Evaluating the Rheological Properties of High-Modulus Asphalt Binders Modified with Rubber Polymer Composite Modifier

Abstract

:1. Introduction

2. Materials and Laboratory Test Methods

2.1. Raw Materials

2.1.1. Asphalt binder

2.1.2. RPCM Material

2.2. Test Methods and Sample Preparation

2.2.1. Dynamic Mechanical Analysis

- (1)

- The Temperature Sweep Test (TST)

- (2)

- The Frequency Sweep Test (FST)

- (3)

- Asphalt binder Sample Preparation

2.2.2. The Bending Beam Rheometer (BBR) Test

2.3. Fluorescence Microscope (FM)

2.4. HMAB Preparation

3. Rheological Test Results, Analysis, and Synthesis

3.1. The Temperature Sweep Test Results

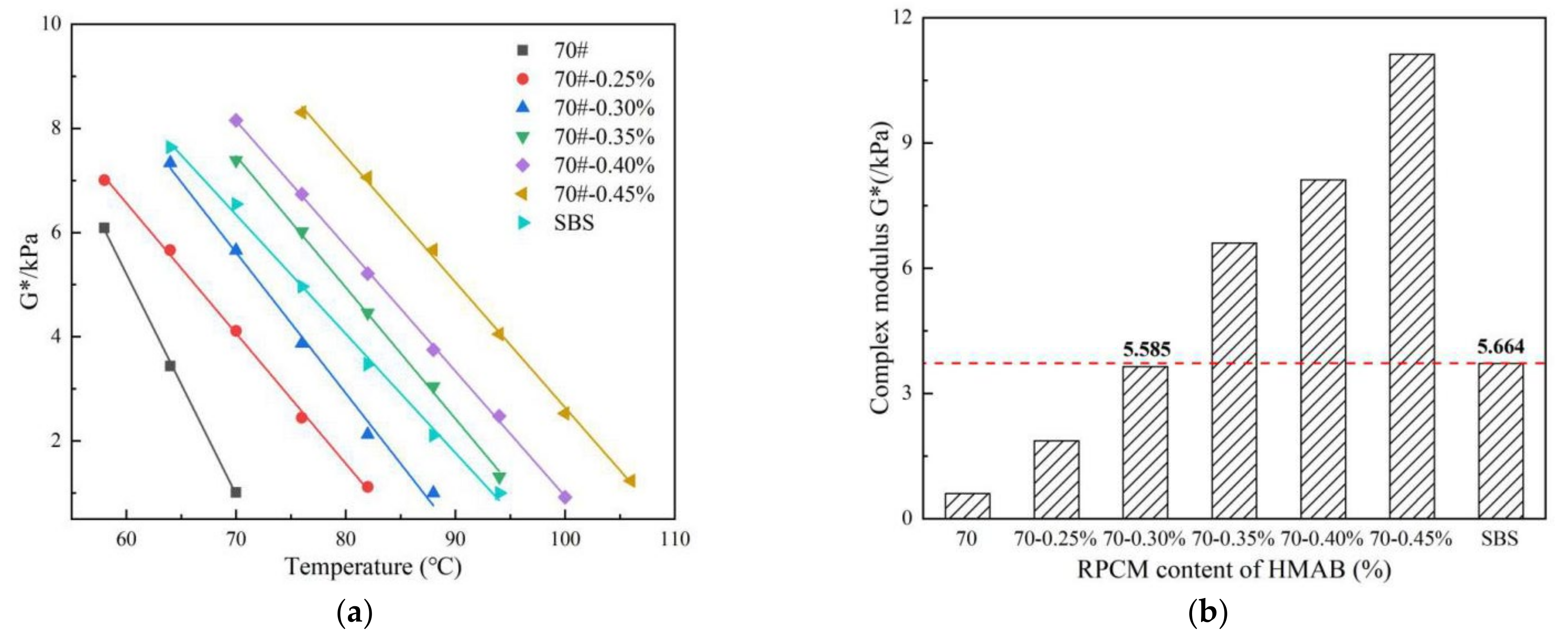

3.1.1. Complex Modulus of HMAB

3.1.2. Phase Angle of HMAB

3.1.3. Rutting Factor of HMAB

3.2. The Frequency Sweep Test Results

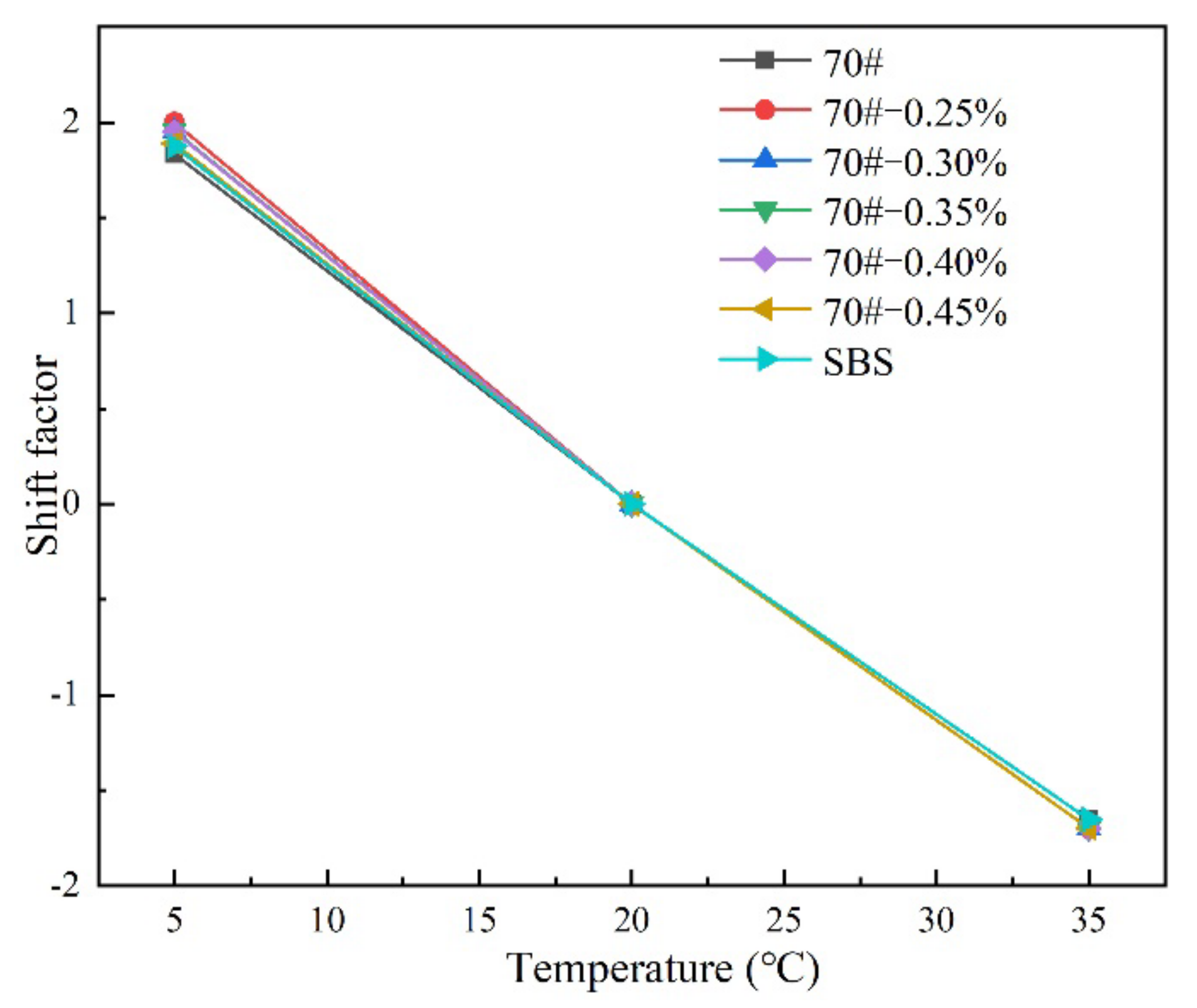

3.2.1. Translational Shift Factors for HMAB

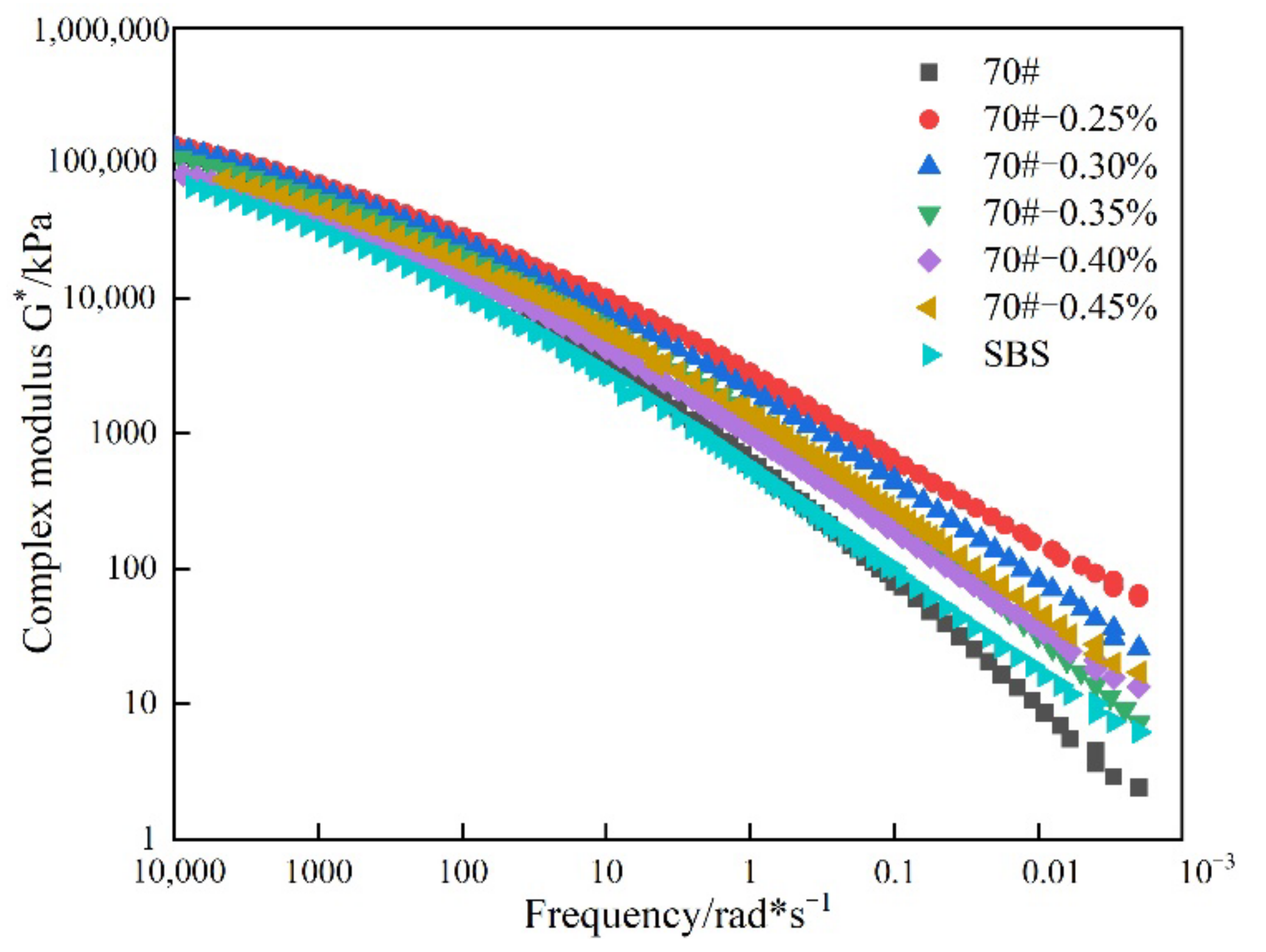

3.2.2. Master curves of the Complex Modulus

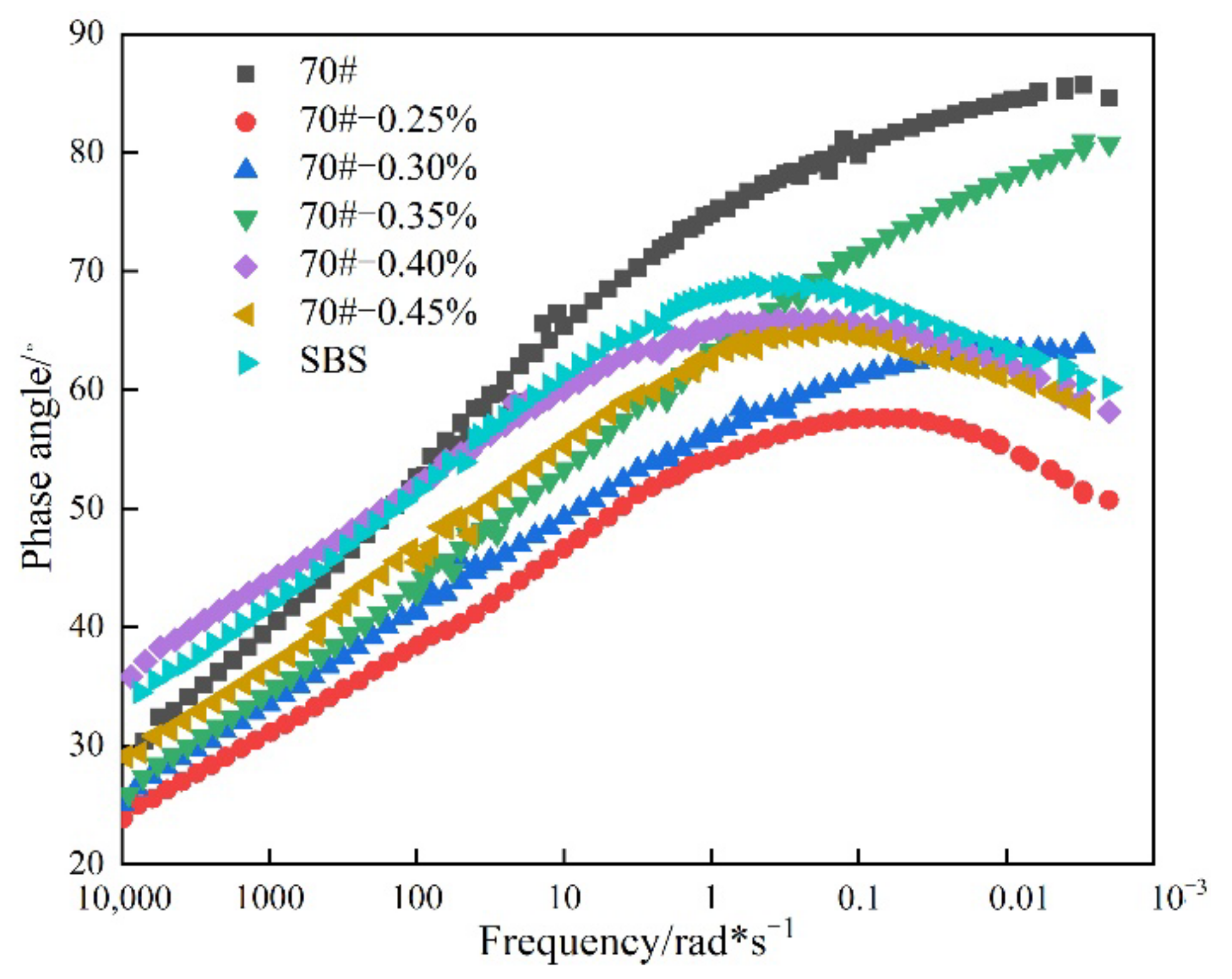

3.2.3. Master curves of the Phase Angle

3.3. The BBR Test Results

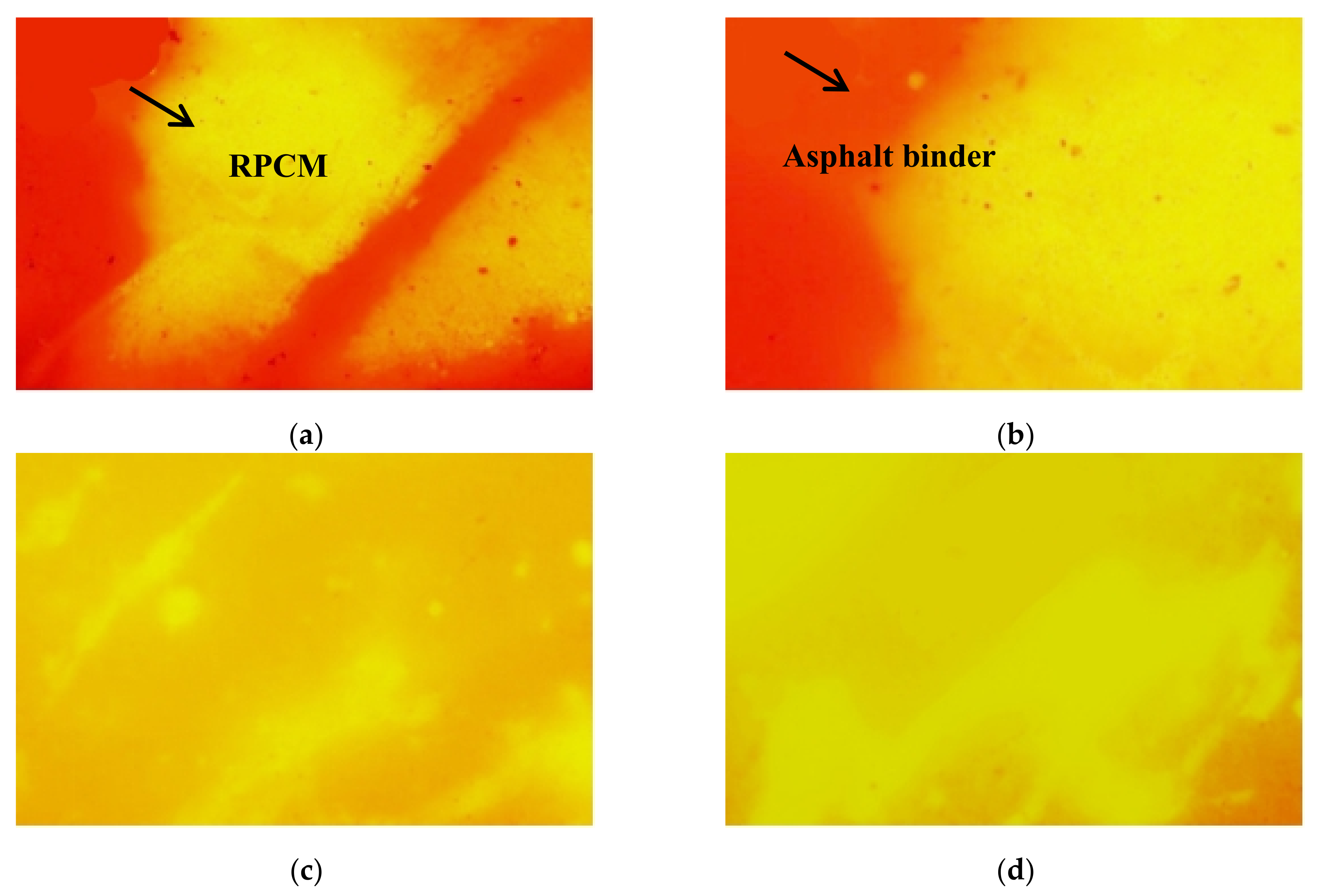

4. Morphological Test Results, Analysis, and Synthesis

5. Conclusions and Recommendations

- The temperature and frequency sweep test results showed that the addition of RPCM reduced the temperature sensitivity of the asphalt binder and correspondingly increased its stiffness (complex modulus). At dosages greater than 0.30%, RPCM exhibited superiority over SBS in enhancing the complex modulus of the asphalt binder.

- With the addition of RPCM under increasing temperature, the phase angle generally exhibited an increasing trend. This result suggested that modification with RPCM had the potential to improve the high-temperature elastic properties of the asphalt binder.

- The rutting parameter (G*/Sinδ) exhibited an increasing nonlinear trend with an increase in the RPCM dosage—illustrating the potential of RPCM modification to reduce the temperature sensitive of the asphalt binder and enhance its high-temperature rutting resistance potential. In comparison to SBS modification, RPCM exhibited superior performance for dosages greater than 0.30%, which was similar to the modulus results.

- The master curve graphical plots indicated that RPCM modification has more pronounced effects in the lower loading frequency domain corresponding to high temperatures when the viscoelastic asphalt binder is more prone to rutting. Based on the phase angle master curves, the SBS-modified asphalt binder tended to be more viscous and prone to high-temperature deformation than the RPCM-modified asphalt binders.

- With an increase in the RPCM content, the asphalt binder generally became softer (i.e., low S, low λ, and high m value, respectively), with better low-temperature crack resistance and decreased risk of cracking damage. However, the low-temperature performance of the asphalt binder significantly declined for RPCM contents greater than 0.35%—indicating that the optimum dosage should not exceed 0.35%.

- The morphological results from fluorescence microscopic imaging indicated that RPCM had good compactibility characteristics with A-70# Petroleum asphalt binder, and thus it could suitably be used as a modifier.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Nanjegowda, V.H.; Biligiri, K.P. Recyclability of rubber in asphalt roadway systems: A review of applied research and advancement in technology. Resour. Conserv. Recycl. 2020, 155, 104655. [Google Scholar] [CrossRef]

- Zaumanis, M.; Poulikakos, L.; Partl, M. Performance-based design of asphalt mixtures and review of key parameters. Mater. Des. 2018, 141, 185–201. [Google Scholar] [CrossRef]

- Xu, T.; Huang, X. Investigation into causes of in-place rutting in asphalt pavement. Constr. Build. Mater. 2012, 28, 525–530. [Google Scholar] [CrossRef]

- Walubita, L.F.; Fuentes, L.; Lee, S.I.; Dawd, I.; Mahmoud, E. Comparative evaluation of five HMA rutting-related laboratory test methods relative to field performance data: DM, FN, RLPD, SPST, and HWTT. Constr. Build. Mater. 2019, 215, 737–753. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Baaj, H. The use of compressible packing model and modified asphalt binders in high-modulus asphalt mix design. Road Mater. Pavement Des. 2020, 21, 1061–1077. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Xu, S.; You, Z. High modulus asphalt concrete: A state-of-the-art review. Constr. Build. Mater. 2020, 237, 117653. [Google Scholar] [CrossRef]

- Xiao, F.; Wang, J.; Yuan, J.; Liu, Z.; Ma, D. Fatigue and Rutting Performance of Airfield SBS-Modified Binders Containing High Modulus and Antirutting Additives. J. Mater. Civ. Eng. 2020, 32, 04019366. [Google Scholar] [CrossRef]

- Zhu, H.; Sun, L.; Yang, J.; Chen, Z.; Gu, W. Developing Master Curves and Predicting Dynamic Modulus of Polymer-Modified Asphalt Mixtures. J. Mater. Civ. Eng. 2011, 23, 131–137. [Google Scholar] [CrossRef]

- Geng, H.; Clopotel, C.S.; Bahia, H.U. Effects of high modulus asphalt binders on performance of typical asphalt pavement structures. Constr. Build. Mater. 2013, 44, 207–213. [Google Scholar] [CrossRef]

- Zou, X.; Sha, A.; Jiang, W.; Liu, Z. Effects of modifier content on high-modulus asphalt mixture and prediction of fatigue property using Weibull theory. Road Mater. Pavement Des. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Wang, X.; Qiu, Y.-J.; Xue, S.-Y.; Yang, Y.; Zheng, Y. Study on durability of high-modulus asphalt mixture based on TLA and fibre composite modification technology. Int. J. Pavement Eng. 2018, 19, 930–936. [Google Scholar] [CrossRef]

- Khiavi, A.K.; Naseri, S. The effect of bitumen types on the performance of high-modulus asphalt mixtures. Pet. Sci. Technol. 2019, 37, 1223–1230. [Google Scholar] [CrossRef]

- Xu, X.; Lu, G.; Yang, J.; Liu, X. Mechanism and Rheological Properties of High-Modulus Asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Ma, T.; Fan, J.; Fang, Z.; Chen, T.; Zhou, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prod. 2020, 263, 121447. [Google Scholar] [CrossRef]

- Zou, X.; Sha, A.; Jiang, W.; Huang, X. Modification mechanism of high modulus asphalt binders and mixtures performance evaluation. Constr. Build. Mater. 2015, 90, 53–58. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, L.; Cao, D. Experimental study on rheological characteristics and performance of high modulus asphalt binder with different modifiers. Constr. Build. Mater. 2017, 155, 26–36. [Google Scholar] [CrossRef]

- JTG F40–2004. Technical Specification for Construction of Highway Asphalt Pavement; Ministry of Transport of the People’s Republic of China: Beijing, China, 2004. [Google Scholar]

- D’Angelo, J.M.; Fee, F. “SUPERPAVE BINDER TESTS AND SPECIFICATIONS: HOW HAVE THEY PERFORMED IN THE REAL WORLD?,”, 2000, vol. 69. Assoc. Asph. Paving Technol. Proc. 2020, 69, 74–109. [Google Scholar]

- Bouldin, M.G.; Dongré, R.; D′angelo, J. Proposed Refinement of Superpave High-Temperature Specification Parameter for Performance-Graded Binders. Transp. Res. Rec. J. Transp. Res. Board 2001, 1766, 40–47. [Google Scholar] [CrossRef]

- ISO. Plastics—Determination of the Melt Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate (MVR) of Thermoplastics; ISO: London, UK, 2005. [Google Scholar]

- Walubita, L.F.; Alvarez, A.E.; Simate, G.S. Evaluating and comparing different methods and models for generating relaxation modulus master-curves for asphalt mixes. Constr. Build. Mater. 2011, 25, 2619–2626. [Google Scholar] [CrossRef]

- Hu, X.; Fan, S.; Li, X.; Pan, P.; Fuentes, L.; Walubita, L.F. Exploring the feasibility of using reclaimed paper-based asphalt felt waste as a modifier in asphalt-binders. Constr. Build. Mater. 2020, 234, 117379. [Google Scholar] [CrossRef]

- Bai, T.; Hu, Z.-A.; Hu, X.; Liu, Y.; Fuentes, L.; Walubita, L.F. Rejuvenation of short-term aged asphalt-binder using waste engine oil. Can. J. Civ. Eng. 2020, 47, 822–832. [Google Scholar] [CrossRef]

- ASTM. ASTM D6373-16. In Standard Specification for Performance Graded Asphalt Binder; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Bahia, H.U.; Anderson, D.A. Strategic highway research program binder rheological parameters: Background and comparison with conventional properties. Transp. Res. Rec. 1995, 1488, 32–39. [Google Scholar]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

| Technical Indexes | Unit | Specification | Results | |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 60~80 | 65 | |

| Penetration index, PI | — | −1.5~+1.0 | −1.33 | |

| Softening point, TR&B | °C | ≥46 | 50.5 | |

| Ductility (15 °C, 5 cm/min) | cm | ≥100 | 138 | |

| Ductility (10 °C, 5 cm/min) | cm | ≥15 | 19.3 | |

| Density @15 °C | g/cm3 | / | 1.02 | |

| Dynamic viscosity @60 °C | Pa∙s | ≥180 | 210 | |

| Kinematic viscosity @135 °C | Pa.s | / | 0.420 | |

| After RTFOT (163 °C 85 min) | Mass change | % | −0.8~+0.8 | 0.095 |

| Penetration ratio @25 °C | % | ≥61 | 73 | |

| Ductility (10°C, 5 cm/min) | cm | ≥6 | 6.4 | |

| Ductility (15 °C, 5 cm/min) | cm | / | 50.0 | |

| Size (mm) | Density (g/cm3) | State | Appearance | Mass-Flow Rate (g/10 min) (190 °C, 2.16 kg) |

|---|---|---|---|---|

| 1~6 | 0.96 | Solid | Black granular | ≥2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Han, C.; Yang, J.; Xu, X.; Zhang, F. Evaluating the Rheological Properties of High-Modulus Asphalt Binders Modified with Rubber Polymer Composite Modifier. Materials 2021, 14, 7727. https://doi.org/10.3390/ma14247727

Zhang X, Han C, Yang J, Xu X, Zhang F. Evaluating the Rheological Properties of High-Modulus Asphalt Binders Modified with Rubber Polymer Composite Modifier. Materials. 2021; 14(24):7727. https://doi.org/10.3390/ma14247727

Chicago/Turabian StyleZhang, Xiaorui, Chao Han, Jun Yang, Xinquan Xu, and Fan Zhang. 2021. "Evaluating the Rheological Properties of High-Modulus Asphalt Binders Modified with Rubber Polymer Composite Modifier" Materials 14, no. 24: 7727. https://doi.org/10.3390/ma14247727

APA StyleZhang, X., Han, C., Yang, J., Xu, X., & Zhang, F. (2021). Evaluating the Rheological Properties of High-Modulus Asphalt Binders Modified with Rubber Polymer Composite Modifier. Materials, 14(24), 7727. https://doi.org/10.3390/ma14247727