Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review

Abstract

:1. Introduction

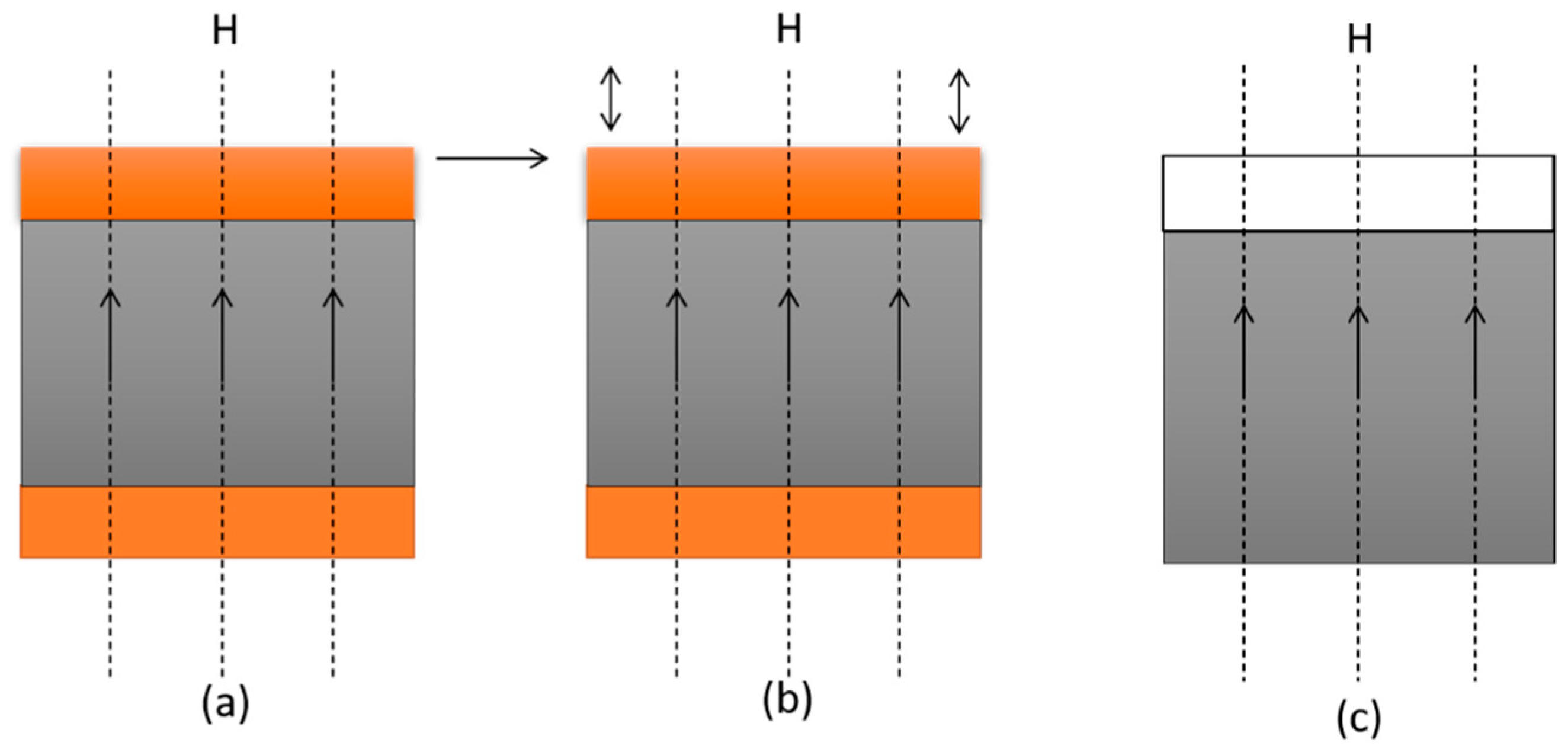

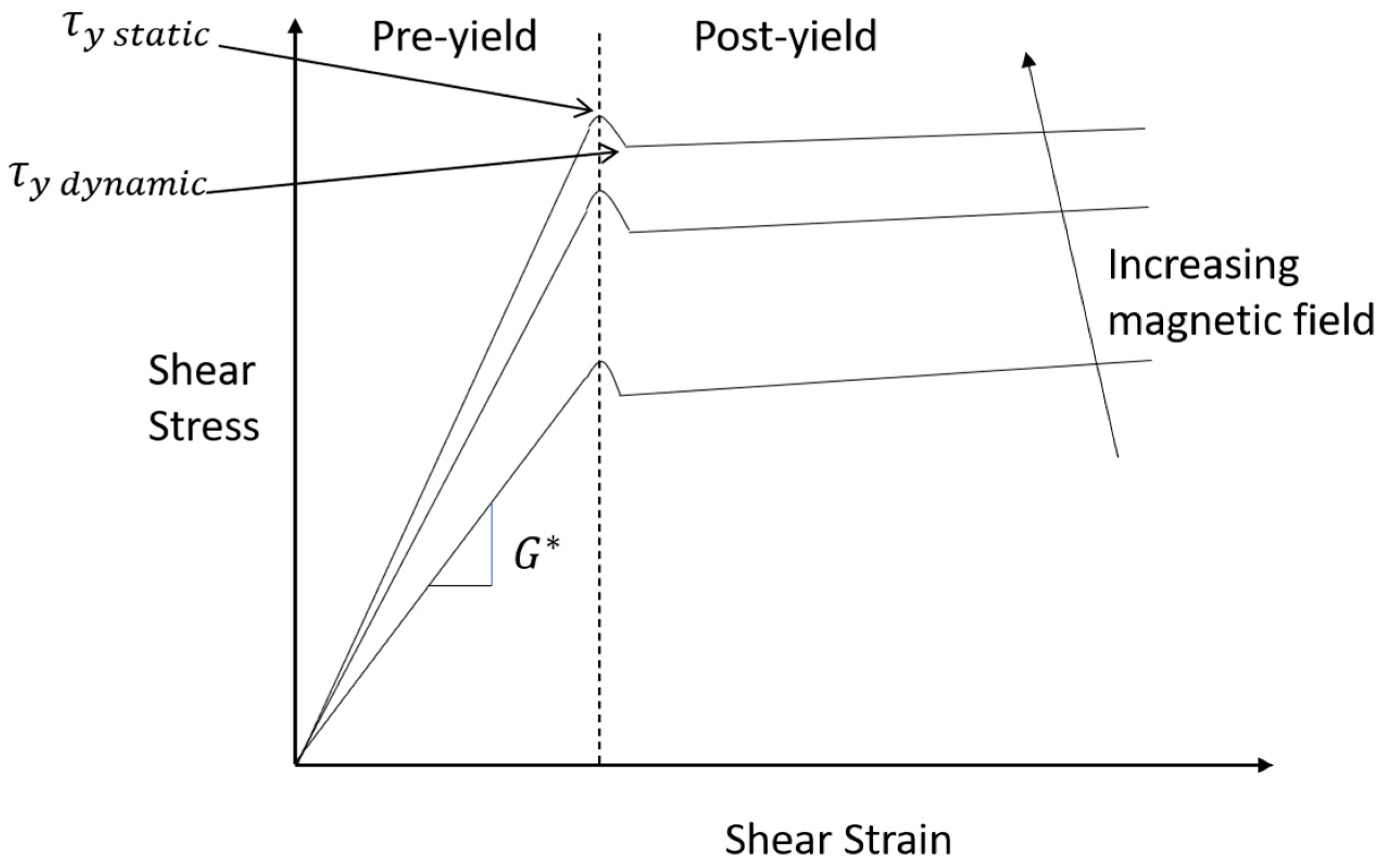

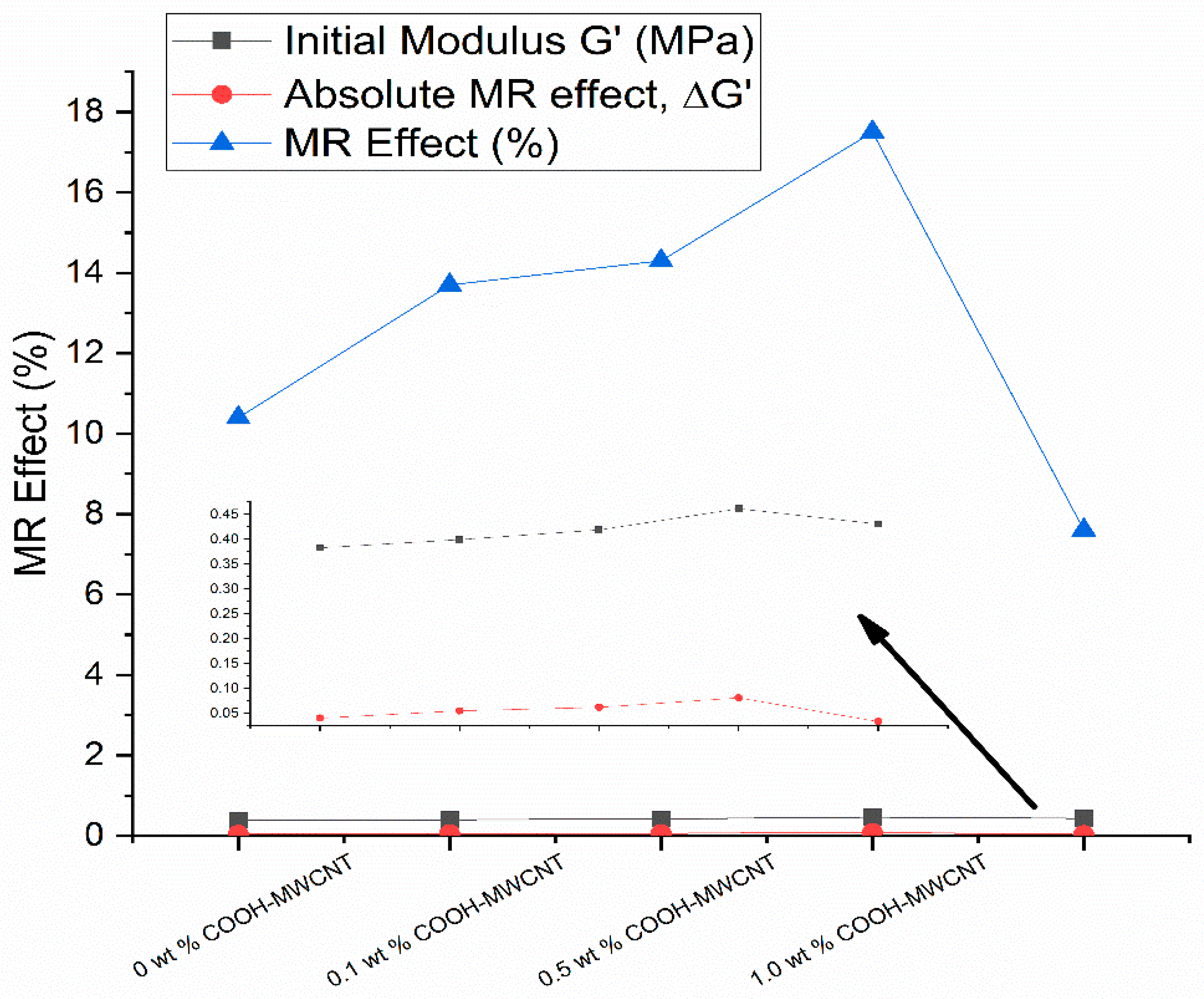

2. Characterization of Magnetorheological Elastomer Material

2.1. The Basic Form of Constitutive Equations

2.2. Mathematical Representation of The Storage and Moduli

2.3. General Linear Viscoelastic Model

2.4. Pre-Yield MRE Rheological Characteristics Represented by Viscoelastic Models

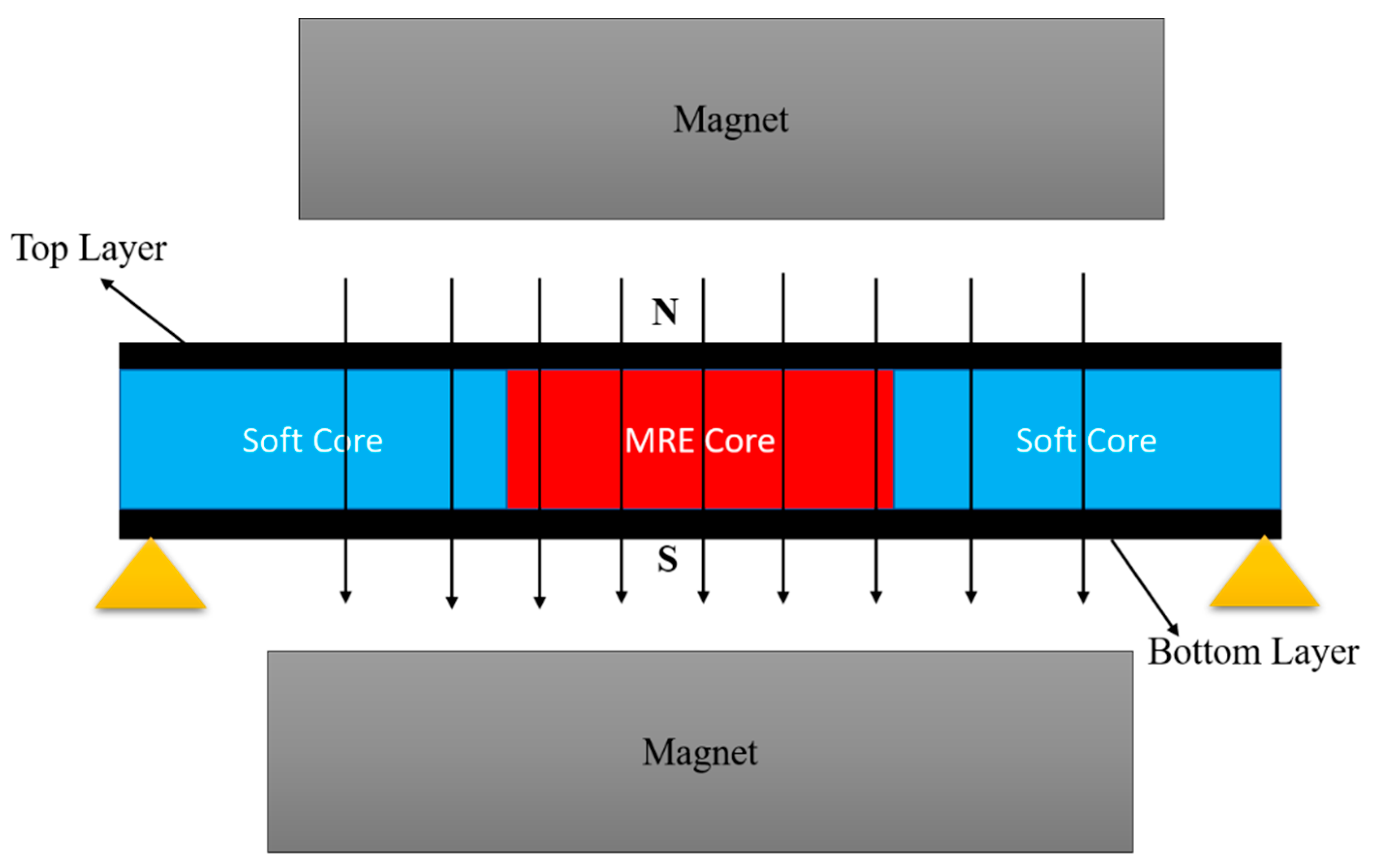

3. Modeling of MRE Sandwich Structures

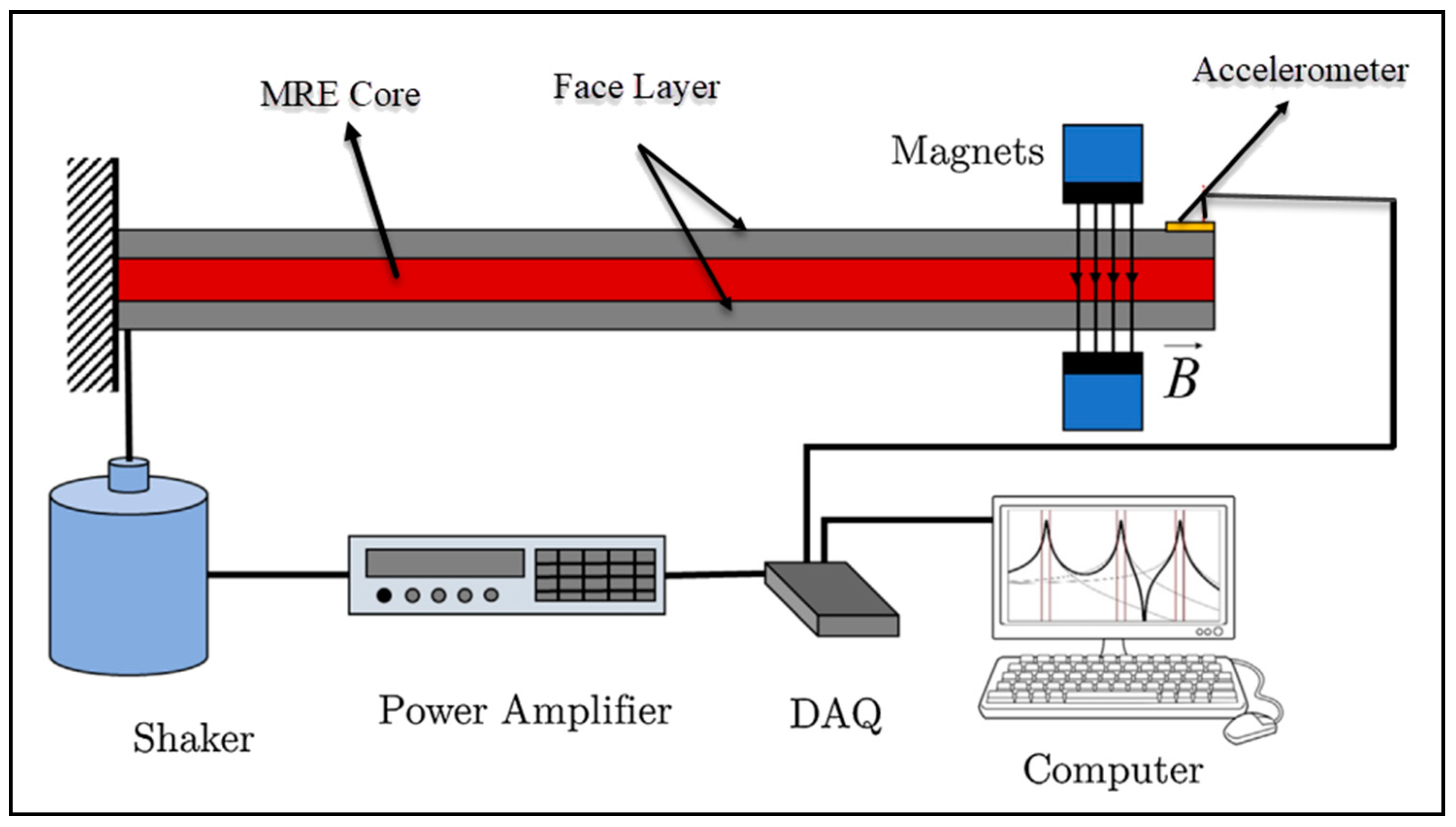

4. Experiment Methods on MRE Sandwich Structures

5. Observations and Findings

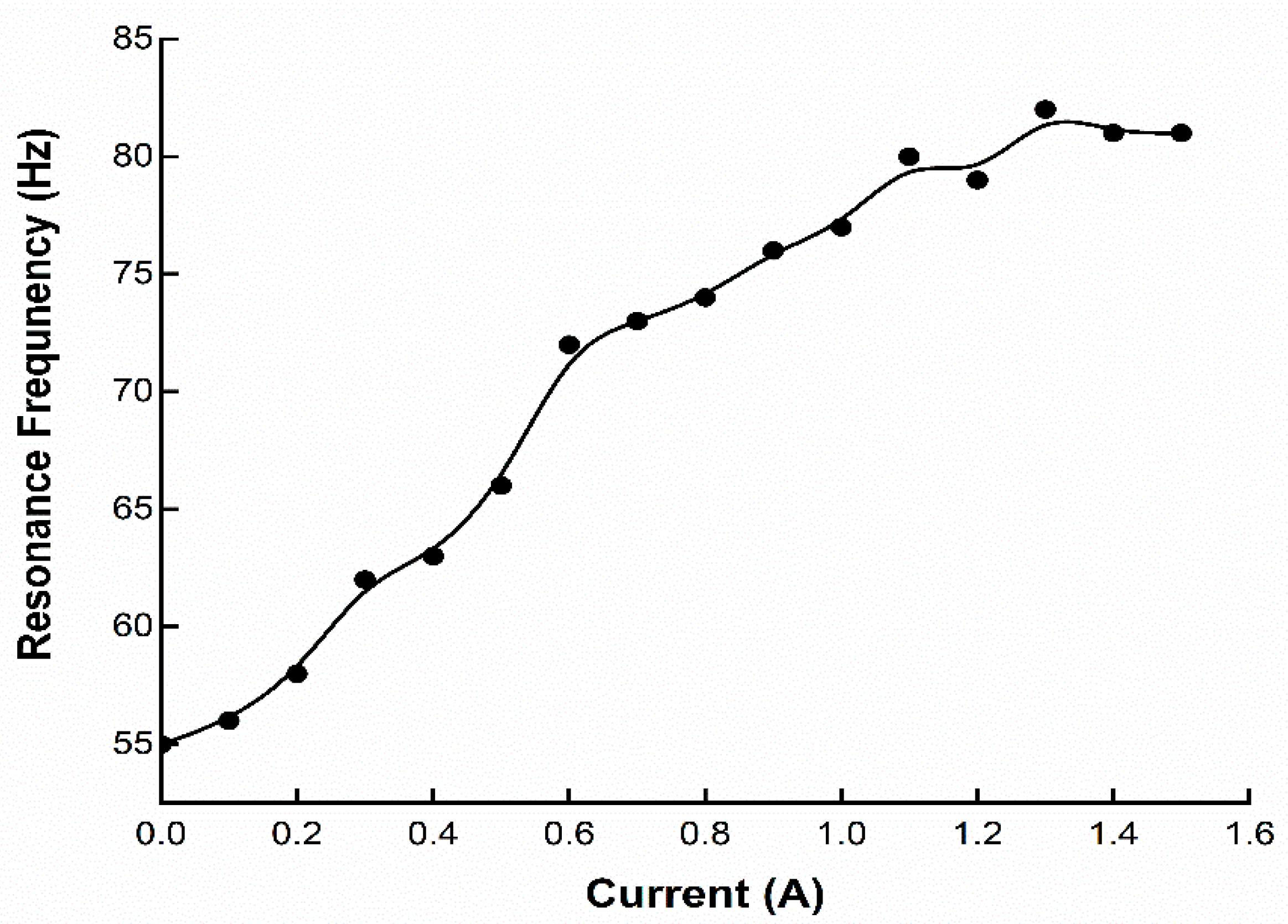

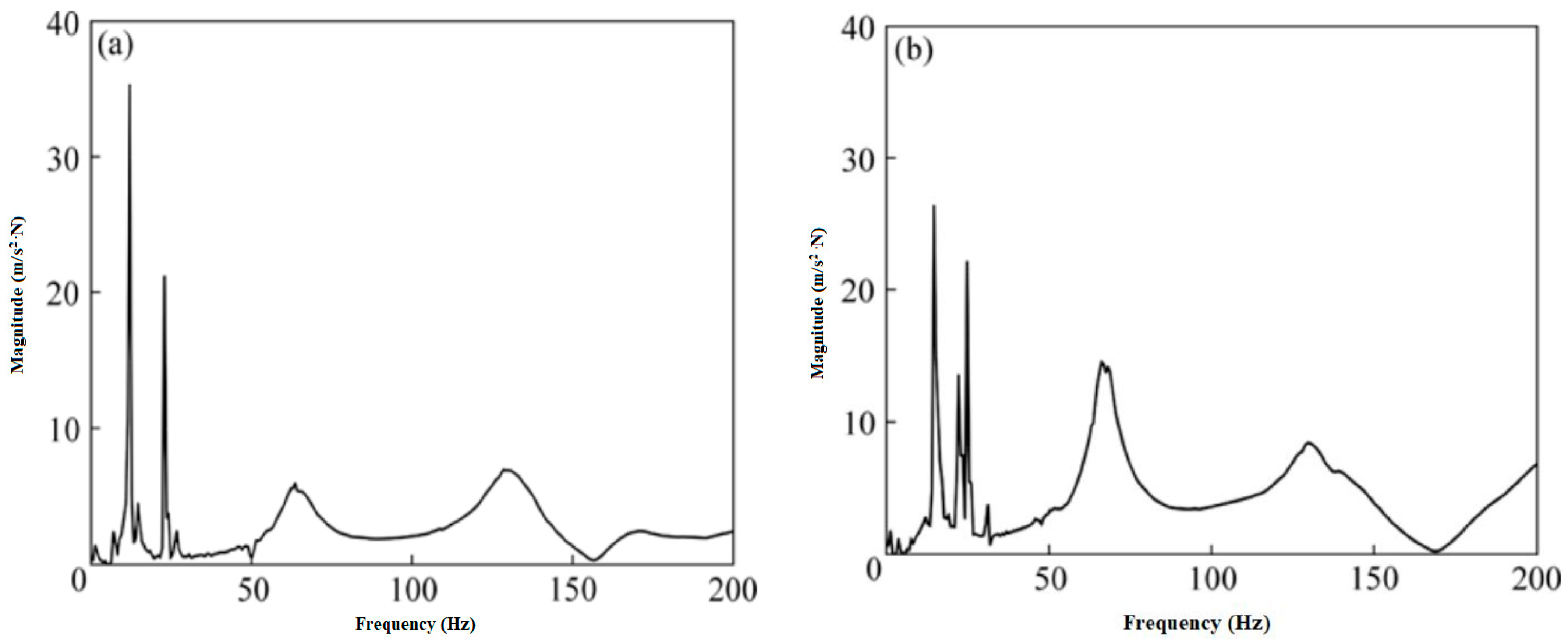

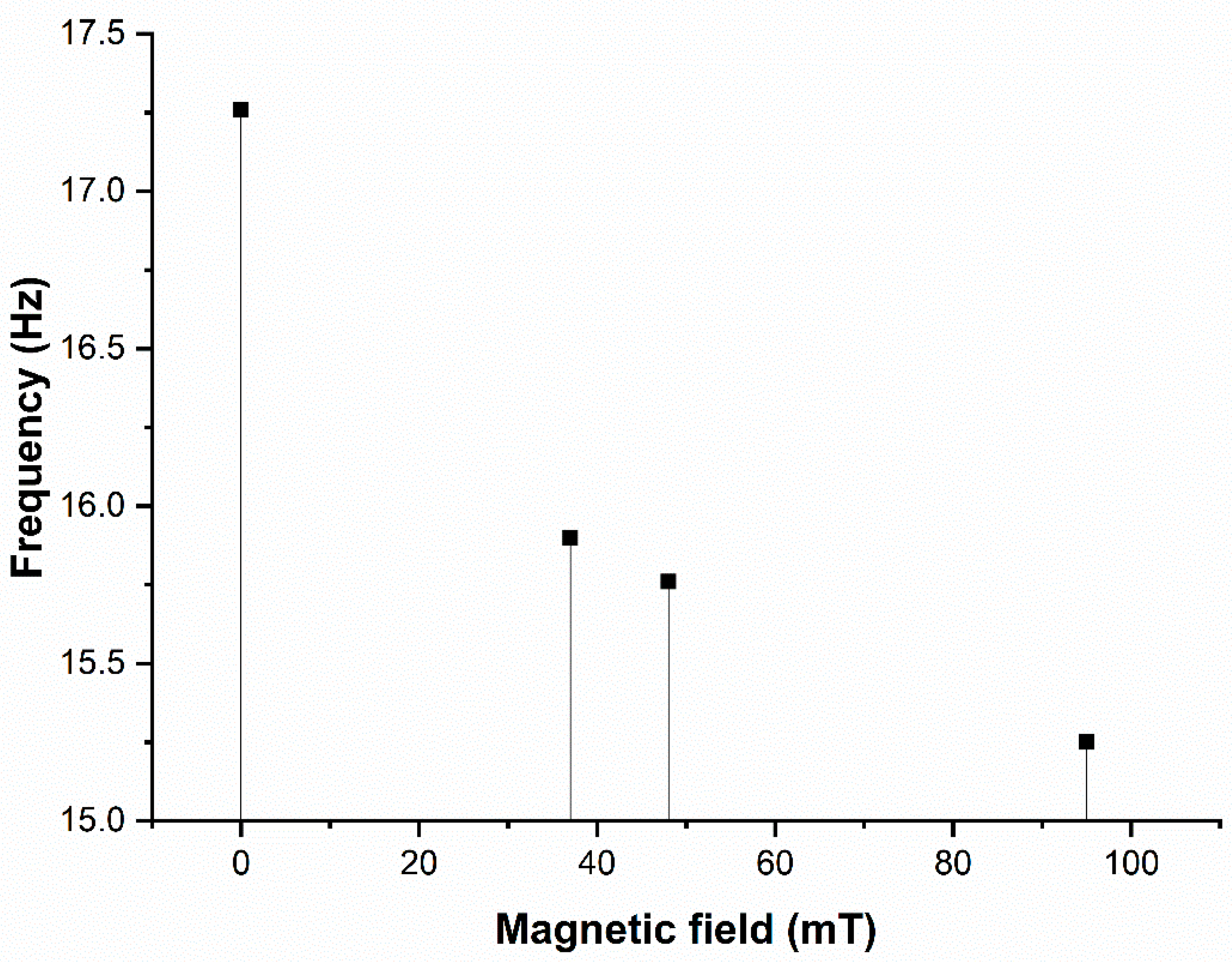

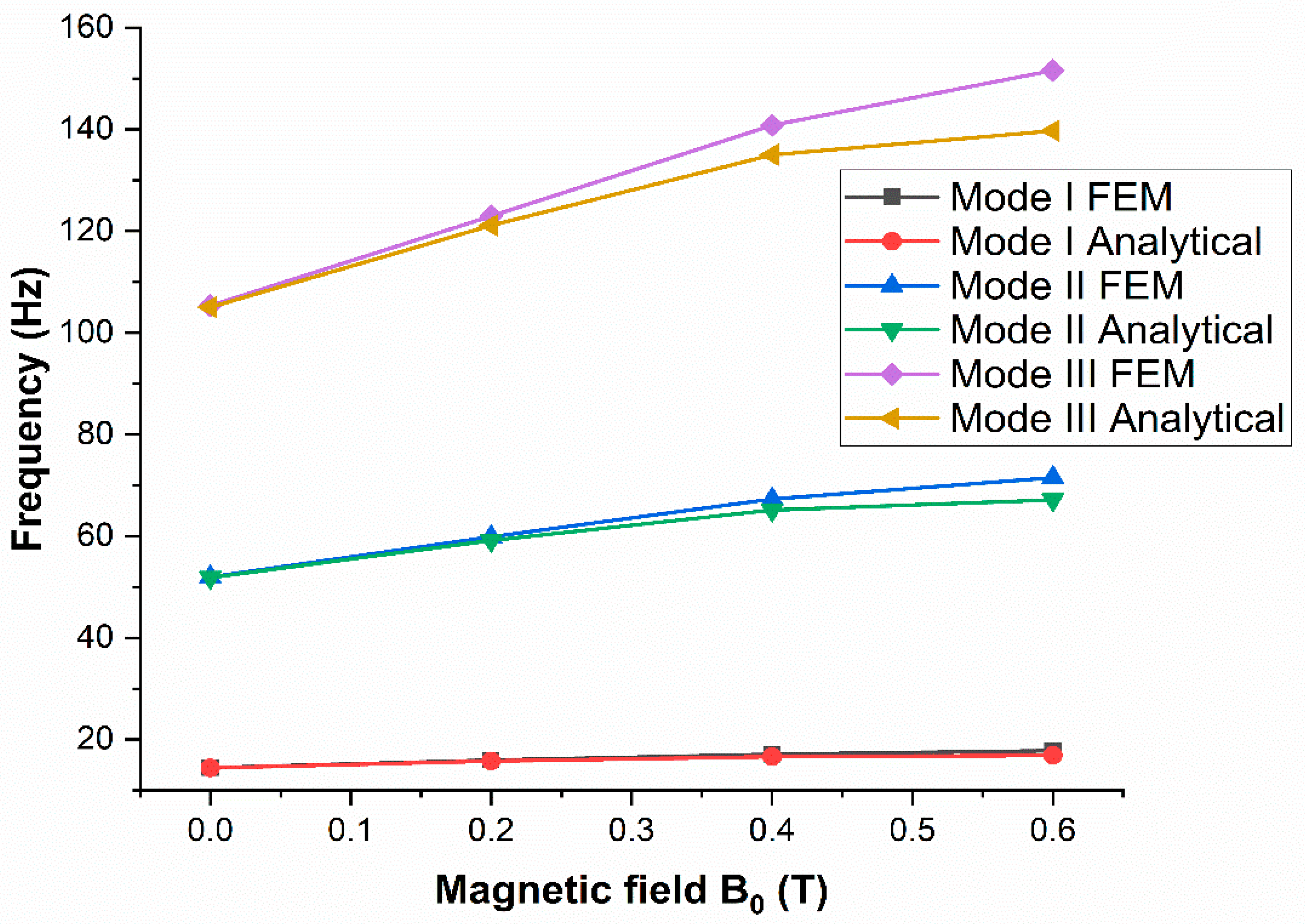

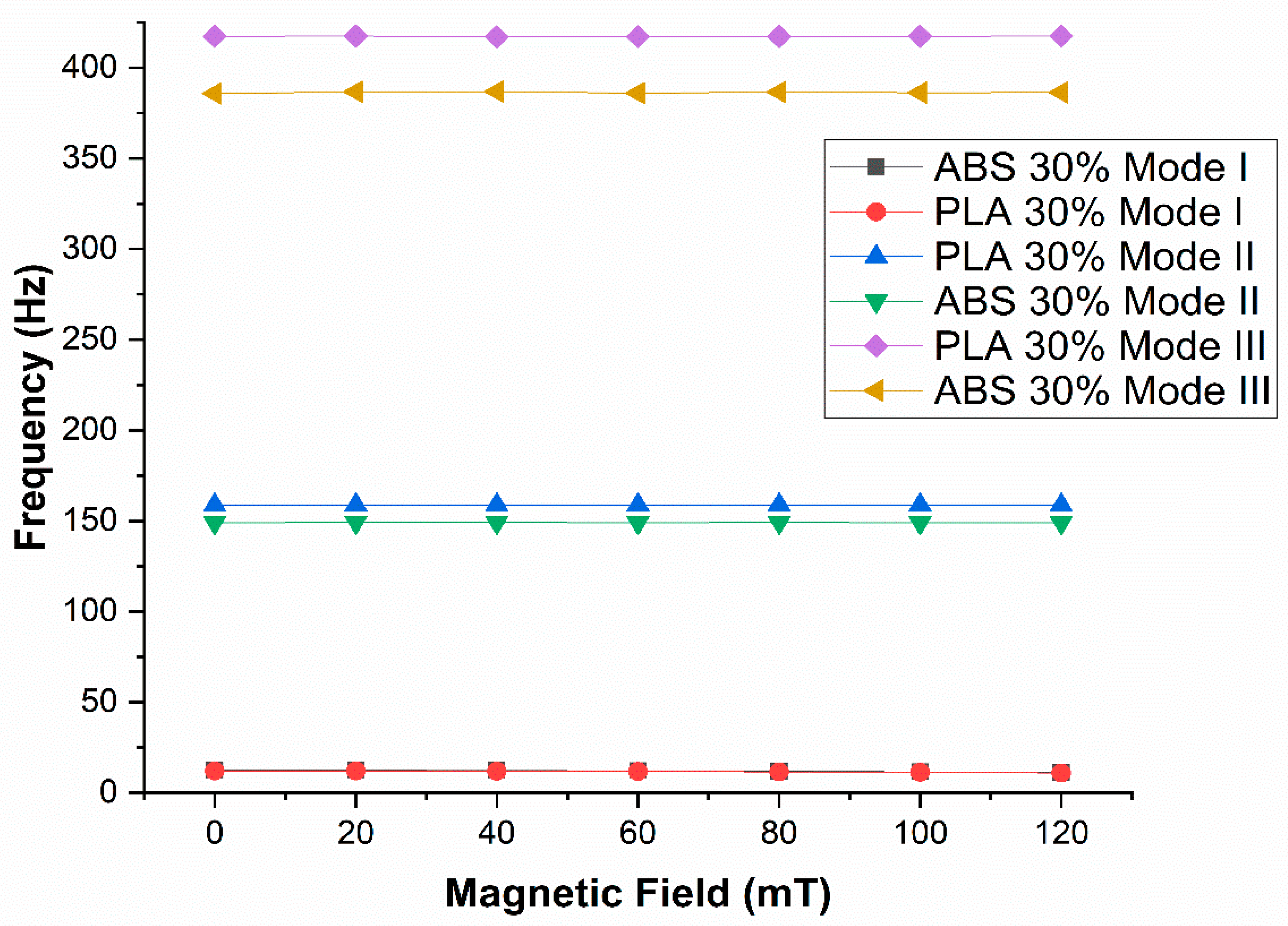

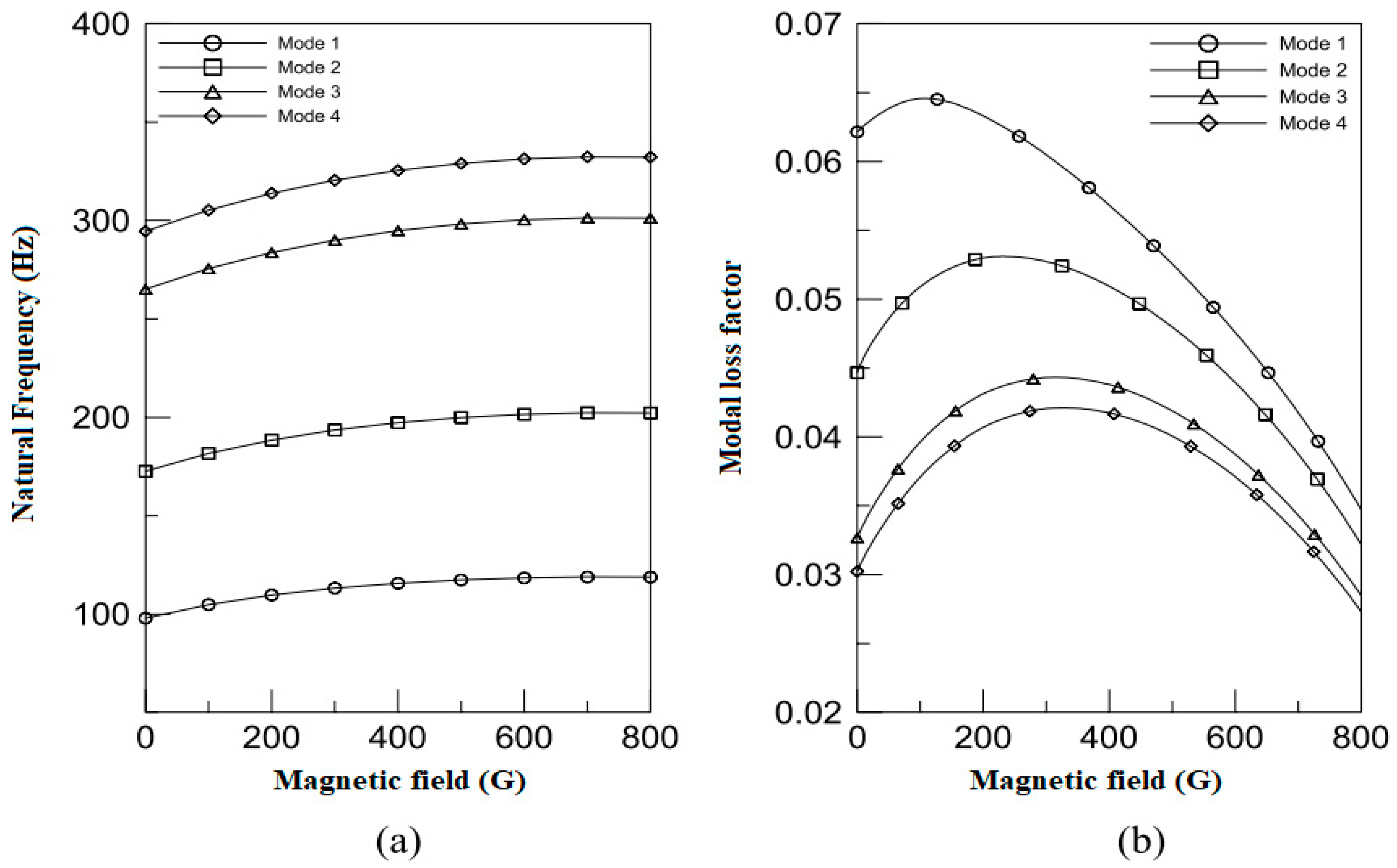

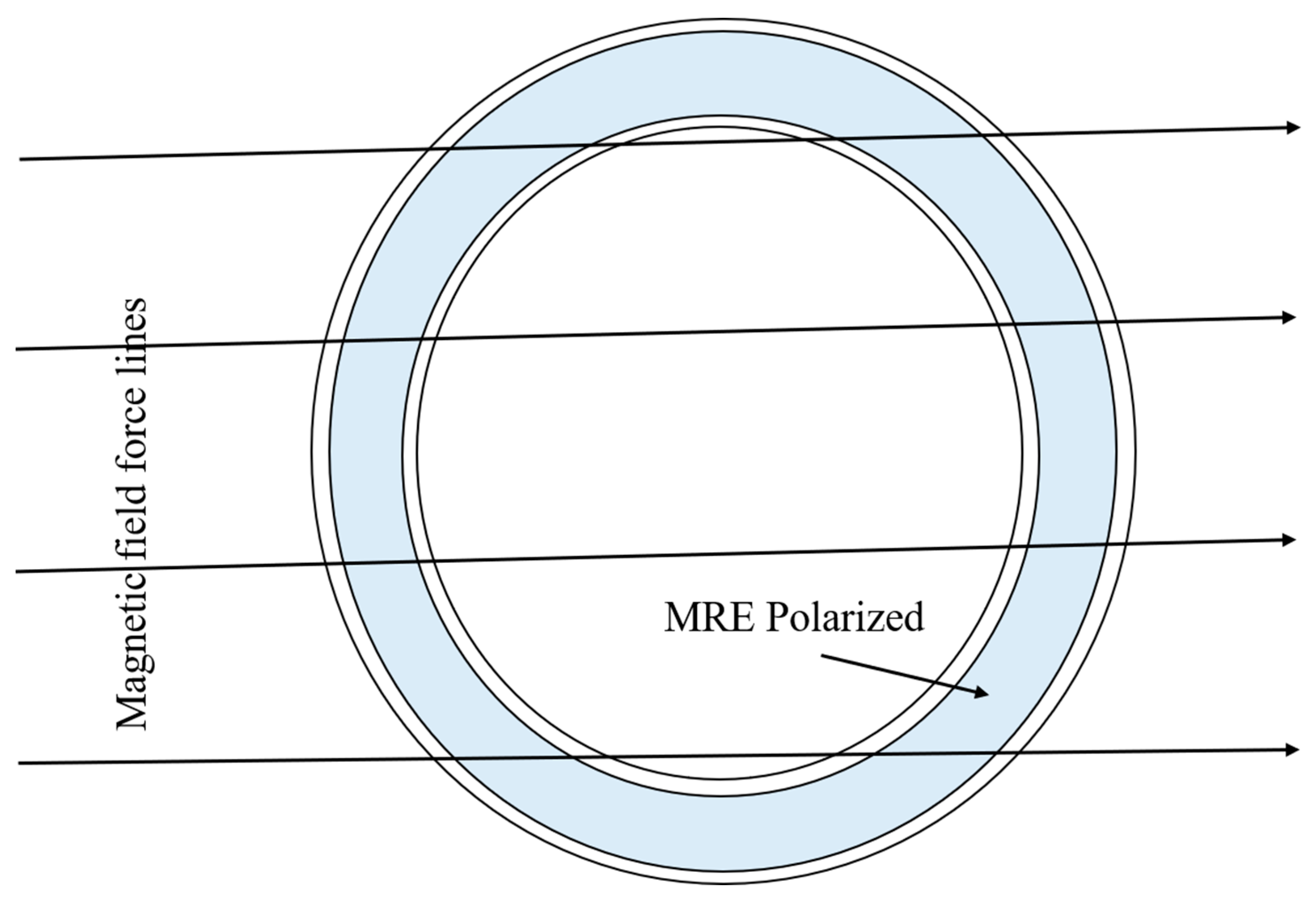

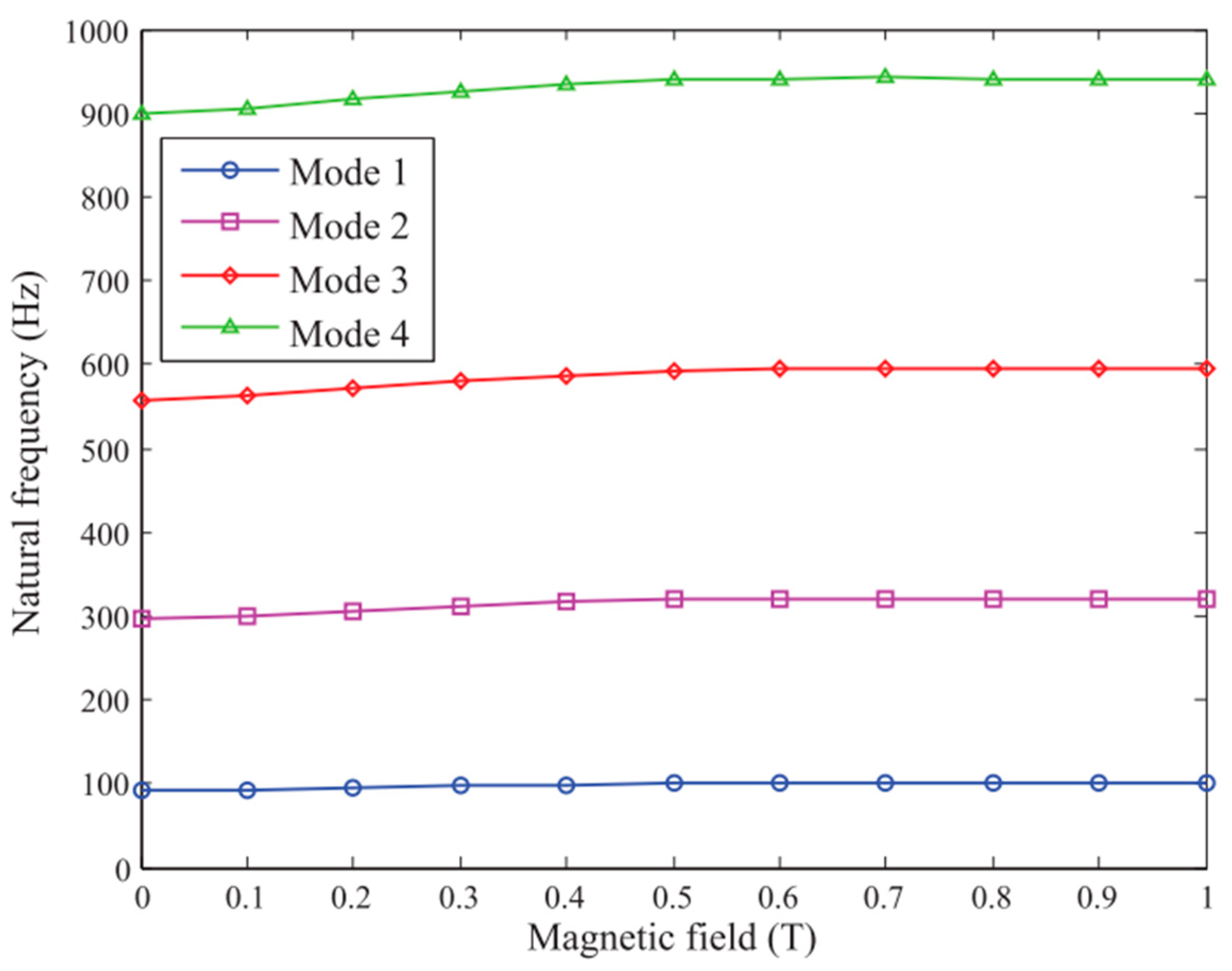

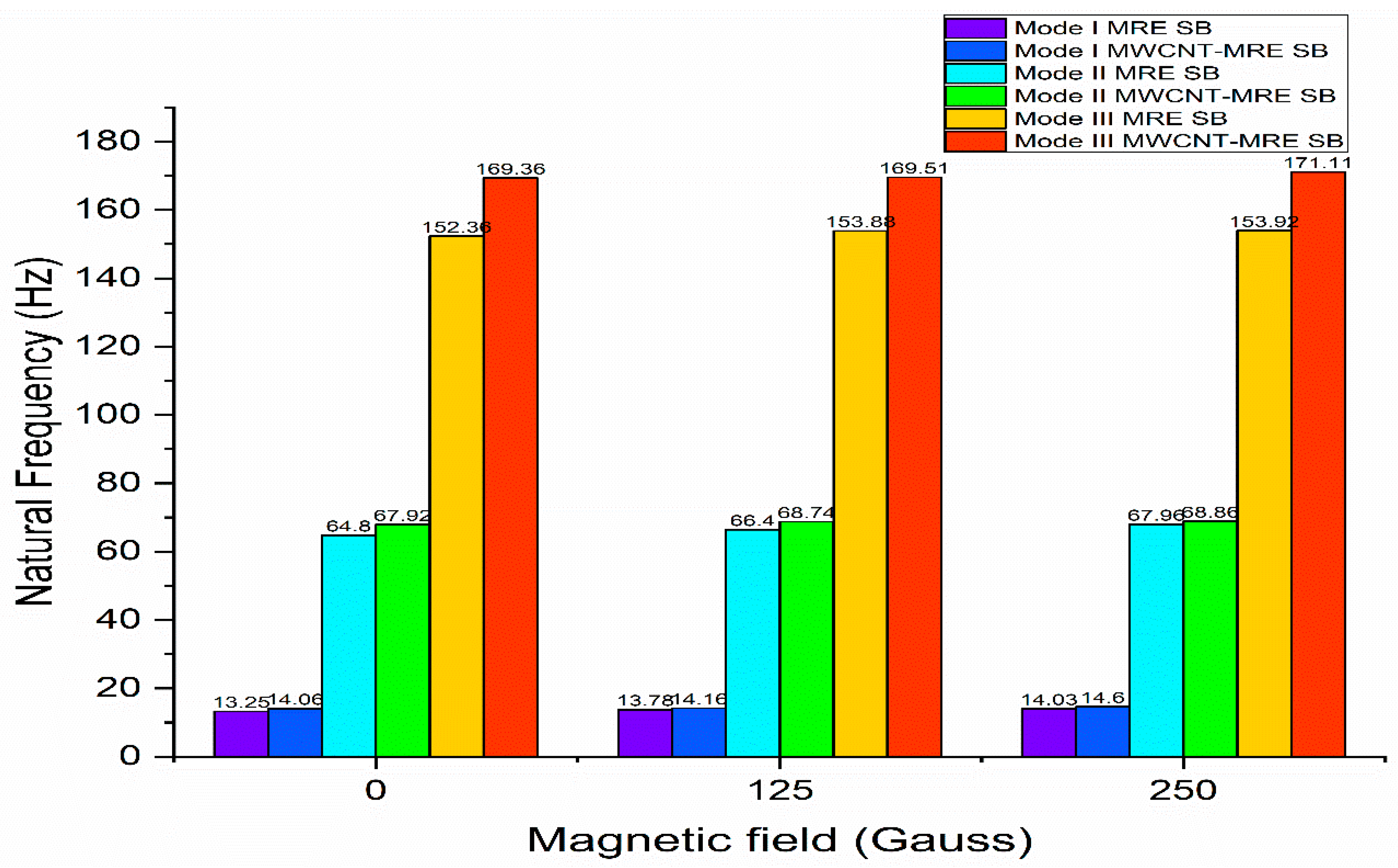

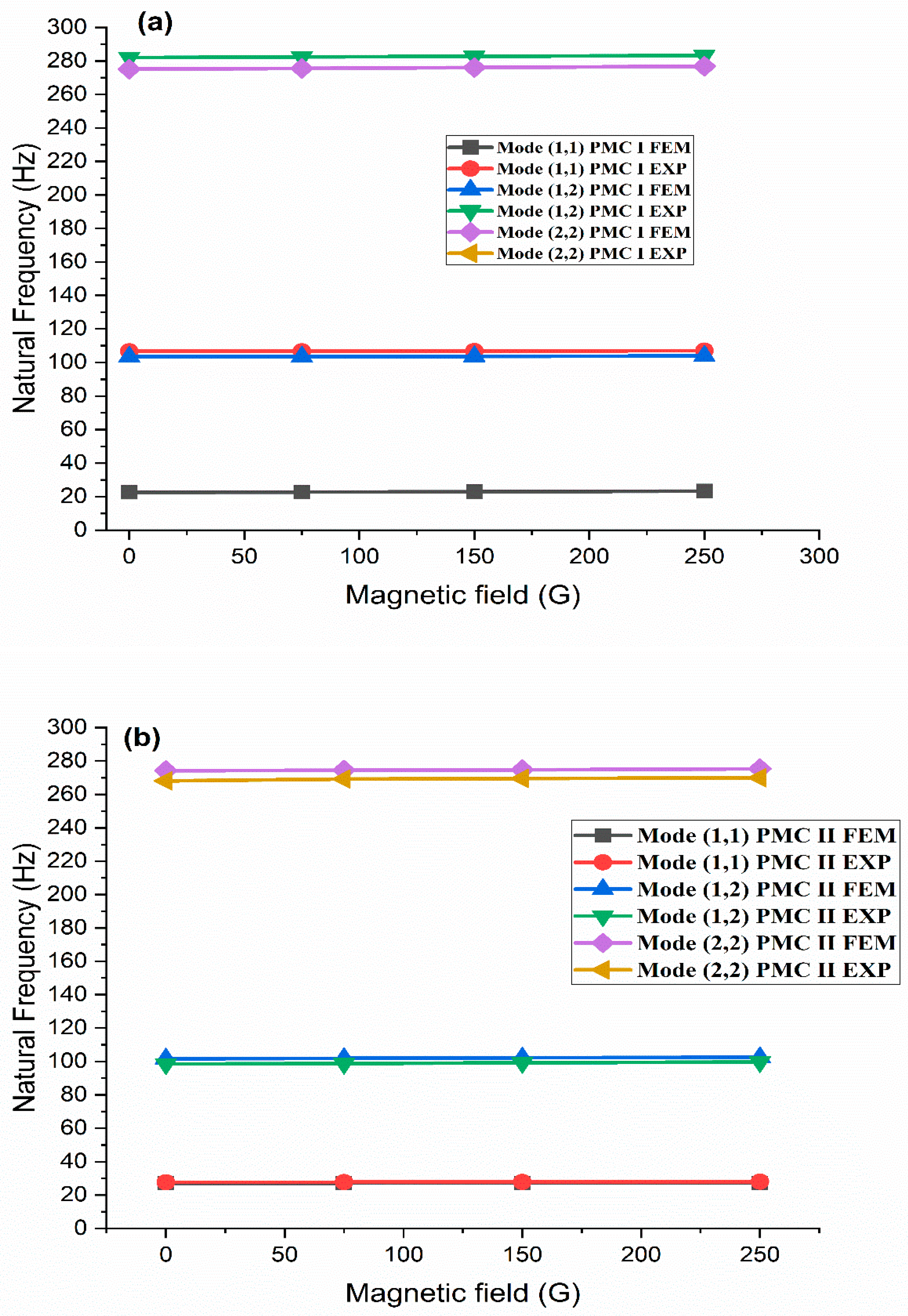

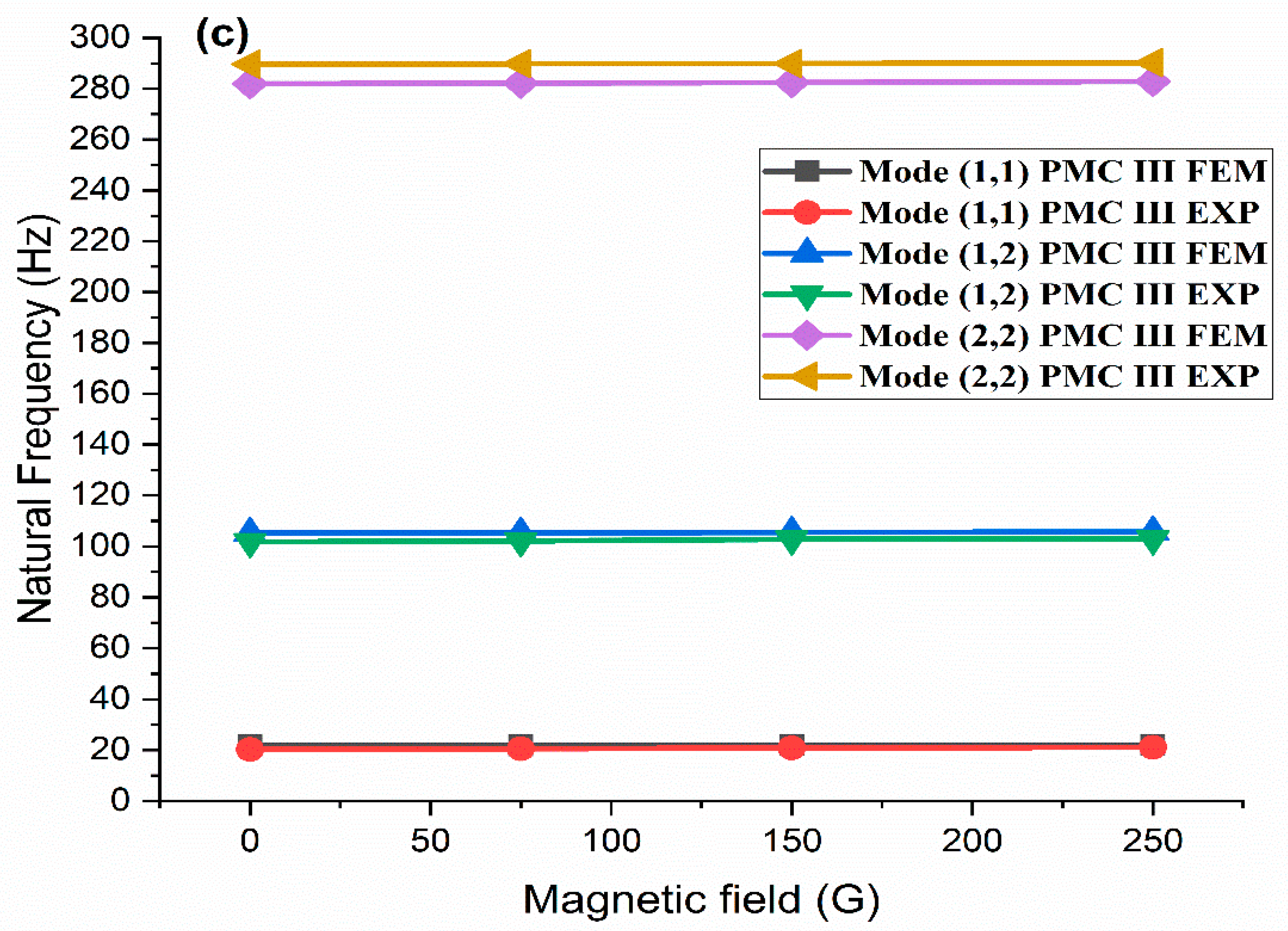

5.1. The Influence of The Applied Field on The Natural Frequencies of MRE Sandwich Structures

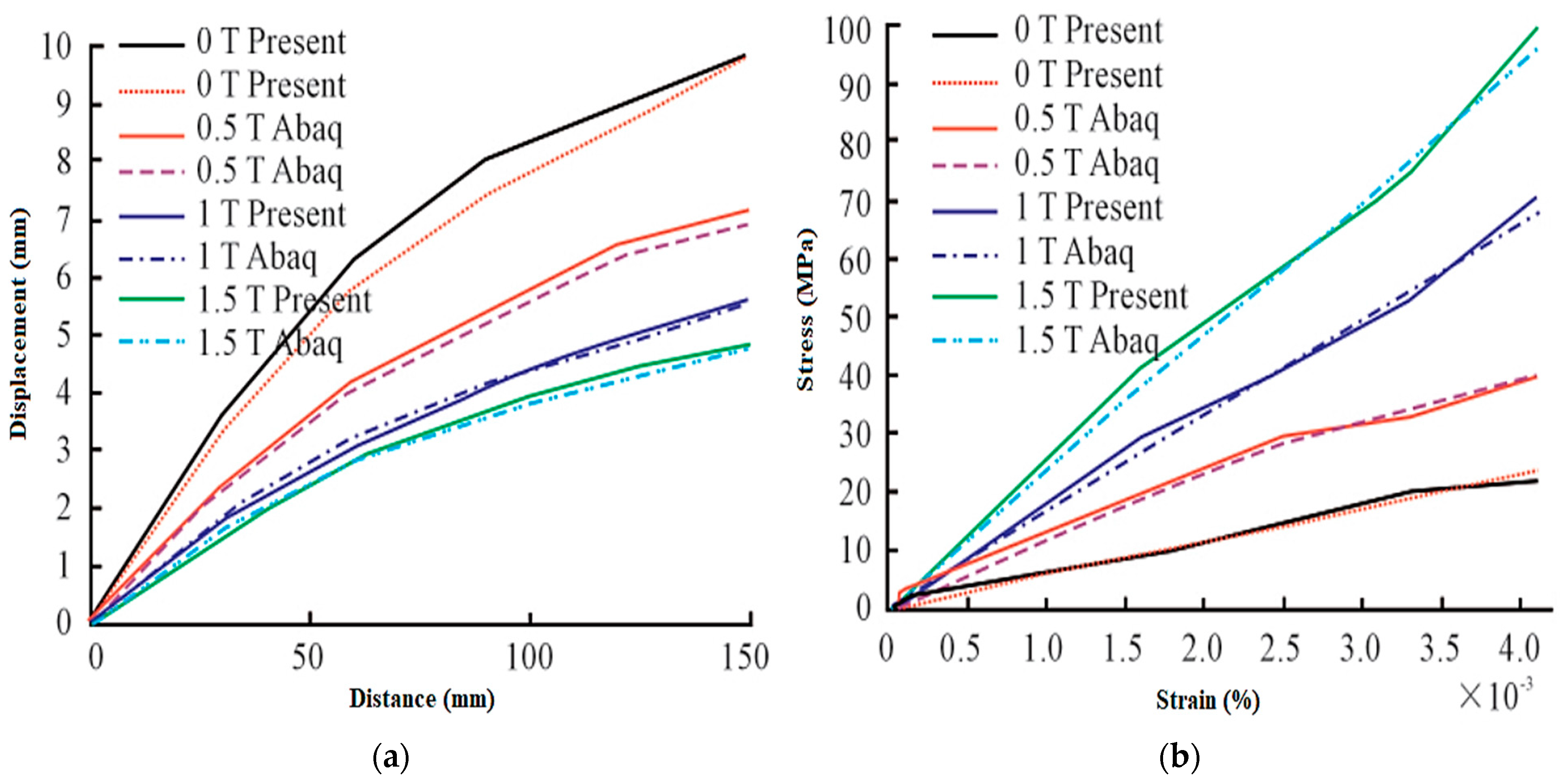

5.2. Effect of The Applied Field on MRE Sandwich Structures Loss Factors and Deflection

5.3. MRE Sandwich Structures Dynamic Responses under Different Parameters

5.4. Non-Linear Behavior of MRE Sandwich Structures

5.5. Dynamic Characteristics and Optimum Design of Partially Treated MRE Sandwich Structures

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Funari, M.F.; Spadea, S.; Lonetti, P.; Lourenço, P.B. On the elastic and mixed-mode fracture properties of PVC foam. Theor. Appl. Fract. Mech. 2021, 112, 102924. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Fam, A.; Benmokrane, B. State-of-the-Art Review on FRP Sandwich Systems for Lightweight Civil Infrastructure. J. Compos. Constr. 2017, 21, 04016068. [Google Scholar] [CrossRef] [Green Version]

- Soong, T.T.; Costantinou, M.C. Passive and Active Structural Vibration Control in Civil Engineering; Springer: New York, NY, USA, 1994. [Google Scholar] [CrossRef]

- Soong, T.T.; Spencer, B.F. Active, semi-active and hybrid control of structures. Bull. N. Z. Soc. Earthq. Eng. 2000, 33, 387–402. [Google Scholar] [CrossRef] [Green Version]

- Funari, M.F.; Greco, F.; Lonetti, P. Sandwich panels under interfacial debonding mechanisms. Compos. Struct. 2018, 203, 310–320. [Google Scholar] [CrossRef]

- Cortes, F.; Elejabarrieta, M.J. Structural vibration of flexural beams with thick unconstrained layer damping. Int. J. Solids Struct. 2008, 45, 5805–5813. [Google Scholar] [CrossRef] [Green Version]

- Carlson, J.D.; Chrzan, M.J.; James, F.O. Magnetorheological Fluid Devices. U.S. Patent 5284330, 8 February 1994. Available online: https://patentimages.storage.googleapis.com/c4/e3/40/70c8d2579309ab/US5284330.pdf (accessed on 23 February 2021).

- Carlson, J.D.; Jolly, M.R. MR fluid, foam and elastomer devices. Mechatronics 2000, 10, 555–569. [Google Scholar] [CrossRef]

- Liu, T.; Xu, Y. Magnetorheological elastomers: Materials and applications. In Smart and Functional Soft Materials; Dong, X., Ed.; IntechOpen: London, UK, 2019; pp. 147–180. [Google Scholar] [CrossRef] [Green Version]

- Ginder, J.M.; Nichols, M.E.; Elie, L.D.; Tardiff, J.L. Magnetorheological elastomers: Properties and applications. Proc. SPIE 1999, 3675, 131138. [Google Scholar] [CrossRef]

- Jolly, M.R.; Carlson, J.D. The magnetroviscoelastic response of elastomer composites consisting of ferrous particles embedded in a polymer matrix. J. Intell. Mater. Syst. Struct. 1996, 7, 613–622. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

- Yu, M.; Wang, S. The composite MRE embedded with a copper coil. Smart Mater. Struct. 2010, 19, 065023. [Google Scholar] [CrossRef]

- Deng, H.X.; Gong, X.L. Adaptive tuned vibration absorber based on magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 2007, 18, 1205–1210. [Google Scholar] [CrossRef]

- Deng, H.X.; Gong, X.L. Application of magnetorheological elastomer to vibration absorber. Commun. Nonlinear Sci. Numer. Simul. 2008, 13, 1938–1947. [Google Scholar] [CrossRef]

- Ni, Z.C.; Gong, X.L.; Li, J.F.; Chen, L. Study on a dynamic stiffness-tuning absorber with squeeze-strain enhanced magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 2009, 20, 1195–1202. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.Z.; Li, W.H. Adaptive tuned dynamic vibration absorbers working with MR elastomers. Smart Struct. Syst. 2009, 5, 517–529. [Google Scholar] [CrossRef]

- Xu, Z.; Gong, X.; Liao, G.; Chen, X. An active-dampingcompensated magnetorheological elastomer adaptive tuned vibration absorber. J. Intell. Mater. Syst. Struct. 2010, 21, 1039–1047. [Google Scholar] [CrossRef]

- Liao, G.J.; Gong, X.L.; Kang, C.J.; Xuan, S.H. The design of an active–adaptive tuned vibration absorber based on magnetorheological elastomer; its vibration attenuation performance. Smart Mater. Struct. 2011, 20, 075015. [Google Scholar] [CrossRef]

- Kim, Y.K.; Koo, J.H.; Kim, K.S.; Kim, S. Developing a real time controlled adaptive MRE-based tunable vibration absorber system for a linear cryogenic cooler. In Proceeding of 2011 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Budapest, Hungary, 3–7 July 2011; pp. 287–290. [Google Scholar]

- Sinko, R.; Karnes, M.; Koo, J.H.; Kim, K.; Kim, K.S. Design and test of an adaptive vibration absorber based on magnetorheological elastomers and a hybrid electromagnet. J. Intell. Mater. Syst. Struct. 2013, 24, 803–812. [Google Scholar] [CrossRef]

- Sun, S.S.; Chen, Y.; Yang, J.; Tian, T.F.; Deng, H.X.; Li, W.H.; Du, H.; Alici, G. The development of an adaptive tuned magnetorheological elastomer absorber working in squeeze mode. Smart Mater. Struct. 2014, 23, 075009. [Google Scholar] [CrossRef]

- Liao, G.J.; Gong, X.L.; Xuan, S.H.; Kang, C.J.; Zong, L.H. Development of a real-time tunable stiffness and damping vibration isolator based on magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 2012, 23, 25–33. [Google Scholar] [CrossRef]

- Opie, S.; Yim, W. Design and control of a real-time variable modulus vibration isolator. J. Intell. Mater. Syst. Struct. 2011, 22, 113–125. [Google Scholar] [CrossRef]

- Eem, S.H.; Jung, H.J.; Koo, J.H. Application of MR elastomers for improving seismic protection of base-isolated structures. IEEE Trans. Mag. 2011, 47, 2901–2904. [Google Scholar] [CrossRef]

- Kim, Y.K.; Bae, H.I.; Koo, J.H.; Kim, K.S.; Kim, S. Real time control of a tunable vibration absorber based on magnetorheological elastomer for suppressing tonal vibrations. Rev. Sci. Instrum. 2012, 83, 046108. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, J.; Li, W.; Samali, B. Development and characterization of a magnetorheological elastomer based adaptive seismic isolator. Smart Mater. Struct. 2013, 22, 035005. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Li, W.; Samali, B. Development of adaptive seismic isolators for ultimate seismic protection of civil structures. Proceeding of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2013, San Diego, CL, USA, 10–14 March 2013; p. 86920H. [Google Scholar]

- Li, Y.; Li, J.; Tian, T.; Li, W. A highly adjustable magnetorheological elastomer base isolator for applications of real-time adaptive control. Smart Mater. Struct. 2013, 22, 095020. [Google Scholar] [CrossRef]

- Behrooz, M.; Wang, X.; Gordaninejad, F. Performance of a new magnetorheological elastomer isolation system. Smart Mater. Struct. 2014, 23, 045014. [Google Scholar] [CrossRef] [Green Version]

- Kavlicoglu, B.; Wallis, B.; Sahin, H.; Liu, Y. Magnetorheological elastomer mount for shock and vibration isolation. Proc. SPIE. 2011, 7977, 79770Y. [Google Scholar]

- Shen, Y.; Golnaraghi, M.F.; Heppler, G.R. Experimental research and modeling of magnetorheological elastomers. J. Intell. Mater. Syst. Struct. 2004, 15, 27–35. [Google Scholar] [CrossRef]

- Davis, L.C. Model of magnetorheological elastomers. J. App. Phys. 1999, 85, 3348–3351. [Google Scholar] [CrossRef]

- Borcea, L.; Bruno, O. On the magneto-elastic properties of elastomer-ferromagnet composites. J. Mech. Phys. Solids. 2001, 49, 2877–2919. [Google Scholar] [CrossRef]

- Yin, H.M.; Sun, L.Z.; Chen, J.S. Magneto-elastic modeling of composites containing chain-structured magnetostrictive particles. J. Mech. Phys. Solids. 2006, 54, 975–1003. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Li, W.H.; Gong, X.L. An effective permeability model to predict field-dependent modulus of magnetorheological elastomers. Commun. Nonlinear Sci. Numer. Simul. 2008, 13, 1910–1916. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Xia, Y.Q.; Yan, X.R. Analysis and verification on the chain-like model with normal distribution of magnetorheological elastomer. Chin. J. Chem. Phys. 2009, 22, 545–550. [Google Scholar] [CrossRef]

- Guan, X.C.; Dong, X.F.; Ou, J.P. Predicting performance of polymer-bonded Terfenol-D composites under different magnetic fields. J. Magnetism Magnetic Mater. 2009, 321, 2742–2748. [Google Scholar] [CrossRef]

- Melenev, P.; Raikher, Y.; Stepanov, G.; Rusakov, V.; Polygalova, L. Modeling of the field-induced plasticity of soft magnetic elastomers. J. Intell. Mater. Syst. Struct. 2011, 22, 531–538. [Google Scholar] [CrossRef]

- Danas, K.; Kankanala, S.V.; Triantafyllidis, N. Experiments and modeling of iron-particle-filled magnetorheological elastomers. J. Mech. Phys. Solids. 2012, 60, 120–138. [Google Scholar] [CrossRef]

- Galipeaua, E.; Castaneda, P.P. A finite-strain constitutive model for magnetorheological elastomers: Magnetic torques and fiber rotations. J. Mech. Phys. Solids. 2013, 61, 1065–1090. [Google Scholar] [CrossRef]

- Demchuk, S.A.; Kuz′min, V.A. Viscoelastic properties of magnetorheological elastomers in the regime of dynamic deformation. J. Eng. Phys. Thermophys. 2002, 75, 396–400. [Google Scholar] [CrossRef]

- Abramchuk, S.S.; Grishin, D.A.; Kramarenko, E.Y.; Stepanov, G.V.; Khokhlov, A.R. Effect of a homogeneous magnetic field on the mechanical behavior of soft magnetic elastomers under compression. Polymer Sci. Ser. A 2006, 48, 138–145. [Google Scholar] [CrossRef]

- Kchit, N.; Lancon, P.; Bossis, G. Thermoresistance and giant magnetoresistance of magnetorheological elastomers. J. Phys. D Appl. Phys. 2009, 42, 105506. [Google Scholar] [CrossRef]

- Koo, J.H.; Khan, F.; Jang, D.D.; Jung, H.J. Dynamic characterization and modeling of magneto-rheological elastomers under compressive loadings. Smart Mater. Struct. 2010, 19, 117002. [Google Scholar] [CrossRef]

- Zhang, W.; Gong, X.L.; Jiang, W.Q.; Fan, Y.C. Investigation of the durability of anisotropic magnetorheological elastomers based on mixed rubber. Smart Mater. Struct. 2010, 19, 085008. [Google Scholar] [CrossRef]

- Gong, X.; Liao, G.; Xuan, S. Full-field deformation of magnetorheological elastomer under uniform magnetic field. Appl. Phys. Lett. 2012, 100, 211909. [Google Scholar] [CrossRef] [Green Version]

- Li, W.H.; Nakano, M. Fabrication and characterization of PDMS based magnetorheological elastomers. Smart Mater. Struct. 2013, 22, 055035. [Google Scholar] [CrossRef] [Green Version]

- Collette, C.; Kroll, G.; Saive, G.; Guillemier, V.; Avraam, M. On magnetorheologic elastomers for vibration isolation, damping, and stress reduction in mass-varying structures. J. Intell. Mater. Syst. Struct. 2010, 21, 1463–1469. [Google Scholar] [CrossRef]

- Li, W.; Kostidis, K.; Zhang, X.; Zhou, Y. Development of a force sensor working with MR elastomers. In Proceeding of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Raffles Blvd, Singapore, 14–17 July 2009; pp. 233–238. [Google Scholar]

- Fu, J.; Yu, M.; Dong, X.M.; Zhu, L.X. Magnetorheological elastomer and its application on impact buffer. J. Phys. Conf. Ser. 2013, 412, 012032. [Google Scholar] [CrossRef]

- Hoang, N.; Zhang, N.; Du, H. A dynamic absorber with a soft magnetorheological elastomer for powertrain vibration suppression. Smart Mater. Struct. 2009, 18, 074009. [Google Scholar] [CrossRef] [Green Version]

- Hoang, N.; Zhang, N.; Li, W.H.; Du, H. Development of a torsional dynamic absorber using a magnetorheological elastomer for vibration reduction of a powertrain test rig. J. Intell. Mater. Syst. Struct. 2013, 24, 2036–2044. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; Du, H. Development and simulation evaluation of a magnetorheological elastomer isolator for seat vibration control. J. Intell. Mater. Syst. Struct. 2012, 23, 1041–1048. [Google Scholar] [CrossRef]

- Jung, H.-J.; Eem, S.-H.; Jang, D.-D.; Koo, J.-H. Seismic Performance analysis of a smart base-isolation system considering dynamics of MR elastomer. J. Intell. Mater. Syst. Struct. 2011, 22, 1439–1450. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Wang, Q. Design of a smart piezoelectric actuator based on a magnetorheological elastomer. Smart Mater. Struct. 2005, 14, 504–510. [Google Scholar] [CrossRef]

- Ying, Z.G.; Ni, Y.Q. Micro-vibration response of a stochastically excited sandwich beam with a magnetorheological elastomer core and mass. Smart Mater. Struct. 2009, 18, 095005. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Wang, Q. Study on the adjustable rigidity of magnetorheological-elastomer-based sandwich beams. Smart Mater. Struct. 2006, 15, 59–74. [Google Scholar] [CrossRef]

- Lara-Prieto, V.; Parkin, R.; Jackson, M.; Silberschmidt, V.; Kesy, Z. Vibration characteristics of MR cantilever sandwich beams: Experimental study. Smart Mater. Struct. 2010, 19, 015005. [Google Scholar] [CrossRef] [Green Version]

- Miedzinska, D.; Boczkowska, A.; Zubko, K. Numerical verification of three point bending experiment of magnetorheological elastomer (MRE) in magnetic field. J. Phys. Conf. Ser. 2010, 240, 012158. [Google Scholar] [CrossRef]

- Korobko, E.V.; Mikhasev, G.I.; Novikova, Z.A.; Zhurauski, M.A. On damping vibrations of threelayered beam containing magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 2012, 23, 1019–1023. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, D.Y. Vibrational analysis theory and application to elastic-viscoelastic composite structures. Comput. Struct. 1990, 37, 585–595. [Google Scholar] [CrossRef]

- Golden, J.M.; Graham, G.A.C. Boundary Value Problems in Linear Viscoelasticity; Springer Science & Business Media: Heidelberg, Berlin, 1998. [Google Scholar]

- Weiss, K.D.; Carlson, J.D.; Nixon, D.A. Viscoelastic properties of magneto- and electro-rheological fluid. J. Intell. Mater. Syst. Struct. 1994, 5, 772–775. [Google Scholar] [CrossRef]

- Qing, S.; Jinxong, Z.; Ling, Z. An adaptive and dynamic characteristics of magnetorheological materials. J. Sound Vib. 2003, 261, 465–481. [Google Scholar]

- Ginder, J.M.; Davis, L.C.; Elie, L.D. Rheology of Magnetorheology Fluid: Models and Measurements. Int. J. Mod. Phys. B 1996, 10, 3293–3303. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, D.Y. Modal theory of elastic viscoelastic composite structure. Chin. J. Solid Mech. 1990, 11, 23–33. [Google Scholar]

- Sims, N.D.; Holmes, N.J.; Stanway, R. A unified modeling and model updating procedure for electrorheological and magnetorheological vibration dampers. Smart Mater. Struct. 2004, 13, 100–121. [Google Scholar] [CrossRef]

- Yen, W.S.; Achorn, P.J. A study of the dynamic behavior of an electrorheological fluid. J. Rheol. 1991, 35, 1375–1384. [Google Scholar] [CrossRef]

- Li, W.H.; Zhou, Y.; Tian, T.F.; Alici, G. Creep and Recovery Behaviors of Magnetorheological Elastomers. Front. Mech Eng. Chin. 2010, 5, 341–346. [Google Scholar] [CrossRef]

- Ross, D.; Ungar, E.E.; Kerwin, E.M. Damping of plate flexural vibrations by means of viscoelastic laminea. In Structural Damping; ASME: New York, NY, USA, 1959; pp. 212–226. [Google Scholar]

- Coulter, J.P.; Duclos, T.G. Applications of Electrotheological Materials in vibration Control. In Proceeding of the Second International Conference on ER Fluids, Raleigh, NC, USA, 7–9 August 1989; Technomic Publishing Company Inc.: Lancaster, PA, USA, 1990; pp. 300–325. [Google Scholar]

- Jacques, N.; Daya, E.M.; P0tier-Ferry, M. Nonlinear vibration of viscoelastic sandwich beams by the harmonic balance and finite element methods. J. Sound Vib. 2010, 329, 4251–4265. [Google Scholar] [CrossRef]

- Nayak, B.; Dwivedy, S.K.; Murthy, K.S.R.K. Dynamic stability of a rotating sandwich with magnetorheological elastomer core. Eur. J. Mech. A/Solids. 2014, 47, 143–155. [Google Scholar] [CrossRef]

- Nayak, B.; Dwivedy, S.K.; Murthy, K.S.R.K. Dynamic stability of magnetorheological elastomer based adaptive sandwich beam with conductive skins using FEM and the harmonic balance method. Int. J. Mech. Sci. 2013, 77, 205–216. [Google Scholar] [CrossRef]

- Aguib, S.; Nour, A.; Zahloul, H.; Bossis, G.; Chevalier, Y.; Lançon, P. Dynamic behavior analysis of a magnetorheological elastomer sandwich plate. Int. J. Mech. Sci. 2014, 87, 118–136. [Google Scholar] [CrossRef]

- Hu, G.L.; Wang, S.L.; Long, M. Vibration characteristics analysis of MRE cantilever sandwich beam. In Proceeding of the Third International Symposium on Innovation & Sustainability of Modern Railway, Nanchang, China, 20–21 September 2012; pp. 153–159. [Google Scholar]

- Sun, S.; Yang, J.; Li, W.; Deng, H.; Du, H.; Alici, G. Development of an MRE adaptive tuned vibration absorber with self-sensing capability. Smart Mater. Struct. 2015, 24, 095012. [Google Scholar] [CrossRef]

- Deng, H.; Gong, X.; Wang, L. Development of an adaptive tuned vibration absorber with magnetorheological elastomer. Smart Mater. Struct. 2006, 15, 111–116. [Google Scholar] [CrossRef]

- Sun, S.; Deng, H.; Yang, J.; Li, W.; Du, H.; Alici, G.; Nakano, M. An adaptive tuned vibration absorber based on multilayered MR elastomers. Smart Mater. Struct. 2015, 24, 045045. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, H.S.; Kim, Y.K. Stiffness control of magnetorheological gels for adaptive tunable vibration absorber. Smart Mater. Struct. 2016, 26, 015016. [Google Scholar] [CrossRef]

- Xin, F.L.; Bai, X.X.; Qian, L.J. Principle, modeling, and control of a magnetorheological elastomer dynamic vibration absorber for powertrain mount systems of automobiles. J. Intel. Mat. Syst. Str. 2016, 28, 2239–2254. [Google Scholar] [CrossRef]

- Liu, G.; Lu, K.; Zou, D.; Xie, Z.; Rao, Z.; Ta, N. Development of a semi-active dynamic vibration absorber for longitudinal vibration of propulsion shaft system based on magnetorheological elastomer. Smart Mater. Struct. 2017, 26, 075009. [Google Scholar] [CrossRef]

- Jang, D.I.; Yun, G.E.; Park, J.-E.; Kim, Y.-K. Designing an attachable and power-efficient all-in-one module of a tunable vibration absorber based on magnetorheological elastomer. Smart Mater. Struct. 2018, 27, 085009. [Google Scholar] [CrossRef]

- Yang, J.; Sun, S.S.; Chi, J.Y.; Ning, D.H.; Zhang, S.W.; Li, W.H.; Mao, S.X. Development and evaluation of an MRE-based absorber with two individually controllable natural frequencies. Smart Mater. Struct. 2018, 27, 095002. [Google Scholar] [CrossRef] [Green Version]

- Lerner, A.A.; Cunefare, K.A. Performance of MREbased vibration absorbers. J. Intell. Mater. Syst. Struct. 2007, 19, 551–563. [Google Scholar] [CrossRef]

- Komatsuzaki, T.; Inoue, T.; Iwata, Y. Experimental investigation of an adaptively tuned dynamic absorber incorporating magnetorheological elastomer with self-sensing property. Exp. Mech. 2016, 56, 871–880. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Zhang, X. Research and applications of MR elastomers. Recent Pat. Mech. Eng. 2008, 1, 161–166. [Google Scholar] [CrossRef]

- Ke-Xiang, W.; Guang, M.; Wen-Ming, Z.; Shi-sha, Z. Experimental investigation on vibration characteristics of sandwich beams with magnetorheological elastomers cores. J. Cent. South Univ. Technol. 2008, 15, 239–242. [Google Scholar]

- Hu, G.; Guo, M.; Li, W.; Du, H.; Alici, G. Experimental investigation of the vibration characteristics of a magnetorheological elastomer sandwich beam under non-homogeneous small magnetic fields. Smart Mater. Struct. 2011, 20, 1–7. [Google Scholar] [CrossRef]

- Kozlowska, J.; Boczkowska, A.; Czulak, A.; Przybyszewski, B.; Holeczek, K.; Stanik, R.; Gude, M. Novel MRE/CFRP sandwich structures for adaptive vibration control. Smart Mater. Struct. 2016, 25, 1–14. [Google Scholar] [CrossRef]

- Eloy, F.S.; Gomes, G.F.; Ancelotti, A.C.; Cunha, S.S.; Bombard, A.J.F.; Junqueira, D.M. Experimental dynamic analysis of composite sandwich beams with magnetorheological honeycomb core. Eng. Struct. 2018, 176, 231–242. [Google Scholar] [CrossRef]

- Eloy, F.S.; Gomes, G.F.; Ancelotti, A.C.; Cunha, S.S.; Bombard, A.J.F.; Junqueira, D.M. Numerical-experimental dynamic analysis of composite sandwich beam with magnetorheological elastomer honeycomb core. Compos. Struct. 2019, 209, 242–257. [Google Scholar] [CrossRef]

- Sharif, U.; Sun, B.; Tariq, I.; Ibrahim, D.S.; Adewale, O.O.; Zafar, A. Static and modal analysis of sandwich beam structure with magnetorheological honeycomb core. In Proceedings of the 2020 6th International Conference on Mechanical Engineering and Automation Science, ICMEAS 2020, Moscow, Russia, 29–31 October 2020; pp. 19–23. [Google Scholar]

- Sharif, U.; Sun, B.; Zhao, P.; Ibrahim, D.S.; Adewale, O.O.; Zafar, A. Dynamic Behavior Analysis of the Sandwich Beam Structure with Magnetorheological Honeycomb Core under Different Magnetic Intensities: A Numerical Approach. Mater. Sci. Forum 2021, 1047, 31–38. [Google Scholar] [CrossRef]

- Fadaee, M.; Talebitooti, M. Dynamic stability of the rotating carbon nanotube-reinforced adaptive sandwich beams with magnetorheological elastomer core. J. Sandw. Struct. Mater. 2019, 1–25. [Google Scholar] [CrossRef]

- Gong, X.L.; Zhang, X.Z.; Zhang, P.Q. Fabrication and characterization of isotropic magnetorheological elastomers. Polym. Test. 2005, 24, 669–676. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Li, W.H. Microstructures and viscoelastic properties of anisotropic magnetorheological elastomers. Smart Mater. Struct 2007, 16, 2645–2650. [Google Scholar] [CrossRef]

- Choi, W.J.; Xiong, Y.P.; Shenoi, R.A. Experimental study on vibration characteristics of sandwich beams with aluminum skins and magnetorheological elastomer cores. Adv. Struct. Eng. 2009, 13, 837–847. [Google Scholar] [CrossRef]

- Wang, X.; Yang, B.; Yu, H.; Gao, Y. Transient vibration analytical modeling and suppressing for vibration absorber system under impulse excitation. J. Sound. Vib. 2017, 394, 90–108. [Google Scholar] [CrossRef]

- Yeh, J.Y. Vibration analysis of sandwich rectangular plates with magnetorheological elastomer damping treatment. Smart Mater. Struct. 2013, 22, 1–8. [Google Scholar] [CrossRef]

- Yeh, J.Y. Dynamic characteristics analysis of sandwich orthotropic rectangular plate with magnetorheological elastomer. J. Eng. Technol. Educ. 2014, 11, 413–420. [Google Scholar]

- Mikhasev, G.I.; Altenbach, H.; Korchevskaya, E.A. On the influence of the magnetic field on the eigenmodes of thin laminated cylindrical shells containing magnetorheological elastomer. Compos. Struct. 2014, 113, 186–196. [Google Scholar] [CrossRef]

- Yeh, J.Y. Vibration characteristic analysis of sandwich cylindrical shells with MR elastomer. Smart Struct. Syst. 2014, 18, 233–247. [Google Scholar] [CrossRef]

- Ulicny, J.C.; Golden, M.A. Releasable Fastener System and Process. U.S. Patent No 6,742,227, 1 June 2004. [Google Scholar]

- Ottaviani, R.A.; Ulicny, J.C.; Golden, M.A. Magnetorheological Nanocomposite Elastomer for Releasable Attachment Applications. U.S. Patent No 7,020,938, 30 March 2006. [Google Scholar]

- Bose, H.; Rabindranath, R.; Ehrlich, J. Soft magnetorheological elastomers as new actuators for valves. J. Intell. Mater. Syst. Struct. 2012, 23, 989–994. [Google Scholar] [CrossRef]

- Kashima, S.; Miyasaka, F.; Hirata, K. Novel soft actuator using magnetorheological elastomer. IEEE Trans. Magn. 2012, 48, 1649–1652. [Google Scholar] [CrossRef]

- Mikhasev, G.I.; Eremeyev, V.A.; Wilde, K.; Maevskaya, S.S. Assessment of dynamic characteristics of thin cylindrical sandwich panels with magnetorheological core. J. Intel. Mater. Syst. Struct. 2019, 30, 2748–2769. [Google Scholar] [CrossRef]

- Navazi, H.M.; Bornassi, S.; Haddadpour, H. Vibration analysis of a rotating magnetorheological tapered sandwich beam. Int. J. Mech. Sci. 2017, 122, 308–317. [Google Scholar] [CrossRef]

- Bornassi, S.; Navazi, H.M.; Haddadpour, H. Edgewise bending vibration analysis of a rotating sandwich beam with magnetorheological elastomer core. Int. J. Struct. Stab. Dyn. 2017, 18, 1850134. [Google Scholar] [CrossRef]

- Bornassi, S.; Navazi, H.M. Torsional vibration analysis of a rotating tapered sandwich beam with magnetorheological elastomer core. J. Intel. Mat. Syst. Struct. 2018, 29, 2406–2423. [Google Scholar] [CrossRef]

- Vemuluri, R.B.; Rajamohan, V. Dynamic analysis of tapered laminated composite magnetorheological elastomer (MRE) sandwich plates. Smart Mater. Struct. 2016, 25, 1–19. [Google Scholar]

- Chena, L.; Gonga, X.L.; Li, W.H. Effect of carbon black on the mechanical performances of magnetorheological elastomers. Polym. Test. 2008, 27, 340–345. [Google Scholar] [CrossRef] [Green Version]

- Nayak, B.; Dwivedy, S.K.; Murthy, M.S. Fabrication and characterization of magnetorheological elastomer with carbon black. J. Intel. Mat. Syst. Struct. 2014, 26, 830–839. [Google Scholar] [CrossRef]

- Rokn-Abadi, M.R.; Shahali, P.; Haddadpour, H. Effects of magnetoelastic loads on free vibration characteristics of the magnetorheological-based sandwich beam. J. Intel. Mat. Syst. Struct. 2020, 31, 1–14. [Google Scholar] [CrossRef]

- Bellan, C.; Bossis, G. Field dependence of viscoelastic properties of MR elastomers. Int. J. Mod. Phys. B 2002, 16, 2447–2453. [Google Scholar] [CrossRef]

- Lu, H.; Wang, W.; Yang, F.; Wang, F.; Rui, X. Effect of carbon black with large particle size on dynamic mechanical analysis of magnetorheological elastomers (MREs). Mater. Res. Express 2018, 5, 095703. [Google Scholar] [CrossRef]

- Li, R.; Sun, L.Z. Dynamic mechanical behavior of nanocomposites filled with carbon nanotubes. Appl. Phys. Lett. 2011, 99, 1–3. [Google Scholar] [CrossRef]

- Li, R.; Sun, L.Z. ASCEM. Dynamic viscoelastic behavior of multiwalled carbon nano tube reinforced magnetorheological (MR) nanocomposites. J. Nanomech. Micromech. 2014, 4, A4013014. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Mazlan, S.A.; Ismail, N.I.N.; Ubaidillah, U.; Choi, S.-B. Effects of multiwall carbon nanotubes on viscoelastic properties of magnetorheological elastomers. Smart Mater. Struct. 2016, 25, 077001. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Mazlan, S.A.; Ismail, N.I.N.; Choi, S.-B.; Ubaidillah, U.; Yunus, N.A.B. An enhancement of mechanical and rheological properties of magnetorheological elastomer with multiwall carbon nanotubes. J. Intel. Mat. Syst. Struct. 2017, 28, 1–12. [Google Scholar] [CrossRef]

- Aziz, S.A.A.; Ubaidillah, U.; Mazlan, S.A.; Ismail, N.I.N.; Choi, S.-B. Implementation of functionalized multiwall carbon nanotubes on magnetorheological elastomer. J. Mater. Sci. 2018, 53, 10122–10134. [Google Scholar] [CrossRef]

- Selvaraj, R.; Ramamoorthy, M. Dynamic analysis of laminated composite sandwich beam containing carbon nanotubes reinforced magnetorheological elastomer. J. Sandw. Struct. Mater. 2020, 23, 1784–1807. [Google Scholar] [CrossRef]

- Yildirim, T.; Ghayesh, M.H.; Li, W.H.; Alici, G. Experimental nonlinear dynamics of a geometrically imperfect magneto-rheological elastomer sandwich beam. Compos. Struct. 2016, 138, 381–390. [Google Scholar] [CrossRef]

- Aguib, S.; Nour, A.; Benkoussas, B.; Tawfiq, I.; Djedid, T.; Chikh, N. Numerical simulation of the nonlinear static behavior of composite sandwich beams with a magnetorheological elastomer core. Compos. Struct. 2016, 139, 111–119. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Wang, Q. Magnetorheological elastomer-based smart sandwich beams with nonconductive skins. Smart Mater. Struct. 2005, 14, 1001–1009. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, Q. Use of magnetorheological elastomer in an adaptive sandwich beam with conductive skins. Part II: Dynamic properties. Int. J. Solids Struct. 2006, 43, 5403–5420. [Google Scholar] [CrossRef] [Green Version]

- Dwivedy, S.K.; Mahendra, N.; Sahu, K.C. Parametric instability regions of a soft and magnetorheological elastomer cored sandwich beam. J. Sound Vib. 2009, 325, 686–704. [Google Scholar] [CrossRef]

- Nayak, B.; Dwivedy, S.K.; Murthy, K.S.R.K. Dynamic analysis of magnetorheological elastomer-based sandwich beam with conductive skins under various boundary conditions. J. Sound Vib. 2011, 330, 1837–1859. [Google Scholar] [CrossRef]

- Vemuluri, R.B.; Rajamohan, V.; Arumugam, A.B. Dynamic characterization of tapered laminated composite sandwich plates partially treated with magnetorheological elastomer. J. Sandw. Struct. Mater. 2016, 20, 308–350. [Google Scholar] [CrossRef]

- Vemuluri, R.B.; Rajamohan, V.; Edwin Sudhagar, P. Structural optimization of tapered composite sandwich plates partially treated with magnetorheological elastomers. Compos. Struct. 2018, 200, 258–276. [Google Scholar] [CrossRef]

| Strain Amplitude | Magnetic Flux Density (mT) | k1/KPa | k2/KPa |

|---|---|---|---|

| 10% | 0 | 514.37 | 1.669 |

| 110 | 557.18 | 1.930 | |

| 220 | 564.21 | 2.406 | |

| 330 | 578.16 | 2.916 | |

| 385 | 621.34 | 3.919 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharif, U.; Sun, B.; Hussain, S.; Ibrahim, D.S.; Adewale, O.O.; Ashraf, S.; Bashir, F. Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review. Materials 2021, 14, 7025. https://doi.org/10.3390/ma14227025

Sharif U, Sun B, Hussain S, Ibrahim DS, Adewale OO, Ashraf S, Bashir F. Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review. Materials. 2021; 14(22):7025. https://doi.org/10.3390/ma14227025

Chicago/Turabian StyleSharif, Umer, Beibei Sun, Shahid Hussain, Dauda Sh. Ibrahim, Orelaja Oluseyi Adewale, Sumaira Ashraf, and Farrukh Bashir. 2021. "Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review" Materials 14, no. 22: 7025. https://doi.org/10.3390/ma14227025

APA StyleSharif, U., Sun, B., Hussain, S., Ibrahim, D. S., Adewale, O. O., Ashraf, S., & Bashir, F. (2021). Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review. Materials, 14(22), 7025. https://doi.org/10.3390/ma14227025