Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model

Abstract

1. Introduction

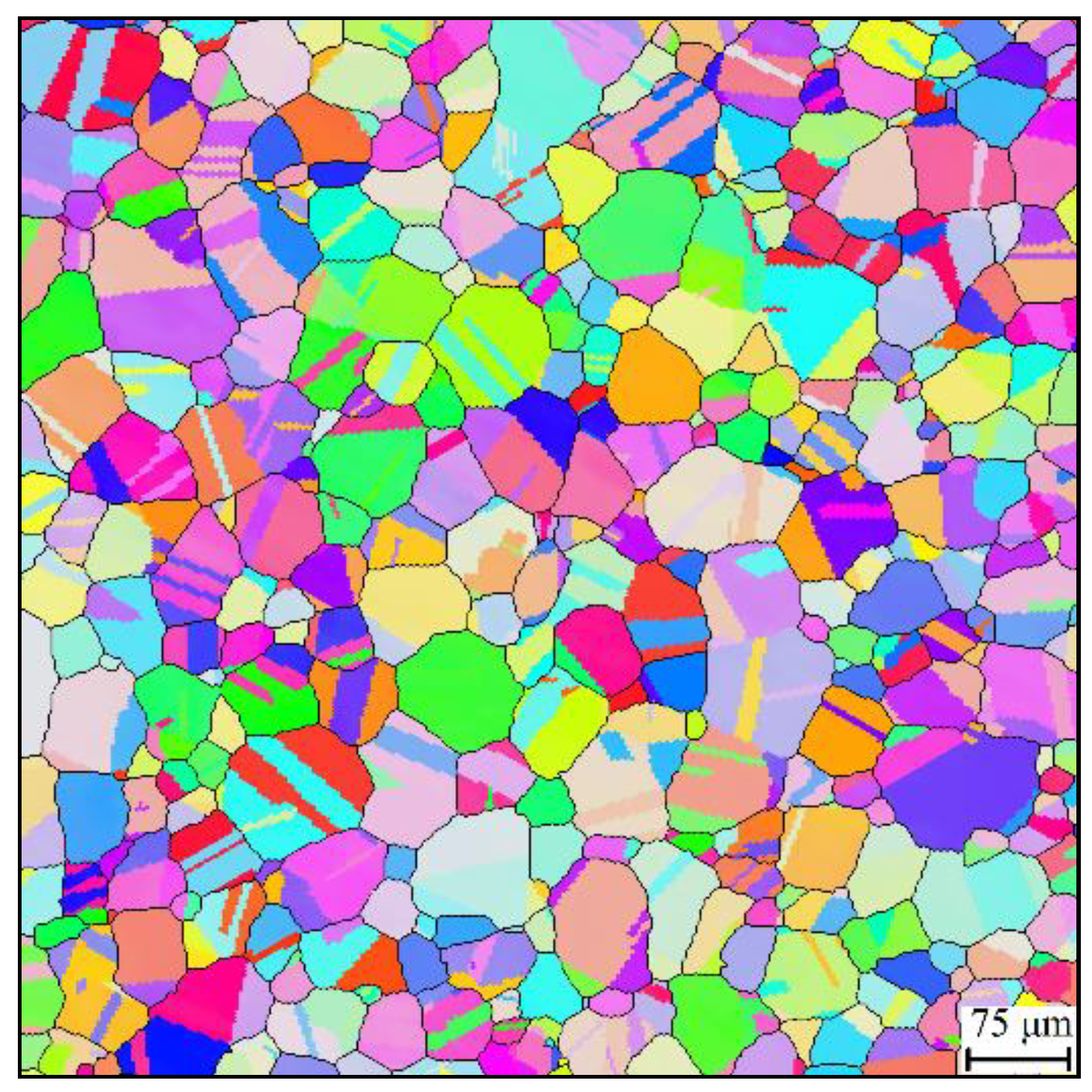

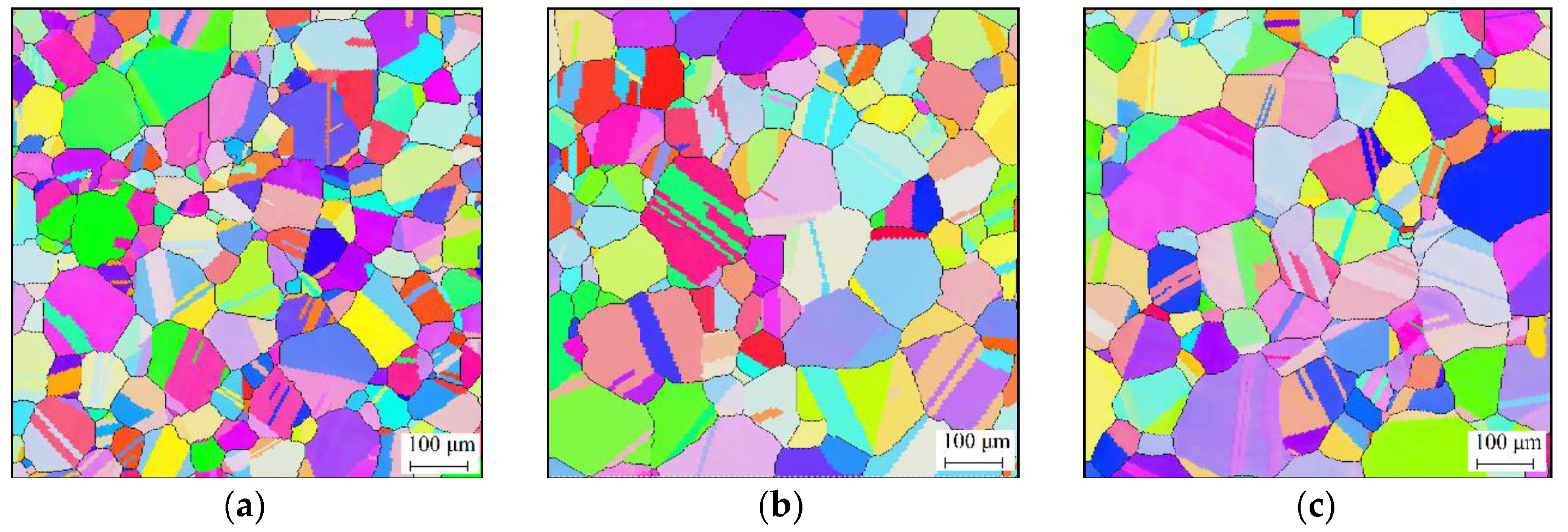

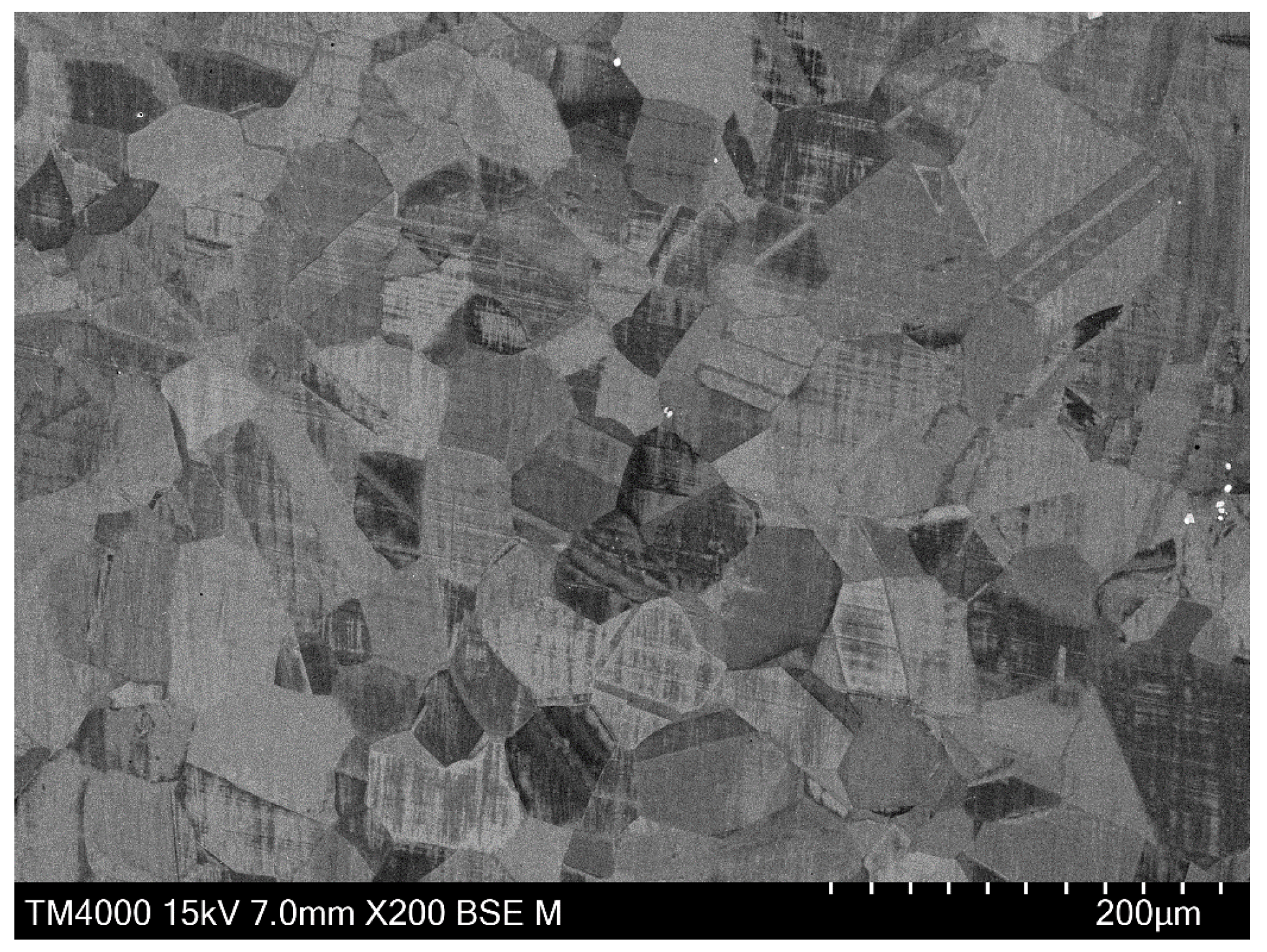

2. Materials and Experiments

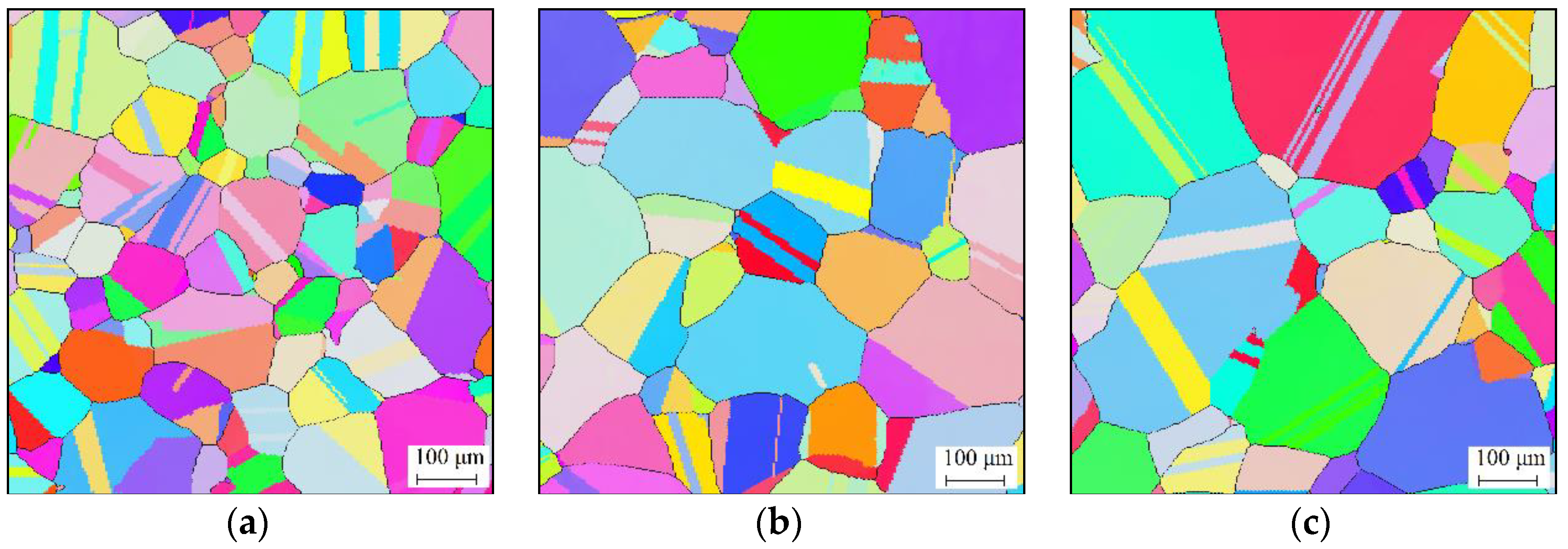

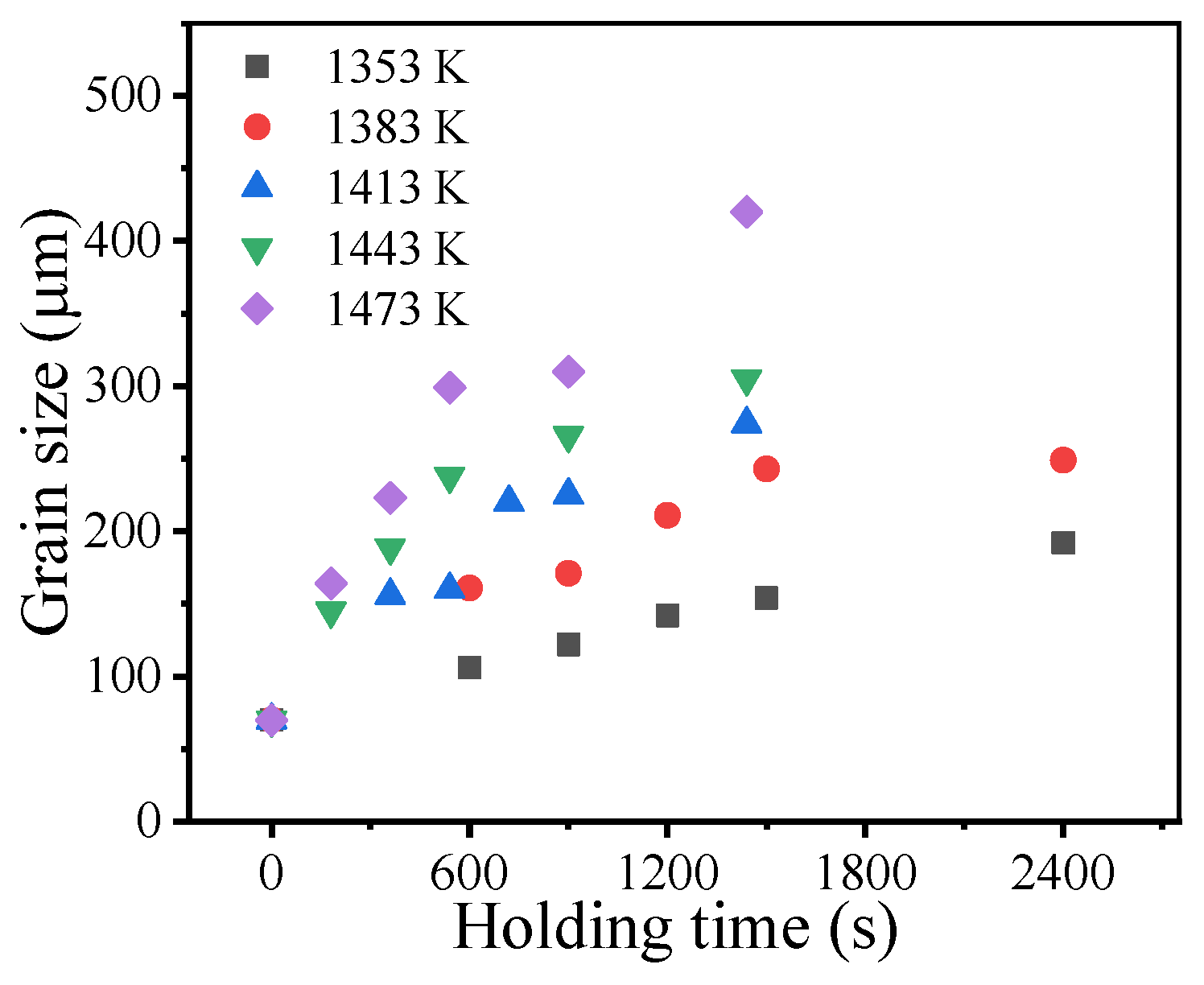

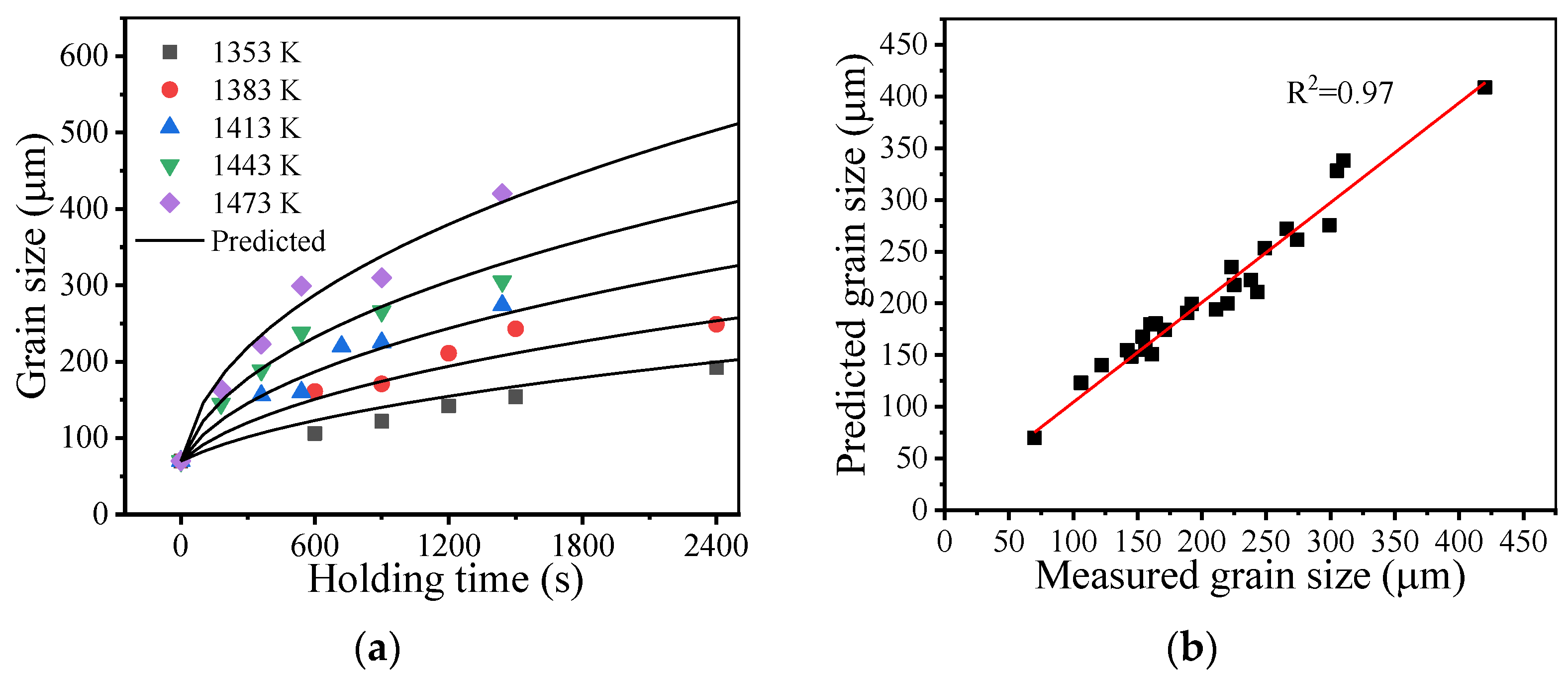

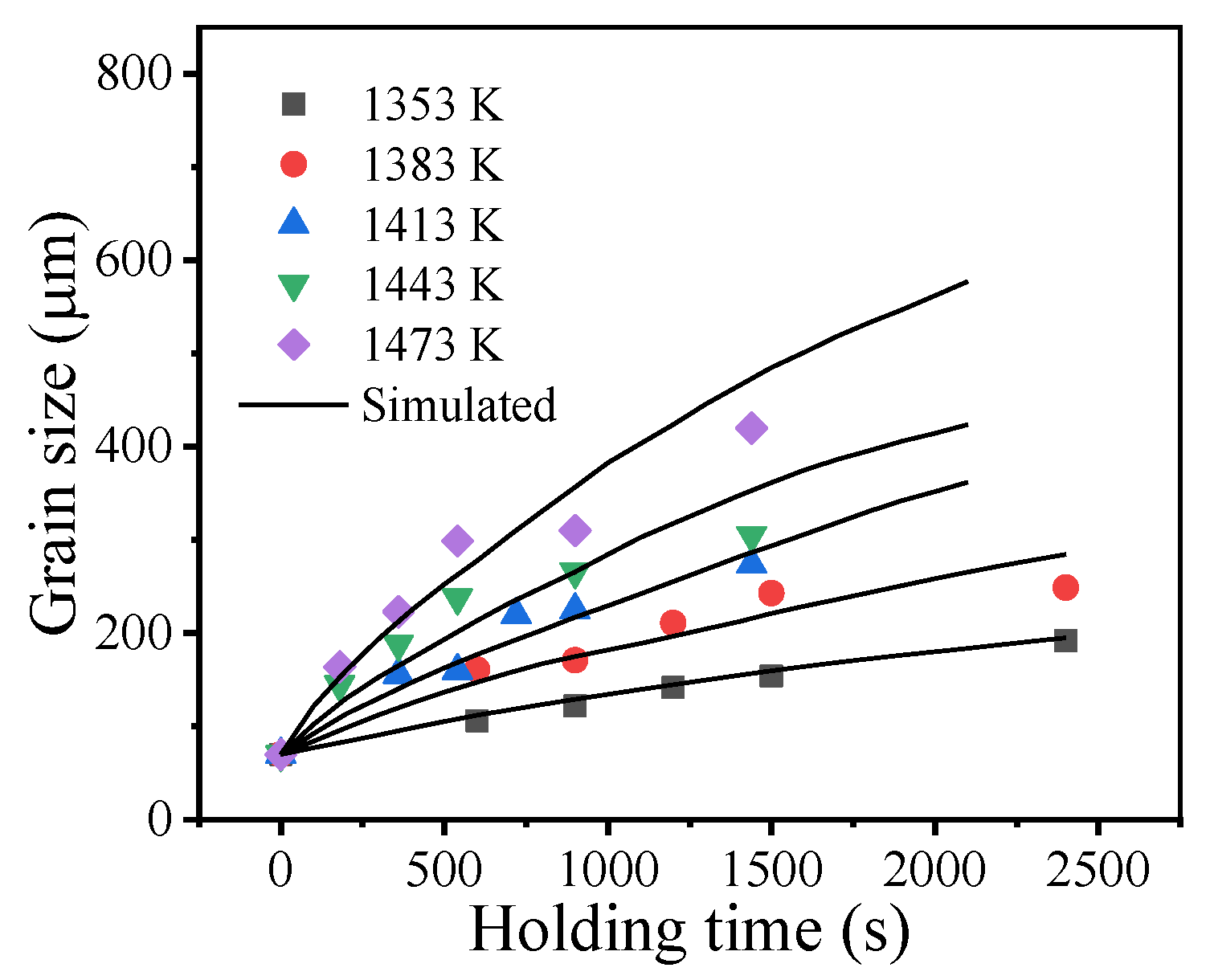

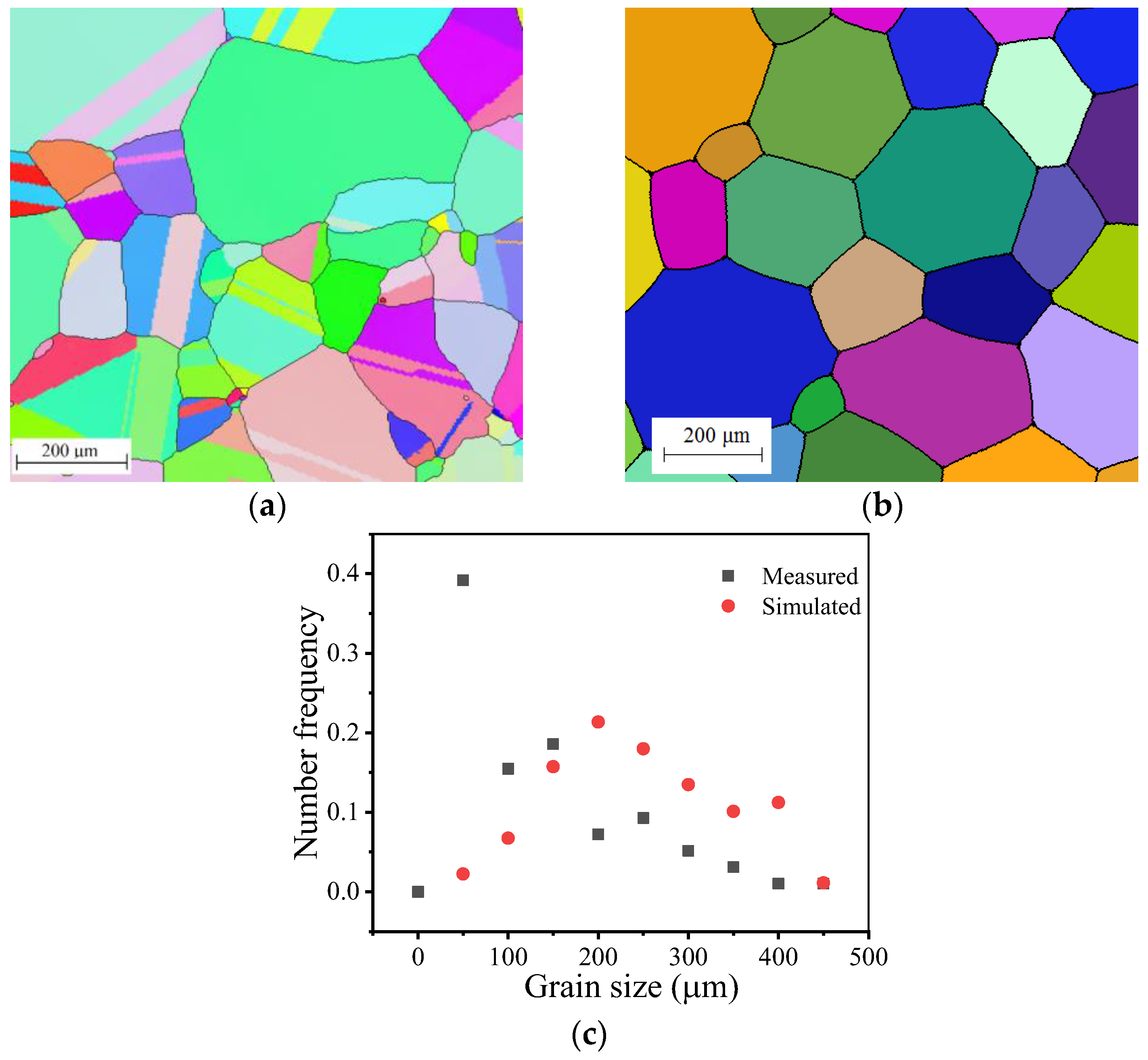

3. Experimental Results and Discussions

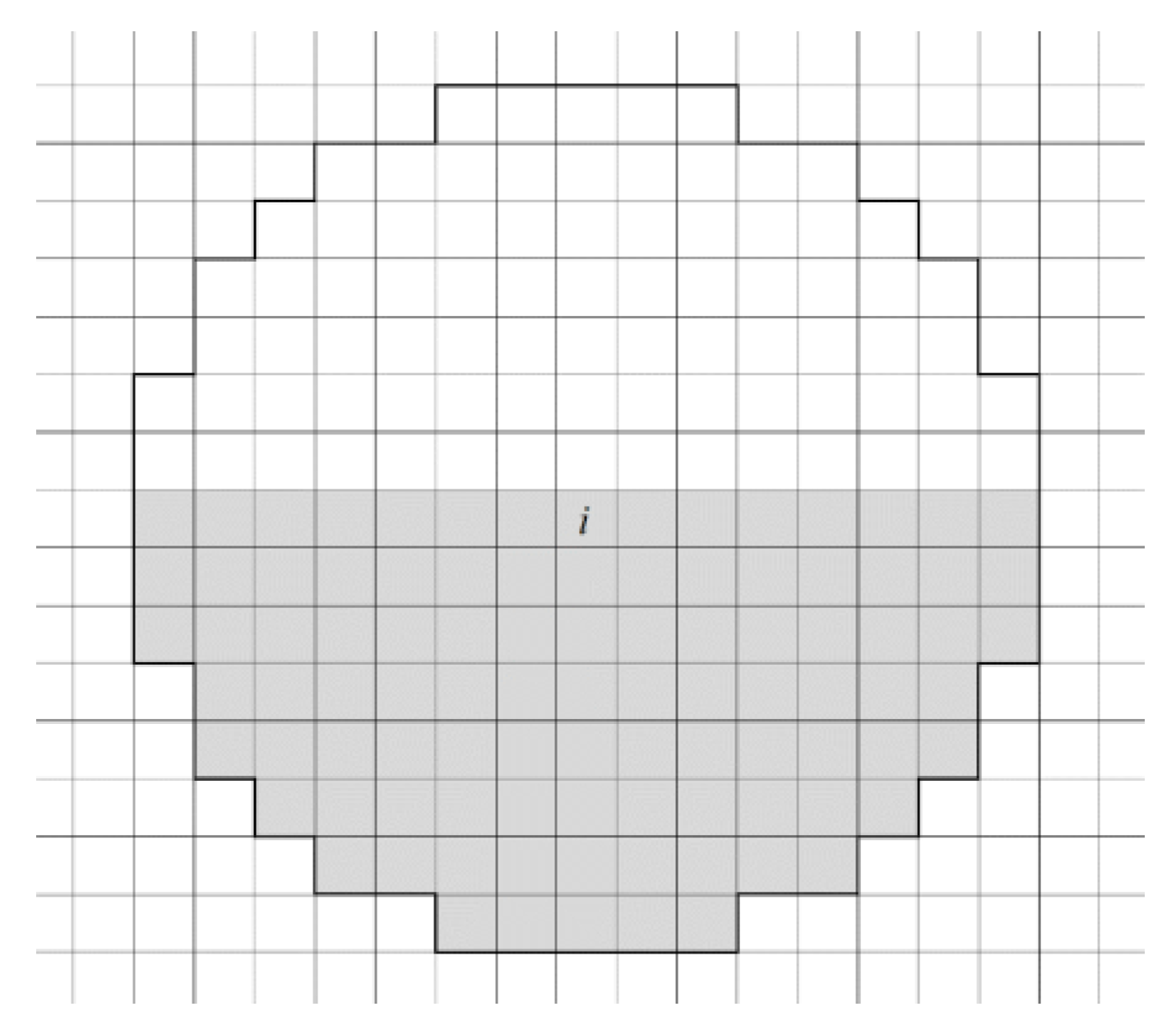

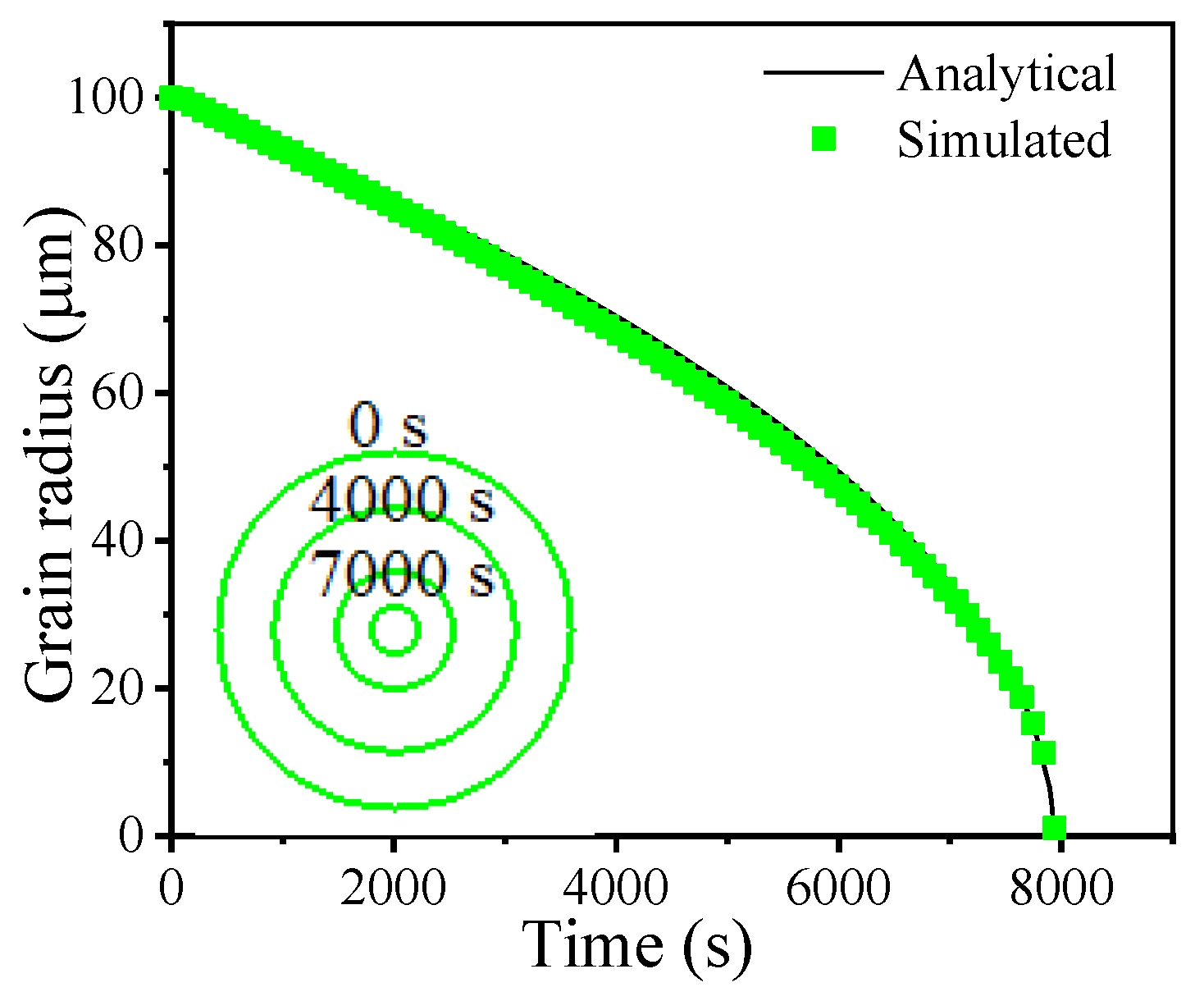

4. Simulating Grain Growth Behavior Using a CA Model

4.1. Models for Grain Growth

4.2. Grain Growth Simulation

5. Conclusions

- (1)

- The holding temperature and holding time have large effects on the grain growth behavior of the studied superalloy. The grain structure gradually coarsens as the holding temperature and holding time increase.

- (2)

- The grain growth behavior of the studied superalloy can be described by the parabolic equation .

- (3)

- A CA model was developed to simulate the evolution of the grain structure in the studied superalloy. The local grain boundary curvature was effectively evaluated and the relationship between the grain boundary mobility and holding temperature was established. The simulated grain growth curves show that the developed CA model can capture the dependence of the grain size on the holding time under different holding temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, F.; Xiong, W.; Faierson, E.J. Grain structure control of additively manufactured metallic materials. Materials 2017, 10, 1260. [Google Scholar] [CrossRef]

- Naghizadeh, M.; Mirzadeh, H. Effects of grain size on mechanical properties and work-hardening behavior of AISI 304 austenitic stainless steel. Steel Res. Int. 2019, 90, 1900153. [Google Scholar] [CrossRef]

- Lawrence, S.K.; Yagodzinskyy, Y.; Hänninen, H.; Korhonen, E.; Tuomisto, F.; Harris, Z.D.; Somerday, B.P. Effects of grain size and deformation temperature on hydrogen-enhanced vacancy formation in Ni alloys. Acta Mater. 2017, 128, 218–226. [Google Scholar] [CrossRef]

- Wang, K.; Wen, D.X.; Li, J.J.; Zheng, Z.Z.; Xiong, Y.B. Hot deformation behaviors of low-alloyed ultrahigh strength steel 30CrMnSiNi2A: Microstructure evolution and constitutive modeling. Mater. Today Commun. 2021, 26, 102009. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wu, Q.; Pang, G.D.; Jiang, X.Y.; He, D.G. Hot tensile deformation mechanism and dynamic softening behavior of Ti–6Al–4V alloy with thick lamellar microstructures. Adv. Eng. Mater. 2020, 22, 1901193. [Google Scholar] [CrossRef]

- Wei, K.; Hu, R.; Yin, D.; Xiao, L.; Pang, S.; Cao, Y.; Zhou, H.; Zhao, Y.; Zhu, Y. Grain size effect on tensile properties and slip systems of pure magnesium. Acta Mater. 2021, 206, 116604. [Google Scholar] [CrossRef]

- Guo, J.; Zhong, M.; Zhou, W.; Zhang, Y.; Wu, Z.; Li, Y.; Zhang, J.; Liu, Y.; Yang, H. Grain size effect of the γ phase precipitation on martensitic transformation and mechanical properties of Ni–Mn–Sn–Fe Heusler alloys. Materials 2021, 14, 2339. [Google Scholar] [CrossRef]

- Chen, Z.J.; Lin, Y.C.; He, D.G.; Lou, Y.M.; Chen, M.S. A unified dislocation density-based model for an aged polycrystalline Ni-based superalloy considering the coupled effects of complicate deformation mechanisms and initial δ phase. Mater. Sci. Eng. A 2021, 827, 142062. [Google Scholar] [CrossRef]

- Petrů, J.; Pagáč, M.; Grepl, M. Laser beam drilling of Inconel 718 and its effect on mechanical properties determined by static uniaxial tensile testing at room and elevated temperatures. Materials 2021, 14, 3052. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.C.; Yang, H.; Chen, D.D.; He, D.G. Stacked auto-encoder network to predict tensile deformation behavior of a typical nickel-based superalloy considering Portevin–Le Chatelier effects. Met. Mater. Int. 2021, 27, 254–261. [Google Scholar] [CrossRef]

- Gupta, M.K.; Pruncu, C.I.; Mia, M.; Singh, G.; Singh, S.; Prakash, C.; Sood, P.K.; Gill, H.S. Machinability investigations of Inconel-800 super alloy under sustainable cooling conditions. Materials 2018, 11, 2088. [Google Scholar] [CrossRef]

- Li, F.; Bai, Y.; Meng, L.; Fu, R.; Zhong, Y.; Du, J.; Yin, F.; Feng, D. Impact of aging heat treatment on microstructure and mechanical properties of a newly developed GH4096 disk superalloy. Mater. Charact. 2020, 161, 110175. [Google Scholar] [CrossRef]

- Ruan, J.J.; Ueshima, N.; Oikawa, K. Phase transformations and grain growth behaviors in superalloy 718. J. Alloy. Compd. 2018, 737, 83–91. [Google Scholar] [CrossRef]

- Lee, S.B.; Yoon, D.Y.; Henry, M.F. Abnormal grain growth and grain boundary faceting in a model Ni-base superalloy. Acta Mater. 2000, 48, 3071–3080. [Google Scholar] [CrossRef]

- Song, K.; Aindow, M. Grain growth and particle pinning in a model Ni-based superalloy. Mater. Sci. Eng. A 2008, 479, 365–372. [Google Scholar] [CrossRef]

- Aoki, C.; Ueno, T.; Ohno, T.; Oikawa, K. Influence of hot-working conditions on grain growth of superalloy 718. J. Mater. Process. Technol. 2019, 267, 26–33. [Google Scholar] [CrossRef]

- Tian, G.; Jia, C.; Liu, J.; Hu, B. Experimental and simulation on the grain growth of P/M nickel-base superalloy during the heat treatment process. Mater. Des. 2009, 30, 433–439. [Google Scholar] [CrossRef]

- Collins, D.M.; Conduit, B.D.; Stone, H.J.; Hardy, M.C.; Conduit, G.J.; Mitchell, R.J. Grain growth behaviour during near-γ′ solvus thermal exposures in a polycrystalline nickel-base superalloy. Acta Mater. 2013, 61, 3378–3391. [Google Scholar] [CrossRef]

- Chen, F.; Zhu, H.; Chen, W.; Ou, H.; Cui, Z. Multiscale modeling of discontinuous dynamic recrystallization during hot working by coupling multilevel cellular automaton and finite element method. Int. J. Plast. 2021, 145, 103064. [Google Scholar] [CrossRef]

- Chen, D.D.; Lin, Y.C.; Wu, F. A design framework for optimizing forming processing parameters based on matrix cellular automaton and neural network-based model predictive control methods. Appl. Math. Model. 2019, 76, 918–937. [Google Scholar] [CrossRef]

- Ogawa, J.; Natsume, Y. Three-dimensional large-scale grain growth simulation using a cellular automaton model. Comp. Mater. Sci. 2021, 199, 110729. [Google Scholar] [CrossRef]

- Babu, K.A.; Prithiv, T.; Gupta, A.; Mandal, S. Modeling and simulation of dynamic recrystallization in super austenitic stainless steel employing combined cellular automaton, artificial neural network and finite element method. Comp. Mater. Sci. 2021, 195, 110482. [Google Scholar] [CrossRef]

- Zhang, S.; Hou, C.; Ma, Z. Grain growth of Ti–6Al–4V alloy predicted with cellular automaton-finite difference (CAFD) model. Int. J. Met. 2021, 1–8. [Google Scholar] [CrossRef]

- Xiong, F.; Huang, C.; Kafka, O.L.; Lian, Y.; Yan, W.; Chen, M.; Fang, D. Grain growth prediction in selective electron beam melting of Ti-6Al-4V with a cellular automaton method. Mater. Des. 2021, 199, 109410. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F.; Seufzer, W.; Taminger, K. A coupled finite element cellular automaton model to predict thermal history and grain morphology of Ti-6Al-4V during direct metal deposition (DMD). Addit. Manuf. 2016, 11, 32–39. [Google Scholar] [CrossRef]

- Ansari Dezfoli, A.R.; Lo, Y.L.; Raza, M.M. Prediction of epitaxial grain growth in single-track laser melting of IN718 using integrated finite element and cellular automaton approach. Materials 2021, 14, 5202. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, J.; Yin, Y.; Shen, X.; Shehabeldeen, T.A.; Ji, X. GPU-Accelerated cellular automaton model for grain growth during directional solidification of nickel-based superalloy. Metals 2021, 11, 298. [Google Scholar] [CrossRef]

- Liu, Y.X.; Lin, Y.C.; Zhou, Y. 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions. Mater. Sci. Eng. A 2017, 691, 88–99. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. In Texture analysis with MTEX–free and open source software toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Nolze, G.; Hielscher, R. Orientations-perfectly colored. J. Appl. Crystallogr. 2016, 49, 1786–1802. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Findley, K.O.; Speer, J.G. Influence of temperature and grain size on austenite stability in medium manganese steels. Metall. Mater. Trans. A 2017, 48, 2140. [Google Scholar] [CrossRef]

- Omori, T.; Kusama, T.; Kawata, S.; Ohnuma, I.; Sutou, Y.; Araki, Y.; Ishida, K.; Kainuma, R. Abnormal grain growth induced by cyclic heat treatment. Science 2013, 341, 1500–1502. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.S.; Zou, Z.H.; Lin, Y.C.; Li, H.B.; Wang, G.Q. Formation mechanism of large grains inside annealed microstructure of GH4169 superalloy by cellular automation method. J. Mater. Sci. Technol. 2019, 35, 1403–1411. [Google Scholar] [CrossRef]

- Wen, D.; Long, P.; Li, J.; Huang, L.; Zheng, Z. Effects of linear heat input on microstructure and corrosion behavior of an austenitic stainless steel processed by wire arc additive manufacturing. Vacuum 2020, 173, 109131. [Google Scholar] [CrossRef]

- Wang, M.J.; Sun, C.Y.; Fu, M.W.; Liu, Z.L.; Qian, L.Y. Study on the dynamic recrystallization mechanisms of Inconel 740 superalloy during hot deformation. J. Alloy. Compd. 2020, 820, 153325. [Google Scholar] [CrossRef]

- Atkinson, H.V. Overview no. 65. Theories of normal grain growth in pure single phase systems. Acta Metall. 1988, 36, 469–491. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Safyari, M. Effect of dwelling time in VIM furnace on chemical composition and mechanical properties of a Ni–Fe–Cr alloy. Vacuum 2019, 169, 108890. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Abbasi, S.M. Effect of vacuum degree in VIM furnace on mechanical properties of Ni–Fe–Cr based alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 2124–2130. [Google Scholar] [CrossRef]

- Illescas, S.; Fernández, J.; Guilemany, J.M. Kinetic analysis of the austenitic grain growth in HSLA steel with a low carbon content. Mater. Lett. 2008, 62, 3478–3480. [Google Scholar] [CrossRef]

- Thomas, S.L.; Chen, K.; Han, J.; Purohit, P.K.; Srolovitz, D.J. Reconciling grain growth and shear-coupled grain boundary migration. Nat. Commun. 2017, 8, 1764. [Google Scholar] [CrossRef]

- Liu, Y.X.; Lin, Y.C.; Li, H.B.; Wen, D.X.; Chen, X.M.; Chen, M.S. Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model. Mater. Sci. Eng. A 2015, 626, 432–440. [Google Scholar] [CrossRef]

- Bullard, J.W.; Garboczi, E.J.; Carter, W.C.; Fuller, E.R. Numerical methods for computing interfacial mean curvature. Comp. Mater. Sci. 1995, 4, 103–119. [Google Scholar] [CrossRef]

- Frette, O.I.; Virnovsky, G.; Silin, D. Estimation of the curvature of an interface from a digital 2D image. Comp. Mater. Sci. 2009, 44, 867–875. [Google Scholar] [CrossRef][Green Version]

- Han, F.; Tang, B.; Kou, H.; Li, J.; Feng, Y. Cellular automata simulations of grain growth in the presence of second-phase particles. Model. Simul. Mater. Sci. 2015, 23, 065010. [Google Scholar] [CrossRef]

- Lin, Y.C.; Liu, Y.X.; Chen, M.S.; Huang, M.H.; Ma, X.; Long, Z.L. Study of static recrystallization behavior in hot deformed Ni-based superalloy using cellular automaton model. Mater. Des. 2016, 99, 107–114. [Google Scholar] [CrossRef]

- Su, F.; Liu, W.; Wen, Z. Three-dimensional cellular automata simulation of the austenitizing process in GCr15 bearing steel. Materials 2019, 12, 3022. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Raabe, D.; Li, D. Prediction of post-dynamic austenite-to-ferrite transformation and reverse transformation in a low-carbon steel by cellular automaton modeling. Acta Mater. 2012, 60, 4768–4779. [Google Scholar] [CrossRef]

- Han, F.B.; Tang, B.; Kou, H.; Li, J.; Feng, Y. Effects of subgrain size and static recrystallization on the mechanical performance of polycrystalline material: A microstructure-based crystal plasticity finite element analysis. Prog. Nat. Sci. Mater. Int. 2015, 25, 58–65. [Google Scholar] [CrossRef]

| Ni | Cr | Nb | Mo | Ti | Al | Co | C | Fe |

|---|---|---|---|---|---|---|---|---|

| 53.82 | 18.38 | 5.42 | 3.03 | 0.95 | 0.41 | 0.2 | 0.027 | Bal. |

| Routine for Solution Heat Treatment | Holding Temperature for Grain Growth Experiments (K) | Holding Time for Grain Growth Experiments (s) |

|---|---|---|

| 1338 K/1200 s + ice water quench | 1353 | 600, 900, 1200, 1500, 2400 |

| 1383 | 600, 900, 1200, 1500, 2400 | |

| 1413 | 360, 540, 720, 900, 1440 | |

| 1443 | 180, 360, 540, 900, 1440 | |

| 1473 | 180, 360, 540, 900, 1440 |

| Parameters | n | Q (kJ·mol−1) | |

|---|---|---|---|

| values | 2.43 | 3.63 × 1014 | 320 |

| Temperature (K) | 1353 | 1383 | 1413 | 1443 | 1473 |

| M (m4 J−1 s−1) | 8.5 × 10−12 | 1.75 × 10−11 | 2.7 × 10−11 | 4 × 10−11 | 6.5 × 10−11 |

| Parameter | δDob (m3·s−1) | Qb (J·mol−1) | R (J·mol−1·K−1) | b (m) | k (J·K−1) |

| Value | 5.76 × 10−12 | 2.55 × 105 | 8.314 | 2.49 × 10−10 | 1.38 × 10−23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-X.; Ke, Z.-J.; Li, R.-H.; Song, J.-Q.; Ruan, J.-J. Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model. Materials 2021, 14, 6922. https://doi.org/10.3390/ma14226922

Liu Y-X, Ke Z-J, Li R-H, Song J-Q, Ruan J-J. Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model. Materials. 2021; 14(22):6922. https://doi.org/10.3390/ma14226922

Chicago/Turabian StyleLiu, Yan-Xing, Zhi-Jiang Ke, Run-Hua Li, Ju-Qing Song, and Jing-Jing Ruan. 2021. "Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model" Materials 14, no. 22: 6922. https://doi.org/10.3390/ma14226922

APA StyleLiu, Y.-X., Ke, Z.-J., Li, R.-H., Song, J.-Q., & Ruan, J.-J. (2021). Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model. Materials, 14(22), 6922. https://doi.org/10.3390/ma14226922