Intelligent Generation Method of Innovative Structures Based on Topology Optimization and Deep Learning

Abstract

:1. Introduction

2. Basic Idea and Correlative Theories

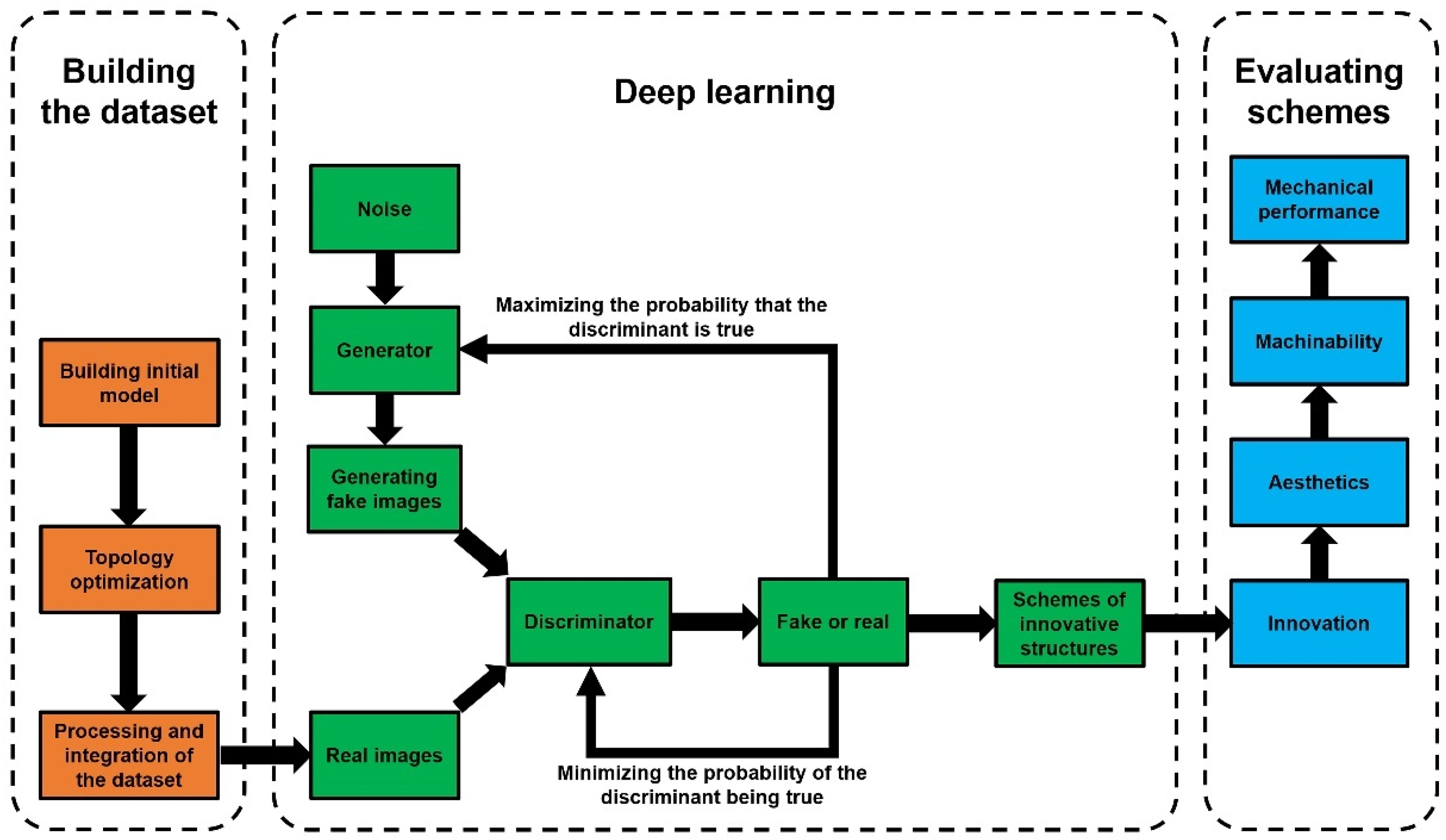

2.1. Basic Idea

- (1)

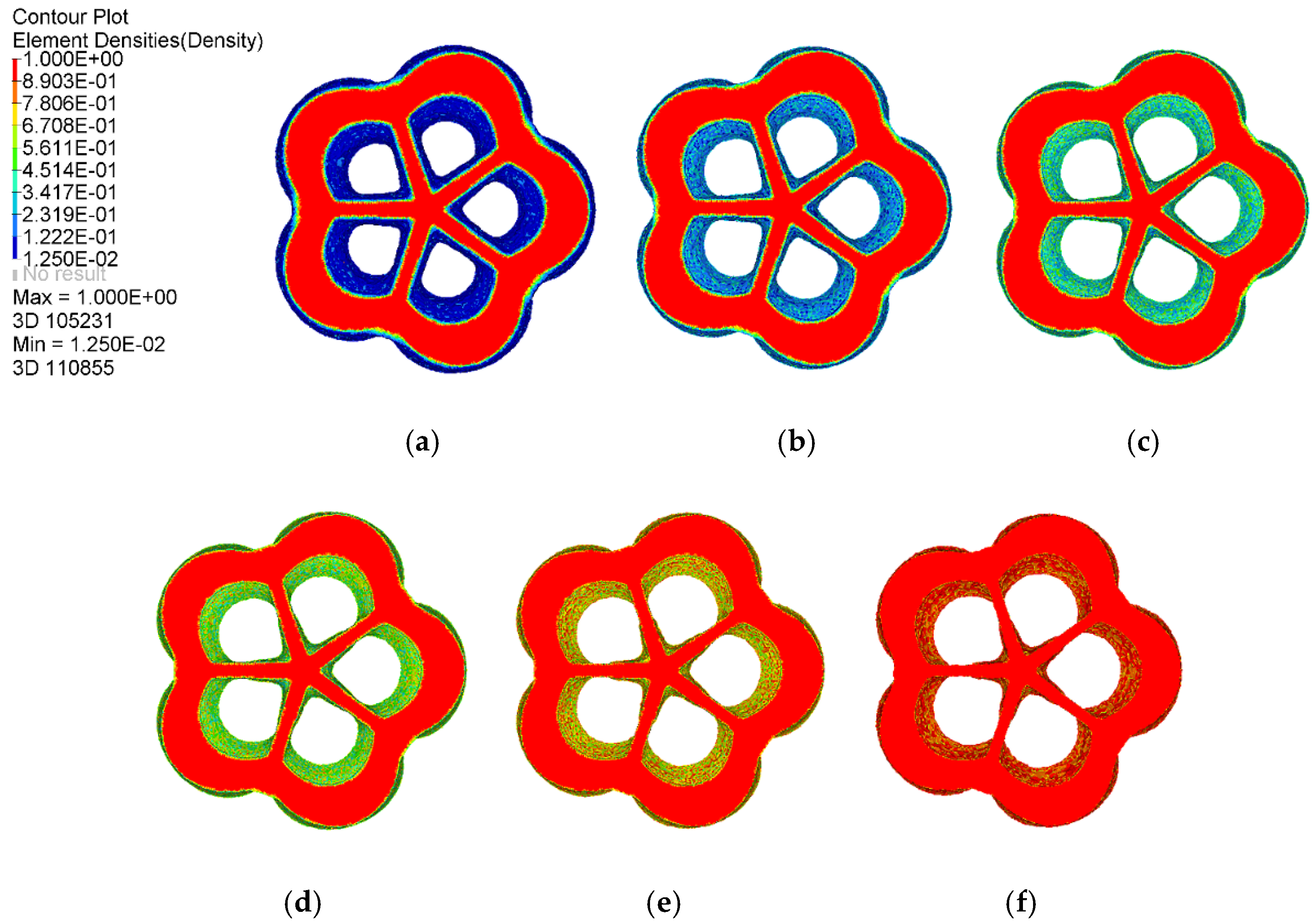

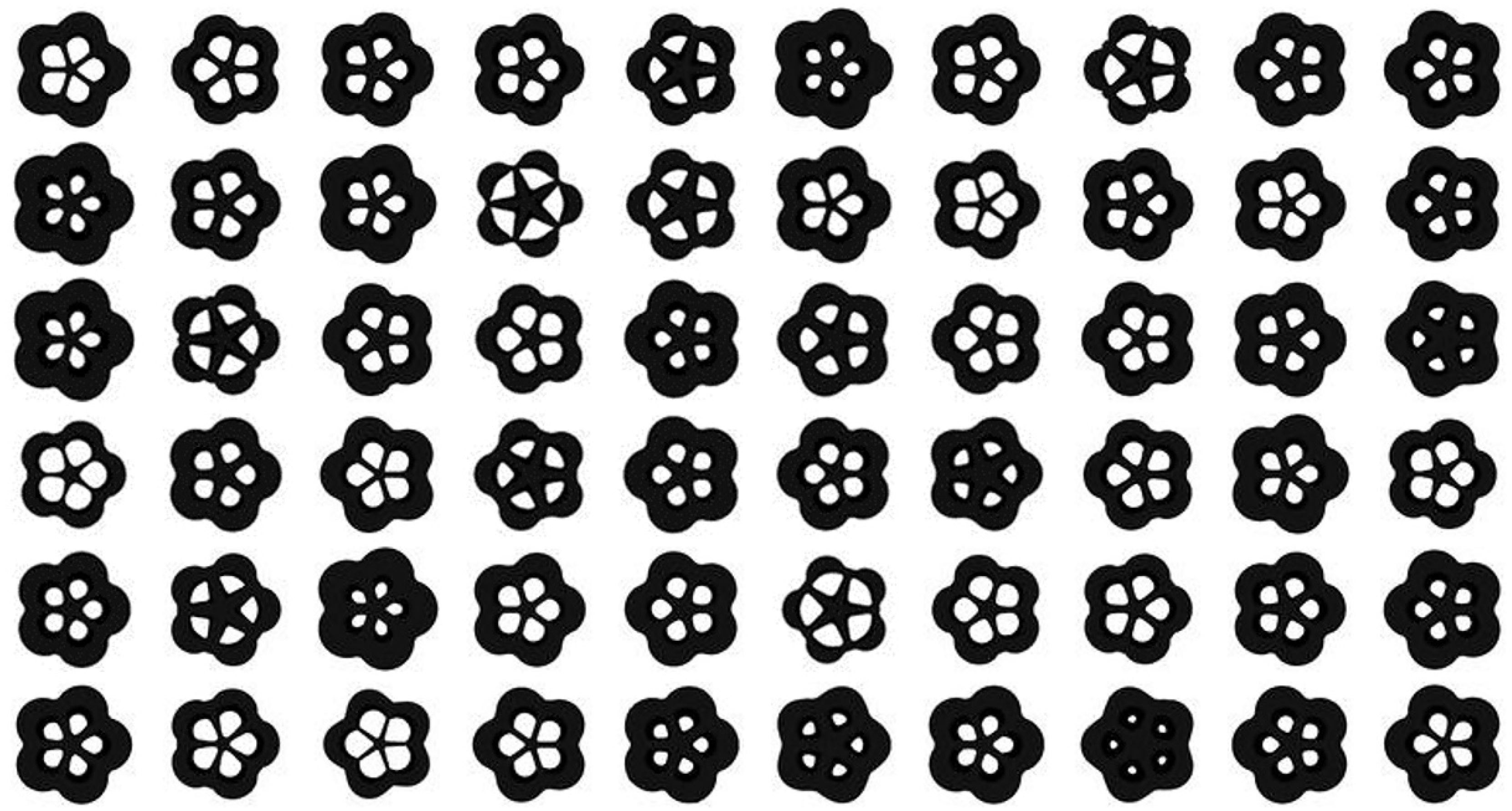

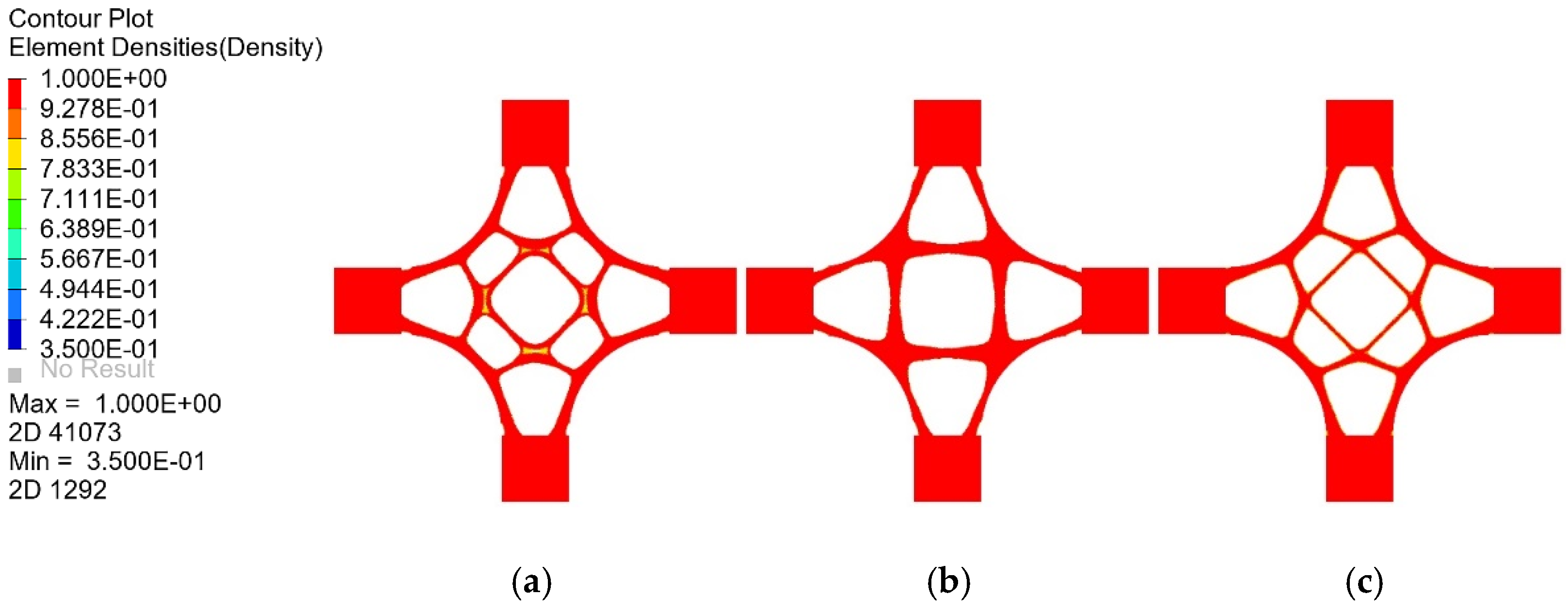

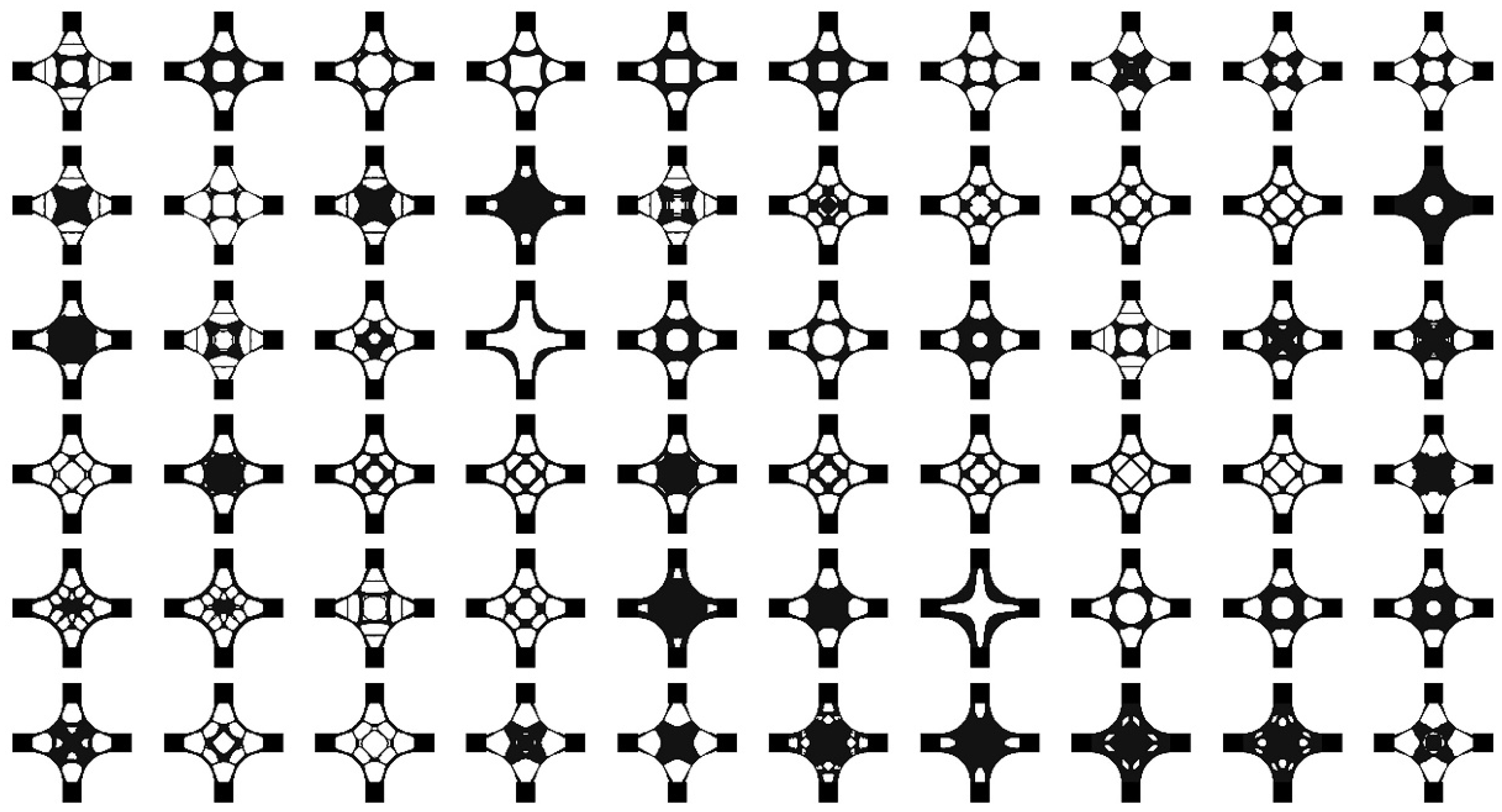

- During the dataset building stage, an initial model is first built and divided into designable and non-designable areas. Then constraint parameters, such as checkerboard control, penalty factor, and minimum member size, are considered in the topology optimization calculation. The topology optimization results are enriched by adjusting the element density thresholds and load case types. Eventually, all images of topology optimization models with different optimization parameters are collected as training set images, and training set labels are defined as the corresponding load case types.

- (2)

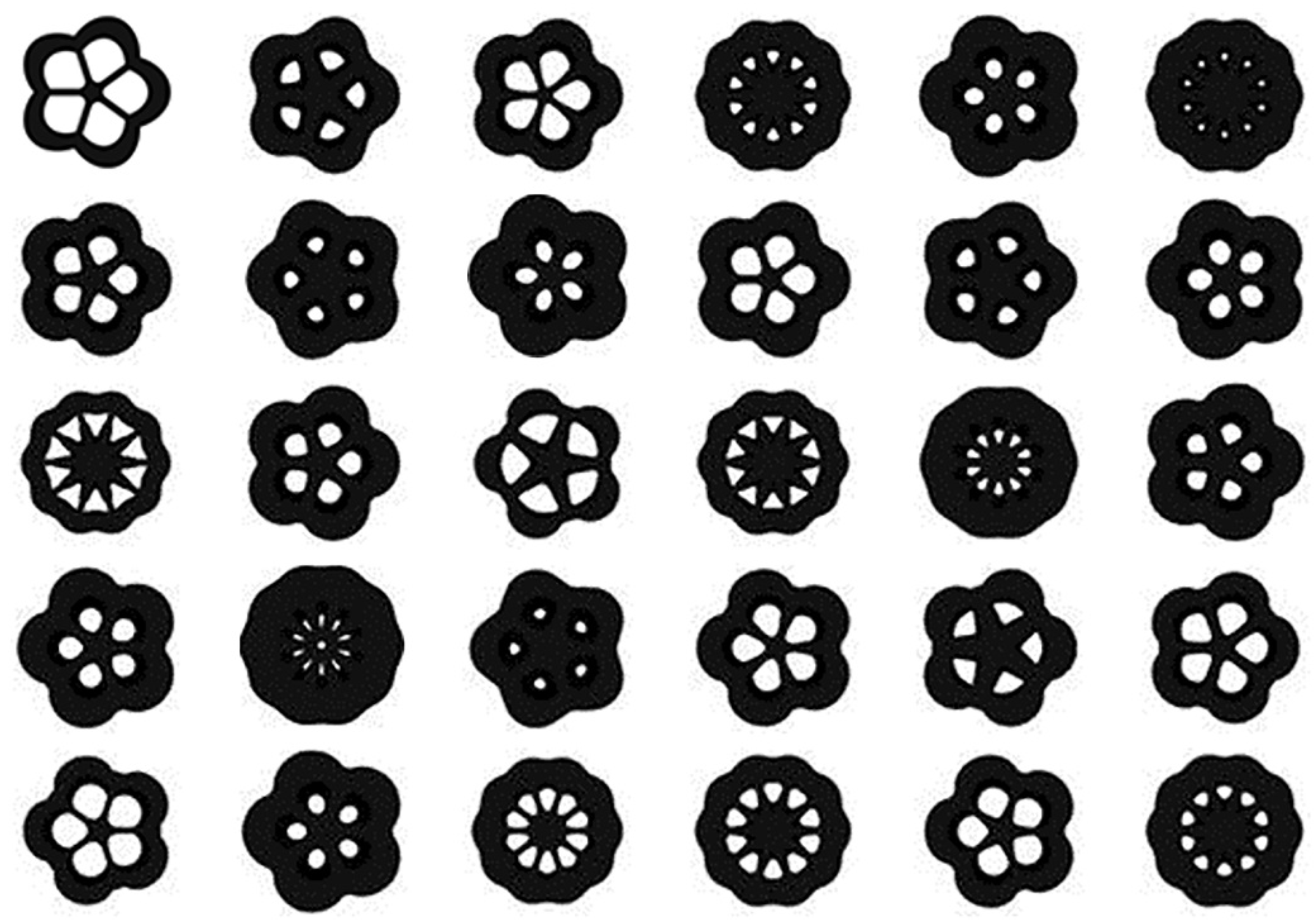

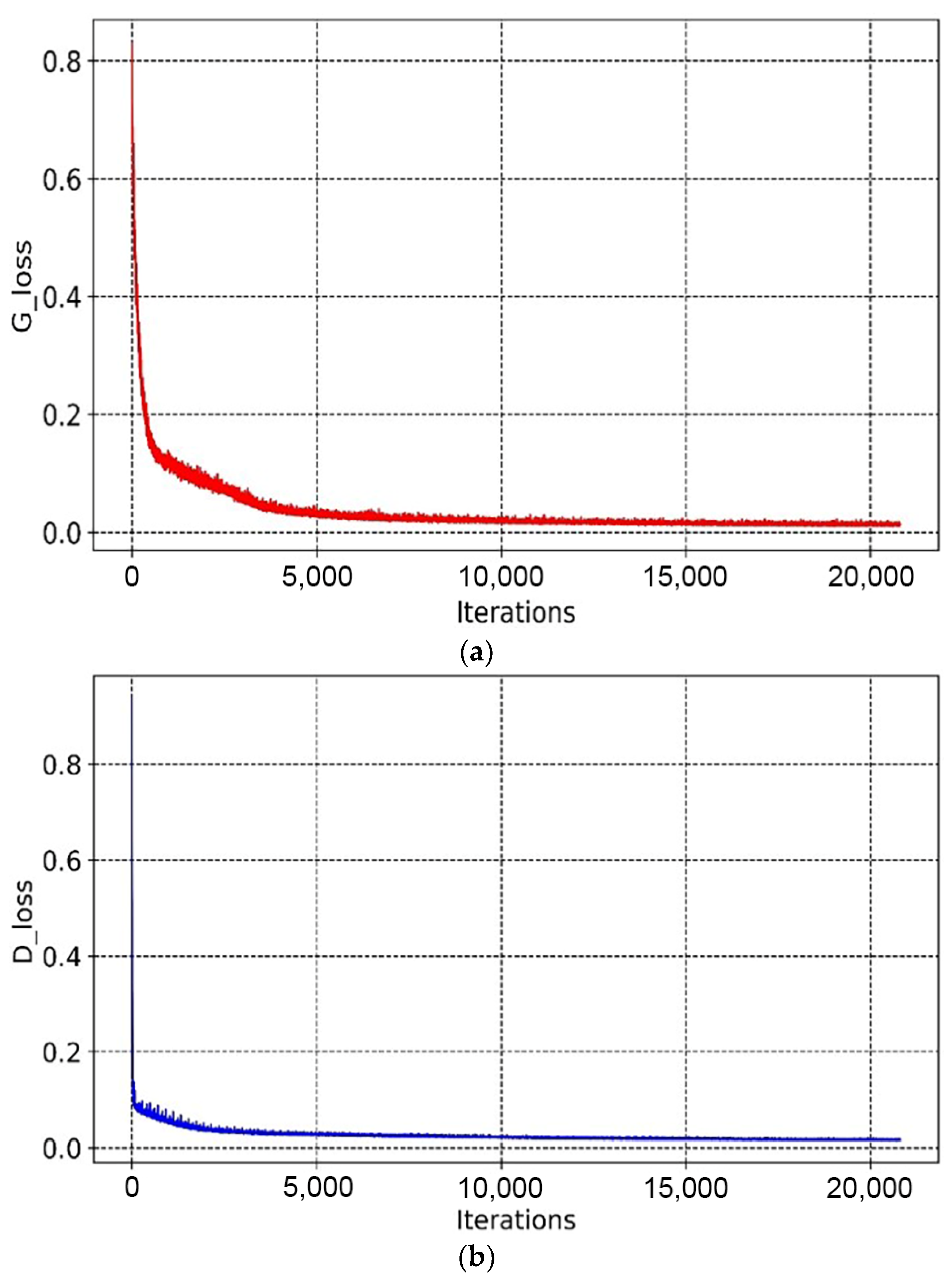

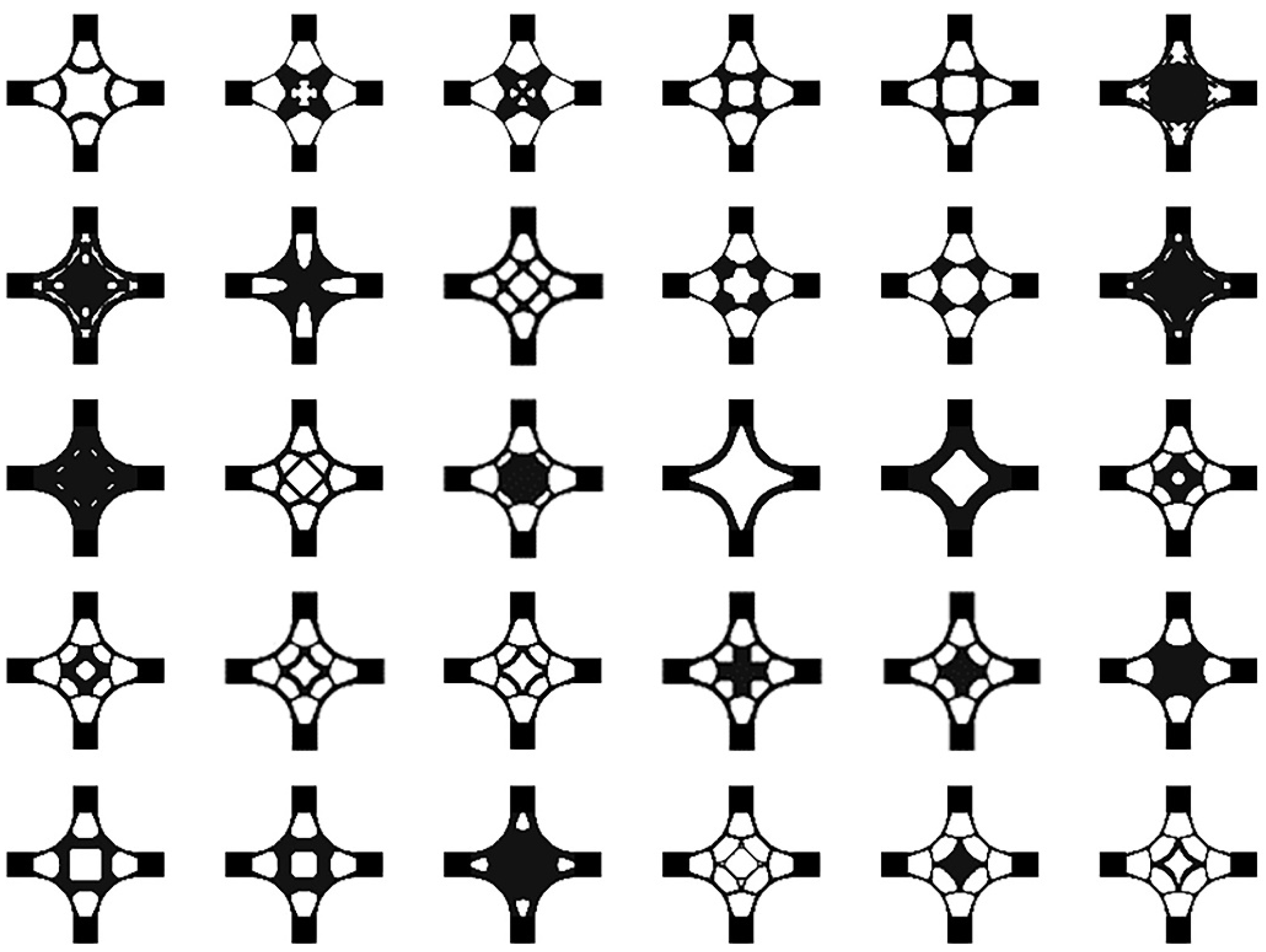

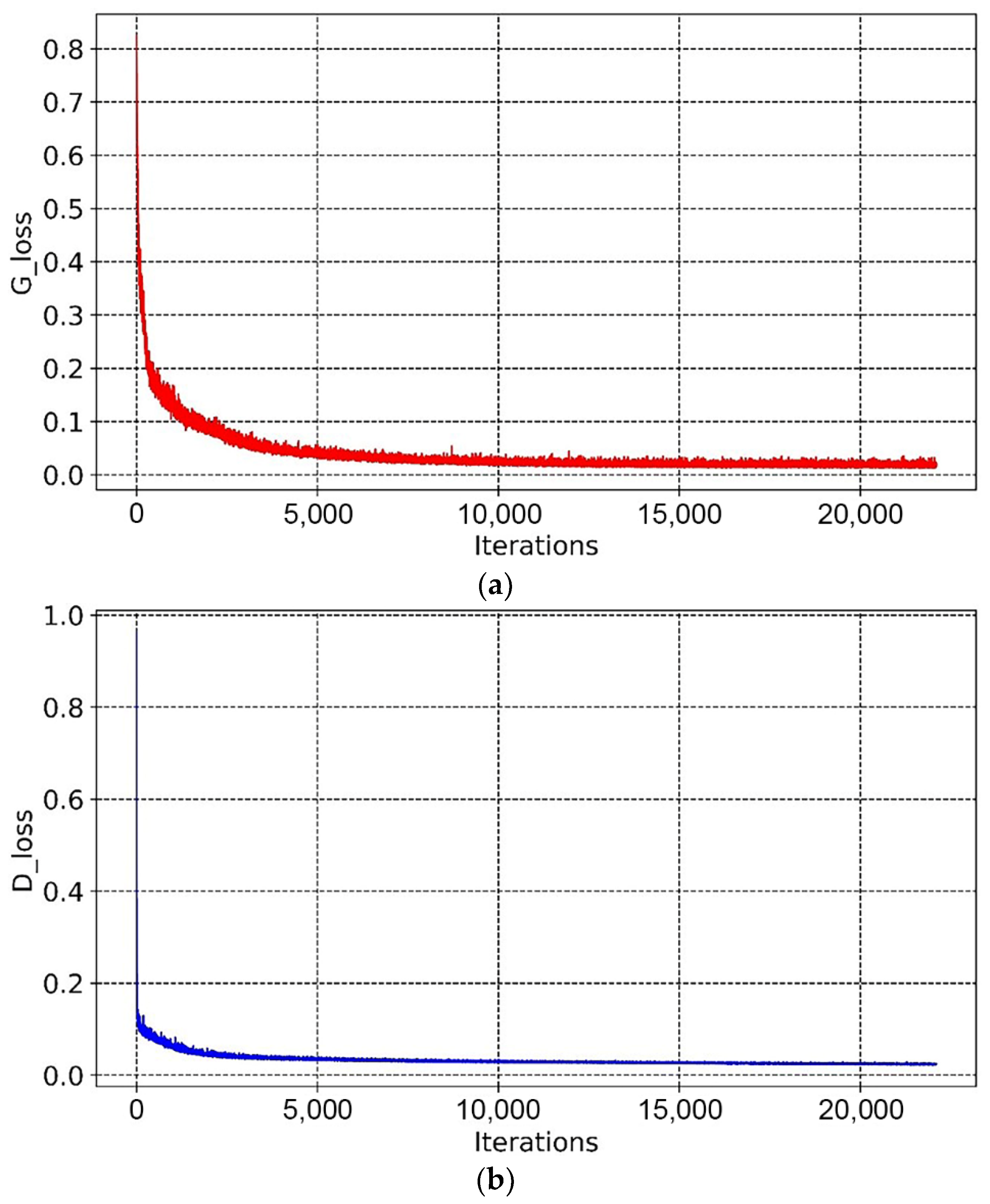

- During the deep learning stage, the BEGAN algorithm is programmed based on the open-source deep learning framework TensorFlow. Two sub-models of the BEGAN, named the generator model and the discriminator model, are set up. The generator is responsible for learning the data distribution and generating examples similar to the input samples. In contrast, the discriminator is responsible for distinguishing the actual samples from the generated fake samples. The generator tries to cheat the discriminator, while the discriminator tries not to be tricked by the generator. Both the generator and the discriminator are alternately optimized and trained to improve. Eventually, they reach Nash equilibrium and generate optimal design schemes of innovative structures.

- (3)

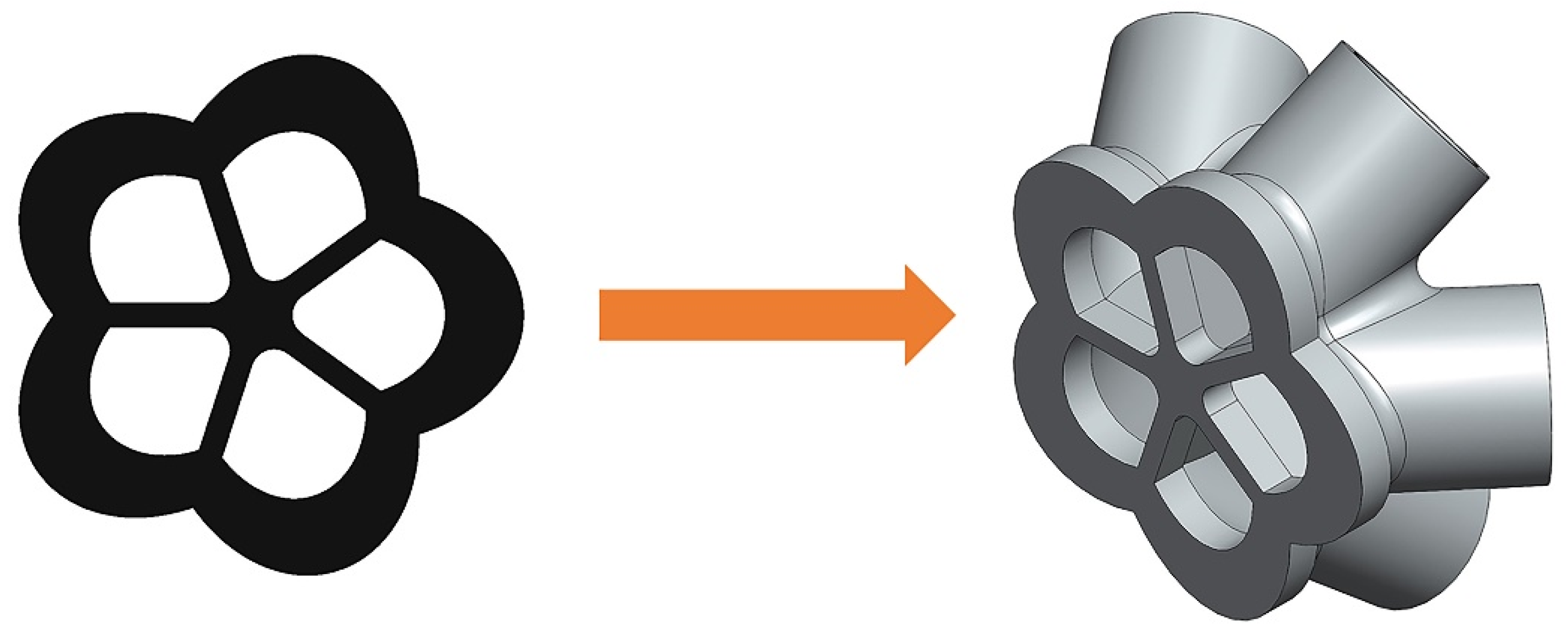

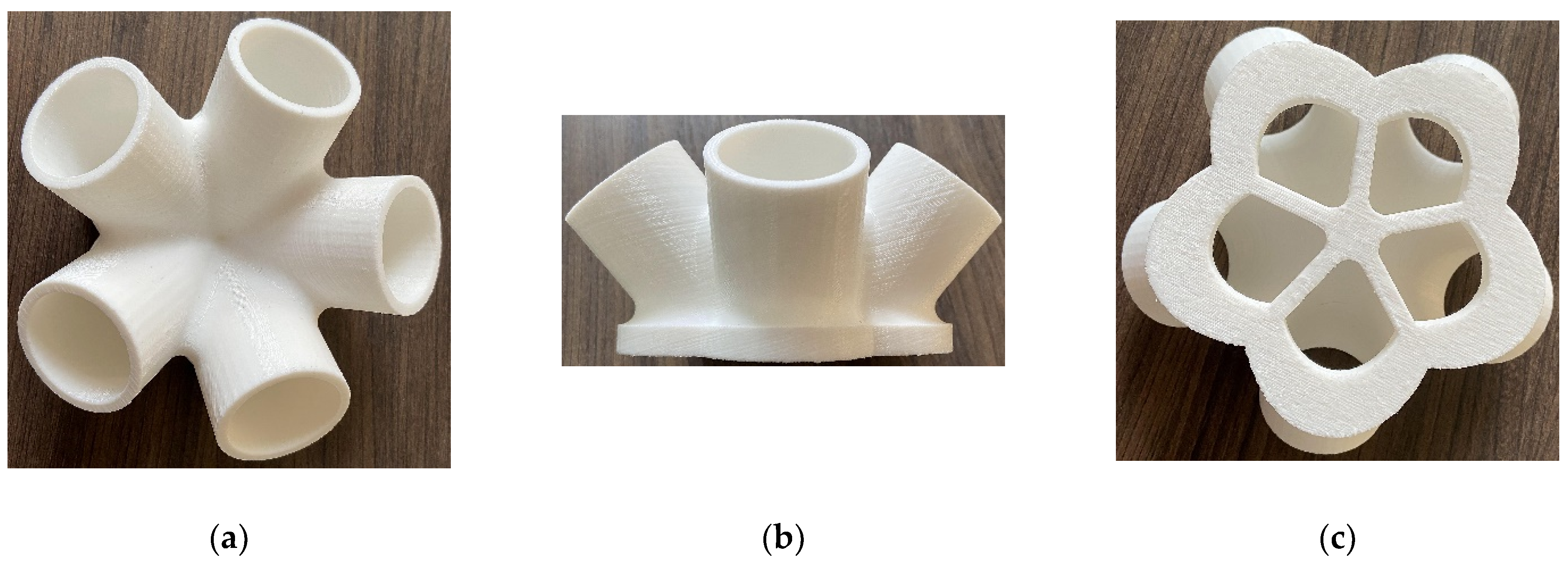

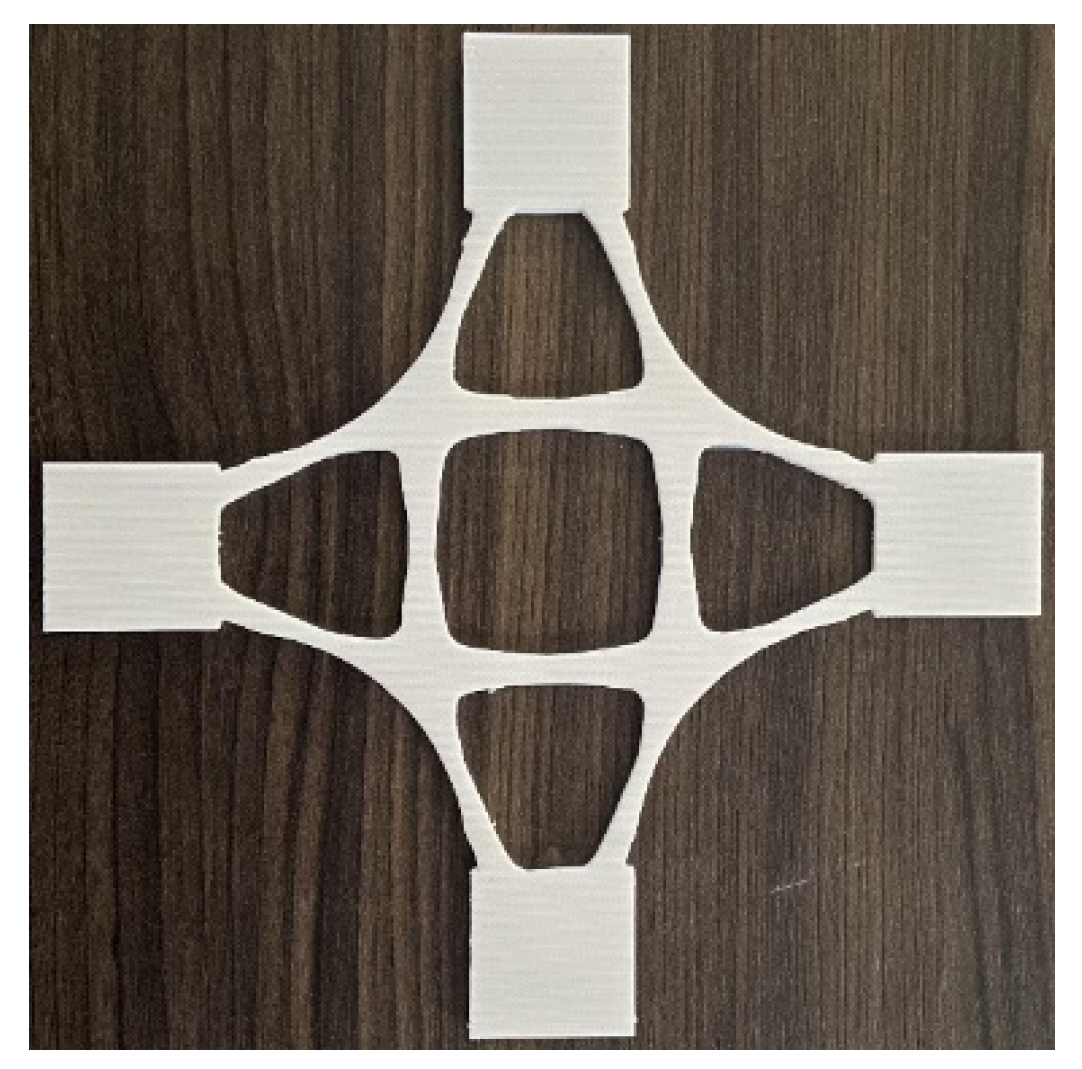

- During the evaluating schemes stage, an innovative representative structure from the results is selected according to the evaluation indexes for comparative argumentation and analysis. The 3D model of the chosen example is built up via 3D reconstruction technology for images, and the structural model is 3D printed by applying additive manufacturing technology.

2.2. Topology Optimization Theory

2.3. BEGAN Theory

3. Intelligent Generation Method of Innovative Structures

3.1. Building the Dataset

3.2. Generating Structures Applying the BEGAN Algorithm

4. Example 1: Baseplate of a Cast-Steel Support Joint

4.1. Engineering Background and Initial Model

4.2. Building the Dataset

4.3. Generating Innovative Baseplates by BEGAN

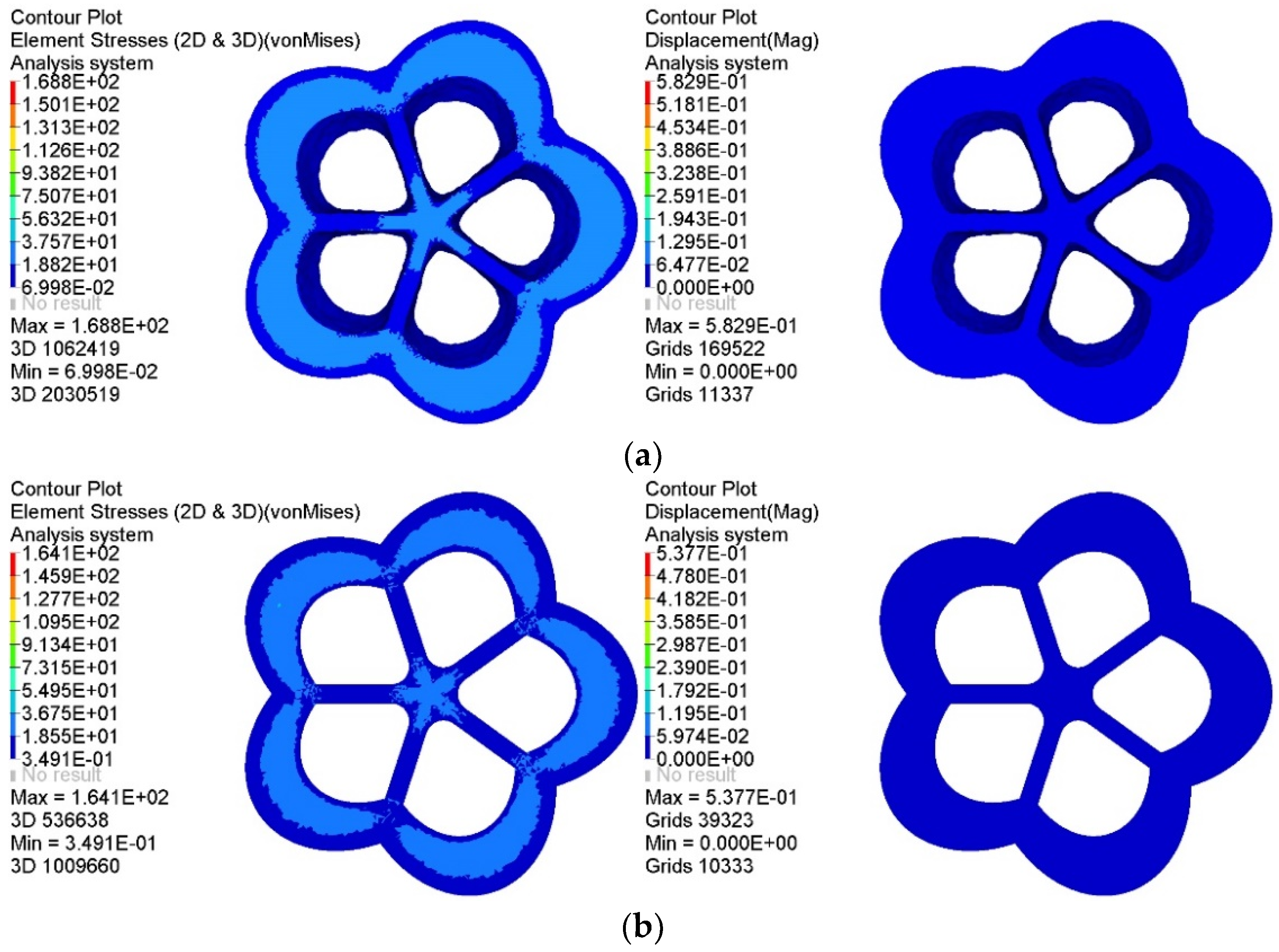

4.4. Analysis and Evaluation of Schemes

5. Example 2: Cross Joint

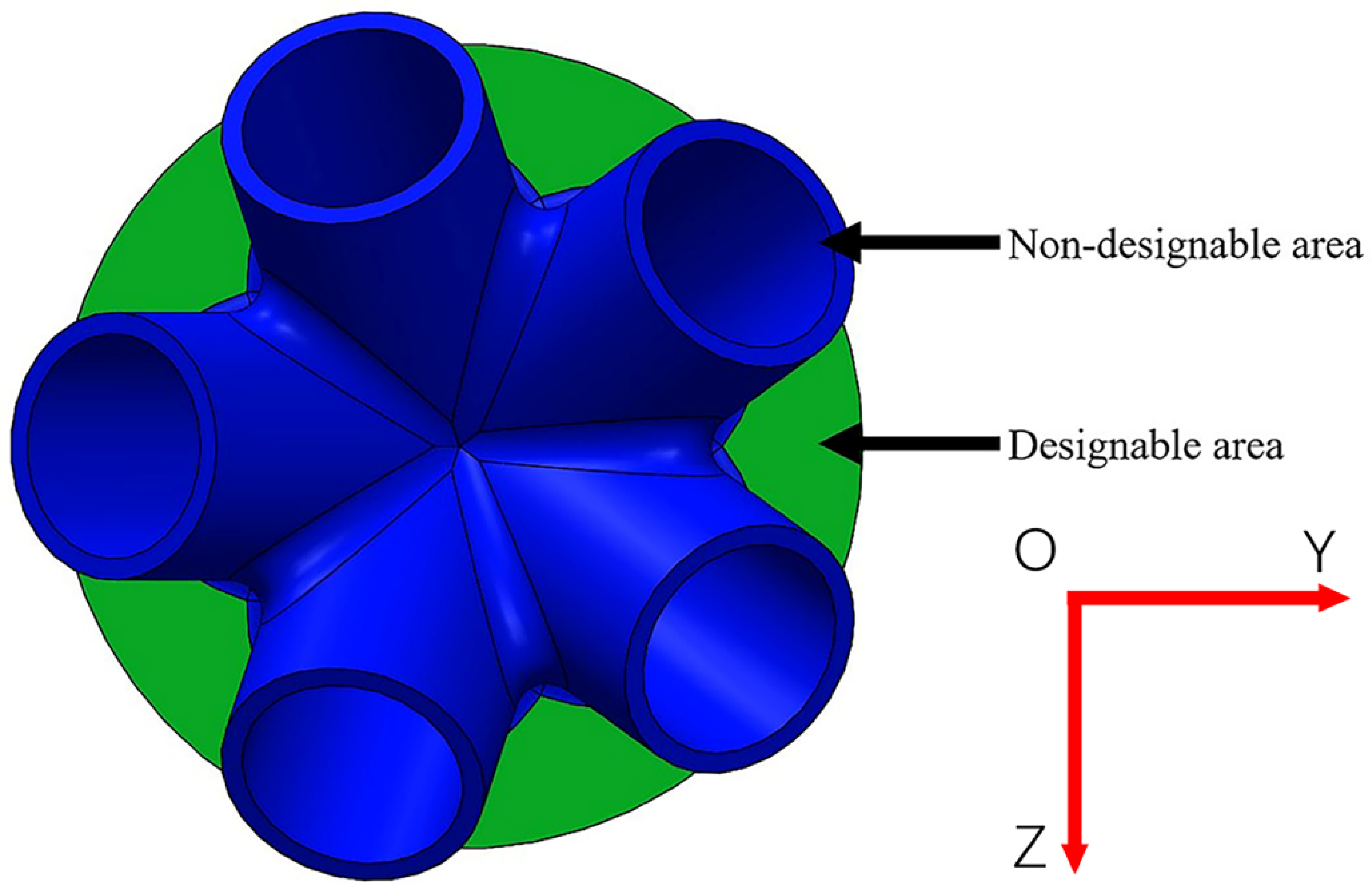

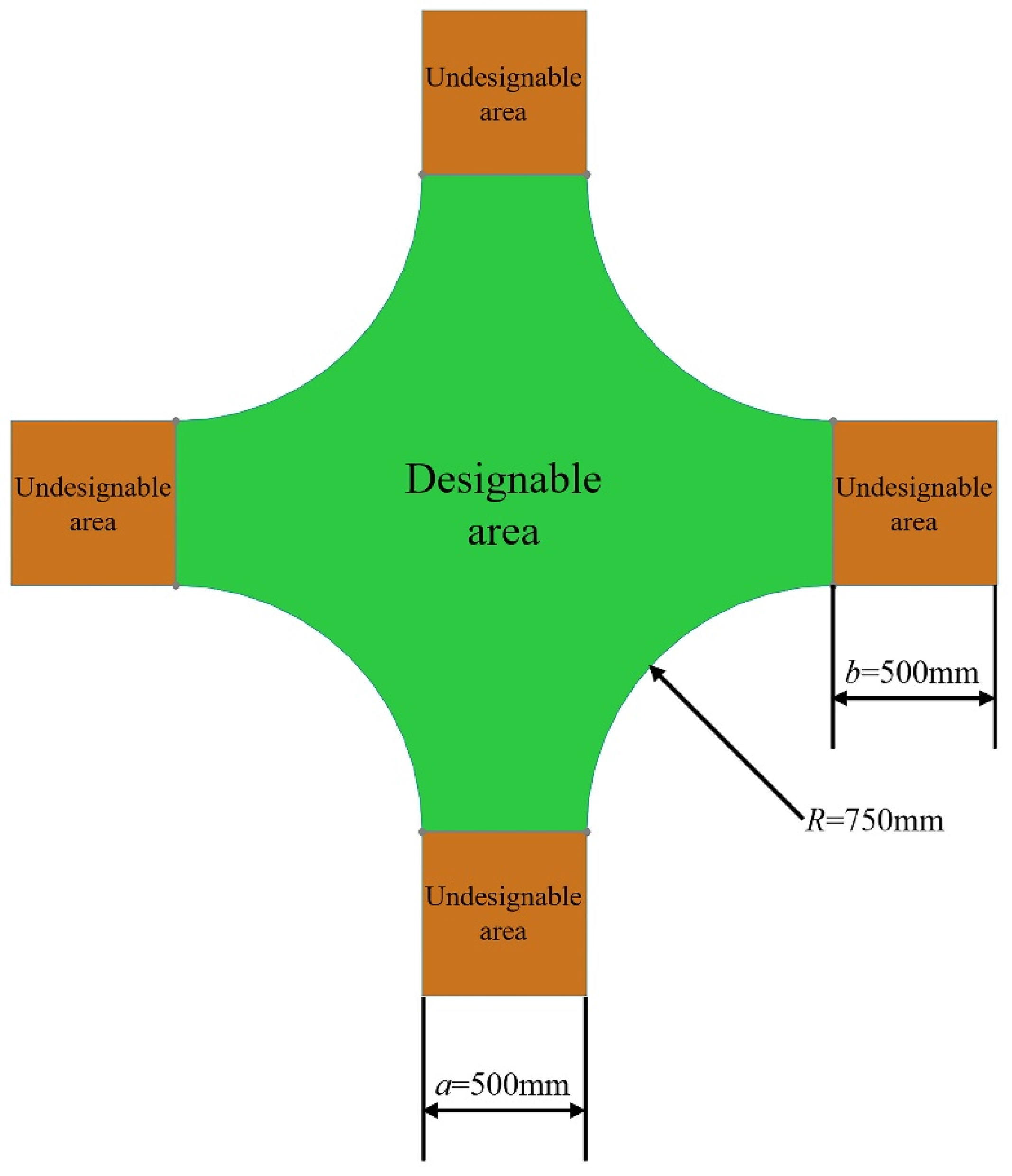

5.1. Engineering Background and Initial Model

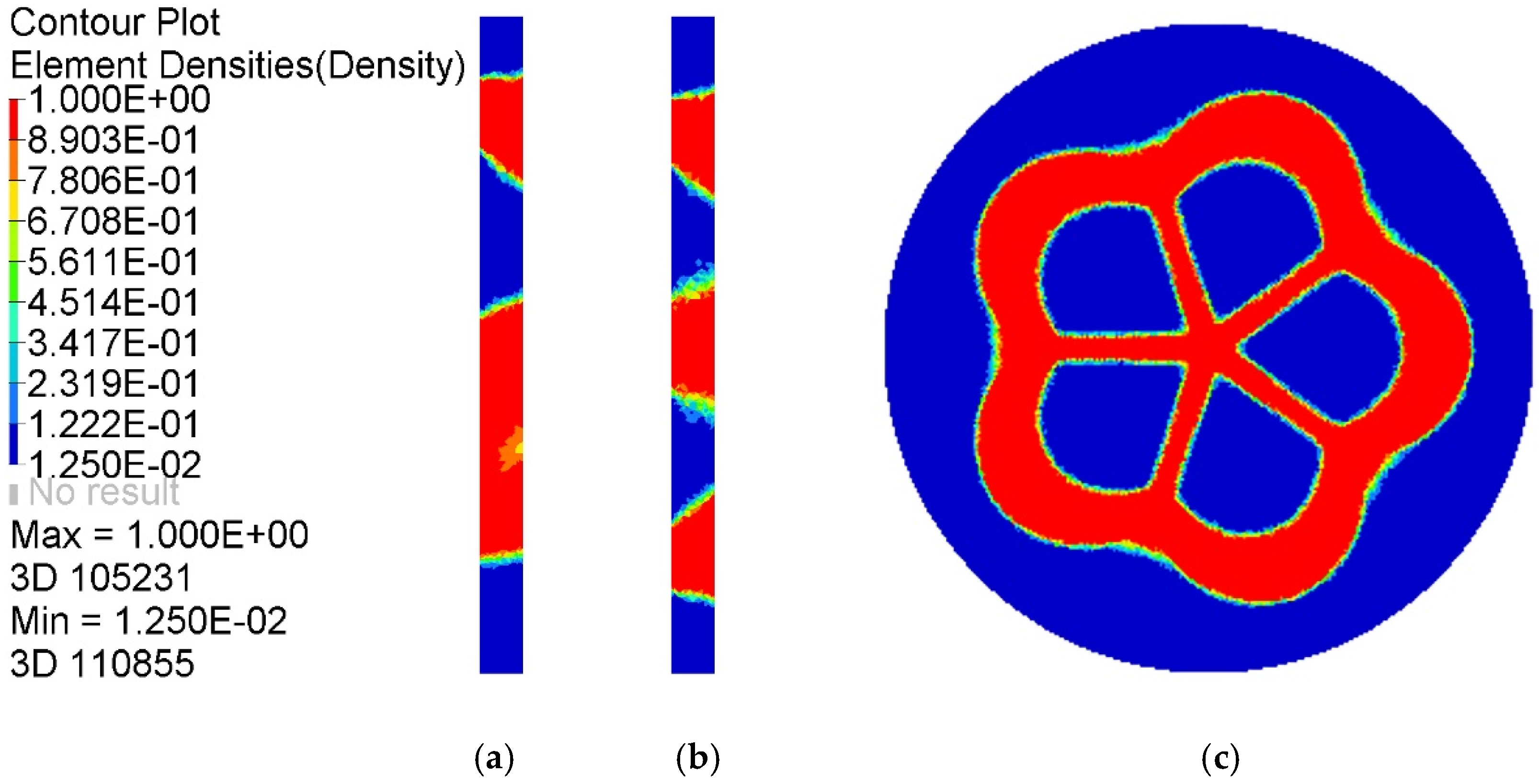

5.2. Building the Dataset

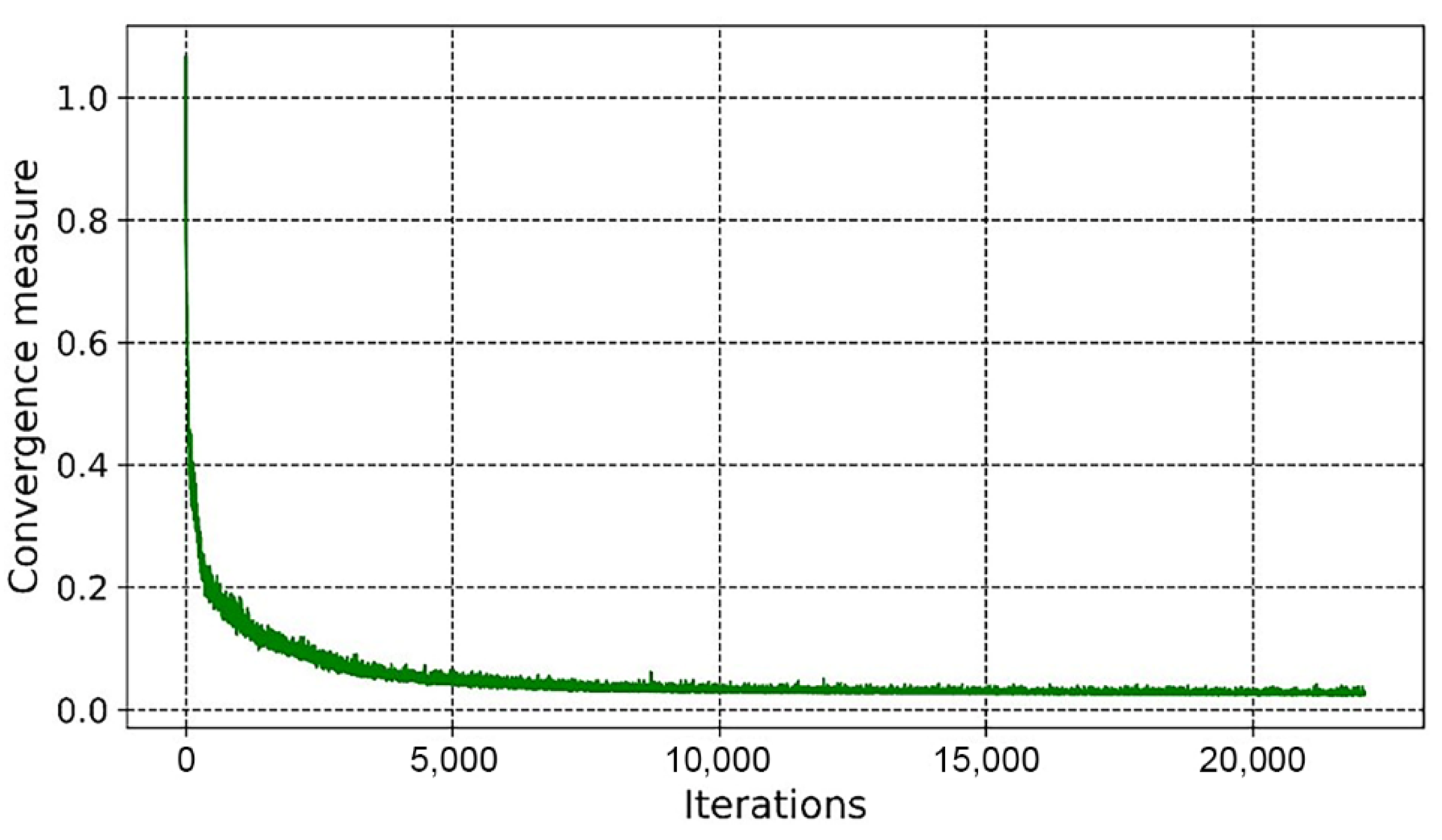

5.3. Generating Innovative Joints Using BEGAN

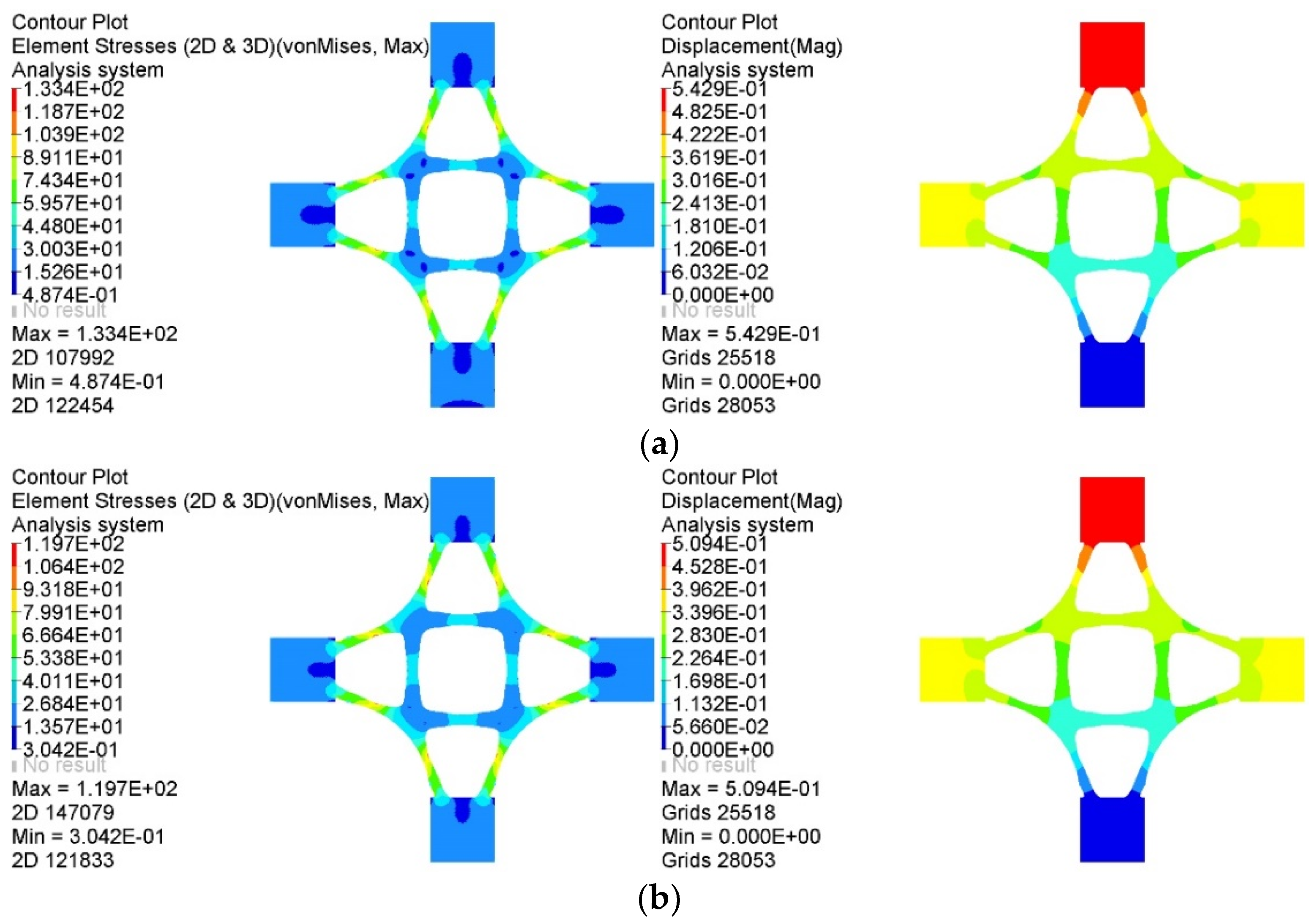

5.4. Analysis and Evaluation of Schemes

6. Conclusions

- (1)

- The traditional design method relies on design experience to build the initial model, and the computer only assists in computational analysis. In contrast, the intelligent generation method proposed in this paper can use the computer to automatically generate a large number of innovative structures with excellent mechanical performance. This method expands the scope of computer-aided design to intelligent structural generation, and designers will only need to select from several model schemes.

- (2)

- It is feasible to obtain abundant topology optimization models under different parameters to provide excellent models for establishing deep learning datasets, which can not only solve the problem of building a model library with a large volume of data but also inherit the advantage of the high material utilization of topology optimization models.

- (3)

- The BEGAN algorithm has a strong convergence and generation ability. It can solve the problems of gradient vanishing and poor quality of generated images encountered in traditional GAN algorithms and improve the robustness of the deep learning model.

- (4)

- The intelligently generated structures are innovative and have good aesthetics, machinability, and mechanical performance that are reasonable and practical. With the development of cloud computing technology, the intelligent generation method can further improve the speed and quality of generated models.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salehi, H.; Burgueno, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- As, I.; Pal, S.; Basu, P. Artificial intelligence in architecture: Generating conceptual design via deep learning. Int. J. Archit. Comput. 2018, 16, 306–327. [Google Scholar] [CrossRef]

- Pena, M.L.C.; Carballal, A.; Rodriguez-Fernandez, N.; Santos, I.; Romero, J. Artificial intelligence applied to conceptual design. Rev. Its Use Archit. Autom. Constr. 2021, 124, 103550. [Google Scholar] [CrossRef]

- Balachandran, M. Knowledge-Based Optimum Design; WIT Press: Southampton, UK, 1992. [Google Scholar]

- Zhao, X.K.; SHEA, K. Intelligent generation and design of spatial truss structures. J. Build. Struct. 2010, 31, 63–69. (In Chinese) [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Krish, S. A practical generative design method. Comput.-Aided Des. 2011, 43, 88–100. [Google Scholar] [CrossRef]

- Wang, L.X.; Du, W.F.; He, P.F.; Yang, M.J. Topology Optimization and 3D Printing of Three-Branch Joints in Treelike Structures. J. Struct. Eng. 2020, 146, 04019167. [Google Scholar] [CrossRef]

- Seifi, H.; Javan, A.R.; Xu, S.Q.; Zhao, Y.; Xie, Y.M. Design optimization and additive manufacturing of nodes in gridshell structures. Eng. Struct. 2018, 160, 161–170. [Google Scholar] [CrossRef]

- Fu, Y.F.; Rolfe, B.; Chiu, L.N.S.; Wang, Y.N.; Huang, X.D.; Ghabraie, K. SEMDOT: Smooth-edged material distribution for optimizing topology algorithm. Adv. Eng. Softw. 2020, 150, 102921. [Google Scholar] [CrossRef]

- Amir, O.; Aage, N.; Lazarov, B.S. On multigrid-CG for efficient topology optimization. Struct. Multidiscip. Optim. 2014, 49, 815–829. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.S.; Zhang, J.; Yuan, J. Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons. Comput. Methods Appl. Mech. Eng. 2016, 310, 711–748. [Google Scholar] [CrossRef]

- Chun, J.; Song, J.; Paulino, G.H. System-reliability-based design and topology optimization of structures under constraints on first-passage probability. Struct. Saf. 2019, 76, 81–94. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep Learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the dimensionality of data with neural networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [Green Version]

- Kallioras, N.A.; Kazakis, G.; Lagaros, N.D. Accelerated topology optimization by means of deep learning. Struct. Multidiscip. Optim. 2020, 62, 1185–1212. [Google Scholar] [CrossRef]

- Sosnovik, I.; Oseledets, I. Neural networks for topology optimization. Russ. J. Numer. Anal. Math. Model. 2019, 34, 215–223. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Kim, H.; Lieu, Q.X.; Lee, J. CNN-based image recognition for topology optimization. Knowl.-Based Syst. 2020, 198, 105887. [Google Scholar] [CrossRef]

- Lin, Q.Y.; Hong, J.; Liu, Z.; Li, B.T.; Wang, J.H. Investigation into the topology optimization for conductive heat transfer based on deep learning approach. Int. Commun. Heat Mass Transf. 2018, 97, 103–109. [Google Scholar] [CrossRef]

- Li, B.T.; Huang, C.J.; Li, X.; Zheng, S.; Hong, J. Non-iterative structural topology optimization using deep learning. Comput. -Aided Des. 2019, 115, 172–180. [Google Scholar] [CrossRef]

- Yu, Y.; Hur, T.; Jung, J.; Jang, I.G. Deep learning for determining a near-optimal topological design without any iteration. Struct. Multidiscip. Optim. 2019, 59, 787–799. [Google Scholar] [CrossRef] [Green Version]

- Sim, E.A.; Lee, S.; Oh, J.; Lee, J. GANs and DCGANs for generation of topology optimization validation curve through clustering analysis. Adv. Eng. Softw. 2021, 152, 102957. [Google Scholar] [CrossRef]

- Abueidda, D.W.; Koric, S.; Sobh, N.A. Topology optimization of 2D structures with nonlinearities using deep learning. Comput. Struct. 2020, 237, 106283. [Google Scholar] [CrossRef]

- Ates, G.C.; Gorguluarslan, R.M. Two-stage convolutional encoder-decoder network to improve the performance and reliability of deep learning models for topology optimization. Struct. Multidiscip. Optim. 2021, 63, 1927–1950. [Google Scholar] [CrossRef]

- Behzadi, M.M.; Ilies, H.T. GANTL: Towards practical and real-time topology optimization with conditional GANs and transfer learning. arXiv 2021, arXiv:2105.03045. [Google Scholar] [CrossRef]

- Chi, H.; Zhang, Y.Y.; Tang, T.L.E.; Mirabella, L.; Dalloro, L.; Song, L.; Paulino, G.H. Universal machine learning for topology optimization. Comput. Methods Appl. Mech. Eng. 2021, 375, 112739. [Google Scholar] [CrossRef]

- Halle, A.; Campanile, L.F.; Hasse, A. An AI-Assisted design method for topology optimization without pre-optimized training data. arXiv 2021, arXiv:2012.06384. [Google Scholar]

- Nie, Z.; Lin, T.; Jiang, H.; Kara, L.B. TopologyGAN: Topology optimization using generative adversarial networks based on physical fields over the initial domain. J. Mech. Des. 2021, 143, 031715. [Google Scholar] [CrossRef]

- Qian, C.; Ye, W.J. Accelerating gradient-based topology optimization design with dual-model artificial neural networks. Struct. Multidiscip. Optim. 2021, 63, 1687–1707. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, B.; Zhou, X.; Xiang, C.; Wang, D. A deep convolutional neural network for topology optimization with strong generalization ability. arXiv 2019, arXiv:1901.07761. [Google Scholar]

- Tcherniak, D. Topology optimization of resonating structures using SIMP method. Int. J. Numer. Methods Eng. 2002, 54, 1605–1622. [Google Scholar] [CrossRef]

- Zhang, W.S.; Zhong, W.L.; Guo, X. An explicit length scale control approach in SIMP-based topology optimization. Comput. Methods Appl. Mech. Eng. 2014, 282, 71–86. [Google Scholar] [CrossRef]

- Deng, Y.B.; Liu, Z.Y.; Liu, Y.S.; Wu, Y.H. Combination of topology optimization and optimal control method. J. Comput. Phys. 2014, 257, 374–399. [Google Scholar] [CrossRef]

- Berthelot, D.; Schumm, T.; Metz, L. BEGAN: Boundary Equilibrium Generative Adversarial Networks. arXiv 2017, arXiv:1703.10717. [Google Scholar]

- Li, Y.C.; Xiao, N.F.; Ouyang, W.L. Improved boundary equilibrium generative adversarial networks. IEEE Access 2018, 6, 11342–11348. [Google Scholar] [CrossRef]

- Hah, J.; Lee, W.; Lee, J.; Park, S. Information-based boundary equilibrium generative adversarial networks with interpretable representation learning. Comput. Intell. Neurosci. 2018, 2018, 6465949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fiore, U.; Santis, A.D.; Perla, F.; Zanetti, P.; Palmieri, F. Using generative adversarial networks for improving classification effectiveness in credit card fraud detection. Inf. Sci. 2019, 479, 448–455. [Google Scholar] [CrossRef]

- Quan, T.M.; Nguyen-Duc, T.; Jeong, W.K. Compressed sensing MRI reconstruction using a generative adversarial network with a cyclic loss. IEEE Trans. Med. Imaging 2018, 37, 1488–1497. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.H.; Xu, L.J.; Chen, X.J.; Yuan, L.M.; Huang, G.Z.; Li, L.M.; Chen, X.; Shi, W. Synthetic spectra generated by boundary equilibrium generative adversarial networks and their applications with consensus algorithms. Opt. Express 2020, 28, 17196–17208. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Wei, Y.D.; Tu, Z.J.; Zeng, H.L.; Kinsy, M.A.; Zheng, N.N.; Ren, P.J. Design space exploration of neural network activation function circuits. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2019, 38, 1974–1978. [Google Scholar] [CrossRef] [Green Version]

- Maguolo, G.; Nanni, L.; Ghidoni, S. Ensemble of convolutional neural networks trained with different activation functions. Expert Syst. Appl. 2021, 166, 114048. [Google Scholar] [CrossRef]

- Liu, M.F.; Wu, W.; Gu, Z.H.; Yu, Z.L.; Qi, F.F.; Li, Y.Q. Deep learning based on Batch Normalization for P300 signal detection. Neurocomputing 2018, 275, 288–297. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.D.; Wei, J.L.; Liu, L.; Huang, X.C.; Gao, S.C.; Liu, W.P.; Li, J.P.; Yu, C.Y.; Li, Z.H. Adaptive moment estimation for polynomial nonlinear equalizer in PAM8-based optical interconnects. Opt. Express 2019, 27, 32210–32216. [Google Scholar] [CrossRef] [PubMed]

- Hou, B.; Khanal, B.; Alansary, A.; McDonagh, S.; Davidson, A.; Rutherford, M.; Hajnal, J.V.; Rueckert, D.; Glocker, B.; Kainz, B. 3-D reconstruction in canonical co-ordinate space from arbitrarily oriented 2-D images. IEEE Trans. Med. Imaging 2018, 37, 1737–1750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

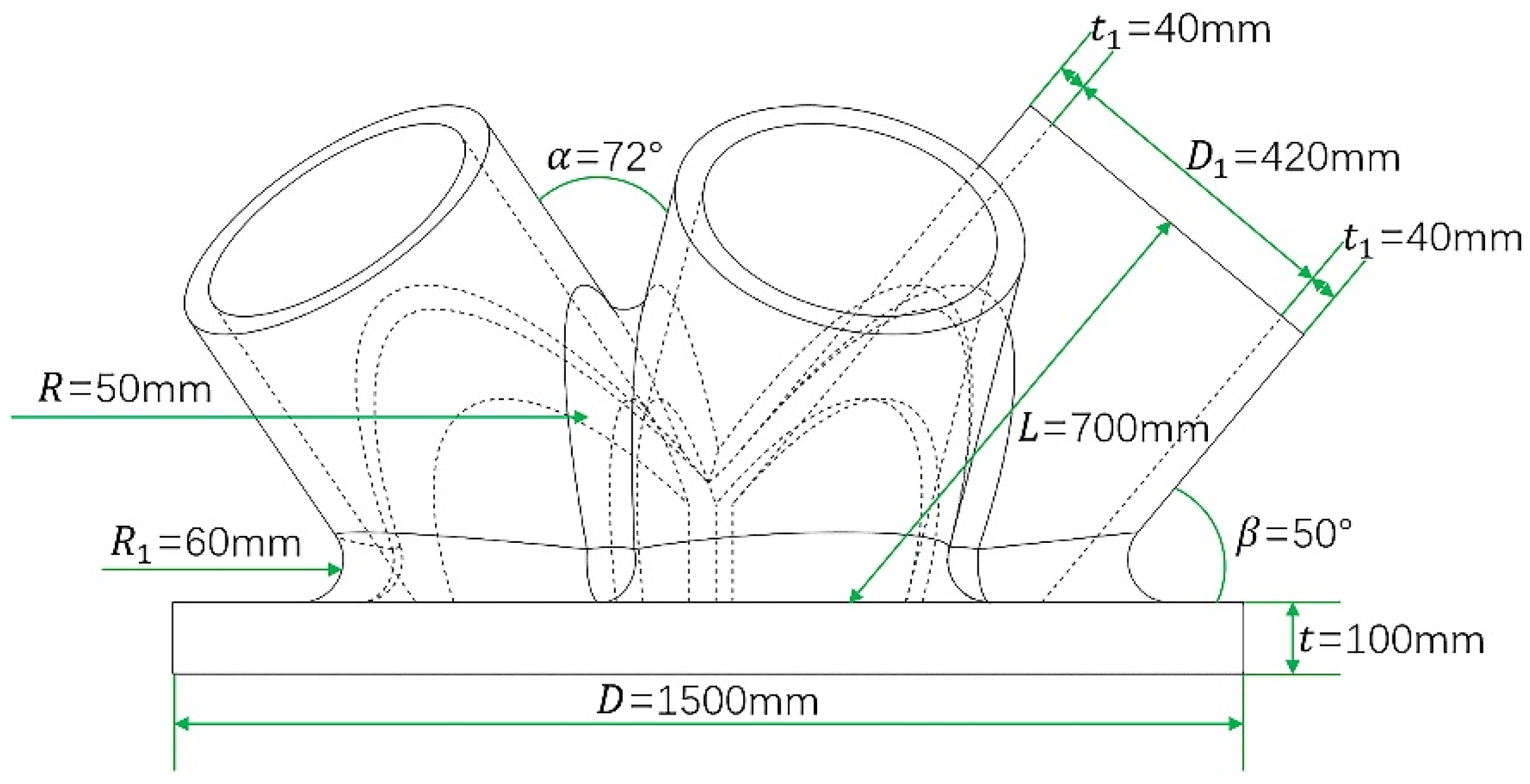

| Parameters | Values |

|---|---|

| Diameter of the baseplate/ | 1500 |

| Thickness of the baseplate/ | 100 |

| Length of branch pipes/ | 700 |

| Inside diameter of branch pipes/ | 420 |

| Thickness of branch pipes/ | 40 |

| Fillet radius between branch pipes/ | 50 |

| Angle between adjacent branch pipes/ | 72 |

| Fillet radius between branch pipes and the baseplate/ | 60 |

| Angle between branch pipes and the baseplate/ | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Du, W.; Wang, H.; Zhao, Y. Intelligent Generation Method of Innovative Structures Based on Topology Optimization and Deep Learning. Materials 2021, 14, 7680. https://doi.org/10.3390/ma14247680

Wang Y, Du W, Wang H, Zhao Y. Intelligent Generation Method of Innovative Structures Based on Topology Optimization and Deep Learning. Materials. 2021; 14(24):7680. https://doi.org/10.3390/ma14247680

Chicago/Turabian StyleWang, Yingqi, Wenfeng Du, Hui Wang, and Yannan Zhao. 2021. "Intelligent Generation Method of Innovative Structures Based on Topology Optimization and Deep Learning" Materials 14, no. 24: 7680. https://doi.org/10.3390/ma14247680

APA StyleWang, Y., Du, W., Wang, H., & Zhao, Y. (2021). Intelligent Generation Method of Innovative Structures Based on Topology Optimization and Deep Learning. Materials, 14(24), 7680. https://doi.org/10.3390/ma14247680