Exfoliation Resistance, Microstructure, and Oxide Formation Mechanisms of the White Oxide Layer on CP Ti and Ti–Nb–Ta–Zr Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results

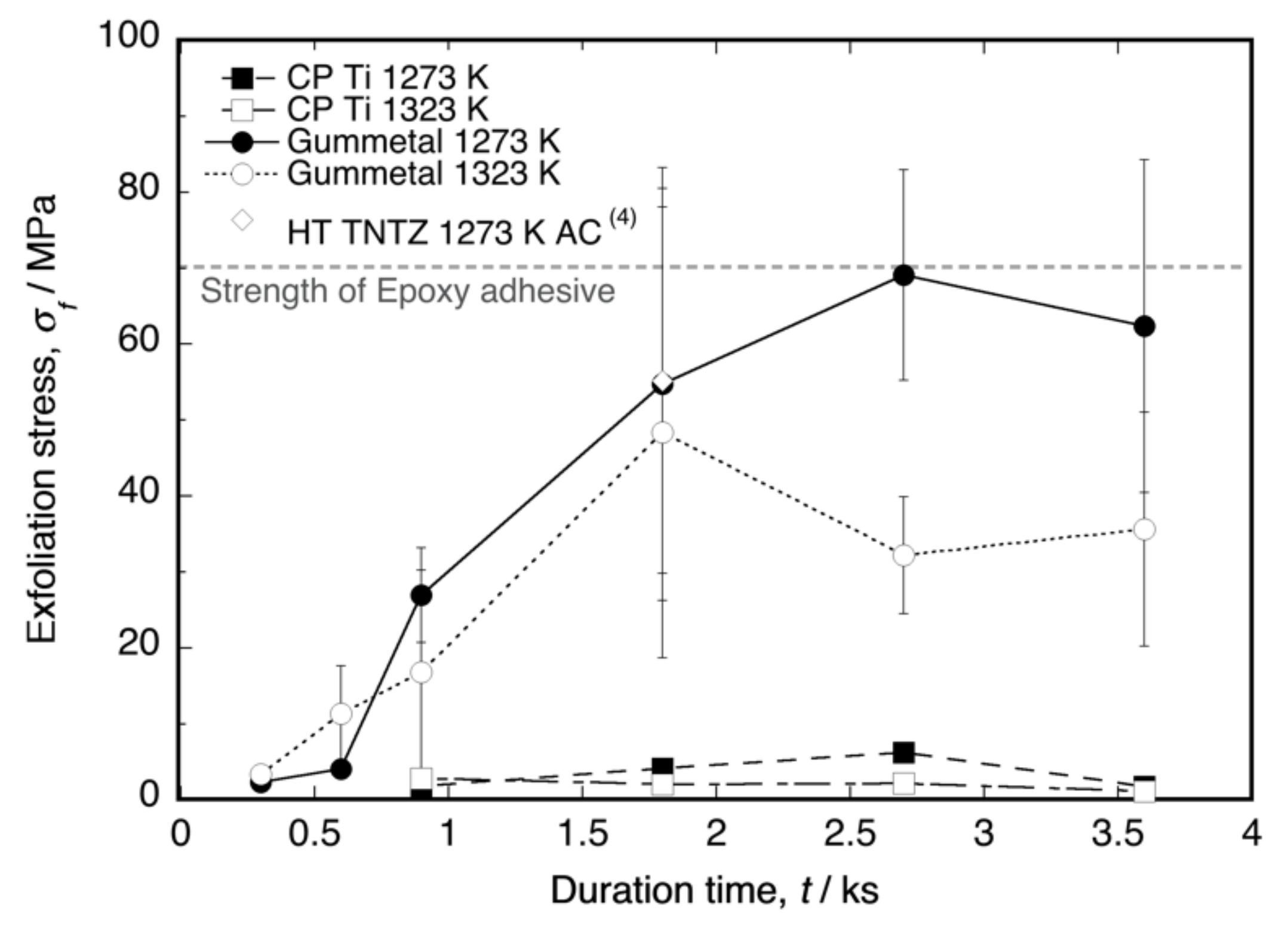

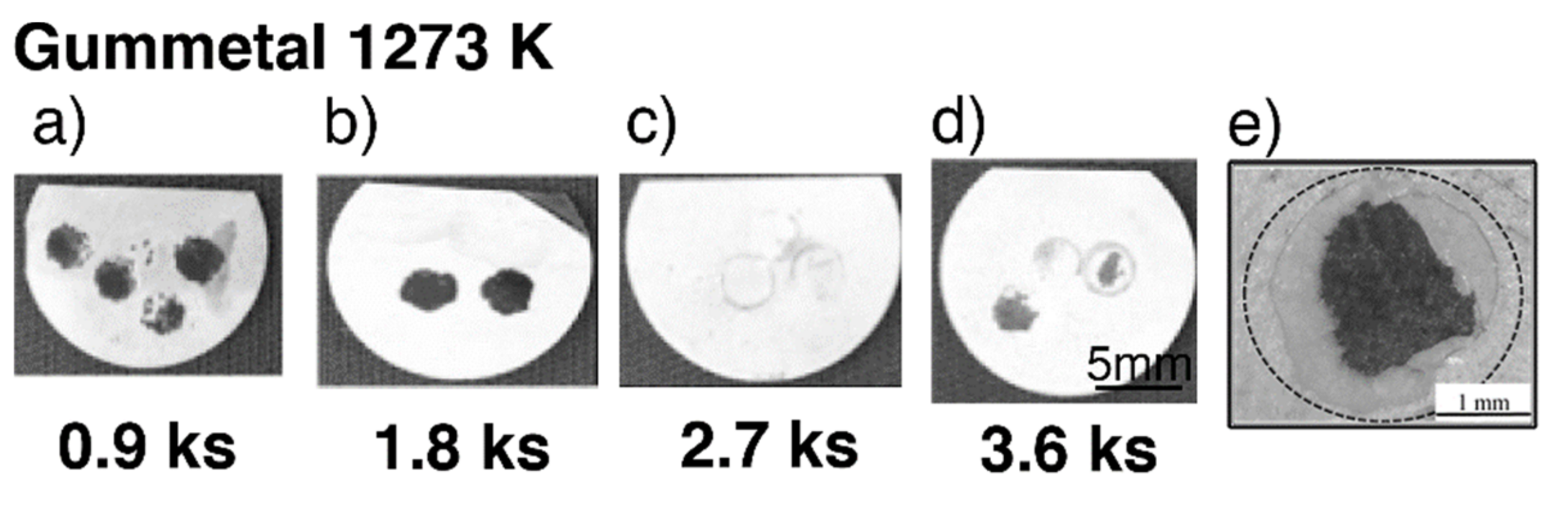

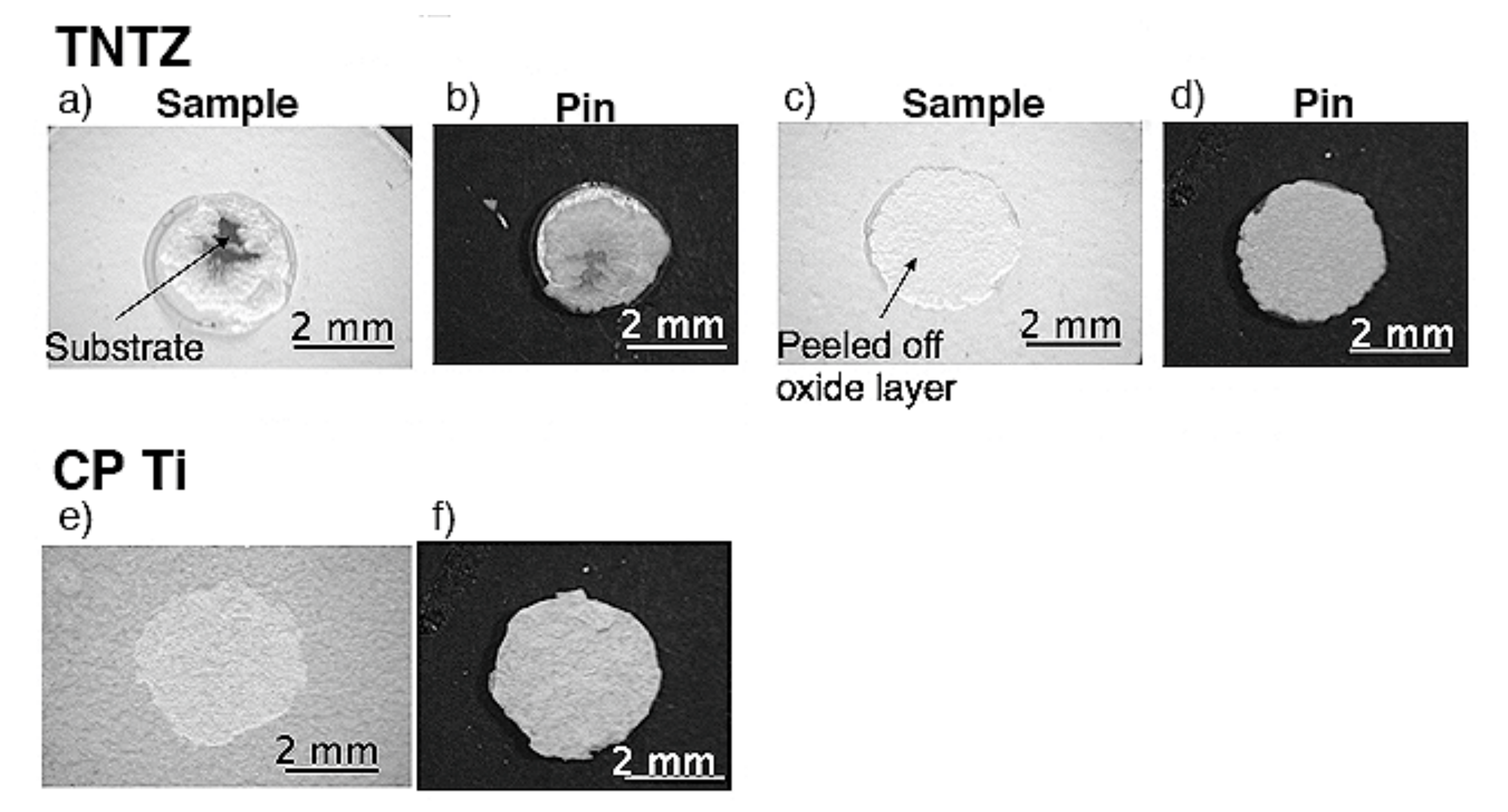

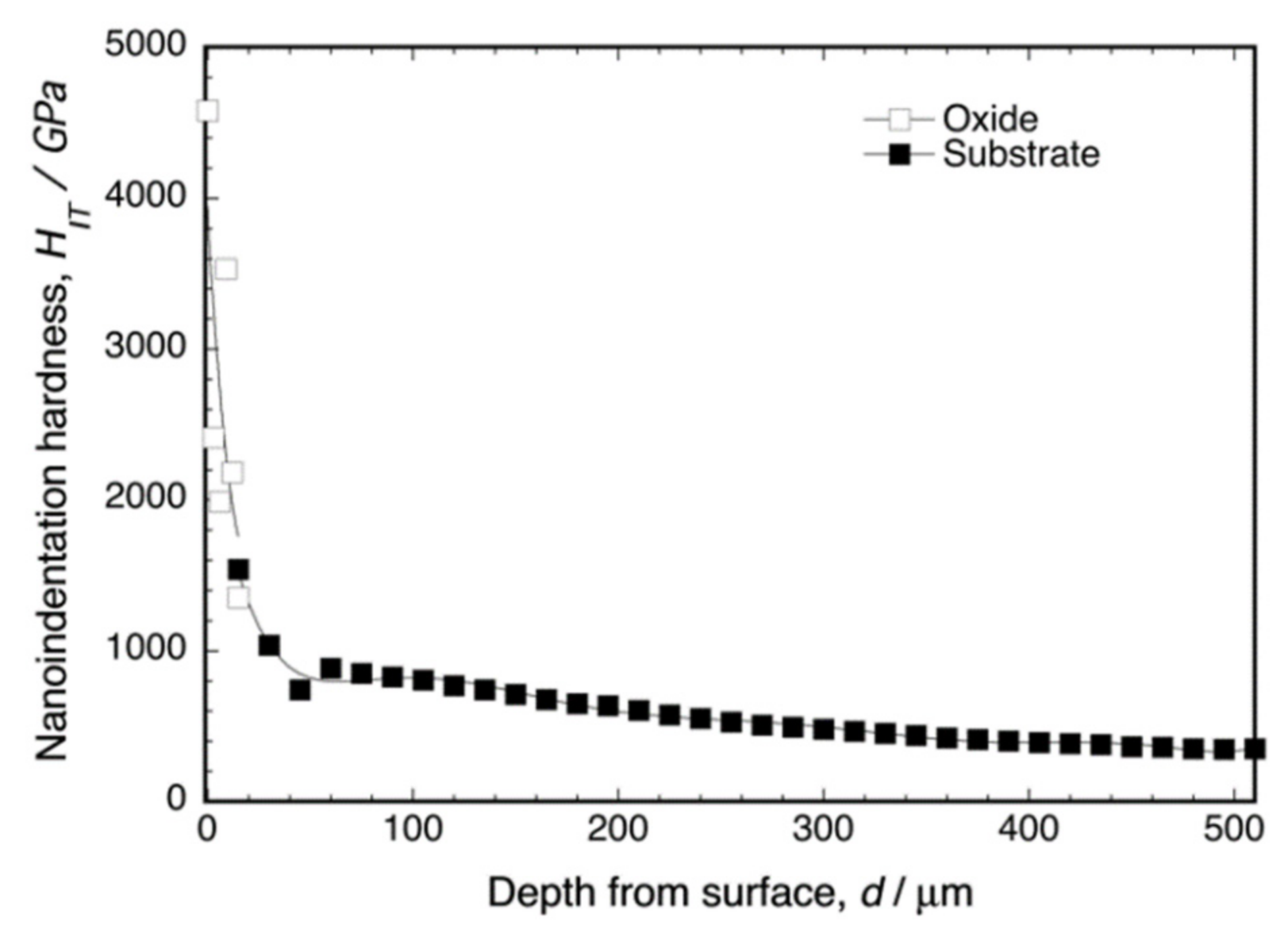

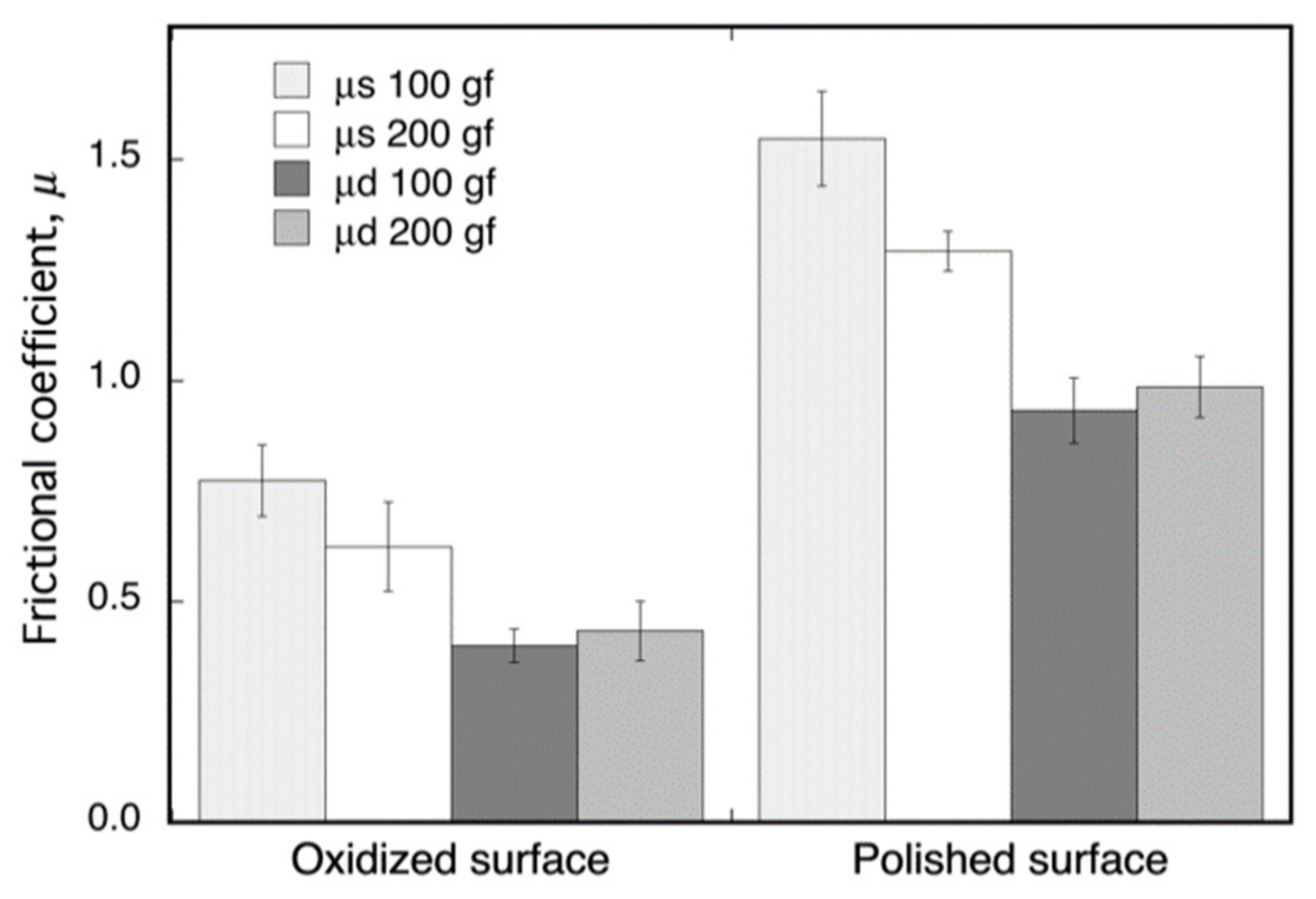

3.1. Exfoliation Resistance, Fretting Wear, and Nanoindentation Hardness of Oxide Layers

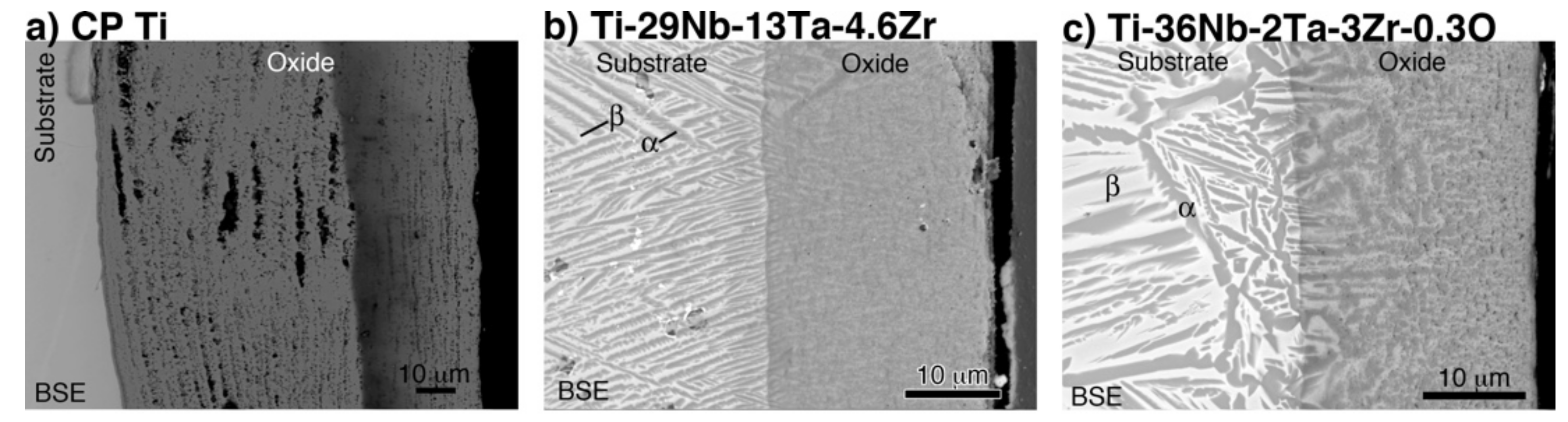

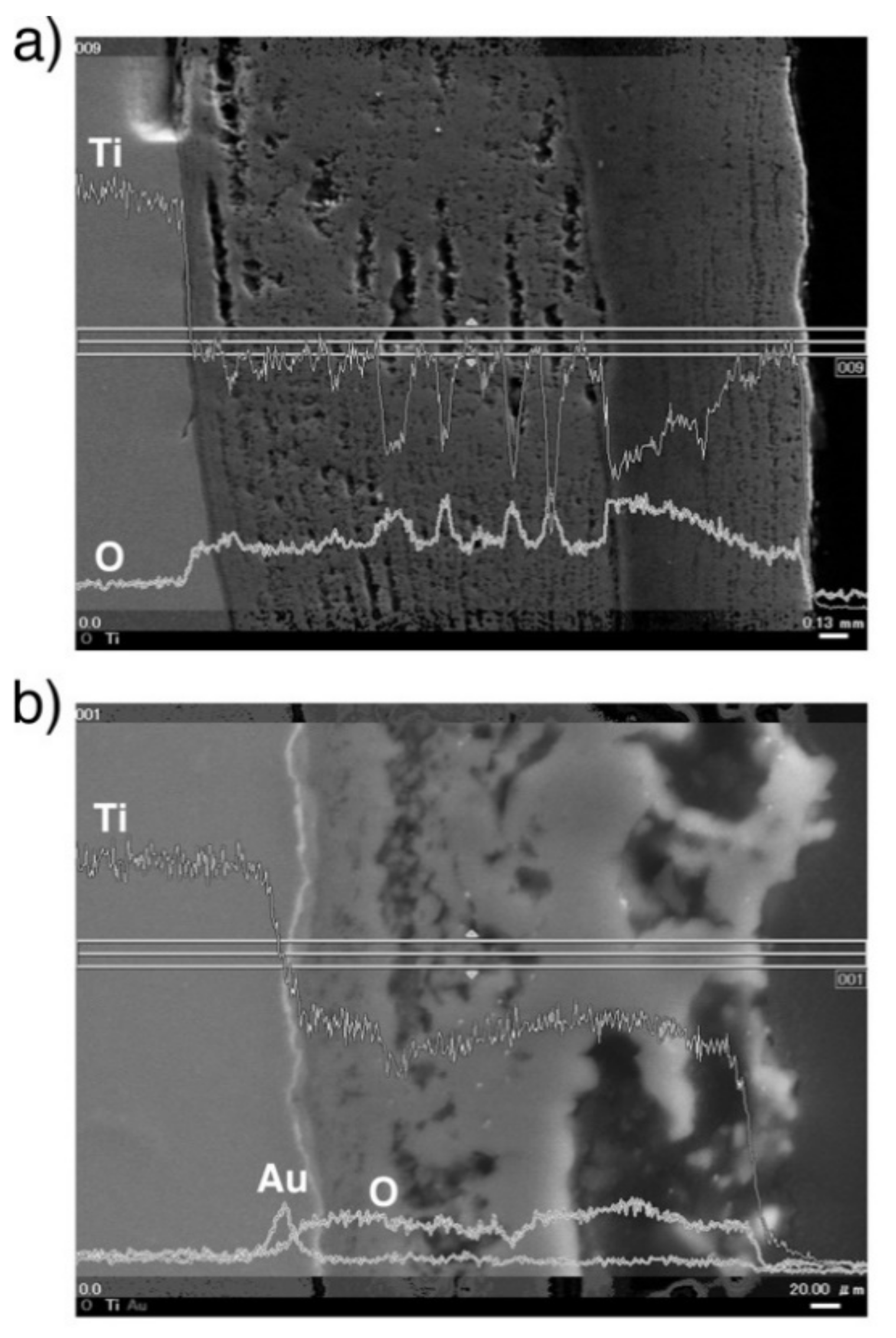

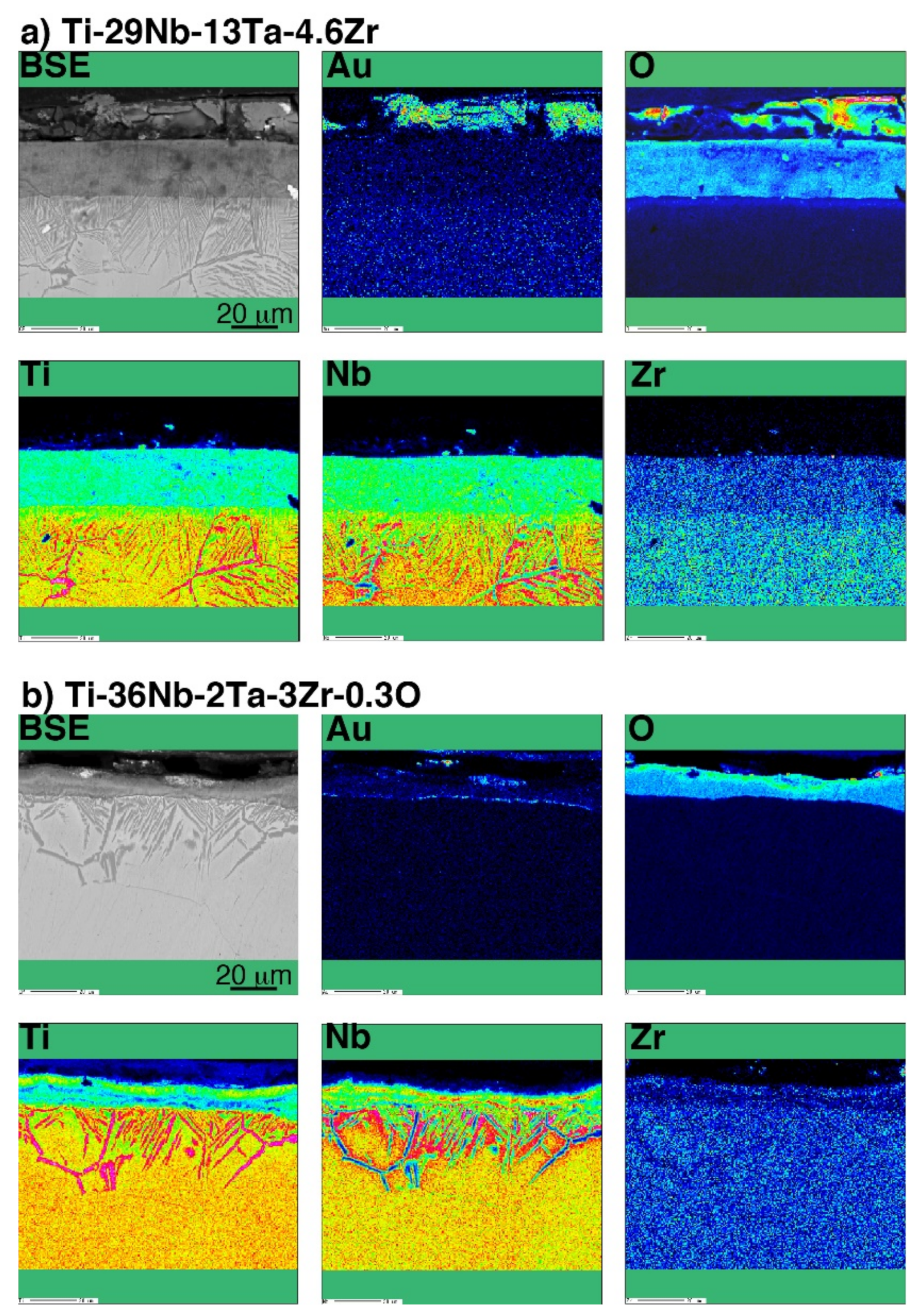

3.2. Results of Cross-Sectional SEM Observations and the Au Marker Method

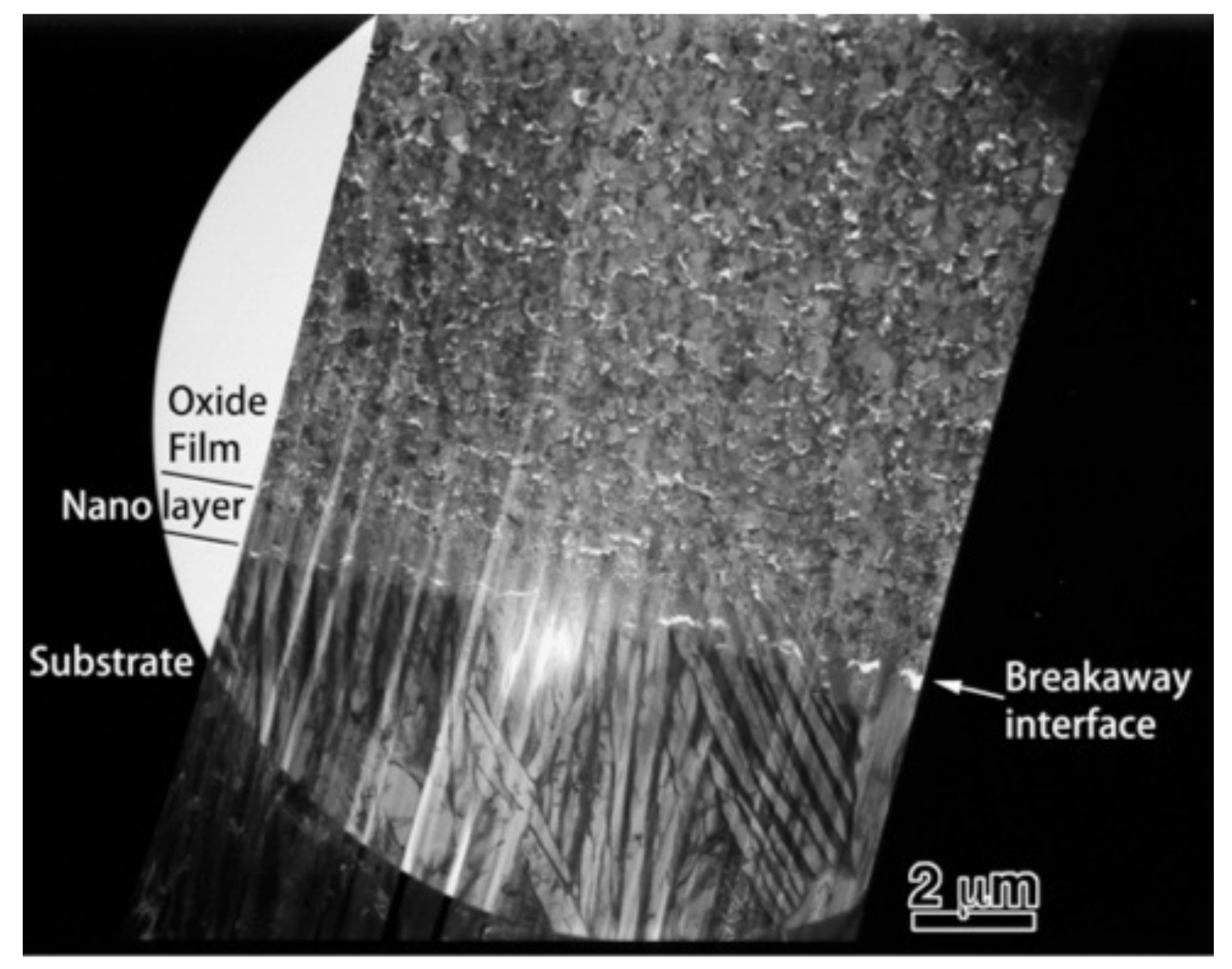

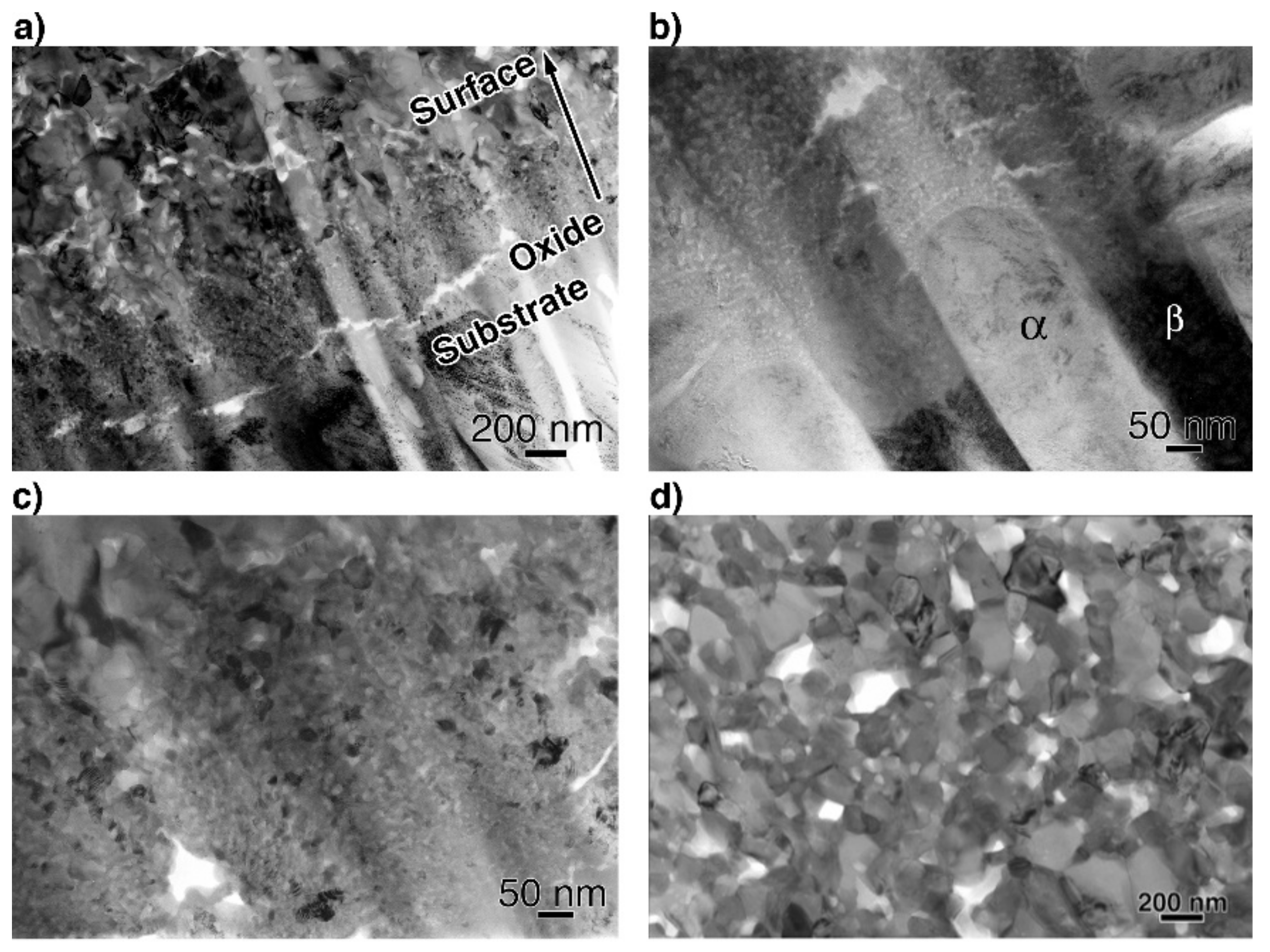

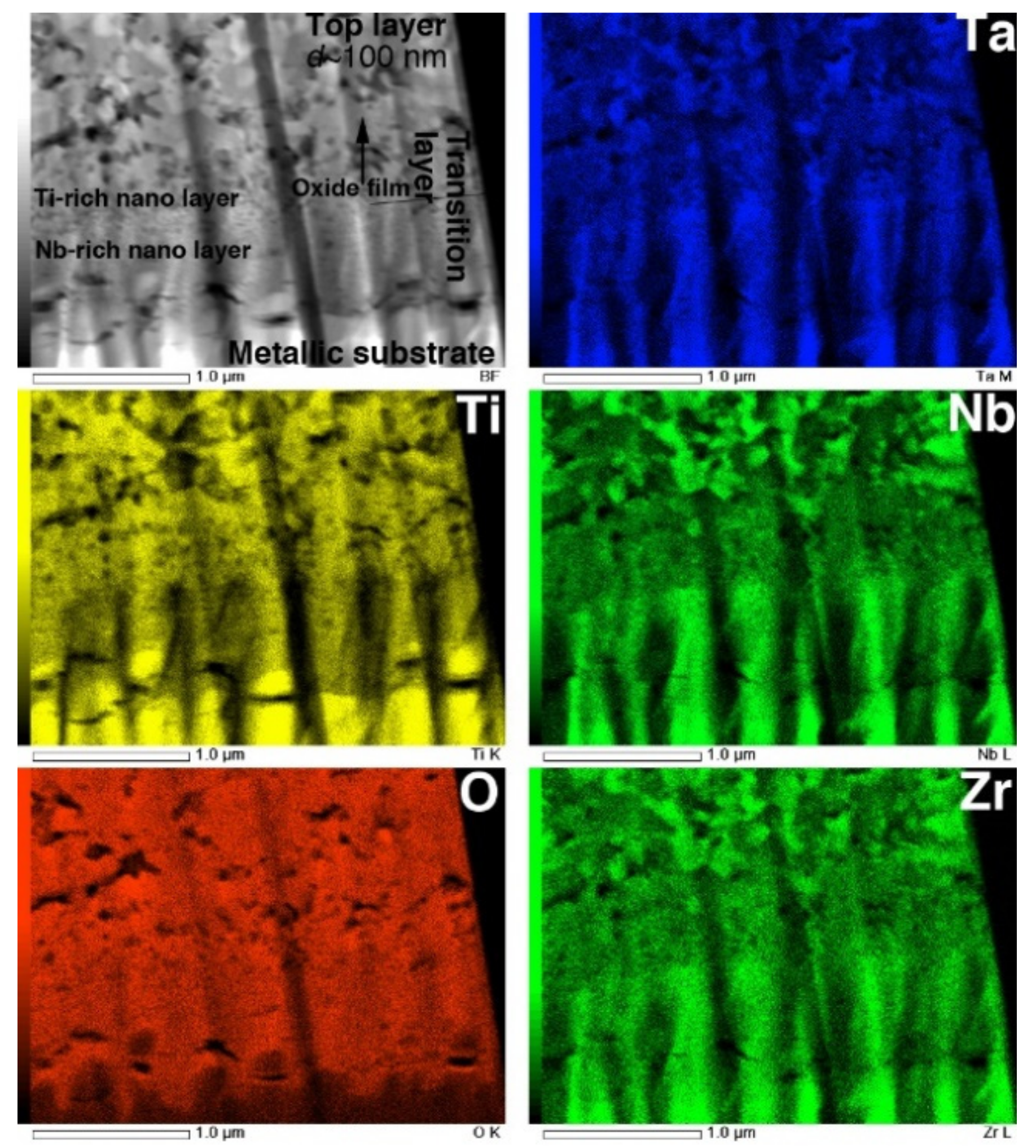

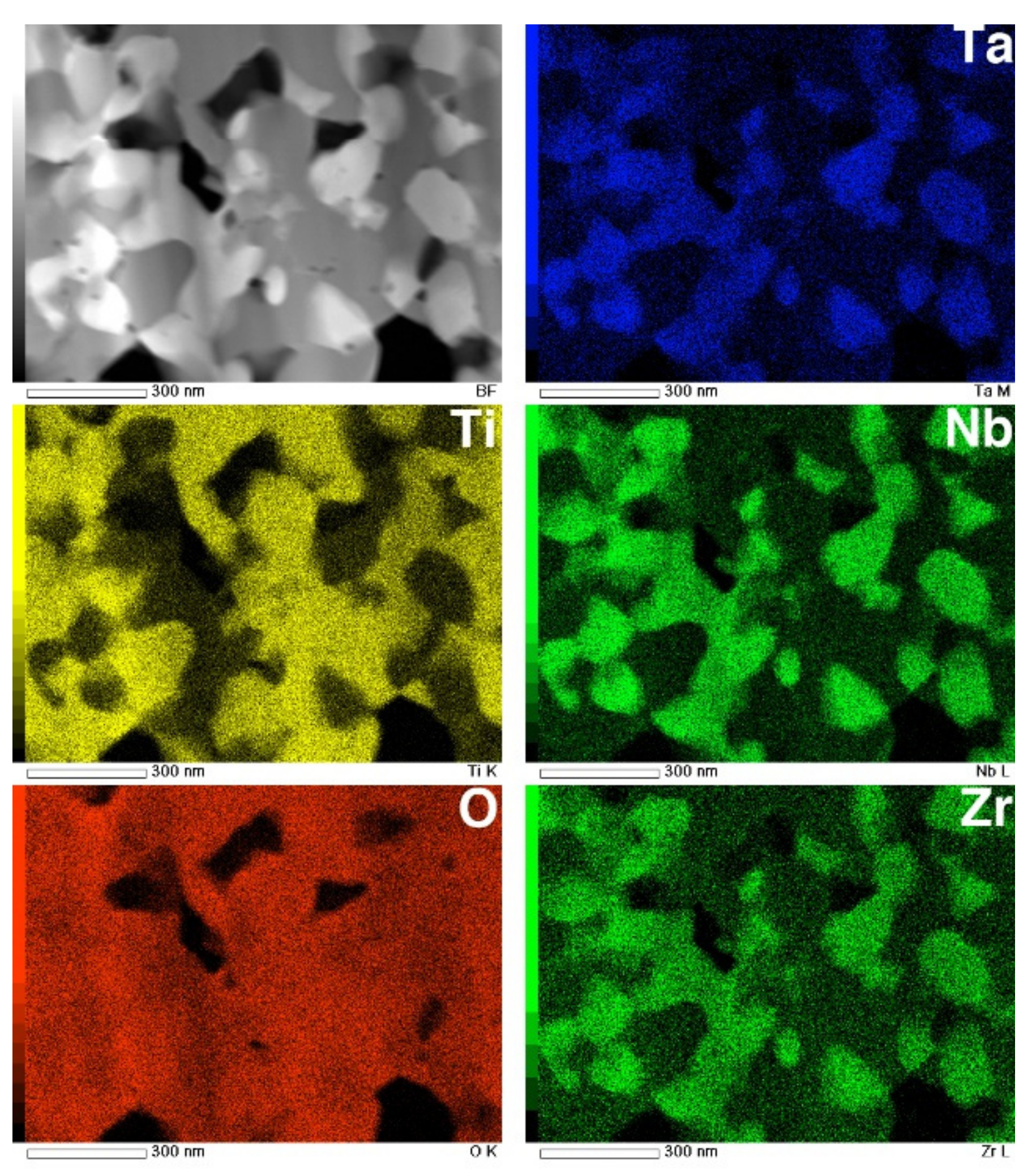

3.3. Microstructural Observations by TEM

4. Discussion

4.1. Exfoliation Stress of Oxide-Coated Ti-Alloys

4.2. Relationship between Oxidation Direction and Exfoliation Resistance in Terms of the Pilling–Bedworth Ratio

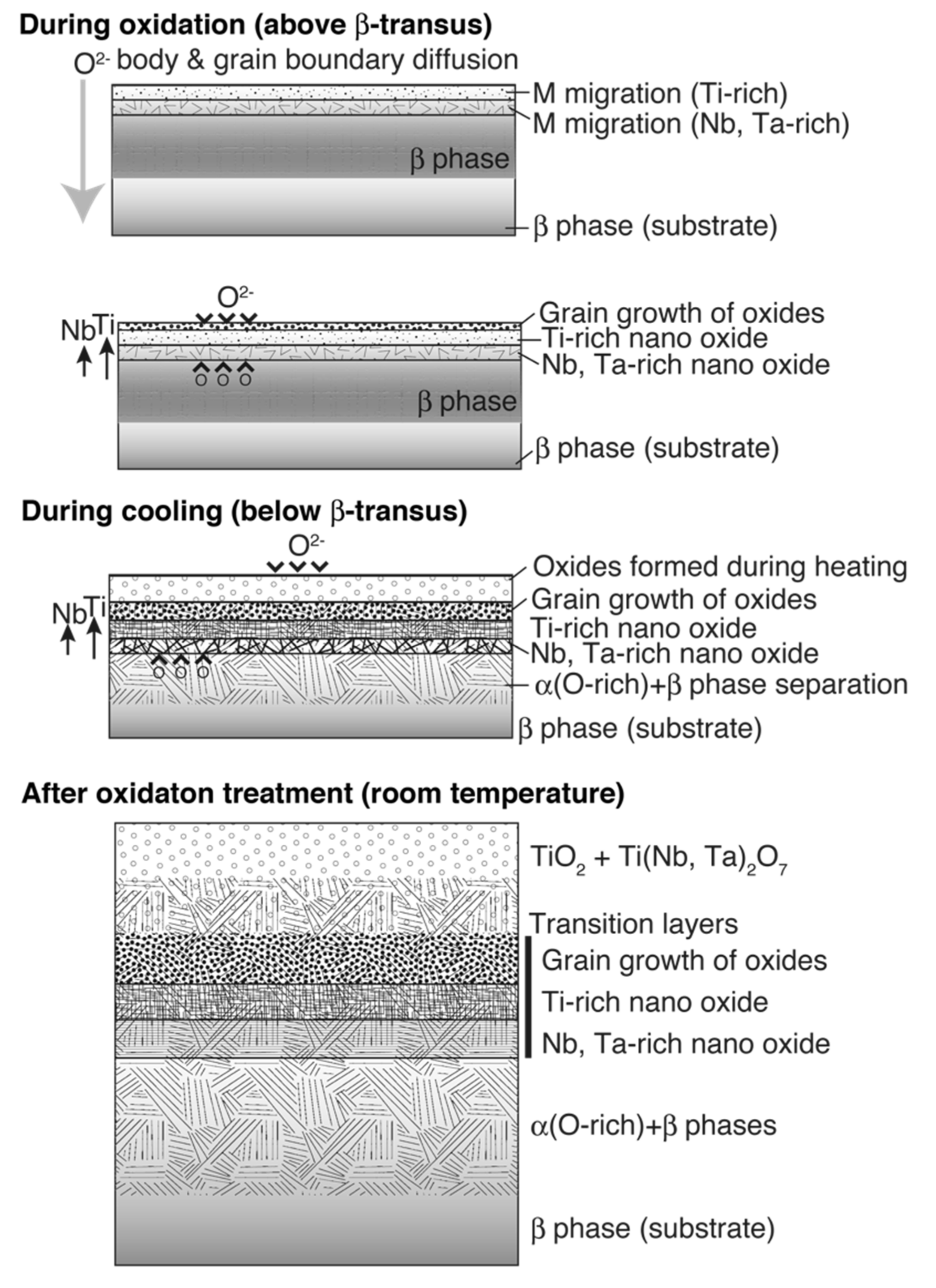

4.3. Oxide Layer Formation Mechanisms

5. Summary and Conclusions

- 1.

- The exfoliation stress, σf, of the oxide layer on CP Ti is always <7 MPa, and its fracture is always caused by cohesion failure. The σf of the oxide layer on Ti–36Nb–2Ta–3Zr–0.3O is much higher than that of the oxide layer on CP Ti, and the maximum σf is approximately 70 MPa, which is approximately equal to the maximum stress of the epoxy adhesives. In the case of Ti–36Nb–2Ta–3Zr–0.3O, interfacial fracture occurs.

- 2.

- The high exfoliation resistances of Ti–36Nb–2Ta–3Zr–0.3O and Ti–29Nb–13Ta–4.6Zr are attributed to their dense and robust oxide microstructures; in addition, fine particles and a composition-graded interfacial microstructure may contribute to their high exfoliation resistance. In the case of CP Ti, its weak “piecrust-like” layered structure is broken prior to exfoliation at the interface.

- 3.

- The nanoindentation hardness of the oxide layers appears to decrease gradually and continuously with increasing depth toward the substrate; the hardness in the substrate also gradually decreases.

- 4.

- According to the results of the fretting frictional tests, both the static and dynamic friction coefficients obviously decrease as a consequence of the oxide layer formation.

- 5.

- The Au marker method indicates that out-diffusion plays a predominant role in oxide formation on CP Ti. Both in- and out-diffusion are involved in oxide formation on Ti–29Nb–13Ta–4.6Zr and Ti–36Nb–2Ta–3Zr–0.3O.

- 6.

- TEM observations of Ti−29Nb−13Ta−4.6Zr revealed that the transition layer consists of nanograins of a Ti-rich oxide phase and an Nb-, Ta-, and Zr-rich oxide phase at the interface between the oxide and the metal substrate. The oxide layer consists of dense submicron-sized TiNb2O7 and TiO2 grains, whereas the oxide layer on CP Ti consists of a layered structure with micron-sized TiO2 grains.

- 7.

- For Ti−29Nb−13Ta−4.6Zr and Ti−36Nb−2Ta−3Zr−0.3O, a robust oxidation layer with a multiphase equiaxed subnanomicrostructure forms continuously on the substrate through the nanostructured transition layer, and the high exfoliation resistance can be attributed to this strong and smooth graded structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, K.; Ogawa, S. Shade-taking using the Shade Communicator. GC Circle 2007, 120, 24–27. [Google Scholar]

- Jinwen, L.; Peng, G.; Yongqing, Z. Recent Development of Effect Mechanism of Alloying Elements in Titanium Alloy Design. Rare Met. Mater. Eng. 2014, 43, 0775–0779. [Google Scholar]

- Miura-Fujiwara, E.; Yamada, S.; Obata, A.; Sato, H.; Watanabe, Y.; Kasuga, T.; Niinomi, M. Oxidation behavior and effect of layer thickness on whiteness and exfoliation behavior of oxide film formed on Ti-Nb-Ta-Zr alloy. In Proceedings of the Ti-2011 Conference, Beijing, China, 19–24 June 2011; Science Press: Beijing, China, 2012; pp. 2116–2120. [Google Scholar]

- Miura-Fujiwara, E.; Mizushima, K.; Yamada, S.; Watanabe, Y.; Kasuga, T.; Niinomi, M.; Yamasaki, T. Aesthetic and Mechanical Properties of Oxide Coated Ti-Nb-Ta-Zr Alloys as a Dental Material. In Proceedings of the PRICM-8, Hilton Waikoloa Village, Waikoloa, HI, USA, 4–9 August 2013; TMS: Warrendale, PA, USA, 2013; pp. 1543–1550. [Google Scholar]

- Obata, A.; Miura-Fujiwara, E.; Shimizu, A.; Maeda, H.; Nakai, M.; Watanabe, Y.; Niinomi, M.; Kasuga, T. White-ceramic conversion on Ti-29Nb-13Ta-4.6Zr surface for dental applications. Adv. Mater. Sci. Eng. 2013, 2013, 501621. [Google Scholar] [CrossRef]

- Mirua-Fujiwara, E.; Mizushima, K.; Watanabe, Y.; Kasuga, T.; Niinomi, M. Color tone and interfacial microstructure of white oxide layer on CP Ti and Ti-Nb-Ta-Zr alloys. Jpn. J. Appl. Phys. 2014, 53, 11RD02. [Google Scholar] [CrossRef]

- Kuroda, D.; Ninomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design, and Mechanical Properties of New Beta Type Titanium Alloys for Implant. Mater. Sci. Eng. 1998, A243, 244–249. [Google Scholar] [CrossRef]

- Morinaga, M.; Murata, Y.; Yukawa, H. An electronic approach to materials design. J. Mater. Sci. Technol. 2003, 19, 73–76. [Google Scholar]

- Morinaga, M.; Murata, Y.; Yukawa, H. Alloy design based on the DV-Xα cluster method. In Hartree-Fock-Slater Method for Materials Science; Springer: Berlin/Heidelberg, Germany, 2006; pp. 23–48. [Google Scholar]

- Niinomi, M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci. Technol. Adv. Mater. 2003, 4, 445. [Google Scholar] [CrossRef]

- Plancher, E.; Tasan, C.C.; Sandloebes, S.; Raabe, D. On dislocation involvement in Ti–Nb gum metal plasticity. Scr. Mater. 2013, 68, 805–808. [Google Scholar] [CrossRef]

- Kuramoto, S.; Furuta, T.; Hwang, J.; Nishino, K.; Saito, T. EBSP Analysis on Microstructure of Gum Metal after Plastic Deformation. J. Jpn. Inst. Met. 2005, 69, 953–961. [Google Scholar] [CrossRef]

- Nii, Y.; Kim, H.Y.; Miyazaki, S. Effect of Nb Content on Plastic Deformation Behavior and Deformation Textures of Ti-Nb-Zr-Ta-O Alloy. J. Jpn. Inst. Met. 2008, 72, 970–974. [Google Scholar] [CrossRef][Green Version]

- Saito, T.; Furuta, T.; Hwang, J.-H.; Kuramoto, S.; Nishino, K.; Suzuki, N.; Chen, R.; Yamada, A.; Ito, K.; Seno, Y.; et al. Multifunctional Alloys Obtained via a Dislocation-Free Plastic Deformation Mechanism. Science 2003, 300, 464–467. [Google Scholar] [CrossRef]

- Hasegawa, S. A New Super Elasto-Plastic Ti Alloy (Gummetal) Simplifies Treatment Procedure, Scientific Report of Rocky Mountain MORITA; Rocky Mountain MORITA: Tokyo, Japan, 2010; pp. 1–8. [Google Scholar]

- Miura, E.; Jie, L.; Watanabe, I.; Tanaka, Y.; Shiraishi, T.; Hisatsune, K. Determination of peeling plane of the fused porcelain to titanium. J. Jpn. Inst. Met. 2001, 65, 819–822. [Google Scholar] [CrossRef][Green Version]

- Miura, E.; Tabaru, T.; Liu, J.; Tanaka, Y.; Shiraishi, T.; Hisatsune, K. Effect of gold coating on interfacial reaction between dental porcelain and titanium. Mater. Trans. 2004, 45, 3044–3049. [Google Scholar] [CrossRef][Green Version]

- Sawa, T. Correlation between nanoindentation test result and vickers hardness. In Proceedings of the IMEKO 2010 TC3, TC5 and TC22 Conferences, Metrology in Modern Context, Pattaya, Thailand, 21–25 November 2010; pp. 171–174. [Google Scholar]

- Miura, E.; Tabaru, T.; Liu, J.; Tanaka, Y.; Shiraishi, T.; Hisatsune, K. Effect of gold coating on interfacial reaction between dental porcelain and titanium. J. Jpn. Inst. Met. 2006, 70, 51–58. [Google Scholar] [CrossRef][Green Version]

- McNeil, L.; French, R. Multiple Scattering from Rutile TiO2 Particles. Acta Mater. 2000, 48, 4571–4576. [Google Scholar] [CrossRef]

- Thiele, E.S.; French, R.H. Light-Scattering Properties of Representative, Morphological Rutile Titania Particles Studied Using a Finite-Element Method. J. Am. Ceram. Soc. 1998, 81, 469–479. [Google Scholar] [CrossRef]

- Ogawa, Y.; Miura-Fujiwara, E. Effect of Nb Addition on Oxide Formation on Ti-xNb Alloys. Mater. Trans. 2019, 60, 2204–2212. [Google Scholar] [CrossRef]

- Birks, N.; Meier, H.G.; Pettit, S.F. Introduction to the High-Temperature Oxidation of Metals, 2nd ed.; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar]

- Gasperin, M. Affinement de la structure de TiNb2O7 et répartition des cations. J. Solid State Chem. 1984, 53, 144–147. [Google Scholar] [CrossRef]

- Kim, D.W.; Enomoto, N.; Nakagawa, Z.; Kawamura, K. Molecular Dynamic Simulation in Titanium Dioxide Polymorphs: Rutile, Brookite, and Anatase. J. Am. Ceram. Soc. 1996, 79, 1095–1099. [Google Scholar] [CrossRef]

- Persson, K. Materials Data on Ti (SG:194) by Materials Project. 2016. Available online: https://materialsproject.org/materials/mp-46/ (accessed on 15 September 2021).

- Persson, K. Materials Data on Ti (SG:229) by Materials Project. 2016. Available online: https://materialsproject.org/materials/mp-73/ (accessed on 15 September 2021).

- Akai, M.; Taniguchi, S.; Shibata, T. High Temperature Oxidation Behavior of Ti-14Al-21Nb Alloy in Oxygen. J. Jpn. Inst. Met. 1994, 58, 1169–1176. [Google Scholar] [CrossRef][Green Version]

- Jiang, H.; Hirohasi, M.; Lu, Y.; Imanari, H. Effect of Nb on the high temperature oxidation of Ti–(0–50 at.%)Al. Scr. Mater. 2002, 46, 639–643. [Google Scholar] [CrossRef]

- Roy, T.K.; Balasubramaniam, R.; Ghosh, A. High-temperature oxidation of Ti3Al-based titanium aluminides in oxygen. Metall. Mater. Trans. A 1996, 27, 3993–4002. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miura-Fujiwara, E.; Yamada, S.; Mizushima, K.; Nishijima, M.; Watanabe, Y.; Kasuga, T.; Niinomi, M. Exfoliation Resistance, Microstructure, and Oxide Formation Mechanisms of the White Oxide Layer on CP Ti and Ti–Nb–Ta–Zr Alloys. Materials 2021, 14, 6599. https://doi.org/10.3390/ma14216599

Miura-Fujiwara E, Yamada S, Mizushima K, Nishijima M, Watanabe Y, Kasuga T, Niinomi M. Exfoliation Resistance, Microstructure, and Oxide Formation Mechanisms of the White Oxide Layer on CP Ti and Ti–Nb–Ta–Zr Alloys. Materials. 2021; 14(21):6599. https://doi.org/10.3390/ma14216599

Chicago/Turabian StyleMiura-Fujiwara, Eri, Soichiro Yamada, Keisuke Mizushima, Masahiko Nishijima, Yoshimi Watanabe, Toshihiro Kasuga, and Mitsuo Niinomi. 2021. "Exfoliation Resistance, Microstructure, and Oxide Formation Mechanisms of the White Oxide Layer on CP Ti and Ti–Nb–Ta–Zr Alloys" Materials 14, no. 21: 6599. https://doi.org/10.3390/ma14216599

APA StyleMiura-Fujiwara, E., Yamada, S., Mizushima, K., Nishijima, M., Watanabe, Y., Kasuga, T., & Niinomi, M. (2021). Exfoliation Resistance, Microstructure, and Oxide Formation Mechanisms of the White Oxide Layer on CP Ti and Ti–Nb–Ta–Zr Alloys. Materials, 14(21), 6599. https://doi.org/10.3390/ma14216599