The Interdiffusion Behavior of NiCoCrAlYHf Coating Deposited by Arc Ion Plating on Carburized Ni-Based Single Crystal Superalloy

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Substrate Material

2.2. Preparation of a Carburized Layer

2.3. Deposition of an HY5 Coating

2.4. Thermal Cyclic Oxidation and Specimen Characterization

3. Results and Discussion

3.1. The Morphology of the Carburized DD10 Superalloy with an HY5 Coating

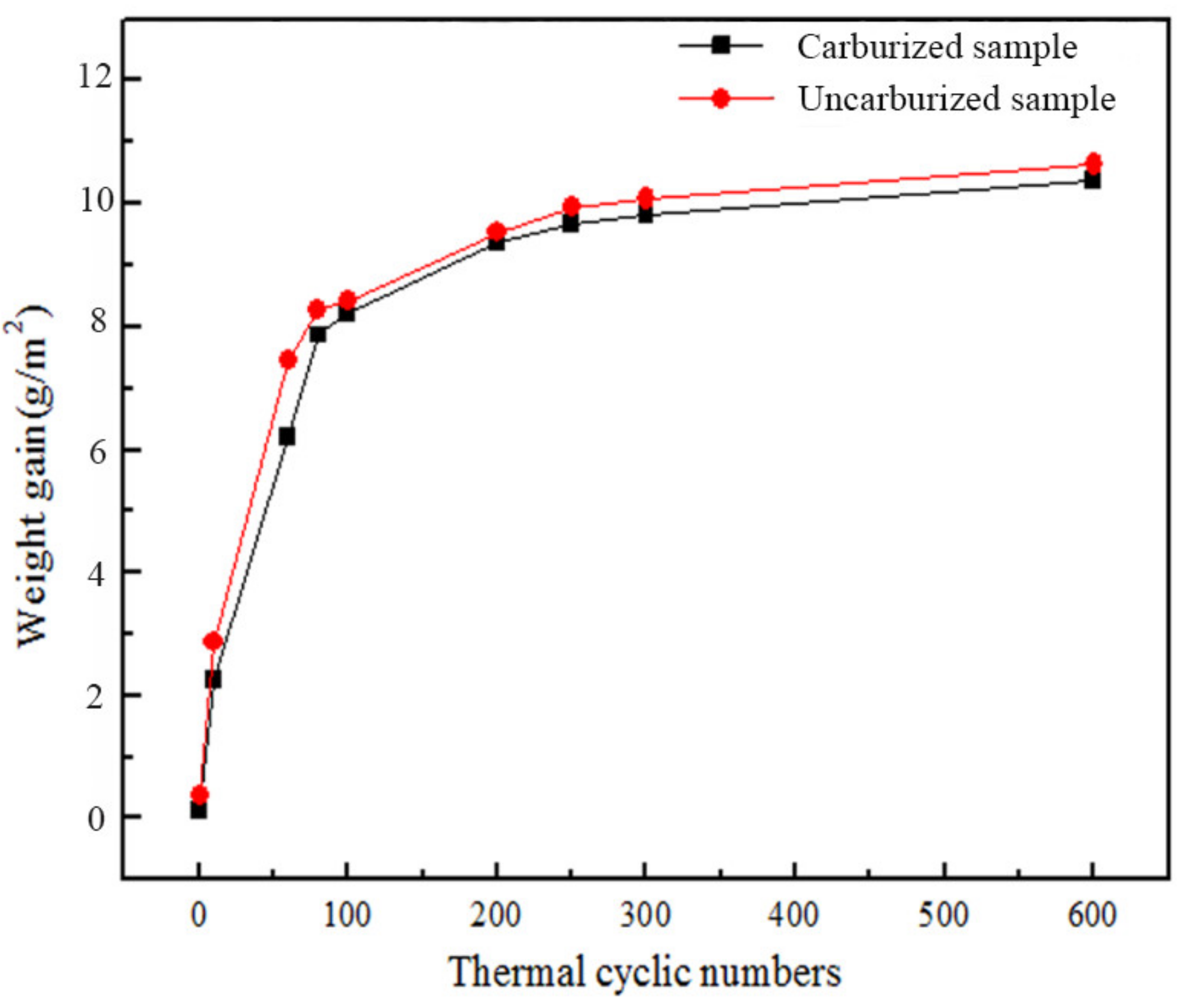

3.2. Thermal Cyclic Oxidation

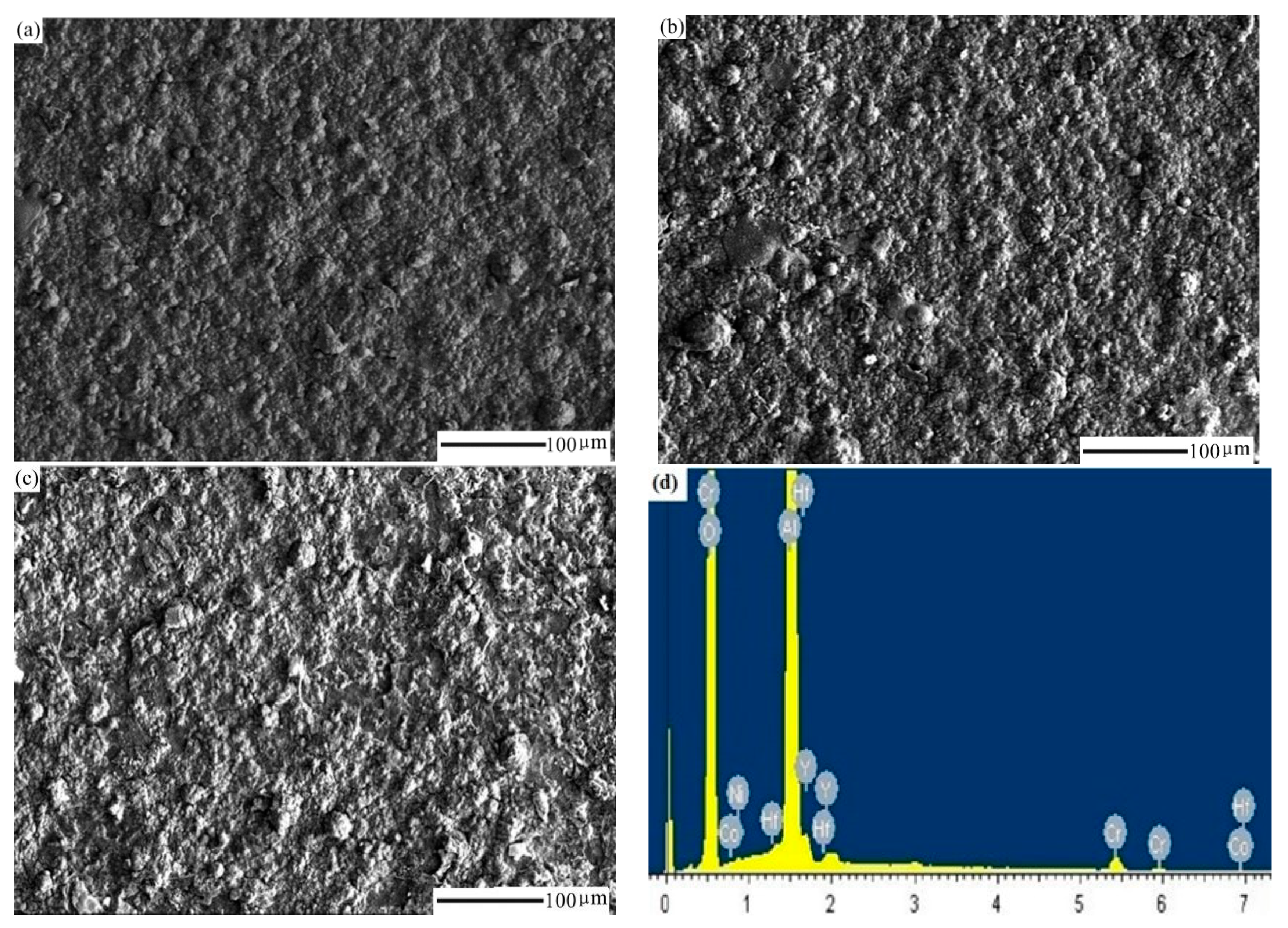

3.3. Morphology of the Carburized DD10 Superalloy with an HY5coating after Thermal Cyclic Oxidation

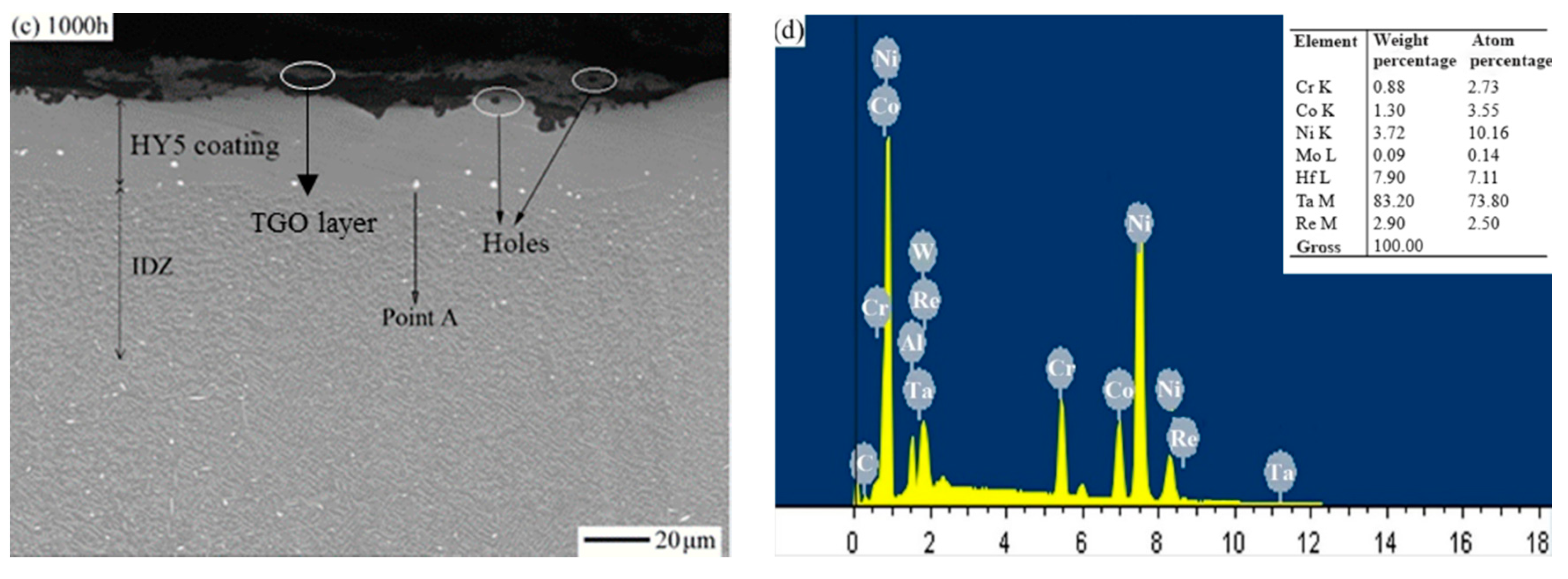

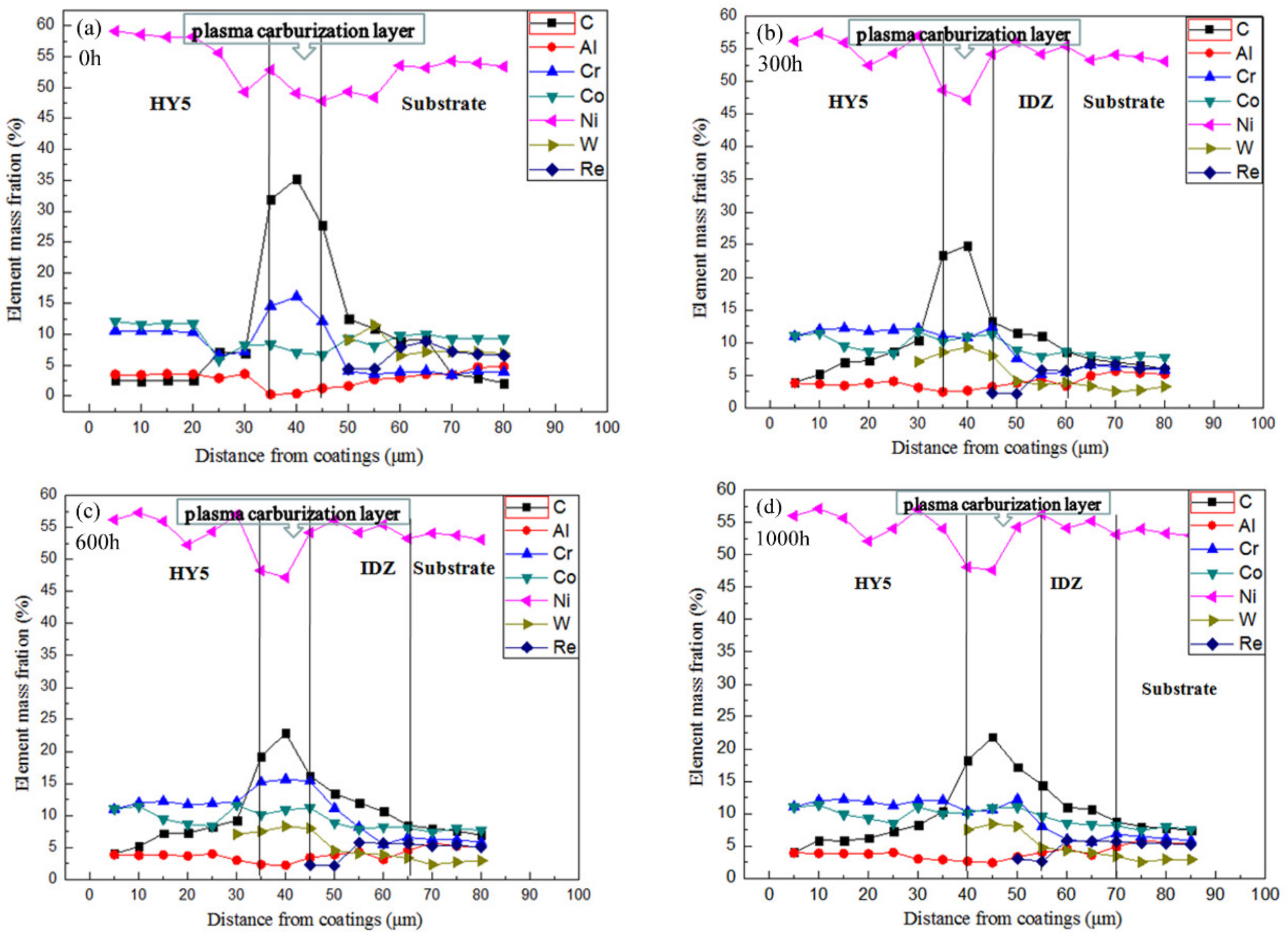

3.4. Interdiffusion Behavior between the HY5 Coating and the Carburized DD10 Superalloy

3.5. Formation of an SRZ in the Carburized DD10 Superalloy with an HY5 Coating

4. Conclusions

- Carburization might enhance the interfacial bonding force and improve the microstructure of the NiCoCrAlYHf coating. The cyclic oxidation stage was steady, and the thermal oxidation resistance of the DD10 superalloy after carburization treatment was desirable after 1000 h.

- The carburized layer, as a barrier at the interface of the single-crystal superalloy and the NiCoCrAlYHf coating, limited the aluminium inward diffusion, and therefore, restrained the γ/γ′ phase transformation in the superalloy during oxidation at 1100 °C. Consequently, the TCP phase, which was due to the dissolution of the refractory elements from the γ phase, was hindered effectively. The carburized layer effectively suppressed the refractory elements rhenium and tungsten from the outward diffusion from the substrate.

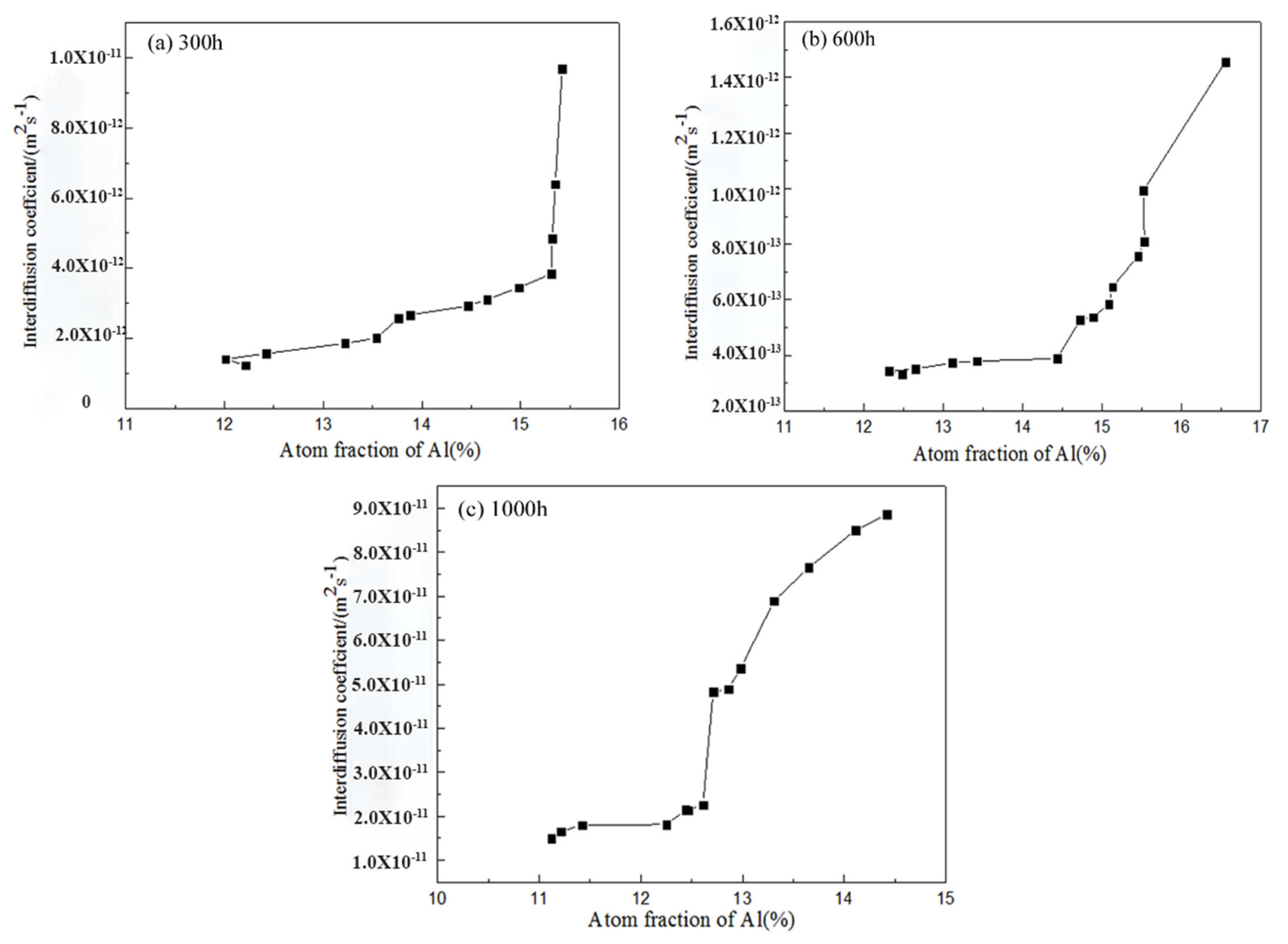

- When the temperature was constant, the diffusion coefficient of aluminium increased significantly with the concentration of aluminium in the NiCoCrAlYHf coating after carburization. The range was five orders of magnitude. The diffusion of aluminium between the NiCoCrAlYHf coating and the carburized single-crystal superalloy can be described by:DAl300 = 4.51 × 10−25 exp(196.1C) (0.12 ≤ C ≤ 0.16),DAl600 = 1.47 × 10−24 exp(82.64C) (0.12 ≤ C ≤ 0.17),DAl1000 = 7.73 × 10−20 exp(135.7C) (0.11 ≤ C ≤ 0.15).Carburization treatment reduced the diffusion rate of aluminium by about one order of magnitude compared with that in previous study.

- After 1000 h thermal cyclic oxidation, TGO had no obvious peeling, and merely a spot of the TCP phase and an SRZ were observed in the substrate, indicating that the carburized layer effectively suppressed the interdiffusion between the NiCoCrAlYHf coating and the DD10 single-crystal superalloy and the formation of an SRZ.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Genova, V.; Paglia, L.; Pulci, G.; Bartuli, C.; Marra, F. Diffusion Aluminide Coatings for Hot Corrosion and Oxidation Protection of Nickel-Based Superalloys: Effect of Fluoride-Based Activator Salts. Coatings 2021, 11, 412. [Google Scholar] [CrossRef]

- Liu, Y.; Ru, Y.; Zhang, H.; Pei, Y.; Li, S.; Gong, S. Coating-assisted deterioration mechanism of creep resistance at a nickel-based single-crystal superalloy. Surf. Coat. Technol. 2020, 406, 126668. [Google Scholar] [CrossRef]

- Song, P.; Liu, M.; Jiang, X.; Feng, Y.; Wu, J.; Zhang, G.; Wang, D.; Dong, J.; Chen, X.-Q.; Lou, L. Influence of alloying elements on hot corrosion resistance of nickel–based single crystal superalloys coated with Na2SO4 salt at 900 °C. Mater. Des. 2020, 197, 109197. [Google Scholar] [CrossRef]

- Wu, J.; Jiang, X.; Song, P.; Wang, Y.; Dong, J.; Lou, L. Anisotropy of interface characteristics between NiCoCrAlY coating and a hot corrosion resistant Ni-Based single crystal superalloy during thermal exposure at different temperatures. Appl. Surf. Sci. 2020, 532, 147405. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, H.; Li, W.; Liu, S.; Fu, L.; Jiang, S. Microstructure and oxidation behaviour of Pt modified NiCrAlYSi coating on a Ni–based single crystal superalloy. Surf. Coat. Technol. 2020, 399, 126164. [Google Scholar] [CrossRef]

- Li, W.; Fu, L.; Li, S.; Peng, X.; Jiang, S.; Gong, J.; Sun, C. An effective and low–cost method to prepare Re–doped aluminide coating on a Ni–based single crystal superalloy. Mater. Lett. 2020, 285, 129112. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Zhong, X.; Xu, Z.; Zhang, J.; Cheng, Y.; Zhao, Y.; Liu, Y.; Fan, X.; Wang, Y.; et al. Thermal cycling behaviors of the plasma sprayed thermal barrier coatings of hexaluminates with magnetoplumbite structure. J. Eur. Ceram. Soc. 2010, 30, 1649–1657. [Google Scholar] [CrossRef]

- Xu, Z.; He, S.; He, L.; Mu, R.; Huang, G.; Cao, X. Novel thermal barrier coatings based on La2(Zr0.7Ce0.3)2O7/8YSZ double-ceramic-layer systems deposited by electron beam physical vapor deposition. J. Alloy. Compd. 2011, 509, 4273–4283. [Google Scholar] [CrossRef]

- Yu, C.; Liu, H.; Ullah, A.; Bao, Z.; Zhu, S.; Wang, F. High-temperature performance of (Ni,Pt)Al coatings on second-generation Ni-base single-crystal superalloy at 1100 °C: Effect of excess S impurities. Corros. Sci. 2019, 159, 108115. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.; Chen, M.; Yang, L.; Wang, J.; Zhu, S.; Wang, F. Oxidation behavior of Al/Y co-modified nanocrystalline coatings with different Al content on a nickel-based single–crystal superalloy. Corros. Sci. 2020, 170, 108700. [Google Scholar] [CrossRef]

- Li, W.; Sun, J.; Liu, S.; Liu, Y.; Fu, L.; Wang, T.; Jiang, S.; Gong, J.; Sun, C. Preparation and cyclic oxidation behaviour of Re doped aluminide coatings on a Ni–based single crystal superalloy. Corros. Sci. 2019, 164, 108354. [Google Scholar] [CrossRef]

- Sohn, Y.; Kim, J.; Jordan, E.; Gell, M. Thermal cycling of EB-PVD/MCrAlY thermal barrier coatings: I. Microstructural development and spallation mechanisms. Surf. Coat. Technol. 2001, 146–147, 70–78. [Google Scholar] [CrossRef]

- Susan, D.; Marder, A. Ni–Al composite coatings: Diffusion analysis and coating lifetime estimation. Acta Mater. 2001, 49, 1153–1163. [Google Scholar] [CrossRef] [Green Version]

- Walston, W.; Schaeffer, J.; Murphy, W. A New Type of Microstructural Instability in Superalloys-SRZ. Superalloys 1996, 9–18. [Google Scholar] [CrossRef]

- Rae, C.; Reed, R. The precipitation of topologically close-packed phases in rhenium–containing superalloys. Acta Mater. 2001, 49, 4113–4125. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Aoki, Y.; Matsumoto, K.; Satou, A.; Suzuki, T.; Chikugo, K.; Murakami, K. The Formation of SRZ on a Fourth Generation Single Crystal Superalloy Applied with Aluminide Coating. Superalloys 2004, 637–642. [Google Scholar] [CrossRef]

- Suzuki, A.; Rae, C.M.F. Secondary Reaction Zone Formations in coated Ni–base Single Crystal Superalloys. J. Phys. Conf. Ser. 2009, 165, 012002. [Google Scholar] [CrossRef]

- Zhong, J.; Liu, J.; Zhou, X.; Li, S.; Yu, M.; Xu, Z. Thermal cyclic oxidation and interdiffusion of NiCoCrAlYHf coating on a Ni-based single crystal superalloy. J. Alloy. Compd. 2016, 657, 616–625. [Google Scholar] [CrossRef]

- Tin, S.; Pollock, T. Phase instabilities and carbon additions in single–crystal nickel-base superalloys. Mater. Sci. Eng. A 2003, 348, 111–121. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Niu, J.; He, L.; Mu, R.; Wang, K. Effects of deposition temperature on the kinetics growth and protective properties of aluminide coatings. J. Alloy. Compd. 2015, 632, 238–245. [Google Scholar] [CrossRef]

- Boissonnet, G.; Grégoire, B.; Bonnet, G.; Pedraza, F. Development of thermal barrier coating systems from Al microparticles. Part I: Influence of processing conditions on the mechanisms of formation. Surf. Coat. Technol. 2019, 380, 125085. [Google Scholar] [CrossRef]

- Pomeroy, M. Coatings for gas turbine materials and long term stability issues. Mater. Des. 2005, 26, 223–231. [Google Scholar] [CrossRef]

- Suzuki, A.; Kawagishi, K.; Yokokawa, T.; Harada, H.; Kobayashi, T. Prediction of initial oxidation behavior of Ni–base single crystal superalloys by regression analysis. Scr. Mater. 2011, 65, 49–52. [Google Scholar] [CrossRef]

- Duhamel, C.; Chieux, M.; Molins, R.; Rémy, L.; Monceau, D.; Put, A.V.; Guedou, J.-Y. Thermal cycling behaviour of thermal barrier coating systems based on first– and fourthgeneration Ni-based superalloys. Mater. High Temp. 2012, 29, 136–144. [Google Scholar] [CrossRef]

- Kailasam, S.K.; Lacombe, J.C.; Glicksman, M.E. Evaluation of the methods for calculating the concentration–dependent diffusivity in binary systems. Met. Mater. Trans. A 1999, 30, 2605–2610. [Google Scholar] [CrossRef]

- Wierzba, B.; Skibiński, W. The generalization of the Boltzmann–Matano method. Phys. A Stat. Mech. Appl. 2013, 392, 4316–4324. [Google Scholar] [CrossRef]

- Schultze, J.; Lohrengel, M. Stability, reactivity and breakdown of passive films. Problems of recent and future research. Electrochim. Acta 2000, 45, 2499–2513. [Google Scholar] [CrossRef]

- Hall, L.D. An Analytical Method of Calculating Variable Diffusion Coefficients. J. Chem. Phys. 1953, 21, 87–89. [Google Scholar] [CrossRef]

- Liu, L. Effect of carbon additions on the microstructure in a Ni–base single crystal superalloy. Mater. Lett. 2004, 58, 2290–2294. [Google Scholar] [CrossRef]

- Liu, L.; Jin, T.; Zhao, N.; Wang, Z.; Sun, X.; Guan, H.; Hu, Z. Effect of carbon addition on the creep properties in a Ni–based single crystal superalloy. Mater. Sci. Eng. A 2004, 385, 105–112. [Google Scholar] [CrossRef]

- Pint, B.; Haynes, J.; More, K.; Wright, I.; Leyens, C. Compositional Effects on Aluminide Oxidation Performance: Objectives for Improved Bond Coats. Superalloys 2000, 629–638. [Google Scholar] [CrossRef]

- Das, D.K.; Gleeson, B.; Murphy, K.S.; Ma, S.; Pollock, T.M. Formation of secondary reaction zone in ruthenium bearing nickel based single crystal superalloys with diffusion aluminide coatings. Mater. Sci. Technol. 2009, 25, 300–308. [Google Scholar] [CrossRef]

- Rae, C.; Hook, M.; Reed, R. The effect of TCP morphology on the development of aluminide coated superalloys. Mater. Sci. Eng. A 2005, 396, 231–239. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, L.; Zhang, J. Effect of carbon addition on carbide morphology of single crystal Ni–based superalloy. Trans. Nonferrous Met. Soc. China 2014, 24, 339–345. [Google Scholar] [CrossRef]

- Li, X.; Liu, T.; Wang, L.; Liu, X.; Lou, L.; Zhang, J. Effect of carbon content on the microstructure and creep properties of a 3rd generation single crystal nickel-base superalloy. Mater. Sci. Eng. A 2015, 639, 732–738. [Google Scholar] [CrossRef]

- Adachi, S.; Ueda, N. Combined plasma carburizing and nitriding of sprayed AISI 316L steel coating for improved wear resistance. Surf. Coat. Technol. 2014, 259, 44–49. [Google Scholar] [CrossRef]

- Wang, L.; Wang, D.; Liu, T.; Li, X.; Jiang, W.; Zhang, G.; Lou, L. Effect of minor carbon additions on the high-temperature creep behavior of a single–crystal nickel-based superalloy. Mater. Charact. 2015, 104, 81–85. [Google Scholar] [CrossRef]

- Cavaletti, E.; Naveos, S.; Mercier, S.; Josso, P.; Bacos, M.; Monceau, D. Ni–W diffusion barrier: Its influence on the oxidation behaviour of a β–(Ni,Pt)Al coated fourth generation nickel–base superalloy. Surf. Coat. Technol. 2009, 204, 761–765. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Peng, H.; Gong, S.; Guo, H. NiAlHf/Ru: Promising bond coat materials in thermal barrier coatings for advanced single crystal superalloys. Corros. Sci. 2013, 78, 304–312. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Zhong, J.; Yang, S.; Li, S.; Liu, J.; Yu, M. The Interdiffusion Behavior of NiCoCrAlYHf Coating Deposited by Arc Ion Plating on Carburized Ni-Based Single Crystal Superalloy. Materials 2021, 14, 7401. https://doi.org/10.3390/ma14237401

Chen Z, Zhong J, Yang S, Li S, Liu J, Yu M. The Interdiffusion Behavior of NiCoCrAlYHf Coating Deposited by Arc Ion Plating on Carburized Ni-Based Single Crystal Superalloy. Materials. 2021; 14(23):7401. https://doi.org/10.3390/ma14237401

Chicago/Turabian StyleChen, Zun, Jinyan Zhong, Shanglin Yang, Songmei Li, Jianhua Liu, and Mei Yu. 2021. "The Interdiffusion Behavior of NiCoCrAlYHf Coating Deposited by Arc Ion Plating on Carburized Ni-Based Single Crystal Superalloy" Materials 14, no. 23: 7401. https://doi.org/10.3390/ma14237401

APA StyleChen, Z., Zhong, J., Yang, S., Li, S., Liu, J., & Yu, M. (2021). The Interdiffusion Behavior of NiCoCrAlYHf Coating Deposited by Arc Ion Plating on Carburized Ni-Based Single Crystal Superalloy. Materials, 14(23), 7401. https://doi.org/10.3390/ma14237401