Fabrication of Hybrid Aluminium Nanocomposite

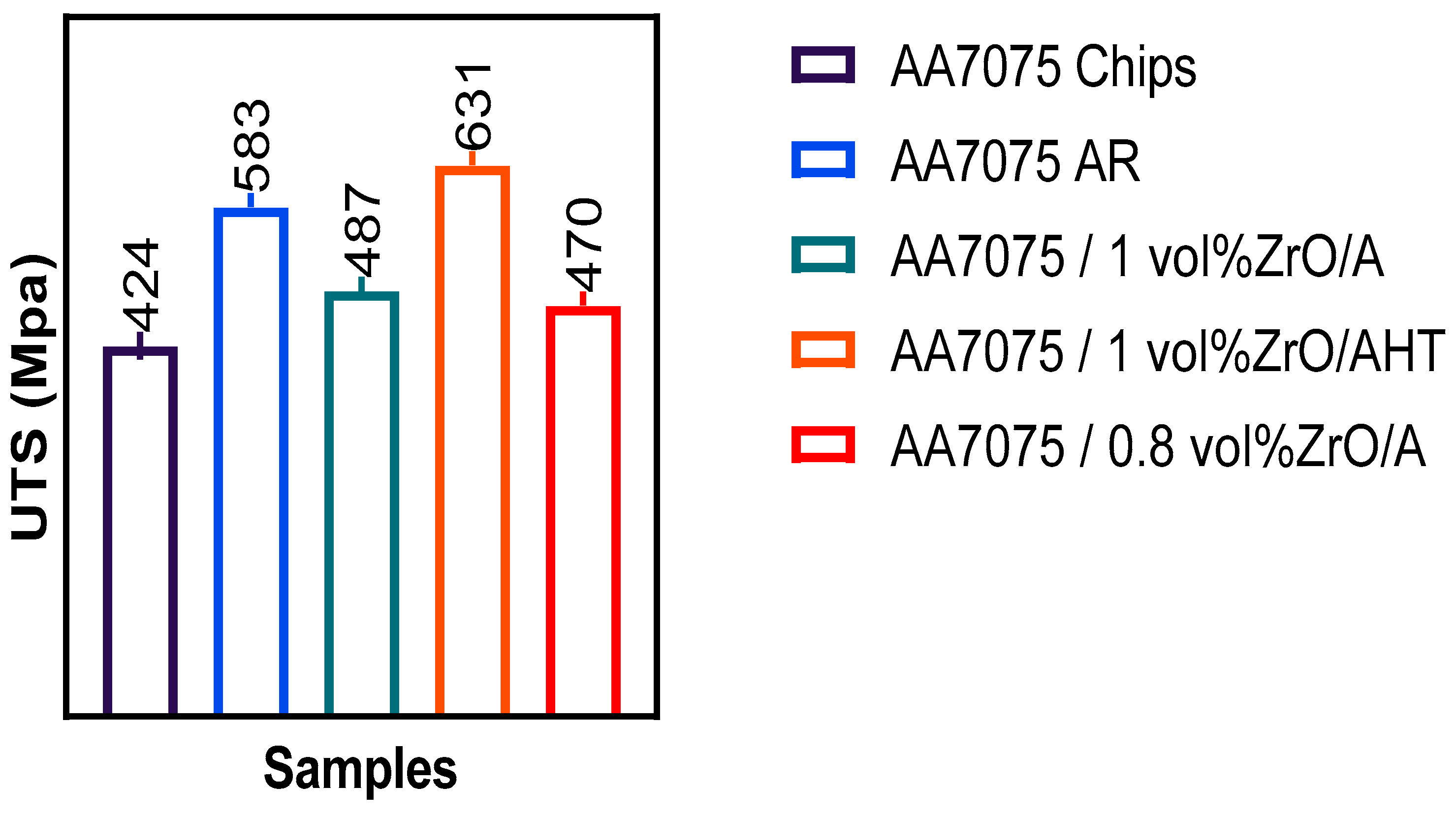

Samples of recycled MMC chips were fabricated with the addition of AA7075 aluminium chips and ZrO

2 particles to enhance the mechanical and physical properties of the alloy. ZrO

2 nanoparticles were added due to their robust mechanical and electrical properties, good wear resistance and corrosion resistance, and a wide bandgap. The sizes of the AA7075 chips (

Table 1) were verified using a digital venire calliper.

Table 2 shows the chemical composition of the AA7075 samples.

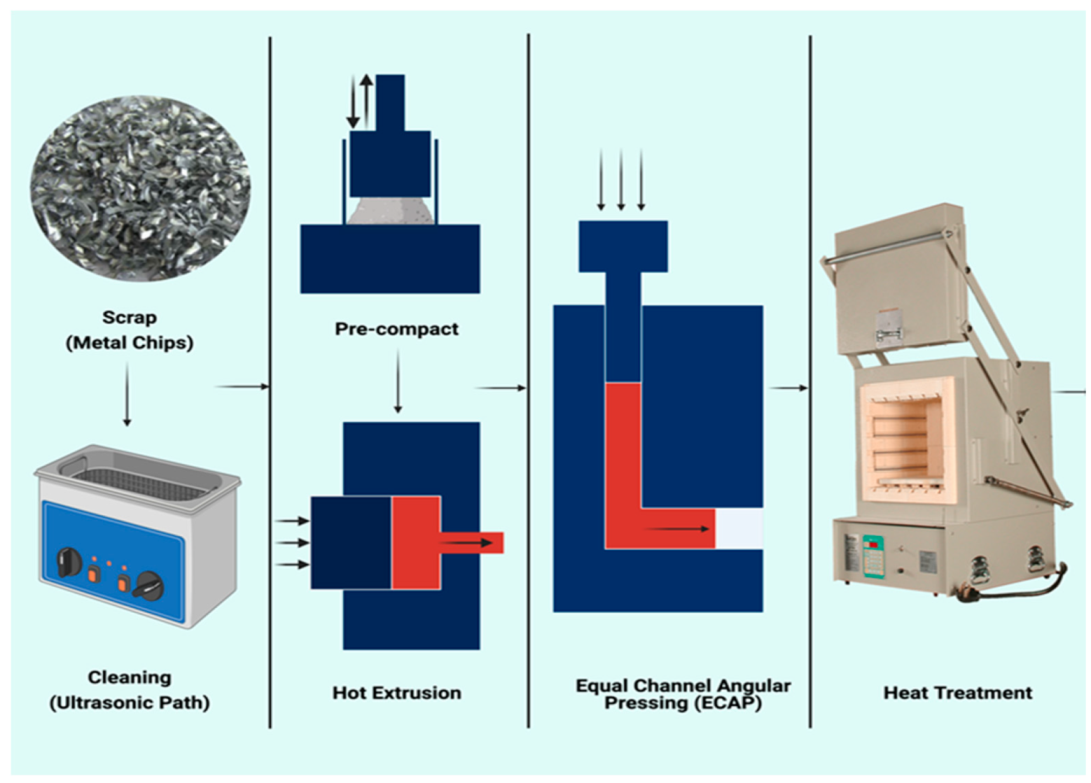

In the fabrication, the AA7075 aluminium alloy chips were snipped using a computer numerical control (CNC) machine with a depth cut of 1 mm. Following the standard method of the American Society for Testing and Materials (ASTM) G131-96, the chips were degreased with acetone in an ultrasonic bath for 30 min to remove the contaminants of the coolant oil and other substances. The chips were dried at 80 °C for 30 min thenmixed separately with 1%, 3%, and 5% ZrO2 nanoparticles using a three-dimensional (3D) mixer (SYH-15), China. for 2 h at the speed of 35 rpm. Billets were formed using cold compaction in a cylindrical die with a diameter of 30 mm and a length of 100 mm with a pressing force of 50 kN.

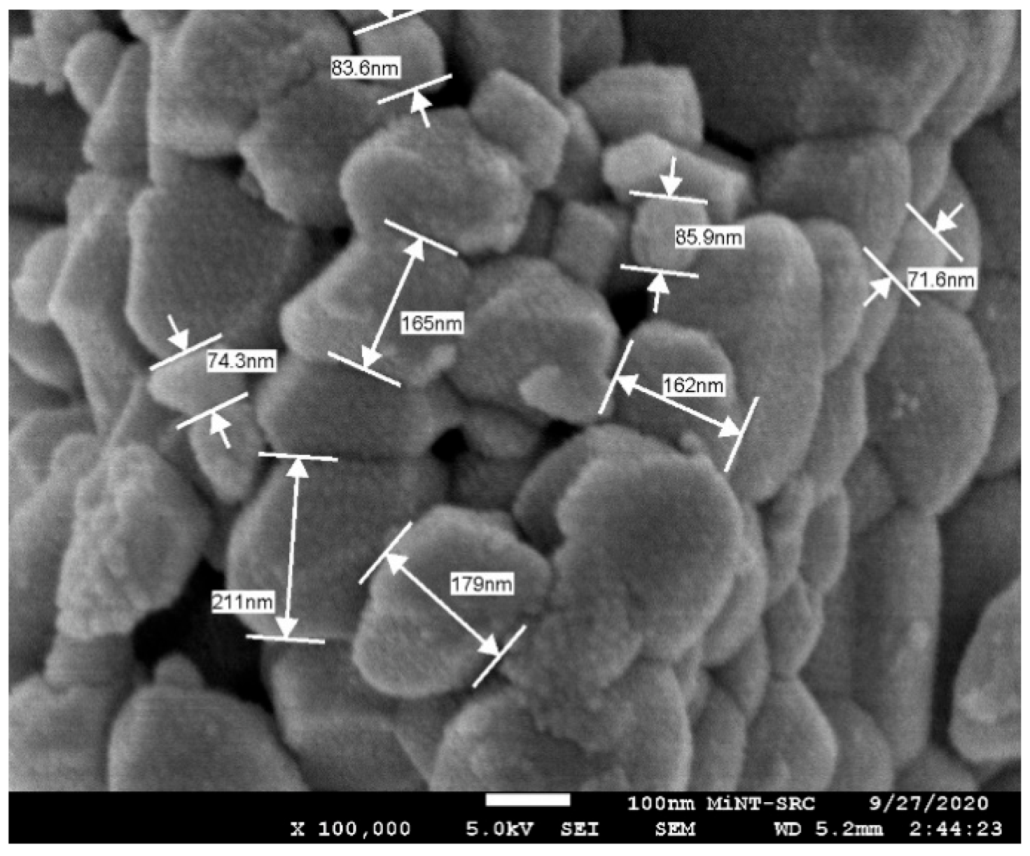

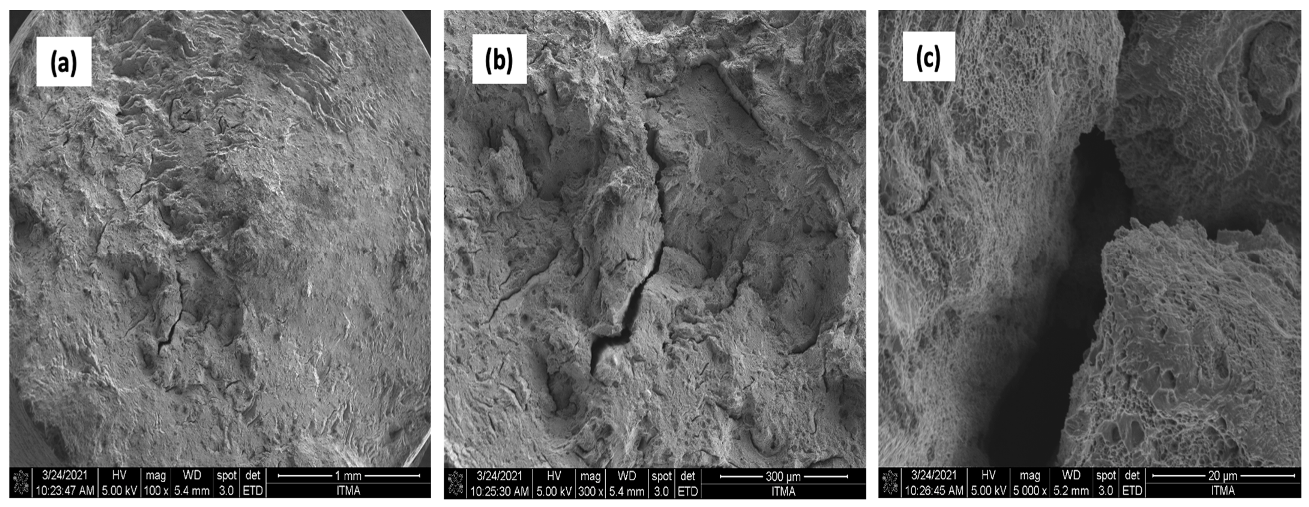

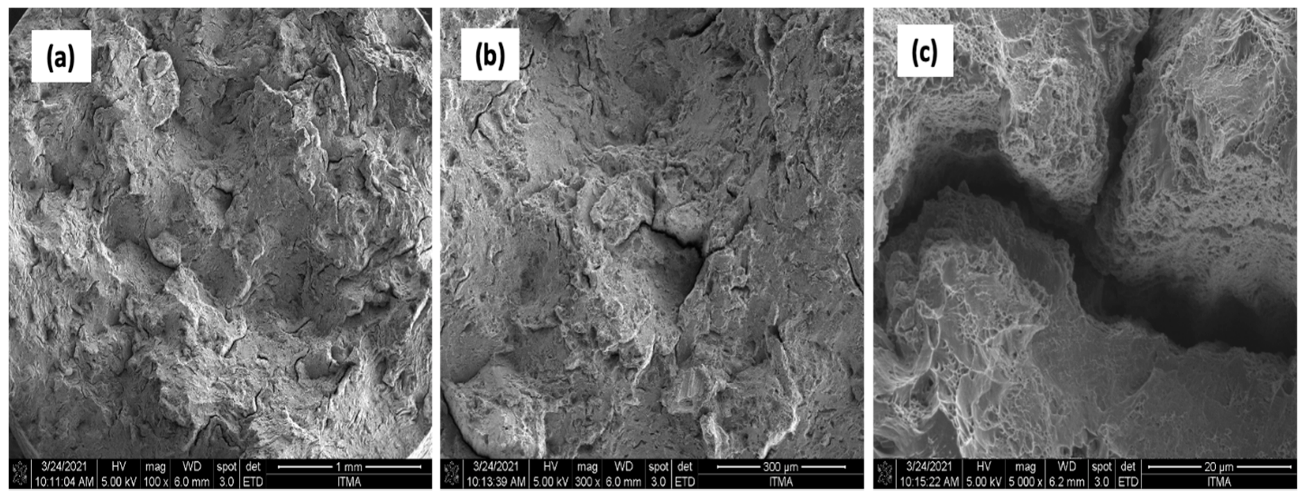

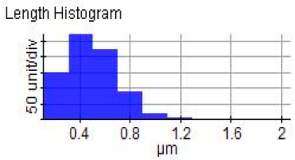

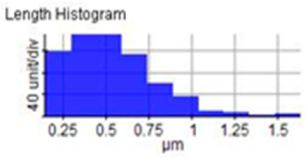

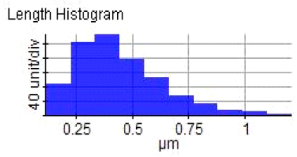

FESEM-EDX were used in the study of the morphology of ZrO

2 particle (Suzhou Beike Technology Co., Suzhou, China) shape and size with the magnification of ×100,000 (

Figure 1 shows the particle sizes of ZrO

2, ranging from 70 to 211 nm). They deviated slightly from previous findings due to the inefficient dispersion of the powder during particle size analysis in this study. The purity of the reinforcement (

Table 3) shows the EDX analysis (

Figure 2) of the ZrO

2 nanopowder, confirming the presence of Zr and O.

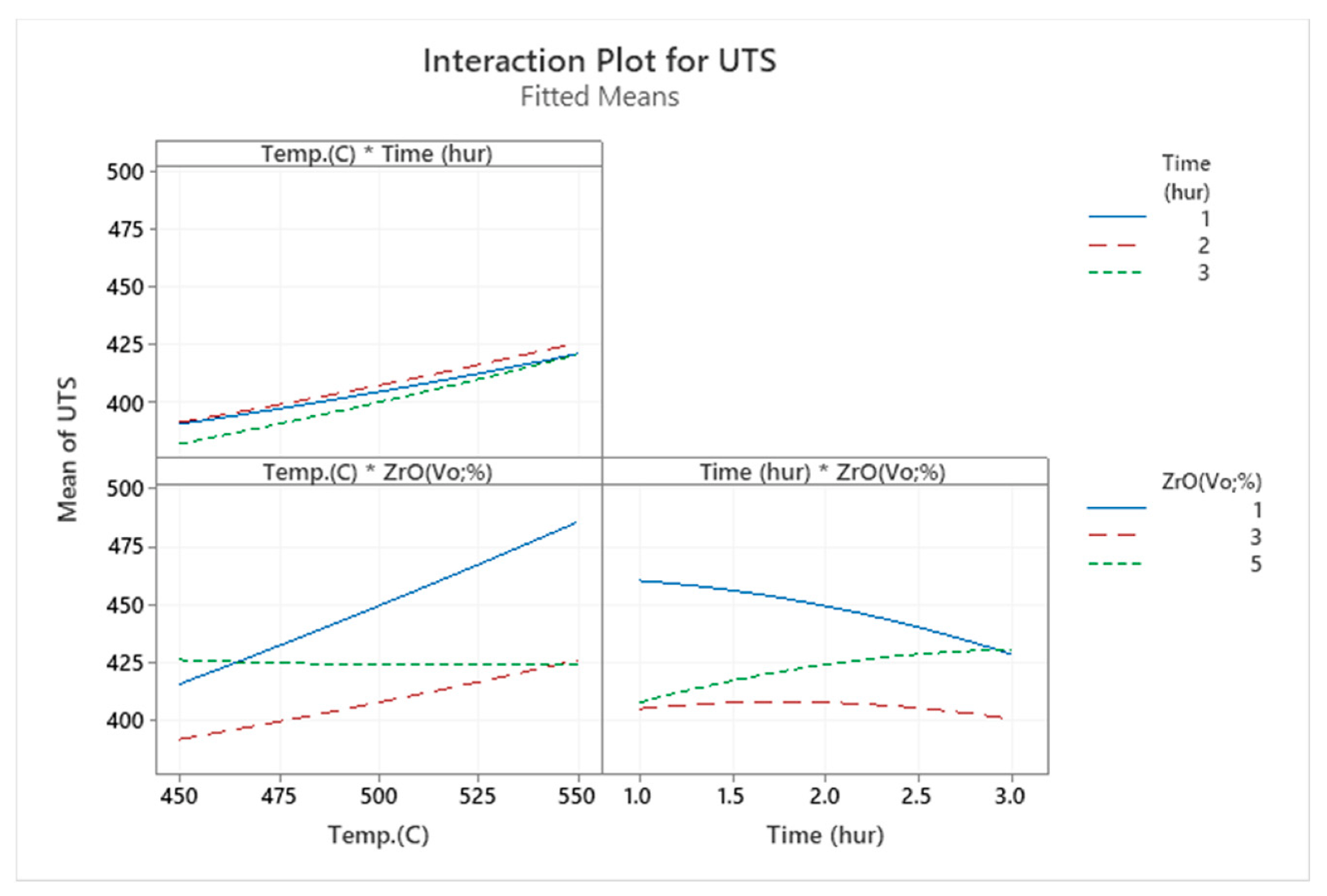

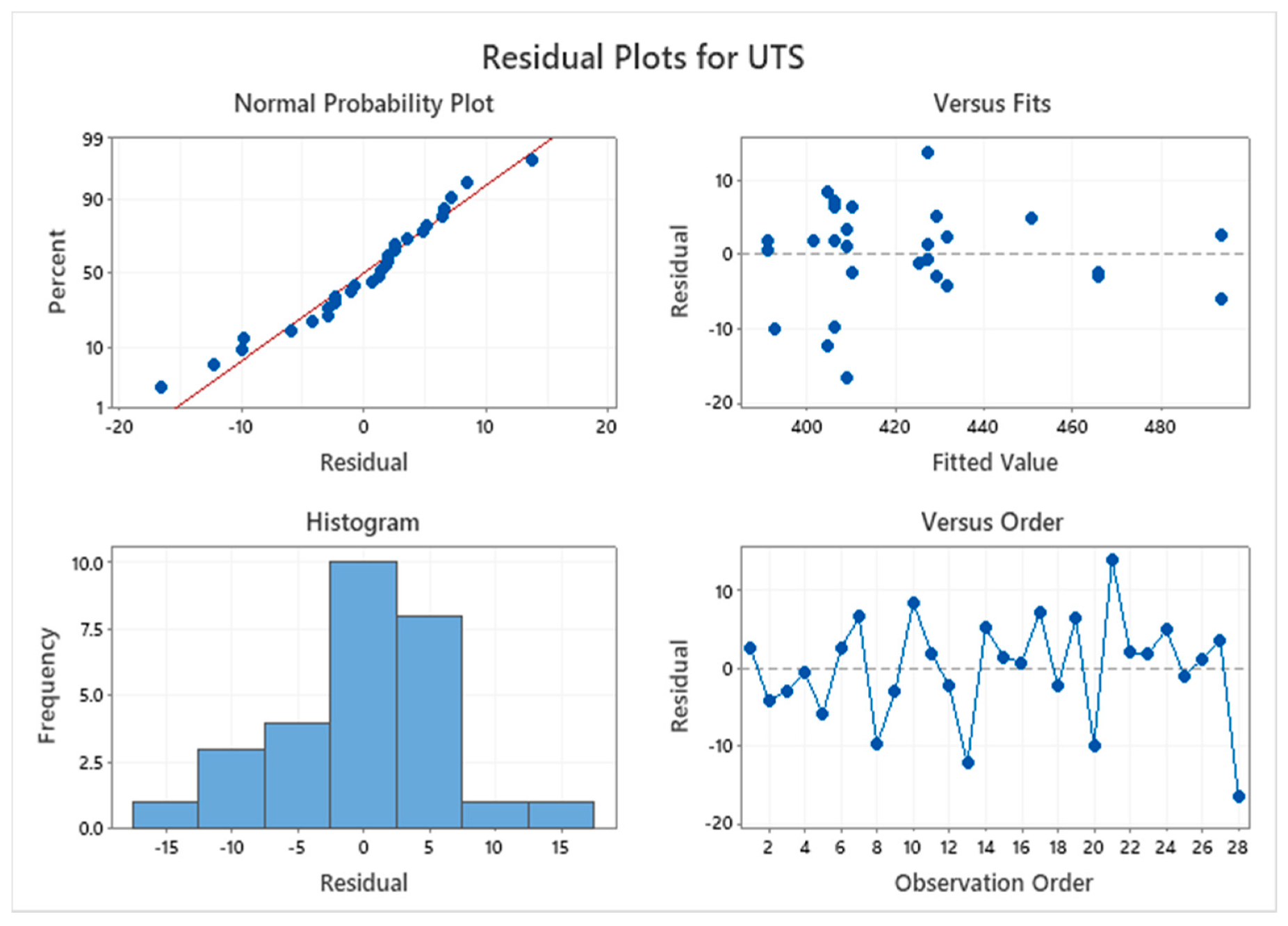

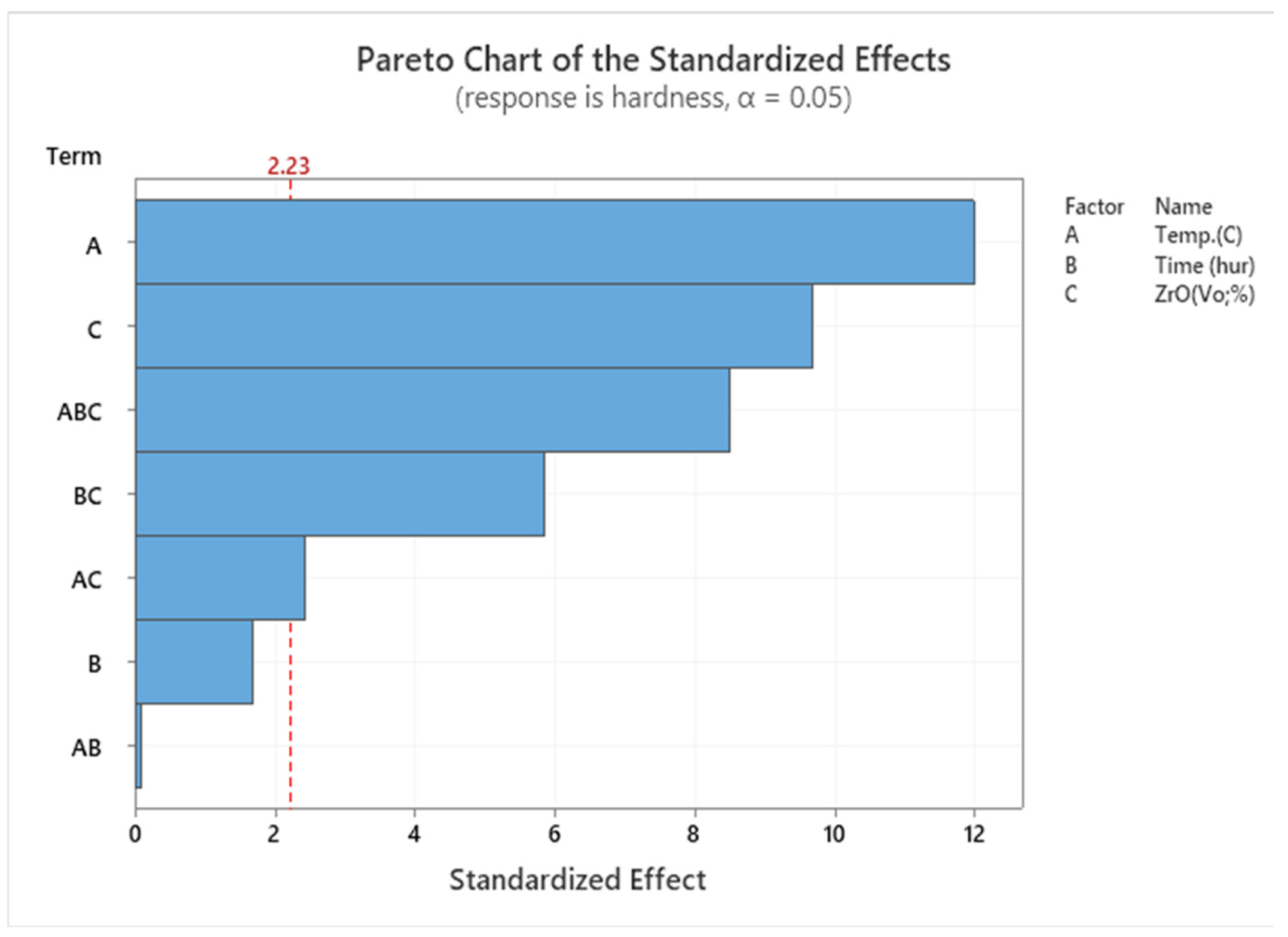

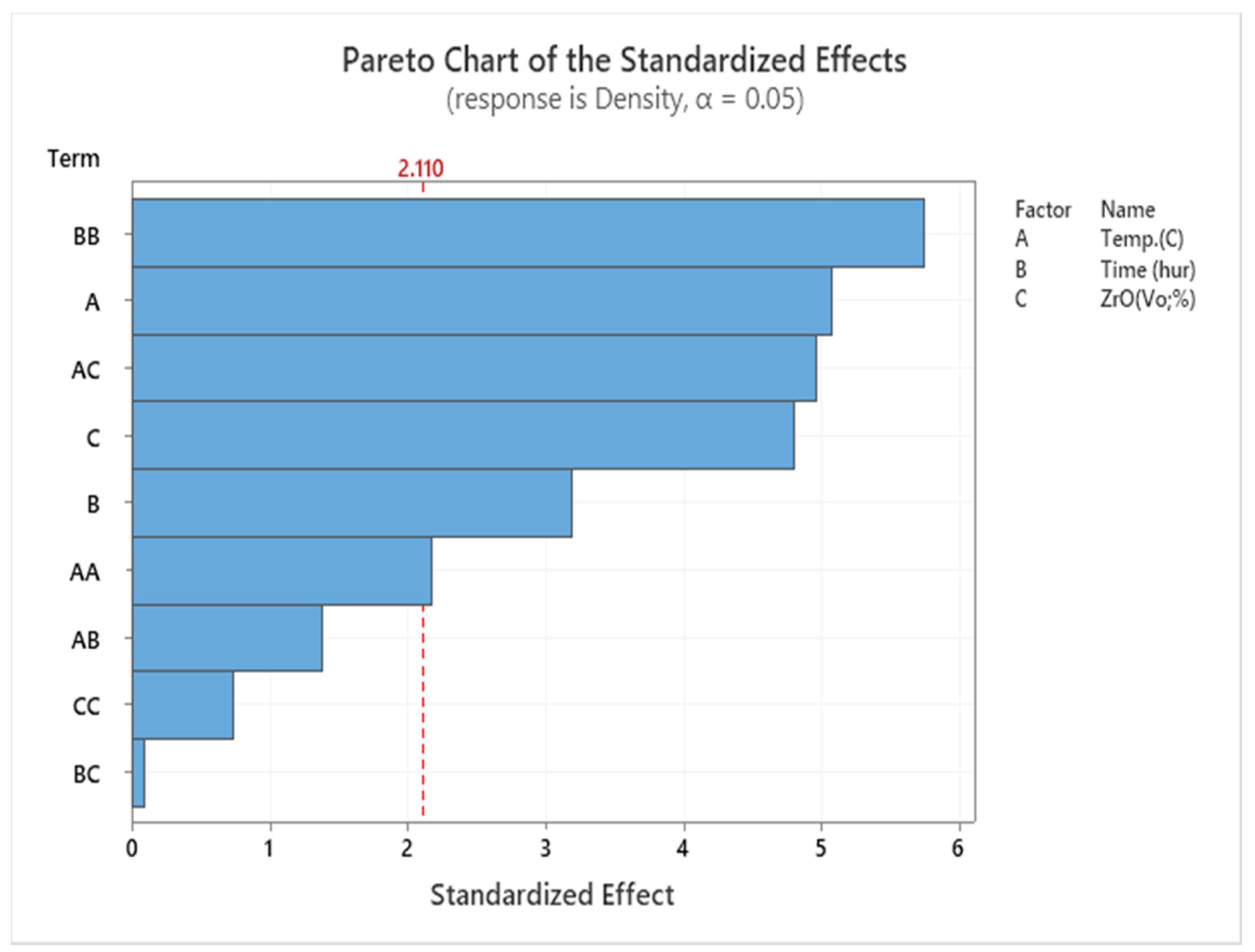

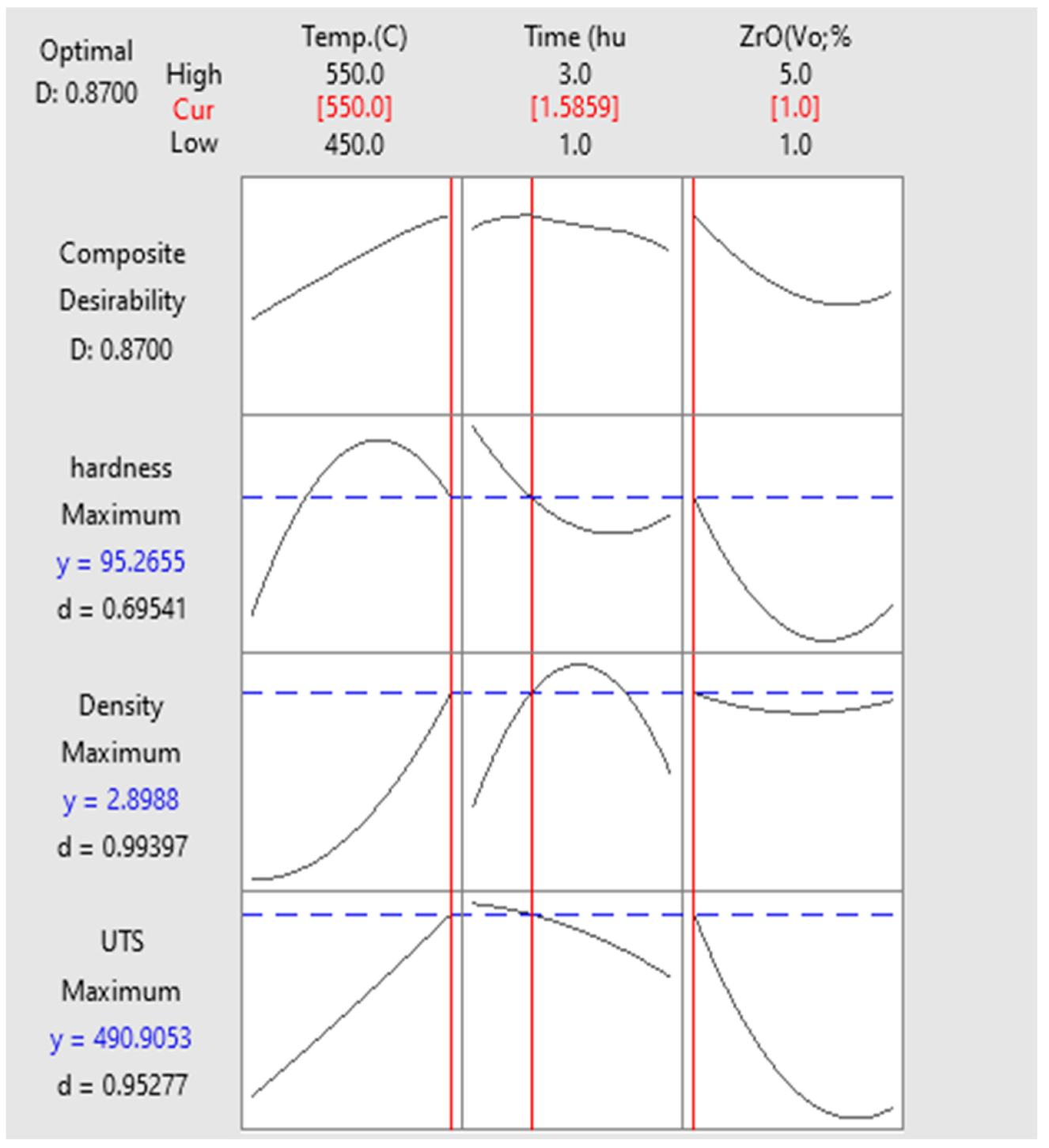

Minitab 18 software was used to perform RSM. The experimental design of the research was performed in the full factorial design, where the three main parameters were 1–5% vol ZrO

2-reinforced nanoparticle, a 1–3 h time period and a temperature of 450–550 °C; these processing values were applied. In this work, the experiment’s design was intended to help develop the optimisation and proposal of MMC composites. The best overall optimum parameters, such as particles and processing temperature, were investigated. Then, the RSM model Equation (1) was suggested as the sufficiency, and the linear model was capable of defining the relationship between the response or other process factors in the process.

In the regression equation, y is the response variable, b0 is the constant, b1, b2, …, bk are the coefficients, and X1, X2, …, Xk are the values of the terms.

Parameters such as preheating temperatures, compositions of the aluminium chip, and ZrO

2 reinforcement materials are shown in

Table 4.

In hot extrusion (the A process), the billet was preheated in a container with a ceramic heater to facilitate plastic deformation (

Table 5) [

13]. A graphite-based lubricant was used in the inner die surface and container in every extrusion cycle to prevent the increase in load in the extrusion due to friction [

3].

After hot extrusion, the final products were divided into 28 specimens; then, the optimal properties were sample treated with hot ECAP (the B process) that used a cold press hydraulic machine of 500 kN, an ECAP die, heaters, and thermocouples, and the ECAP die consisted of two parts, with a channel of 12 mm × 12 mm with an inner angle of 90° and an outer angle of 20°. Temperatures were measured using a K-type thermocouple with a diameter of 3 mm.

Figure 3 shows the details of the setup.

Heat treatment (HT) was performed using an electrical box furnace at a quenching temperature of 465 °C for 55 min and an artificial aging process at 120 °C for 24 h (

Figure 4). Water was used as the quenching medium.

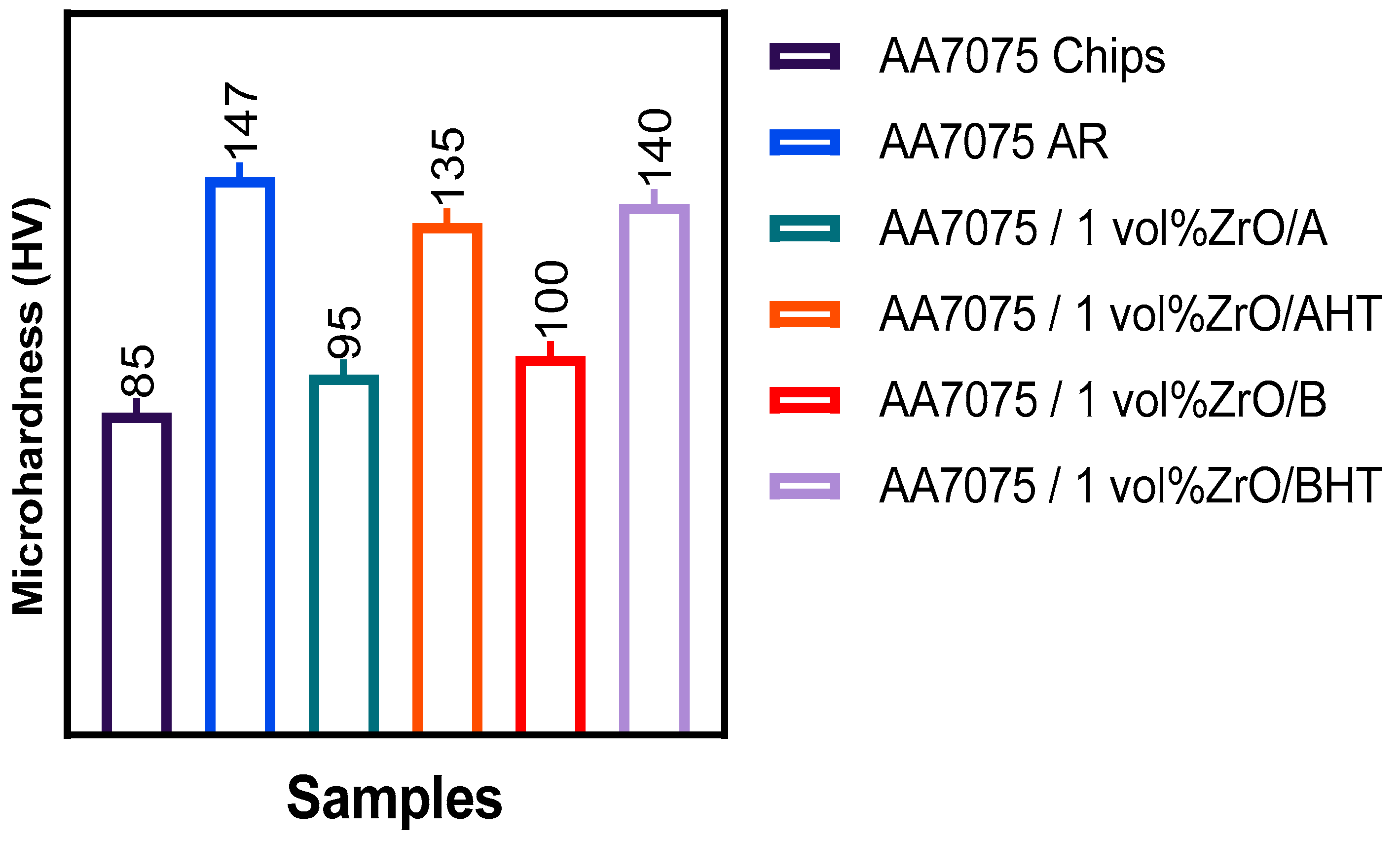

The samples extruded from the hot extrusion die underwent tensile and microhardness tests. For tensile testing, the extruded samples were snipped according to the ASTM E8-E8M standard for producing dog-bone-shaped samples. The tensile test with an initial strain rate of 2.53 × 10−3 s–1 was performed at room temperature until failure. Based on the ASTM E92-82 standards, the microhardness test was performed using a Micro Vikers Hardness tester (Shimadzu) with a Knoop indenter, 25 g load (0.9807 N), indent time of 15 s, and a holding time of 10 s at room temperature following the grinding of the surfaces for each sample for a balanced indentation. Samples were tested using a square-based, pyramid-shaped diamond indenter, indenting the samples in three places (top, centre, and bottom). These three values were averaged to yield the hardness for each sample. Microhardness was dependent on the plasticity, elasticity, strength, and ductility of the samples.

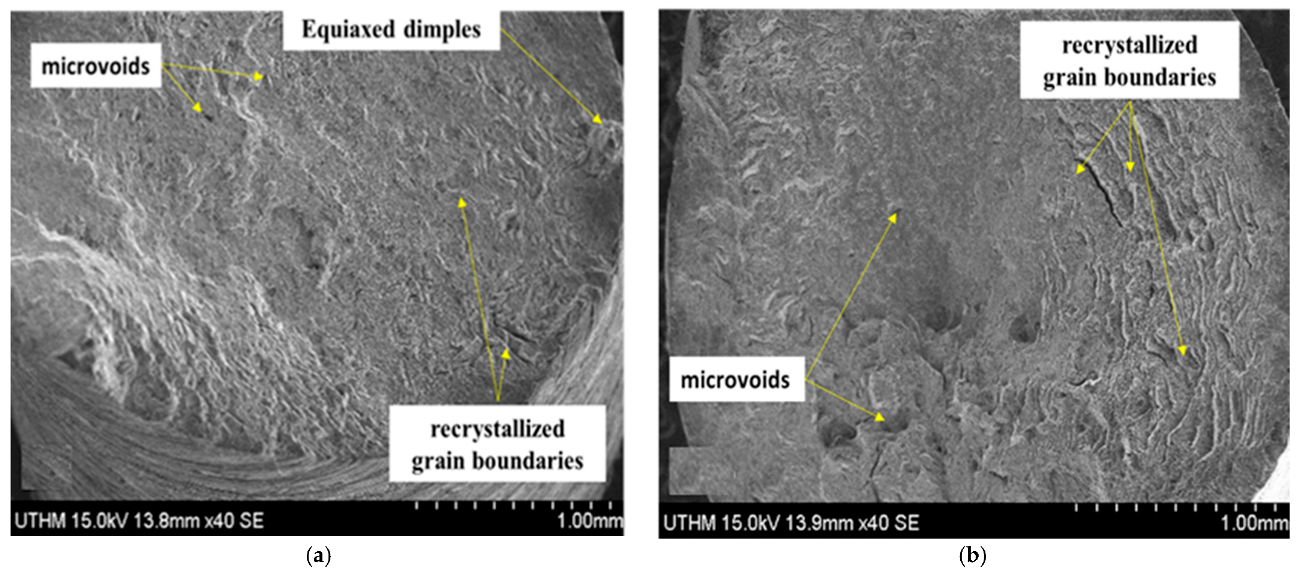

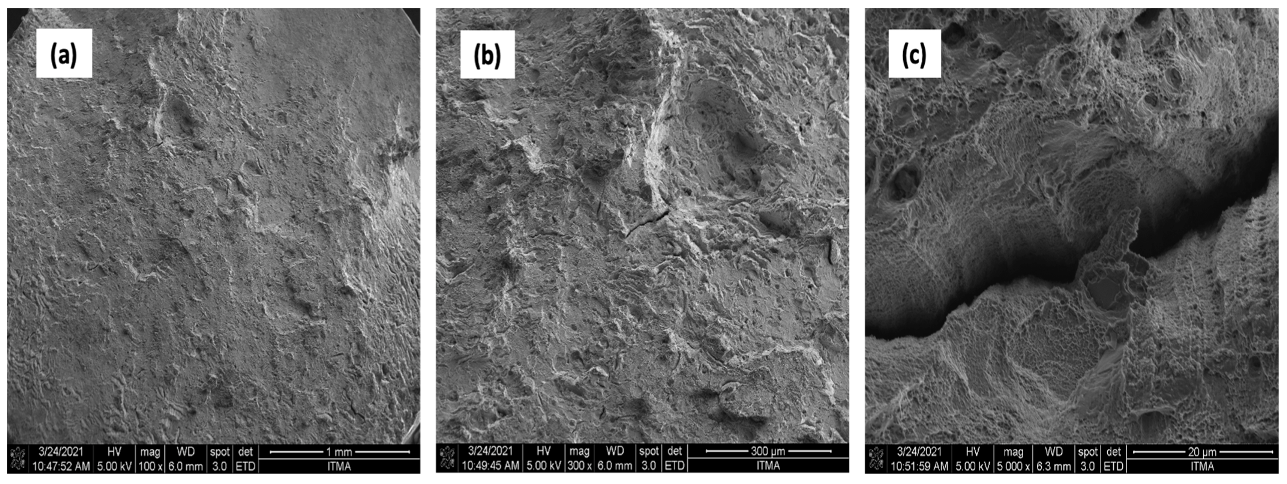

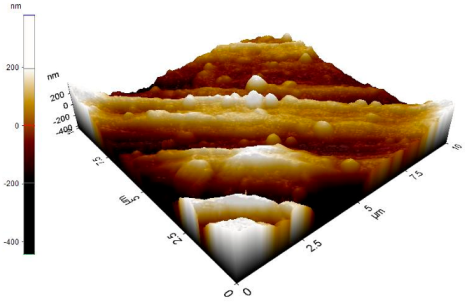

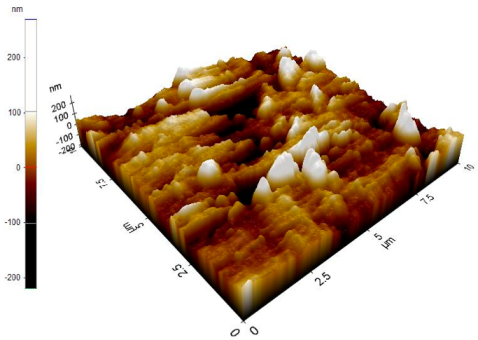

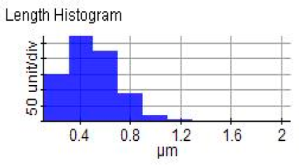

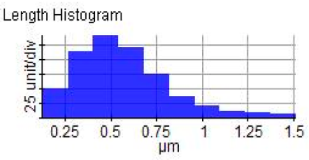

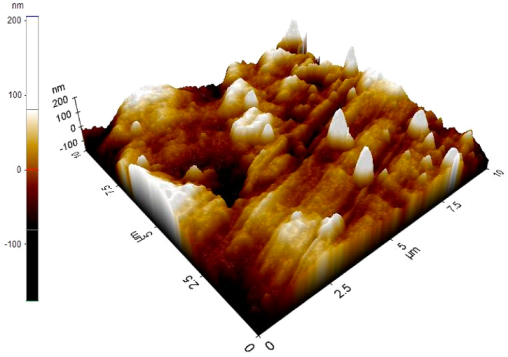

The reinforced particles distribution, chip boundaries, and the grain size of the samples were evaluated using atomic force microscopy (AFM) and Scanning Electron Microscopy (SEM). Specifically, AFM was used to test the conductive materials by investigating the roughness of surface topography from the micro- to nanoscales of the prepared samples [

15].The morphology of ZrO

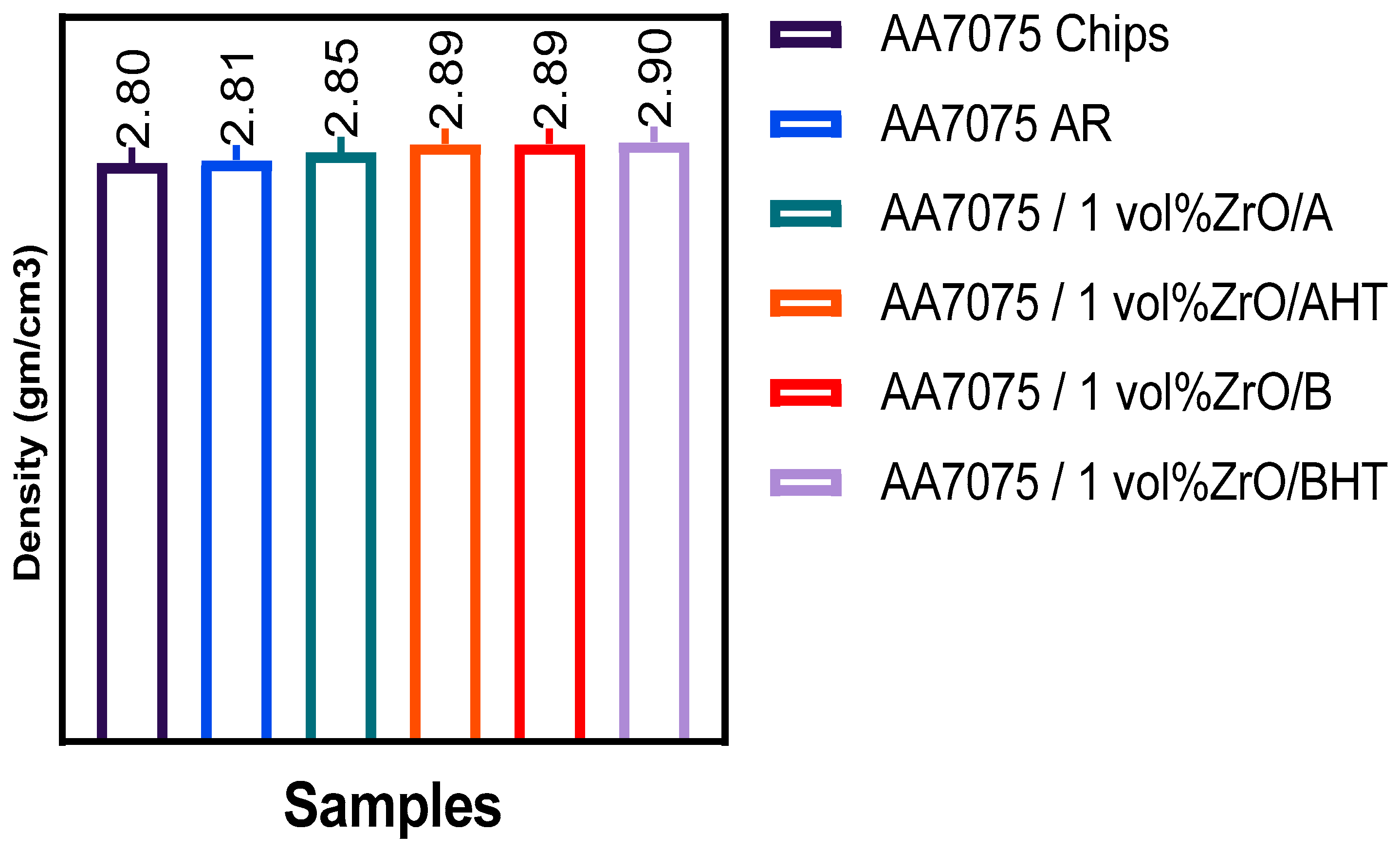

2 (shape and size) was evaluated using Field Emission Scanning Electron Microscopy with Energy Dispersive X-Ray Spectroscopy (FESEM-EDX) in three magnifications, i.e., 100×, 300×, and 500×. Meanwhile, the density was evaluated using Archimedes’ water immersion principle with samples in circular pieces of approximately 1 mm in diameter and thickness and with the help of the HR-250AZ-Compact Analytical Balance density determination kit. Specimens were weighed in the air and distilled water to record the weight in different environments. Each sample was immersed in distilled water during the density measurement at room temperature. The density of the composite material was calculated using Equation (2) below [

16].

where

A = weight in the air and

B = weight in liquid. The difference of theoretical and measured density values gave the percentage of pores.