Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete

Abstract

:1. Introduction

2. Research Significance

3. Experimental Procedure

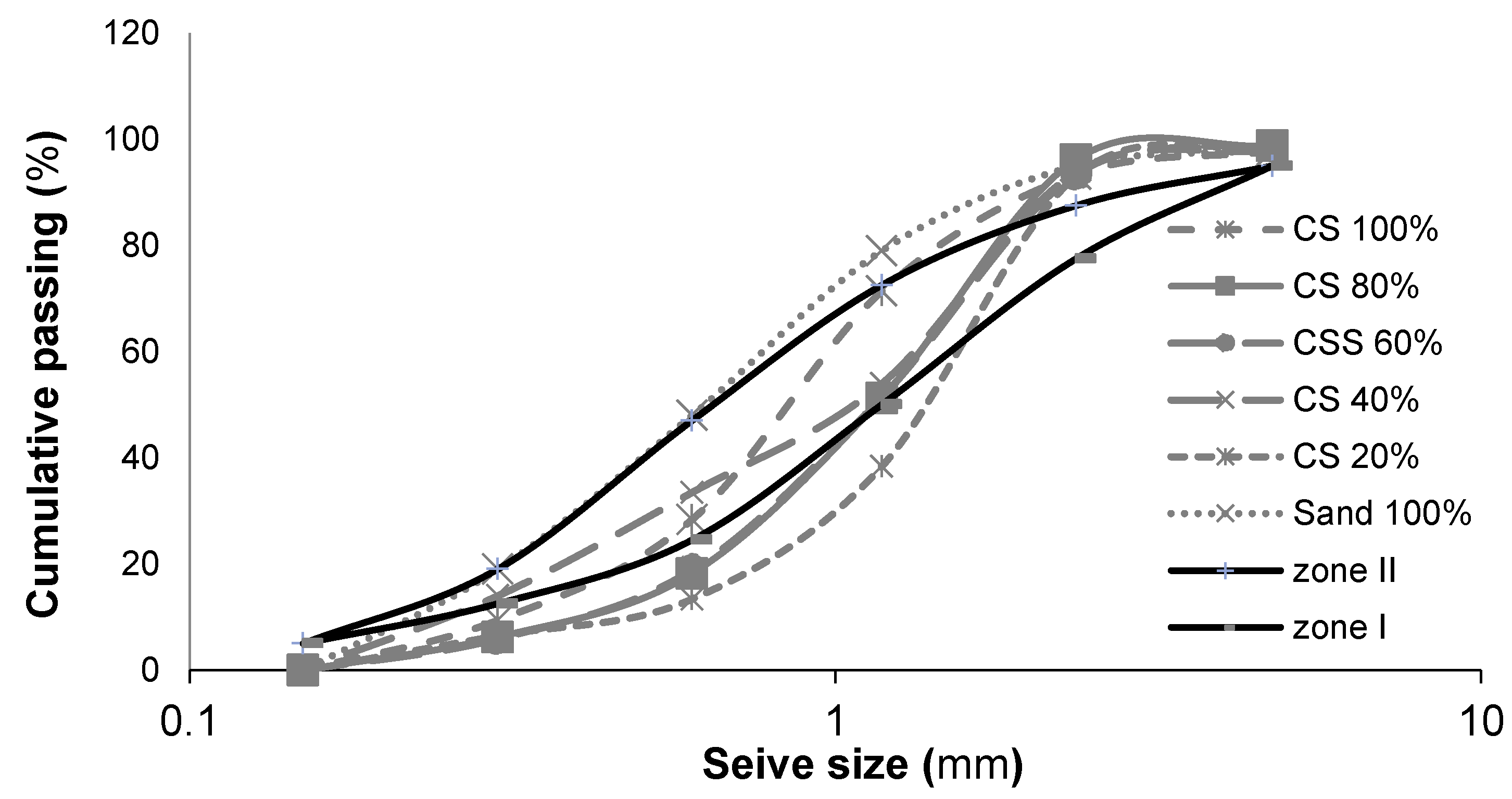

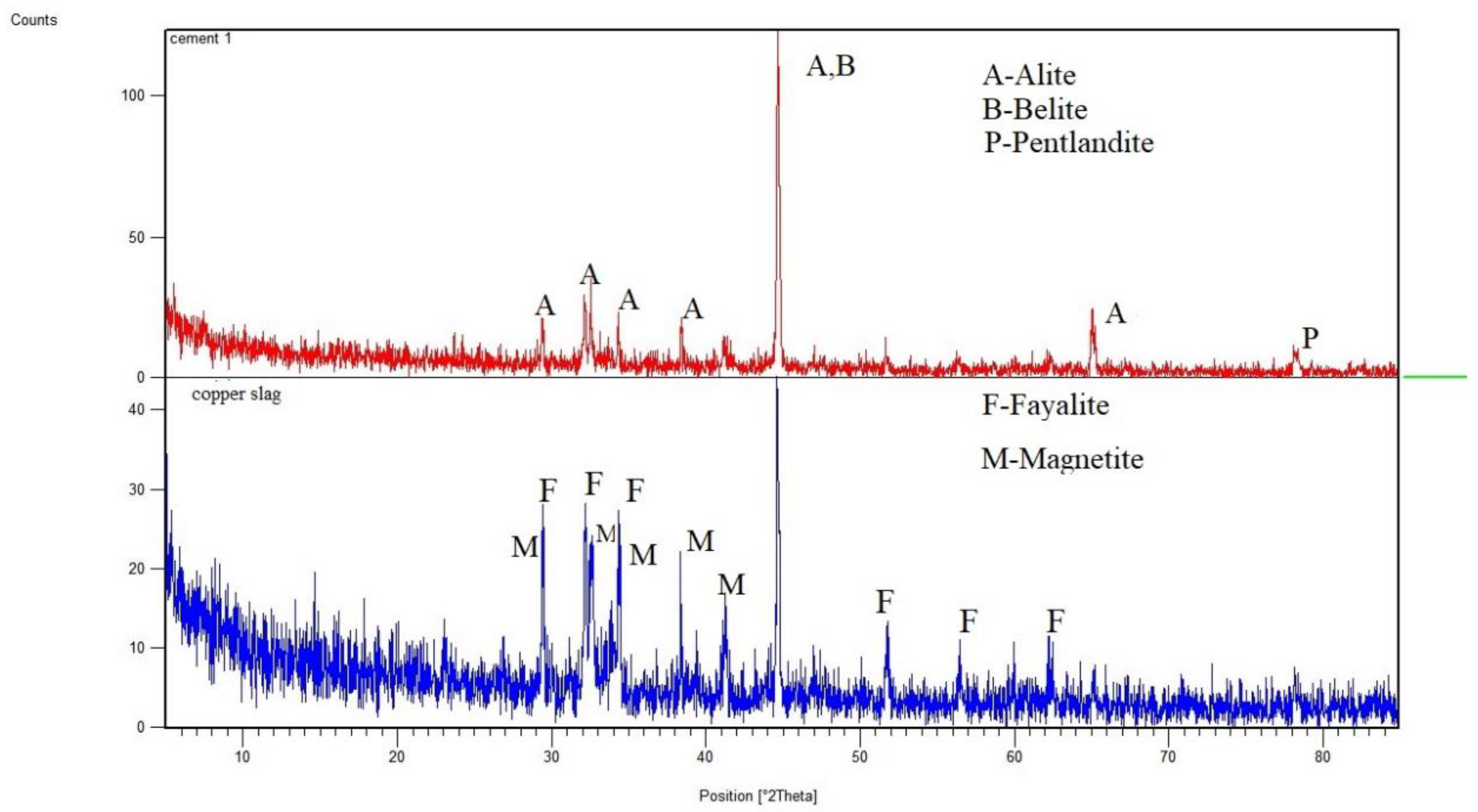

3.1. Materials

3.2. Concrete Mix Proportion

3.3. Equipment Description and Impact Testing Procedure

4. Results and Discussions

4.1. Compressive Strength of CS-PPF Concrete

4.2. Tensile Strength of CS-PPF Concrete

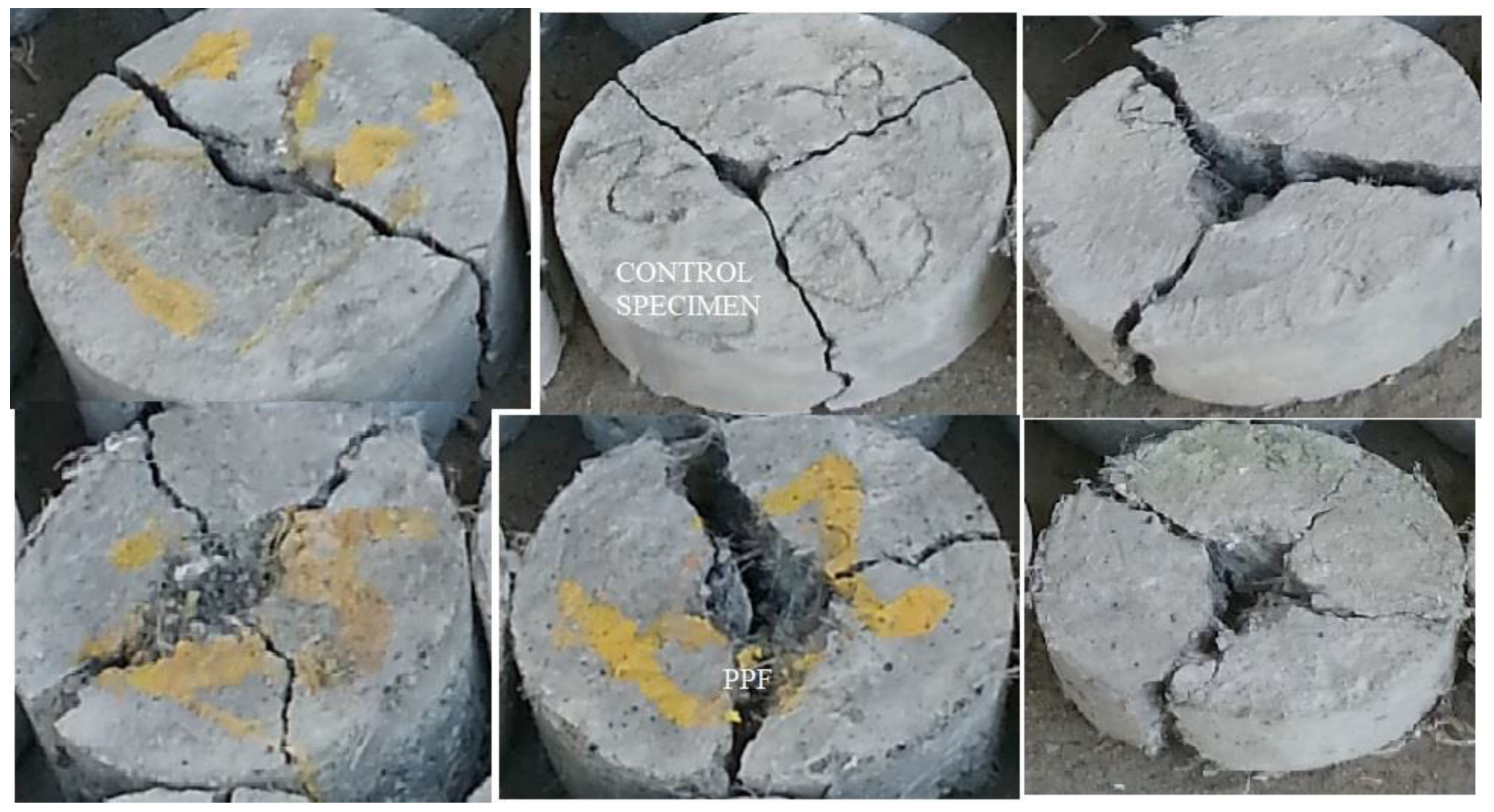

4.3. Failure Pattern on Impact Specimens

4.4. Impact Resistant at First Crack

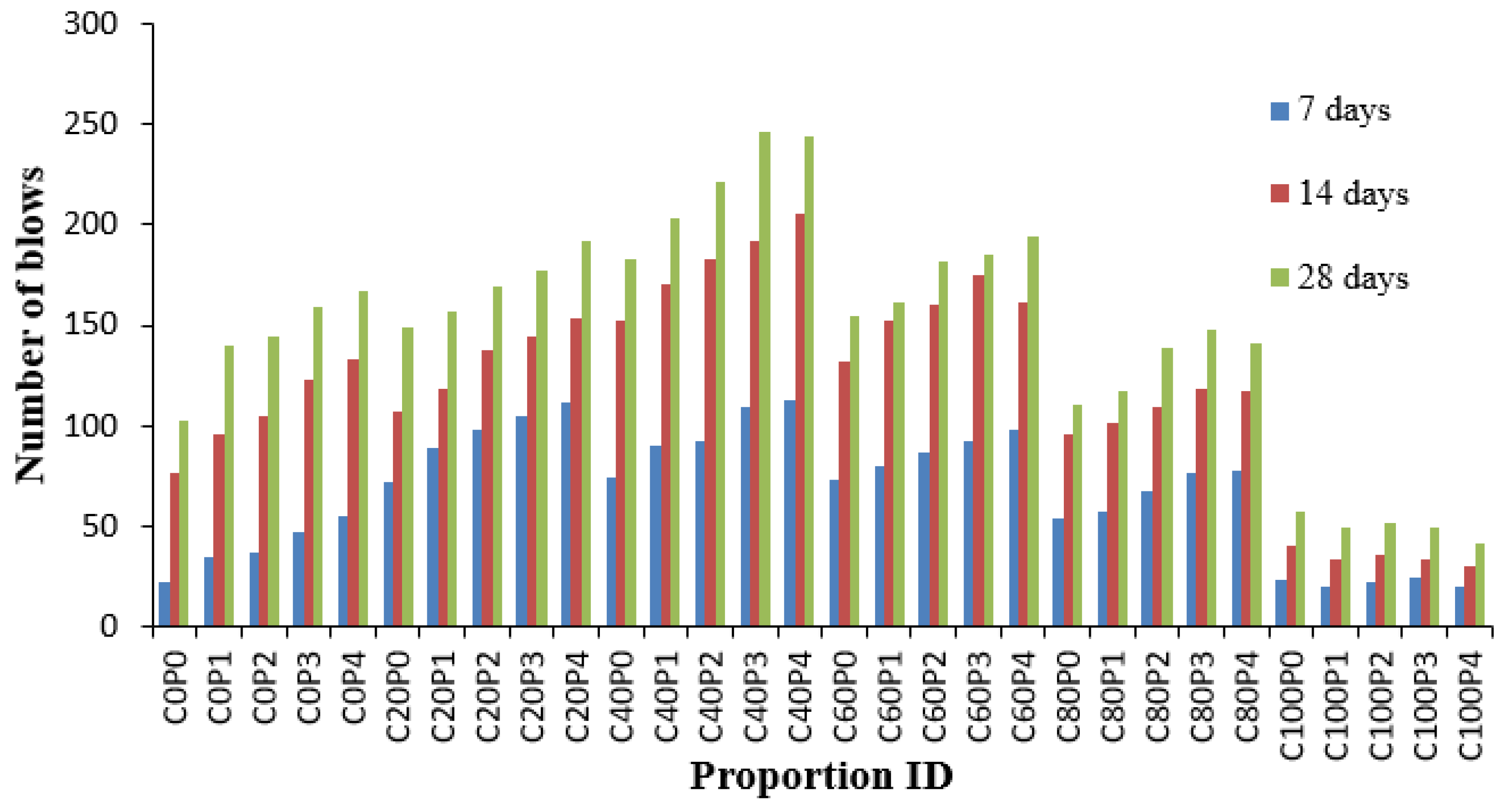

4.5. Impact Resistant at Ultimate Failure

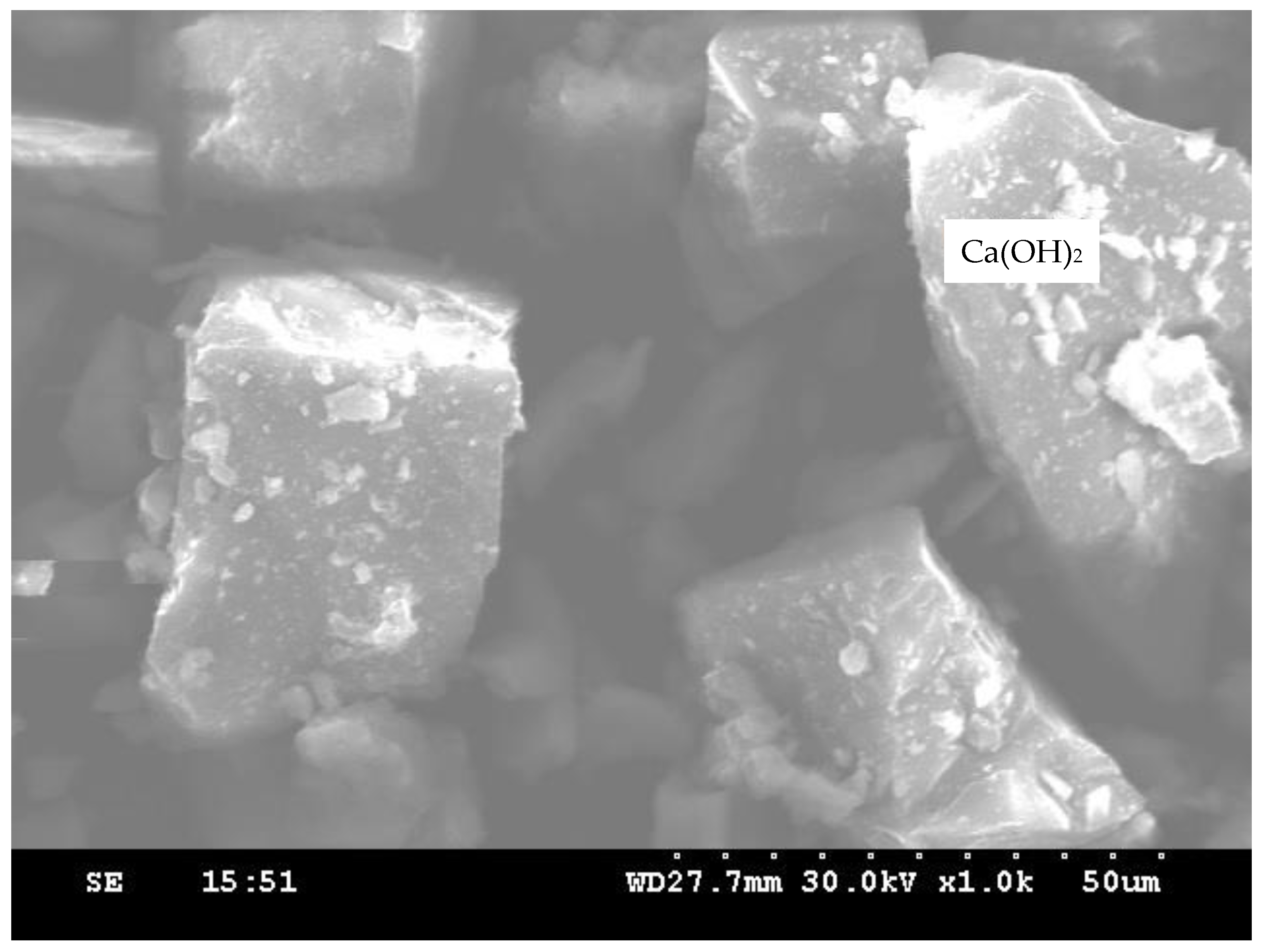

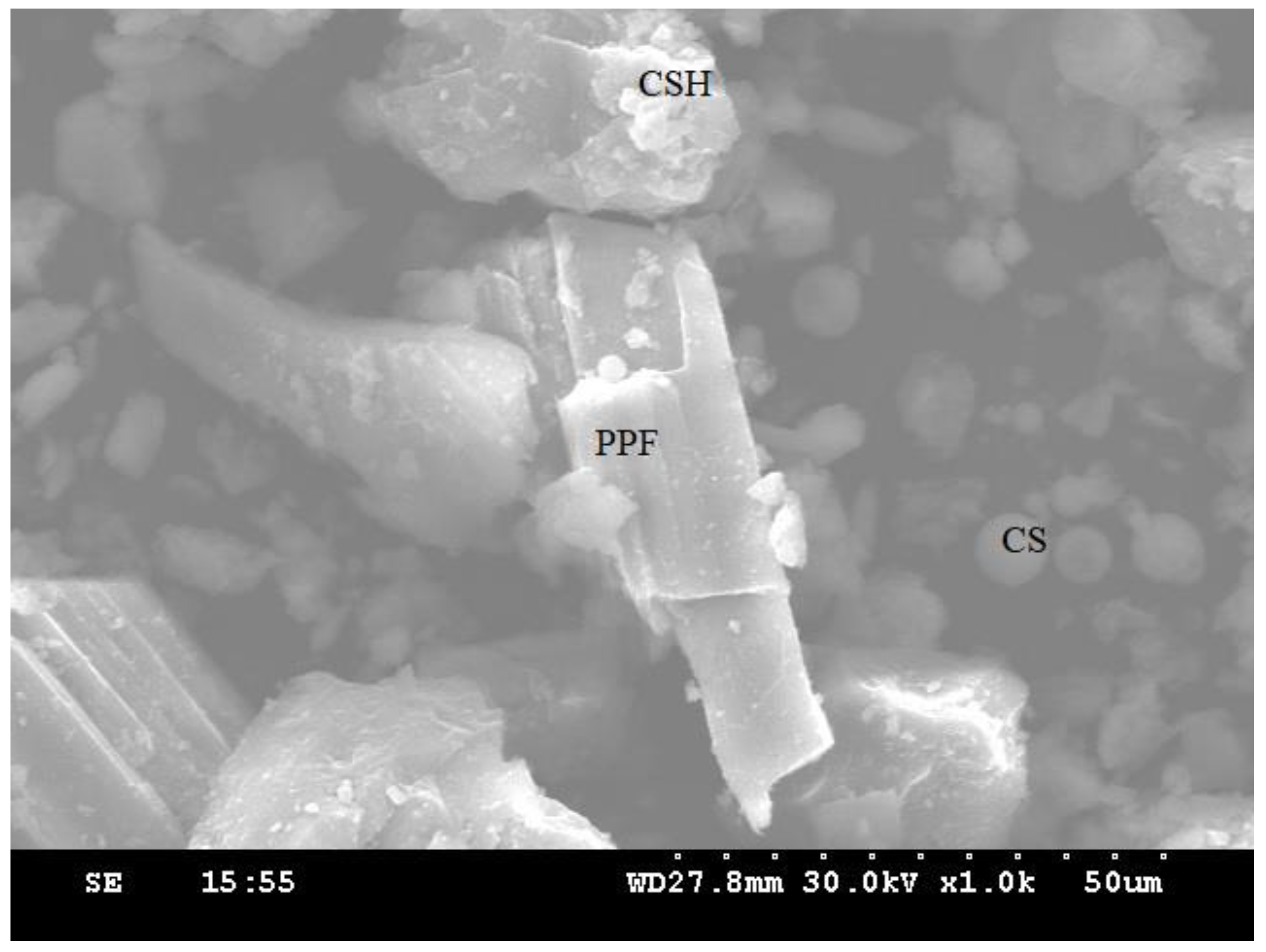

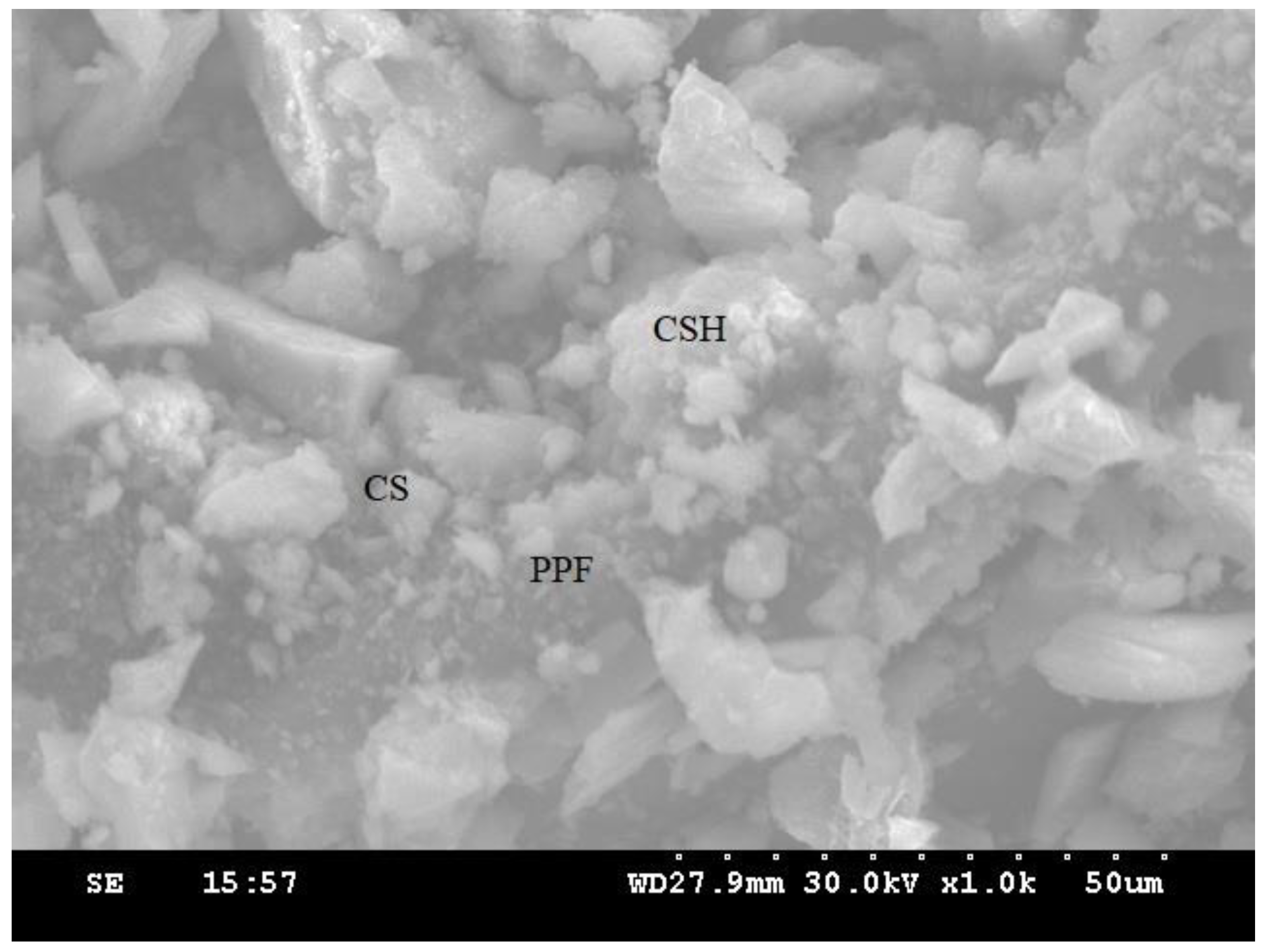

4.6. Microstructural Analysis

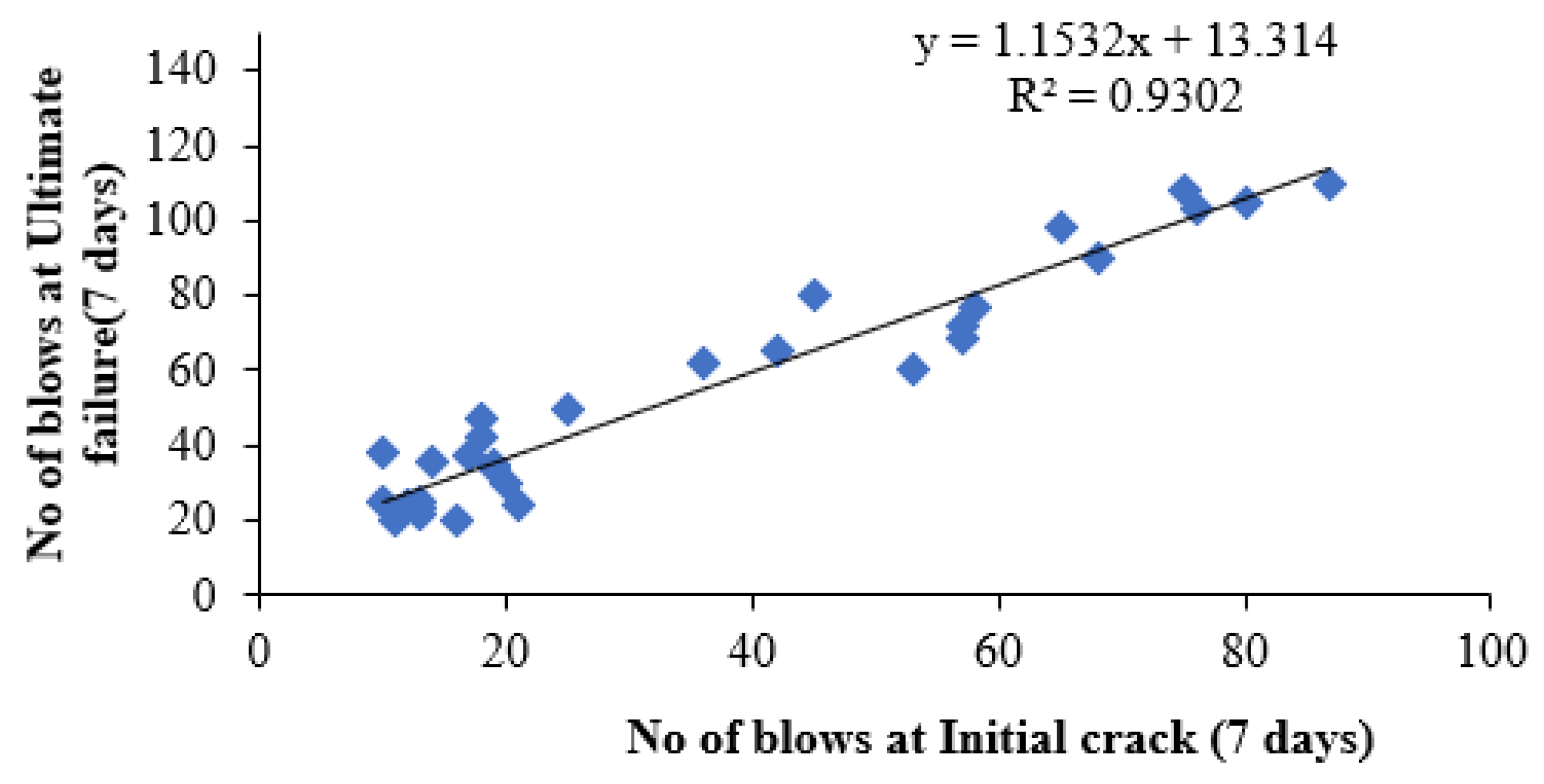

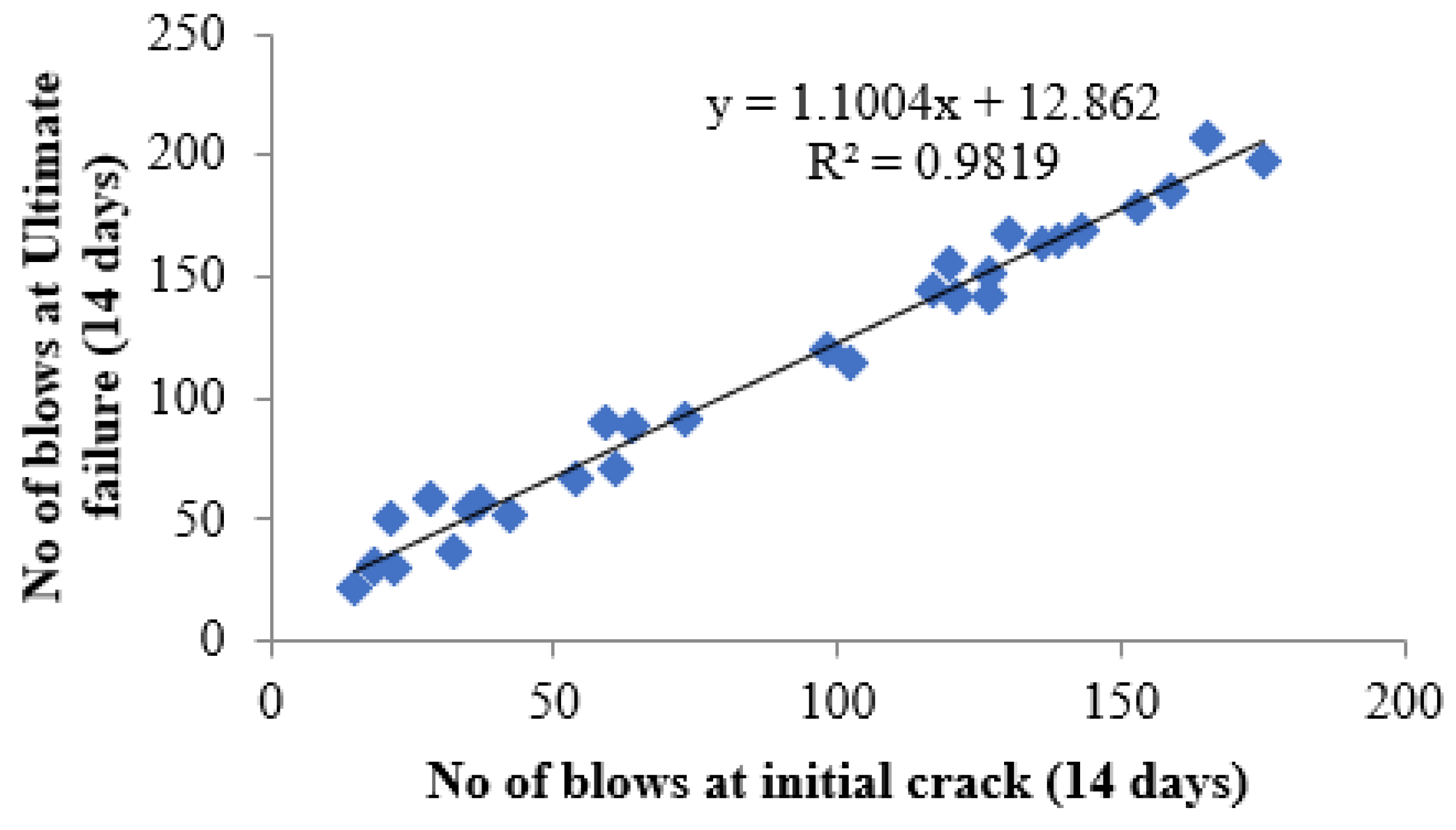

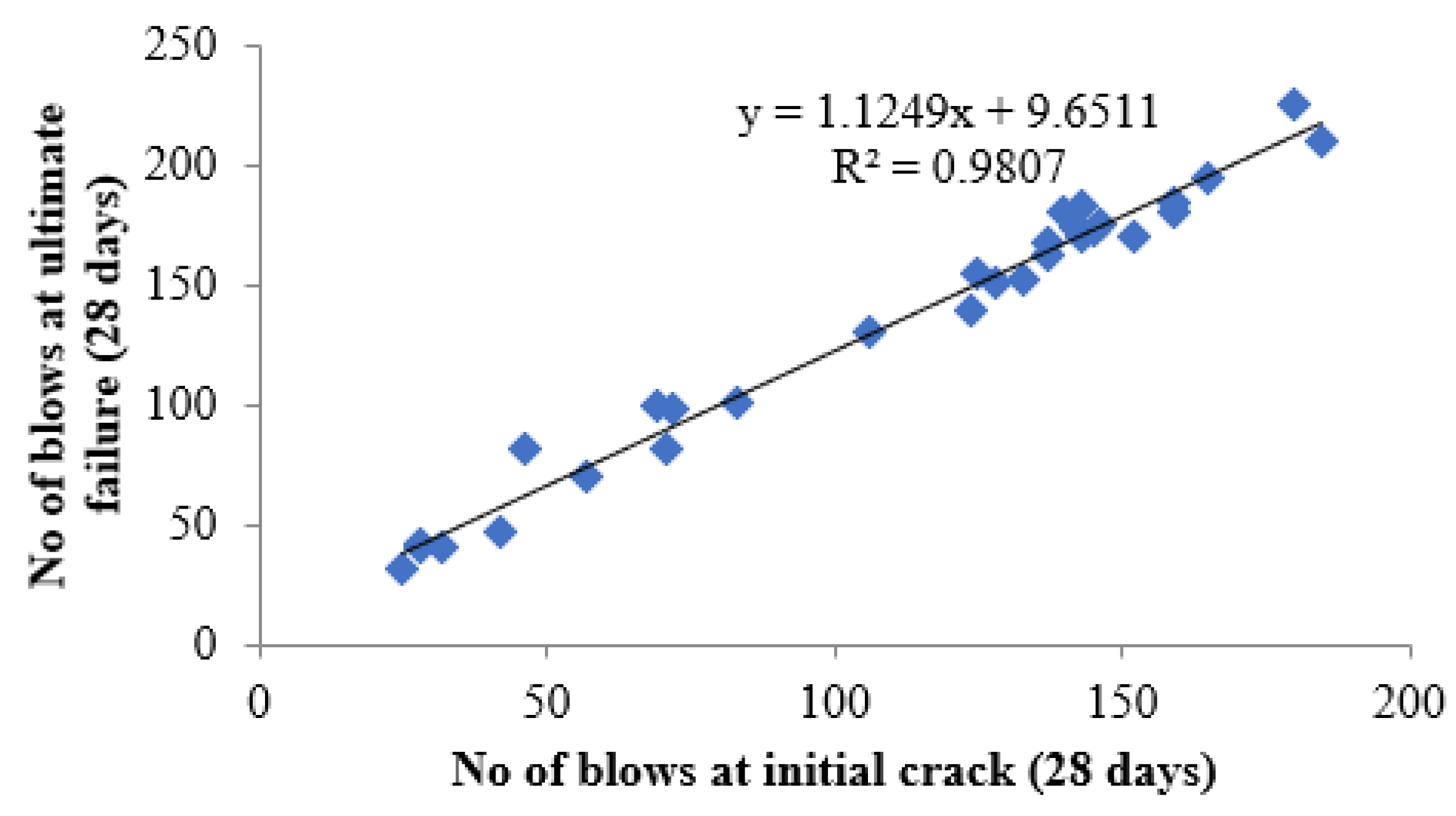

4.7. Regression Analysis

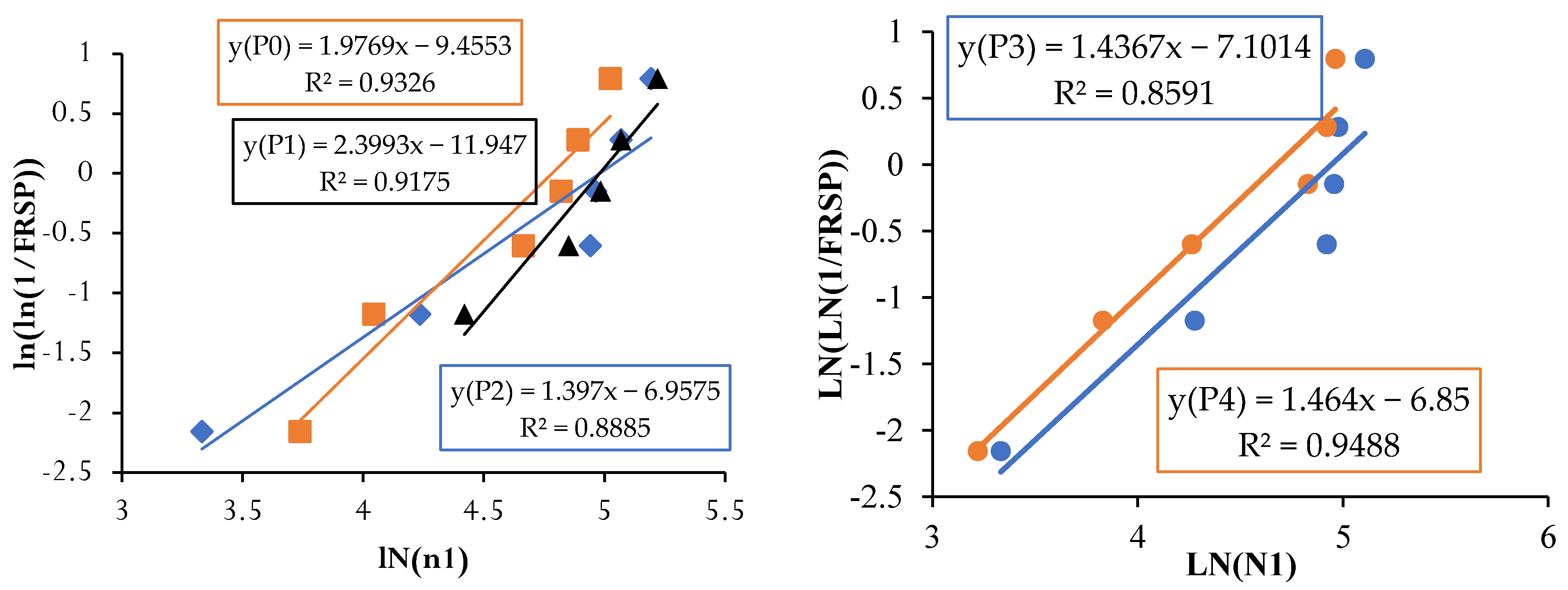

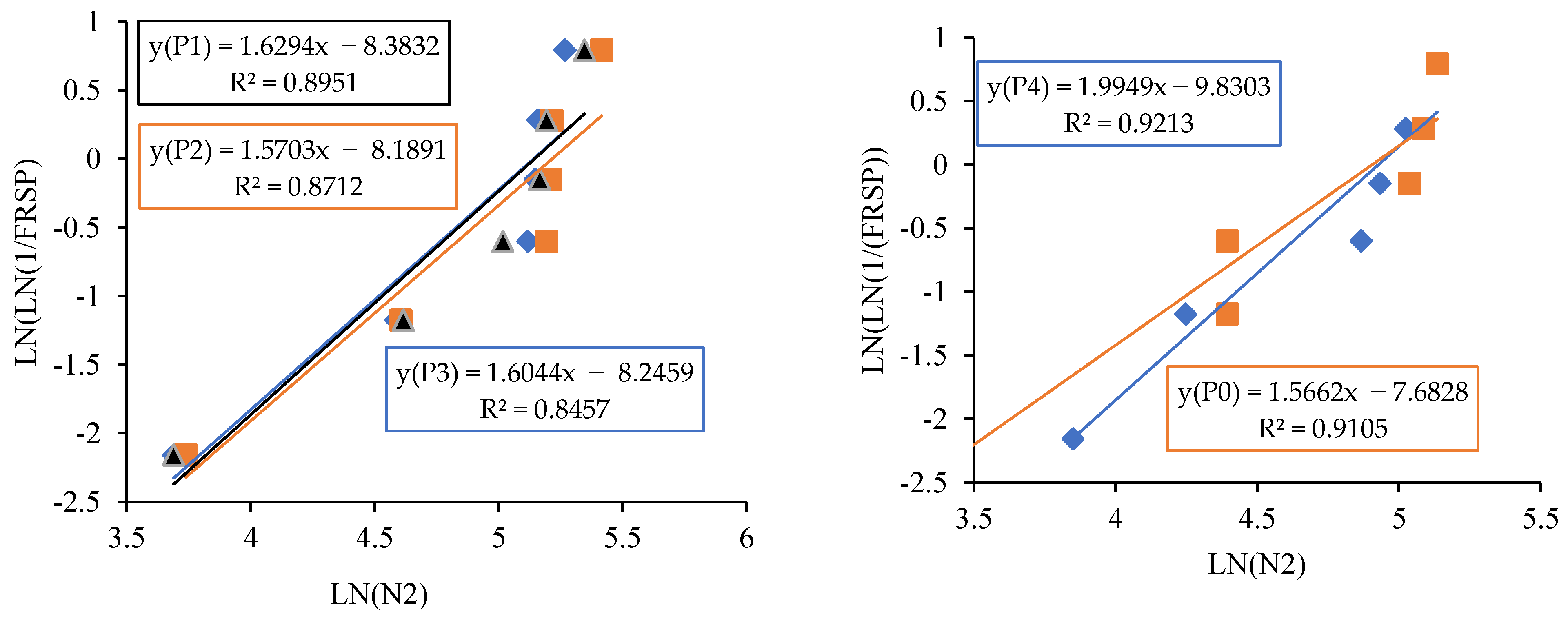

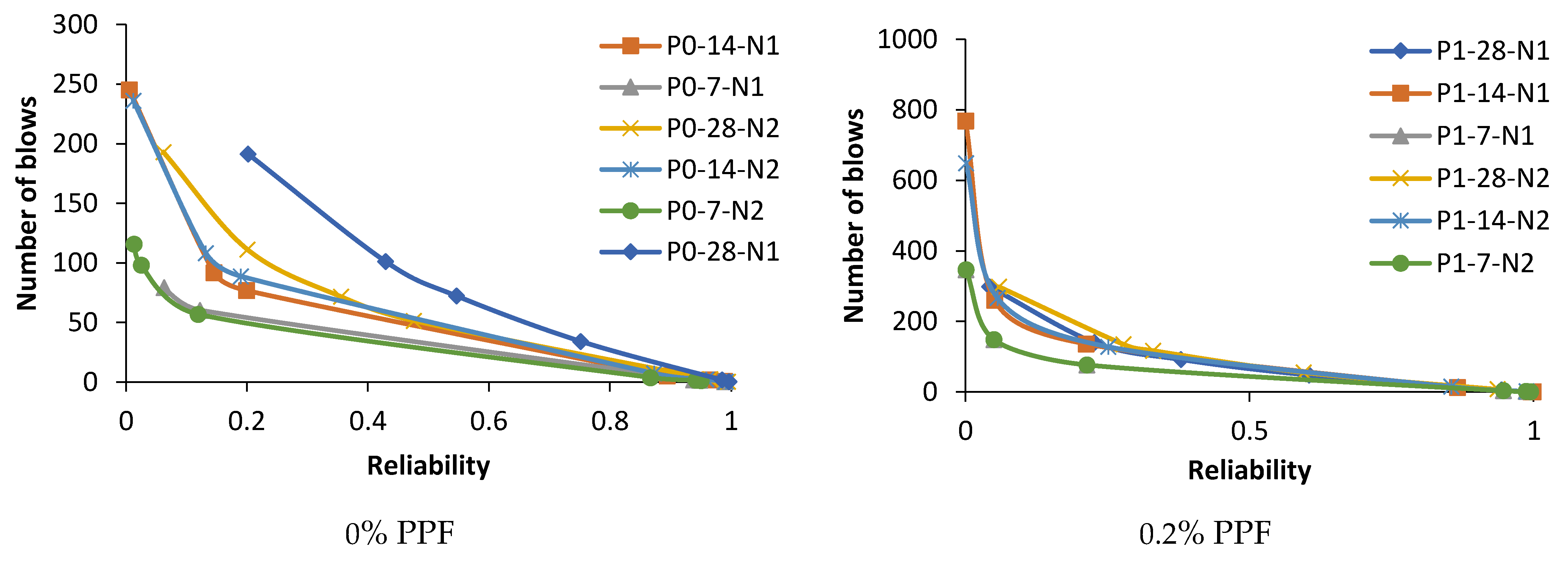

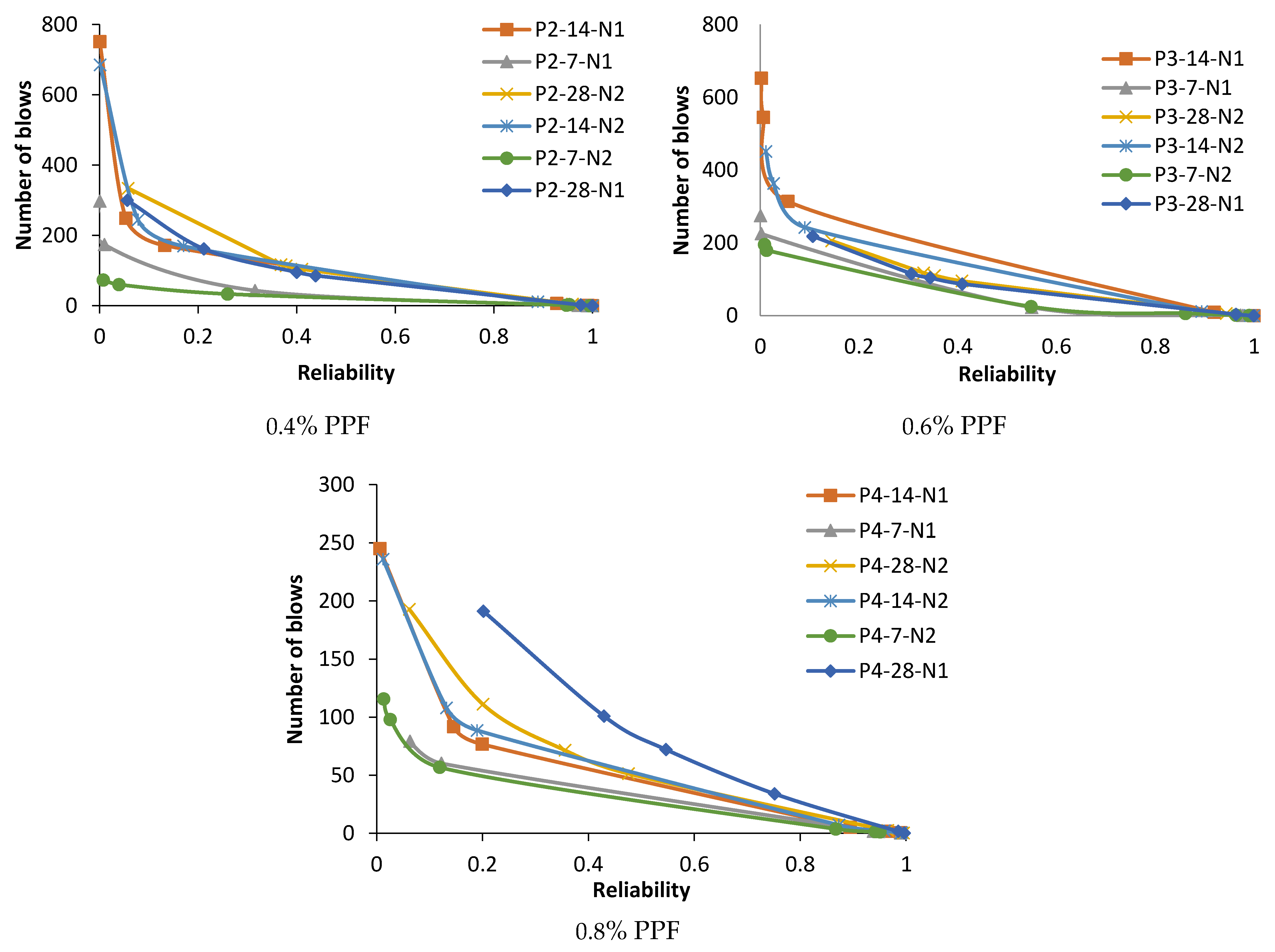

4.8. Reliability Analysis Using Weibull Distribution

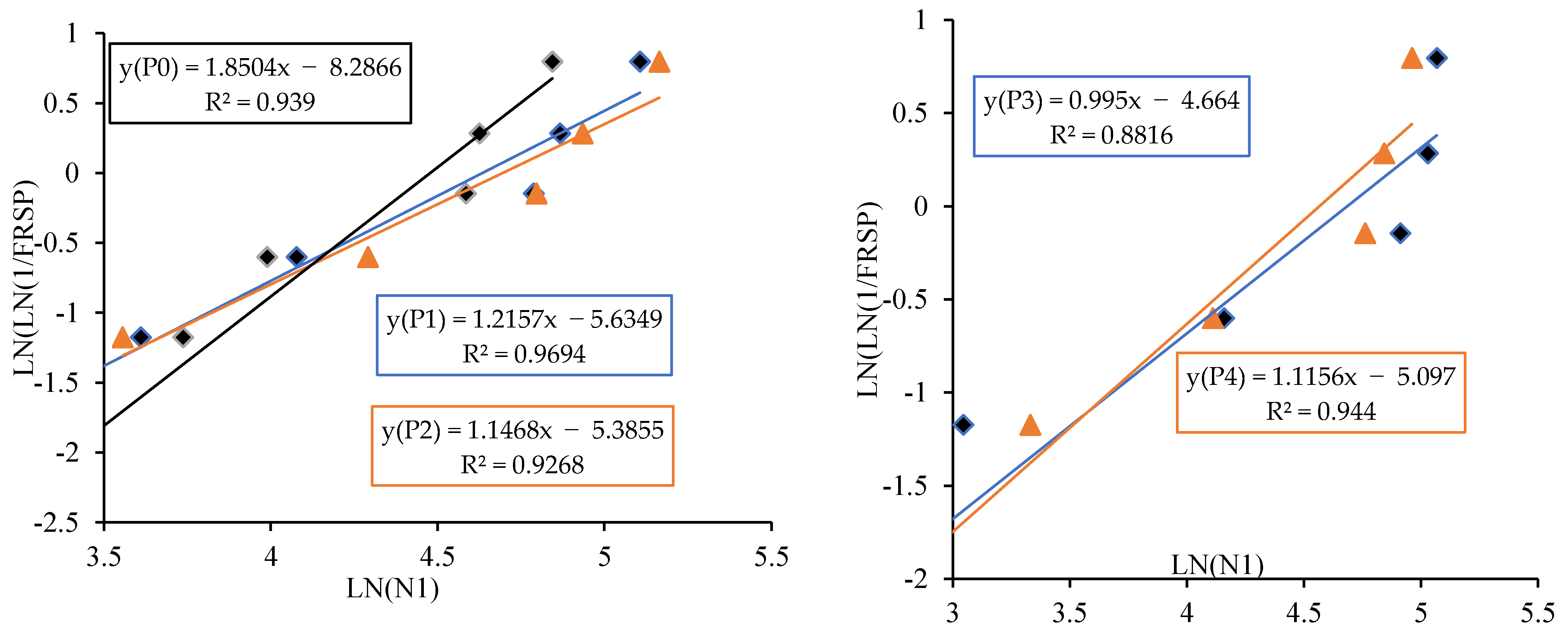

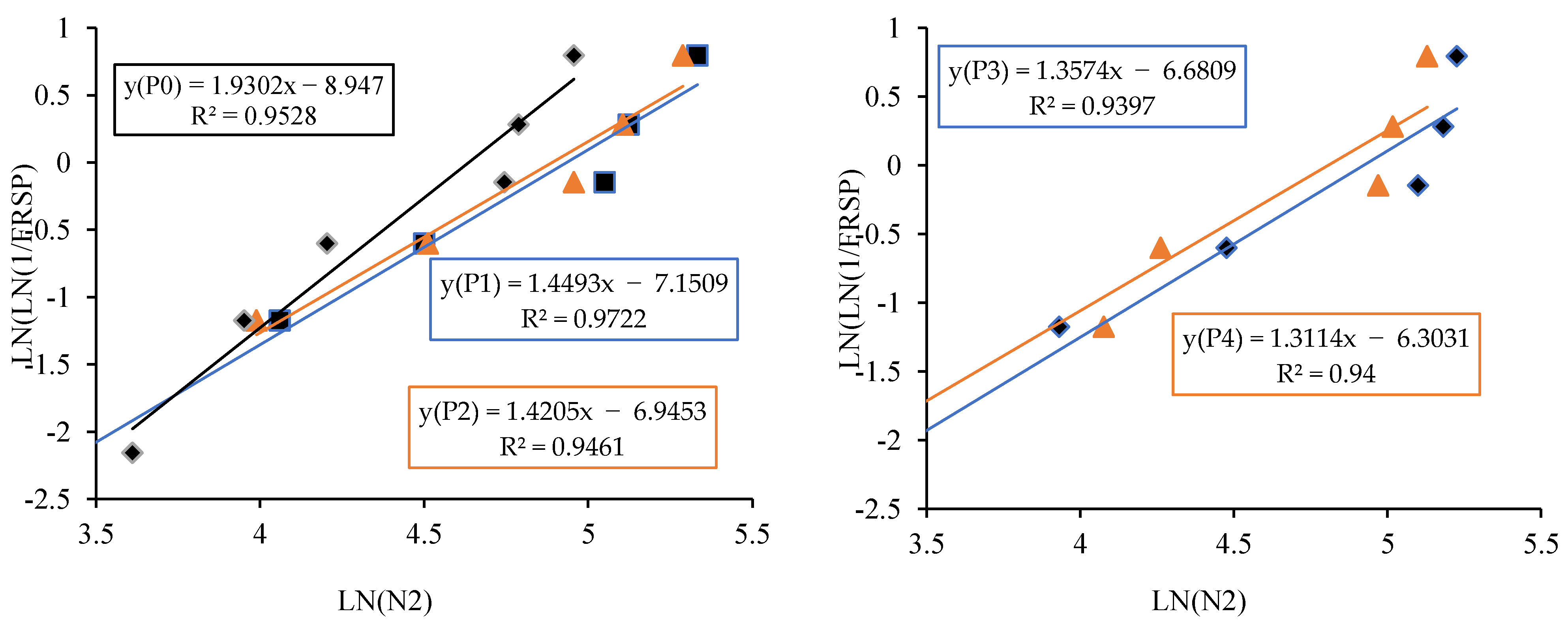

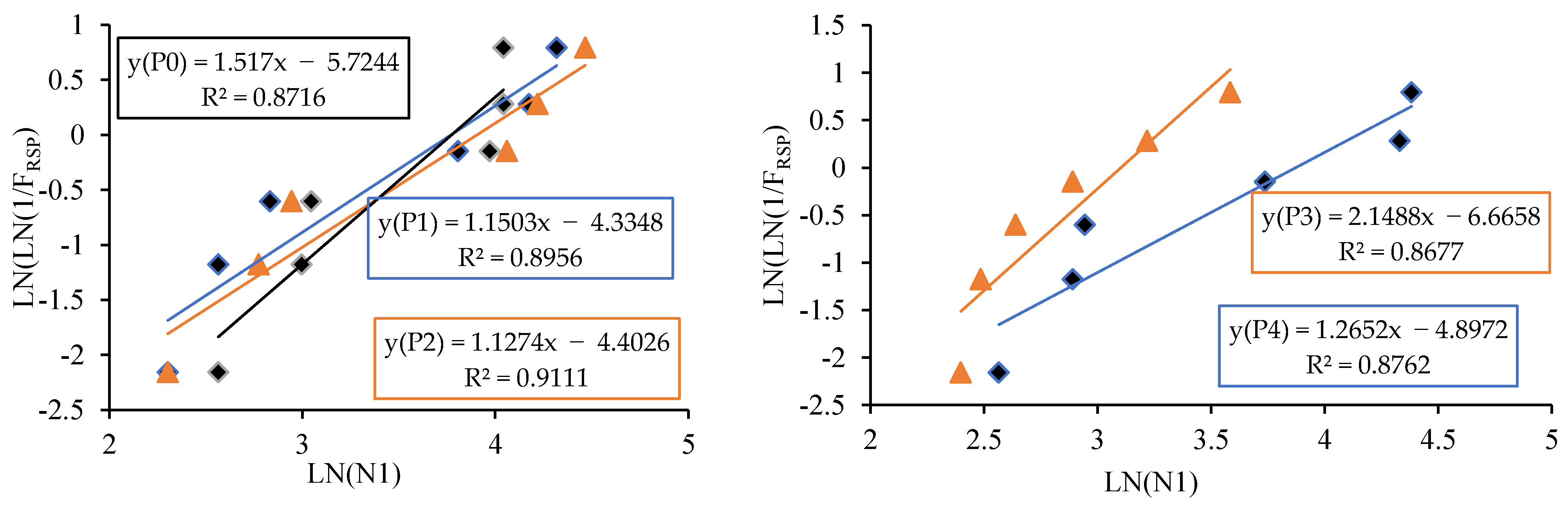

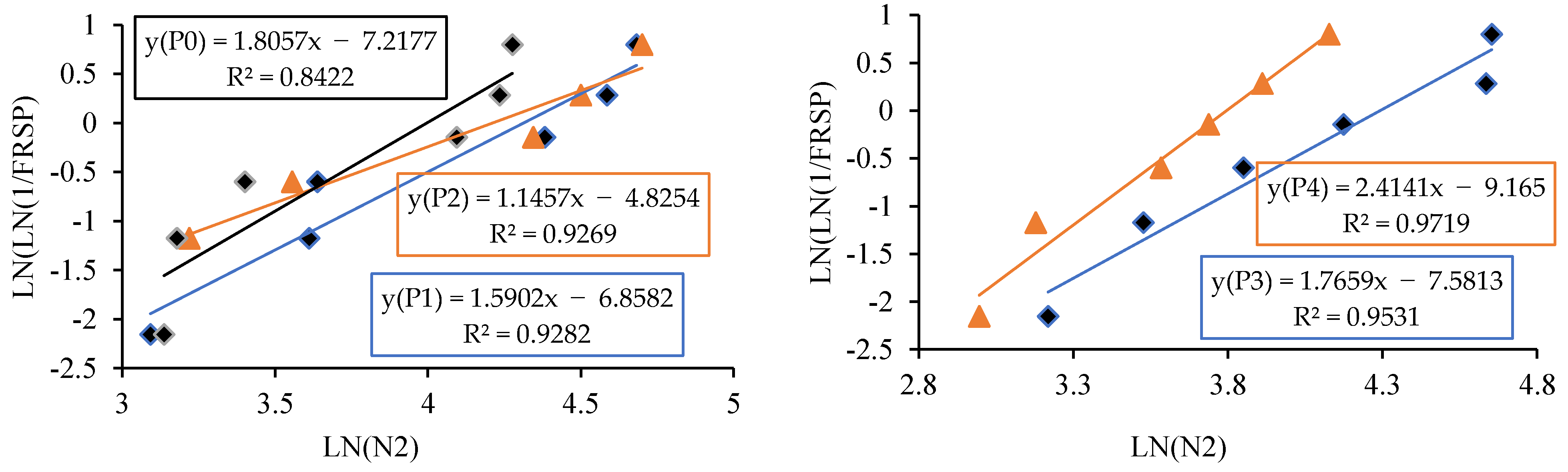

- The experimental observation includes the number of impacts at cracking and failure stage on 7, 14 and 28 days. The results are grouped into P0 (0.0% PPF), P1 (0.2% PPF), P2 (0.4% PPF), P3 (0.6% PPF) and P4 (0.8% PPF).

- The number of blows in each group was sorted in ascending order and the serial number was assigned from 1 to x where x is the respective serial number.

- The failure probability F(RSP) was calculated using the formula given in Equation (9).

- The natural logarithm value of N1 or N2 was determined.

- The value of equation ln was calculated.

- The graph was drawn taking ln (N1 or N2) as x axis and ln as y axis.

- The points in the graph were picked to obtain a linear trendline with equation and R2 value on the graph. The equation is used to obtain the value of slope and intercept C. Figure 13, Figure 14, Figure 15, Figure 16, Figure 17 and Figure 18 illustrate the linear trendline and its equation including the coefficient of regression for all batches of PPF.

- The slope of the trendline is taken as β.

- The intercept C = . Using the value of β and intercept C the value of was calculated. Table 6 lists the shape parameter, scale parameter and regression coefficient from the trendline for different groups of PPF volume fraction, such as 0.2%, 0.4%, 0.6% and 0.8%.

- The Weibull cumulative distribution was performed using the Weibull formula. Dist (N1 or N2, , β, FALSE).

- Reliability probability (R) was calculated by subtracting Revised Survivorship Probability (FRSP) from 1.

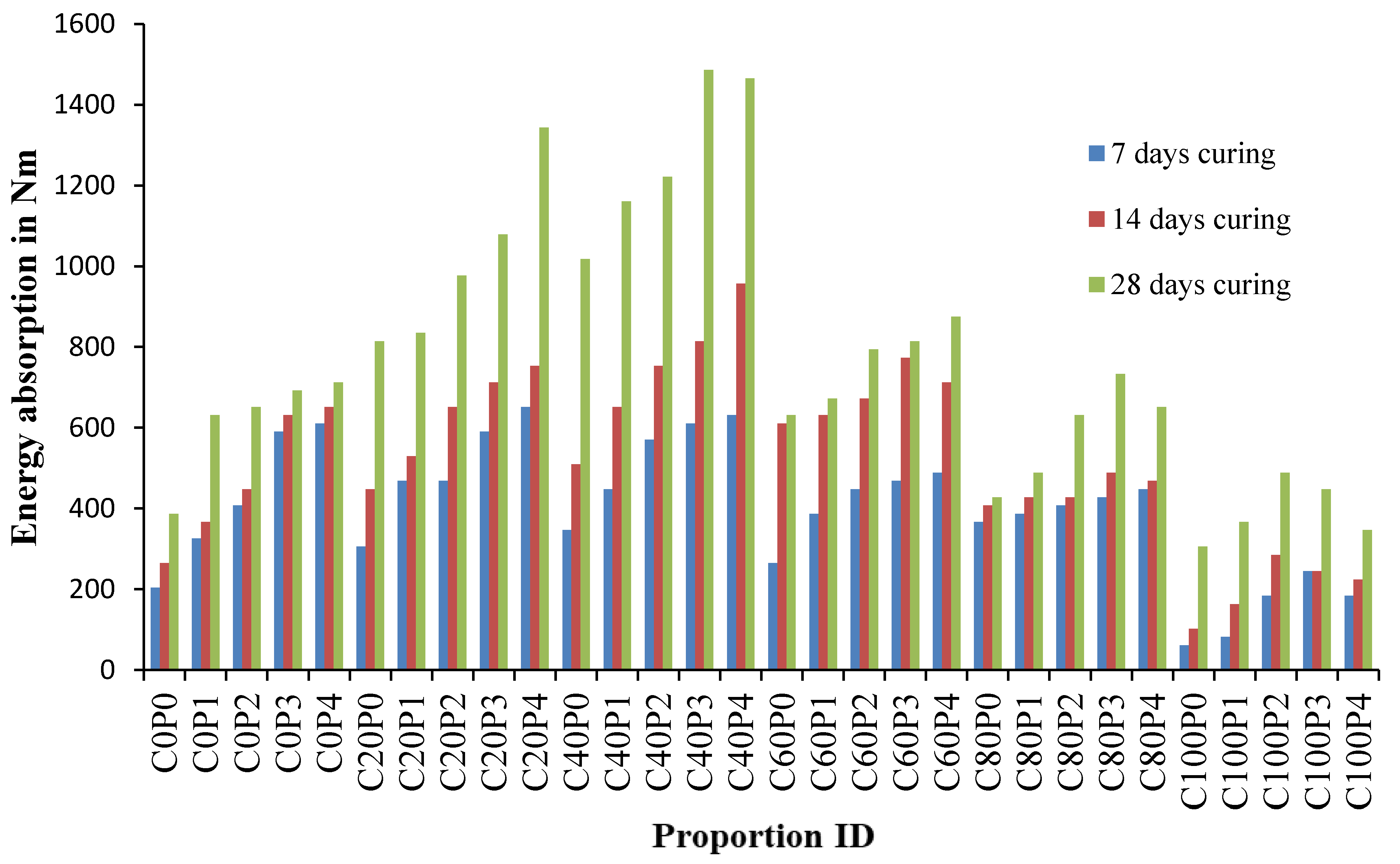

4.9. Energy Absorption Capacity of Concrete

5. Conclusions

- −

- Copper slag has many potential benefits such as improving workability, increasing impact resistance and producing pozzolanic properties. Copper slag would be an exceptional substitute for fine aggregate. There is no detrimental effect detected on replacing the fine aggregate up to 80% CS. CS 40% and PPF 0.4% shows optimum replacement according to compressive strength results. The C100 group does not attain required target strength due to the free water content in the mix. The free water content is attributed to the low water absorption of CS.

- −

- PPF in CS concrete enhances the ductility, post crack performance and increases the capacity against failure compared to the mixes without PPF. A 0.2–0.6% of PPF volume fraction shows improved performance compared to 0.8% PPF. The networking structure of bonding within the fibre concrete matrix reduces the linear and lateral expansion of cracks and hence the count at first crack itself increased. Fibrillated fibre shows higher post-cracking resistance.

- −

- The impact count gradually increases up to 80% replacement of copper slag. In each batch of CS replacement there is an increasing trend of blows according to PPF content. Concrete containing 100% copper slag replaced with sand tolerated 35–47% less blows to break the specimen. C40P4 tolerated the highest number of blows of 82, 158 and 172 at 7, 14 and 28 days, respectively. Blows at initial crack increased from 2.66 to 2.91 times. The impact blows increase from 2.75 to 3.10 times over the control concrete at 28 days at ultimate failure.

- −

- The hydration product increases in CS mixes compared to the control concrete can be evidenced through microstructure images. Due to the excellent pozzolanic activity of CS the amount of CSH gel formation increases with each increment of CS, and thereby a reduction of unreacted Ca(OH)2 is visualized in SEM images. The microstructure of concrete evidences homogeneous spread of CSH gel, pore filling effect and dense microstructure.

- −

- Regression analysis was performed to derive a relationship between early cracking and ultimate failure. The proposed best fit of linear equations predicts the N2 values from N1 derived the regression coefficients of 0.9302, 0.9819 and 0.9807, respectively at 7, 14 and 28 days.

- −

- Weibull distribution using shape and scale parameters is suitable for distributing the variation in number of blows at initial crack and ultimate failure. The impact blow counts observed at reliability level 0.8 or greater is significantly related to the tabulated blows during experimentation.

- −

- The energy absorption values are doubled in the case of fibre reinforced proportions. Maximum values of energy absorption were found in the C40P3 mix, respectively, 610.61, 814.14 and 1485.81 Nm at 7, 14 and 28 days. At the same time, the energy absorption values of the control concrete at 7, 14 and 28 days were 203.54, 264.6 and 386.72 Nm, respectively.

- −

- The outcome of this study describes the mix proportioning of CS-PPF concrete, characterization of microstructure, crack propagation during impact loading and finally, the optimum content of CS and PPF. Since copper slag is a pozzolanic material, like fly ash, the copper slag would be an essential alternative to fine aggregate in the future. Copper slag PPF concrete can be employed to produce solid blocks, hollow blocks and precast elements. This research work can be extended to other types of concrete-like high-density concretes, self-compacting concrete, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chaudhary, M.; Srivastava, V.; Agarwal, V.C. Effect of Waste Low Density Polyethylene on Mechanical Properties of Concrete. J. Acad. Ind. Res. (JAIR) 2014, 3, 2278–5213. [Google Scholar]

- Bahoria, B.; Parbat, D.; Nagarnaik, P. XRD Analysis of Natural sand, Quarry dust, waste plastic (LDPE) to be used as a fine aggregate in concrete. Mater. Today Proc. 2018, 5, 1432–1438. [Google Scholar] [CrossRef]

- Hasan, M.R.; Siddika, A.; Akanda, M.P.A.; Islam, M.R. Effects of Waste Glass Addition on the Physical and Mechanical Properties of Brick. Innov. Infrastruct. Solut. 2021, 6, 26. [Google Scholar] [CrossRef]

- Siddika, A.; Amin, M.R.; Rayhan, M.A.; Islam, M.S.; Mamun, M.A.A.; Alyousef, R.; Mugahed Amran, Y.H. Performance of Sustainable Green Concrete Incorporated with Fly Ash, Rice Husk Ash, and Stone Dust. Acta Polytech. 2021, 61, 279–291. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Gao, X.; Huang, Y.; Yu, R.; Li, X.; Yang, R. Utilizing Coral Waste and Metakaolin to Produce Eco-Friendly Marine Mortar: Hydration, Mechanical Properties and Durability. J. Clean. Prod. 2019, 219, 763–774. [Google Scholar] [CrossRef]

- Tang, Y.; Feng, W.; Chen, Z.; Nong, Y.; Guan, S.; Sun, J. Fracture Behavior of a Sustainable Material: Recycled Concrete with Waste Crumb Rubber Subjected to Elevated Temperatures. J. Clean. Prod. 2021, 318, 128553. [Google Scholar] [CrossRef]

- Siddique, S.; Shrivastava, S.; Chaudhary, S. Durability Properties of Bone China Ceramic Fine Aggregate Concrete. Constr. Build. Mater. 2018, 173, 323–331. [Google Scholar] [CrossRef]

- Ho, H.J.; Iizuka, A.; Shibata, E. Chemical Recycling and Use of Various Types of Concrete Waste: A Review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Samarakoon, S.M.S.M.K.; Ruben, P.; Wie Pedersen, J.; Evangelista, L. Mechanical Performance of Concrete Made of Steel Fibers from Tire Waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Li, X. Recycling and Reuse of Waste Concrete in China. Part I. Material Behaviour of Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Lim, T.T.; Chu, J. Assessment of the Use of Spent Copper Slag for Land Reclamation. Waste Manag. Res. 2006, 24, 67–73. [Google Scholar] [CrossRef]

- Shi, C.; Meyer, C.; Behnood, A. Utilization of Copper Slag in Cement and Concrete. Resour. Conserv. Recycl. 2008, 52, 1115–1120. [Google Scholar] [CrossRef]

- Hanio Merinkline, H.; Manjula Devi, S.; Christy, F. Fresh and Hardened Properties of Fly Ash Based Geopolymer Concrete with Copper Slag; IJERT: Gujarat, India, 2013; Volume 2. [Google Scholar]

- Siddique, R.; Singh, M.; Jain, M. Recycling Copper Slag in Steel Fibre Concrete for Sustainable Construction. J. Clean. Prod. 2020, 271, 122559. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Hisada, M.; Al-Saidy, A.H.; Al-Oraimi, S.K. Performance of High Strength Concrete Made with Copper Slag as a Fine Aggregate. Constr. Build. Mater. 2009, 23, 2132–2140. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of Copper Slag as a Fine Aggregate on the Properties of Cement Mortars and Concrete. Constr. Build. Mater. 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Vijayaprabha, C.; Brindha, D.; Ashokkumar, E. Copper Slag Concrete Admixed with Polypropylene Fibres. Gradjevinar 2016, 68, 95–104. [Google Scholar] [CrossRef] [Green Version]

- Vijayaprabha, C.; Brindha, D.; Siva, A. Durability Performance of Copper Slag Concrete Admixed with Polypropylene Fiber. J. Chem. Pharm. Sci. 2017, 521, 0974–2115. [Google Scholar]

- Tixier, R.; Devaguptapu, R.; Mobasher, B. The Effect of Copper Slag on the Hydration and Mechanical Properties of Cementitious Mixtures. Cem. Concr. Res. 1997, 27, 1569–1580. [Google Scholar] [CrossRef]

- Li, Y.; Ding, H.; Nie, Y.; Hesp, S.A.M. Effective Control of Flexible Asphalt Pavement Cracking through Quality Assurance Testing of Extracted and Recovered Binders. Constr. Build. Mater. 2021, 273, 121769. [Google Scholar] [CrossRef]

- Ariño, A.M.; Mobasher, B. Effect of Ground Copper Slag on Strength and Toughness of Cementitious Mixes. ACI Mater. J. 1999, 96, 68–73. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.A.; Najafi, M.H. Laboratory Study on the Effect of Polypropylene Fiber on Durability, and Physical and Mechanical Characteristic of Concrete for Application in Sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Mohebi, Z.H.; Bahnamiri, A.B.; Dehestani, M. Effect of Polypropylene Fibers on Bond Performance of Reinforcing Bars in High Strength Concrete. Constr. Build. Mater. 2019, 215, 401–409. [Google Scholar] [CrossRef]

- Ahmed, S.; Taxila, T.; Bukhari, I.A.; Qureshi, S.A. A Study on Properties of Polypropylene Fiber Reinforced Concrete. Our World Concr. Struct. 2006, 7, 2454–9150. [Google Scholar]

- Liu, J.; Jia, Y.; Wang, J. Experimental Study on Mechanical and Durability Properties of Glass and Polypropylene Fiber Reinforced Concrete. Fibers Polym. 2019, 20, 1900–1908. [Google Scholar] [CrossRef]

- Mahadik, S.A.; Kamane, S.K.; Lande, A.C. Effect of Steel Fibers on Compressive and Flexural Strength of Concrete. In Proceedings of the World Conference on Applied Sciences, Engineering & Technology, Kathmandu, Nepal, 27–29 September 2014. [Google Scholar]

- Madhavi, T.C.; Raju, L.S.; Deepak, M. Polypropylene Fiber Reinforced Concrete- A Review. Int. J. Appl. Eng. Res. 2014, 4, 212590284. [Google Scholar]

- Ahmed, T.W.; Aljubory, N.H.; Zidan, R.S. Properties and Performance of Polypropylene Fiber Reinforced Concrete: A Review. Tikrit J. Eng. Sci. 2020, 27. [Google Scholar] [CrossRef]

- Yu, P.; Manalo, A.; Ferdous, W.; Abousnina, R.; Salih, C.; Heyer, T.; Schubel, P. Investigation on the Physical, Mechanical and Microstructural Properties of Epoxy Polymer Matrix with Crumb Rubber and Short Fibres for Composite Railway Sleepers. Constr. Build. Mater. 2021, 295, 123700. [Google Scholar] [CrossRef]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravinthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending Behaviour of Precast Concrete Slab with Externally Flanged Hollow FRP Tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Vijayaprabha, C. Evaluation of Long Term Compressive Strength of Concrete Made with Copper Slag and Polypropylene Fiber. J. Struct. Eng. 2020, 441, 441–448. [Google Scholar]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of High Strength Polypropylene Fiber Concrete Containing Recycled Aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Sharmila, S.; Thirugnanam, G. Behavior of Reinforced Concrete Flexural Member with Hybrid Fibre under Cyclic Loading. Int. J. Sci. Environ. Technol. 2013, 2, 725–734. [Google Scholar]

- Xiong, Z.; Fang, Z.; Feng, W.; Liu, F.; Yang, F.; Li, L. Review of Dynamic Behaviour of Rubberised Concrete at Material and Member Levels. J. Build. Eng. 2021, 38, 102237. [Google Scholar] [CrossRef]

- BIS 8112. Ordinary Portland Cement, 43 Grade Specification. Bur. Indian Stand. 2013, 6, 125. [Google Scholar]

- Methods of Test for Pozzolanic Materials; IS 1727; Bureau of Indian Standards: New Delhi, India, 2004.

- Indian Standard 4031 (Part IV): Methods of Physical Tests for Hydraulic Cement; IS 4031—Part 4; Bureau of Indian Standards: New Delhi, Indian, 1988.

- Methods of Physical Tests for Hydraulic Cement. Part V—Determination of Initial and Final Setting Times; IS 4031—Part V; Bureau of Indian Standards: New Delhi, Indian, 1988. [Google Scholar]

- Bureau of Indian Standards. Specification for Concrete Admixtures BIS; IS 9103: 1999; Bureau of Indian Standards: New Delhi, Indian, 1999. [Google Scholar]

- Saraswathy, V.; Karthick, S.; Muralidharan, S. Corrosion and Leaching Studies in Blended Copper Slag Mortar. J. Eng. Technol. 2014, 4, 29. [Google Scholar] [CrossRef] [Green Version]

- Alter, H. The Composition and Environmental Hazard of Copper Slags in the Context of the Basel Convention. Resour. Conserv. Recycl. 2005, 43, 353–360. [Google Scholar] [CrossRef]

- Dos Anjos, M.A.G.; Sales, A.T.C.; Andrade, N. Blasted Copper Slag as Fine Aggregate in Portland Cement Concrete. J. Environ. Manag. 2017, 196, 607–613. [Google Scholar] [CrossRef] [PubMed]

- Gupta, N.; Siddique, R. Strength and Micro-Structural Properties of Self-Compacting Concrete Incorporating Copper Slag. Constr. Build. Mater. 2019, 224, 894–908. [Google Scholar] [CrossRef]

- Methods of Test for Aggregates for Concrete; IS: 2386—Part II; Bureau of Indian Standards: New Delhi, Indian, 1963.

- Standard Specification for Fiber-Reinforced Concrete. In Annual Book of ASTM Standards; ASTM C 1116; ASTM: West Conshohocken, PA, USA, 2009; Volume 200.

- Specification for Coarse and Fine Aggregates from Natural Sources for Concrete; BIS: 383-1970; Bureau of Indian Standards: New Delhi, India, 1997.

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM C618-17a; Annual Book of ASTM Standards; ASTM: West Conshohocken, PA, USA, 2017; Volume 4, p. 5.

- BIS 10262-2019 Concrete Mix Proportioning-Guidelines, 2nd ed.; Bureau of Indian Standards: New Delhi, Indian, 2019.

- Ramesh, K.; Arunachalam, K.; Rooban Chakravarthy, S. Experimental Investigation on Impact Resistance of Flyash Concrete and Flyash Fiber Reinforced Concrete. Int. J. Eng. Res. Appl. (IJERA) 2013, 3, 990–999. [Google Scholar]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated Drop-Weight Impact Tests on Self-Compacting Concrete Reinforced with Micro-Steel Fiber. Heliyon 2020, 6, e03198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ACI Committee 544. ACI 544.2R-89. Measurement of Properties of Fiber Reinforced Concrete (Reapproved 1999). Am. Concr. Inst. (ACI) 1984, 89, 1–12. [Google Scholar]

- Deepa Shri, S.; Thenmozhi, R. Prediction of Impact Energy Absorption Using Modified Regression Theory. Life Sci. J. 2013, 10, 264–269. [Google Scholar]

- Parveen, J.; Sharma, A. Structural Behaviour of Fibrous Concrete Using Polypropylene Fibres. Int. J. Mod. Eng. Res. 2013, 3, 1279–1282. [Google Scholar]

- Li, Q.; Zhao, X.; Xu, S.; Leung, C.K.Y.; Wang, B. Multiple Impact Resistance of Hybrid Fiber Ultrahigh Toughness Cementitious Composites with Different Degrees of Initial Damage. J. Mater. Civil. Eng. 2019, 31, 04018368. [Google Scholar] [CrossRef]

- Banthia, N.; Mindess, S.; Bentur, A.; Pigeon, M. Impact Testing of Concrete Using a Drop-Weight Impact Machine. Exp. Mech. 1989, 29, 63–69. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Statistical Analysis of Impact Strength and Strength Reliability of Steel-Polypropylene Hybrid Fiber-Reinforced Concrete. Constr. Build. Mater. 2005, 19, 1–9. [Google Scholar] [CrossRef]

- Poongodi, K.; Murthi, P. Impact strength enhancement of banana fibre reinforced lightweight self-compacting concrete. Mater. Today: Proc. 2020, 27, 1203–1209. [Google Scholar] [CrossRef]

- Vivas, J.C.; Zerbino, R.; Torrijos, M.C.; Giaccio, G. Effect of the Fibre Type on Concrete Impact Resistance. Constr. Build. Mater. 2020, 264, 120200. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Influence of Copper Slag and Metakaolin on the Durability of Self Compacting Concrete. J. Clean. Prod. 2018, 171, 1171–1186. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Materials: Introduction and Applications; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Wu, W.; Zhang, W.; Ma, G. Optimum Content of Copper Slag as a Fine Aggregate in High Strength Concrete. Mater. Des. 2010, 31, 2878–2883. [Google Scholar] [CrossRef]

- Dash, M.K.; Patro, S.K.; Rath, A.K. Sustainable Use of Industrial-Waste as Partial Replacement of Fine Aggregate for Preparation of Concrete—A Review. Int. J. Sustain. Built Environ. 2016, 5, 484–516. [Google Scholar] [CrossRef] [Green Version]

- Areef, D.M.; Rao, P.S.; Reddy, V.S.; Zubair, D.M.A. Flexural behaviour of steel fibre reinforced concrete beams made with copper slag as partial fine aggregate replacement. E3S Web Conf. 2020, 184, 01077. [Google Scholar] [CrossRef]

- Badr, A.; Ashour, A.F.; Platten, A.K. Statistical Variations in Impact Resistance of Polypropylene Fibre-Reinforced Concrete. Int. J. Impact Eng. 2006, 32, 1907–1920. [Google Scholar] [CrossRef] [Green Version]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined Effect of Silica Fume and Steel Fibers on the Impact Resistance and Mechanical Properties of Concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Sivasakthi, M.; Jeyalakshmi, R.; Rajamane, N.P. Fly Ash Geopolymer Mortar: Impact of the Substitution of River Sand by Copper Slag as a Fine Aggregate on Its Thermal Resistance Properties. J. Clean. Prod. 2021, 279, 123766. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R. Utilization of Copper Slag in Self-Compacting Concrete—Strength and Permeation Properties. In Rheology and Processing of Construction Materials; RILEM Book Series; Springer: Berlin/Heidelberg, Germany, 2020; Volume 23. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M. Assessment of Strength and Durability Characteristics of Copper Slag Incorporated Ultra High Strength Concrete. J. Clean. Prod. 2019, 208, 402–414. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Nithiyanantham, S. Microstructural, Mechanical, and Electrical Properties of Copper Slag Admixtured Cement Mortar. J. Build. Eng. 2020, 31, 101375. [Google Scholar] [CrossRef]

- Naraganti, S.R.; Pannem, R.M.R.; Putta, J. Impact Resistance of Hybrid Fibre Reinforced Concrete Containing Sisal Fibres. Ain Shams Eng. J. 2019, 10, 297–305. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and Experimental Analysis on the Behavior of Fiber Reinforced Concretes Subjected to Drop Weight Test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Murali, G.; Asrani, N.P.; Ramkumar, V.R.; Siva, A.; Haridharan, M.K. Impact Resistance and Strength Reliability of Novel Two-Stage Fibre-Reinforced Concrete. Arab. J. Sci. Eng. 2019, 44, 4477–4490. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory of the Strength of Materials. Generalstabens Litografiska Anstalts Förlag, Stockholm. Gen. Litogr. Anst. Förlag 1939, 151, 189–206. [Google Scholar]

- Singh, S.P.; Mohammadi, Y.; Kaushik, S.K. Flexural Fatigue Analysis of Steel Fibrous Concrete Containing Mixed Fibers. ACI Mater. J. 2005, 102, 438–444. [Google Scholar] [CrossRef]

- Benard, A.; Bos-Levenbach, E.C. The Plotting of Observations on Probability Paper. Stat. Neerl. 1953, 7, 163–173. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.Y.; Ding, Y.N.; Azevedo, C. Combined Effect of Steel Fibres and Steel Rebars on Impact Resistance of High Performance Concrete. J. Cent. South Univ. Technol. 2011, 18, 1677–1684. [Google Scholar] [CrossRef] [Green Version]

- Murali, G.; Abid, S.R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact Performance of Novel Multi-Layered Prepacked Aggregate Fibrous Composites under Compression and Bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Murali, G.; Gayathri, R.; Ramkumar, V.R.; Karthikeyan, K. Two Statistical Scrutinize of Impact Strength and Strength Reliability of Steel Fibre-Reinforced Concrete. KSCE J. Civ. Eng. 2018, 22, 257–269. [Google Scholar] [CrossRef]

- Alfayez, S.; Ali, M.A.E.M.; Nehdi, M.L. Eco-Efficient Fiber-Reinforced Preplaced Recycled Aggregate Concrete under Impact Loading. Infrastructures 2019, 4, 37. [Google Scholar] [CrossRef] [Green Version]

- Mindess, S.; Vondran, G. Properties of Concrete Reinforced with Fibrillated Polypropylene Fibres under Impact Loading. Cem. Concr. Res. 1988, 18, 109–115. [Google Scholar] [CrossRef]

- Prem, P.R.; Verma, M.; Ambily, P.S. Sustainable Cleaner Production of Concrete with High Volume Copper Slag. J. Clean. Prod. 2018, 193, 43–58. [Google Scholar] [CrossRef]

| Properties | Fine Aggregate | Copper Slag | Coarse Aggregate |

|---|---|---|---|

| Bulk density, kg/m3 | 1420 | 1750 | 1380 |

| Specific gravity | 2.51 | 3.56 | 2.80 |

| Water absorption (%) | 1.25 | 0.15 | 0.92 |

| Fineness modulus | 2.742 | 2.99 | 6.133 |

| Components | Cement (%) | CS (%) |

|---|---|---|

| SiO2 | 20.85 | 33.05 |

| Al2O3 | 4.78 | 2.79 |

| Fe2O3 | 3.51 | 53.45 |

| CaO | 63.06 | 6.06 |

| MgO | 2.32 | 1.56 |

| SO3 | 2.48 | 1.89 |

| K2O | 0.55 | 0.61 |

| Na2O | 0.24 | 0.28 |

| TiO2 | 0.25 | 0 |

| Na2O | 0.05 | 0.06 |

| SiO2 + Al2O3 + Fe2O3 + CaO | 92.2 | 95.35 |

| Constituents | Cement | Sand | Coarse Aggregate | Water |

|---|---|---|---|---|

| Quantity per m3 | 363 kg/m3 | 620 kg/m3 | 1343 kg/m3 | 148.8 kg/m3 |

| Proportion | 1 | 1.71 | 3.71 | 0.41 |

| S.No. | Mix ID | Cement | Fine Aggregate | Copper Slag | Coarse Aggregate | Water Content | Polypropylene Fibre |

|---|---|---|---|---|---|---|---|

| kg/m3 | |||||||

| 1 | C0P0 | 363 | 620 | 0 | 1343 | 148.8 | 0 |

| 2 | C0P1 | 363 | 620 | 0 | 1343 | 148.8 | 1.82 |

| 3 | C0P2 | 363 | 620 | 0 | 1343 | 148.8 | 3.64 |

| 4 | C0P3 | 363 | 620 | 0 | 1343 | 148.8 | 5.46 |

| 5 | C0P4 | 363 | 620 | 0 | 1343 | 148.8 | 7.28 |

| 6 | C20P0 | 363 | 495 | 177 | 1343 | 148.8 | 0 |

| 7 | C20P1 | 363 | 495 | 177 | 1343 | 148.8 | 1.82 |

| 8 | C20P2 | 363 | 494 | 177 | 1343 | 148.8 | 3.64 |

| 9 | C20P3 | 363 | 493 | 176 | 1343 | 148.8 | 5.46 |

| 10 | C20P4 | 363 | 492 | 176 | 1343 | 148.8 | 7.28 |

| 11 | C40P0 | 363 | 371 | 354 | 1343 | 148.8 | 0 |

| 12 | C40P1 | 363 | 371 | 354 | 1343 | 148.8 | 1.82 |

| 13 | C40P2 | 363 | 371 | 354 | 1343 | 148.8 | 3.64 |

| 14 | C40P3 | 363 | 370 | 353 | 1343 | 148.8 | 5.46 |

| 15 | C40P4 | 363 | 369 | 352 | 1343 | 148.8 | 7.28 |

| 16 | C60P0 | 363 | 247 | 531 | 1343 | 148.8 | 0 |

| 17 | C60P1 | 363 | 247 | 531 | 1343 | 148.8 | 1.82 |

| 18 | C60P2 | 363 | 247 | 530 | 1343 | 148.8 | 3.64 |

| 19 | C60P3 | 363 | 246 | 529 | 1343 | 148.8 | 5.46 |

| 20 | C60P4 | 363 | 246 | 528 | 1343 | 148.8 | 7.28 |

| 21 | C80P0 | 363 | 124 | 708 | 1343 | 148.8 | 0 |

| 22 | C80P1 | 363 | 124 | 708 | 1343 | 148.8 | 1.82 |

| 23 | C80P2 | 363 | 124 | 707 | 1343 | 148.8 | 3.64 |

| 24 | C80P3 | 363 | 123 | 705 | 1343 | 148.8 | 5.46 |

| 25 | C80P4 | 363 | 123 | 704 | 1343 | 148.8 | 7.28 |

| 26 | C100P0 | 363 | 620 | 0 | 1343 | 148.8 | 0 |

| 27 | C100P1 | 363 | 620 | 0 | 1343 | 148.8 | 1.82 |

| 28 | C100P2 | 363 | 620 | 0 | 1343 | 148.8 | 3.64 |

| 29 | C100P3 | 363 | 620 | 0 | 1343 | 148.8 | 5.46 |

| 30 | C100P4 | 363 | 620 | 0 | 1343 | 148.8 | 7.28 |

| Mix ID | N1 | N2 | N2 − N1 | E | N1 | N2 | N2 − N1 | E | N1 | N2 | N2 − N1 | E |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 Days | 14 Days | 28 Days | ||||||||||

| C0P0 | 13 | 23 | 10 | 203.54 | 64 | 77 | 13 | 264.6 | 84 | 103 | 19 | 386.72 |

| C0P1 | 19 | 35 | 16 | 325.66 | 78 | 96 | 18 | 366.36 | 109 | 140 | 31 | 630.96 |

| C0P2 | 17 | 37 | 20 | 407.07 | 83 | 105 | 22 | 447.78 | 112 | 144 | 32 | 651.31 |

| C0P3 | 18 | 47 | 29 | 590.25 | 92 | 123 | 31 | 630.96 | 125 | 159 | 34 | 692.02 |

| C0P4 | 25 | 55 | 30 | 610.61 | 101 | 133 | 32 | 651.31 | 132 | 167 | 35 | 712.38 |

| C20P0 | 57 | 72 | 15 | 305.3 | 85 | 107 | 22 | 447.78 | 109 | 149 | 40 | 814.14 |

| C20P1 | 66 | 89 | 23 | 468.13 | 92 | 118 | 26 | 529.19 | 116 | 157 | 41 | 834.5 |

| C20P2 | 75 | 98 | 23 | 468.13 | 106 | 138 | 32 | 651.31 | 121 | 169 | 48 | 976.97 |

| C20P3 | 76 | 105 | 29 | 590.25 | 110 | 145 | 35 | 712.38 | 124 | 177 | 53 | 1078.74 |

| C20P4 | 80 | 112 | 32 | 651.31 | 117 | 154 | 37 | 753.08 | 126 | 192 | 66 | 1343.34 |

| C40P0 | 57 | 74 | 17 | 346.01 | 127 | 152 | 25 | 508.84 | 133 | 183 | 50 | 1017.68 |

| C40P1 | 68 | 90 | 22 | 447.78 | 138 | 170 | 32 | 651.31 | 146 | 203 | 57 | 1160.15 |

| C40P2 | 65 | 93 | 28 | 569.9 | 146 | 183 | 37 | 753.08 | 161 | 221 | 60 | 1221.22 |

| C40P3 | 80 | 110 | 30 | 610.61 | 152 | 192 | 40 | 814.14 | 173 | 246 | 73 | 1485.81 |

| C40P4 | 82 | 113 | 31 | 630.96 | 158 | 205 | 47 | 956.62 | 172 | 244 | 72 | 1465.46 |

| C60P0 | 60 | 73 | 13 | 264.6 | 102 | 132 | 30 | 610.61 | 124 | 155 | 31 | 630.96 |

| C60P1 | 61 | 80 | 19 | 386.72 | 121 | 152 | 31 | 630.96 | 128 | 161 | 33 | 671.67 |

| C60P2 | 65 | 87 | 22 | 447.78 | 127 | 160 | 33 | 671.67 | 143 | 182 | 39 | 793.79 |

| C60P3 | 69 | 92 | 23 | 468.13 | 137 | 175 | 38 | 773.44 | 145 | 185 | 40 | 814.14 |

| C60P4 | 74 | 98 | 24 | 488.49 | 127 | 162 | 35 | 712.38 | 151 | 194 | 43 | 875.2 |

| C80P0 | 36 | 54 | 18 | 366.36 | 76 | 96 | 20 | 407.07 | 90 | 111 | 21 | 427.43 |

| C80P1 | 39 | 58 | 19 | 386.72 | 81 | 102 | 21 | 427.43 | 93 | 117 | 24 | 488.49 |

| C80P2 | 48 | 68 | 20 | 407.07 | 89 | 110 | 21 | 427.43 | 108 | 139 | 31 | 630.96 |

| C80P3 | 56 | 77 | 21 | 427.43 | 94 | 118 | 24 | 488.49 | 112 | 148 | 36 | 732.73 |

| C80P4 | 56 | 78 | 22 | 447.78 | 94 | 117 | 23 | 468.13 | 109 | 141 | 32 | 651.31 |

| C100P0 | 21 | 24 | 3 | 61.06 | 36 | 41 | 5 | 101.77 | 42 | 57 | 15 | 305.3 |

| C100P1 | 16 | 20 | 4 | 81.41 | 26 | 34 | 8 | 162.83 | 32 | 50 | 18 | 366.36 |

| C100P2 | 13 | 22 | 9 | 183.18 | 22 | 36 | 14 | 284.95 | 28 | 52 | 24 | 488.49 |

| C100P3 | 13 | 25 | 12 | 244.24 | 22 | 34 | 12 | 244.24 | 28 | 50 | 22 | 447.78 |

| C100P4 | 13 | 20 | 9 | 183.18 | 19 | 30 | 11 | 223.89 | 25 | 42 | 17 | 346.01 |

| Mix Identification | Curing Period | Number Blows | Scale Parameter (β) | Intercept | Shape Parameter (α) | Regression Coefficient (R2) |

|---|---|---|---|---|---|---|

| P0 (0.0% PPF) | 7 | N1 | 1.517 | −5.724 | 43.532 | 0.8716 |

| N2 | 1.805 | −7.217 | 49.432 | 0.8422 | ||

| 14 | N1 | 1.850 | −8.286 | 88.086 | 0.939 | |

| N2 | 1.93 | −8.947 | 103.056 | 0.9528 | ||

| 28 | N1 | 1.976 | −9.455 | 119.440 | 0.9326 | |

| N2 | 1.995 | −9.830 | 138.063 | 0.9213 | ||

| P1 (0.2% PPF) | 7 | N1 | 1.407 | −5.967 | 69.517 | 0.915 |

| N2 | 1.127 | −4.4026 | 49.654 | 0.9111 | ||

| 14 | N1 | 1.258 | −5.92 | 110.276 | 0.9625 | |

| N2 | 1.438 | −7.0336 | 132.937 | 0.9775 | ||

| 28 | N1 | 1.556 | −7.769 | 146.930 | 0.9087 | |

| N2 | 1.624 | −8.383 | 171.564 | 0.8951 | ||

| P2 (0.4% PPF) | 7 | N1 | 1.15 | −4.334 | 43.311 | 0.8956 |

| N2 | 1.59 | −6.858 | 74.648 | 0.9282 | ||

| 14 | N1 | 1.215 | −5.634 | 103.039 | 0.9694 | |

| N2 | 1.449 | −7.15 | 138.939 | 0.9722 | ||

| 28 | N1 | 1.397 | −6.957 | 145.520 | 0.8885 | |

| N2 | 1.570 | −8.189 | 184.010 | 0.8712 | ||

| P3 (0.6% PPF) | 7 | N1 | 1.265 | −4.897 | 47.975 | 0.8762 |

| N2 | 1.765 | −7.581 | 73.197 | 0.9531 | ||

| 14 | N1 | 0.995 | −4.664 | 108.574 | 0.8816 | |

| N2 | 1.357 | −6.68 | 137.254 | 0.9397 | ||

| 28 | N1 | 1.437 | −7.101 | 140.160 | 0.8591 | |

| N2 | 1.604 | −8.245 | 170.639 | 0.8457 | ||

| P4 (0.8% PPF) | 7 | N1 | 2.148 | −6.665 | 22.244 | 0.8677 |

| N2 | 2.414 | −9.165 | 44.54 | 0.9719 | ||

| 14 | N1 | 1.115 | −5.097 | 96.432 | 0.944 | |

| N2 | 1.311 | −6.303 | 122.289 | 0.94 | ||

| 28 | N1 | 1.464 | −6.850 | 107.650 | 0.9488 | |

| N2 | 1.566 | −7.682 | 135.013 | 0.9105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chakrawarthi, V.; Avudaiappan, S.; Amran, M.; Dharmar, B.; Raj Jesuarulraj, L.; Fediuk, R.; Aepuru, R.; Vatin, N.I.; Saavedra Flores, E. Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete. Materials 2021, 14, 7735. https://doi.org/10.3390/ma14247735

Chakrawarthi V, Avudaiappan S, Amran M, Dharmar B, Raj Jesuarulraj L, Fediuk R, Aepuru R, Vatin NI, Saavedra Flores E. Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete. Materials. 2021; 14(24):7735. https://doi.org/10.3390/ma14247735

Chicago/Turabian StyleChakrawarthi, Vijayaprabha, Siva Avudaiappan, Mugahed Amran, Brindha Dharmar, Leon Raj Jesuarulraj, Roman Fediuk, Radhamanohar Aepuru, Nikolai Ivanovich Vatin, and Erick Saavedra Flores. 2021. "Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete" Materials 14, no. 24: 7735. https://doi.org/10.3390/ma14247735

APA StyleChakrawarthi, V., Avudaiappan, S., Amran, M., Dharmar, B., Raj Jesuarulraj, L., Fediuk, R., Aepuru, R., Vatin, N. I., & Saavedra Flores, E. (2021). Impact Resistance of Polypropylene Fibre-Reinforced Alkali–Activated Copper Slag Concrete. Materials, 14(24), 7735. https://doi.org/10.3390/ma14247735