analysis of the FG-GRC structures. Using Reddy’s higher-order theory, Shen et al. studied the nonlinear bending [

34], buckling and postbuckling [

35,

36], and nonlinear vibration [

37,

38] of FG-GRC-laminated structures in thermal environments. Wang et al. [

39] investigated the free vibration and bending of doubly-curved FG-GRC shallow shells. By applying the sinusoidal shear-deformation theory, Arefi et al. [

40] analyzed the free vibration of FG-GRC nanoplates. A statistical analysis of the free vibration of FG-GRC plates was conducted by Pashmforoush [

41]. In terms of the refined four-variable model, a NURBS formulation for the bending, buckling and free vibration analysis of multilayer FG-GRC plates was proposed by Thai et al. [

42]. The vibro-acoustic analysis of FG-GRC-laminated plates was achieved by Xu and Huang [

43]. Based on the three-dimensional, refined higher-order shear-deformation theory, Al-Furjan et al. [

44] studied the bending responses of an FG-GRC disk. More studies of the mechanical analysis of FG-GRC structures can be found in the published articles [

45,

46,

47,

48,

49].

Static, buckling and dynamic analyses of laminated composite plates with MFC actuators have been extensively investigated [

8,

9,

10,

11,

12,

13,

50,

51,

52,

53,

54]. In addition, piezoelectric materials were used in the smart structures for shape, vibration and buckling control [

7,

12,

55,

56,

57]. However, the research on the structural behaviors of FG-GRC-laminated plates with piezoelectric actuators is quite limited. Mao and Zhang [

58,

59] analyzed the linear and nonlinear vibration and buckling behaviors of piezoelectric FG-GRC plates. Using the transformed-differential-quadrature method, Malekzadeha et al. [

60] studied the free vibration of eccentric annular FG-GRC plates that were embedded in piezoelectric layers. Nguyena et al. [

61] proposed an isogeometric finite-element formulation for the bending and transient analysis of porous FG-GRC plates that were embedded in piezoelectric layers. The free vibration of FG-GRC sandwich plates that were enclosed by piezoelectric layers was investigated by Majidi-Mozafari et al. [

62]. The wave-characteristic analysis of cylindrical FG-GRC sandwich structures with piezoelectric surface layers was reported by Li and Han [

63,

64]. Khayat at al. [

65] investigated the uncertainty propagation in the nonlinear dynamic responses of smart, porous cylindrical FG-GRC sandwich shells. Guo et al. [

66] investigated the nonlinear dynamic behavior of three-phase composite plates that were made with MFCs in the polymer and with graphene skins.

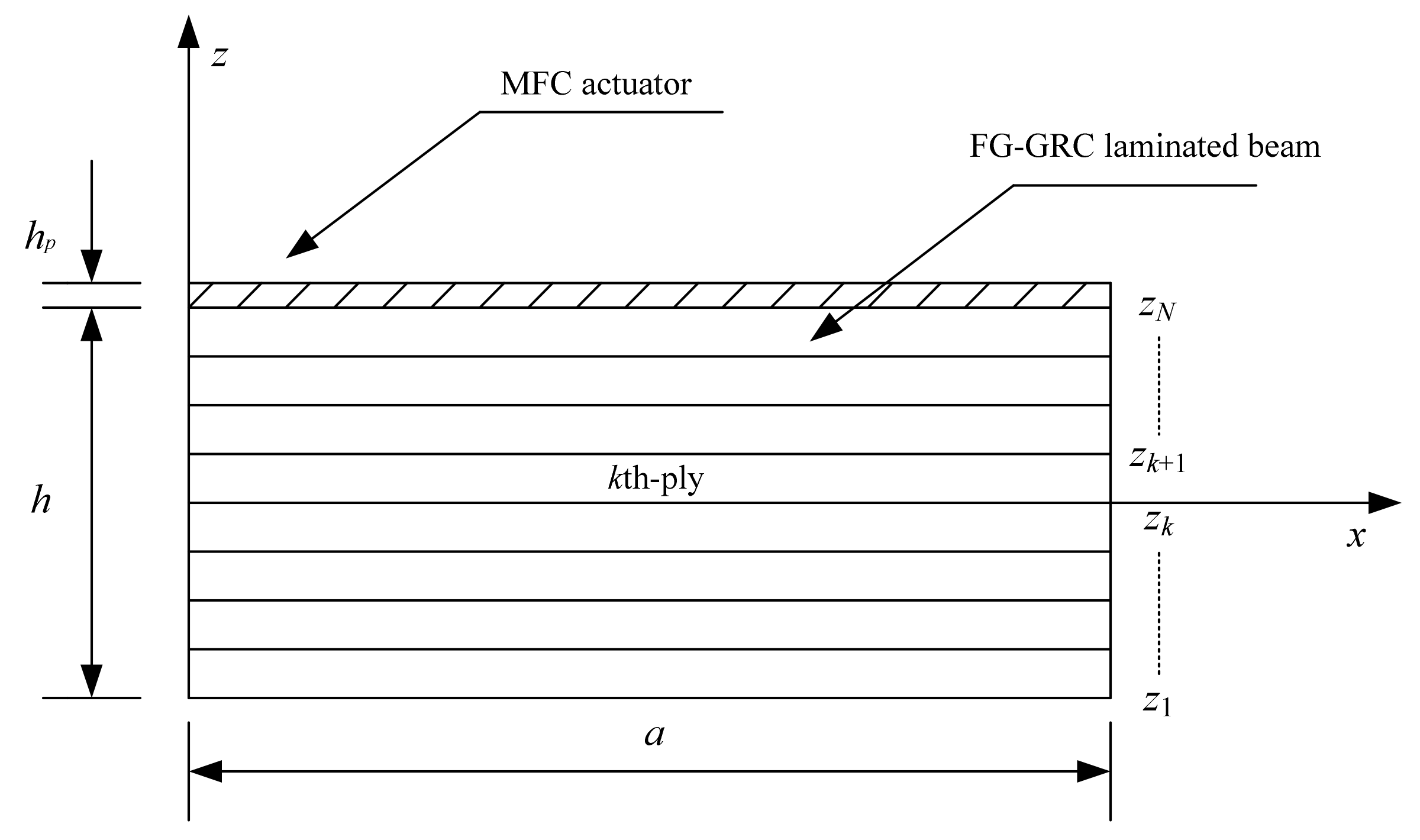

Owing to the electro-mechanical coupling effect and the discontinuity of the material properties throughout the thickness of the FG-GRC-laminated structures with piezoelectric layers, transverse shear deformations play an important role. In order to precisely predict the transverse shear stresses of FG-GRC-laminated structures with MFC actuators, the compatible conditions of transverse shear stresses at the interfaces must be fulfilled. As can be observed in the above literature, FSDT and HSDT combined with different solution methods are used for the mechanical analysis of FG-GRC structures with piezoelectric layers. However, FSDT and HSDT are unable to satisfy the compatible conditions of transverse shear stresses at the interfaces. As a result, FSDT and HSDT may fail to model the transverse shear stresses of the FG-GRC-laminated plates with MFC actuators. Therefore, there is a genuine requirement to propose an efficient and accurate model with which to study this issue.

From the above literature survey, it was found that the comprehensive interlaminar shear-stress analysis of the thick FG-GRC-laminated beams with MFC actuators are scarce in the open literature. This paper aims to fill this research gap by developing an efficient finite-element formulation based on an attractive electro-mechanically coupled model. The proposed model fulfills the compatible conditions of transverse shear stresses at the interfaces. By using the 3D elasticity equations and the HW variational principle [

67,

68], the accuracy of the transverse shear stresses in terms of the electro-mechanical coupling effect is improved. Due to the second-order derivatives of the in-plane displacement, variables are removed from the interlaminar shear-stress components, such that the finite-element formulation can be easily developed. Thus, based on the proposed electro-mechanical model, a simple C

0-type two-node beam element is developed for the interlaminar-stress analysis of thick FG-GRC-laminated beams with MFC actuators. The performance of this finite-element formulation is appraised by comparing it with the 3D elasticity solutions and the results are calculated from the chosen models. Comprehensive parametric studies are conducted in order to explore the influences of distribution pattern, volume fraction, lamination sequence, as well as geometric parameters of the beams on the deformations and stresses of FG-GRC-laminated beams with MFC actuators. The research findings will provide essential information for the reliable design of smart FG-GRC-laminated structures with great potential for engineering applications.

3. Finite-Element Formulation

In this section, a two-node beam element is used in order to study the FG-GRC-laminated beams with MFC actuators. Accordingly, the displacement variables for each element can be expressed as

where

,

;

,

,

;

and

are defined in

Figure 3.

By means of Equations (11)–(13), the strain vector is written as

in which

,

,

and

are the degrees of freedom at the

ith node. The degrees of freedom at each node are given by

According to the Equation (33), the element-stiffness matrix of the proposed beam element can be obtained. Equation (33) within the

ith element can be rewritten as

where

Wi represents the work of external forces.

Introducing Equations (11)–(17), (39) into Equation (45), the element-stiffness matrix is expressed as

in which

Q is the material-constant matrix, the strain matrix

B is given in Equation (44), and the strain matrix

is expressed as

where

where

,

are given in Equation (39), and

j = 1~3.

By means of the following equation, the vector of nodal displacement

can be expressed as

where

and

are the loading vector and the applied-electric-potential vector for an element, respectively.

in which

Assembling all the element-stiffness matrices, the global equation is obtained in the following form:

where

is the stiffness matrix;

and

are the global loading vector and the applied-electric-potential vector, respectively.

5. Conclusions

Based on an attractive electro-mechanical coupled-beam model, a C0-type finite-element formulation was developed for the interlaminar shear stress analysis of a thick FG-GRC-laminated beam with an MFC actuator. Using the HW variational principle, the improved transverse shear stresses in terms of the electro-mechanical coupling effect were derived. In order to assess the accuracy and efficiency of the present formulation, the results acquired from other models and the 3D elasticity solutions were also utilized for comparison. Furthermore, comprehensive parametric studies were carried out in order to analyze the effects of various parameters on the deformations and stresses. By analyzing typical static problems, some conclusions can be drawn:

(1) The present model can satisfy the compatible conditions of transverse shear stresses, and the results acquired from the present model agreed well with the 3D elasticity solutions.

(2) The stiffness of the FG-GRC-laminated beam with an MFC actuator can be significantly enhanced by adding a small amount of graphene. The displacements and stresses of the FG-GRC-laminated beam with an MFC layer are sensitive to the graphene distribution pattern. Therefore, the transverse shear stresses can be optimized by adjusting the graphene distribution pattern.

(3) The actuating responses of the thick FG-GRC-laminated beams with MFC actuators are more significant than that of the thin beams. When the electric voltages were applied, the maximum transverse shear stress was obtained at the interface between the MFC piezoelectric layer and the GRC laminates.

In addition, the effects of interlaminar stresses on the stability and dynamic behaviors of smart FG-GRC-laminated structures will be conducted in future work.