Low-Carbon and Fundamental Properties of Eco-Efficient Mortar with Recycled Powders

Abstract

:1. Introduction

2. Materials and Methods

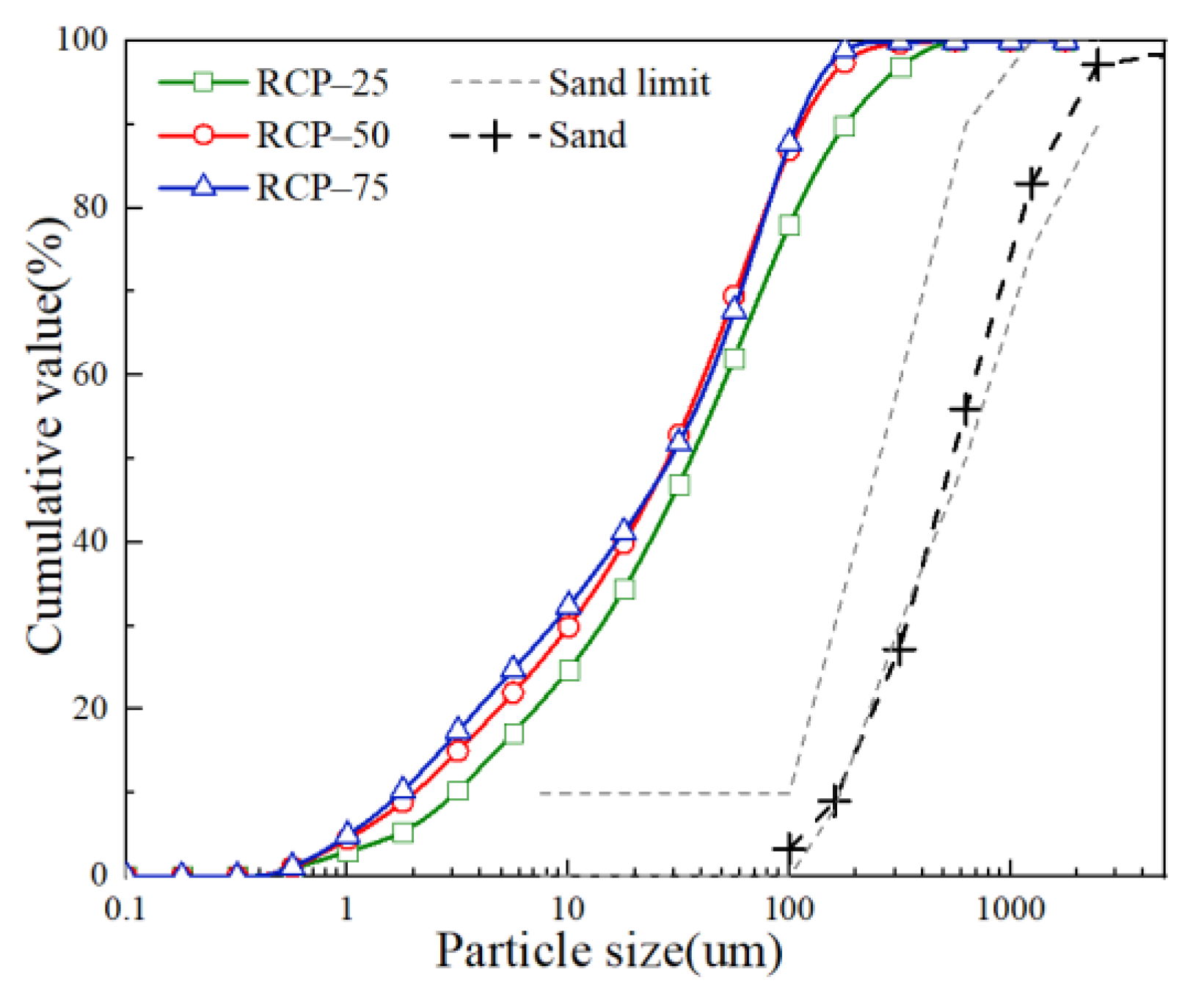

2.1. Materials

2.2. Mortar Mixture

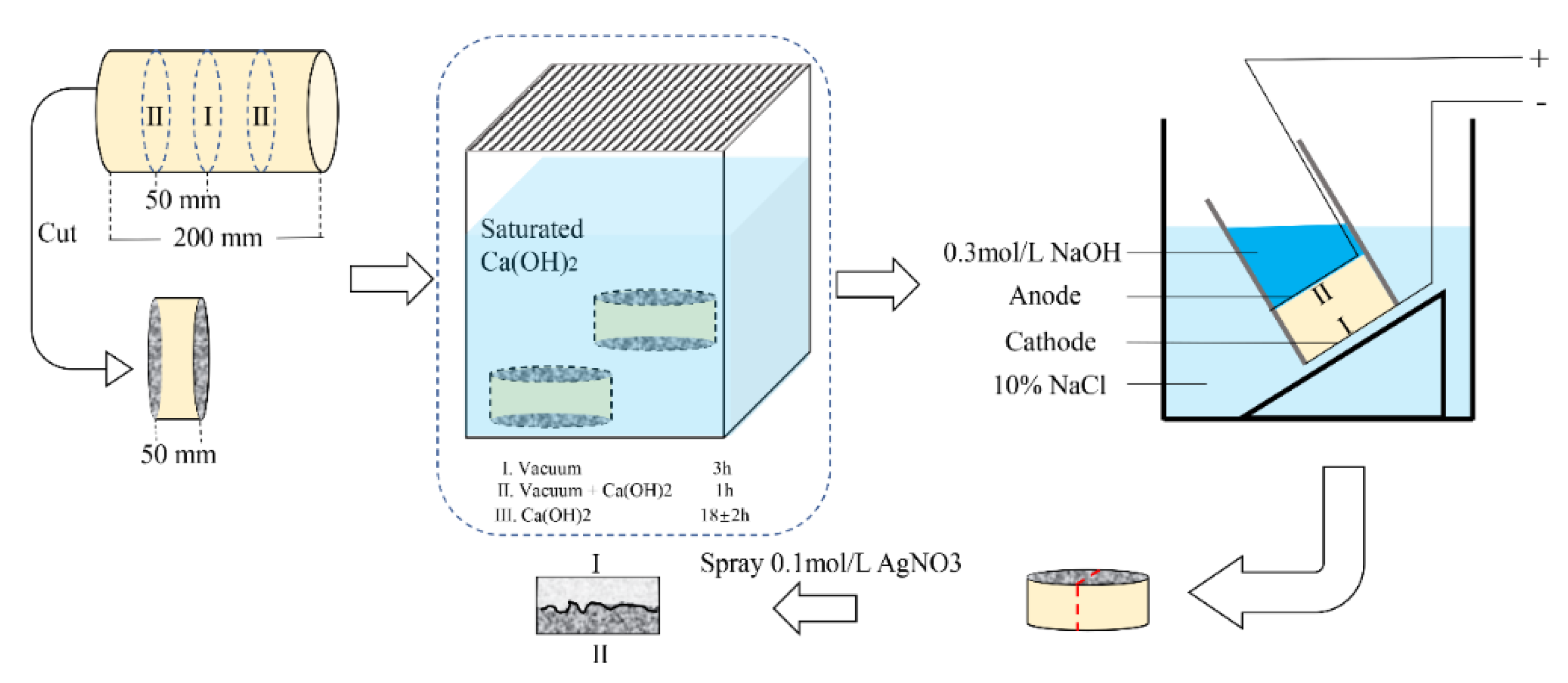

2.3. Test Methods

2.3.1. Mechanical Properties Tests

2.3.2. Long-Term Properties Tests

3. Results and Discussions

3.1. Performance of Eco-Efficient Mortar

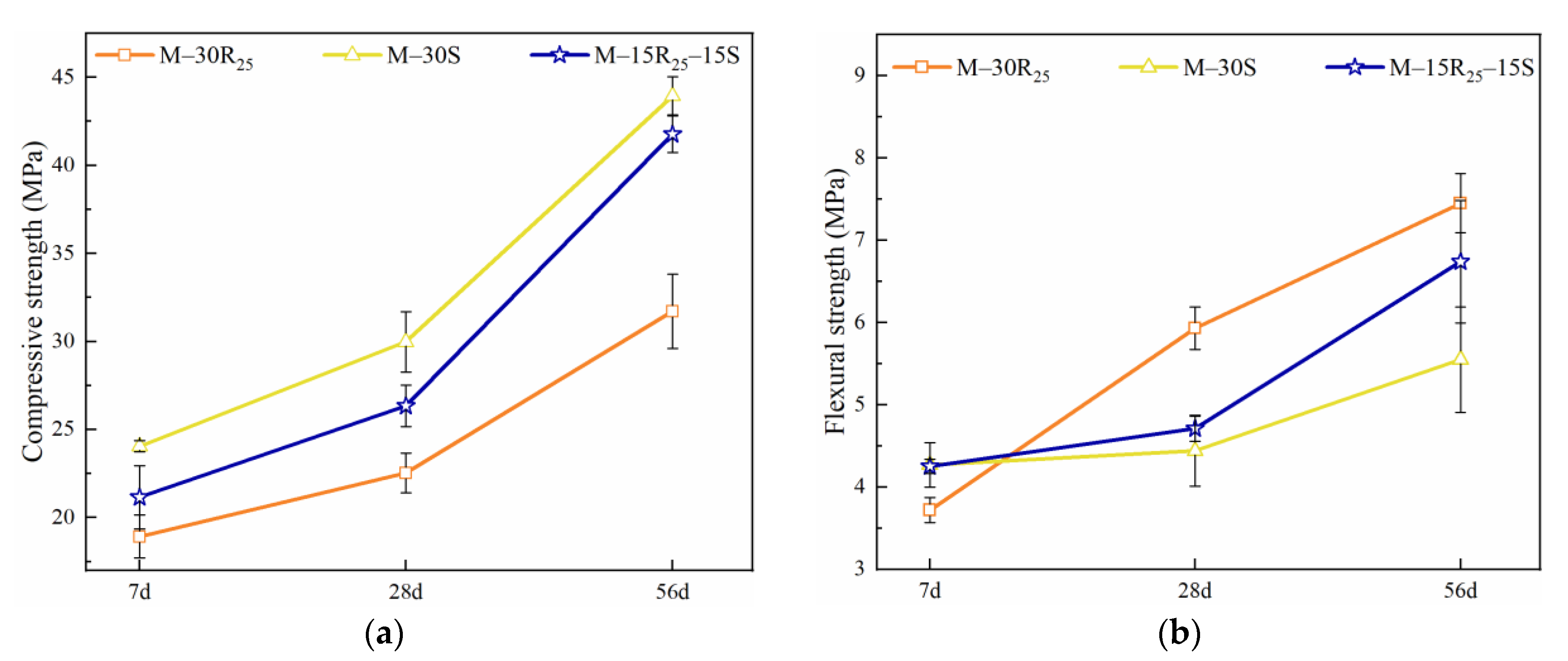

3.1.1. Performance of Eco-Efficient Mortar in Series A

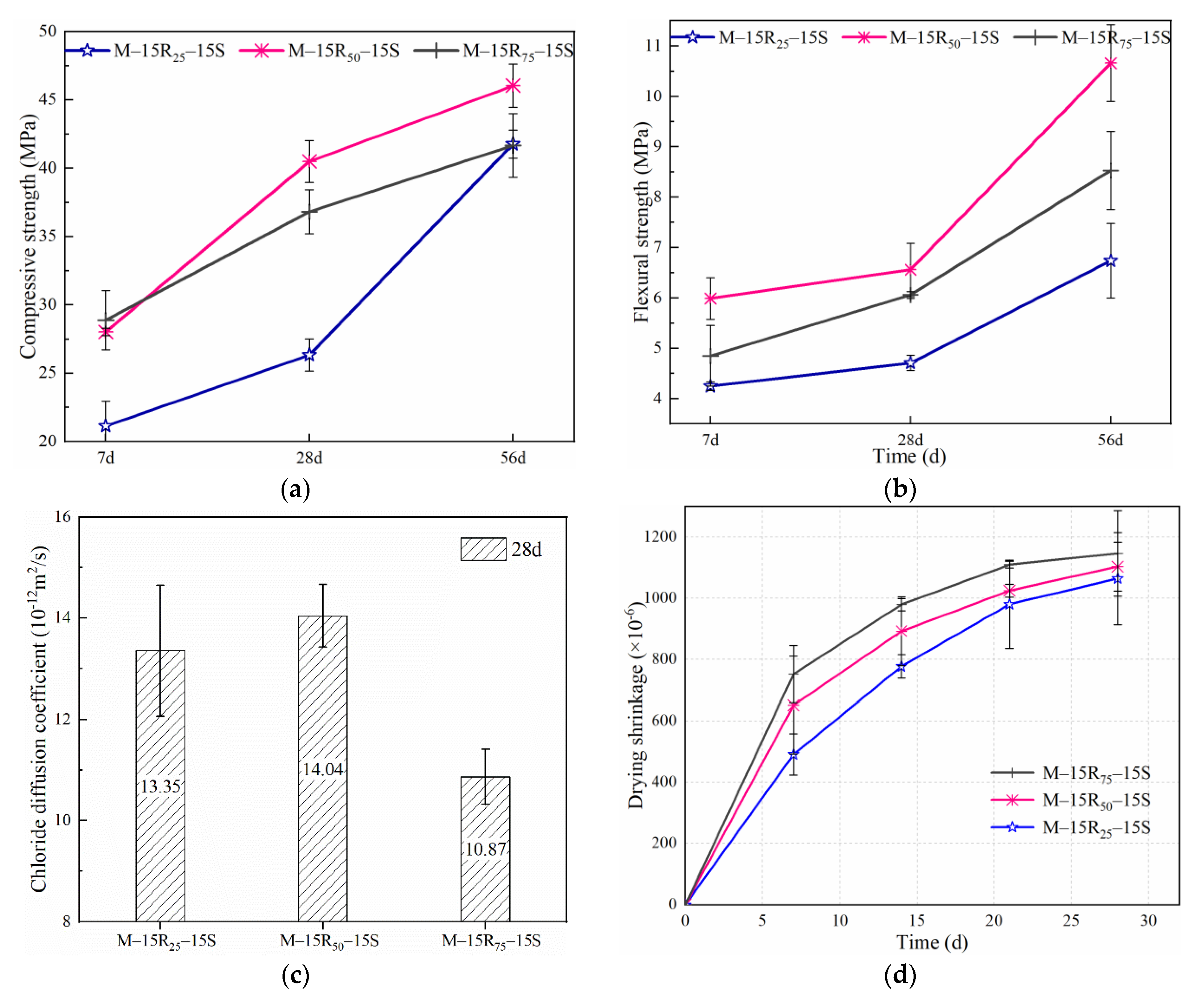

3.1.2. Performance of Eco-Efficient Mortar in Series B

3.2. Fundamental Analysis

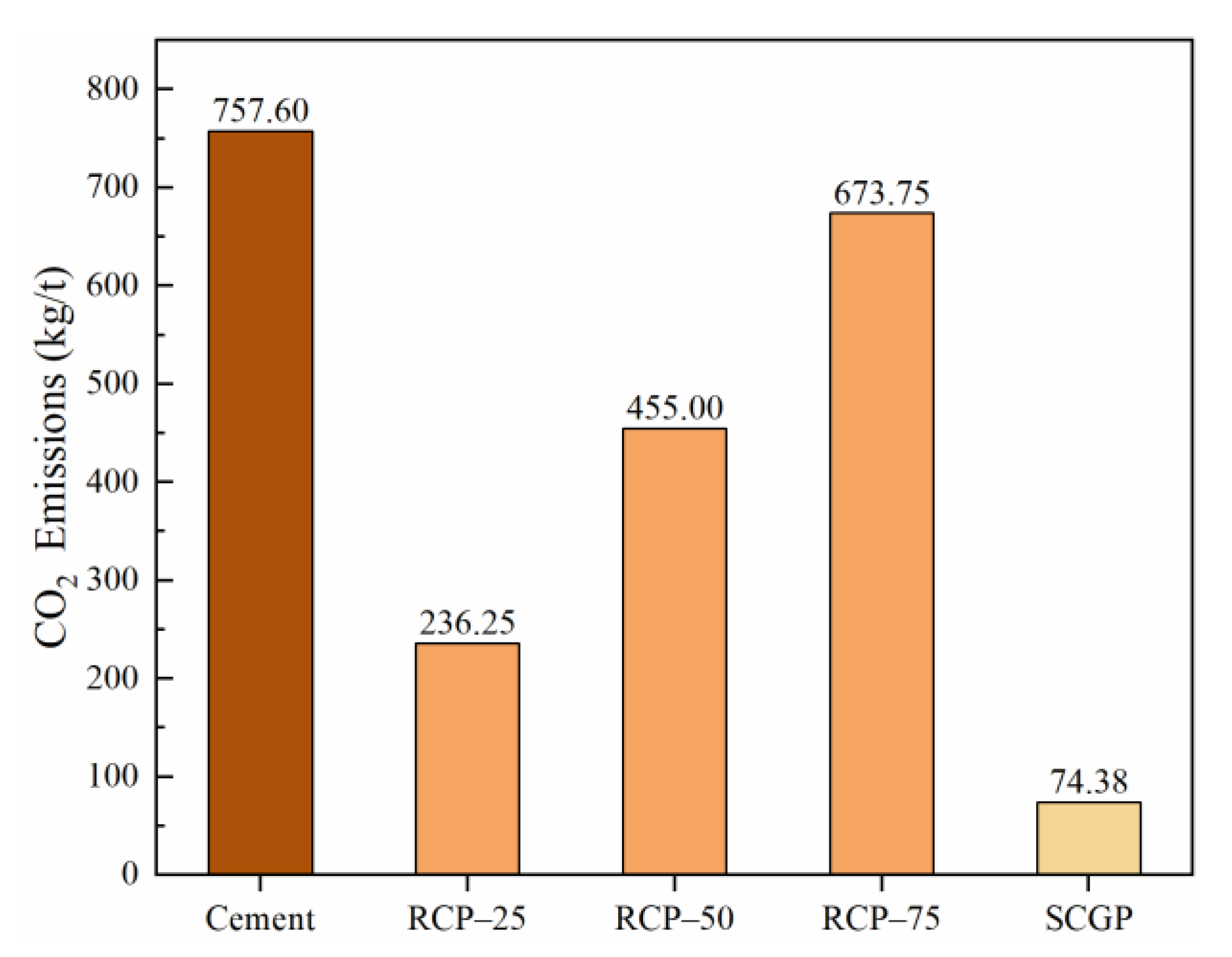

3.2.1. CO2 Emissions Analysis

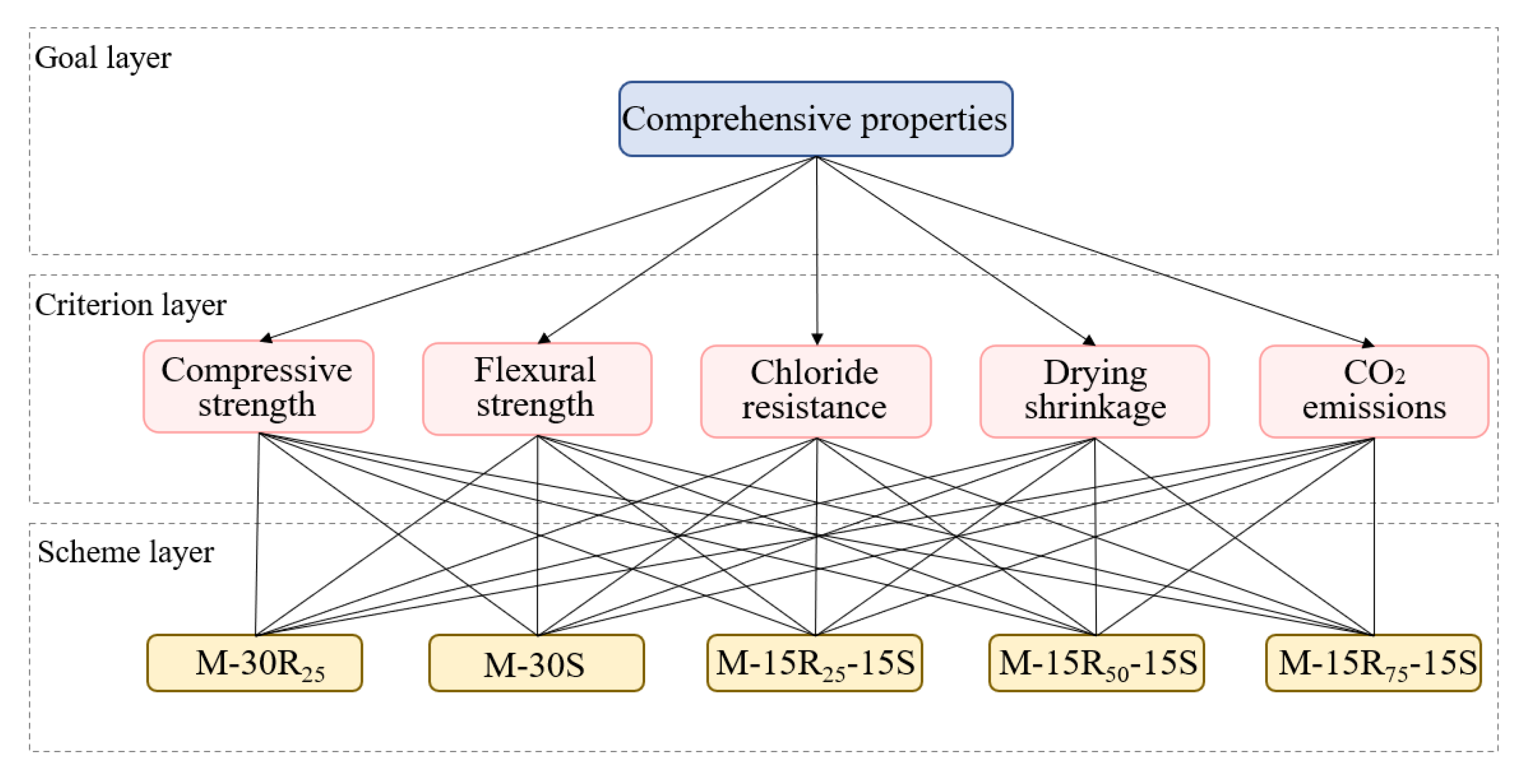

3.2.2. AHP Model

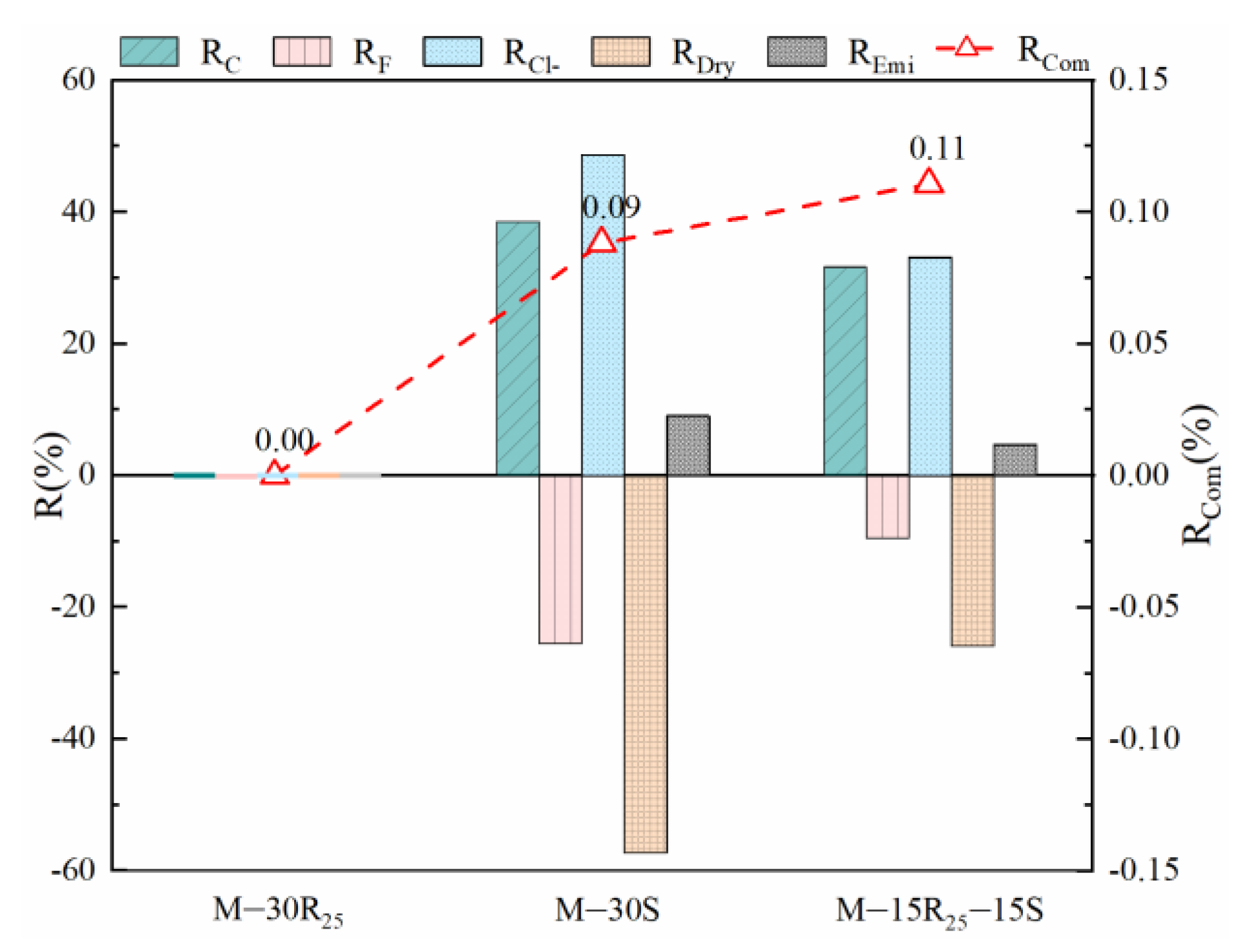

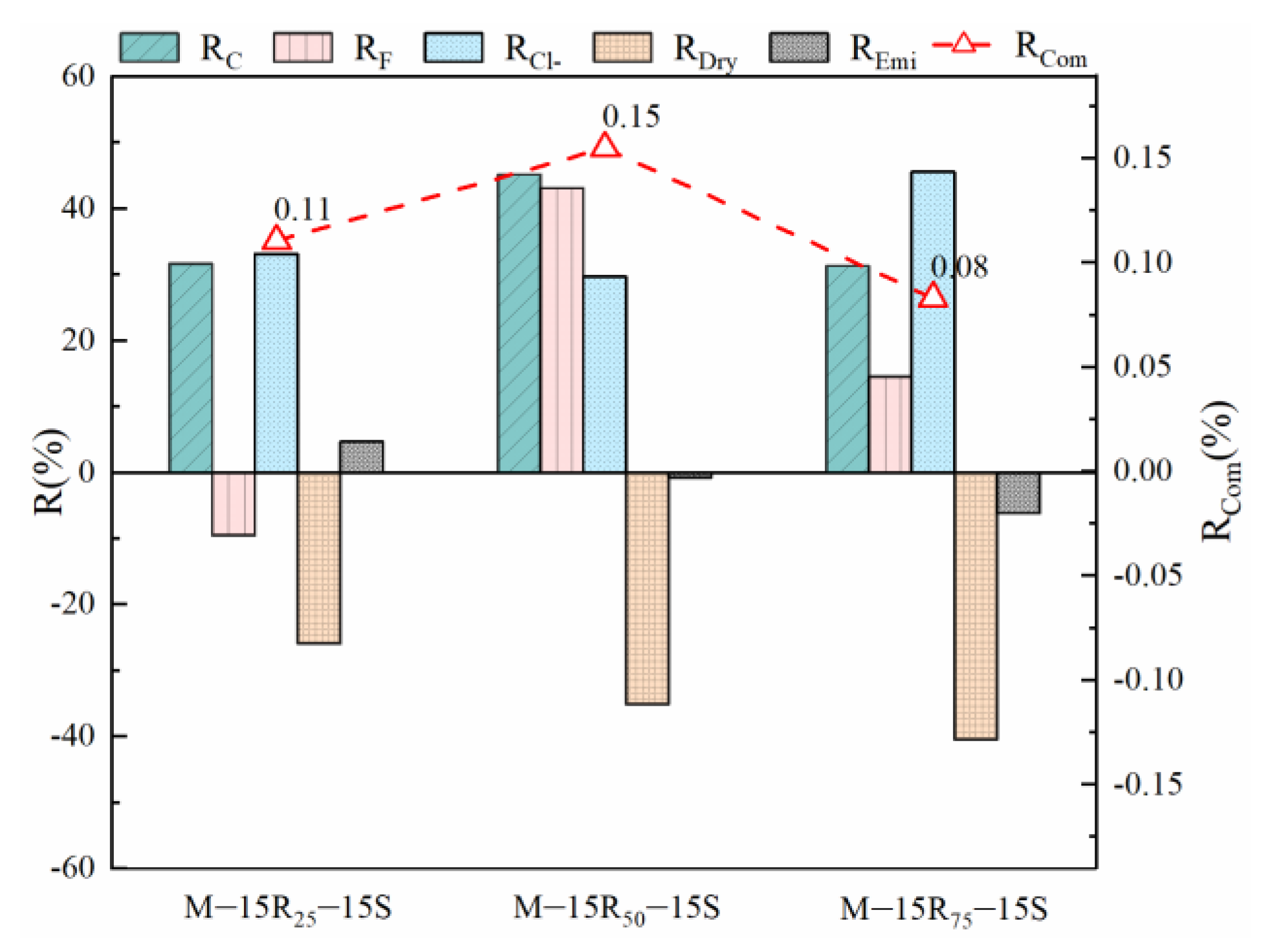

3.2.3. Optimized Mixtures Proportion Analysis

4. Conclusions

- Attributed to the acceptable pozzolanic activity of SCGP, the mortar containing SCGP shows high compressive strength and chloride resistance. The incorporation of RCP contributes to improving the flexural strength and dry shrinkage resistance of mortar, which results from the filling ability of RCP. The eco-efficient mortar containing 15% RCP + 15% SCGP shows relatively good mechanical and long-term properties, which benefit from the synergetic effect of RCP and SCGP.

- The grinding process leads to a little improvement in the pozzolanic activity. The improvement of RCP powder fineness will be limited when the grinding time exceeds 50 min. Compared to RCP ground for under 25 min, increasing the grinding time to 50 min is beneficial to the mechanical properties of mortar but unfavorable to the long-term properties. The fusion and aggregation between RCP particles observed after 75 min of grinding lead to inferior properties of M-15R75-15S compared to M-15R50-15S.

- Among all binder materials, cement production produces the highest CO2 emissions. Influenced by the relatively immature production process of RCP, the CO2 emission from M-30S is less than that from M-30R25. Although inferior to SCGP, RCP ground for 75 min still emits 11.07% lower CO2 than cement production. Realizing the reuse of solid waste as substitutes for cement will be the appropriate method to reduce carbon emissions in the construction industry.

- Through the AHP model, the priority of various influencing factors, including mechanical properties, long-term performance, and carbon emission, on the fundamental performance is determined. As per the fundamental evaluation of this paper, M-15R50-15S performs the best. For different engineering applications, the evaluation priority needs to be adjusted to achieve the optimal use of solid waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pierrehumbert, R. There is no Plan B for dealing with the climate crisis. Bull. At. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef] [Green Version]

- Eurostat. 2017, CO2 Emissions in the EU Estimated to Have Increased Compared with 2016; European Comission: Bruselss, Belgium, 2018; pp. 2016–2017.

- Eurostat. 2018, CO2 Emissions in the EU Decreased Compared with 2017; European Comission: Bruselss, Belgium, 2019.

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Xiao, J.; Xiao, Y.; Liu, Y.; Ding, T. Carbon emission analyses of concretes made with recycled materials considering CO2 uptake through carbonation absorption. Struct. Concr. 2021, 22, E58–E73. [Google Scholar] [CrossRef]

- Mora-Ortiz, R.S.; Del Angel-Meraz, E.; Díaz, S.A.; Magaña-Hernández, F.; Munguía-Balvanera, E.; Pantoja Castro, M.A.; Alavez-Ramírez, J.; Quiroga, L.A. Effect of pre-wetting recycled mortar aggregate on the mechanical properties of masonry mortar. Materials 2021, 14, 1547. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing waste to landfill: A need for cultural change in the UK construction industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Istrate, I.-R. Construction and Demolition Waste Management; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780128190555. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A.; Kadiri, K.O. Waste effectiveness of the construction industry: Understanding the impediments and requisites for improvements. Resour. Conserv. Recycl. 2015, 102, 101–112. [Google Scholar] [CrossRef]

- National Development and Reform Commission. Development Plan of Circular Economy in the 14th Five Year Plan; National Development and Reform Commission: Beijing, China, 2021.

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Changxin Wang, C.; Tam, V.W.Y. Effective construction and demolition waste management assessment through waste management hierarchy; a case of Australian large construction companies. J. Clean. Prod. 2021, 312, 127790. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Changxin Wang, C.; Vivian, W.Y.T. A conceptual foundation for effective construction and demolition waste management. Clean. Eng. Technol. 2020, 1, 100019. [Google Scholar] [CrossRef]

- Mora-Ortiz, R.S.; Munguía-Balvanera, E.; Díaz, S.A.; Magaa-Hernández, F.; Bolaina-Juárez, L. Mechanical Behavior of Masonry Mortars Made with Recycled Mortar Aggregate. Materials 2020, 13, 2373. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of dimensional stone waste in concrete: A review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Torres-Gómez, A.I.; Ledesma, E.F.; Otero, R.; Fernández, J.M.; Jiménez, J.R.; de Brito, J. Combined effects of non-conforming fly ash and recycled masonry aggregates on mortar properties. Materials 2016, 9, 729. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Gao, Y.; Zhang, J.; Zhang, C.; Chen, J.; Liu, C. Effect of particle size and thermal activation on the coal gangue based geopolymer. Mater. Chem. Phys. 2021, 267, 124657. [Google Scholar] [CrossRef]

- Li, M.; Li, A.; Zhang, J.; Huang, Y.; Li, J. Effects of particle sizes on compressive deformation and particle breakage of gangue used for coal mine goaf backfill. Powder Technol. 2020, 360, 493–502. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, X.; Hu, S.; Shao, H.; Liao, Q.; Fan, Y. Experimental study of the effects of stacking modes on the spontaneous combustion of coal gangue. Process Saf. Environ. Prot. 2019, 123, 39–47. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Li, A.; Zhou, N. Reutilisation of coal gangue and fly ash as underground backfill materials for surface subsidence control. J. Clean. Prod. 2020, 254, 120113. [Google Scholar] [CrossRef]

- Parameswari, K.; Majid Salim Al Aamri, A.; Gopalakrishnan, K.; Arunachalam, S.; Ali Said Al Alawi, A.; Sivasakthivel, T. Sustainable landfill design for effective municipal solid waste management for resource and energy recovery. Mater. Today Proc. 2021, 47, 2441–2449. [Google Scholar] [CrossRef]

- Safiuddin, M.; Alengaram, U.J.; Rahman, M.M.; Salam, M.A.; Jumaat, M.Z. Use of recycled concrete aggregate in concrete: A review. J. Civ. Eng. Manag. 2013, 19, 796–810. [Google Scholar] [CrossRef]

- Kabir, S.; Al-Shayeb, A.; Khan, I.M. Recycled Construction Debris as Concrete Aggregate for Sustainable Construction Materials. Procedia Eng. 2016, 145, 1518–1525. [Google Scholar] [CrossRef] [Green Version]

- Roque, S.; Pederneiras, C.M.; Farinha, C.B.; Brito, J.D.; Veiga, R. Concrete-Based and Mixed Waste Aggregates in Rendering Mortars. Materials 2020, 13, 1976. [Google Scholar] [CrossRef] [Green Version]

- Fan, C.C.; Huang, R.; Hwang, H.; Chao, S.J. The effects of different fine recycled concrete aggregates on the properties of Mortar. Materials 2015, 8, 2658–2672. [Google Scholar] [CrossRef] [Green Version]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Ma, X.; Wang, Z. Effect of Ground Waste Concrete Powder on Cement Properties. Adv. Mater. Sci. Eng. 2013, 2013, 918294. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Ho, H.J.; Iizuka, A.; Shibata, E.; Tomita, H.; Takano, K.; Endo, T. CO2 utilization via direct aqueous carbonation of synthesized concrete fines under atmospheric pressure. ACS Omega 2020, 5, 15877–15890. [Google Scholar] [CrossRef]

- Ho, H.J.; Iizuka, A.; Shibata, E. Chemical recycling and use of various types of concrete waste: A review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Kim, Y.J.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Sun, C.; Chen, L.; Xiao, J.; Singh, A.; Zeng, J. Compound utilization of construction and industrial waste as cementitious recycled powder in mortar. Resour. Conserv. Recycl. 2021, 170, 105561. [Google Scholar] [CrossRef]

- Florea, M.V.A.; Ning, Z.; Brouwers, H.J.H. Activation of liberated concrete fines and their application in mortars. Constr. Build. Mater. 2014, 50, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Menéndez, G.; Bonavetti, V.; Irassar, E.F. Strength development of ternary blended cement with limestone filler and blast-furnace slag. Cem. Concr. Compos. 2003, 25, 61–67. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Zhang, N.; Sun, H.; Liu, X.; Zhang, J. Early-age characteristics of red mud-coal gangue cementitious material. J. Hazard. Mater. 2009, 167, 927–932. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, T.C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- García-Giménez, R.; Frías, M.; Arribas, I.; Vegas, I.; de la Villa, R.V.; Rubio, V. Freeze-thaw effect on the durability of binary cements containing activated coal-mining waste. Constr. Build. Mater. 2018, 190, 140–149. [Google Scholar] [CrossRef]

- GB175-2007. Common Portland Cement; Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2007; p. 30.

- GB/T17671-1999. Method of Testing Cements-Determination of Strength; The State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- JGJ55-2011. Specification for Mix Proportion Design of Ordinary Concrete; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- JGJ-T70-2009. Standard for Test Method of Performance on Building Mortar; Ministry of Construction of the People’s Republic of China: Beijing, China, 2009; p. 17.

- GB/T50082-2009. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- ASTM:C157/C157M-08. Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete; ASTM International: West Conshohocken, PA, USA, 2008; Volume 8, pp. 1–7. [CrossRef]

- ASTMC618-19. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019.

- Ghrici, M.; Kenai, S.; Said-Mansour, M. Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem. Concr. Compos. 2007, 29, 542–549. [Google Scholar] [CrossRef]

- Mao, X.; Qu, W.; Zhu, P. Mixture Optimization of Green Reactive Powder Concrete with Recycled Powder. J. Mater. Civ. Eng. 2019, 31, 04019033. [Google Scholar] [CrossRef]

- Elfmarkova, V.; Spiesz, P.; Brouwers, H.J.H. Determination of the chloride diffusion coefficient in blended cement mortars. Cem. Concr. Res. 2015, 78, 190–199. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Shi, C.; Shi, Z.; Zhang, L. Compressive strength, pore structure and chloride transport properties of alkali-activated slag/fly ash mortars. Cem. Concr. Compos. 2019, 104, 103392. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Tang, X. Studies on the activation of phosphorus slag. In Proceedings of the 3rd International Conference on the Use of Fly Ash, New Delhi, India, 19–21 February 1989. [Google Scholar]

- Liu, C.; Yang, L.; Wang, F.; Hu, S. Enhance the durability of heat-cured mortars by internal curing and pozzolanic activity of lightweight fine aggregates. Constr. Build. Mater. 2021, 270, 121439. [Google Scholar] [CrossRef]

- Florea, M.V.A.; Brouwers, H.J.H. Chloride binding related to hydration products: Part I: Ordinary Portland Cement. Cem. Concr. Res. 2012, 42, 282–290. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Hooton, R.D.; Scott, A.; Zibara, H. The effect of supplementary cementitious materials on chloride binding in hardened cement paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Melo Neto, A.A.; Cincotto, M.A.; Repette, W. Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Autogenous relative humidity change and autogenous shrinkage of high-performance cement pastes. Cem. Concr. Res. 2005, 35, 1539–1545. [Google Scholar] [CrossRef]

- Zhang, W.; Hama, Y.; Na, S.H. Drying shrinkage and microstructure characteristics of mortar incorporating ground granulated blast furnace slag and shrinkage reducing admixture. Constr. Build. Mater. 2015, 93, 267–277. [Google Scholar] [CrossRef]

- Ye, H.; Cartwright, C.; Rajabipour, F.; Radlińska, A. Understanding the drying shrinkage performance of alkali-activated slag mortars. Cem. Concr. Compos. 2017, 76, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Alex, T.C.; Kumar, R.; Roy, S.K.; Mehrotra, S.P. Mechanically induced reactivity of gibbsite: Part 1. Planetary milling. Powder Technol. 2014, 264, 105–113. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Ma, Z.; Sun, X. Eco-friendly treatment of coal gangue for its utilization as supplementary cementitious materials. J. Clean. Prod. 2021, 285, 124834. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; Su, Y.; He, X.; Tan, H.; Yang, W.; Strnadel, B. Eco-friendly treatment of low-calcium coal fly ash for high pozzolanic reactivity: A step towards waste utilization in sustainable building material. J. Clean. Prod. 2019, 238, 117962. [Google Scholar] [CrossRef]

- Kumar, S.; Mucsi, G.; Kristály, F.; Pekker, P. Mechanical activation of fly ash and its influence on micro and nano-structural behaviour of resulting geopolymers. Adv. Powder Technol. 2017, 28, 805–813. [Google Scholar] [CrossRef]

- Liang, C.; Cai, Z.; Wu, H.; Xiao, J.; Zhang, Y.; Ma, Z. Chloride transport and induced steel corrosion in recycled aggregate concrete: A review. Constr. Build. Mater. 2021, 282, 122547. [Google Scholar] [CrossRef]

- Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W. Climate Change 2014 Synthesis Report: Summary for Policymakers; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2014. [Google Scholar]

- European Environment Agency. Closing the Loop: An EU Action Plan for the Circular Economy; European Environment Agency: København, Denmark, 2017.

- Liu, Q.; Li, B.; Xiao, J.; Singh, A. Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Constr. Build. Mater. 2020, 238, 117721. [Google Scholar] [CrossRef]

- Yu, S.; Wei, Y.M.; Guo, H.; Ding, L. Carbon emission coefficient measurement of the coal-to-power energy chain in China. Appl. Energy 2014, 114, 290–300. [Google Scholar] [CrossRef]

- Reffold, E.; Leighton, F.; Choudhury, F.; Rayner, P.S. Greenhouse Gas Emissions of Water Supply and Demand Management Options; The Environment Agency: Bristol, UK, 2008; ISBN 9781844329212.

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Kalinowska-Wichrowska, K.; Fernández, J.M.; Jiménez, J.R. Accelerated carbonation of fresh cement-based products containing recycled masonry aggregates for CO2 sequestration. J. CO2 Util. 2021, 46, 101461. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef] [Green Version]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Saaty, R.W. The analytic hierarchy process-what it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef] [Green Version]

| Material | Chemical Composition (%) | Physical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Al2O3 | Fe2O3 | K2O | SO3 | TiO2 | Na2O | Specific Surface Area (m2/g) | Density (g/cm3) | |

| PC | 17.77 | 63.88 | 7.03 | 5.41 | 0.97 | 1.54 | 0.68 | 0.16 | 10.96 | 3.15 |

| SCGP | 52.64 | 0.96 | 42.2 | 0.99 | 0.71 | 0.68 | 1.3 | 0.13 | 8.23 | 2.72 |

| RCP | 37.01 | 24.22 | 13.09 | 9.86 | 2.75 | 1.41 | 1.03 | 0.71 | 13.17 | 3.15 |

| No. | Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| A | SCMs | RCP | SCGP | RCP + SCGP |

| B | RCP grinding time | 25 min | 50 min | 75 min |

| Mix No | Mix ID | W/B | Sand (kg/m3) | OPC (kg/m3) | RCP (kg/m3) | SCGP (kg/m3) |

|---|---|---|---|---|---|---|

| RM1 | M-30R25 | 0.4 | 1309 | 493.5 | 211.5 | 0 |

| RM2 | M-30S | 0.4 | 1294 | 488 | 0 | 209 |

| RM3 | M-15R25-15S | 0.4 | 1301 | 490 | 105 | 105 |

| RM4 | M-15R50-15S | 0.4 | 1301 | 490 | 105 | 105 |

| RM5 | M-15R75-15S | 0.4 | 1301 | 490 | 105 | 105 |

| Item | Cement | RCP (25, 50, 75 min) | SCGP | Sand |

|---|---|---|---|---|

| Raw material transport (kg/t) | 0.678 | 6.400 | 6.400 | 0.422 |

| Solid waste landfill (kg/t) | 0 | 1.055 | 1.055 | 0 |

| Solid waste transport (kg/t) | 0 | 4.523 | 4.523 | 0 |

| Intensity of Importance on an Absolute Scale | Definition |

|---|---|

| 1 | Equal importance |

| 3 | Moderate importance |

| 5 | Obviously important |

| 7 | Strong importance |

| 9 | Extremely important |

| 2, 4, 6, 8 | Intermediate values between the two adjacent judgments |

| Reciprocal | aji = 1/aij |

| Factors | Compressive Strength | Flexural Strength | Chloride Resistance | Dry Shrinkage | Carbon Emissions | Priority |

|---|---|---|---|---|---|---|

| Compressive strength | 1 | 5 | 3 | 2 | 2 | 0.379 |

| Flexural strength | 1/5 | 1 | 1/3 | 1/4 | 1/4 | 0.056 |

| Chloride resistance | 1/3 | 3 | 1 | 1/2 | 1/2 | 0.127 |

| Dry shrinkage | 1/2 | 4 | 2 | 1 | 1 | 0.219 |

| Carbon emissions | 1/2 | 4 | 2 | 1 | 1 | 0.219 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; Chen, L.; Xiao, J.; Liu, Q.; Zuo, J. Low-Carbon and Fundamental Properties of Eco-Efficient Mortar with Recycled Powders. Materials 2021, 14, 7503. https://doi.org/10.3390/ma14247503

Sun C, Chen L, Xiao J, Liu Q, Zuo J. Low-Carbon and Fundamental Properties of Eco-Efficient Mortar with Recycled Powders. Materials. 2021; 14(24):7503. https://doi.org/10.3390/ma14247503

Chicago/Turabian StyleSun, Chang, Lulu Chen, Jianzhuang Xiao, Qiong Liu, and Junqing Zuo. 2021. "Low-Carbon and Fundamental Properties of Eco-Efficient Mortar with Recycled Powders" Materials 14, no. 24: 7503. https://doi.org/10.3390/ma14247503

APA StyleSun, C., Chen, L., Xiao, J., Liu, Q., & Zuo, J. (2021). Low-Carbon and Fundamental Properties of Eco-Efficient Mortar with Recycled Powders. Materials, 14(24), 7503. https://doi.org/10.3390/ma14247503