The Design of a Reflection Electron Energy Loss Spectrometer Attachment for Low Voltage Scanning Electron Microscopy

Abstract

:1. Introduction

2. Materials and Methods

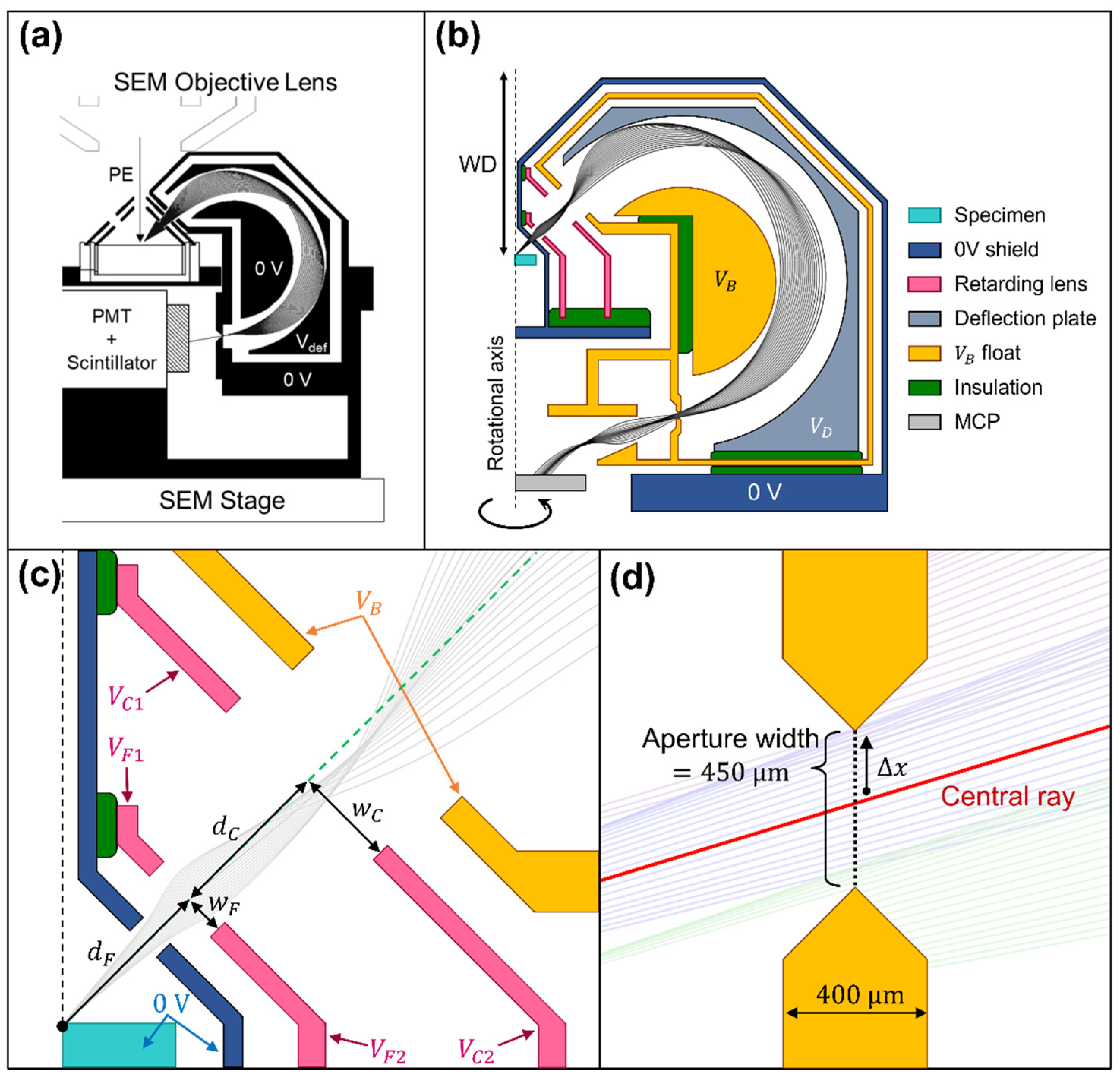

2.1. The Previous SE Toroidal Energy Analyzer Attachment

2.2. The Retarding Field Toroidal Analyzer Attachment Design

2.3. The Simulation Procedure

3. Results and Discussion

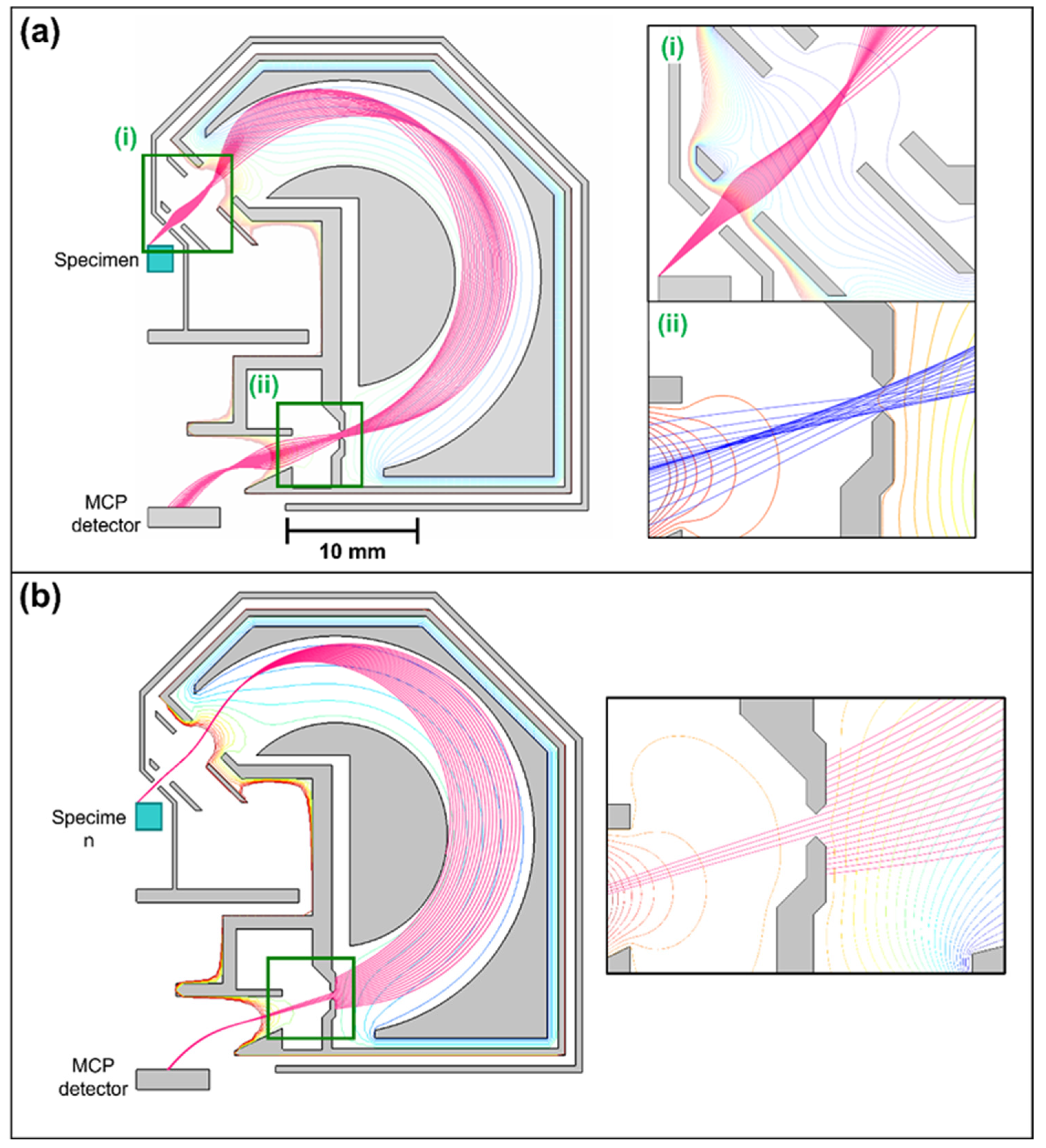

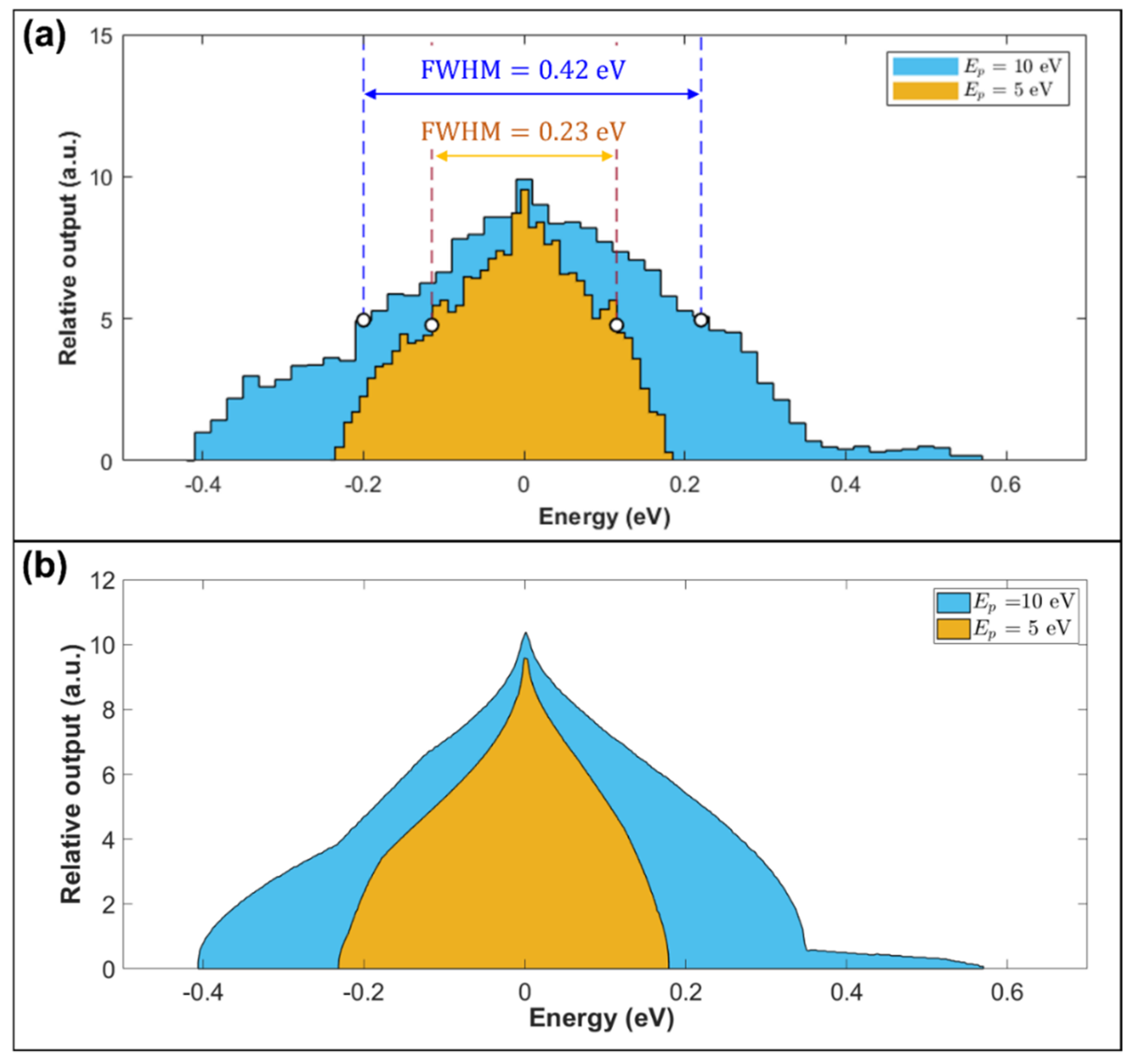

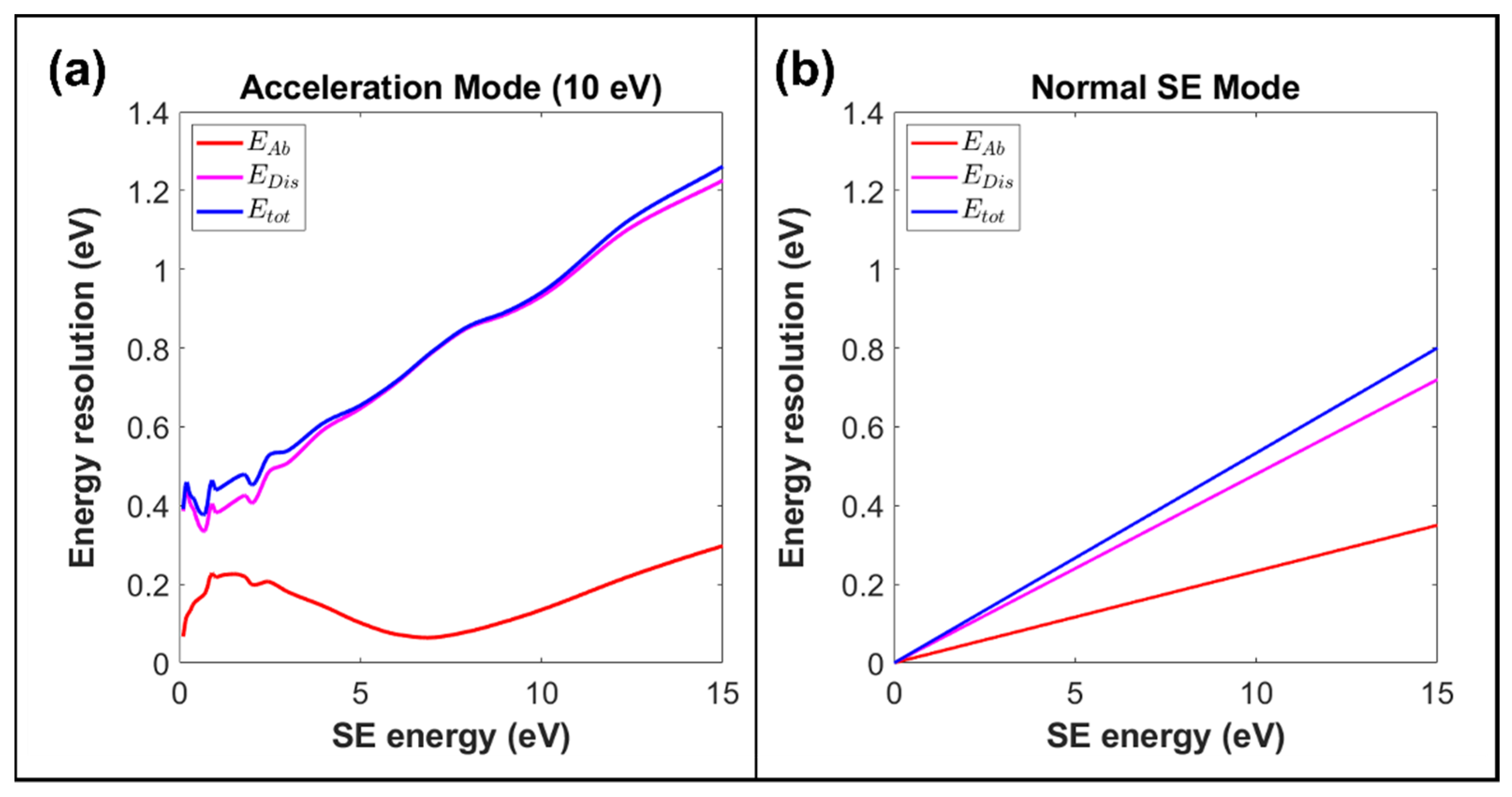

3.1. Toroidal Analyzer Simulated Performance in REELS Mode

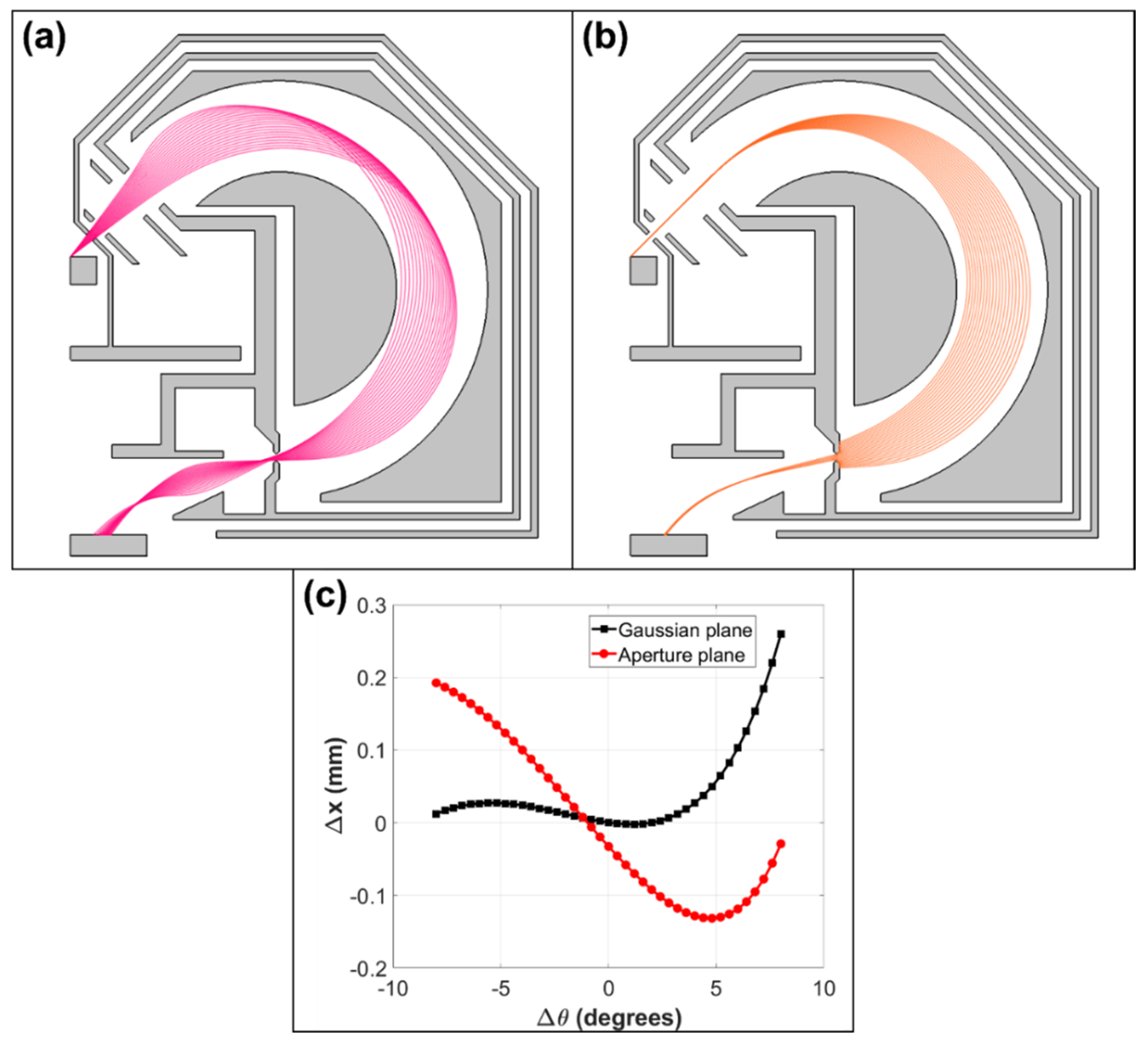

3.2. Toroidal Analyzer Performance in SE Mode

4. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Joy, D.C.; Joy, C.S. Low voltage scanning electron microscopy. Micron 1996, 27, 247–263. [Google Scholar] [CrossRef]

- Brodusch, N.; Demers, H.; Gauvin, R. Field Emission Scanning Electron Microscopy: New Perspectives for Materials Characterization; Springer: Singapore, 2018. [Google Scholar]

- Sato, M.; Konomi, M.; Tamochi, R.; Ishikawa, T. Development of FE-SEM technologies for life science fields. In Biological Field Emission Scanning Electron Microscopy; John Wiley & Sons Ltd.: New York, NY, USA, 2019; Chapter 3; pp. 25–51. [Google Scholar] [CrossRef]

- Fleck, R.A.; Humbel, B.M. Biological Field Emission Scanning Electron Microscopy; John Wiley & Sons Ltd.: New York, NY, USA, 2019; Volume 2. [Google Scholar]

- Zarraoa, L.; Gonzalez, M.U.; Paulo, A.S. Imaging low-dimensional nanostructures by very low voltage scanning electron microscopy: Ultra-shallow topography and depth-tunable material contrast. Sci. Rep. 2019, 9, 16263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis; Springer: Cham, Germany, 2017. [Google Scholar]

- Wuhrer, R.; Moran, K. Low voltage imaging and X-ray microanalysis in the SEM: Challenges and opportunities. IOP Conf. Ser. Mater. Sci. Eng. 2016, 109, 012019. [Google Scholar] [CrossRef]

- Vos, M. Extracting detailed information from reflection electron energy loss spectra. J. Electron Spectrosc. Relat. Phenom. 2013, 191, 65–70. [Google Scholar] [CrossRef]

- Vosa, M.; King, S.W.; French, B.L. Measurement of the band gap by reflection electron energy loss spectroscopy. J. Electron Spectrosc. Relat. Phenom. 2016, 212, 74–80. [Google Scholar] [CrossRef]

- Taguchi, N.; Kitta, M.; Sakaebe, H.; Kohyama, M.; Akita, T. Lithium analysis using reflection EELS for lithium compounds. J. Electron Spectrosc. Relat. Phenom. 2015, 203, 40–44. [Google Scholar] [CrossRef]

- Gergely, G. Elastic peak electron spectroscopy. Scanning 1986, 8, 203–214. [Google Scholar] [CrossRef]

- Han, W.; Zheng, M.; Banerjee, A.; Luo, Y.; Lei, S.; Khursheed, A. Quantitative material analysis using secondary electron energy spectromicroscopy. Sci. Rep. 2020, 10, 22144. [Google Scholar] [CrossRef]

- Han, W.; Srinivasan, A.; Banerjee, A.; Chew, M.; Khursheed, A. Beyond conventional secondary electron imaging using spectromicroscopy and its applications in dopant profiling. Mater. Today Adv. 2019, 2, 100012. [Google Scholar] [CrossRef]

- Srinivasan, A.; Han, W.; Khursheed, A. Secondary Electron Energy Contrast of Localized Buried Charge in Metal–Insulator–Silicon Structures. Microsc. Microanal. 2018, 24, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, A.; Khursheed, A. Probing and Analyzing Buried Interfaces of Multifunctional Oxides Using a Secondary Electron Energy Analyzer. Microsc. Microanal 2014, 20, 1494–1498. [Google Scholar] [CrossRef] [PubMed]

- Khursheed, A.; Hoang, H.Q. A second-order focusing electrostatic toroidal electron spectrometer with 2π radian collection. Ultramicroscopy 2008, 109, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Hoang, H.Q.; Osterberg, M.; Khursheed, A. A high signal-to-noise ratio toroidal electron spectrometer for the SEM. Ultramicroscopy 2011, 111, 1093–1100. [Google Scholar] [CrossRef] [PubMed]

- Hoang, H.Q.; Osterberg, M.; Khursheed, A. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment. Nucl. Instrum. Methods Phys. Res. A 2011, 645, 241–244. [Google Scholar] [CrossRef]

- Kruit, P. Cathodes for electron microscopy and lithography. In Modern Developments in Vacuum Electron Sources; Gaertner, G., Knapp, W., Forbes, R.G., Eds.; Topics in Applied Physics; Springer: Cham, Germany, 2020; Volume 135. [Google Scholar]

- Lorentz-2EM. LORENTZ-2EM.; Integrated Engineering Software Inc.: Winnipeg, MB, Canada, 2015. [Google Scholar]

- Coleman, T.F.; Li, Y. An interior, trust region approach for nonlinear minimization subject to bounds. SIAM J. Optim. 1996, 6, 418–445. [Google Scholar] [CrossRef] [Green Version]

- Sise, O.; Martínez, G.; Madesis, I.; Laoutaris, A.; Dimitriou, A.; Fernández-Martín, M.; Zouros, T.J.M. The voltage optimization of a four-element lens used on a hemispherical spectrograph with virtual entry for highest energy resolution. J. Electron Spectrosc. Relat. Phenom. 2016, 211, 19–31. [Google Scholar] [CrossRef]

| Parameter | Units | ||

|---|---|---|---|

| −990.000 | −995.000 | V | |

| −996.565 | −998.237 | V | |

| −965.094 | −959.238 | V | |

| −846.882 | −839.943 | V | |

| −957.577 | −1015.521 | V | |

| −982.404 | −992.471 | V | |

| 0.0 | 0.0 | V | |

| 5.0 | 4.7 | ||

| Aberration spot size (2 × RMS) | 0.309 | 0.303 | |

| 1.382 | 2.727 | ||

| on the Gaussian Plane (2 × RMS) | 0.0510 | 0.0199 | % |

| (2 × RMS) | 0.0224 | 0.0111 | % |

| (0.45 mm wide aperture) | 0.0325 | 0.0165 | % |

| 0.0395 | 0.0199 | % |

| Parameter | Value | Units |

|---|---|---|

| 0.0 | V | |

| V | ||

| 0.0 | V | |

| 0.0 | V | |

| 0.0 | V | |

| 0.0 | V | |

| 100.0 | V | |

| 8.0 | ||

| Spot size on aperture plane (2 × RMS) | 0.217 | |

| on Gaussian plane (2 × RMS) | 1.571 | % |

| on aperture plane (2 × RMS) | 2.331 | % |

| for a 0.45 mm wide aperture | 4.799 | % |

| ) | 5.334 | % |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuah, J.; Khursheed, A. The Design of a Reflection Electron Energy Loss Spectrometer Attachment for Low Voltage Scanning Electron Microscopy. Materials 2021, 14, 7511. https://doi.org/10.3390/ma14247511

Chuah J, Khursheed A. The Design of a Reflection Electron Energy Loss Spectrometer Attachment for Low Voltage Scanning Electron Microscopy. Materials. 2021; 14(24):7511. https://doi.org/10.3390/ma14247511

Chicago/Turabian StyleChuah, Jonathan, and Anjam Khursheed. 2021. "The Design of a Reflection Electron Energy Loss Spectrometer Attachment for Low Voltage Scanning Electron Microscopy" Materials 14, no. 24: 7511. https://doi.org/10.3390/ma14247511

APA StyleChuah, J., & Khursheed, A. (2021). The Design of a Reflection Electron Energy Loss Spectrometer Attachment for Low Voltage Scanning Electron Microscopy. Materials, 14(24), 7511. https://doi.org/10.3390/ma14247511