Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR)

Abstract

:1. Introduction

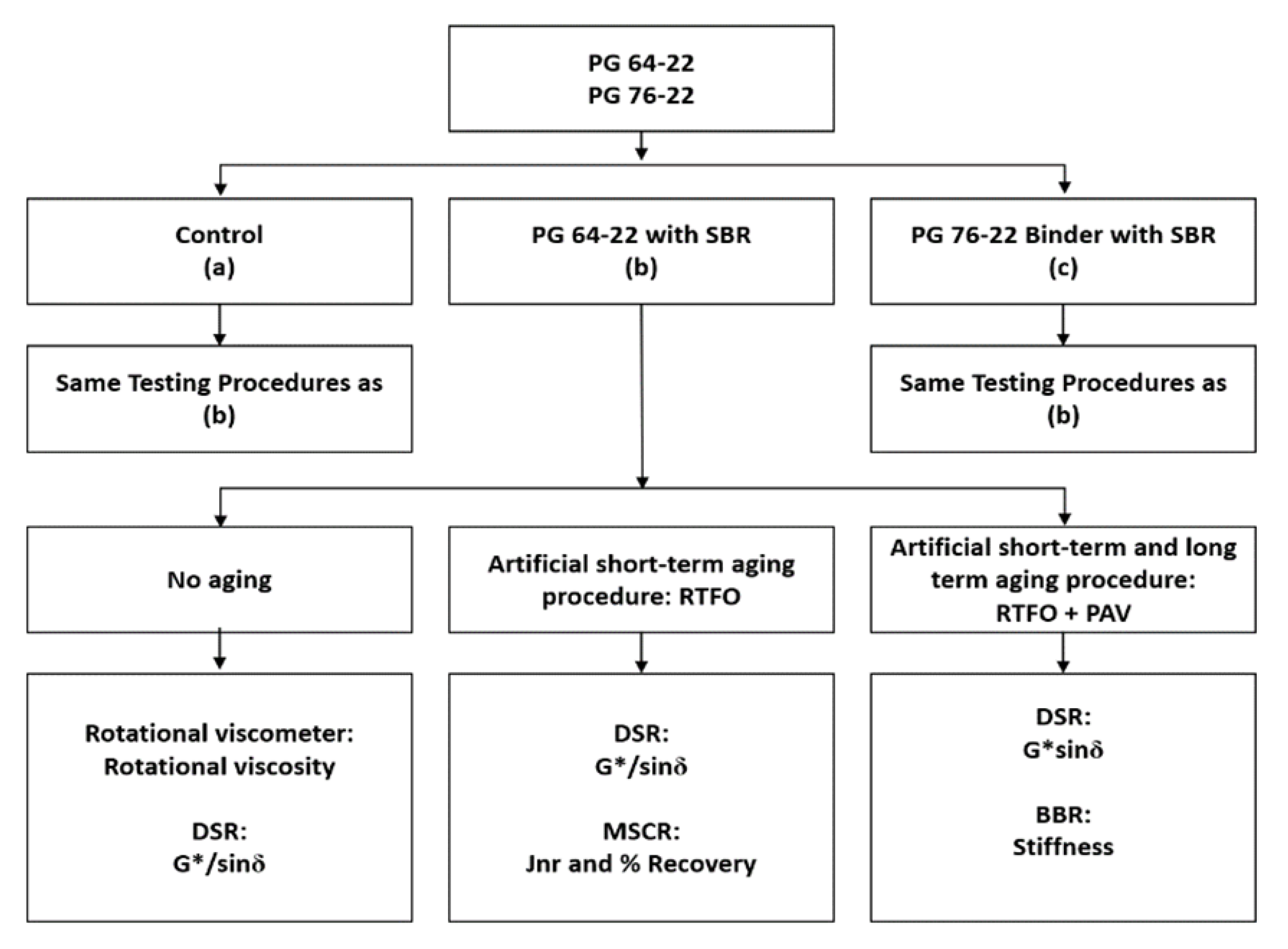

2. Experimental Design

2.1. Materials

2.2. Production and Sampling of SBR Asphalt Binders

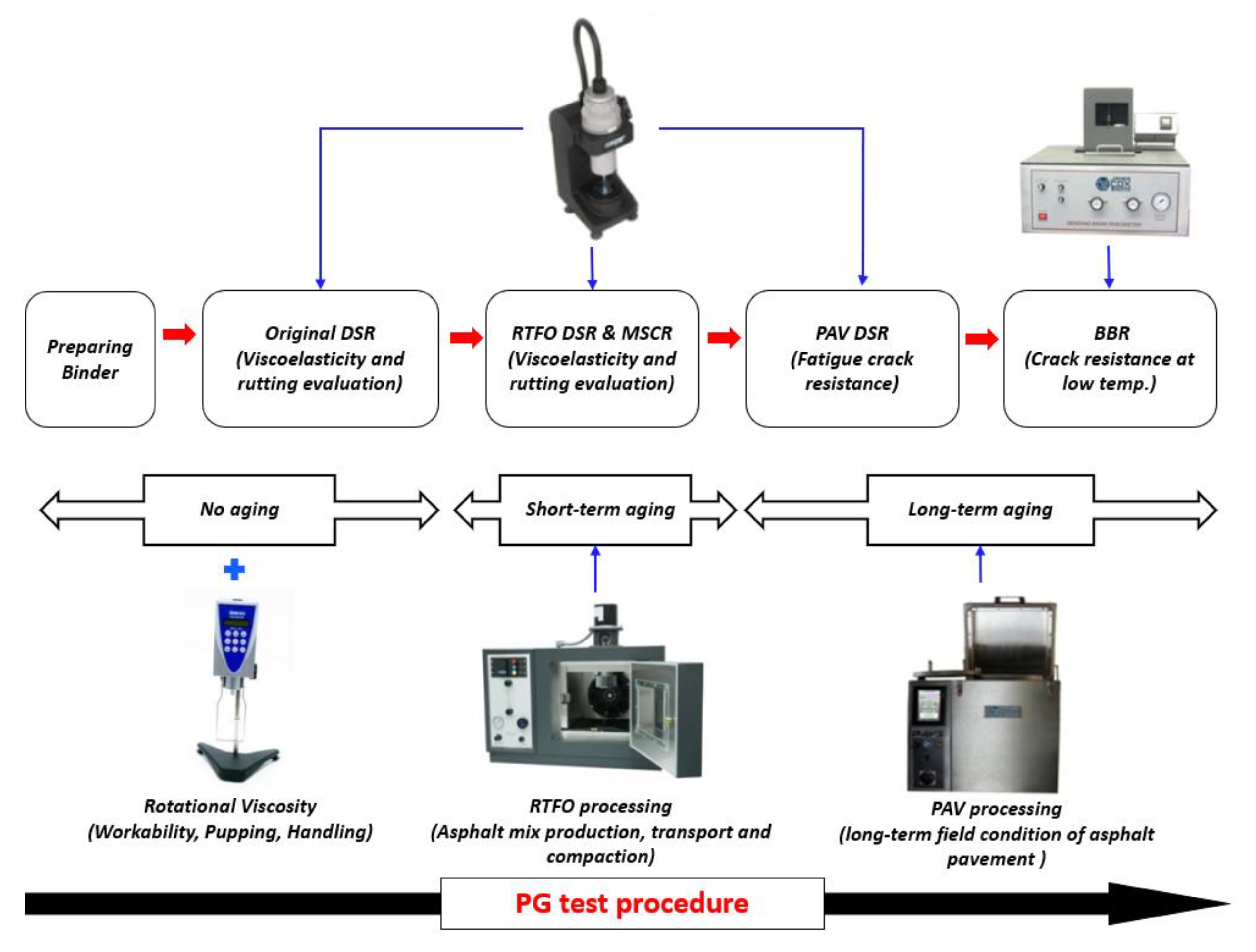

2.3. Binder Tests for Basic Characteristics

2.4. Statistical Analysis Method

3. Results and Discussion

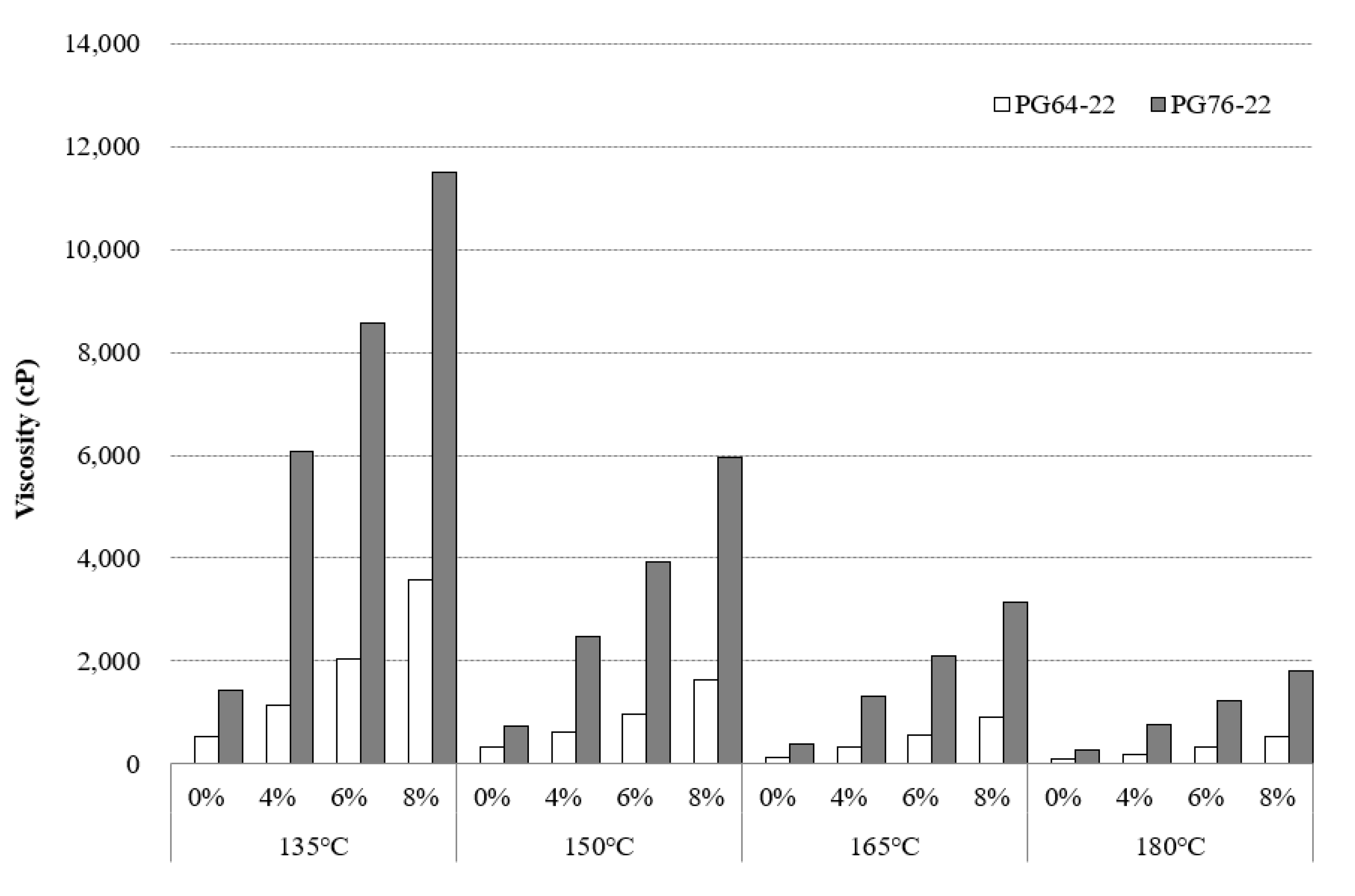

3.1. Rotational Viscosity

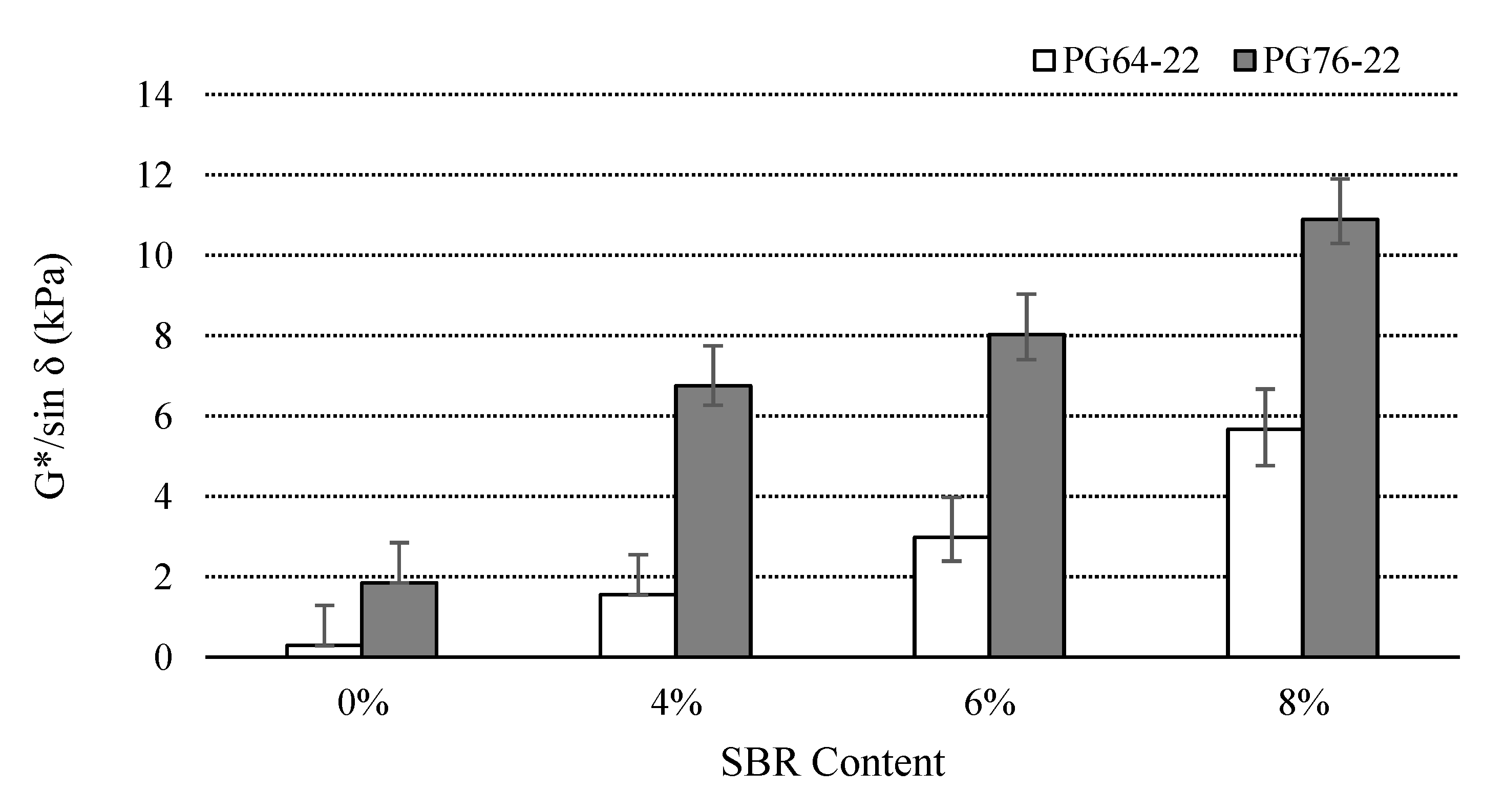

3.2. Rutting Property

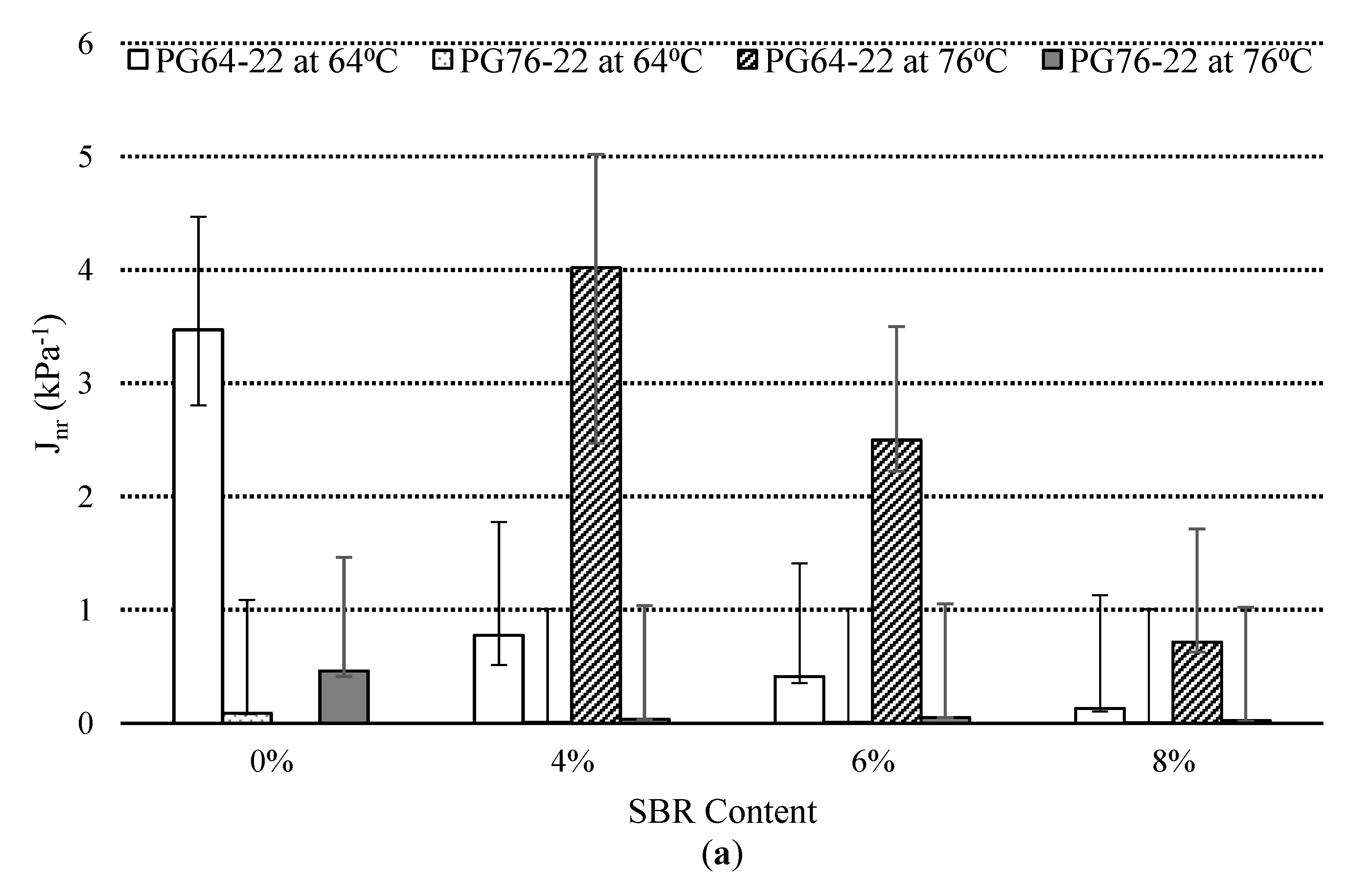

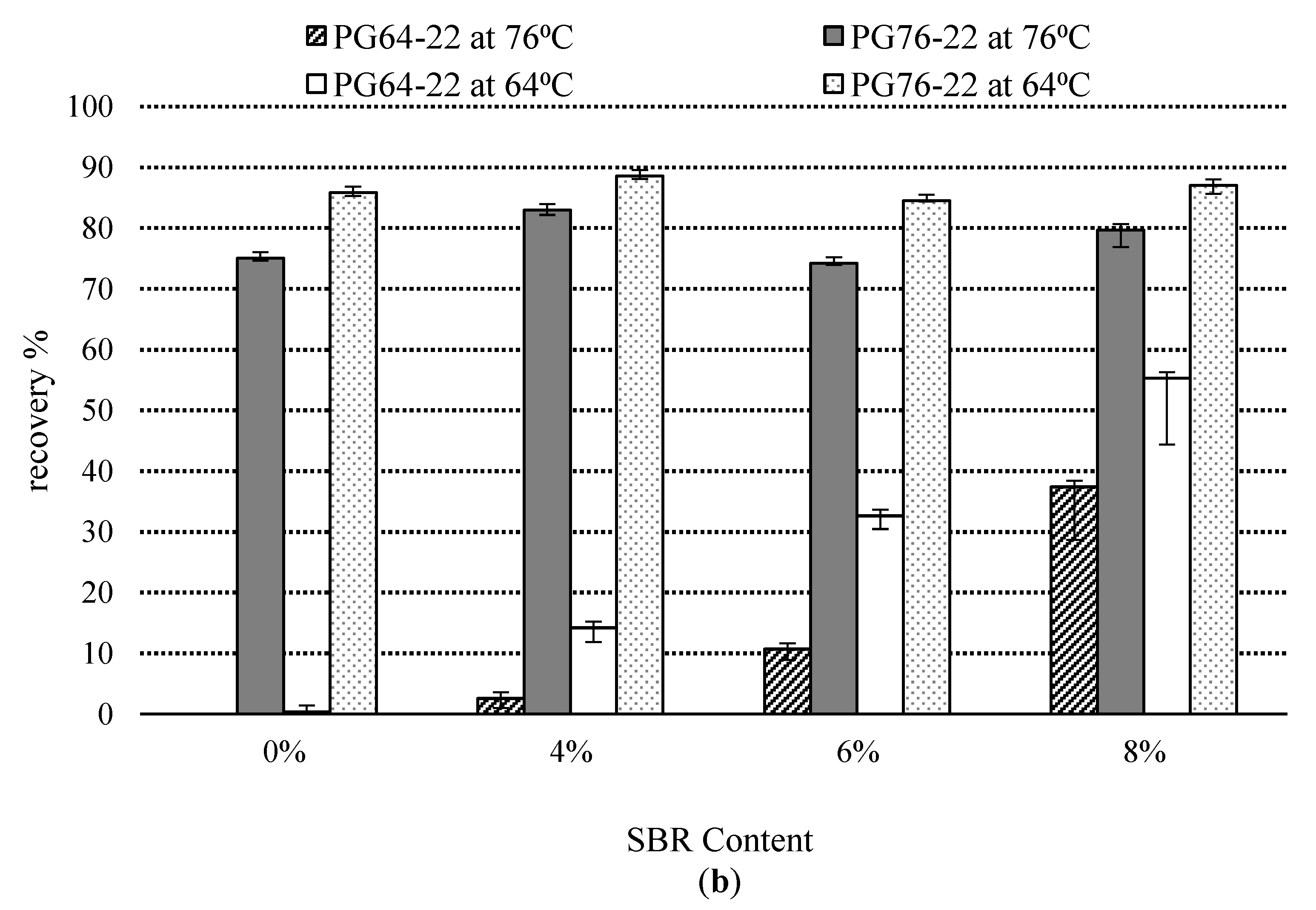

3.3. Multiple Stress Creep Recovery (MSCR) Test

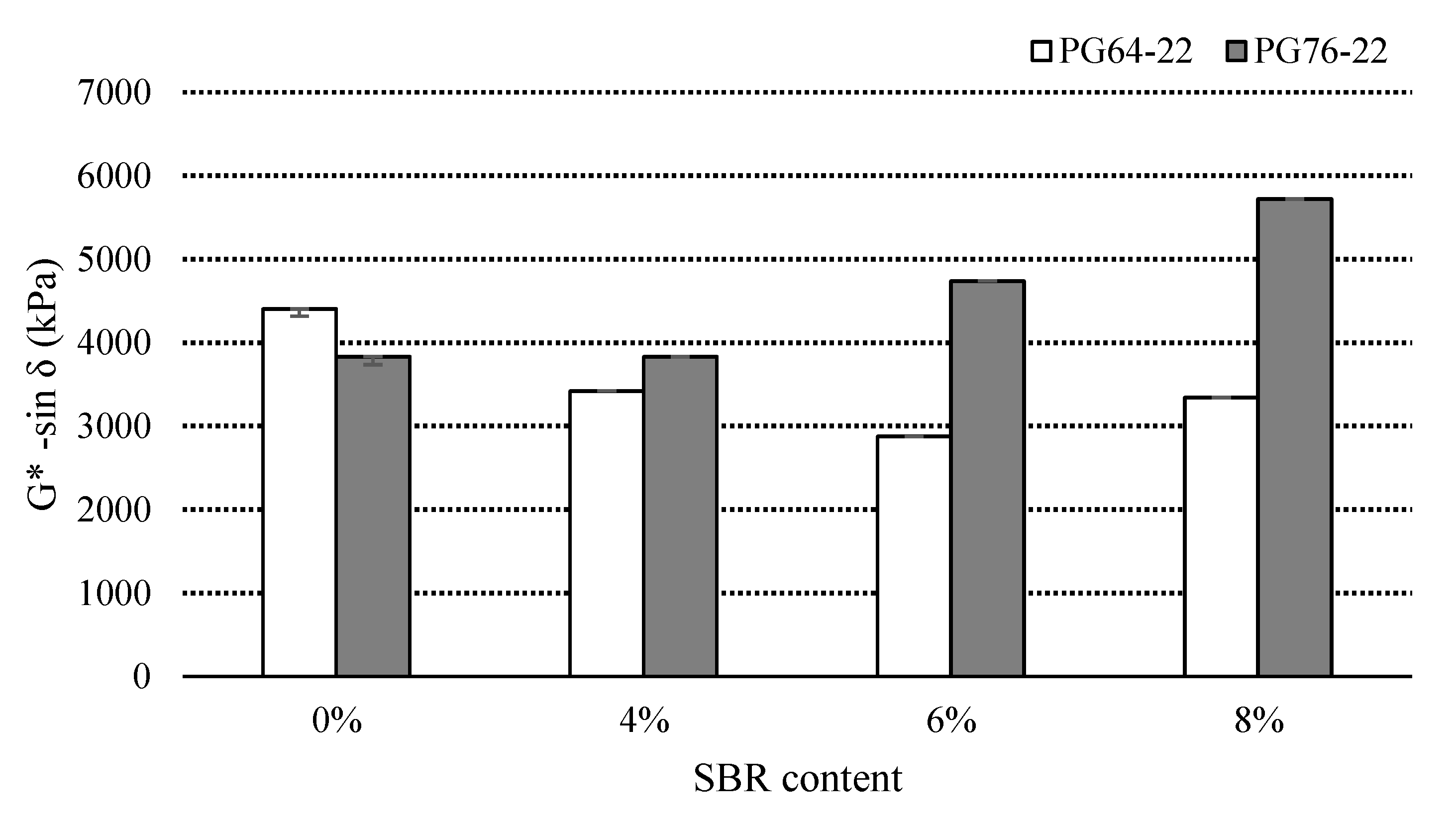

3.4. Fatigue Cracking

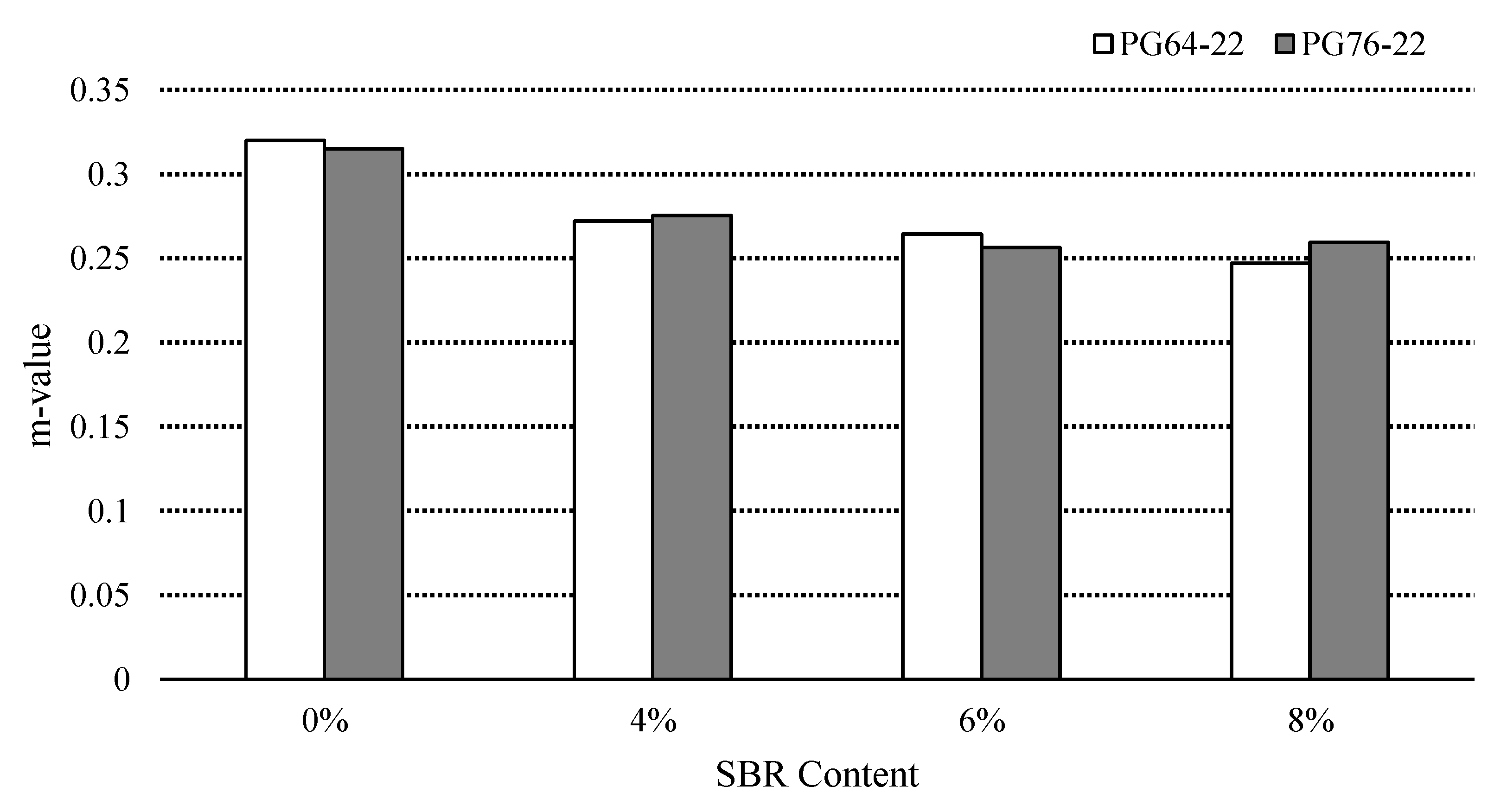

3.5. Low Temperature Cracking Property

4. Summary and Conclusions

- The viscosity of all the modified binders was increased due to the addition of SBR content. Therefore, it is believed that the workability of the SBR modified binders must be considered during mixing and construction.

- The results of G*/sin δ showed a significant improvement in the rutting resistance of the asphalt binders due to the addition of SBR content. The high viscosity and tackiness of SBR modified contributed to maintaining the improved rutting resistance at high temperatures.

- According to the MSCR test results, the addition of an SBR modifier improves the rutting resistance significantly by increasing the percentage recovery of the modified binders.

- From the BBR tests at −12 °C, both PG64-22 and PG76-22 modified binders showed that the addition of SBR content of 4%, 6%, and 8% has no significant effect on stiffness values of the modified binders.

- Based on G*sin δ results, the addition of SBR content did not show any significant changes on fatigue resistance.

- Based on G*/sin δ and G*sin δ results, it is recommended that the incorporation of SBR is considered to obtain high rutting resistance as it does not have any significant effect on the cracking resistance of the binder.

- The conclusions of this study are very limited and cannot be generalized. Further research is needed using different types of asphalt binders and mixtures to draw more general findings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chopra, T.; Parida, M.; Kwatra, N.; Chopra, P. Development of Pavement Distress Deterioration Prediction Models for Urban Road Network Using Genetic Programming. Adv. Civ. Eng. 2018, 2018, 1253108. [Google Scholar] [CrossRef] [Green Version]

- He, D.; Yang, W. Effect of Thickness of Gravel Base and Asphalt Pavement on Road Deformation. Adv. Civ. Eng. 2018, 2018, 2076597. [Google Scholar] [CrossRef]

- Król, J.B.; Khan, R.; Collop, A.C. The study of the effect of internal structure on permeability of porous asphalt. Road Mater. Pavement Des. 2018, 19, 935–951. [Google Scholar] [CrossRef]

- Kim, H.H.; Mazumder, M.; Lee, S.-J.; Lee, M.-S. Characterization of recycled crumb rubber modified binders containing wax warm additives. J. Traffic Transp. Eng. Engl. Ed. 2018, 5, 197–206. [Google Scholar] [CrossRef]

- Kim, H.H.; Mazumder, M.; Torres, A.; Lee, S.-J.; Lee, M.-S. Characterization of CRM Binders with Wax Additives Using an Atomic Force Microscopy (AFM) and an Optical Microscopy. Adv. Civ. Eng. Mater. 2017, 6, 504–525. [Google Scholar] [CrossRef]

- Kim, H.H.; Mazumder, M.; Lee, S.-J.; Lee, M.-S. Effect of production process on performance properties of warm rubberized binders. J. Traffic Transp. Eng. Engl. Ed. 2019, 6, 589–597. [Google Scholar] [CrossRef]

- Zhang, B.; Xi, M.; Zhang, D.; Zhang, H.; Zhang, B. The effect of styrene–butadiene–rubber/montmorillonite modification on the characteristics and properties of asphalt. Constr. Build. Mater. 2009, 23, 3112–3117. [Google Scholar] [CrossRef]

- Ameri, M.; Vamegh, M.; Rooholamini, H.; Haddadi, F. Investigating Effects of Nano/SBR Polymer on Rutting Performance of Binder and Asphalt Mixture. Adv. Mater. Sci. Eng. 2018, 2018, 5891963. [Google Scholar] [CrossRef] [Green Version]

- Cong, Y.; Liao, K.; Huang, W.; Zhai, Y. Performance of SBR-Modified Asphalt Yufeng Cong. Pet. Sci. Technol. 2006, 24, 1187–1194. [Google Scholar] [CrossRef]

- Tabatabaei, S.A.; Kiasat, A.; Alkouhi, F.K. The effect of Styrene-Butadiene-Rubber (SBR) polymer modifier on properties of bitumen. World Acad. Sci. Eng. Technol. Int. J. Mater. Metall. Eng. 2013, 7, 785–788. [Google Scholar]

- Mazumder, M.; Siddique, A.; Ahmed, R.; Lee, S.-J.; Lee, M.-S. Rheological and Morphological Characterization of Styrene-Isoprene-Styrene (SIS) Modified Asphalt Binder. Adv. Civ. Eng. 2020, 2020, 8877371. [Google Scholar] [CrossRef]

- Asphalt Institute. Asphalt Institute. Individual Asphalt Binder Tests. Lexington, KY. 2003. Available online: https://interstatetesting.com/binder-lab/ (accessed on 19 November 2021).

- Liu, J.; Yan, K.; Liu, J.; Guo, D. Evaluation of the characteristics of Trinidad Lake Asphalt and Styrene–Butadiene–Rubber compound modified binder. Constr. Build. Mater. 2019, 202, 614–621. [Google Scholar] [CrossRef]

- Ali, A.W. Multiple Stress Creep Recovery (MSCR) characterization of polymer modified asphalt binder containing wax additives. Chin. Soc. Pavement Eng. 2018, 11, 774–778. [Google Scholar]

| Aging States | Test Properties | PG 64-22 | PG 76-22 |

|---|---|---|---|

| No aging binder | Viscosity @ 135 °C (cP) | 538 | 1425 |

| G*/sin δ @ 76 °C (kPa) | 0.29 | 1.85 | |

| RTFO aged residual | G*/sin δ @ 76 °C (kPa) | 1.06 | 3.58 |

| RTFO + PAV aged residual | G*sin δ @ 25 °C (kPa) | 4400 | 3830 |

| Stiffness @ −12 °C (MPa) | 187 | 195 | |

| m-value @ −12 °C | 0.32 | 0.315 |

| Items | Properties |

|---|---|

| Appearance | Powder |

| Color | White |

| Odor | Aromatic |

| Solubility | Soluble in bitumen and different varieties of oil |

| Relative density | 0.93~0.97 |

| Flash point | 246 °C |

| Auto Ignition Temperature | >388 °C |

| Viscosity | 135 °C | 150 °C | 165 °C | 180 °C | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 4% | 6% | 8% | 0% | 4% | 6% | 8% | 0% | 4% | 6% | 8% | 0% | 4% | 6% | 8% | ||

| PG64-22 | 0% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S |

| 4% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| 6% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| 8% | - | S | S | S | S | S | S | S | S | S | S | S | S | ||||

| PG76-22 | 0% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S |

| 4% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| 6% | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| 8% | - | S | S | S | S | S | S | S | S | S | S | S | S | ||||

| G*/sin δ (Original) | 0% | 4% | 6% | 8% | |

|---|---|---|---|---|---|

| PG64-22 | 0% | - | S | S | S |

| 4% | - | S | S | ||

| 6% | - | S | |||

| 8% | - | ||||

| G*/sin δ (RTFO) | 0% | 4% | 6% | 8% | |

| PG64-22 | 0% | - | S | S | S |

| 4% | - | S | S | ||

| 6% | - | S | |||

| 8% | - | ||||

| Recovery | 0% | 4% | 6% | 8% | |

|---|---|---|---|---|---|

| PG 64-22 | 0% | - | S | S | S |

| 4% | - | S | S | ||

| 6% | - | S | |||

| 8% | - | ||||

| PG 76-22 | 0% | - | S | N | N |

| 4% | - | S | N | ||

| 6% | - | N | |||

| 8% | - | ||||

| Jnr | 0% | 4% | 6% | 8% | |

|---|---|---|---|---|---|

| PG 64-22 | 0% | - | S | N | S |

| 4% | - | S | S | ||

| 6% | - | S | |||

| 8% | - | ||||

| PG 76-22 | 0% | - | N | N | N |

| 4% | - | N | N | ||

| 6% | - | N | |||

| 8% | - | ||||

| G*sin δ | SBR Content | ||||

|---|---|---|---|---|---|

| 0% | 4% | 6% | 8% | ||

| PG 64_22 | 0% | - | N | N | N |

| 4% | - | N | N | ||

| 6% | - | N | |||

| 8% | - | ||||

| PG 76_22 | 0% | - | N | N | S |

| 4% | - | N | S | ||

| 6% | - | N | |||

| 8% | - | ||||

| Stiffness | 0% | 4% | 6% | 8% | |

|---|---|---|---|---|---|

| PG64-22 | 0% | - | N | N | N |

| 4% | - | N | N | ||

| 6% | - | N | |||

| 8% | - | ||||

| PG76-22 | 0% | - | N | N | N |

| 4% | - | S | N | ||

| 6% | - | N | |||

| 8% | - | ||||

| m-value | 0% | 4% | 6% | 8% | |

|---|---|---|---|---|---|

| PG64-22 | 0% | - | S | S | S |

| 4% | - | N | S | ||

| 6% | - | S | |||

| 8% | - | ||||

| PG76-22 | 0% | - | S | S | S |

| 4% | - | S | N | ||

| 6% | - | N | |||

| 8% | - | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemmati, N.; Yun, J.; Mazumder, M.; Lee, M.-S.; Lee, S.-J. Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR). Materials 2021, 14, 7666. https://doi.org/10.3390/ma14247666

Hemmati N, Yun J, Mazumder M, Lee M-S, Lee S-J. Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR). Materials. 2021; 14(24):7666. https://doi.org/10.3390/ma14247666

Chicago/Turabian StyleHemmati, Navid, Jihyeon Yun, Mithil Mazumder, Moon-Sup Lee, and Soon-Jae Lee. 2021. "Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR)" Materials 14, no. 24: 7666. https://doi.org/10.3390/ma14247666

APA StyleHemmati, N., Yun, J., Mazumder, M., Lee, M.-S., & Lee, S.-J. (2021). Laboratory Characterization of Asphalt Binders Modified with Styrene Butadiene Rubber (SBR). Materials, 14(24), 7666. https://doi.org/10.3390/ma14247666