An Experimental Study of Damage Detection on Typical Joints of Jackets Platform Based on Electro-Mechanical Impedance Technique

Abstract

1. Introduction

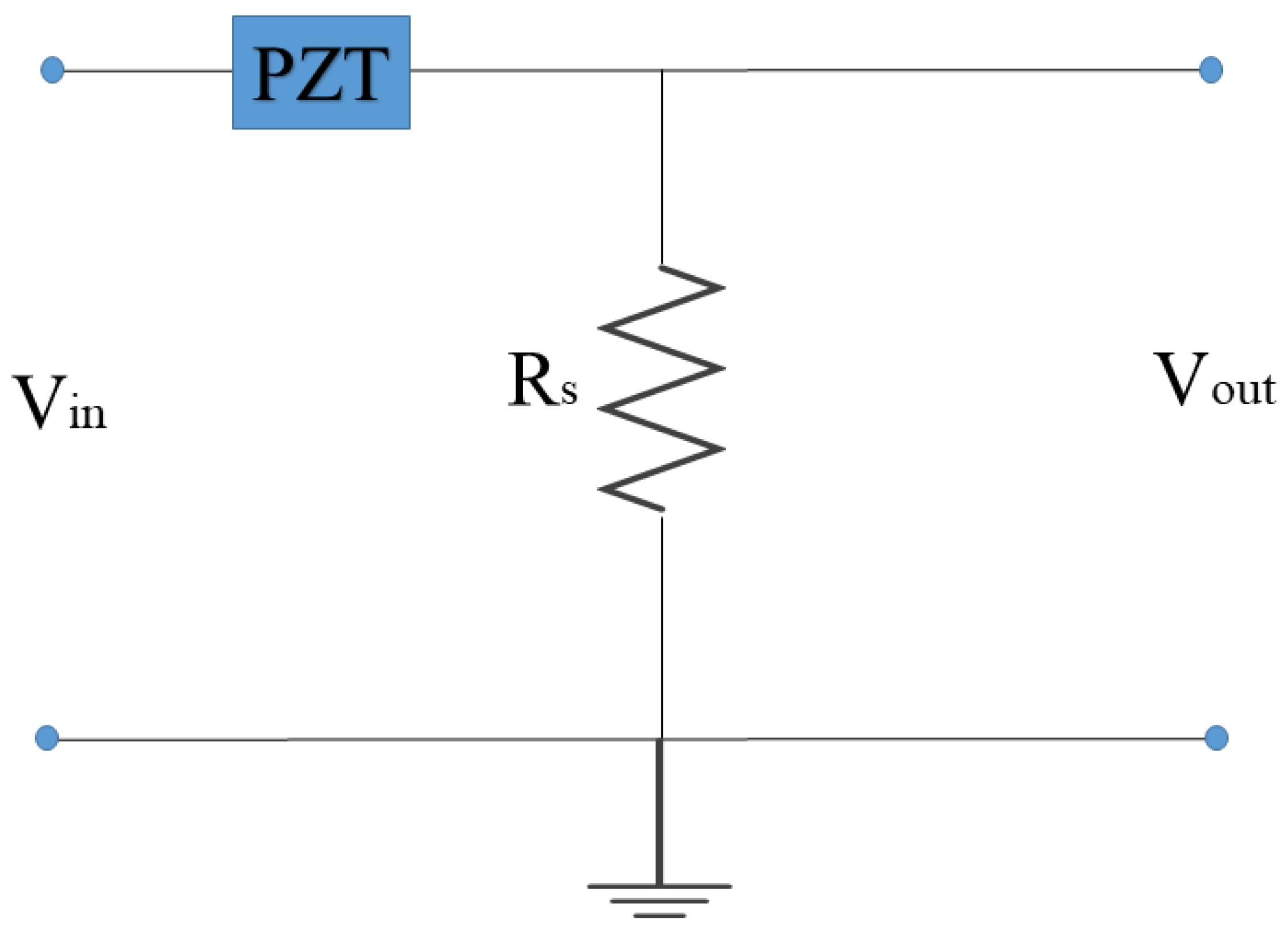

2. Theory of Electro-Mechanical Impedance Techniques

3. Experiment Setup

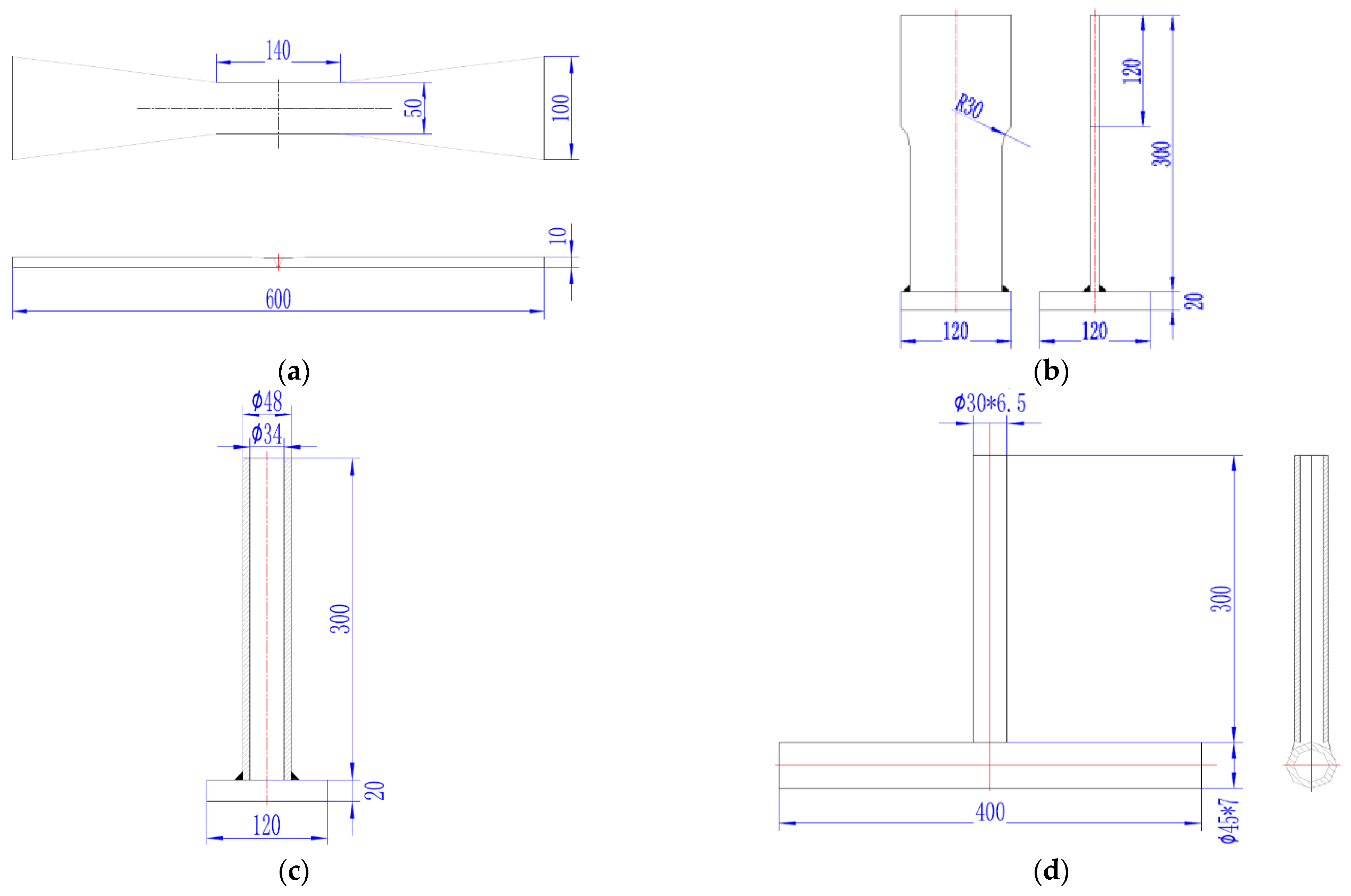

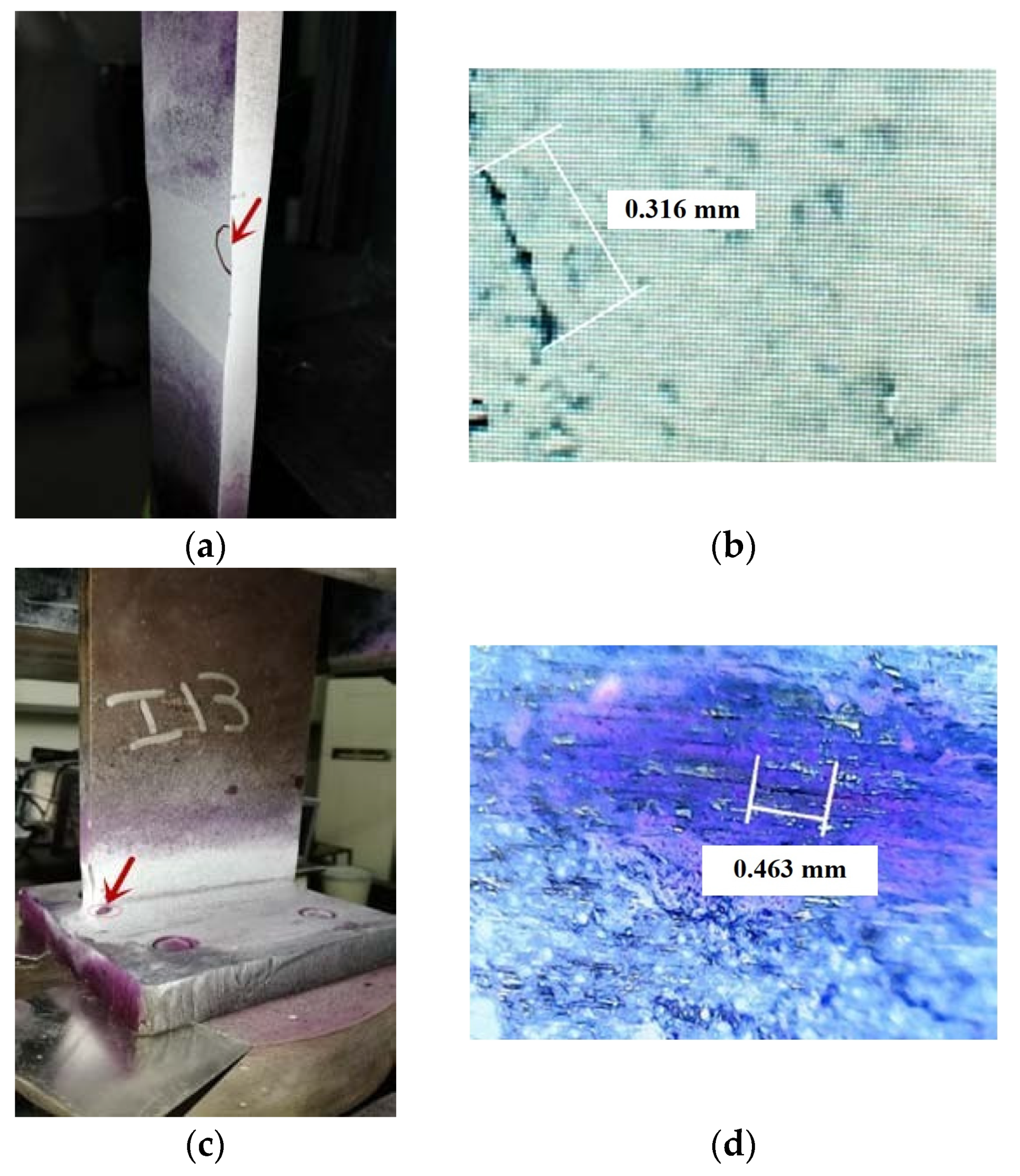

3.1. Specimens and Load

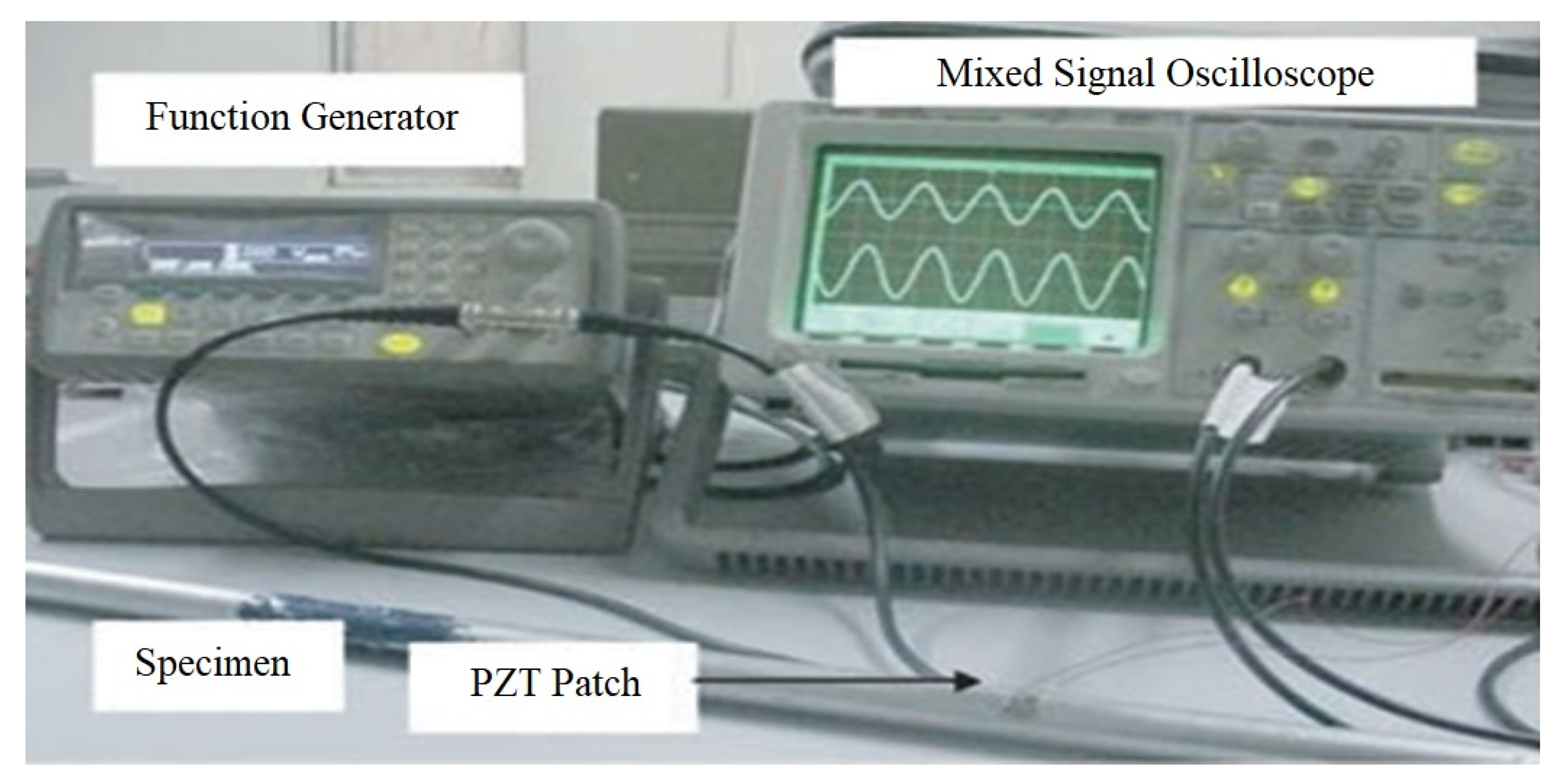

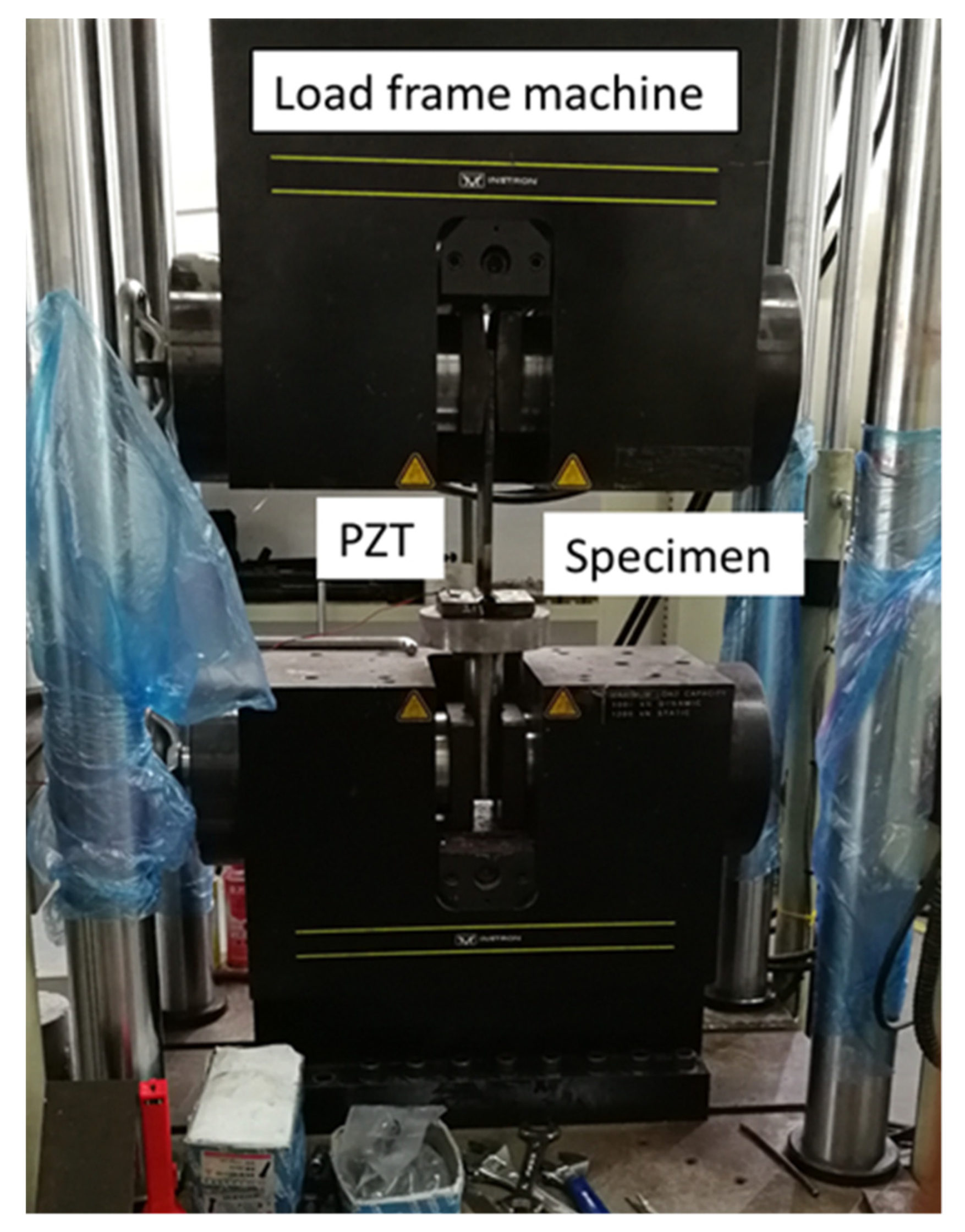

3.2. Experimental Arrangement

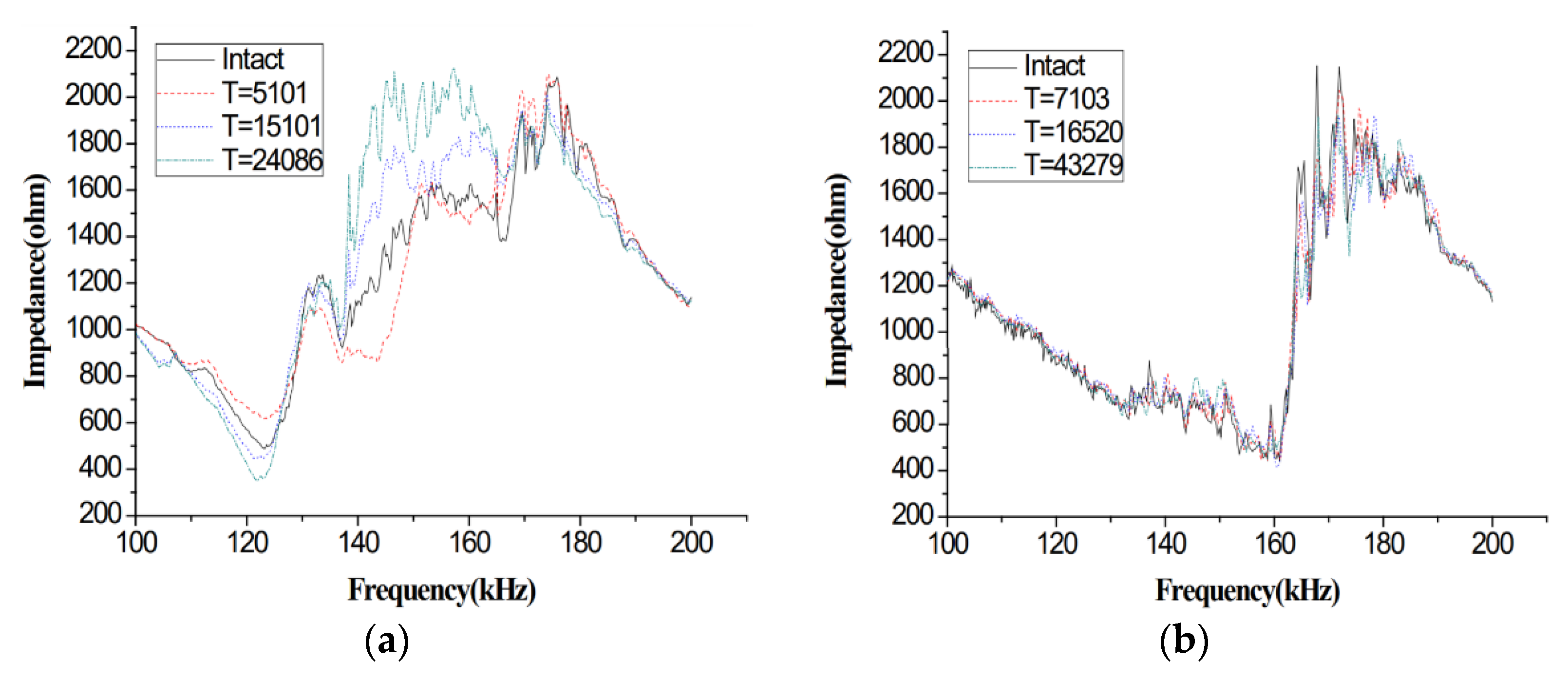

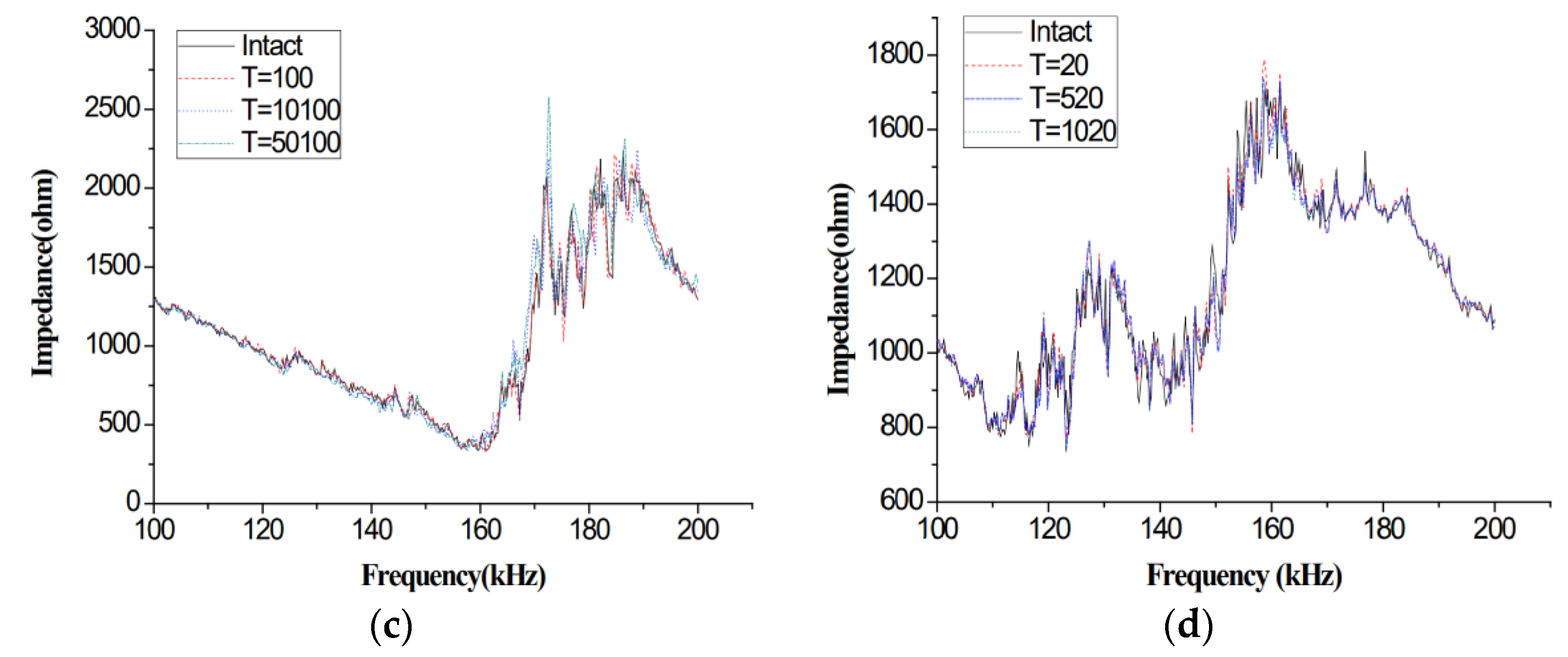

4. Results and Discussion

5. Summary

- The admittance signals from PZTs cause the reflection of cracks inside welded steel joints. When the damage appears in the welded zone of the specimen, it influences the recorded impedance plots and presents the variations of dynamic properties in the host structures that help in locating the initiated cracks.

- The maximum value of the impedance corresponds to occurrence of the damage in the welded specimens. Load acting on the host structure continuously changes its dynamical properties, and therefore, the EMI results from each damage case would be different from other cases for a specific host structure during the entire loading condition.

- The value of the RMSD smartly displays the modifications of the EM impedance entrance signs among the intact and discovered destruction cases. The largest RMSD value of damage cases represents very effectively the occurrence of damage. The RMSD analysis provides significant data for destruction detection.

- The EMI technique has the strength of detecting cracks in the welded joints in initial phases which can help in avoiding catastrophic failures of offshore structures.

- The efficiency of the EMI technique, based on the root means square deviation method, expresses a good capability of the proposed methodology for detecting cracks in welded metallic structures.

- Based on the crack detection results in the current study, the EMI technique is highly efficient and reliable and can be used in a variety of engineering applications.

6. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Na, S.; Lee, H. Steel wire electromechanical impedance method using a piezoelectric material for composite structures with complex surfaces. Compos. Struct. 2013, 98, 79–84. [Google Scholar] [CrossRef]

- Chopra, I. Review of state-of-art of smart structures and integrated systems. AIAA J. 2002, 40, 2145–2187. [Google Scholar] [CrossRef]

- Tawie, R.; Lee, H. Piezoelectric-based non-destructive monitoring of hydration of reinforced concrete as an indicator of bond development at the steel–concrete interface. Cem. Concr. Res. 2010, 40, 1697–1703. [Google Scholar] [CrossRef]

- Song, H.; Lim, H.; Sohn, H. Electromechanical impedance measurement from large structures using a dual piezoelectric transducer. J. Sound Vib. 2013, 332, 6580–6595. [Google Scholar] [CrossRef]

- Na, S.; Lee, H.K. Resonant frequency range utilized electro-mechanical impedance method for damage detection performance on composite structures. Compos. Struct. 2012, 94, 2383–2389. [Google Scholar] [CrossRef]

- Na, S.; Tawie, R.; Lee, H.K. Electro-mechanical impedance method of FRP adhesive joints in corrosive environment using a reusable piezoelectric device. J. Intell. Mate. Syst. Struct. 2012, 23, 737–747. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.; Inman, D.J. Feasibility of using impedance-based damage assessment for pipeline systems. Earthq. Eng. Struct. Dyn. 2001, 30, 1463–1474. [Google Scholar] [CrossRef]

- Sodano, H.A.; Park, G.; Inman, D.J. An investigation into the performance of microfiber composites for sensing and structural vibration applications. Mech. Syst. Signal Process. 2004, 18, 683–697. [Google Scholar] [CrossRef]

- Sun, F.P.; Chaudhry, Z.; Liang, C.; Rogers, C.A. Truss Structure Integrity Identification Using PZT Sensor-Actuator. J. Intell. Mater. Syst. Struct. 1995, 6, 134–139. [Google Scholar] [CrossRef]

- Peairs, D.M.; Park, G.; Inman, D.J. Improving Accessibility of the Impedance-Based Structural Health Monitoring Method. J. Intell. Mater. Syst. Struct. 2004, 15, 129–139. [Google Scholar] [CrossRef]

- Xu, B.; Giurgiutiu, V. A Low-cost and field portable electromechanical (E/M) impedance analyzer for active structural health monitoring. In Proceedings of the 5th International Workshop on Structural Health Monitoring, Stanford University, Stanford, CA, USA, 15–17 September 2005. [Google Scholar]

- Panigrahi, R.; Bhalla, S.; Gupta, A. A cost-effective variant of electromechanical impedance technique for structural health monitoring. Exp. Tech. 2008, in press. [Google Scholar]

- Tseng, K.K.-H.; Naidu, A.S.K. Non-parametric damage detection and characterization using smart piezoceramic material. Smart Mater. Struct. 2002, 11, 317–329. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Active sensors for health monitoring of aging aerospace structures. In Proceedings of the 7th International Conference on Nondestructive Evaluation and Health Monitoring of Aging Infrastructure, Newport Beach, CA, USA, 6–9 March 2000; Paper 3. Volume 3985, pp. 294–305. [Google Scholar]

- Park, G.; Inman, D.J. Impedance-Based Structural Health Monitoring Damage Prognosis for Aerospace, Civil and Mechanical Systems. Part II; Wiley: New York, NY, USA, 2005; pp. 275–292. [Google Scholar]

- Giurgiutiu, V.; Rogers, C.A. Electro-mechanical (E/M) impedance method for structural health monitoring and non-destructive evaluation. In Proceedings of the International Workshop on Structural Health Monitoring, Stanford University, Stanford, CA, USA, 18–20 September 1997; pp. 433–444. [Google Scholar]

- Seunghee, P.; Chung-Bang, Y.; Yongrae, R.; Jong, J.L. PZT-based active damage detection techniques for steel bridge components. Smart Mater. Struct. 2006, 15, 957–966. [Google Scholar]

- Venu, G.M.; Chee, K.S. Application of electromechanical impedance technique for engineering structures: Review and future issues. J. Intell. Mater. Syst. Struct. 2009, 21, 41–59. [Google Scholar]

- Soh, C.K.; Tseng, K.K.; Bhalla, S.; Gupta, A.K. Performance of smart piezoceramic patches in health monitoring of a RC bridge. Smart Mater. Struct. 2000, 9, 533–542. [Google Scholar] [CrossRef]

- Zagrai, A.N.; Giurgiutiu, V. Electro-Mechanical Impedance Method for Crack Detection in Thin Plates. J. Intell. Mater. Syst. Struct. 2001, 12, 709–718. [Google Scholar] [CrossRef]

- Rosiek, M.; Martowicz, A.; Uhl, T. Structural health monitoring system based on electromechanical impedance measurements. In Proceedings of the 8th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 13–15 September 2011; pp. 314–321. [Google Scholar]

- Yaowen, Y.; Yuhang, H. Electromechanical impedance modeling of PZT transducers for health monitoring of cylindrical shell structures. Smart Mater. Struct. 2007, 17, 015005. [Google Scholar]

- Xu, J.F.; Yang, Y.W.; Soh, C.K. Electromechanical impedance-based structural health monitoring with evolutionary programming. J. Aerosp. Eng. 2004, 17, 182–193. [Google Scholar] [CrossRef]

- Pessoa, E.C.P.; Liu, S. The state of the art of underwater wet welding practice: Part 2. Weld. J. 2021, 100, 171–182. [Google Scholar] [CrossRef]

- Zhang, M.; Han, Y.; Jia, C.; Dong, S.; Maksimov, S.; Wu, C. Process Stability, Microstructure and Mechanical Properties of Underwater Submerged-Arc Welded Steel. Metals 2021, 11, 1249. [Google Scholar] [CrossRef]

- Qiang, X.; Bijlaard, F.S.; Kolstein, H. Elevated-temperature mechanical properties of high strength structural steel S460N: Experimental study and recommendations for fire-resistance design. Fire Saf. J. 2013, 55, 15–21. [Google Scholar] [CrossRef]

- Topaç, M.; Günal, H.; Kuralay, N. Fatigue failure prediction of a rear axle housing prototype by using finite element analysis. Eng. Fail. Anal. 2009, 16, 1474–1482. [Google Scholar] [CrossRef]

- Omajane, J.; Martikainen, J.; Kah, P. Weldability of thermo-mechanically rolled steels used in oil and gas offshore structures. Int. J. Eng. Sci. 2014, 3, 62–69. [Google Scholar]

- Skowrońska, B.; Szulc, J.; Chmielewski, T.; Sałaciński, T.; Świercz, R. Properties and microstructure of hybrid Plasma+ MAG welded joints of thermomechanically treated S700MC steel. In Proceedings of the 27th Anniversary International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 25–27 May 2018. [Google Scholar]

- Pańcikiewicz, K.; Tuz, L.; Żurek, Z.; Rakoczy, Ł. Optimization of Filler Metals Consumption in the Production of Welded Steel Structures. Adv. Mater. Sci. 2016, 16, 27–34. [Google Scholar] [CrossRef][Green Version]

- Sajek, A.; Nowacki, J. Comparative evaluation of various experimental and numerical simulation methods for determination of t8/5 cooling times in HPAW process weldments. Arch. Civ. Mech. Eng. 2018, 18, 583–591. [Google Scholar] [CrossRef]

- Górka, J. Assessment of Steel Subjected to the Thermomechanical Control Process with Respect to Weldability. Metals 2018, 8, 169. [Google Scholar] [CrossRef]

- Łabanowski, J.; Prokop-Strzelczyńska, K.; Rogalski, G.; Fydrych, D. The Effect of Wet Underwater Welding on Cold Cracking Susceptibility of Duplex Stainless Steel. Adv. Mater. Sci. 2016, 16, 68–77. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Guo, N.; Chen, H.; Du, Y.; Feng, J. The effect of alumino-thermic addition on underwater wet welding process stability. J. Mater. Process. Technol. 2017, 245, 149–156. [Google Scholar] [CrossRef]

- Purnama, D.; Winarto, W.; Susilo, F.H. Mechanical properties of underwater wet welded marine steel plates using different low hydrogen electrodes. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 1977; Volume 030015, pp. 1–5. [Google Scholar]

- Yin, Y.; Yang, X.; Cui, L.; Cao, J.; Xu, W. Microstructure and mechanical properties of underwater friction taper plug weld on X65 steel with carbon and stainless steel plugs. Sci. Technol. Weld. Join. 2016, 21, 259–266. [Google Scholar] [CrossRef]

- Heirani, F.; Abbasi, A.; Ardestani, M. Effects of processing parameters on microstructure and mechanical behaviors of underwater friction stir welding of Al5083 alloy. J. Manuf. Process. 2017, 25, 77–84. [Google Scholar] [CrossRef]

- Rogalski, G.; Fydrych, D.; Łabanowski, J. Underwater Wet Repair Welding of API 5L X65M Pipeline Steel. Pol. Marit. Res. 2017, 24, 188–194. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Shi, X.; Du, Y.; Feng, J.; Wang, G. Effect of water flow on the arc stability and metal transfer in underwater flux-cored wet welding. J. Manuf. Process. 2018, 31, 103–115. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, S.; Hu, Y.; Yi, Y.; Li, Z. Porosity and Microstructure of Underwater Wet FCAW of Duplex Stainless Steel. Met. Microstruct. Anal. 2017, 6, 383–389. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G.; Łabanowski, J. Temper Bead Welding of S460N Steel in Wet Welding Conditions. Adv. Mater. Sci. 2018, 18, 5–14. [Google Scholar] [CrossRef]

- Fydrych, D.; Łabanowski, J.; Tomków, J.; Rogalski, G. Cold Cracking Of Underwater Wet Welded S355G10+N High Strength Steel. Adv. Mater. Sci. 2015, 15, 48–56. [Google Scholar] [CrossRef]

- Maksimov, S. Underwater arc welding of higher strength low-alloy steels. Weld. Int. 2010, 24, 449–454. [Google Scholar] [CrossRef]

- Cheng, F.; Hu, S.; Gao, W.; Deng, C.; Wang, D.; Jing, H. Diffusible hydrogen content and microstructure characteristic in the joint by underwater shielded metal arc welding. Trans. China Weld. Inst. 2014, 35, 45–48. [Google Scholar]

- Świerczyńska, A.; Fydrych, D.; Rogalski, G. Diffusible hydrogen management in underwater wet self-shielded flux cored arc welding. Int. J. Hydrogen Energy 2017, 42, 24532–24540. [Google Scholar] [CrossRef]

- Fydrych, D.; Świerczyńska, A.; Tomków, J. Diffusible Hydrogen Control in Flux Cored Arc Welding Process. Key Eng. Mater. 2013, 597, 171–178. [Google Scholar] [CrossRef]

- Schaupp, T.; Rhode, M.; Kannengiesser, T. Influence of welding parameters on diffusible hydrogen content in high-strength steel welds using modified spray arc process. Weld. World 2017, 62, 9–18. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Saini, N. Effect of Weld Consumable Conditioning on the Diffusible Hydrogen and Subsequent Residual Stress and Flexural Strength of Multipass Welded P91 Steels. Metall. Mater. Trans. B 2018, 49, 2881–2895. [Google Scholar] [CrossRef]

- Hanzaei, A.T.; Marashi, S.P.H.; Ranjbarnodeh, E. The effect of hydrogen content and welding conditions on the hydrogen induced cracking of the API X70 steel weld. Int. J. Hydrogen Energy 2018, 43, 9399–9407. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Technol. 2020, 109, 717–725. [Google Scholar] [CrossRef]

- Di, Q.H.; Ning, L.; Kun, Y.Y.; Shao, Y.Y. Microstructure and Mechanical Properties of Friction Stir Welded Q345 Steel. Mater. Trans. 2014, 55, 137–140. [Google Scholar]

- Mihajlo, A.; Simon, S.; Radomir, J.; Srđa, P.; Zijah, B.; Dorin, R.; Zoran, R. Numerical and Experimental Investigations of Fracture Behaviour of Welded Joints with Multiple Defects. Materials 2021, 14, 4832. [Google Scholar]

- Chalioris, C.E.; Violetta, K.K.; Maristella, E.V.; Chris, G.K. Flexural damage diagnosis in reinforced concrete beams using a wireless admittance monitoring system—Tests and finite element analysis. Sensors 2021, 21, 679. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Providakis, C.P.; Favvata, M.J.; Papadopoulos, N.A.; Angeli, G.M.; Karayannis, C.G. Experimental ap-plication of a wireless earthquake damage monitoring system (WiAMS) using PZT transducers in reinforced concrete beams. Earthq. Resist. Eng. Struct. 2015, 1, 233–243. [Google Scholar]

- Khan, S.; Al-Shuhail, A.A.; Khulief, Y.A. Numerical modeling of the geomechanical behavior of Ghawar Arab-D carbonate petroleum reservoir undergoing CO2 injection. Environ. Earth Sci. 2016, 75, 1–15. [Google Scholar] [CrossRef]

- Israf, U.D.; Usman, M.; Khan, S.; Aasif, H.; Alotaibi, M.A.; Alharthi, A.I.; Centi, G. Prospects for a green methanol thermo-catalytic process from CO2 by using MOFs based materials: A mini-review. J. CO2 Util. 2021. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. The effect of injection well arrangement on CO2 injection into carbonate petroleum reservoir. Int. J. Glob. Warm. 2018, 14, 462–487. [Google Scholar] [CrossRef]

- Garba, M.D.; Muhammad, U.; Khan, S.; Farrukh, K.; Ahmad, S.; Muhamad, G.; Akram, F.E.; Muhammad, H. CO2 towards fuels: A review of catalytic conversion of carbon dioxide to hydrocarbons. J. Environ. Chem. Eng. 2021, 9, 104756. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. Numerical modeling of the geomechanical behavior of Biyadh Reservoir undergoing CO2 injection. Int. J. Geomech. 2017, 17, 1–12. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A.; Al-Shuhail, A.A. Alleviation of pore pressure buildup and ground uplift during carbon dioxide injection into Ghawar Arab-D carbonate naturally fractured reservoir. Environ. Earth Sci. 2018, 77, 449. [Google Scholar] [CrossRef]

- Hamad, H.; Bai, Y.; Ali, L. A risk-based inspection planning methodology for integrity management of subsea oil and gas pipelines. Ships Offshore Struct. 2020. [Google Scholar] [CrossRef]

- Ali, L.; Khan, S.; Bashmal, S. Fatigue Crack Monitoring of T-Type Joints in Steel Offshore Oil and Gas Jacket Platform. Sensors 2021, 21, 3294. [Google Scholar] [CrossRef]

- Berradia, M.; Mohamed, H.O.; Ali, L.; Raza, A.; Babar, A. Data-oriented analysis of axial capacity of externally CFRP-confined concrete columns transversely reinforced with steel hoops or spirals. Mech. Adv. Mater. Struct. 2021, 1, 1–14. [Google Scholar] [CrossRef]

- Ali, L.; Makhdoom, N.; Gao, Y.; Fang, P.; Khan, S.; Bai, Y. Metocean Criteria for Internal Solitary Waves Obtained from Numerical Models. Water 2021, 13, 1554. [Google Scholar] [CrossRef]

- Ali, L.; Bai, Y.; Jin, S. Risk Assessment and reliability analysis of subsea production Systems. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual, Online, 3–7 August 2020. [Google Scholar] [CrossRef]

- Ali, L.; Bai, Y.; Xu, Y. A methodology to derive design metocean internal wave current for submarine structures. Ships Offshore Struct. 2020. [Google Scholar] [CrossRef]

- Liang, C. Coupled electomechanical analysis of adaptive material system-determination of actuator power consumption and system energy transfer. J. Intell. Mater. Syst. Struct. 1994, 5, 12–20. [Google Scholar] [CrossRef]

- Park, G.; Sohn, H.; Farrar, C.R.; Inman, D.J. Overview of peizoelectric impedance-based health monitoring and path forward. Shock Vib. Dig. 2003, 35, 451–464. [Google Scholar] [CrossRef]

- Sun, F.P.; Liang, C.; Rogers, C.A. Structural modal analysis using collocated piezoelectric actuator/sensors: An electromechanical approach. Smart Struct. Intell. Syst. 1994, 2190, 238–250. [Google Scholar] [CrossRef]

- Zhou, S.-W.; Liang, C.; Rogers, C.A. An Impedance-Based System Modeling Approach for Induced Strain Actuator-Driven Structures. J. Vib. Acoust. 1996, 118, 323–331. [Google Scholar] [CrossRef]

- Esteban, J. Analysis of the Sensing Region of a PZT Actuator-Sensor. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1996. [Google Scholar]

- Park, G.; Cudney, H.H.; Inman, D.J. An integrated health monitoring technique using structural impedance sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 448–455. [Google Scholar] [CrossRef]

- Xu, Y.G.; Liu, G.R. A Modified Electro-Mechanical Impedance Model of Piezoelectric Actuator-Sensors for Debonding Detection of Composite Patches. J. Intell. Mater. Syst. Struct. 2002, 13, 389–396. [Google Scholar] [CrossRef]

- Zagrai, A.N.; Giurgiutiu, V. Health monitoring of aging aerospace structures using the electromechanical impedance method. Smart Nondestruct. Eval. Health Monit. Struct. Biol. Syst. 2002, 4702, 289–301. [Google Scholar]

- Bhalla, S.; Kumar, P.; Gupta, A.; Datta, T.K. Simplified Impedance Model for Adhesively Bonded Piezo-Impedance Transducers. J. Aerosp. Eng. 2009, 22, 373–382. [Google Scholar] [CrossRef]

- Bhalla, S.; Soh, C.K. Electromechanical Impedance Modeling for Adhesively Bonded Piezo-Transducers. J. Intell. Mater. Syst. Struct. 2004, 15, 955–972. [Google Scholar] [CrossRef]

- Girugiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors; Elsevier: London, UK, 2008. [Google Scholar]

- Su, S.; Xuran, Z.; Wei, W.; Xiaohui, Z. Metal magnetic memory inspection of Q345 steel specimens with butt weld in tensile and bending test. J. Nondestruct. Eval. 2019, 38, 1–17. [Google Scholar] [CrossRef]

- Mechanical Properties and Chemical Composition of Q345B Steel. Available online: https://www.steeljrv.com/what-is-q345-steel.html (accessed on 10 November 2021).

- Chemical Composition of Q345B Steel. Available online: https://www.bestarpipe.com/pipe-knowledge/124.html (accessed on 10 November 2021).

- Parshin, S.; Levchenko, A.; Parshin, S. Underwater hyperbaric dry welding of high strength steel arctic oil and gas pipelines. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volumn 539, p. 012159. [Google Scholar]

- Tomków, J.; Janeczek, A.; Rogalski, G.; Wolski, A. Underwater Local Cavity Welding of S460N Steel. Materials 2020, 13, 5535. [Google Scholar] [CrossRef]

- Garg, S.; Kakkar, I.; Pandey, A.; Gupta, M.; Kishor, N. Effect of different coating composition’s rutile-type welding elec-trodes on undercut defect in manual electric arc welding. Int. J. Mech. Eng. Technol. 2013, 3, 381–388. [Google Scholar]

- Tomków, J.; Fydrych, D.; Wilk, K. Effect of Electrode Waterproof Coating on Quality of Underwater Wet Welded Joints. Materials. 2020, 13, 2947. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 17642:2005. Destructive Tests on Welds in Metallic Materials—Cold Cracking Tests for Weldments—Arc Welding Processes; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- Tomków, J. Weldability of Underwater Wet-Welded HSLA Steel: Effects of Electrode Hydrophobic Coatings. Materials 2021, 14, 1364. [Google Scholar] [CrossRef] [PubMed]

- Lynch, J.P.; Sundararajan, A.; Law, K.H.; Sohn, H.; Farrar, C.R. Design of a wireless active sensing unit for structural health monitoring. In Proceedings of the SPIE, 11th Annual Symposium, San Diego, CA, USA, 2 March 2004; Volume 5394, pp. 157–169. [Google Scholar]

| Properties | Value |

|---|---|

| Tensile Strength | 490–675 (MPa) |

| Yield Strength | ≥345 (MPa) |

| Elongation after Fracture | ≥21% |

| Elements | Contents |

|---|---|

| C≤ | 0.2 |

| Mn | 1.0–1.6 |

| Si≤ | 0.035 |

| S≤ | 0.035 |

| Al≥ | 0.02–0.15 |

| Nb | 0.015–0.06 |

| V | 0.02–0.15 |

| Specimen | Welding Current [A] 50–100 | Arc Voltage [V] 18–21 | Welding Speed [mm/s] 5–20 | Heat Input [kJ/mm] |

|---|---|---|---|---|

| B03 | 90 | 20.0 | 6.5 | 0.28 |

| 75 | 19.0 | 5.0 | 0.27 | |

| I13 | 85 | 19.5 | 5.35 | 0.31 |

| 94 | 20.5 | 6.5 | 0.30 | |

| H09 | 98 | 18.5 | 5.0 | 0.37 |

| 88 | 21.0 | 6.18 | 0.30 | |

| T04 | 95 | 19.0 | 6.3 | 0.35 |

| 82 | 18.5 | 5.1 | 0.31 |

| Specimen | Load (kN) | Note |

|---|---|---|

| B03 | 180 | Repeated tension without compression in the case of buckling |

| I13 | 150 | Push–pull fatigue |

| H09 | 150 | Push–pull fatigue |

| T04 | 100 | Push–pull fatigue with fixed period |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, L.; Khan, S.; Iqbal, N.; Bashmal, S.; Hameed, H.; Bai, Y. An Experimental Study of Damage Detection on Typical Joints of Jackets Platform Based on Electro-Mechanical Impedance Technique. Materials 2021, 14, 7168. https://doi.org/10.3390/ma14237168

Ali L, Khan S, Iqbal N, Bashmal S, Hameed H, Bai Y. An Experimental Study of Damage Detection on Typical Joints of Jackets Platform Based on Electro-Mechanical Impedance Technique. Materials. 2021; 14(23):7168. https://doi.org/10.3390/ma14237168

Chicago/Turabian StyleAli, Liaqat, Sikandar Khan, Naveed Iqbal, Salem Bashmal, Hamad Hameed, and Yong Bai. 2021. "An Experimental Study of Damage Detection on Typical Joints of Jackets Platform Based on Electro-Mechanical Impedance Technique" Materials 14, no. 23: 7168. https://doi.org/10.3390/ma14237168

APA StyleAli, L., Khan, S., Iqbal, N., Bashmal, S., Hameed, H., & Bai, Y. (2021). An Experimental Study of Damage Detection on Typical Joints of Jackets Platform Based on Electro-Mechanical Impedance Technique. Materials, 14(23), 7168. https://doi.org/10.3390/ma14237168