Comparative Analysis of Fracture Resistance between CAD/CAM Materials for Interim Fixed Prosthesis

Abstract

:1. Introduction

2. Materials and Methods

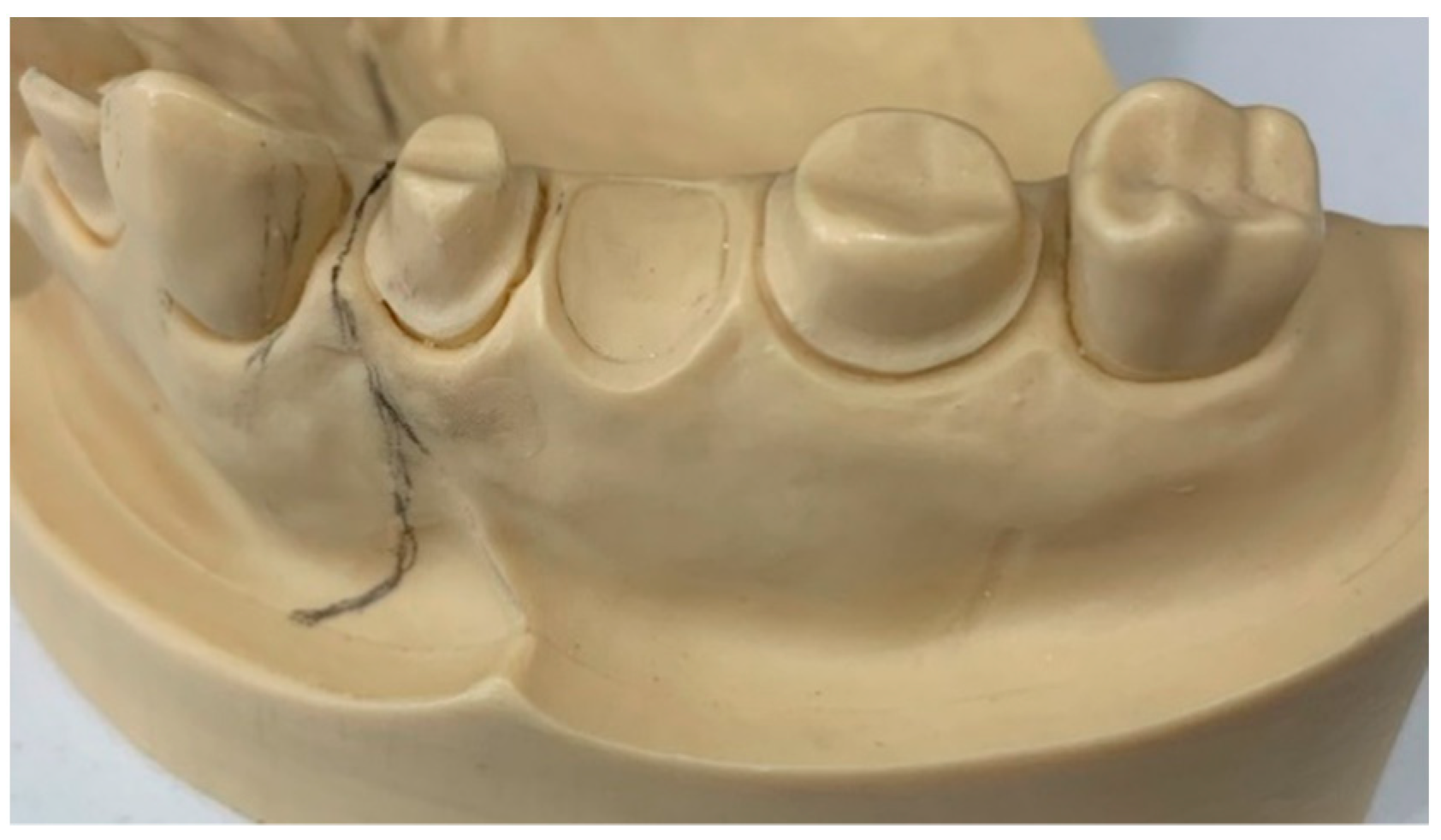

2.1. Sample Preparation

2.2. Sample Scanning and Design Process

2.3. Samples Materialization

2.3.1. Milling Process

2.3.2. Three-dimensional Printing Process

2.3.3. Postproduction

2.4. Thermocycling

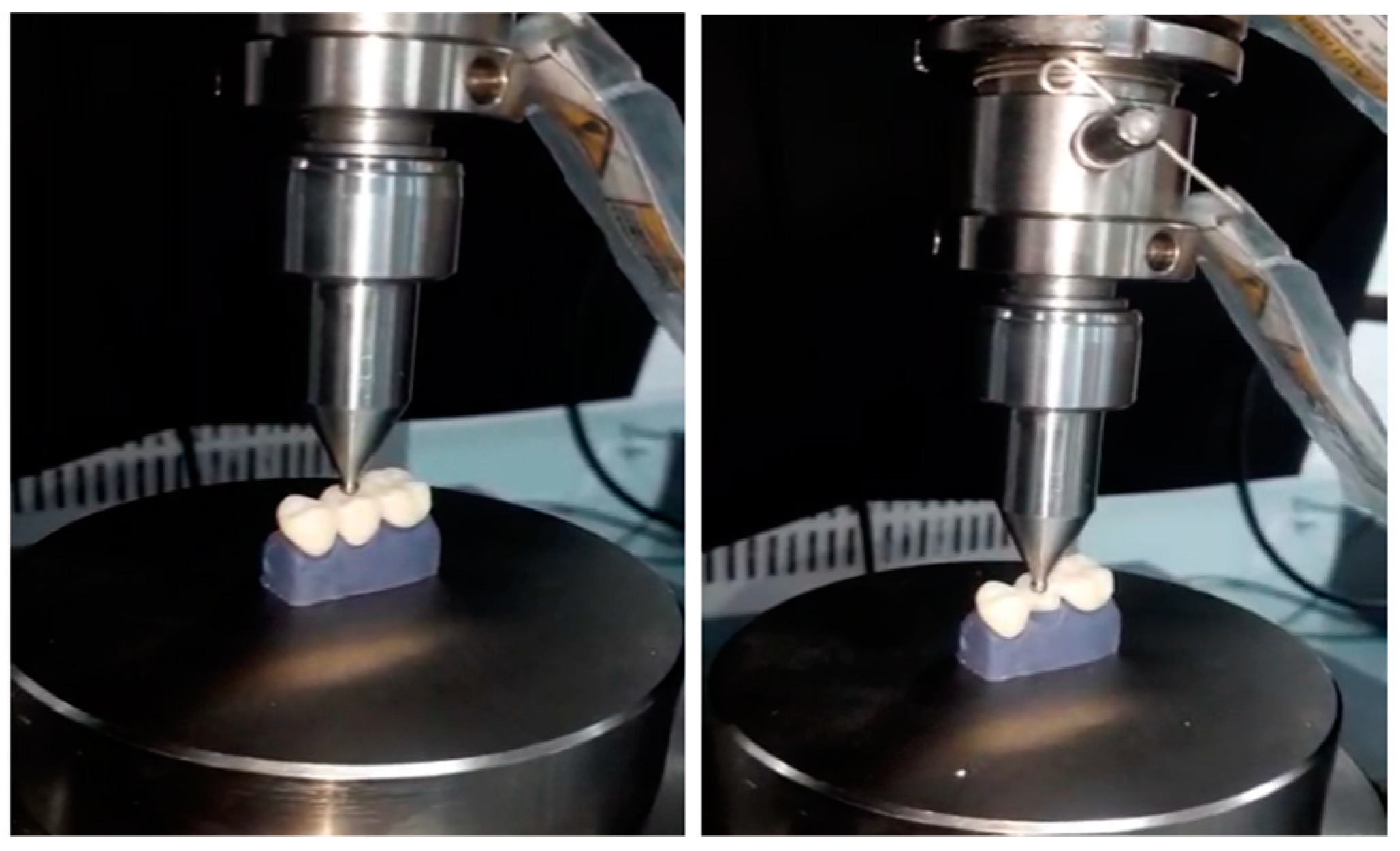

2.5. Fracture Strength Test

2.6. Evaluation of Fracture Mode

2.7. Statistical and Analysis Evaluation

3. Results

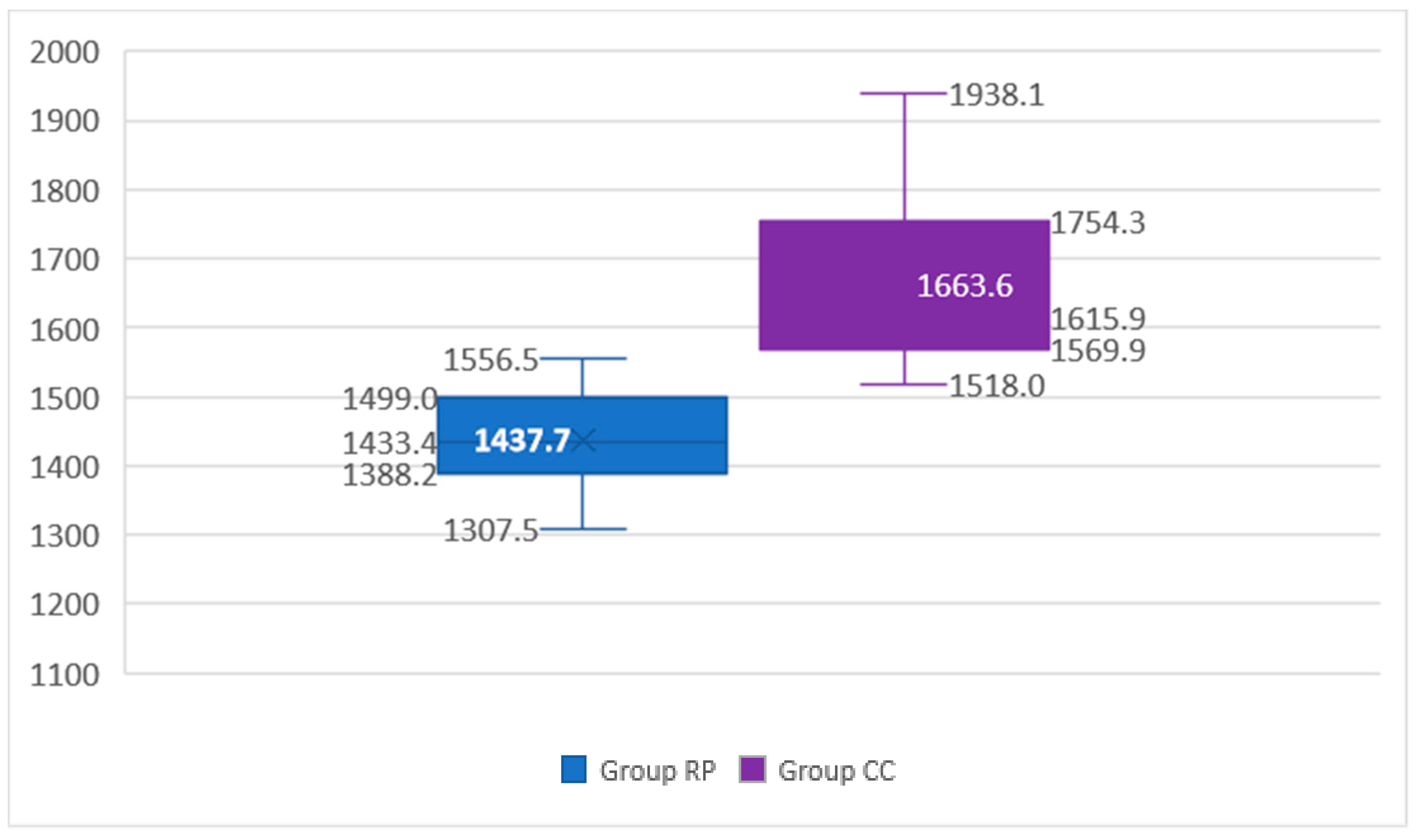

3.1. Descriptive Analysis

3.2. Inferential Analysis

4. Discussion

5. Conclusions

- The interim restorations materialized by a milling technique showed a higher resistance to fracture compared to the provisional restorations obtained by 3D printing.

- The fabrication of interim restorations using a subtractive technique, or milling technique, could be considered a reliable and conservative method for the production of stronger provisional restorations.

- Although the strength values of the printed restorations were lower, the rapid prototyping material could be considered in certain scenarios with reduced chewing loads and surfaces exposed to less stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferro, K.J.; Morgano, S.M.; Driscoll, C.F.; Freilich, M.A.; Guckes, A.D.; Knoernschild, K.L.; McGarry, T.J.; Twain, M. The Glossary of Prosthodontic Terms. J. Prosthet. Dent. 2017, 117, e1–e105. [Google Scholar]

- Singla, M.; Padmaja, K.; Arora, J.; Shah, A. Provisional Restorations in Fixed Prosthodontics. Int. Dent. Res. 2014, 1, 148–151. [Google Scholar]

- Patras, M.; Naka, O.; Doukoudakis, S.; Pissiotis, A. Management of Provisional Restorations’ Deficiencies: A Literature Review. J. Esthet. Restor. Dent. 2012, 24, 26–38. [Google Scholar] [CrossRef] [PubMed]

- Miura, S.; Fujisawa, M.; Komine, F.; Maseki, T.; Ogawa, T.; Takebe, J.; Nara, Y. Importance of interim restorations in the molar region. J. Oral Sci. 2019, 61, 195–199. [Google Scholar] [CrossRef] [Green Version]

- Ruse, N.D.; Sadoun, M.J. Resin-composite Blocks for Dental CAD/CAM Applications. J. Dent. Res. 2014, 93, 1232–1234. [Google Scholar] [CrossRef] [Green Version]

- Skorulska, A.; Piszko, P.; Rybak, Z.; Szymonowicz, M.; Dobrzyński, M. Review on Polymer, Ceramic and Composite Materials for CAD/CAM Indirect Restorations in Dentistry—Application, Mechanical Characteristics and Comparison. Materials 2021, 14, 1592. [Google Scholar] [CrossRef] [PubMed]

- Lambert, H.; Durand, J.C.; Jacquot, B.; Fages, M. Dental biomaterials for chairside CAD/CAM: State of the art. Korean Acad. Prosthodont. 2017, 9, 486–495. [Google Scholar] [CrossRef] [Green Version]

- Al Jabbari, Y.S.; Al-Rasheed, A.; Smith, J.W.; Iacopino, A.M. An indirect technique for assuring simplicity and marginal integrity of provisional restorations during full mouth rehabilitation. Saudi Dent. J. 2013, 25, 39–42. [Google Scholar] [CrossRef] [Green Version]

- Regish, K.M.; Sharma, D.; Prithviraj, D.R. Techniques of Fabrication of Provisional Restoration: An Overview. Int. J. Dent. 2011, 2011, 134659. [Google Scholar] [CrossRef]

- Digholkar, S.; Madhav, V.N.V.; Palaskar, J. Evaluation of the flexural strength and microhardness of provisional crown and bridge materials fabricated by different methods. J. Indian Prosthodont. Soc. 2016, 16, 328–334. [Google Scholar]

- Alp, G.; Murat, S.; Yilmaz, B. Comparison of Flexural Stregth of Different CADCAM PMMA-Based Polymers. J. Prosthodont. 2018, 28, e491–e495. [Google Scholar] [CrossRef]

- Beuer, F.; Schweiger, J.; Edelhoff, D. Digital dentistry: An overview of recent developments for CAD/CAM generated restorations. Br. Dent. J. 2008, 204, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Alt, V.; Hannig, M.; Wöstmann, B.; Balkenhol, M. Fracture strength of temporary fixed partial dentures: CAD/CAM versus directly fabricated restorations. Dent. Mater. 2011, 27, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Güth, J.F.; e Silva, J.A.; Edelhoff, D. Enhancing the predictability of complex rehabilitation with a removable CAD/CAM-fabricated long-term provisional prosthesis: A clinical report. J. Prosthodont. Dent. 2021, 107, 1–6. [Google Scholar] [CrossRef]

- Taufall, S.; Eichberger, M.; Schmidlin, P.R.; Stawarczyk, B. Fracture load and failure types of different veneered polyetheretherketone fixed dental prostheses. Clin. Oral Investig. 2016, 20, 2493–2500. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, A.O.; Pollington, S.; Liu, Y. Comparison between direct chairside and digitally fabricated temporary crowns. Dent. Mater. J. 2018, 37, 957–963. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nassani, M.Z.; Ibraheem, S.; Shamsy, E.; Darwish, M.; Faden, A.; Kujan, O. A Survey of Dentists’ Perception of Chair-Side CAD/CAM Technology. Healthcare 2021, 9, 68. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.S.; Lee, D.H.; Lee, K.B. Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. J. Adv. Prosthodont. 2017, 9, 265–270. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ibrahim, A.; El Shehawy, D.; El-Naggar, G. Fracture resistance of interim restoration constructed by 3D printing versus CAD/CAM technique (In vitro study). Ain Shams Dent. J. 2020, 23, e14–e20. [Google Scholar]

- Astudillo-Rubio, D.; Delgado-Gaete, A.; Bellot-Arcís, C.; Montiel-Company, J.M.; Pascual-Moscardó, A.; Almerich-Silla, J.M. Mechanical properties of provisional dental materials: A systematic review and meta-analysis. PLoS ONE 2018, 13, e0193162. [Google Scholar]

- Kang, S.Y.; Park, J.H.; Kim, J.H.; Kim, W.C. Accuracy of provisional crowns made using stereolithography apparatus and subtractive technique. J. Adv. Prosthodont. 2018, 10, 354–360. [Google Scholar] [CrossRef] [Green Version]

- Federick, D.R. The provisional fixed partial denture. J. Prosthet. Dent. 1975, 34, 520–526. [Google Scholar] [CrossRef]

- Mantri, S.S.; Bhasin, A.S. CAD/CAM in dental restorations: An overview. Ann. Essences Dent. 2010, 2, 123–128. [Google Scholar]

- Poticny, D.J.; Klim, J. CAD/CAM in-office technology Innovations after 25 years for predictable, esthetic outcomes. Am. Dent. Assoc. 2010, 141, 5S–9S. [Google Scholar] [CrossRef] [PubMed]

- Mehl, A.; Hickel, R. Current State of Development and Perspectives of Machine-based Production Methods for Dental Restorations. Int. J. Comput. Dent. 2009, 2, 9–35. [Google Scholar]

- Liu, P.R. A panorama of dental CAD/CAM restorative systems. Compendium 2005, 26, 507–513. [Google Scholar] [PubMed]

- Fasbinder, D.J. Clinical performance of chairside CAD/CAM restorations. J. Am. Dent. Assoc. 2006, 137, 22S–31S. [Google Scholar] [CrossRef]

- Culp, L.; Touchstone, A. CAD/CAM Dentistry: A New Forum for Dentist-Technician Teamwork. Inside Dent. 2006, 2, e15–e19. [Google Scholar]

- Freedman, M.; Quinn, F.; O’Sullivan, M. Single unit CAD/CAM restorations: A literature review. J. Ir. Dent. Assoc. 2007, 53, 38–45. [Google Scholar] [PubMed]

- Galhano, G.Á.P.; Pellizzer, E.P.; Mazaro, J.V.Q. Optical impression systems for CAD-CAM restorations. Craniofac. Surg. 2012, 23, e575–e579. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, M.; Mehl, A.; Mörmann, W.H.; Reich, S. Intraoral scanning systems—A current overview. Int. J. Comput. Dent. 2015, 18, 101–129. [Google Scholar]

- Pollington, S.; van Noort, R. An Update of ceremics in dentistry. Int. J. Clin. Dent. 2009, 2, 283–307. [Google Scholar]

- Li, R.W.K.; Chow, T.W.; Matinlinna, J.P. Ceramic dental biomaterials and CAD/CAM technology: State of the art. J. Prosthodont. Res. 2014, 58, 208–216. [Google Scholar] [CrossRef] [Green Version]

- Miyazaki, T.; Hotta, Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust. Dent. J. 2011, 56, 97–106. [Google Scholar] [CrossRef]

- Silva, L.H.D.; Lima, E.D.; Miranda, R.B.D.P.; Favero, S.S.; Lohbauer, U.; Cesar, P.F. Dental ceramics: A review of new materials and processing methods. Braz. Oral Res. 2017, 31, e133–e146. [Google Scholar] [CrossRef]

- Abdullah, A.; Muhammed, F.; Zheng, B.; Liu, Y. An Overview of Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) in Restorative Dentistry. J. Dent. Mater. Tech. 2018, 7, 1–10. [Google Scholar]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Hazeveld, A.; Slater, J.J.H.; Ren, Y. Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques. Am. J. Orthod. Dentofac. Orthop. 2014, 145, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, S.; Alqahtani, N.M.; Addas, M.K.; Alfarsi, M.A. Marginal and internal fit of provisional crowns fabricated using 3D printing technology. Technol Health Care 2020, 28, 635–642. [Google Scholar] [CrossRef] [PubMed]

- Sampaio, C.S.; Niemann, K.D.; Schweitzer, D.D.; Hirata, R.; Atria, P.J. Microcomputed tomography evaluation of cement film thickness of veneers and crowns made with conventional and 3D printed provisional materials. J. Esthet. Restor. Dent. 2021, 33, 487–495. [Google Scholar] [CrossRef]

- Molinero-Mourelle, P.; Canals, S.; Gómez-Polo, M.; Fernanda Solá-Ruiz, M.; del Río Highsmith, J.; Celemín Viñuela, A.; Solá-Ruiz, M.F.; Viñuela, A.C. Polylactic Acid as a Material for Three-Dimensional Printing of Provisional Restorations. Int. J. Prosthodont. 2018, 31, 349–350. [Google Scholar] [CrossRef] [PubMed]

- Jeong, K.W.; Kim, S.H. Influence of surface treatments and repair materials on the shear bond strength of CAD/CAM provisional restorations. J. Adv. Prosthodont. 2019, 11, 95–104. [Google Scholar] [CrossRef]

- Lorenz Holmer, A.O.; Lührs, A.K.; von See, C. Comparison of the shear bond strength of 3D printed temporary bridges materials, on different types of resin cements and surface treatment. J. Clin. Exp. Dent. 2019, 11, e367. [Google Scholar]

- Mayer, J.; Stawarczyk, B.; Vogt, K.; Hickel, R.; Edelhoff, D.; Reymus, M. Influence of cleaning methods after 3D printing on two-body wear and fracture load of resin-based temporary crown and bridge material. Clin. Oral Investig. 2021, 25, 5987–5996. [Google Scholar] [CrossRef] [PubMed]

- Benlİ, M.; Eker-GÜmÜŞ, B.; Kahraman, Y.; Huck, O.; Özcan, M. Can polylactic acid be a CAD/CAM material for provisional crown restorations in terms of fit and fracture strength? Dent. Mater. J. 2021, 40, 772–780. [Google Scholar] [CrossRef]

- Singh, A.; Garg, S. Comparative Evaluation of Flexural Strength of Provisional Crown and Bridge Materials-An Invitro Study. J. Clin. Diagn. Res. 2016, 10, ZC72. [Google Scholar] [CrossRef]

| Product Name | Brand/Manufacturer | Batch | Base Material |

|---|---|---|---|

| Vipiblock Trilux | VIPI | 0000054908 | PMMA CAD/CAM Disk |

| PriZma 3D Bio Prov | MarkertechLabs | E1488 | Light-Curing Micro Hybrid Resin |

| Group | Statistics | Strength (N) |

|---|---|---|

| RP (rapid prototyping) | Mean | 1437.74 |

| Standard deviation | 73.41 | |

| VC | 5.11% | |

| Minimum | 1307.49 | |

| Maximum | 1556.45 | |

| CC (computer-assisted milling) | Mean | 1663.57 |

| Standard deviation | 130.25 | |

| VC | 7.83% | |

| Minimum | 1517.98 | |

| Maximum | 1938.09 |

| Author | Objective | Resistance to Fracture/Milled Restorations | Resistance to Fracture/Printed Restorations |

|---|---|---|---|

| Ibrahim, et al. (2020) | Resistance to fracture between milled and printed restorations | 933 N | 1226.48 N |

| Suralik, et al. (2020) | Investigate the impact of the manufacturing technique on the resistance to fracture of the 3-unit temporary resin fixed dental prostheses | 412.03 N | 603.33 N |

| Digholkar, et al. (2016) | Flexural strength values in temporary crowns manufactured through 3 different techniques | 104.20 MPa | 79.54 MPa |

| Merve, et al. (2021) | Measurement of fracture strength and fracture modes | 752.00 N | 681.00 N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abad-Coronel, C.; Carrera, E.; Mena Córdova, N.; Fajardo, J.I.; Aliaga, P. Comparative Analysis of Fracture Resistance between CAD/CAM Materials for Interim Fixed Prosthesis. Materials 2021, 14, 7791. https://doi.org/10.3390/ma14247791

Abad-Coronel C, Carrera E, Mena Córdova N, Fajardo JI, Aliaga P. Comparative Analysis of Fracture Resistance between CAD/CAM Materials for Interim Fixed Prosthesis. Materials. 2021; 14(24):7791. https://doi.org/10.3390/ma14247791

Chicago/Turabian StyleAbad-Coronel, Cristian, Elena Carrera, Nancy Mena Córdova, Jorge I. Fajardo, and Paulina Aliaga. 2021. "Comparative Analysis of Fracture Resistance between CAD/CAM Materials for Interim Fixed Prosthesis" Materials 14, no. 24: 7791. https://doi.org/10.3390/ma14247791

APA StyleAbad-Coronel, C., Carrera, E., Mena Córdova, N., Fajardo, J. I., & Aliaga, P. (2021). Comparative Analysis of Fracture Resistance between CAD/CAM Materials for Interim Fixed Prosthesis. Materials, 14(24), 7791. https://doi.org/10.3390/ma14247791