3D Multi-Track and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting

Abstract

:1. Introduction

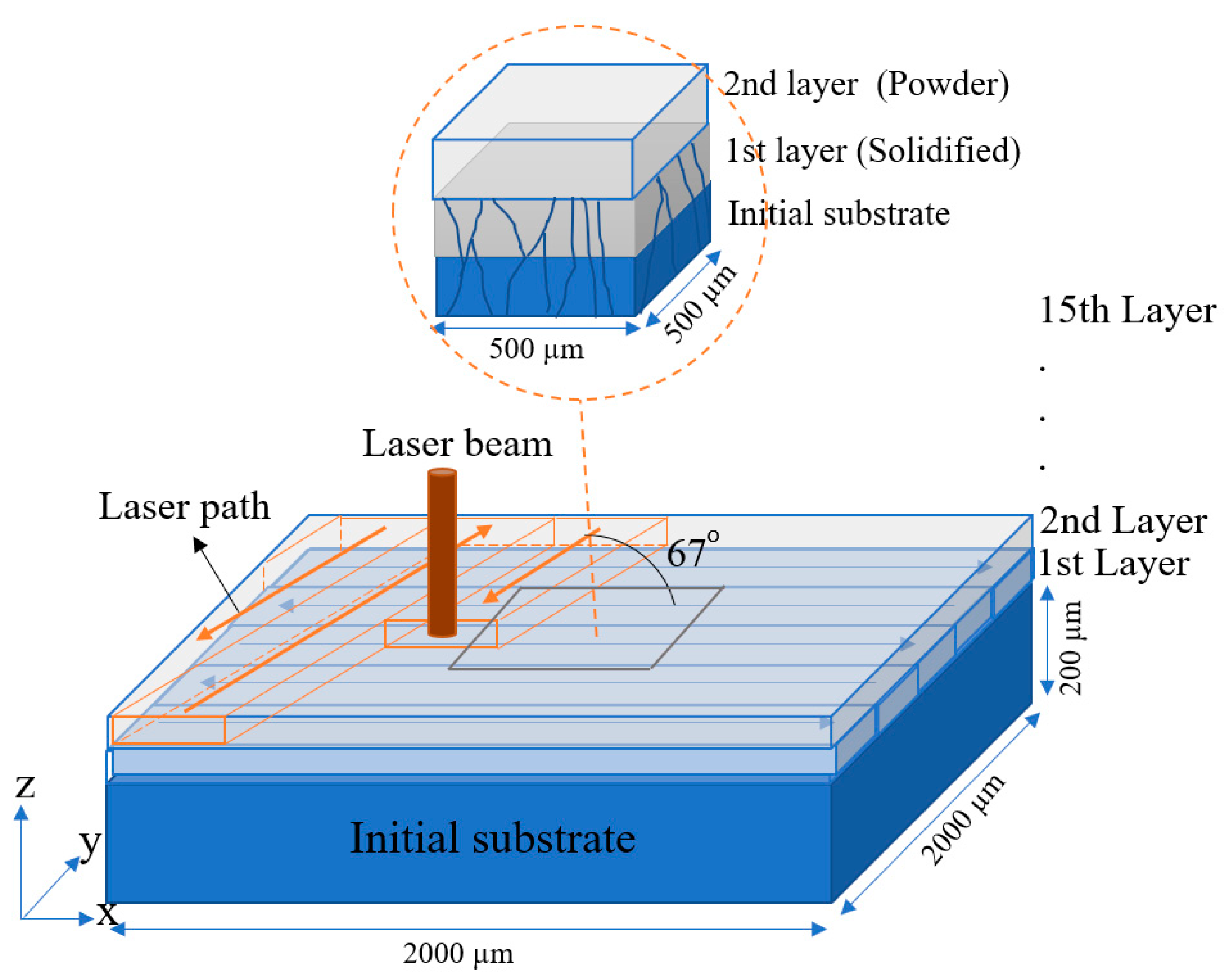

2. Model Description

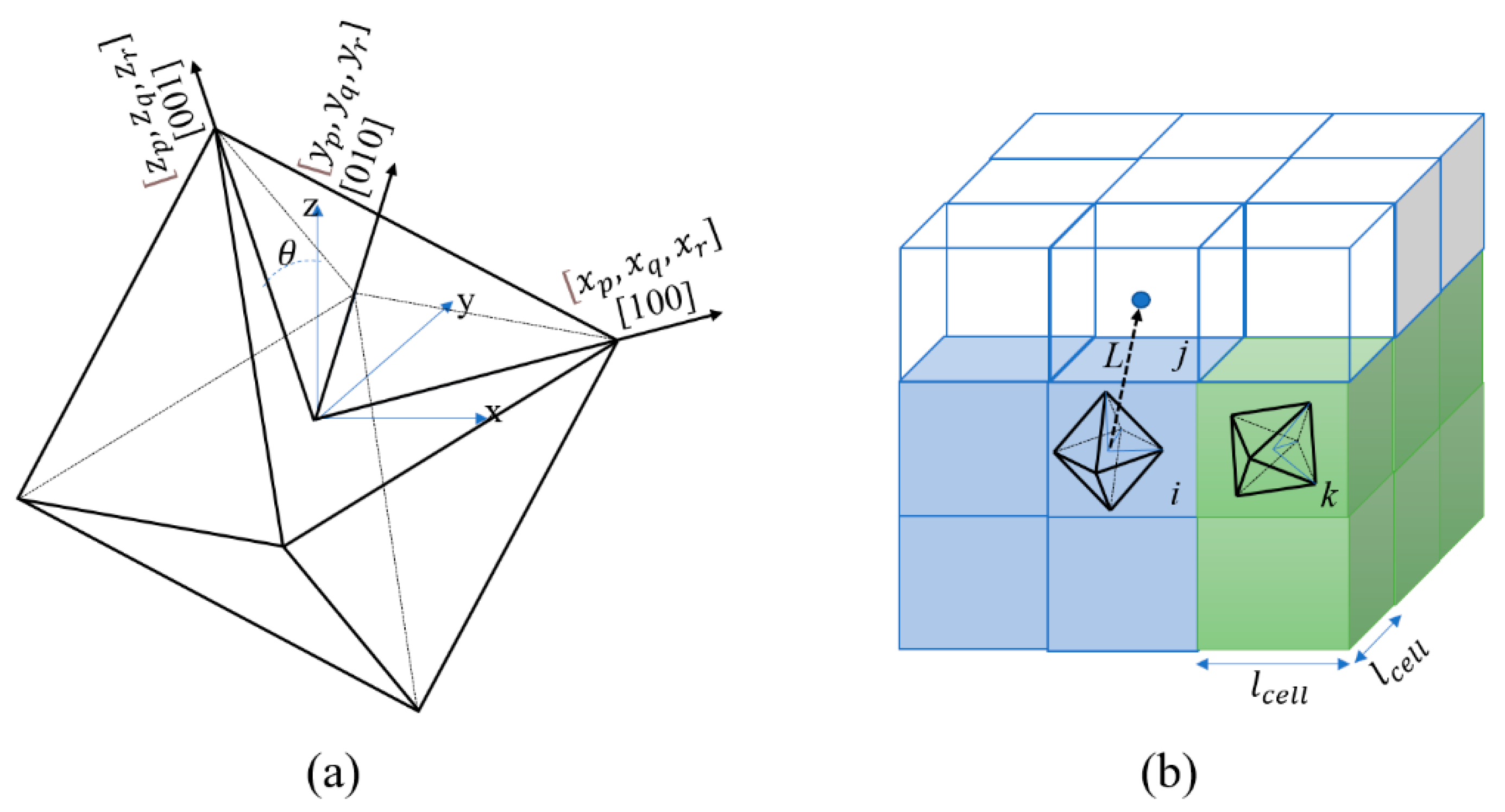

2.1. Nucleation and Growth Kinetics

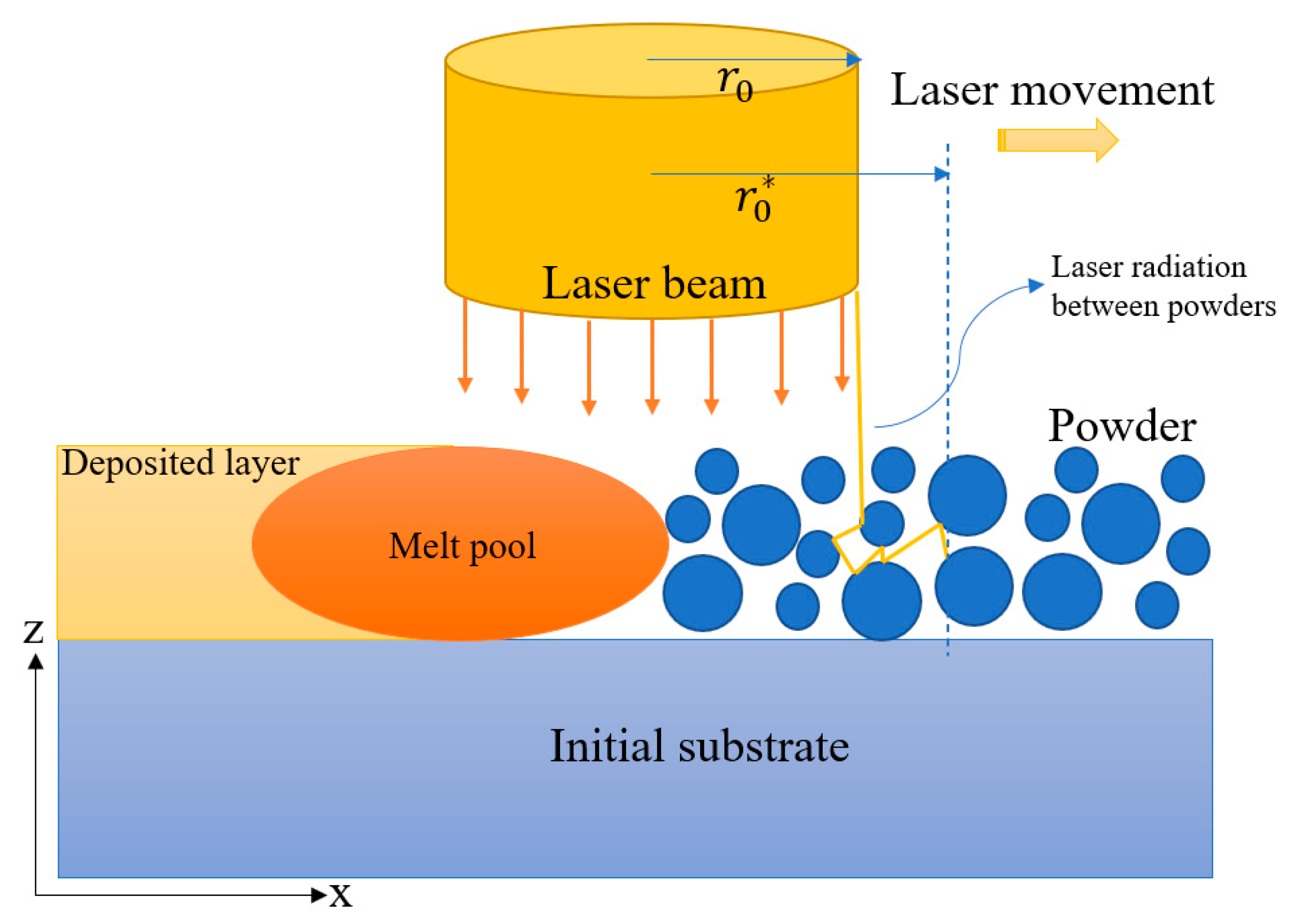

2.2. Heat Transfer

2.3. Coupling of CA and Heat Transfer Model

2.4. Simulation Parameters

3. Results and Discussion

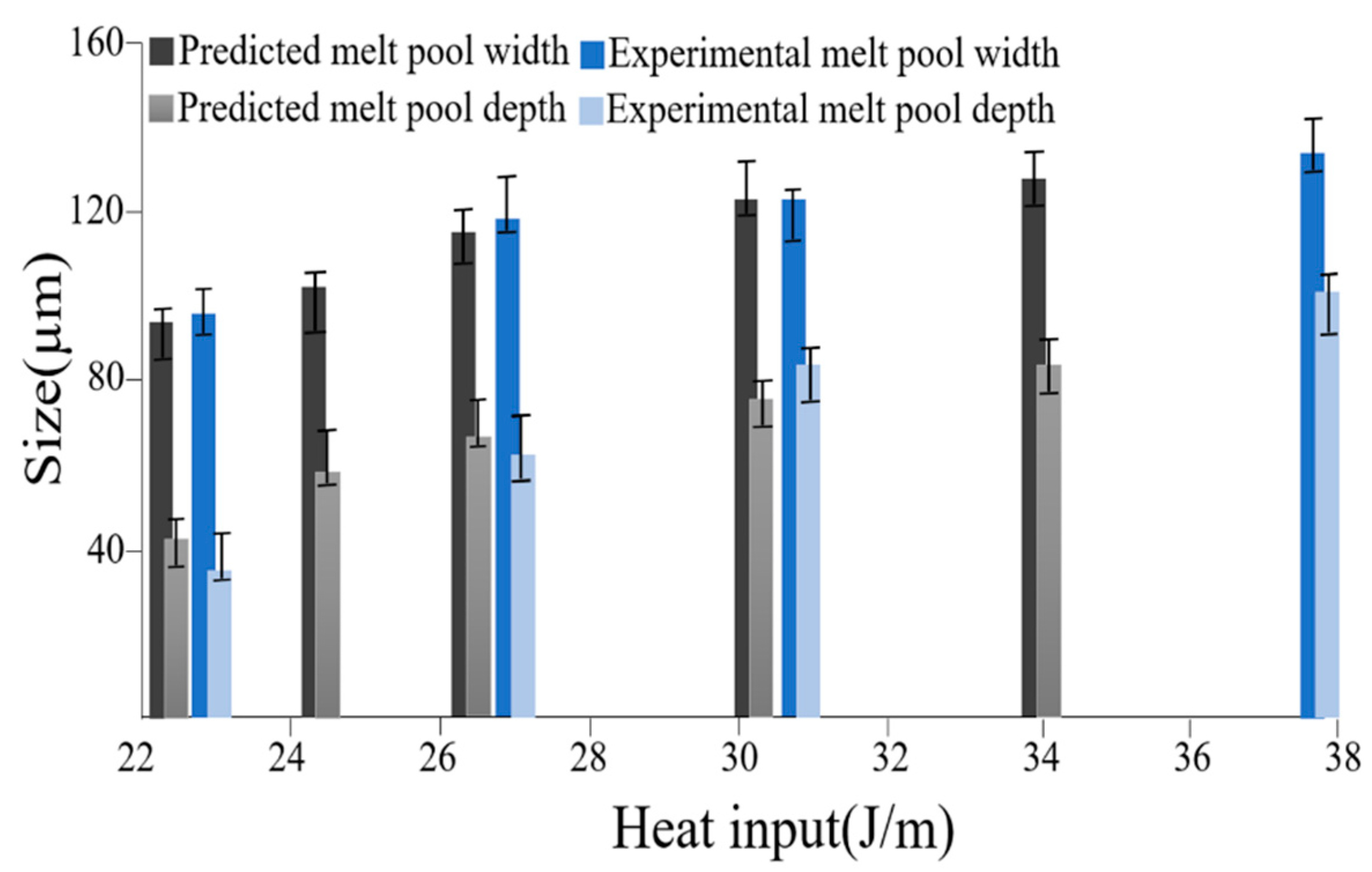

3.1. Thermal Model Validation

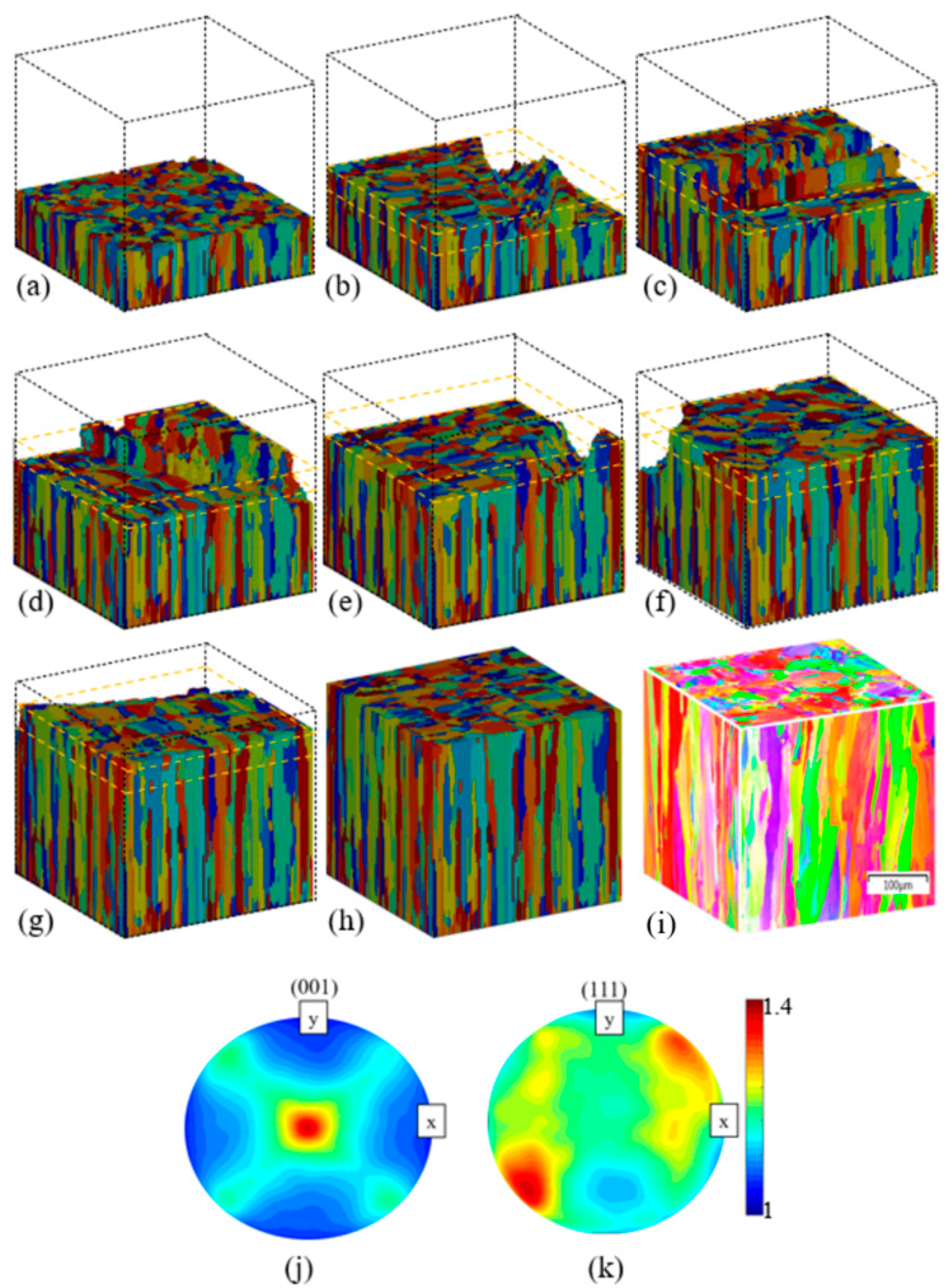

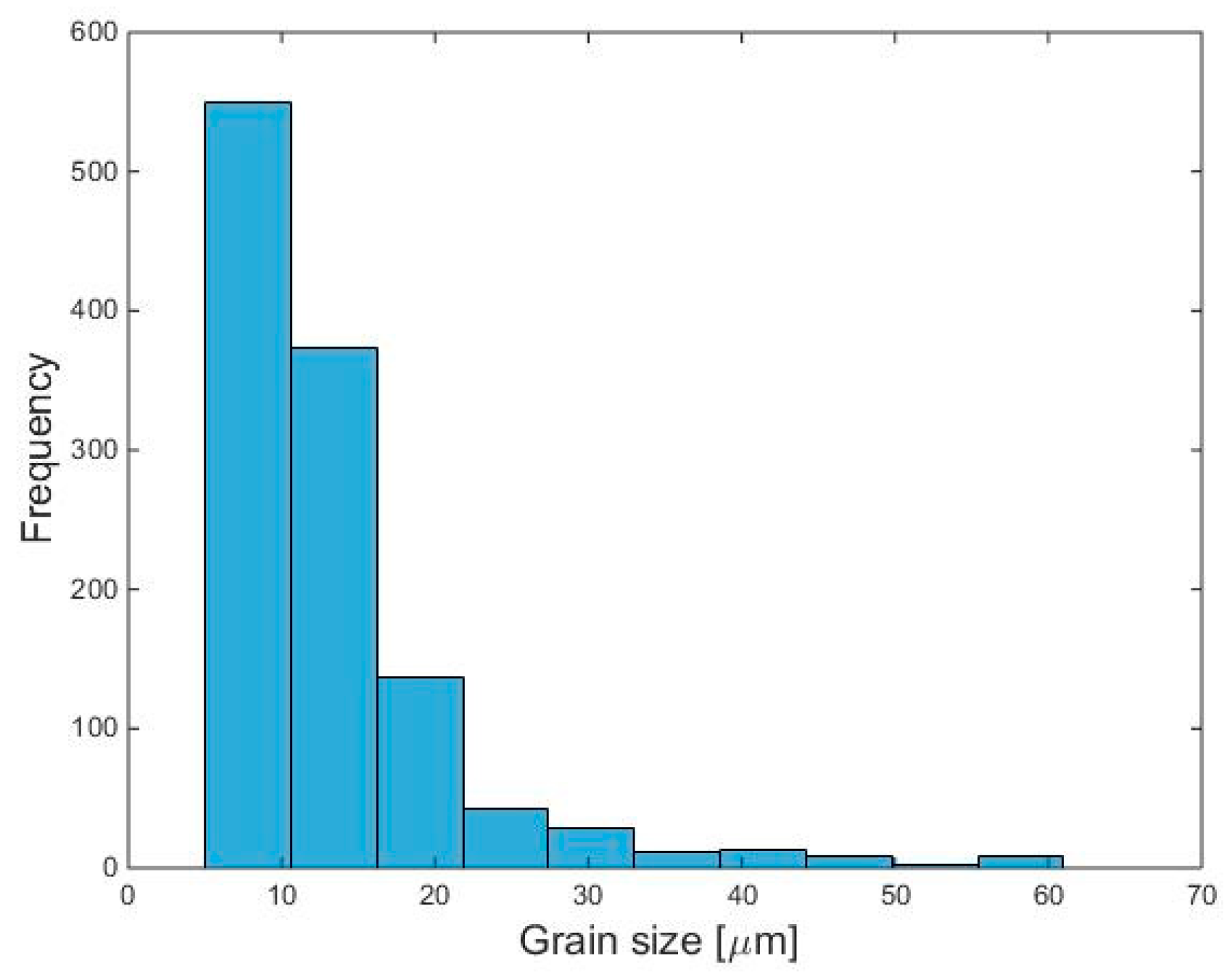

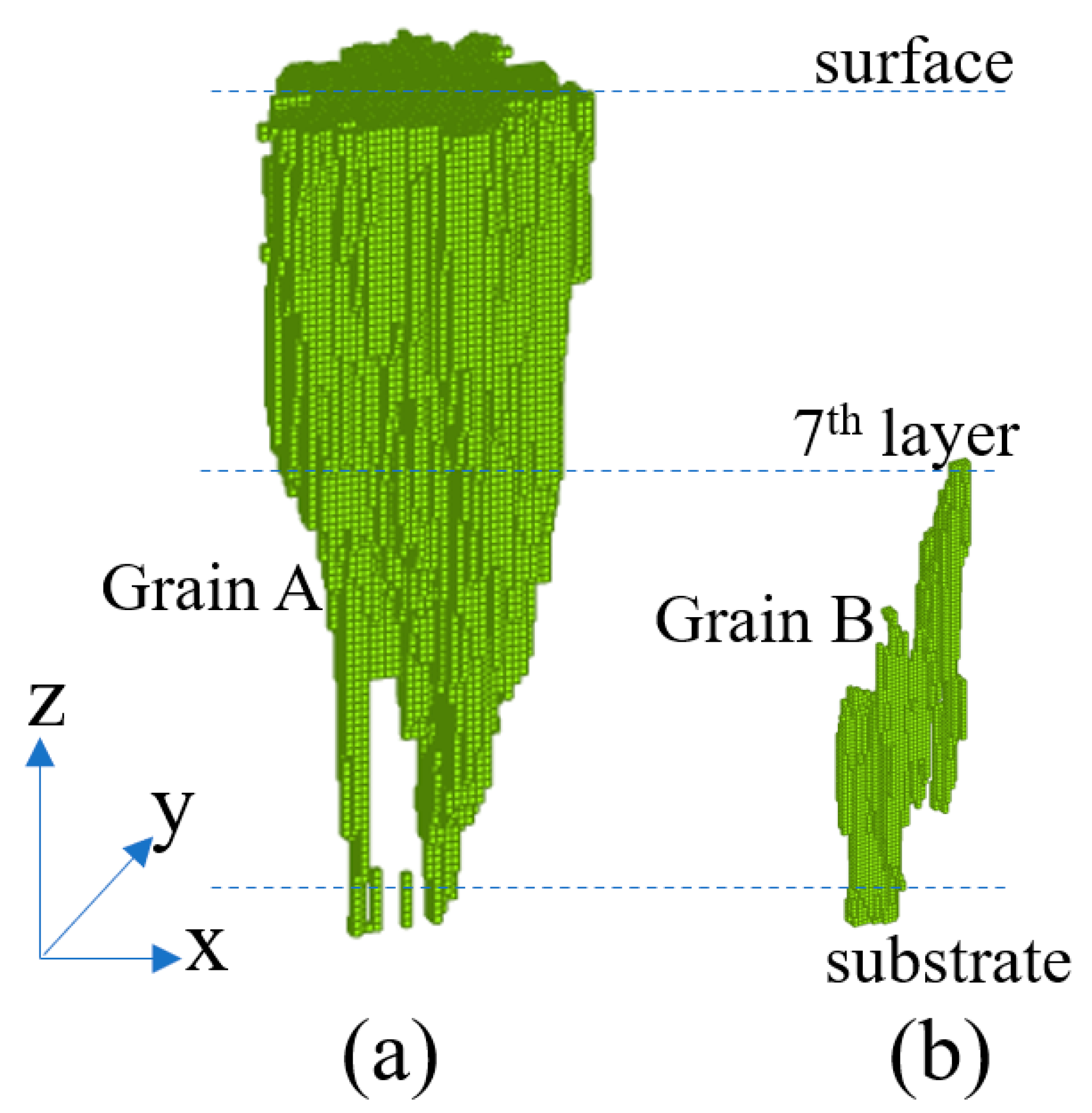

3.2. Microstructural Evolution and Validation

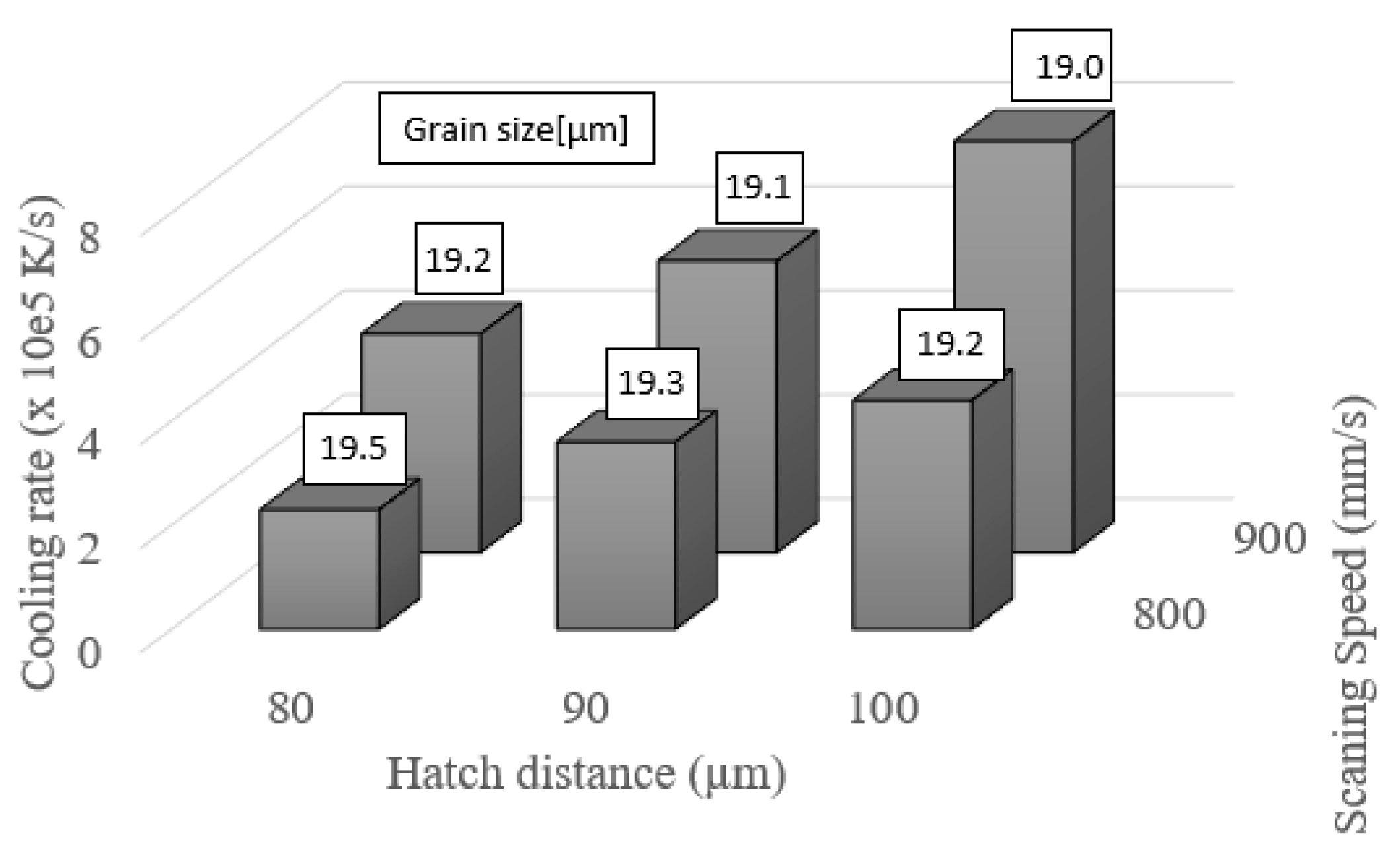

3.3. Microstructural Analysis Results for Different SLM Process Parameters

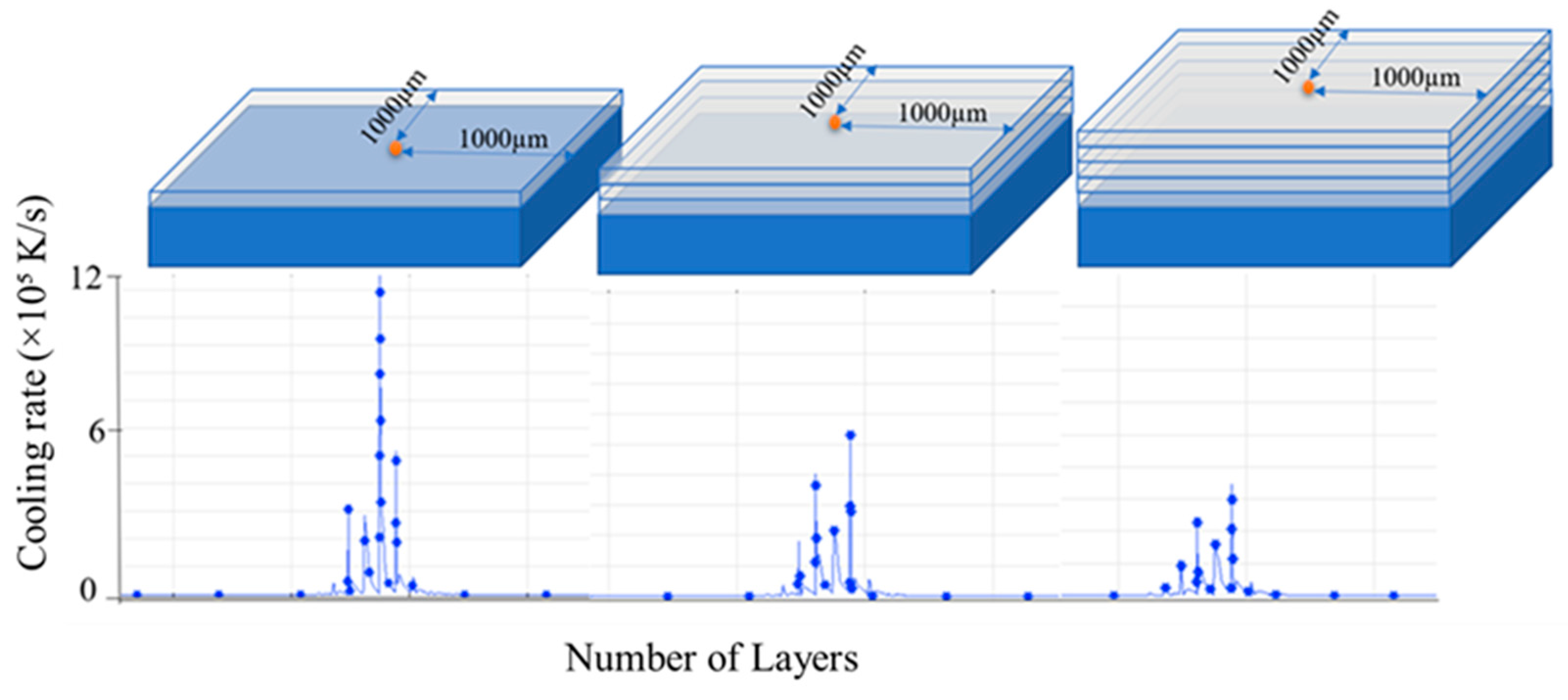

3.4. Effects of Cooling Rate on Grain Size

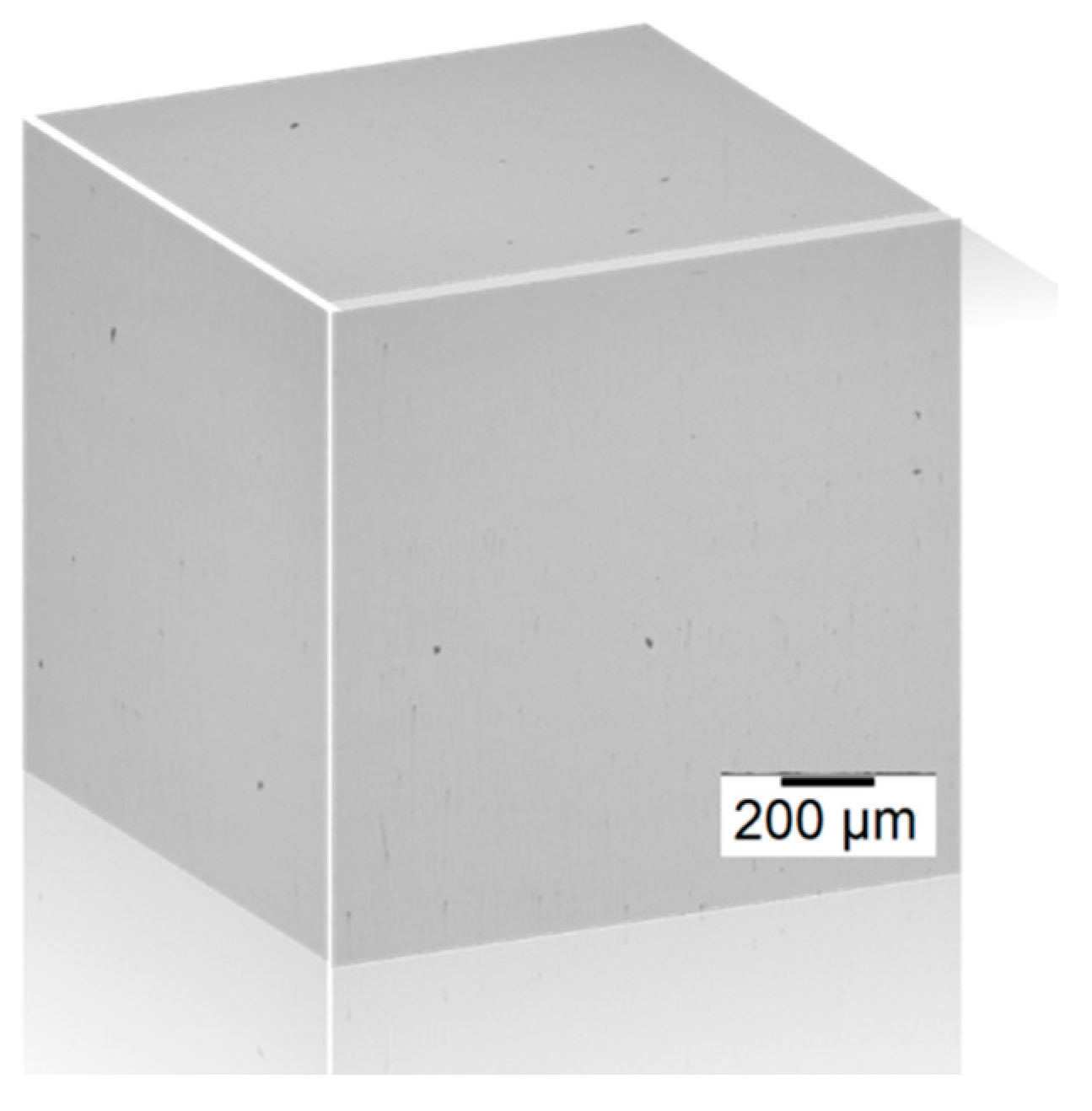

3.5. Predication of Pores

4. Conclusions

- An equiaxed grain structure is formed in the XY plane of the printed part in a direction perpendicular to the build direction. In addition, elongated grains with a length extending through several layers are formed in the vertical XZ and YZ planes.

- The final SLM component has a strong (001) texture, which indicates that most of the grains that win the epitaxy competitive grain growth process undergo preferred orientation in the <001> direction relative to the build direction (i.e., the z-axis).

- The grain size in the built part is directly related to the cooling rate. In particular, a lower cooling rate gives rise to a more uniform grain structure. The cooling rate can be actively controlled by adjusting the SLM process parameters such as the laser power, scanning speed, and hatch distance, and it also decreases naturally as a function of the build height.

- The density of the lack of fusion pores formed in the built component reduces with an increasing energy density and a reducing hatch distance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rehman, A.U.; Sglavo, V.M. 3D printing of geopolymer-based concrete for building applications. Rapid Prototyp. J. 2020, 26, 1783–1788. [Google Scholar] [CrossRef]

- Rehman, A.U.; Sglavo, V.M. 3D printing of Portland cement-containing bodies. Rapid Prototyp. J. 2021, in press. [Google Scholar] [CrossRef]

- Tran, H.C.; Lo, Y.L.; Le, T.N. A strategy to determine the optimal parameters for producing high density part in selective laser melting process. Stainl. Steel 2019, 316, 316L. [Google Scholar]

- Tran, H.-C.; Lo, Y.-L. Systematic approach for determining optimal processing parameters to produce parts with high density in selective laser melting process. Int. J. Adv. Manuf. Technol. 2019, 105, 4443–4460. [Google Scholar] [CrossRef]

- Lo, Y.-L.; Liu, B.-Y.; Tran, H.-C. Optimized hatch space selection in double-scanning track selective laser melting process. Int. J. Adv. Manuf. Technol. 2019, 105, 2989–3006. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Raza, M.M.; Lo, Y.-L. Experimental investigation into microstructure, mechanical properties, and cracking mechanism of IN713LC processed by laser powder bed fusion. Mater. Sci. Eng. A 2021, 819, 141527. [Google Scholar] [CrossRef]

- Rehman, A.U.; Pitir, F.; Salamci, M.U. Laser Powder Bed Fusion (LPBF) of In718 and the Impact of Pre-Heating at 500 and 1000 °C: Operando Study. Materials 2021, 14, 6683. [Google Scholar] [CrossRef]

- Rehman, A.U.; Pitir, F.; Salamci, M.U. Full-Field Mapping and Flow Quantification of Melt Pool Dynamics in Laser Powder Bed Fusion of SS316L. Materials 2021, 14, 6264. [Google Scholar] [CrossRef]

- Rehman, A.U.; Mahmood, M.A.; Pitir, F.; Salamci, M.U.; Popescu, A.C.; Mihailescu, I.N. Mesoscopic Computational Fluid Dynamics Modelling for the Laser-Melting Deposition of AISI 304 Stainless Steel Single Tracks with Experimental Correlation: A Novel Study. Metals 2021, 11, 1569. [Google Scholar] [CrossRef]

- Arısoy, Y.M.; Criales, L.E.; Özel, T.; Lane, B.; Moylan, S.; Donmez, A. Influence of scan strategy and process parameters on microstructure and its optimization in additively manufactured nickel alloy 625 via laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2016, 90, 1393–1417. [Google Scholar] [CrossRef]

- Amirjan, M.; Sakiani, H. Effect of scanning strategy and speed on the microstructure and mechanical properties of selective laser melted IN718 nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2019, 103, 1769–1780. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Ferrario, E.; Fornaci, A.; Riccio, M.; Romeo, M.; Tuissi, A. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 4913–4924. [Google Scholar] [CrossRef]

- Dezfoli, A.R.A.; Lo, Y.-L.; Raza, M.M. Microstructure and Elements Concentration of Inconel 713LC during Laser Powder Bed Fusion through a Modified Cellular Automaton Model. Crystals 2021, 11, 1065. [Google Scholar] [CrossRef]

- Song, J.; Zhang, L.; Wu, W.; He, B.; Ni, X.; Xu, J.; Zhu, G.; Yang, Q.; Wang, T.; Lu, L. Understanding processing parameters affecting residual stress in selective laser melting of Inconel 718 through numerical modeling. J. Mater. Res. 2019, 34, 1395–1404. [Google Scholar] [CrossRef]

- Lu, L.-X.; Sridhar, N.; Zhang, Y.-W. Phase field simulation of powder bed-based additive manufacturing. Acta Mater. 2017, 144, 801–809. [Google Scholar] [CrossRef]

- Fallah, V.; Amoorezaei, M.; Provatas, N.; Corbin, S.; Khajepour, A. Phase-field simulation of solidification morphology in laser powder deposition of Ti–Nb alloys. Acta Mater. 2012, 60, 1633–1646. [Google Scholar] [CrossRef]

- Gránásy, L.; Tóth, G.I.; Warren, J.A.; Podmaniczky, F.; Tegze, G.; Rátkai, L.; Pusztai, T. Phase-field modeling of crystal nucleation in undercooled liquids–A review. Prog. Mater. Sci. 2019, 106, 100569. [Google Scholar] [CrossRef]

- Gandin, C.-A.; Rappaz, M. A 3D Cellular Automaton algorithm for the prediction of dendritic grain growth. Acta Mater. 1997, 45, 2187–2195. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.-A. Probabilistic modelling of microstructure formation in solidification processes. Acta Met. Mater. 1993, 41, 345–360. [Google Scholar] [CrossRef]

- Lopez-Botello, O.E.; Martinez-Hernandez, U.; Ramírez, J.; Pinna, C.; Mumtaz, K. Two-dimensional simulation of grain structure growth within selective laser melted AA-2024. Mater. Des. 2017, 113, 369–376. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of grain structure during laser additive manufacturing. Simulation by a cellular automata method. Mater. Des. 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Rai, A.; Markl, M.; Körner, C. A coupled Cellular Automaton–Lattice Boltzmann model for grain structure simulation during additive manufacturing. Comput. Mater. Sci. 2016, 124, 37–48. [Google Scholar] [CrossRef]

- Dezfoli, A.R.A.; Hwang, W.S.; Huang, W.C.; Tsai, T.W. Determination and controlling of grain structure of metals after laser incidence: Theoretical approach. Sci. Rep. 2017, 7, 41527. [Google Scholar] [CrossRef] [Green Version]

- Koepf, J.A.; Gotterbarm, M.R.; Markl, M.; Körner, C. 3D multi-layer grain structure simulation of powder bed fusion additive manufacturing. Acta Mater. 2018, 152, 119–126. [Google Scholar] [CrossRef]

- Tao, P.; Li, H.; Huang, B.; Hu, Q.; Gong, S.; Xu, Q. The crystal growth, intercellular spacing and microsegregation of selective laser melted Inconel 718 superalloy. Vacuum 2018, 159, 382–390. [Google Scholar] [CrossRef]

- Calandri, M.; Yin, S.; Aldwell, B.; Calignano, F.; Lupoi, R.; Ugues, D. Texture and Microstructural Features at Different Length Scales in Inconel 718 Produced by Selective Laser Melting. Materials 2019, 12, 1293. [Google Scholar] [CrossRef] [Green Version]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloy. Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Thévoz, P.; Desbiolles, J.L.; Rappaz, M. Modeling of equiaxed microstructure formation in casting. Met. Mater. Trans. A 1989, 20, 311–322. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Met. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Geiger, M.; Leitz, K.-H.; Koch, H.; Otto, A. A 3D transient model of keyhole and melt pool dynamics in laser beam welding applied to the joining of zinc coated sheets. Prod. Eng. 2009, 3, 127–136. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, X. Study on the numerical simulation of the SLM molten pool dynamic behavior of a nickel-based superalloy on the workpiece scale. Materials 2019, 14, 2272. [Google Scholar]

- De Baere, D.; Bayat, M.; Mohanty, S.; Hattel, J. Thermo-fluid-metallurgical modelling of the selective laser melting process chain. Procedia CIRP 2018, 74, 87–91. [Google Scholar] [CrossRef]

- Morville, S.; Carin, M.; Muller, M.; Gharbi, M.; Peyre, P.; Carron, D.; Le, P.; Masson, R. 2D axial-symmetric model for fluid flow and heat transfer in the melting and resolidification of a vertical cylinder. In Proceedings of the COMSOL Conference Paris, Paris, France, 17–19 November 2010. [Google Scholar]

- Li, S.; Xiao, H.; Liu, K.; Xiao, W.; Li, Y.; Han, X.; Mazumder, J.; Song, L. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed- and continuous-wave laser additive manufacturing: A comparative study. Mater. Des. 2017, 119, 351–360. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Q.; Guillemot, G.; Gandin, C.A.; Bellet, M. Numerical modelling of fluid and solid thermomechanics in additive manufacturing by powder-bed fusion: Continuum and level set formulation applied to track- and part-scale simulations. Comptes Rendus Mécanique 2018, 346, 1055–1071. [Google Scholar] [CrossRef]

- The beer-lambert law. J. Chem. Educ. 1962, 39, 333. [CrossRef]

- Xiang, Z.; Yin, M.; Dong, G.; Mei, X.; Yin, G. Modeling of the thermal physical process and study on the reliability of linear energy density for selective laser melting. Results Phys. 2018, 9, 939–946. [Google Scholar] [CrossRef]

- Sih, S.S.; Barlow, J.W. The Prediction of the Emissivity and Thermal Conductivity of Powder Beds. Part. Sci. Technol. 2004, 22, 427–440. [Google Scholar] [CrossRef]

- Loh, L.-E.; Chua, C.K.; Yeong, W.Y.; Song, J.; Mapar, M.; Sing, S.L.; Liu, Z.H.; Zhang, D.Q. Numerical investigation and an effective modelling on the Selective Laser Melting (SLM) process with aluminium alloy 6061. Int. J. Heat Mass Transf. 2015, 80, 288–300. [Google Scholar] [CrossRef]

- Ovsienko, D.; Alfintsev, G.; Maslov, V. Kinetics and shape of crystal growth from the melt for substances with low L/kT values. J. Cryst. Growth 1974, 26, 233–238. [Google Scholar] [CrossRef]

- Zhu, M.F.; Hong, C.P. A Three Dimensional Modified Cellular Automaton Model for the Prediction of Solidification Microstructures. ISIJ Int. 2002, 42, 520–526. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Sawston, UK, 2002. [Google Scholar]

- Queva, A.; Mayi, Y.; Bellet, M.; Guillemot, G.; Peyre, P.; Dal, M.; Moriconi, C.; Metton, C. Thermo-mechanical simulation of track development in the Laser Beam Melting process—Effect of laser-metal interaction. IOP Conf. Series: Mater. Sci. Eng. 2019, 529, 012005. [Google Scholar] [CrossRef]

- Queva, A.; Guillemot, G.; Moriconi, C.; Metton, C.; Bellet, M. Numerical study of the impact of vaporisation on melt pool dynamics in Laser Powder Bed Fusion—Application to IN718 and Ti–6Al–4V. Addit. Manuf. 2020, 35, 101249. [Google Scholar] [CrossRef]

- Lenart, R.; Eshraghi, M. Modeling columnar to equiaxed transition in directional solidification of Inconel 718 alloy. Comput. Mater. Sci. 2019, 172, 109374. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Tang, Y.; Hu, Z.; Yukawa, N.; Morinaga, M.; Murata, Y. Rapidly solidified MC carbide morphologies of a laser-glazed single-crystal nickel-base superalloy. Mater. Sci. Eng. A 1992, 156, 109–116. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. Effects of thermal cycles on the microstructure evolution of Inconel 718 during selective laser melting process. Addit. Manuf. 2017, 18, 1–14. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloy. Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Faria, S.; Carvalho, O.; Pinto, E.; Alves, N.; Silva, F.; Miranda, G. Predictive models for physical and mechanical properties of Ti6Al4V produced by Selective Laser Melting. Mater. Sci. Eng. A 2016, 663, 181–192. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Steinbach, I. Modelling of Microstructure Formation in Metal Additive Manufacturing: Recent Progress, Research Gaps and Perspectives. Metals 2021, 11, 1425. [Google Scholar] [CrossRef]

- Bhutada, A.; Kumar, S.; Gunasegaram, D.; Alankar, A. Machine Learning Based Methods for Obtaining Correlations between Microstructures and Thermal Stresses. Metals 2021, 11, 1167. [Google Scholar] [CrossRef]

| Property (Unit) | Nomenclature | Value | Reference |

|---|---|---|---|

| Liquidus temperature [°C] | Tl | 1336 | [44] |

| Solidus temperature [°C] | Ts | 1260 | [44] |

| Evaporation temperature [°C] | Tv | 2911 | [45] |

| Density of liquid [kg.m3] | ρl | 7300 | [46] |

| Density of solid [kg.m3] | ρs | 8190 | [46] |

| Conductivity of liquid [J/m.s.K] | kl | 29.3 | [44] |

| Conductivity of solid [J/m.s.K] | ks | −7.0 × 10−6 T2 + 0.0294 T + 0.5603 | [44] |

| Specific heat of liquid [J/kg.K] | cl | 720 | [46] |

| Specific heat of solid [J/kg.K] | cs | 512 | [46] |

| Latent heat of fusion [kJ/kg] | ΔHm | 270 | [44] |

| Latent heat of vaporization [kJ/kg] | ΔHv | 6690 | [44] |

| Viscosity [kg/ms] | µ | 7.8 × 10−3 | [45] |

| Surface tension [N/m] | γ | 1.89 | [45] |

| Marangoni coefficient [N/m.K] | −1.1 × 10−4 | [45] | |

| Absorption (liquid) [mm−1] | A | 25 | [45,46] |

| Reflection coefficient | R | 0.7 | [46] |

| Liquidus slope [K/wt %] | ml | −10.5 | [47] |

| Initial equilibrium concentration [wt %] | C0 | 0.5 | [47] |

| Gibbs-Thomson coefficient [K.m] | Γ | 3.65 × 10−7 | [48] |

| Solute diffusion coefficient [m2/s] | Dl | 3 × 10−9 | [48] |

| Energy Density (J/mm3) | Laser Power (W) | Scanning Speed (mm/s) | Hatch Distance (µm) | Average Grain Size (µm) |

|---|---|---|---|---|

| 55.5 | 150 | 900 | 80 | 18.7 |

| 49.4 | 150 | 900 | 90 | 18.3 |

| 62.5 | 150 | 800 | 80 | 19.0 |

| 55.5 | 150 | 800 | 90 | 18.9 |

| 50 | 150 | 800 | 100 | 18.8 |

| 69.4 | 200 | 900 | 80 | 19.2 |

| 61.7 | 200 | 900 | 90 | 19.1 |

| 55.5 | 200 | 900 | 100 | 19.0 |

| 78.1 | 200 | 800 | 80 | 19.5 |

| 69.4 | 200 | 800 | 90 | 19.3 |

| 62.5 | 200 | 800 | 100 | 19.2 |

| Energy Density (J/mm3) | Laser Power (W) | Scanning Speed (mm/s) | Hatch Distance (µm) | Porosity % |

|---|---|---|---|---|

| 55.5 | 150 | 900 | 80 | 1.30 |

| 49.4 | 150 | 900 | 90 | 7.30 |

| 62.5 | 150 | 800 | 80 | 1.10 |

| 55.5 | 150 | 800 | 90 | 2.90 |

| 50 | 150 | 800 | 100 | 3.60 |

| 69.4 | 200 | 900 | 80 | 0.09 |

| 61.7 | 200 | 900 | 90 | 0.77 |

| 55.5 | 200 | 900 | 100 | 1.80 |

| 78.1 | 200 | 800 | 80 | 0.03 |

| 69.4 | 200 | 800 | 90 | 0.19 |

| 62.5 | 200 | 800 | 100 | 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dezfoli, A.R.A.; Lo, Y.-L.; Raza, M.M. 3D Multi-Track and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting. Materials 2021, 14, 7346. https://doi.org/10.3390/ma14237346

Dezfoli ARA, Lo Y-L, Raza MM. 3D Multi-Track and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting. Materials. 2021; 14(23):7346. https://doi.org/10.3390/ma14237346

Chicago/Turabian StyleDezfoli, Amir Reza Ansari, Yu-Lung Lo, and M. Mohsin Raza. 2021. "3D Multi-Track and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting" Materials 14, no. 23: 7346. https://doi.org/10.3390/ma14237346

APA StyleDezfoli, A. R. A., Lo, Y.-L., & Raza, M. M. (2021). 3D Multi-Track and Multi-Layer Epitaxy Grain Growth Simulations of Selective Laser Melting. Materials, 14(23), 7346. https://doi.org/10.3390/ma14237346