High-Power Fiber Laser Welding of High-Strength AA7075-T6 Aluminum Alloy Welds for Mechanical Properties Research

Abstract

:1. Introduction

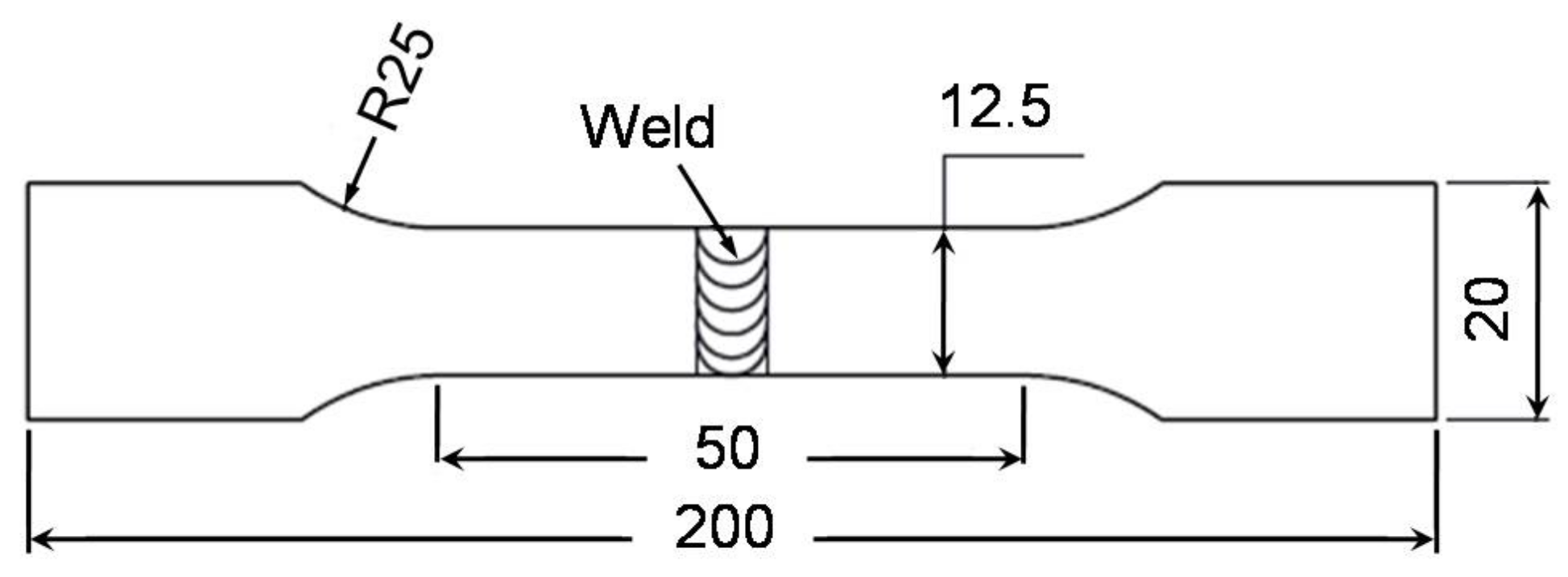

2. Materials and Methods

3. Results and Discussion

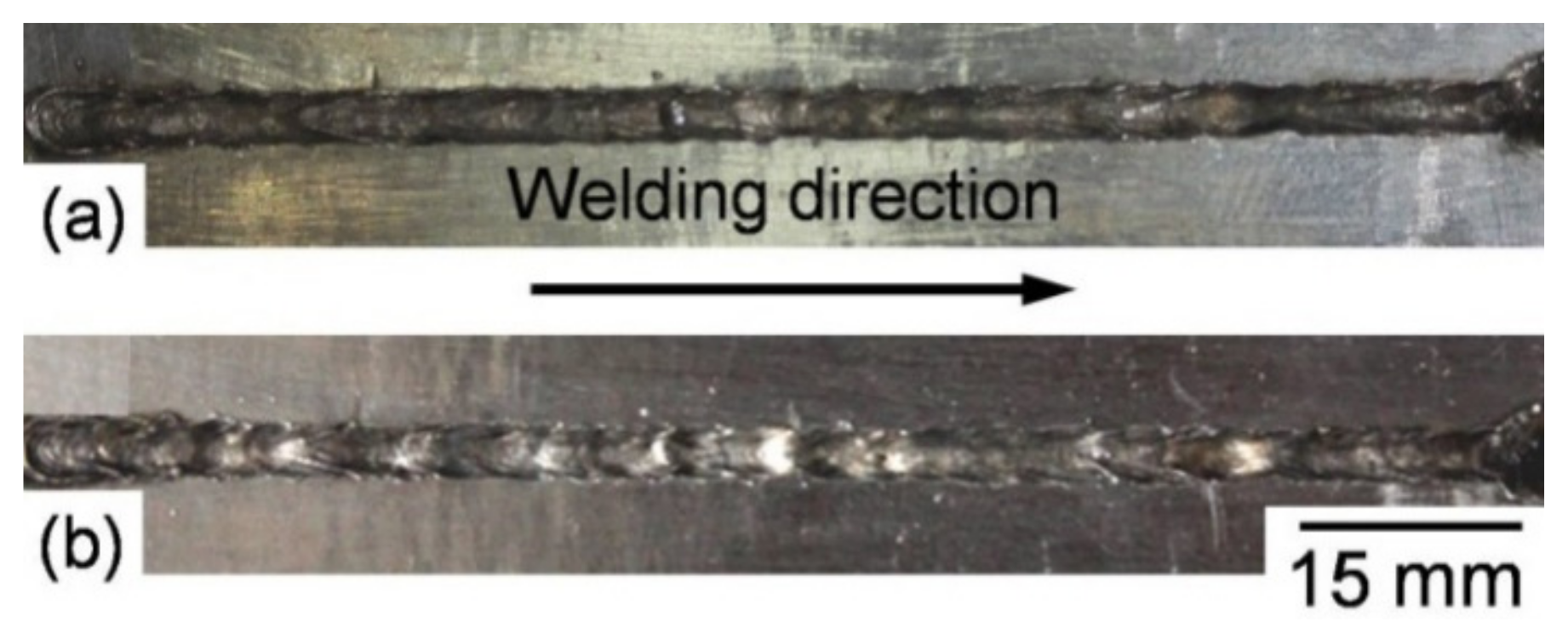

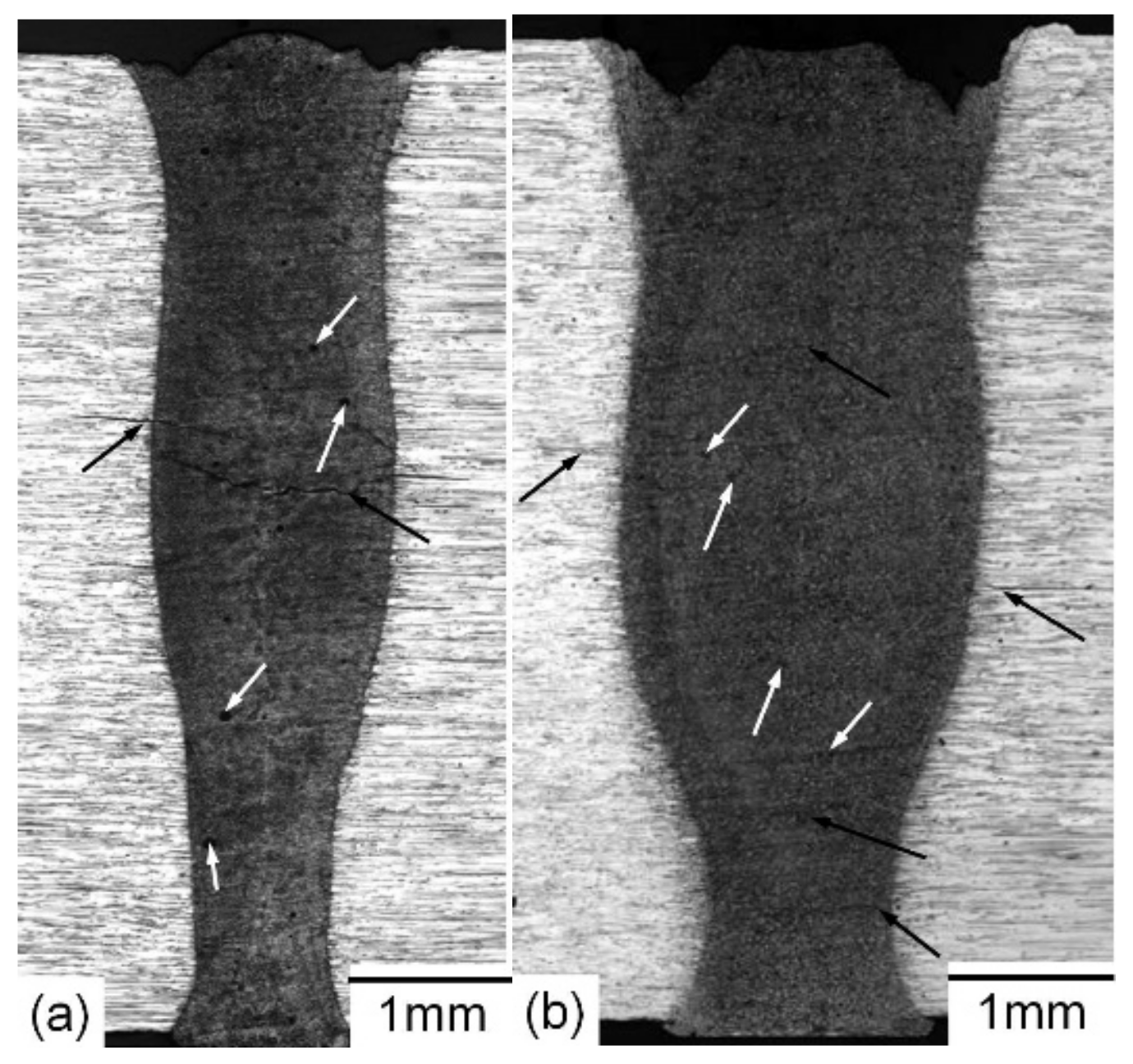

3.1. Macrostructure of Laser Beam-Welded Joints

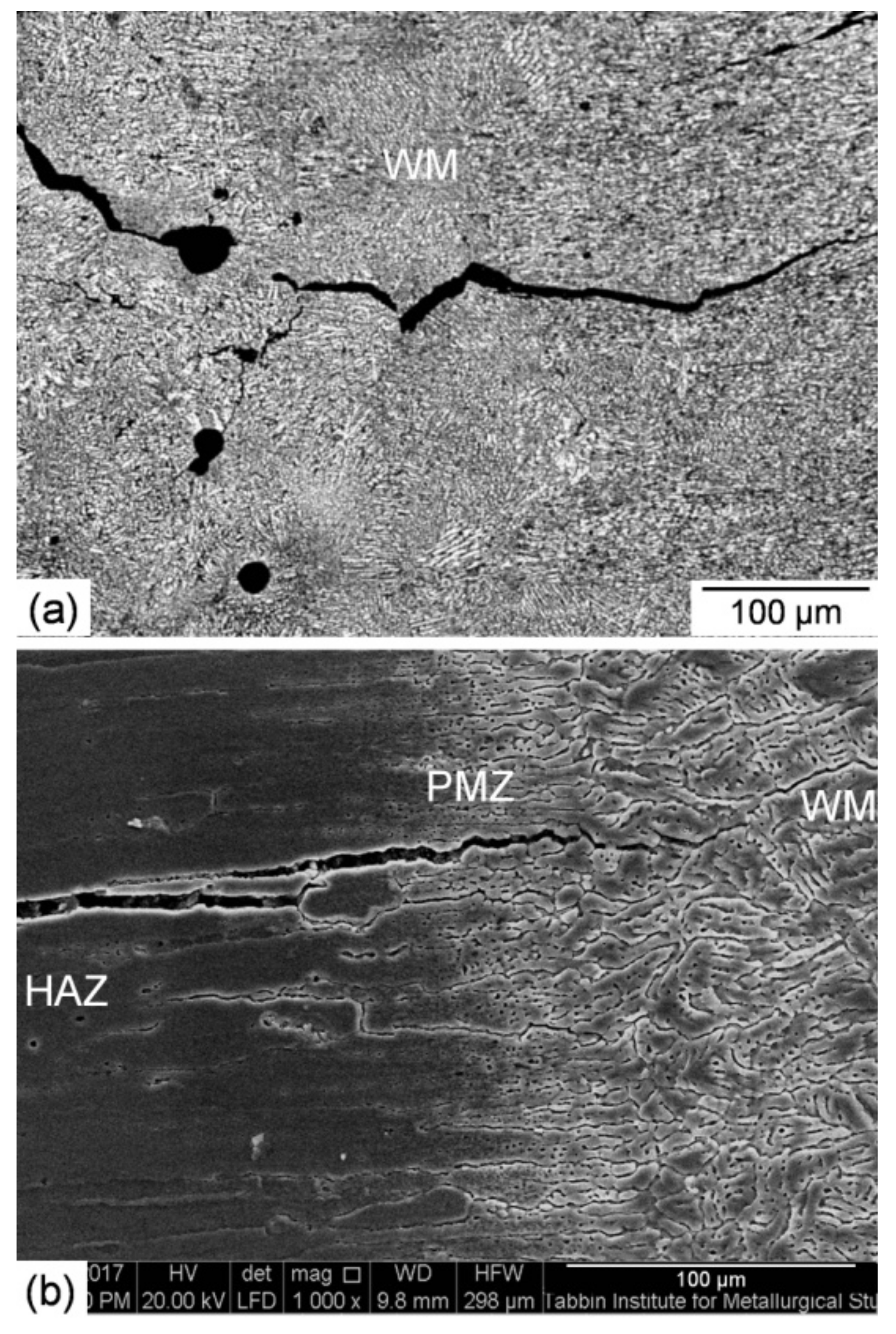

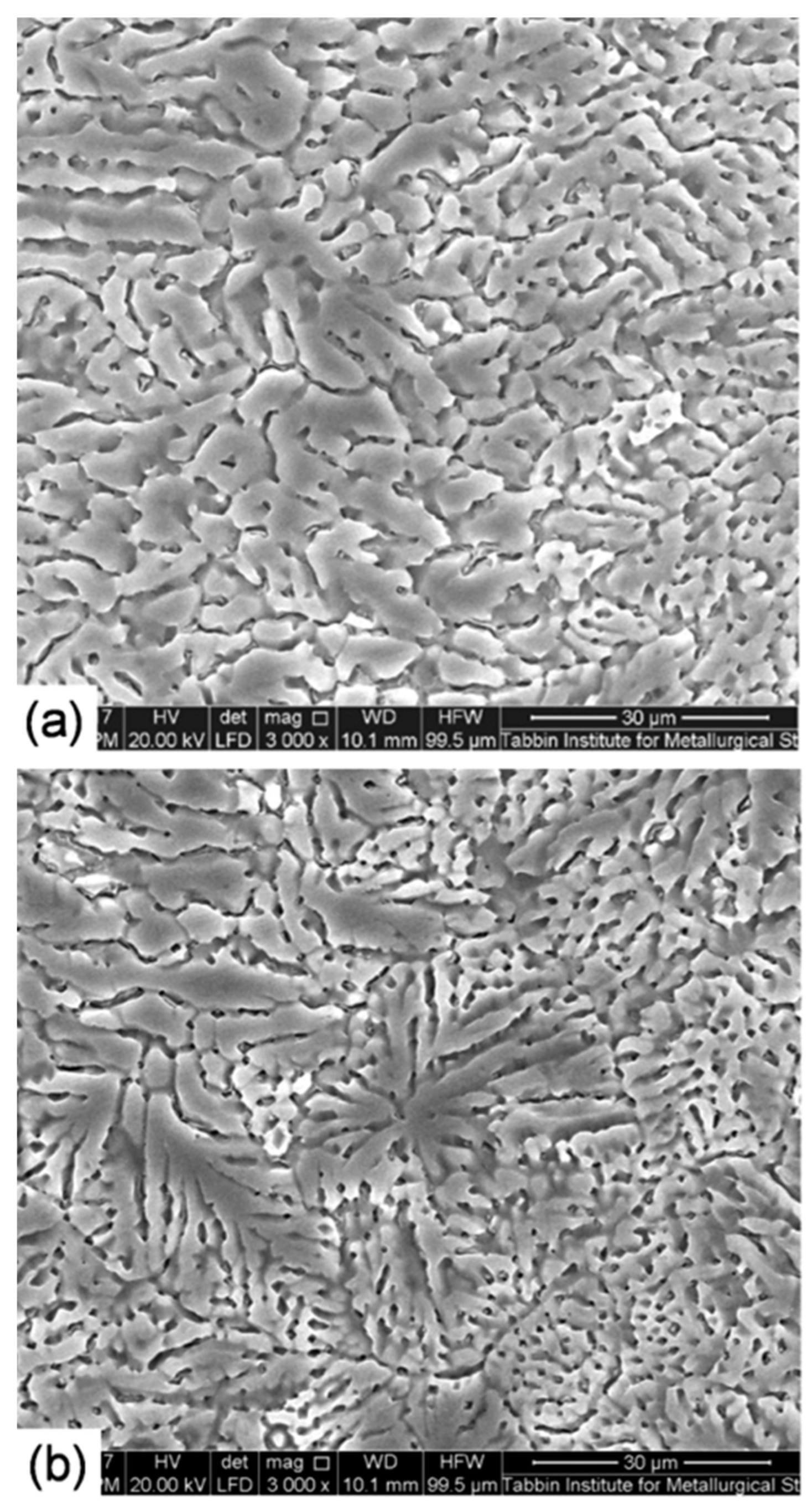

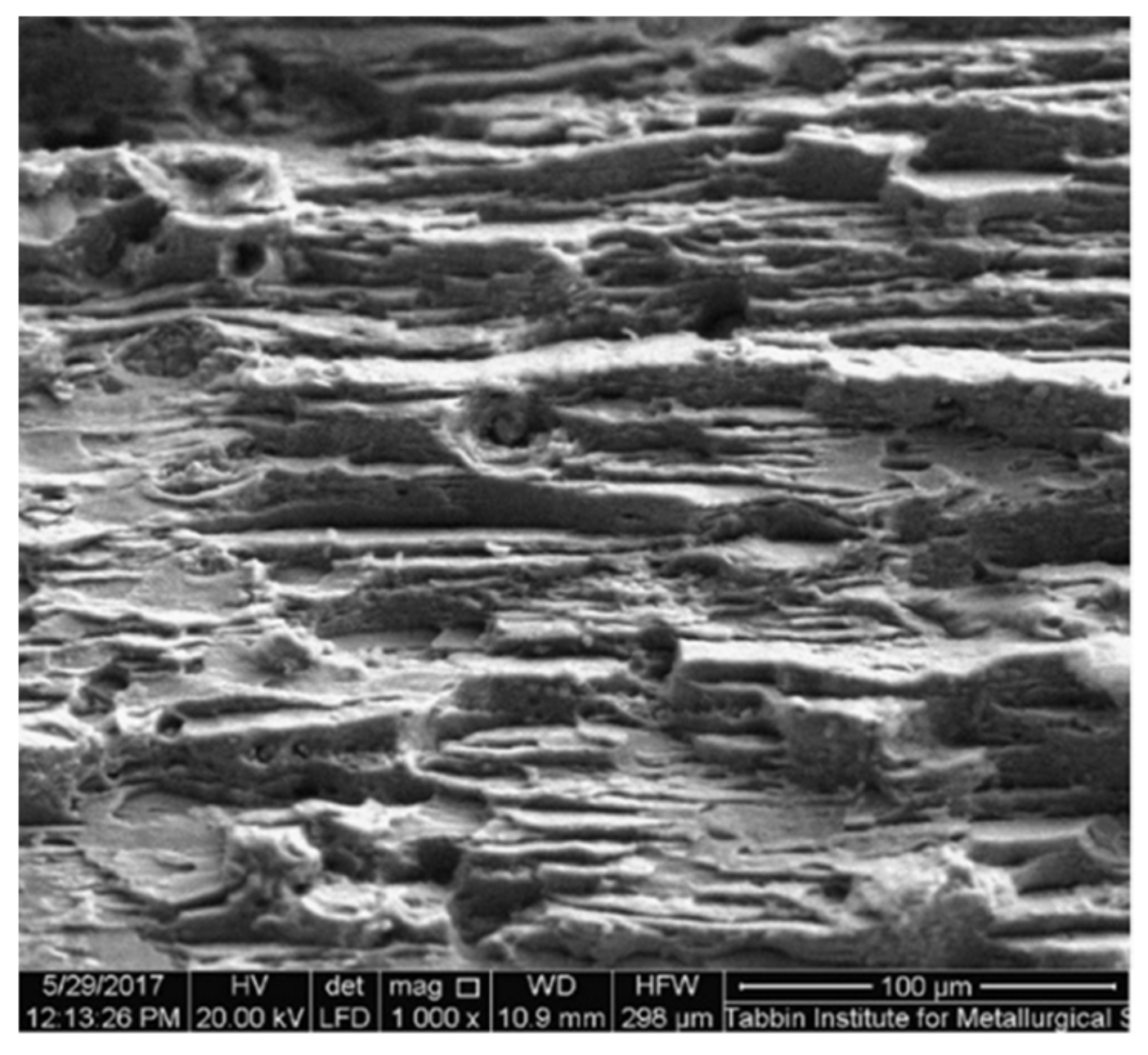

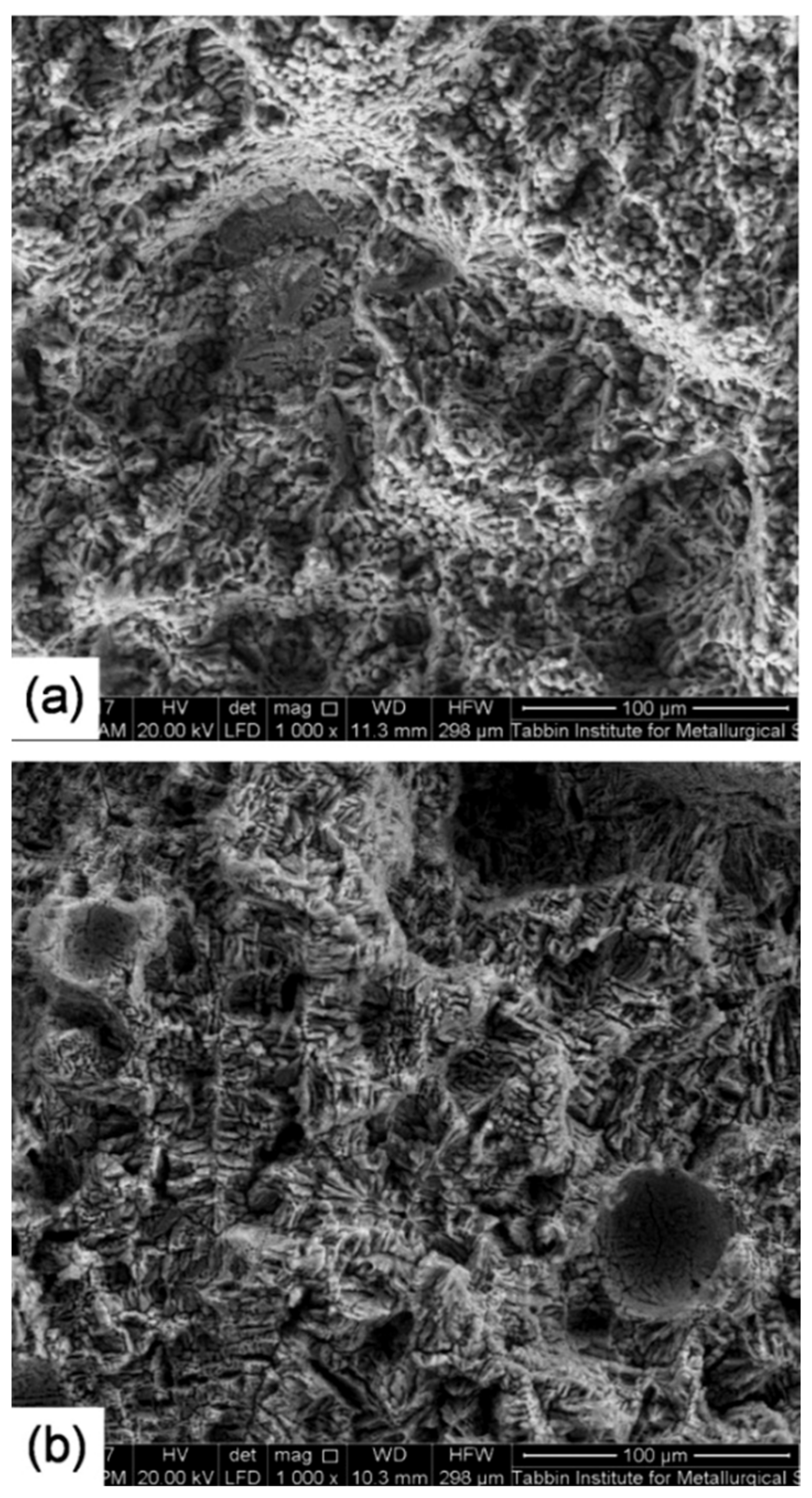

3.2. Microstructure of Laser Beam-Welded Joints

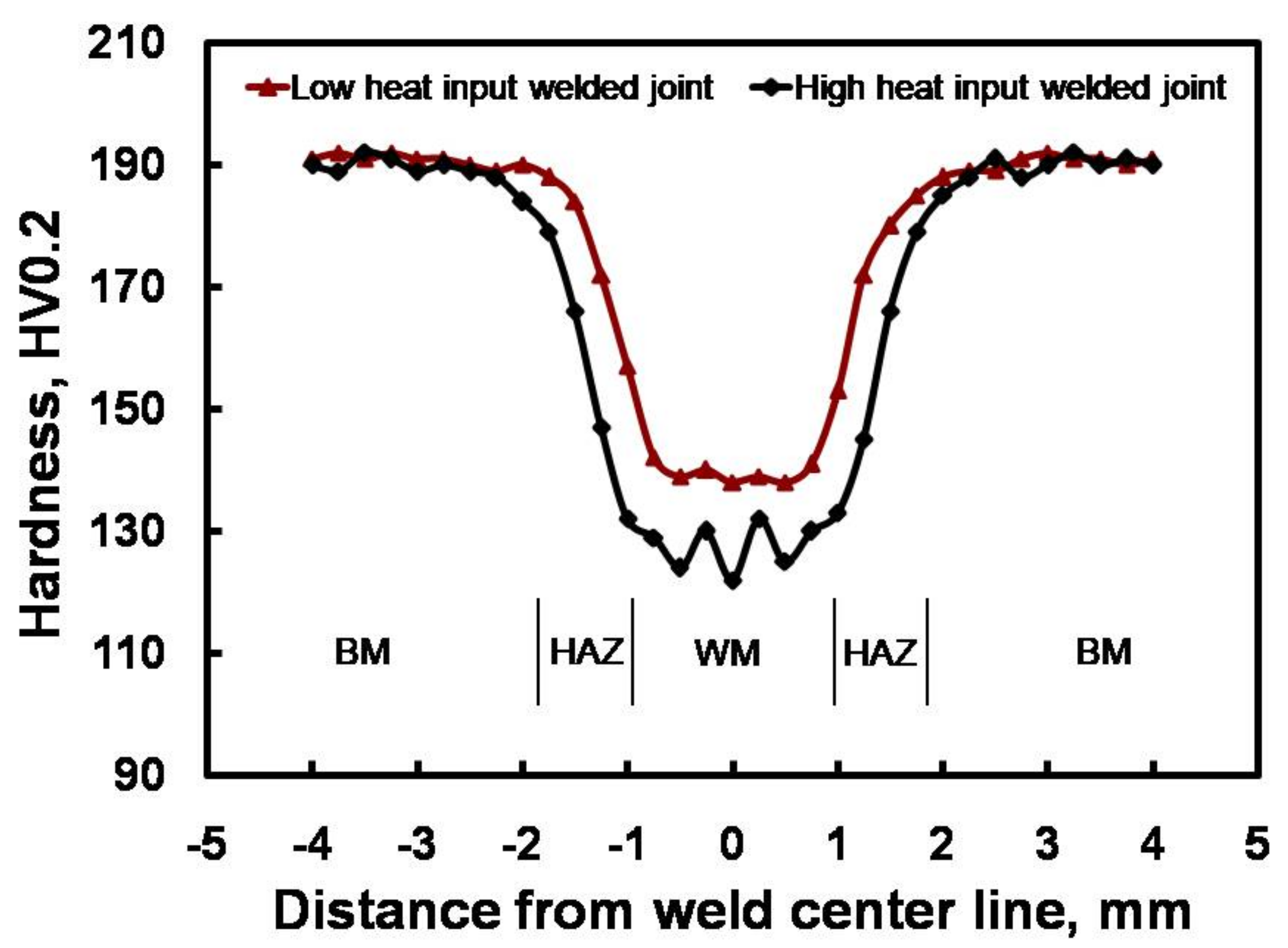

3.3. Hardness Measurements of Welded Joints

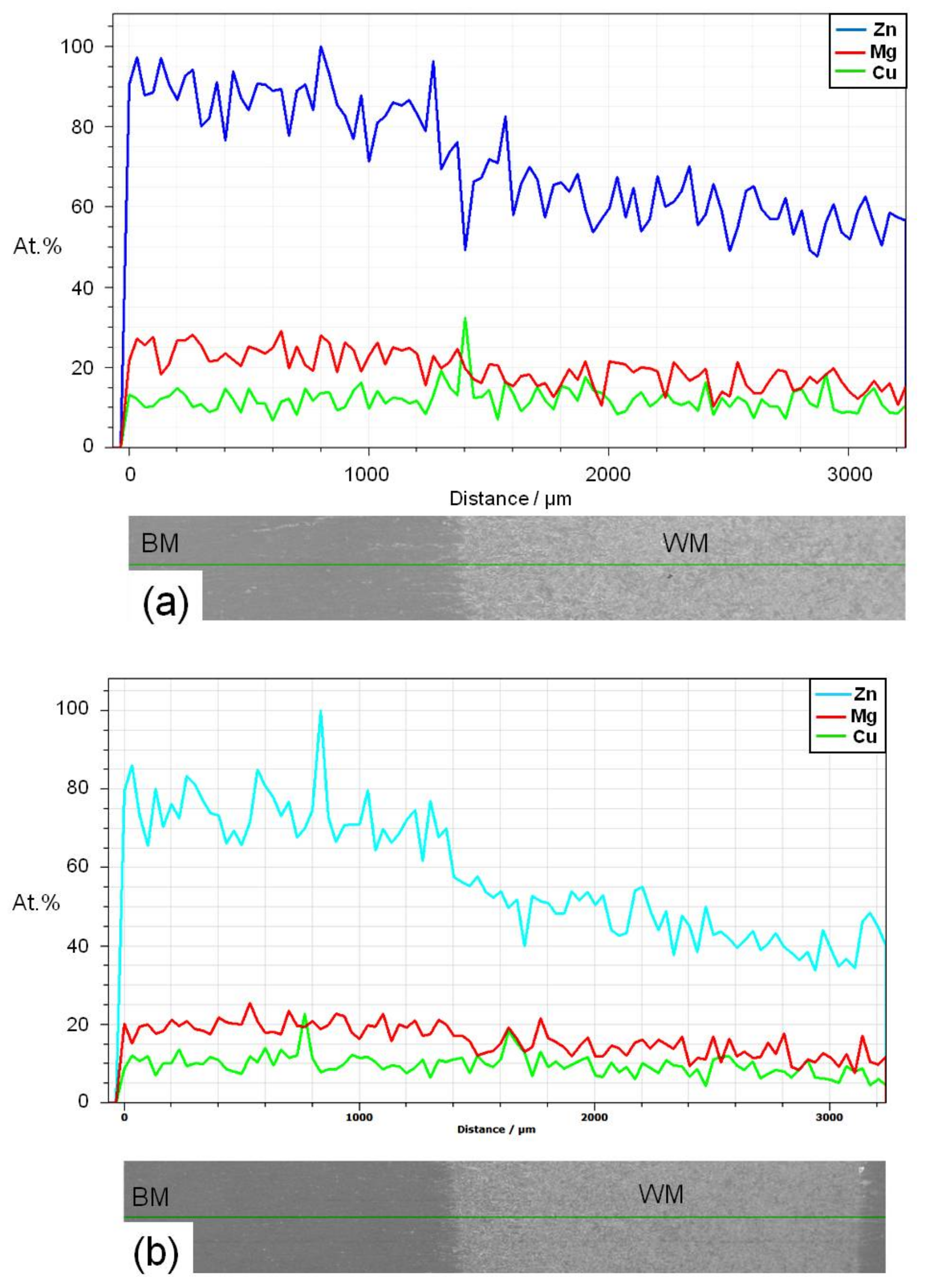

3.4. Micro-Chemical Analysis

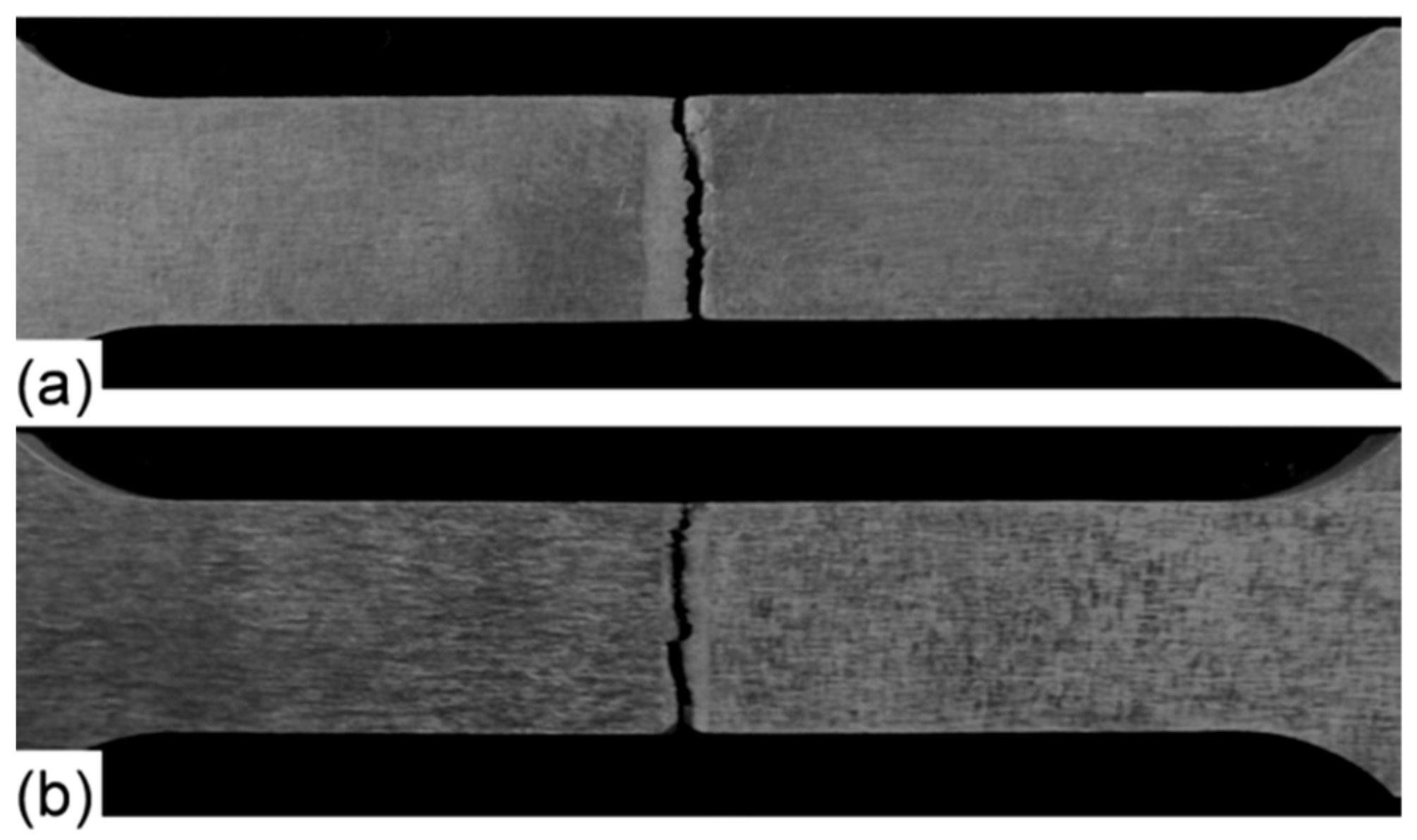

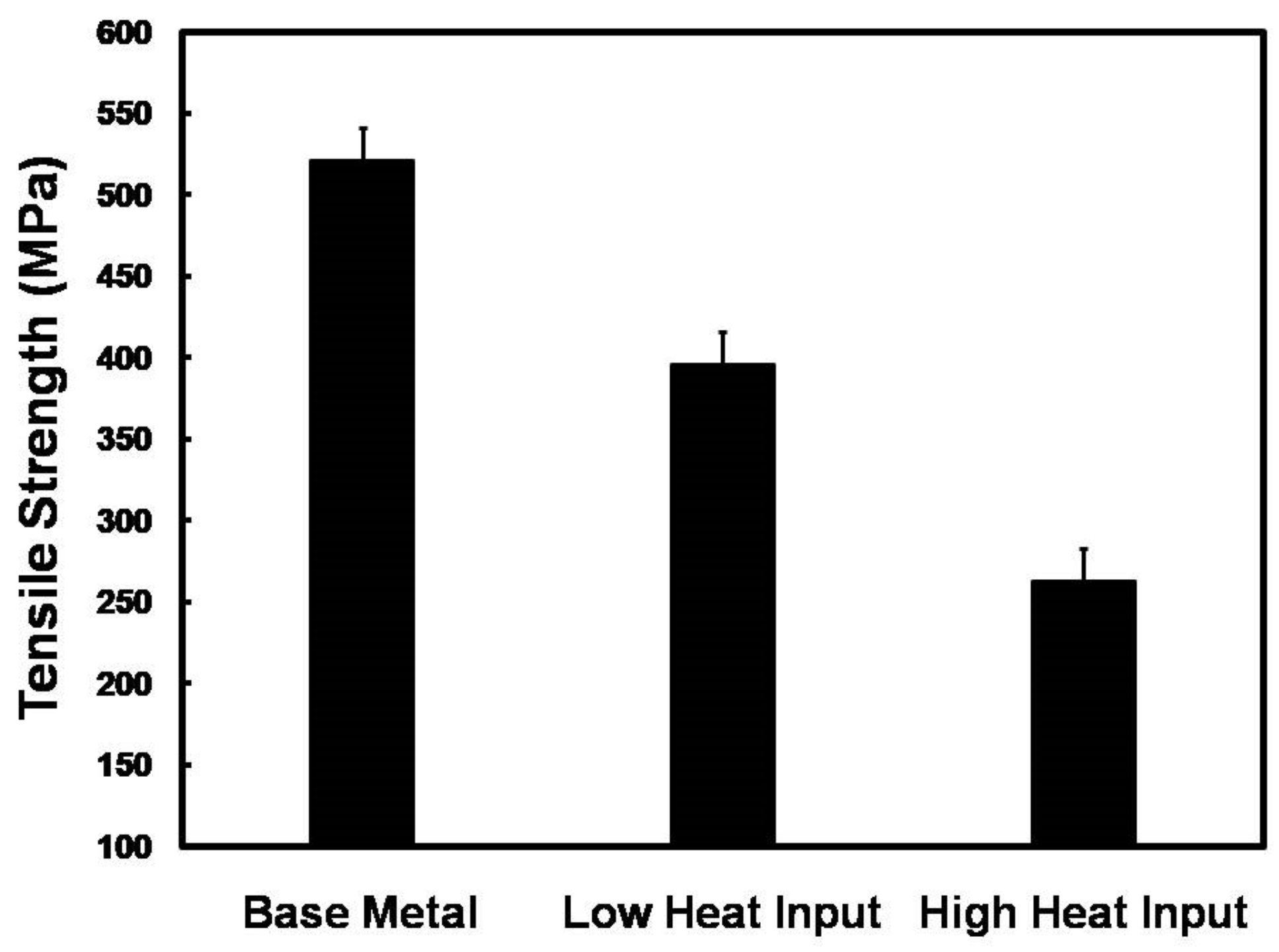

3.5. Tensile Properties of Welded Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 263–339. [Google Scholar]

- Fridlyander, I.N.; Sister, V.G.; Grushko, O.E.; Berstenev, V.V.; Sheveleva, L.M.; Ivanova, L.A. Aluminum alloys: Promising materials in the automotive industry. Met. Sci. Heat Treat. 2002, 44, 365–370. [Google Scholar] [CrossRef]

- Sakurai, T. The latest trends in aluminum alloy sheets for automotive body panels. Kobelco Technol. Rev. 2008, 28, 22–28. [Google Scholar]

- Hirsch, J. Aluminum Alloys for Automotive Application, Materials Science Forum-Mater Sci. Forum; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 1997; Volume 242, pp. 33–50. [Google Scholar]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminum alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Shin, J.; Kim, T.; Kim, D.; Kim, D.; Kim, K. Castability and mechanical properties of new 7xxx aluminum alloys for automotive chassis/body applications. J. Alloys Compd. 2017, 698, 577–590. [Google Scholar] [CrossRef]

- Hirsch, J. Recent development in aluminium for automotive applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Zhou, J.; Wan, X.; Li, Y. Advanced aluminium products and manufacturing technologies applied on vehicles presented at the EuroCarBody conference. Mater. Today Proc. 2015, 2, 5015–5022. [Google Scholar] [CrossRef]

- Li, J.F.; Peng, Z.W.; Li, C.X.; Jia, Z.Q.; Chen, W.J.; Zheng, Z.Q. Mechanical properties, corrosion behaviors and microstructures of 7075 aluminum alloy with various aging treatments. Trans. Nonferrous Met. Soc. China 2008, 18, 755–762. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-Hanzaki, A.; Roostaei, A.A.; Abedi, H.R. An investigation into the hot deformation characteristics of 7075 aluminum alloy. Mater. Des. 2011, 32, 2339–2344. [Google Scholar] [CrossRef]

- Isadare, A.D.; Aremo, B.; Adeoye, M.O.; Olawale, O.J.; Shittu, M.D. Effect of heat treatment on some mechanical properties of 7075 aluminum alloy. Mater. Res 2013, 16, 190–194. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.M.; Chou, C.P.; Lee, I.K.; Lin, H.Y. Hot cracking of welds on heat treatable aluminium alloys. Sci. Technol. Weld. Join. 2005, 10, 344–352. [Google Scholar] [CrossRef]

- Coniglio, N.; Cross, C.E.; Michael, T.; Lammers, M. Defining a critical weld dilution to avoid solidification cracking in aluminum. Weld. J. 2008, 87, 237–247. [Google Scholar]

- Sevim, I.; Hayat, F.; Kaya, Y.; Kahraman, N.; Şahin, S. The study of MIG weldability of heat-treated aluminum alloys. Int. J. Adv. Manuf. Technol. 2013, 66, 1825–1834. [Google Scholar] [CrossRef]

- Lakshminarayanan, A.K.; Balasubramanian, V.; Elangovan, K. Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int. J. Adv. Manuf. Technol. 2009, 40, 286–296. [Google Scholar] [CrossRef]

- Kumar, A.; Milton, M.S. A Comparison of welding techniques of aluminium alloys, A literature review. Int. J. Sci. Res. Sci. Eng. Technol. 2016, 2, 172–175. [Google Scholar]

- Rajan, R.; Kah, P.; Mvola, B.; Martikainen, J. Trends in aluminium alloy development and their joining methods. Rev. Adv. Mater. Sci. 2016, 44, 383–397. [Google Scholar]

- Ola, O.; Doern, F. Fusion weldability studies in aerospace AA7075-T651 using high-power continuous wave laser beam techniques. Mater. Des. 2015, 77, 50–58. [Google Scholar] [CrossRef]

- Hwang, R.Y.; Chou, C.P. The study on microstructural and mechanical properties of weld heat affected zone of 7075-T651 aluminum alloy. Scr. Mater. 1998, 38, 215–221. [Google Scholar] [CrossRef]

- Cross, C.E.; Olson, D.L.; Liu, S. Aluminum Welding, Handbook of Aluminum; Dekker: New York, NY, USA, 2003; Volume 1. [Google Scholar]

- Kang, M.; Kim, C. A review of joining processes for high strength 7xxx series aluminum alloys. J. Weld. Join. 2017, 35, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, A.; Arruti, E.; Janeiro, G.; Aldanondo, E.; Alvarez, P.; Echeverria, A. Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 Aluminum alloys friction stir welds. Mater. Des. 2011, 32, 2021–2027. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints. Acta Mater. 2010, 58, 2056–2067. [Google Scholar] [CrossRef]

- Huang, X.; Scheuring, J.; Reynolds, A.P. FSW of High Strength 7xxx Aluminum Using Four Process Variants. In Friction Stir Welding and Processing VIII; Walt Disney World: Orlando, FL, USA, 2015. [Google Scholar]

- Williams, N.T.; Parker, J.D. Review of resistance spot welding of steel sheets Part 2–Factors influencing electrode life. Int. Mater. Rev. 2004, 49, 77–108. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Manladan, S.M.; Yusof, F.; Ramesh, S.; Fadzil, M.; Luo, Z.; Ao, S. A review on resistance spot welding of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 90, 605–634. [Google Scholar] [CrossRef]

- Han, L.; Thornton, M.; Shergold, M. A comparison of the mechanical behaviour of self-piercing riveted and resistance spot welded aluminum sheets for the automotive industry. Mater. Des. 2010, 31, 1457–1467. [Google Scholar] [CrossRef] [Green Version]

- Cam, G.; Ipekoglu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Cam, G.; Kocak, M. Microstructural and mechanical characterization of electron beam welded Al-alloy 7020. J. Mater. Sci. 2007, 42, 7154–7161. [Google Scholar] [CrossRef]

- Cam, G.; Ventzke, V.; Santos, J.F.D.; Kocak, M.; Jennequin, G.; Gonthier-Maurin, P. Characterization of electron beam welded aluminum alloys. Sci. Technol. Weld. Join. 2013, 4, 317–323. [Google Scholar] [CrossRef]

- El-Batahgy, A.; Kutsuna, M. Laser beam welding of AA5052, AA5083 and AA6061 aluminum alloys. Adv. Mater. Sci. Eng. 2009, 2009, 9. [Google Scholar] [CrossRef] [Green Version]

- Vinas, J.; Abel, M. Analysis of Laser Welds on Automotive Steel Sheets. Mater. Sci. Forum. 2015, 818, 239–242. [Google Scholar] [CrossRef]

- Zhao, H.; White, D.R.; Debroy, T. Current issues and problems in laser welding of automotive aluminum alloys. Int. Mater. Rev. 1999, 44, 238–266. [Google Scholar] [CrossRef]

- Kerstens, N.F.H. Nd:YAG Laser Welding of AA7075 High Strength Aluminium. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2002. [Google Scholar]

- Badini, C.; Pavese, M.; Fino, P.; Biamino, S. Laser beam welding of dissimilar aluminum alloys of 2000 and 7000 series- effect of post-welding thermal treatments on T joint strength. Sci. Technol. Weld. Join. 2009, 14, 484–492. [Google Scholar] [CrossRef]

- Chang, C.C.; Chou, C.P.; Hsu, S.N.; Hsiung, G.Y.; Chen, J.R. Effect of laser welding on properties of dissimilar joint of Al-Mg-Si and Al-Mn aluminum alloys. J. Mater. Sci. Technol. 2010, 26, 276–282. [Google Scholar] [CrossRef]

- He, X.; Zhang, J.; Pei, Y.; Gong, S. Effects of heat input on laser welding residual stress and distortion of TC4 titanium alloy. Rare Met. Mater. Eng. 2007, 36, 774–777. [Google Scholar]

- Lida, T.; Guthrie, R.I.L. The Physical Properties of Liquid Metals; Clarendon Press: Oxford, UK, 1988. [Google Scholar]

| Chemical Composition (wt %) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 0.14 | 0.23 | 1.37 | 0.16 | 2.51 | 0.21 | 5.56 | 0.03 | balance |

| Mechanical Properties | ||||||||

| 0.2% Proof stress (MPa) | Tensile strength (MPa) | Elongation (%) | Hardness (HV) | |||||

| 453 | 521 | 8 | 189 | |||||

| Power (P) (kW) | Welding Speed (S) (m/min) | Defocusing Distance (Dd) (mm) | Top and Bottom Sides Shielding Gas/Flow Rate (L/min) |

|---|---|---|---|

| 5.0–9.0 | 2.0–7.8 | −10.0 to +10.0 | Argon/13.0–25.0 |

| Power (P) (kW); Heat Input (kJ/m) | Welding Speed (S) (m/min) | Defocusing Distance (Dd) (mm) | Top and Bottom Sides Shielding Gas/Flow Rate (L/min) |

|---|---|---|---|

| 9/(90 kJ/m) | 6 | −10.0 | Argon/20 |

| 6/(180 kJ/m) | 2 | −10.0 | Argon/20 |

| BM (wt %) | WM (wt %) | Difference (wt %) | Vapor Pressure (mbar) | Tm (K) | |

|---|---|---|---|---|---|

| Zn | 5.56 | 4.71 | 0.85 | 7.53 | 693 |

| Mg | 2.51 | 2.01 | 0.5 | 0.49 | 923 |

| Cu | 1.37 | 1.31 | 0.06 | 3.24 × 10−12 | 1358 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Batahgy, A.-M.; Klimova-Korsmik, O.; Akhmetov, A.; Turichin, G. High-Power Fiber Laser Welding of High-Strength AA7075-T6 Aluminum Alloy Welds for Mechanical Properties Research. Materials 2021, 14, 7498. https://doi.org/10.3390/ma14247498

El-Batahgy A-M, Klimova-Korsmik O, Akhmetov A, Turichin G. High-Power Fiber Laser Welding of High-Strength AA7075-T6 Aluminum Alloy Welds for Mechanical Properties Research. Materials. 2021; 14(24):7498. https://doi.org/10.3390/ma14247498

Chicago/Turabian StyleEl-Batahgy, Abdel-Monem, Olga Klimova-Korsmik, Aleksandr Akhmetov, and Gleb Turichin. 2021. "High-Power Fiber Laser Welding of High-Strength AA7075-T6 Aluminum Alloy Welds for Mechanical Properties Research" Materials 14, no. 24: 7498. https://doi.org/10.3390/ma14247498

APA StyleEl-Batahgy, A.-M., Klimova-Korsmik, O., Akhmetov, A., & Turichin, G. (2021). High-Power Fiber Laser Welding of High-Strength AA7075-T6 Aluminum Alloy Welds for Mechanical Properties Research. Materials, 14(24), 7498. https://doi.org/10.3390/ma14247498