1. Introduction

Due to the scarcity and insufficiency of natural resources, the need for energy has become one of the most important problems of today. In addition, it became difficult to find new energy sources. Therefore, energy efficiency has become an important issue. Energy is consumed in both heating and cooling of buildings. Thermal insulation in buildings is of great importance in terms of energy efficiency. Accordingly, research on new thermal insulation materials are still up-to-date. In addition to thermal insulation in buildings, fire resistance is a situation that should be considered in terms of building safety. Recently, research on the development of cement-based heat-insulating and fire-resistant lightweight composite materials have increasingly continued [

1,

2,

3,

4,

5,

6,

7].

One of the most important methods known to produce lightweight concrete is to use lightweight aggregate. Another method is to produce concrete with polymer-based plastic granulated plastic aggregates [

8]. Natural or industrial aggregates such as pumice, expanded clay, basalt powder and vermiculite, perlite, blast furnace slag, floor ash are used in concrete production [

9,

10,

11]. Concretes produced with lightweight aggregates have positive properties such as heat [

12,

13,

14] and sound insulation [

15,

16,

17,

18], reduced structure dead load [

19,

20,

21], and high-temperature resistance [

22,

23,

24] due to their low density. Lightweight mortars and concretes present some superior properties for structural applications such as fire resistance, thermal insulation, and sound insulation [

15,

16,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37]. In addition, light mortars and concretes provide reductions in the cross-sections of the bearing elements and the earthquake loads acting on the structure by reducing the dead load of the structures [

19,

38,

39].

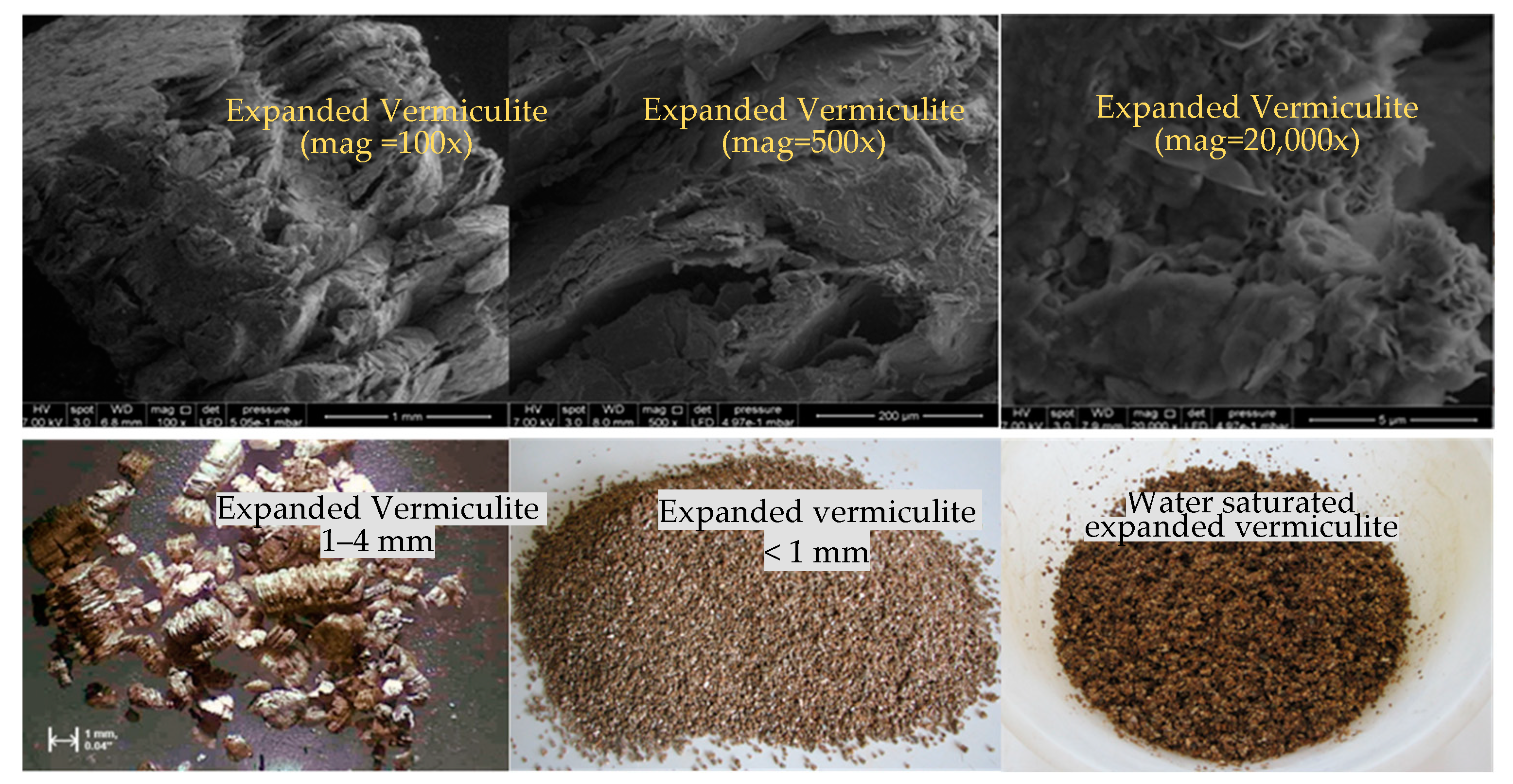

One of the aggregates used in the production of high temperature resistant and lightweight concrete is vermiculite [

13,

22]. Vermiculite is a magnesium aluminosilicate clay mineral formed by the natural erosion of mica. Mineralogically, vermiculite, which represents a different group alone, is used as a general term covering all mica minarets (phlogopite, biotite, and hydrobiotite) which have industrial expansion properties. Vermiculite can also be described as aqueous magnesium, aluminum, iron silicate [

40].

Vermiculite is a natural mineral and member of the Montmorillonite/Smectite Group. It is also placed in Clay and Mica Groups. Vermiculite is generally extremely hydrated biotite or phlogopite. These characteristic minerals later changed to vermiculite by weathering or hydrothermal processes. Vermiculite structures include water inside the interlayer cavities. The dilution properties are controlled via interlayered cations Mg

2+ and small amounts of Ca

2+, Na

+, and K

+. It influences the cation range and the level of hydration in the charge, intermediate and discharges layer arrays. The hydration status of vermiculite was determined by the quantity of water layers in the intermediate layer cavity. Water and cations among layers decide the thickness of the structural unit [

41,

42,

43]. Vermiculites are divided into four groups as metamorphic vermiculite [

44], macroscopic vermiculite, clay vermiculite [

45], and autogenic vermiculite [

46]. Vermiculite is crystallized in the monoclinic system and has a uniform slice. It can be green, yellowish coffee, or even black. Its hardness is between 1, 2 and 2.0 according to the Mohs scale and its specific weight is between 2.4 and 2.7. When vermiculite is suddenly subjected to heat-shock at high temperatures, it extends like an accordion. This characteristic expansion is thought to be due to the vapor pressure caused by the sudden evaporation of crystal water in the structure. The reason why thermal expansion has not yet been fully explained is that even samples containing the same total amount of water by weight can expand at different rates. Chemical bonding and the bonding of the water molecules between the leaves to the structure are other important parameters affecting the expansion event. As a result of the expansion, the bulk density of the material decreases by approximately 10 times from 0.8 g/ m

3 to 0.08 g/cm

3. The decrease in bulk density depends on the quality of the vermiculite and the performance of the furnace where the expansion is performed, and an approximate 30-fold expansion can be achieved as a result of heat treatment [

47].

Silica fume, an industrial waste, is a very fine-grained powder obtained by the reduction of high-purity quartzite with coal and wood particles in electric arc furnaces used during the production of silicon metal or ferrosilicon alloys. In the upper parts of the furnaces at low temperatures, SiO gas is rapidly oxidized by contact with air and condenses as amorphous SiO2 to form almost all of the silica fume composition [

48]. The unit weight of silica fume changes 250 and 300 kg/m³ [

49]. Silica fume is composed of fine particles with a surface area of about 20,000 m²/kg [

50]. It has been observed that compressive strength is increased [

51,

52], the interface is improved [

53], and high-temperature resistance is increased in concretes produced with silica fume additive [

21,

52].

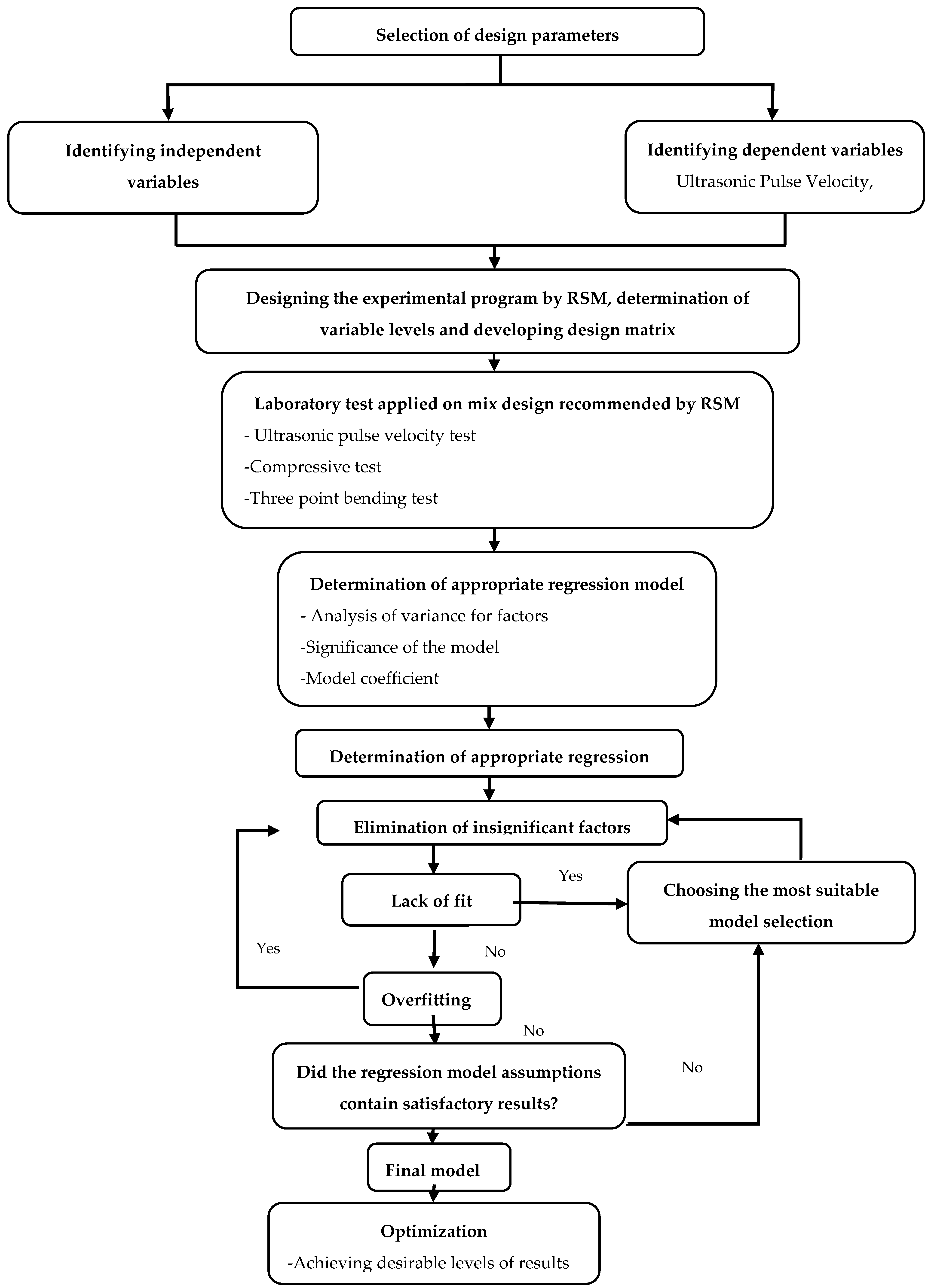

In recent years, experimental design methods have been extensively used in engineering studies. One of the experimental design methods is RSM which is used for the optimization of engineering problems and/or industrial processes. This methodology is a statistical method to investigate the best relationship between the dependent and independent parameters in experimental design and to determine their optimal use.

When the literature is examined, it is seen that this method has attracted the attention of the researchers especially in recent years and it has started to be used widely. Yıldırım et al. [

54] studied to find optimal conditions for the effective waste coal additive on the effects of asphalt concrete utilizing a RSM strategy. Statistical analysis demonstrated that the model attained from the RSM study is appropriate for representing the best solution group model parameters. Miličević, Štirmer, and Bjegović [

55], analyzed the effect of recycled aggregate on basic concrete properties (density, porosity e.g.,) by using Central Composite Design (CCD) and BBD. The comparison of values attained from prediction models with the experimental results showed that the BBD is feasible to find for basic properties of concrete including recycled aggregate and the number of experiments could be decreased. Rooholamini, Hassani, and Aliha [

56], used CCD for choosing the best model of macro-synthetic fiber on the mechanical properties of roller-compacted concrete pavement (RCCP). The BBD methodology is accustomed to optimizing variables such as pH 3–7, the flow rate of 0.3–0.7 mL/min, and filter depth of 10–20 as well as seeing the effects of the determined parameters on column performance. The pH value has been shown to be the most important factor affecting the performance characteristics of fluorine removal with a fixed-bad column [

57]. Adamu, Mohammed, and Liew [

58] examined the effects of high-volume fly ash, crumb rubber, and nano-silica on roller-compacted concrete. Compressive, flexural, and splitting tensile strength were defined as response variables, and optimization of mixture proportions were carried out by using BBD design strategy. Analysis results demonstrated that nano-silica increases the performance and mechanical properties of high-volume fly ash samples of roller-compacted concrete with or without addition of crumb rubber. Asadzadeh and Khoshbayan [

59] investigated the optimal conditions for foam concrete production including water, cement, and foam volume to obtain minimum density and maximum compressive strength along with the minimum cost. Total of 15 experimental samples were conducted, and the results were settled as response variables in statistical software for analyzing optimization. It was shown that the cost, compressive strength, and dry density response variables could be optimized simultaneously by BBD approach in foam concretes. Performance properties of the additives used in lightweight concretes have been examined by RSM methods and the usability of these techniques has been proven by many studies. Kockal and Ozturan investigated the optimization of the properties of lightweight fly ash aggregates in the production of high strength lightweight concrete using RSM. The effects of temperature, binder content and binder type independent parameters on specific gravity, water absorption, and crushing strength were evaluated and the process was optimized [

60]. Using RSM techniques of lightweight mortars, the effect of curing temperatures, binder contents, and curing times on the compressive strength of geopolymer mortar [

61], the effects of thermal permeability in different geometries on conduction and convection events [

62], cement content, water ratio, and hydrogen peroxide ratios on pressure and the effects on bending strengths [

63] were examined in detail in their studies.

The aim of the paper is to assess the effect of silica fume and expanded vermiculite on the behavior of mortars at elevated temperatures and establish a model depending on the test results by using a computer-based experimental program. It is aimed to see the effects of the changes at different levels of the independent variables on the dependent variables through the models created. In addition, multi-objective optimization cases will be evaluated at the desirability levels determined by simultaneous evaluation of dependent and independent variables. The novelty of this study is the evaluation of silica fume and expanded vermiculite mortars with RSM and the determination of critical temperatures in the conditions of multi-objective optimization.

5. Results and Discussions

Table 4 shows the BBD and the experimentally obtained responses (i.e., UPV, Bending Strength, and Compressive Strength). The value range from 2181 m/s to 2737 m/s, 0.90 MPa to 3.80 MPa, 3.50 MPa to 11.80 MPa for the UPV, bending strength and compressive strength, respectively.

In experimental design, variance analysis is used to evaluate whether independent parameters have a statistically significant effect on dependent parameters. In the statistical analysis, in addition to independent parameter effects (linear), two-factor interactions and quadratic form of independent parameters on dependent parameters may be observed, if it is appropriate to statistically significant levels [

80,

81,

82]. In the analysis of variance, the contribution of statistically significant parameters to the model is evaluated by considering the predefined confidence level. In current study, the confidence interval was selected as 95%, which means that the p value was less than 0.05 (

p-level < 0.05). In addition, the lack of fit is checked at the significance level of the

p-value. If the lack of fit is statistically insignificant and

p value of the lack of fit is greater than 0.05, then the model can be evaluated as significant. ANOVA results on response variables are given in

Table 5.

The F-values of the models which found as −141.64 for UPV, 177.69 for Bending Strength, and 77.61 for Compressive Strength, demonstrate that the models were all significant, with only 0.09%, 0.01%, and 0.01% possibility, respectively. The significance of all models and terms was controlled using the 95% confidence interval (

p < 0.05). For UPV, the model and terms B, AB, AC, C

2, A

2B, and AB

2 were significant as their p values were <0.05, whereas A, C, BC, A

2, and B

2 were all insignificant. Bending strength model and its terms A, B, C, AC, BC, A

2, C

2, and A

2 C were all significant as their Prob > F values were <0.05, whereas AB and B

2 were all insignificant. For compressive strength, the model and terms A, B, C, AC, A

2, B

2, and C

2 were all significant as their p values were <0.05, where AB and BC were all insignificant. The empirical models in terms of actual factors for UPV (

y1), bending strength (

y2), and compressive strength (

y3) are presented in Equations (7)–(9).

The final models’ equations were created by removing all insignificant terms for UPV (

y1), bending strength (

y2), and compressive strength (

y3), respectively. These equations are given in Equations (10)–(12).

After selecting statistically significant parameters for each response variable, the regression model equations of these responses may be obtained. As mentioned in Equations (1)–(3), the interactions can be linear, two factor, and quadratic interactions, the most appropriate statistical model is found and accepted as the regression model of that response variable. The adjusted models for each of the response variables are specified in Equations (4)–(6). The negative and positive signs before a model term indicate the antagonistic or synergistic effects of independent variables on response variables.

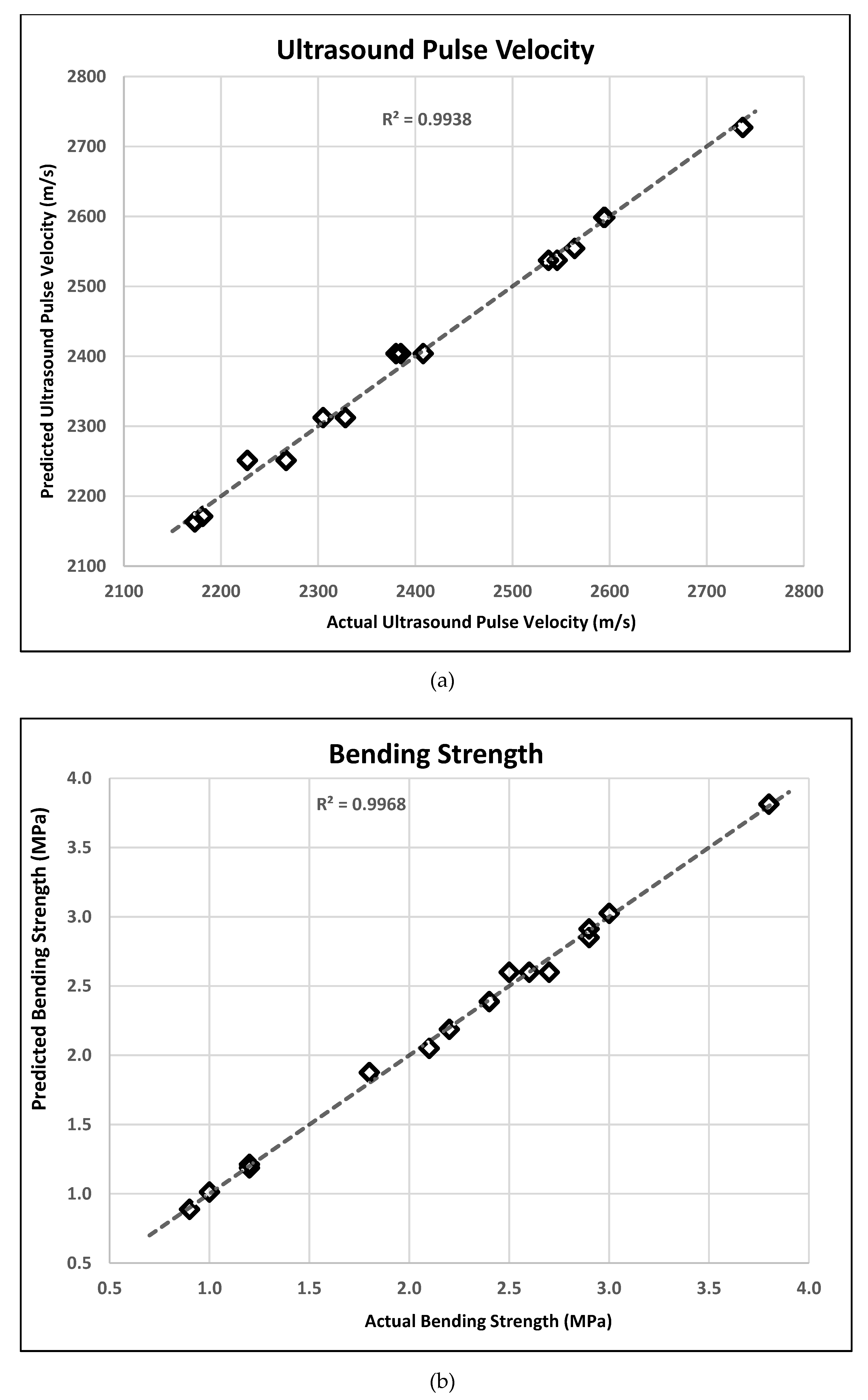

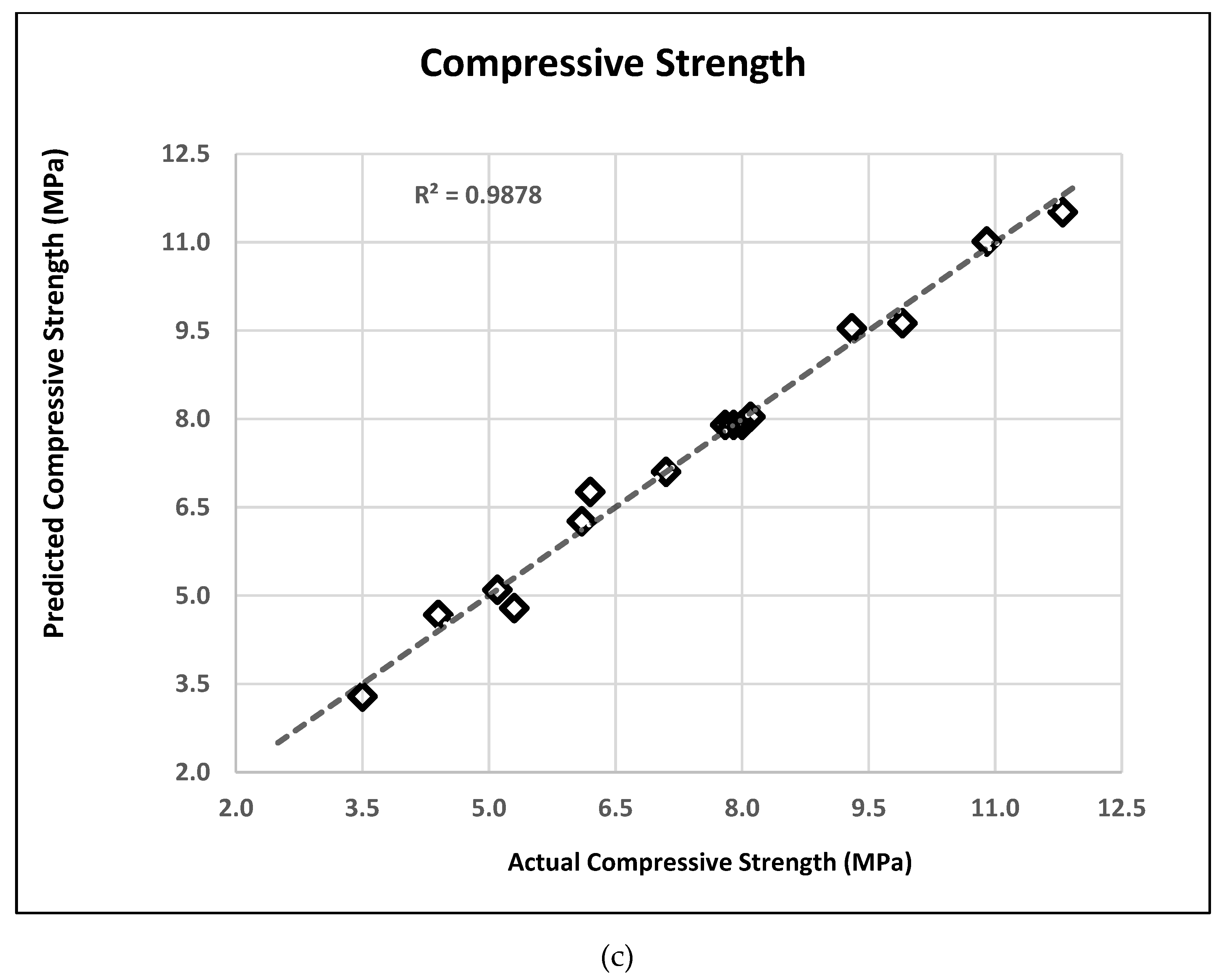

The degree of correlation values was used to evaluate the adequacy and quality of the established models.

Table 6 shows the coefficients of determination for responses investigated. In

Table 6, all of the generated response variable models have significant R

2 values that were greater than 0.85. Thus, nearly 99.38%, 99.68%, and 98.78% of the experimental data of the UPV, bending strength, and compressive strength models, respectively, can be correlated with the models. For the R

2 values of the models to be in good agreement, the difference between the two should be <0.2. As can be seen differences between those values, it is seen that all response variables were in good agreement. In addition, the adequate precision (AP) values are given in

Table 6. AP is a parameter that measures the signal to noise ratio, and it has to be greater than 4 to accept the desirability of responses. Considering the AP values, all models were in good agreement. The graphs indicating the relationship between predicted values from the established models and actual values are given in

Figure 3a–c for UPV, bending strength, and compressive strength, respectively. As can be seen in

Figure 3, the results obtained from the BBD model are very close to the experimental results.

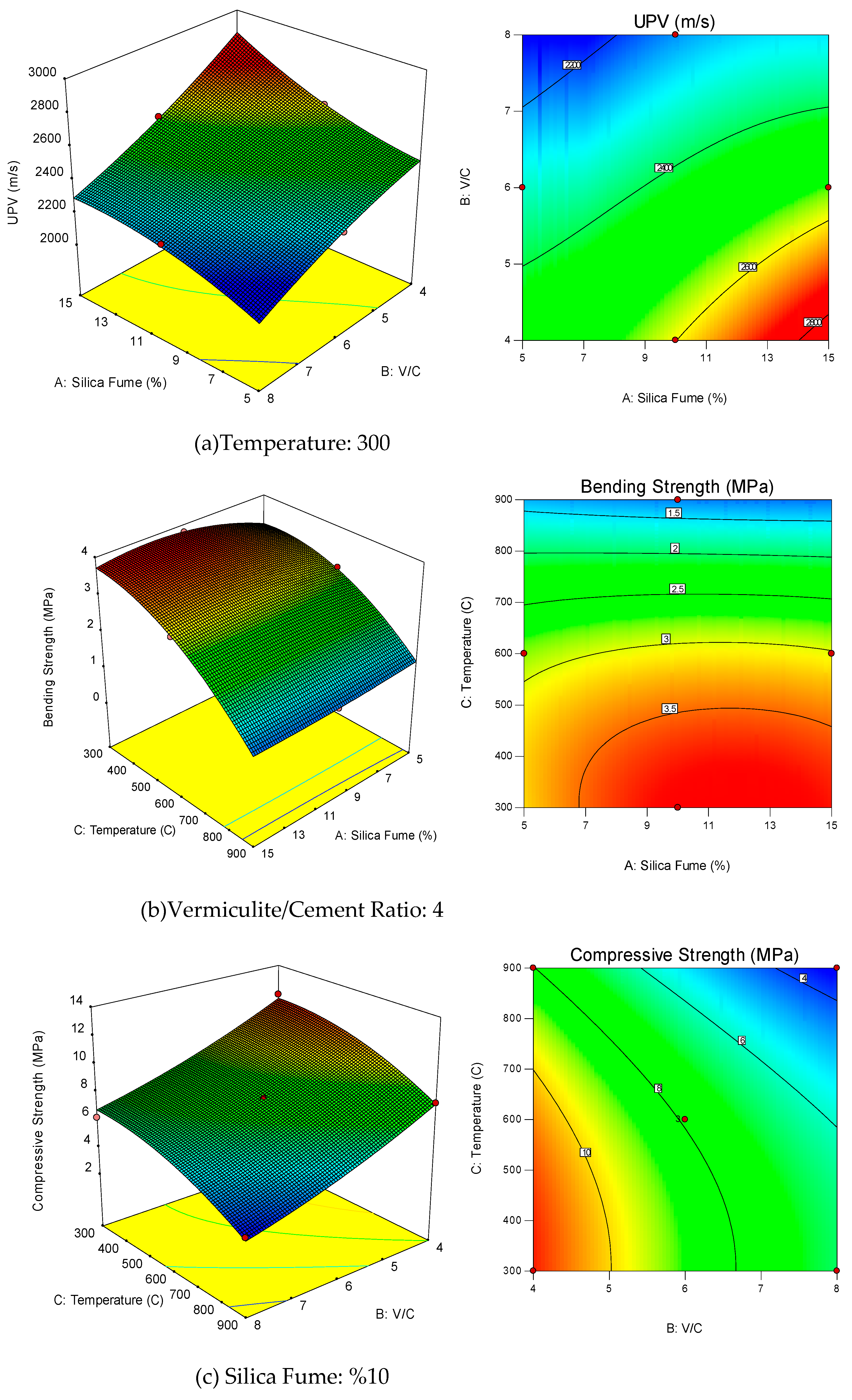

A three-dimensional (3-D) surface graphs were used to present the relationship between two independent parameters and response parameters.

Figure 4a shows 3-D response surface graphs of changes in UPV, the relationship between silica fume and V/C ratio when the temperature is taken as constant 300 °C.

Figure 4b shows the relationship between silica fume and temperature, assuming the 3-D response surface graphs of the change in flexural strength, assuming the V/C ratio of 4.

Figure 4c shows the 3-D response surface graphs of changes in compressive strength, the relationship between temperature and V/C ratio, when silica fume is taken as constant 10%.

For a better interpretation of the 3D response surface graphs, their 2D cases are also given. The color changes in these graphics represent the 3rd dimension. Blue values indicate low levels of the parameter, red values indicate high levels. Parabolic and linear effects can also be seen on these graphs.

When the response surface graphs are analyzed, the interaction between silica fume and V/C (A and B) (

Figure 4a) is observed; at low levels of silica fume, the increasing V/C ratio has a parabolic decreasing effect on the UPV value, and at high levels of silica fume, the increase in the V/C ratio has a linear decreasing effect on the UPS value. In addition, increasing silica fume at all levels of the V/C ratio has a slightly increased parabolic effect on the UPS value.

In the interaction between silica fume and temperature (A and C) (

Figure 4b), increasing the temperature at all levels of silica fume has a parabolic effect, which initially increases the bending strength value slightly and then decreases it. Moreover, increase in silica fume at all levels of temperature has a parabolic effect, which slightly decreases the bending strength value.

When the interaction between temperature and V/C ratio (B and C) is examined (

Figure 4c), an increase in V/C ratio at all levels of temperature exhibits a linear decrease. Moreover, increasing in temperature at all levels of V/C ratio has a parabolic decrease in compressive strength value.

Simultaneously multi-objective optimization is the determination of the proportions of independent variables that can be used to obtain an optimized mortar mix based on the desired performance levels of response variables. In this study, optimization of response parameters was achieved by using desirability function in Design-Expert software version 10.0.2. In the simultaneous optimization criteria, critical temperatures were determined for all combinations of levels of 5–10–15% silica fume and 4–6–8 ratio of V/C. For this purpose, temperature and UPV variables were set to be in range, compressive and bending strength response variables were determined to be at maximum desirable levels as presented in

Table 7.

Multi-objective optimization results are presented in

Table 8. Desirability is the most important parameter to evaluate the success of optimization. As seen in the table, when the V/C ratio was kept constant as 4 and silica fume levels were chosen as 5%, 10%, and 15%, the critical temperatures were obtained as 371.6 °C, 306.3 °C, and 436 °C with the highest desirability percentages.