Prediction of Geometric Characteristics of Melt Track Based on Direct Laser Deposition Using M-SVR Algorithm

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Experimental Materials

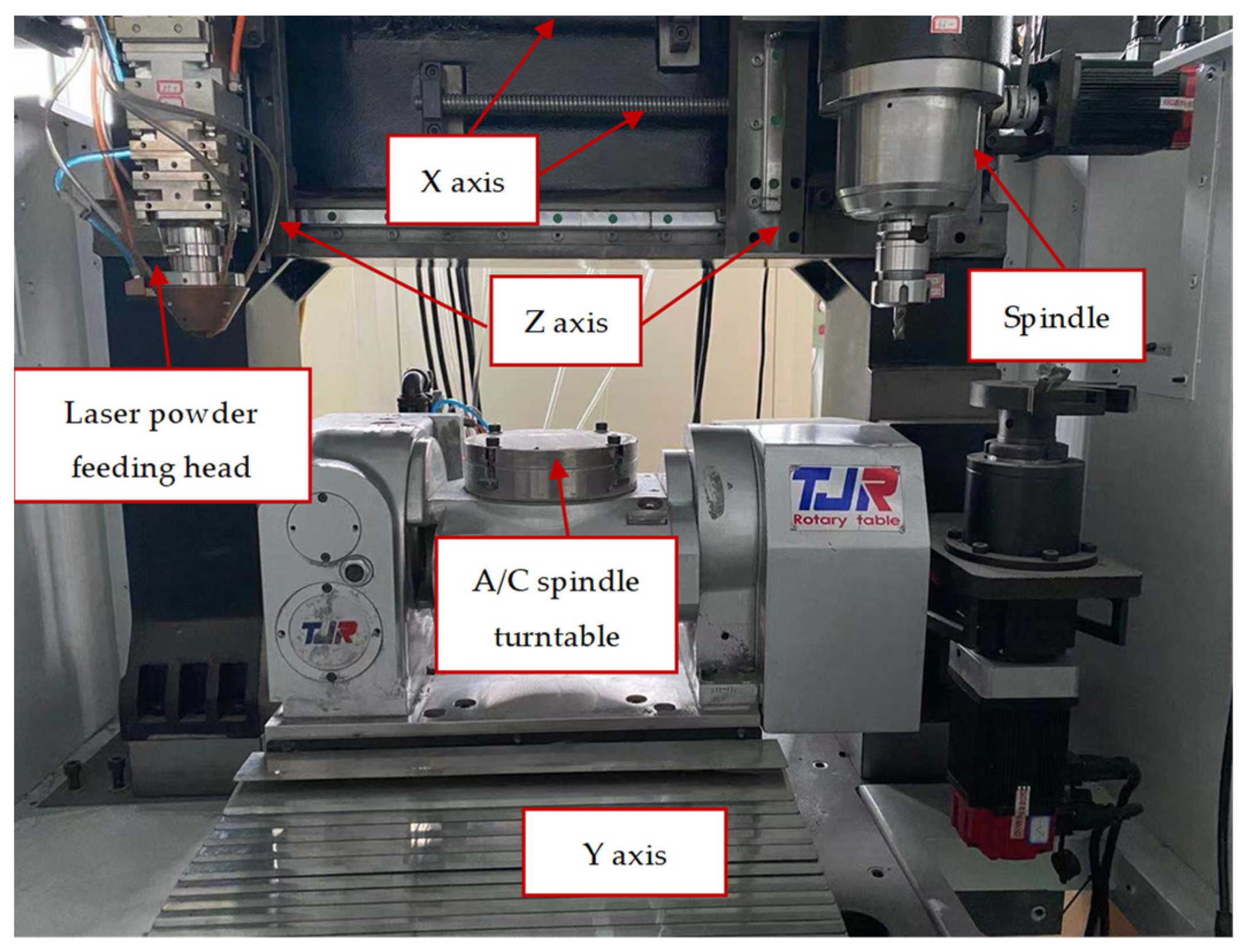

2.2. Experimental Setup

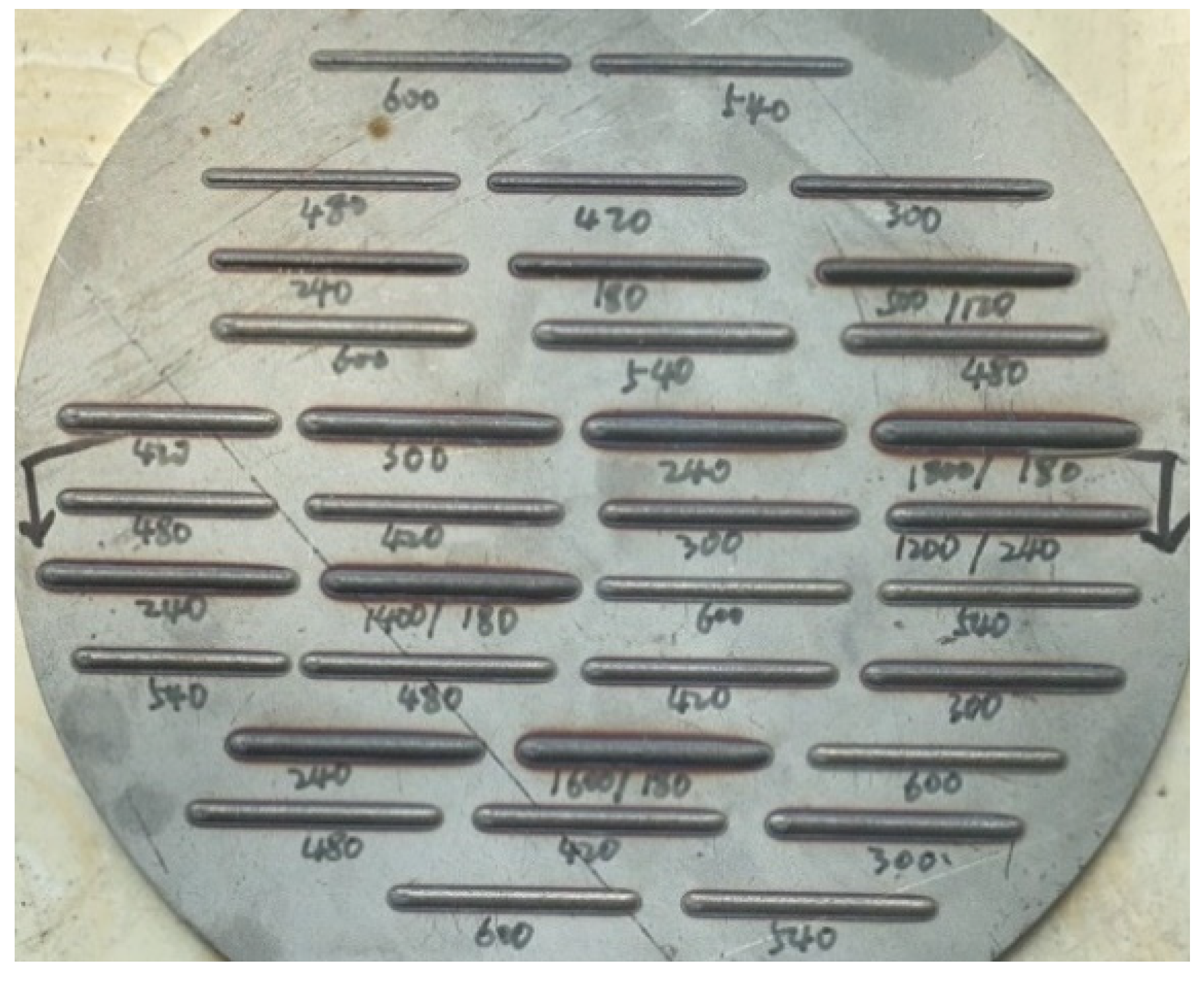

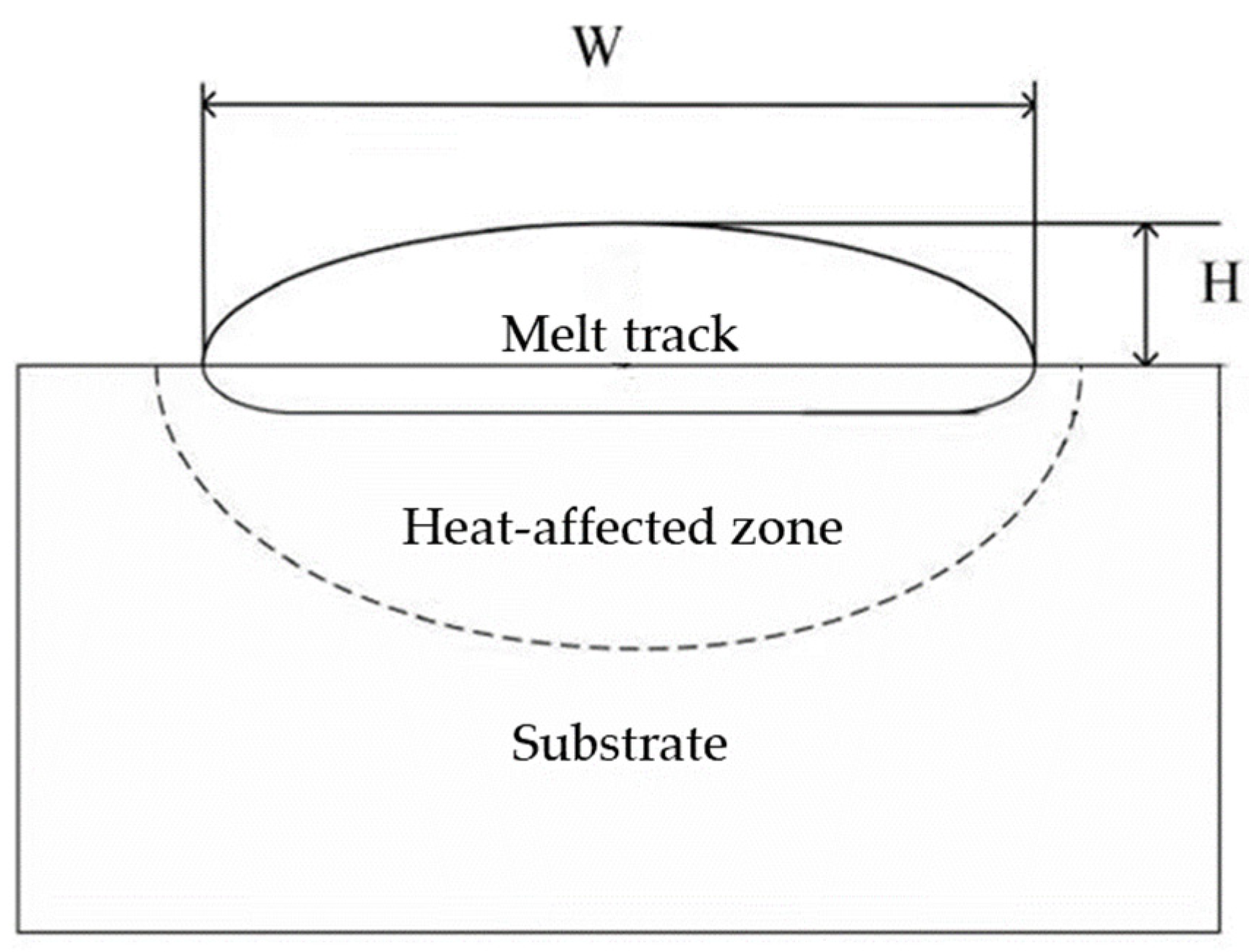

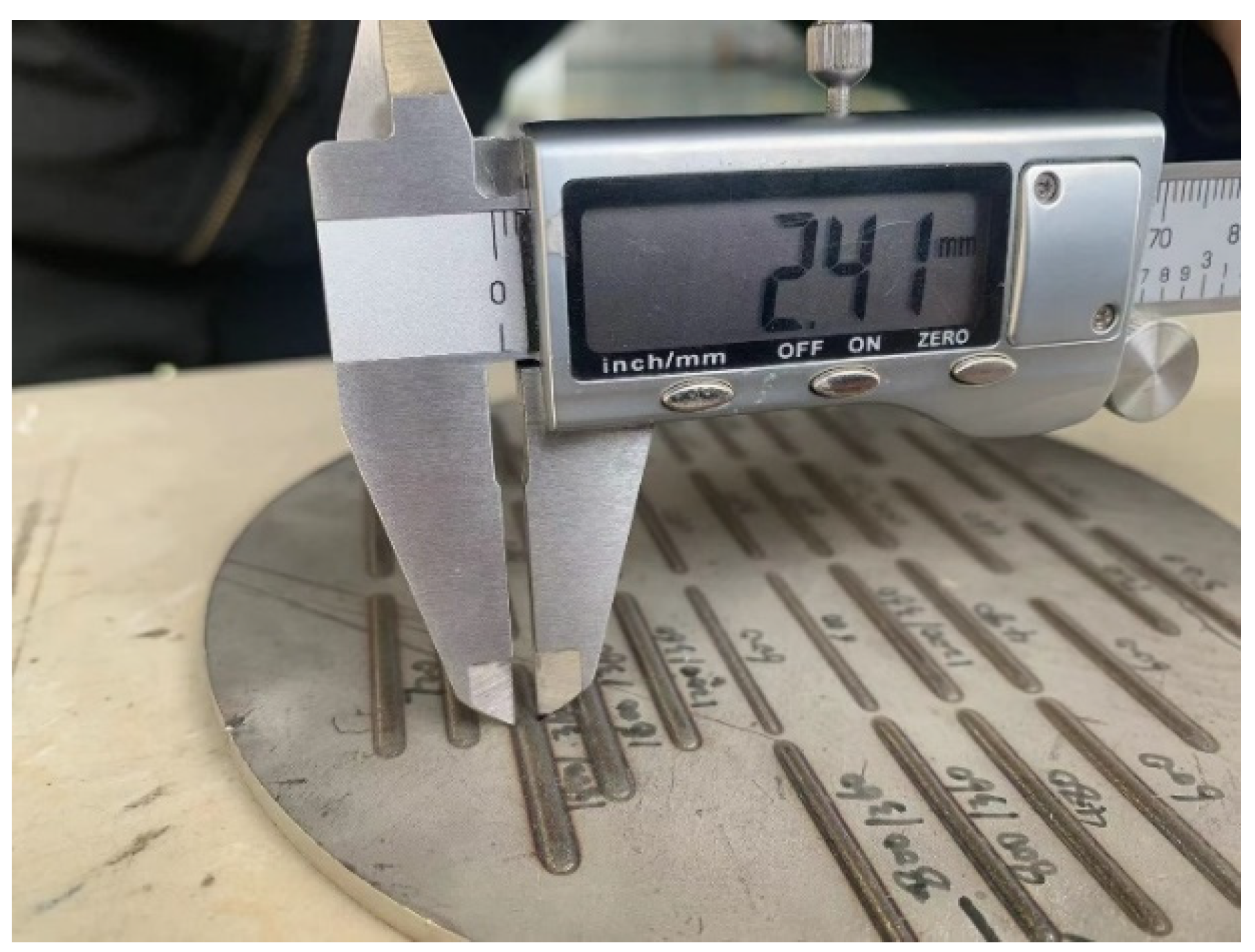

2.3. Experimental Data

3. Principles and Methods

3.1. Basic Principles of the Multi-Output Support Vector Regression Algorithm

3.2. Basic Principles of Backpropagation Neural Network

4. Result and Discussion

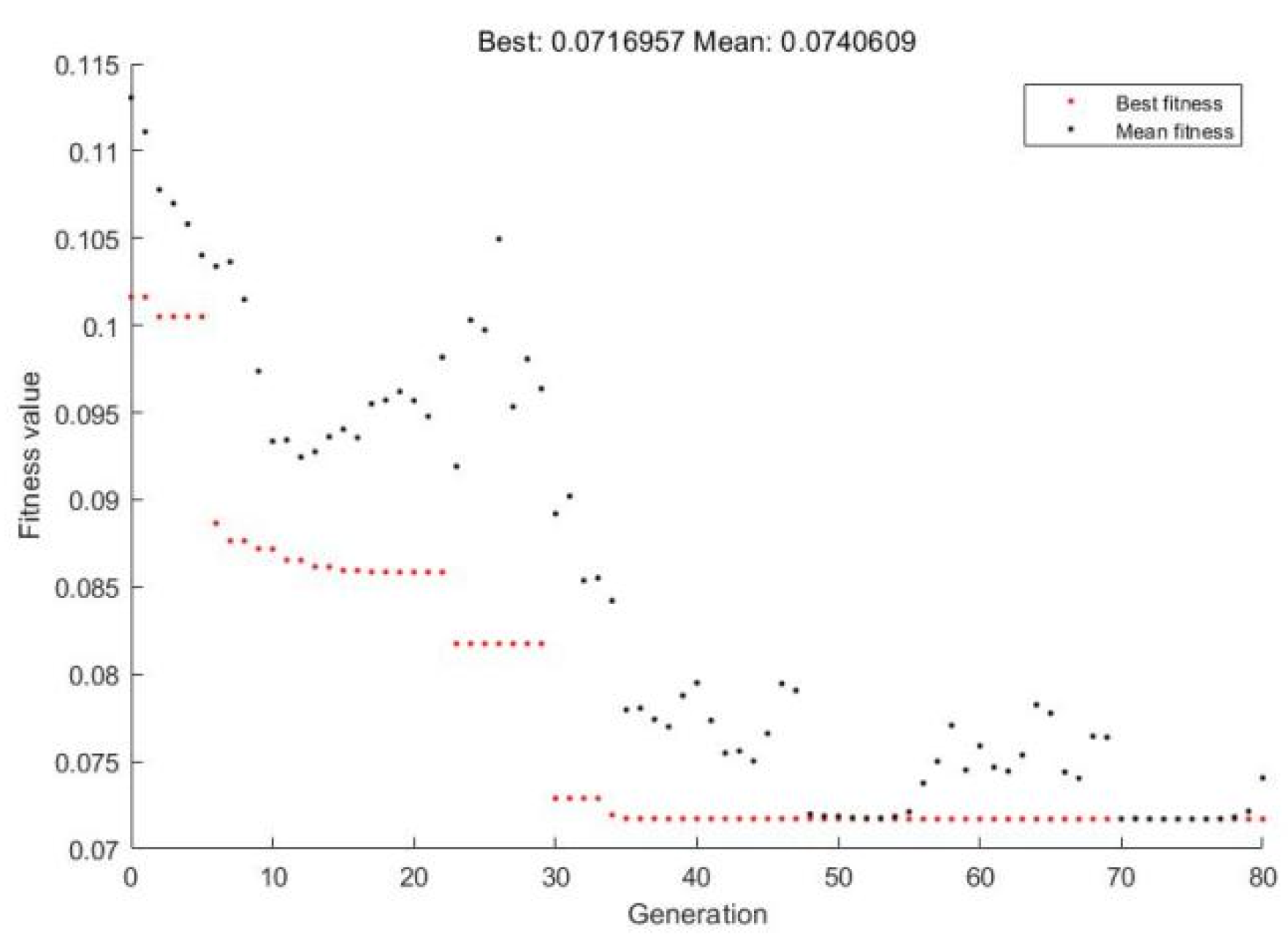

4.1. Prediction Model Establishment

4.2. Performance Evaluation

4.3. Prediction Accuracy Analysis

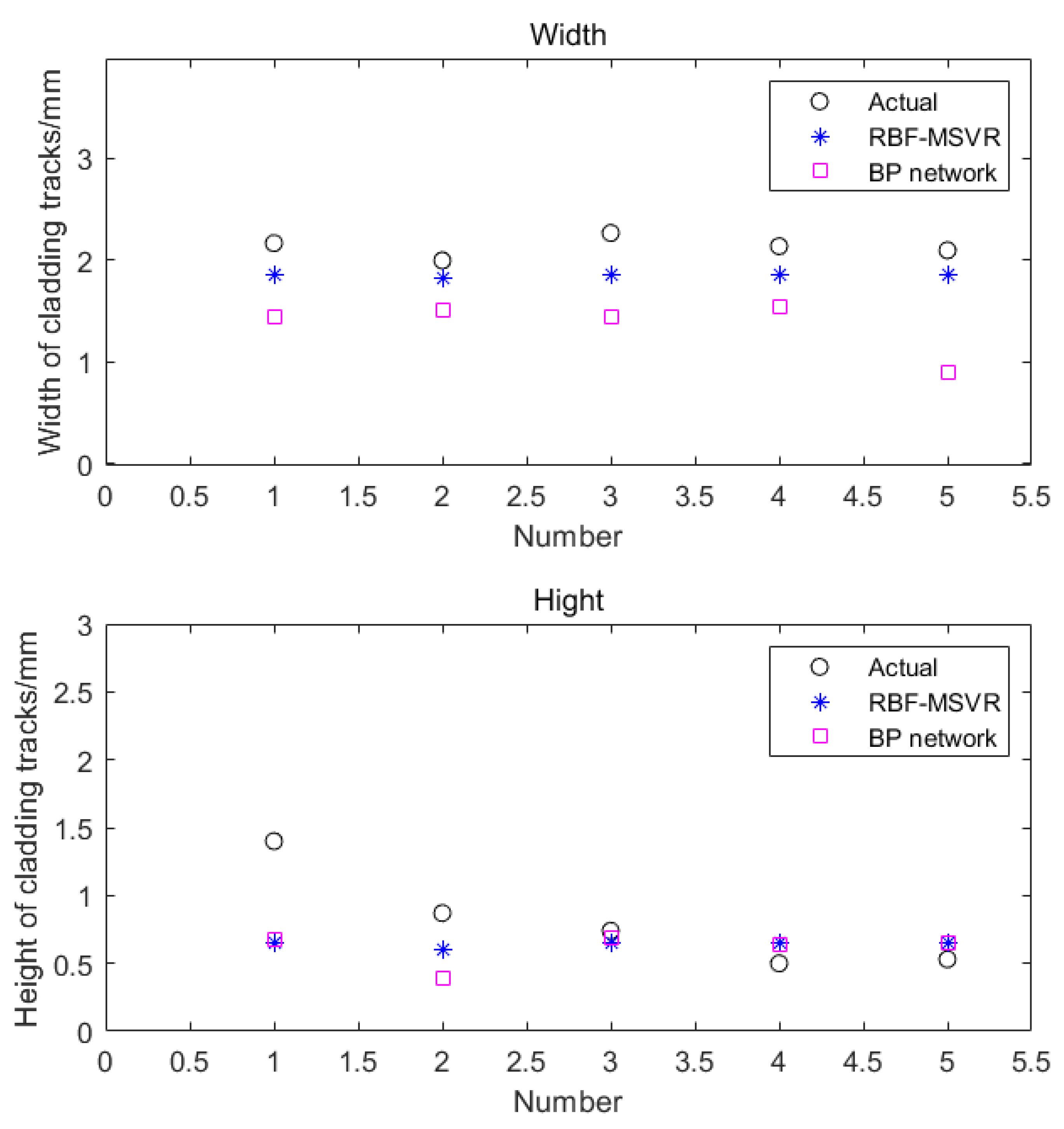

4.4. Model Validation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Long, R.S.; Liu, W.J.; Shang, X.F. Numerical Simulation of Temperature Field on Laser Metal Deposition Shaping. Laser Technol. 2007, 31, 394–396. (In Chinese) [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Guo, C.; H, S.; Y, H.; L, Q.; H, G. Prediction modelling and process optimization for forming multi-layer cladding structures with laser directed energy deposition. Opt. Laser Technol. 2020, 134, 1–10. [Google Scholar] [CrossRef]

- Boddu, M.R.; Landers, R.G.; Liou, F.W. Control of Laser Cladding for Rapid Prototyping—A Review. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2001; pp. 6–8. [Google Scholar]

- Lei, K.; Qin, X.; Liu, H.; Ran, Y. Prediction on characteristics of molten pool in wide-band laser cladding based on neural network. Optoelectr. Laser 2018, 29, 1212–1220. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, M. Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd:YAG laser. Opt. Lasers Eng. 2012, 50, 985–995. [Google Scholar] [CrossRef]

- Nabhani, M.; Razavi, R.S.; Barekat, M. An empirical-statistical model for laser cladding of Ti-6Al-4V powder on Ti-6Al-4V substrate. Opt. Laser Technol. 2018, 100, 265–271. [Google Scholar] [CrossRef]

- Fan, P.; Zhang, G. Study on process optimization of WC-Co50 cermet composite coating by laser cladding. Int. J. Refract. Met. Hard Mater. 2019, 87, 105133. [Google Scholar] [CrossRef]

- Davim, J.P.; Oliveira, C.; Cardoso, A. Predicting the geometric form of clad in laser cladding by powder using multiple regression analysis (MRA). Mater. Des. 2008, 29, 554–557. [Google Scholar] [CrossRef]

- Xu, Z.M.; Wu, H.B.; Hong, Z.H. Quality Prediction of Laser Cladding Based on Evolutionary Neural Network. Appl. Mech. Mater. 2011, 44, 1012–1017. [Google Scholar] [CrossRef]

- Acherjee, B.; Mondal, S.; Tudu, B.; Misra, D. Application of artificial neural network for predicting weld quality in laser transmission welding of thermoplastics. Appl. Soft Comput. J. 2011, 11, 2548–2555. [Google Scholar] [CrossRef]

- Mondal, S.; Bandyopadhyay, A.; Pal, P.K. Application of artificial neural network for the prediction of laser cladding process characteristics at Taguchi-based optimized condition. Int. J. Adv. Manuf. Technol. 2014, 70, 2151–2158. [Google Scholar] [CrossRef]

- Fabrizia, C.; Alessandra, C. Laser Direct Metal Deposition of 2024 Al Alloy: Trace Geometry Prediction via Machine Learning. Materials 2018, 11, 444. [Google Scholar]

- Yin, F.; Mao, H.; Hua, L. A hybrid of back propagation neural network and genetic algorithm for optimization of injection molding process parameters. Mater. Des. 2011, 32, 3457–3464. [Google Scholar] [CrossRef]

- Yuguang, Z.; Kai, X.; Dongyan, S. An improved artificial neural network for laser welding parameter selection and prediction. Int. J. Adv. Manuf. Technol. 2013, 68, 755–762. [Google Scholar] [CrossRef]

- Xiao, T.T.; Cai, C.Z.; Tang, J.L.; Huang, S.J. Modeling of Transition Temperature for Pulsed Laser Deposition NdBa2Cu3O7-δ Thin Films via Support Vector Regression. Int. J. Mod. Phys. B 2013, 27, 1362040. [Google Scholar] [CrossRef]

- Yang, L.; Li, W.G. Optimization of Process of In-Situ Technology Based on SVR and PSO. Mater. Technol. 2012, 20, 44–48. [Google Scholar] [CrossRef]

- Ye, J.X.; Li, Z.G.; Wu, J. Optimal underwater welding process based on SVR model. Trans. China Weld. Inst. 2017, 38, 69–72. [Google Scholar] [CrossRef]

- Chen, T.; Wu, W.; Li, W.; Liu, D. Laser cladding of nanoparticle TiC ceramic powder: Effects of process parameters on the quality characteristics of the coatings and its prediction model. Opt. Laser Technol. 2019, 116, 345–355. [Google Scholar] [CrossRef]

- Yao, W.; Huang, Y.L.; Yang, Y.Q. Size Prediction of Directed Energy Deposited Cladding Tracks Based on Support Vector Regression. Chin. J. Lasers 2020, 47, 0802007. [Google Scholar] [CrossRef]

- Xu, S.; An, X.; Qiao, X.; Zhu, L.; Li, L. Multi-output least-squares support vector regression machines. Pattern Recognit. Lett. 2013, 34, 1078–1084. [Google Scholar] [CrossRef]

- Liu, H.; Qin, X.; Huang, S.; Jin, L.; Wang, Y.; Lei, K. Geometry Characteristics Prediction of Single Track Cladding Deposited by High Power Diode Laser Based on Genetic Algorithm and Neural Network. Int. J. Precis. Eng. Manuf. 2018, 19, 1061–1070. [Google Scholar] [CrossRef]

- Akhtar, T.M.N.; Sathish, V.M. Optimization of Process Parameters in CNC Turning of Aluminum 7075 Alloy Using L27 Array-Based Taguchi Method. Materials 2021, 14, 4470. [Google Scholar] [CrossRef] [PubMed]

- Hu, R. Multi-output support vector regression algorithm. J. East China Jiaotong Univ. 2007, 24, 129–132. (In Chinese) [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E. Learning Internal Representations by Error Propagation. In Parallel Distributed Processing; Mechanisms of Sentence Processing: Assigning Roles to Constituents of Sentences; Springer: Boston, MA, USA, 1986; pp. 318–362. [Google Scholar] [CrossRef]

| Cr | Ni | Mo | Si | Mn | O | S | C | Fe |

|---|---|---|---|---|---|---|---|---|

| 17.92 | 12.04 | 2.42 | 0.52 | 0.051 | 0.0451 | 0.010 | 0.0095 | allowance |

| Type | Measurement Uncertainty | Measurement Range | Resolution |

|---|---|---|---|

| Deloitte: DL91150 | 0.03 mm | 150 mm | 0.01 mm |

| Test Number | P/W | W/mm | H/mm | ||

|---|---|---|---|---|---|

| 1 | 800 | 360 | 0.25 | 1.60 | 0.62 |

| 2 | 800 | 360 | 0.35 | 1.54 | 0.80 |

| 3 | 800 | 360 | 0.45 | 1.60 | 0.94 |

| 4 | 800 | 480 | 0.25 | 1.49 | 0.45 |

| 5 | 800 | 480 | 0.35 | 1.44 | 0.65 |

| 6 | 800 | 480 | 0.45 | 1.50 | 0.83 |

| 7 | 800 | 540 | 0.25 | 1.46 | 0.35 |

| 8 | 800 | 600 | 0.35 | 1.36 | 0.56 |

| 9 | 800 | 600 | 0.45 | 1.40 | 0.64 |

| 10 | 1200 | 360 | 0.25 | 2.05 | 0.72 |

| 11 | 1200 | 360 | 0.35 | 2.00 | 0.87 |

| 12 | 1200 | 360 | 0.45 | 2.14 | 1.10 |

| 13 | 1200 | 480 | 0.25 | 1.81 | 0.47 |

| 14 | 1200 | 480 | 0.35 | 1.90 | 0.71 |

| 15 | 1200 | 480 | 0.45 | 2.00 | 0.94 |

| 16 | 1200 | 600 | 0.25 | 1.76 | 0.35 |

| 17 | 1200 | 600 | 0.35 | 1.78 | 0.62 |

| 18 | 1200 | 600 | 0.45 | 1.80 | 0.73 |

| 19 | 1800 | 360 | 0.25 | 2.45 | 0.53 |

| 20 | 1800 | 360 | 0.35 | 2.39 | 0.95 |

| 21 | 1800 | 360 | 0.45 | 2.42 | 1.05 |

| 22 | 1800 | 480 | 0.25 | 2.20 | 0.40 |

| 23 | 1800 | 480 | 0.35 | 2.21 | 0.70 |

| 24 | 1800 | 480 | 0.45 | 2.28 | 0.78 |

| 25 | 1800 | 600 | 0.25 | 2.00 | 0.32 |

| 26 | 1800 | 600 | 0.35 | 2.15 | 0.58 |

| 27 | 1800 | 600 | 0.45 | 2.20 | 0.65 |

| Model | RMSE | R2 |

|---|---|---|

| M-SVR | 0.07 | 0.92 |

| S-SVR | 0.54 | 0.92 |

| Test Number | P/W | W/mm | H/mm | ||

|---|---|---|---|---|---|

| 1 | 1000 | 180 | 0.25 | 2.17 | 1.40 |

| 2 | 1200 | 600 | 0.35 | 2.00 | 0.87 |

| 3 | 1400 | 240 | 0.25 | 2.27 | 0.74 |

| 4 | 1600 | 420 | 0.25 | 2.14 | 0.50 |

| 5 | 1800 | 660 | 0.35 | 2.10 | 0.53 |

| Model | Prediction of Track Width(mm) | Prediction of Track Height (mm) | ||

|---|---|---|---|---|

| RMSE | MAE | RMSE | MAE | |

| BP neural network | 0.15 | 0.15 | 0.05 | 0.06 |

| M-SVR | 0.02 | 0.05 | 0.05 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Xiao, M.; Kang, D.; Sang, Y.; Zhang, Z.; Jin, X. Prediction of Geometric Characteristics of Melt Track Based on Direct Laser Deposition Using M-SVR Algorithm. Materials 2021, 14, 7221. https://doi.org/10.3390/ma14237221

Chen X, Xiao M, Kang D, Sang Y, Zhang Z, Jin X. Prediction of Geometric Characteristics of Melt Track Based on Direct Laser Deposition Using M-SVR Algorithm. Materials. 2021; 14(23):7221. https://doi.org/10.3390/ma14237221

Chicago/Turabian StyleChen, Xiyi, Muzheng Xiao, Dawei Kang, Yuxin Sang, Zhijing Zhang, and Xin Jin. 2021. "Prediction of Geometric Characteristics of Melt Track Based on Direct Laser Deposition Using M-SVR Algorithm" Materials 14, no. 23: 7221. https://doi.org/10.3390/ma14237221

APA StyleChen, X., Xiao, M., Kang, D., Sang, Y., Zhang, Z., & Jin, X. (2021). Prediction of Geometric Characteristics of Melt Track Based on Direct Laser Deposition Using M-SVR Algorithm. Materials, 14(23), 7221. https://doi.org/10.3390/ma14237221