Al0.5CoCrFeNi2 High Entropy Alloy Particle Reinforced AZ91 Magnesium Alloy-Based Composite Processed by Spark Plasma Sintering

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructural Characterization

3.1.1. Characterization of AZ91, HEA and SiC Powders

3.1.2. Characterization of SPS Samples

3.2. Mechanical Properties of SPS Samples

4. Discussion

5. Conclusions

- AZ91–HEA composite with a uniform distribution of HEA particles in the matrix could be manufactured using spark plasma sintering process. The composite consisted of α-Mg, Mg17Al12 and FCC phase. Phase transformation was not observed in the sintered composite compared to the as-milled powder. No reaction layer was formed in the interfacial region between HEA and α-Mg matrix.

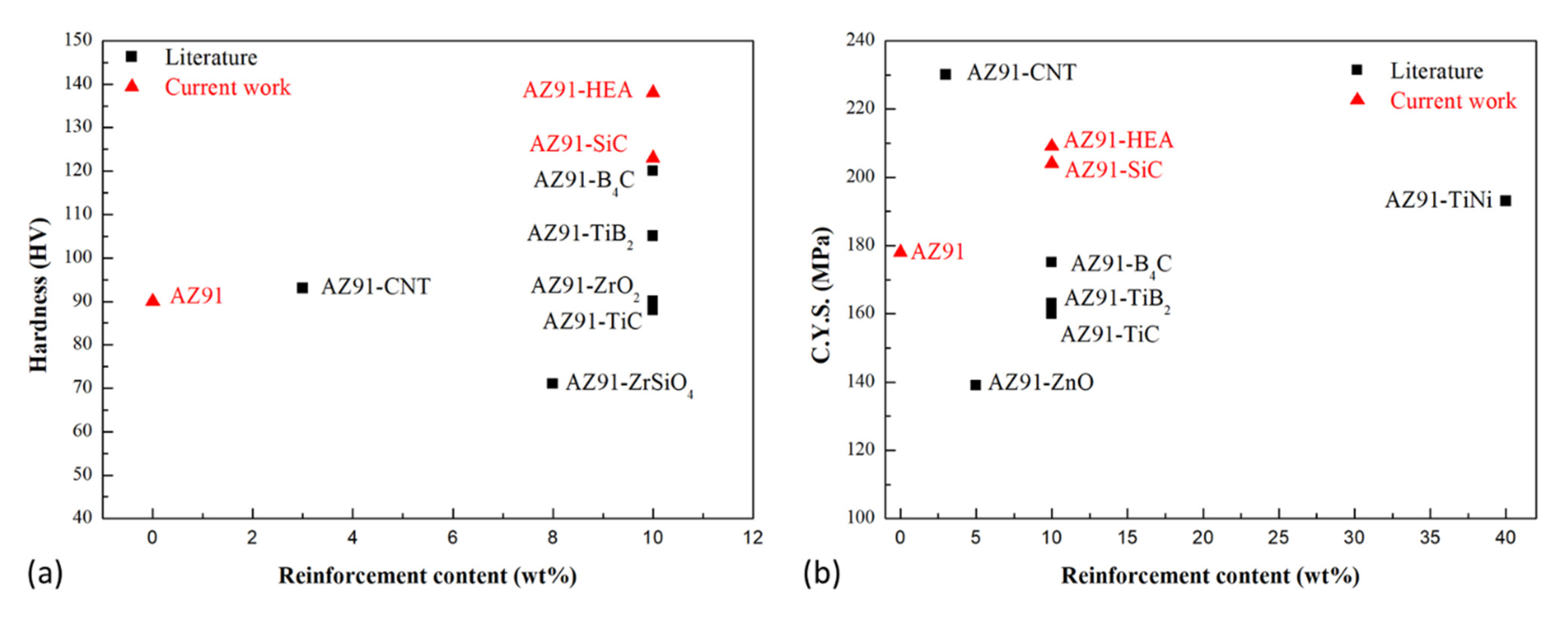

- The addition of HEA efficiently enhances hardness and compressive yield strength (C.Y.S) of AZ91–HEA. After adding HEA particles, hardness and C.Y.S of the composite were increased by 48% and 17%, respectively.

- In AZ91–HEA composite, thermal mismatch effect, load transfer effect and grain-refinement effect contributed to the increment in yield strength. Among them, the thermal mismatch effect was the major factor.

- AZ91–HEA displayed a slightly higher C.Y.S (209 MPa) than that of AZ91–SiC (204 MPa). The strengthening effect of HEA was comparable to that of the commonly used SiC reinforcement in metal matrix composite. The reason was due to the less porosity and enhanced interfacial bonding between α-Mg matrix and HEA particles.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schumann, S. The paths and strategies for increased magnesium applications in vehicles. Mater. Sci. Forum 2005, 488, 1–8. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Pan, F.S.; Yang, M.B.; Chen, X.H. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Cabibbo, M.; Spigarelli, S. A TEM quantitative evolution of strengthening in an Mg-RE alloy reinforced with SiC. Mater. Charact. 2011, 62, 959–969. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloys 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Deng, K.K.; Hu, X.S.; Wu, K. Magnesium matrix composite reinforced by nanoparticles—A review. J. Magnes. Alloy. 2021, 9, 57–77. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Li, Y.; Aljerf, M.; LeMoulec, A.; Yavari, A.R.; Inoue, A. A magnesium alloy matrix composite reinforced with metallic glass. Compos. Sci. Technol. 2009, 69, 2734–2736. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Muskeri, S.; Hasannaeimi, V.; Salloom, R.; Sadeghilaridjani, M.; Mukherjee, S. Small-scale mechanical behavior of a eutectic high entropy alloy. Sci Rep. 2020, 10, 2669. [Google Scholar] [CrossRef] [Green Version]

- Muskeri, S.; Choudhuri, D.; Jannotti, P.A.; Schuster, B.E.; Lloyd, J.T.; Mishra, R.S.; Mukherjee, S. Ballistic Impact Response of Al0.1CoCrFeNi High-Entropy Alloy. Adv. Eng. Mater. 2020, 22, 2000124. [Google Scholar] [CrossRef]

- Rao, J.C.; Ocelík, V.; Vainchtein, D.; Tang, Z.; Liaw, P.K.; De Hosson, J.T.M. The fcc-bcc crystallographic orientation relationship in AlxCoCrFeNi high-entropy alloys. Mater. Lett. 2016, 176, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.X.; Zhu, S.; Wang, X.M.; Yang, B.J.; Han, G.F.; Qiu, L. Microstructure evolution and strengthening mechanism of Al0.4CoCu0.6NiSix (x = 0–0.2) high entropy alloys prepared by vacuum arc melting and copper injection fast solidification. Vacuum 2018, 150, 84–95. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Chen, Z.; Chen, Y.Z.; Shi, J.C.; Wang, Z.Y.; Wang, S.; Liu, F. Effect of Al content on high temperature oxidation resistance of AlxCoCrCuFeNi high entropy alloys (x = 0, 0.5, 1, 1.5, 2). Vacuum 2019, 169, 108837. [Google Scholar] [CrossRef]

- Liang, J.T.; Cheng, K.C.; Chen, S.H. Effect of heat treatment on the phase evolution and mechanical properties of atomized AlCoCrFeNi high-entropy alloy powders. J. Alloys Compd. 2019, 30, 484–490. [Google Scholar] [CrossRef]

- Kai, W.; Cheng, F.P.; Lin, Y.R.; Chuang, C.W.; Huang, R.T.; Chen, D.; Kai, J.J.; Liu, C.T.; Wang, C.J. The oxidation behavior of Ni2FeCoCrAlx high-entropy alloys in dry air. J. Alloys Compd. 2020, 836, 155518. [Google Scholar] [CrossRef]

- Kai, W.; Cheng, F.P.; Chien, F.C.; Lin, Y.R.; Chen, D.; Kai, J.J.; Liu, C.T.; Wang, C.J. The oxidation behavior of a Ni2FeCoCrAl0.5 high-entropy superalloy in O2-containing environments. Corros. Sci. 2019, 158, 108053. [Google Scholar] [CrossRef]

- Cheng, Y.; Cui, Z.; Cheng, L.; Gong, D.; Wang, W. Effect of particle size on densification of pure magnesium during spark plasma sintering. Adv. Powder Technol. 2017, 28, 1129–1135. [Google Scholar] [CrossRef]

- Mondet, M.; Barraud, E.; Lemonnier, S.; Guyon, J.; Allain, N.; Grosdidier, T. Microstructure and mechanical properties of AZ91 magnesium alloy developed by spark plasma sintering. Acta Mater. 2016, 119, 55–67. [Google Scholar] [CrossRef]

- Mathieu, M.; Elodie, B.; Sebastien, L. Optimization of the mechanical properties of a Spark Plasma Sintered (SPS) magnesium alloy through a post-sintering in-situ precipitation treatment. J. Alloys Compd. 2017, 698, 259–266. [Google Scholar] [CrossRef]

- Liang, J.T.; Cheng, K.C.; Chen, Y.C.; Chiu, S.M.; Chiu, C.; Lee, J.W.; Chen, S.H. Comparisons of plasma-sprayed and sputtering Al0.5CoCrFeNi2 high-entropy alloy coatings. Surf. Coat. Technol. 2020, 403, 126411. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Enhancing compressive response of AZ31B magnesium alloy using alumina nanoparticles. Compos. Sci. Technol. 2008, 68, 2185–2192. [Google Scholar] [CrossRef]

- Armstrong, R.; Codd, I.; Douthwaite, R.M.; Petch, N.J. The plastic deformation of polycrystalline aggregate. Philos. Mag. 1962, 7, 45–58. [Google Scholar] [CrossRef]

- Sun, X.; Wang, C.; Deng, K.; Nie, K.; Zhang, X.; Xiao, X. High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase. J. Alloys Compd. 2018, 732, 328–335. [Google Scholar] [CrossRef]

- Caceres, C.H.; Mann, G.; Griffiths, J.R. Grain size hardening in Mg and Mg-Zn solid solutions. Metall. Mater. Trans. A 2011, 42, 1950–1959. [Google Scholar] [CrossRef] [Green Version]

- Hutchinson, C.R.; Nie, J.F.; Gorsse, S. Modeling the precipitation processes and strengthening mechanisms in a Mg-Al-(Zn) AZ91 alloy. Metal. Mater. Trans. A 2005, 36, 2093–2105. [Google Scholar] [CrossRef]

- Deng, K.; Shi, J.; Wang, C.; Wang, X.; Wu, Y.; Nie, K.; Wu, K. Microstructure and strengthening mechanism of bimodal size particle reinforced magnesium matrix composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1280–1284. [Google Scholar] [CrossRef]

- Miller, W.S.; Humphreys, F.J. Strengthening mechanisms in particulate metal matrix composites. Scr. Metall. Mater. 1991, 25, 33–38. [Google Scholar] [CrossRef]

- Dai, L.H.; Ling, Z.; Bai, Y.L. Size-dependent inelastic behavior of particle-reinforced metal–matrix composites. Compos. Sci. Technol. 2001, 61, 1057–1063. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Properties and deformation behaviour of Mg-Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Li, Q.; Viereckl, A.; Rottmair, C.A.; Singer, R.F. Improved processing of carbon nanotube/magnesium alloy composite. Comp. Sci. Technol. 2009, 69, 1193–1199. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Turan, M.E. The effect of TiB2 content on wear and mechanical behavior of AZ91 magnesium matrix composites produced by powder metallurgy. Powder Metall. Met. Ceram. 2019, 57, 564–572. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Turan, M.E. Influence of TiC content on mechanical, wear and corrosion properties of hot-pressed AZ91/TiC composites. J. Compos. Mater. 2019, 54, 141–152. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y. Microstructure and wear of a sintered composite with a magnesium alloy AZ91 matrix reinforced with ZrO2 particles. Met. Sci. Heat Treat. 2019, 61, 325–329. [Google Scholar] [CrossRef]

- Mohanavel, V.; Vijay, K.; Vigneswaran, A.; Srinath, S.; Gokulnath, S. Mechanical and tribological behavior of AZ91/ZrSiO4 composites. Mater. Today 2021, 37, 1529–1534. [Google Scholar] [CrossRef]

- Kelen, F.; Gavgali, M.; Aydogmus, T. Microstructure and mechanical properties of a novel TiNi particulate reinforced AZ91 metal matrix composite. Mater. Lett. 2018, 233, 12–15. [Google Scholar] [CrossRef]

| Sample ID | Processing |

|---|---|

| AZ91 | AZ91 powder compacted by SPS |

| AZ91–HEA | AZ91-10 wt% Al0.5CoCrFeNi2 compacted by SPS |

| AZ91–SiC | AZ91-10 wt% SiC compacted by SPS |

| Sample | Area | Element | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mg | Al | Mn | Zn | Co | Cr | Fe | Ni | Si | C | ||

| HEA | - | - | 8.64 | - | - | 18.15 | 18.34 | 18.72 | 36.15 | - | - |

| AZ91 | A | 90.91 | 8.76 | 0.13 | 0.21 | - | - | - | - | - | - |

| AZ91 | B | 80.11 | 19.56 | 0.10 | 0.13 | - | - | - | - | - | - |

| AZ91–HEA | A | 91.45 | 8.13 | 0.10 | 0.31 | - | - | - | - | - | - |

| AZ91–HEA | B | - | 8.87 | - | - | 18.16 | 18.11 | 18.99 | 35.87 | - | - |

| AZ91–SiC | A | 91.36 | 8.21 | 0.13 | 0.30 | - | - | - | - | - | - |

| AZ91–SiC | B | - | - | - | - | - | - | - | - | 47.09 | 52.91 |

| Sample | Hardness (HV) | C.Y.S (MPa) | Failure Strain (%) |

|---|---|---|---|

| AZ91 | 93 ± 2 | 178 ± 4 | 12.2 ± 0.3 |

| AZ91–HEA | 138 ± 2 | 209 ± 8 | 13.7 ± 0.5 |

| AZ91–SiC | 123 ± 8 | 204 ± 10 | 12.0 ± 0.4 |

| Sample | Mechanism | Value (MPa) |

|---|---|---|

| AZ91–HEA | Thermal mismatch | 10.0 |

| AZ91–HEA | Grain boundary | 1.0 |

| AZ91–HEA | Load transfer | 3.0 |

| AZ91–HEA | Orowan | 0.1 |

| AZ91–HEA | Solid solution | 0.3 |

| AZ91–SiC | Thermal mismatch | 9.9 |

| AZ91–SiC | Grain boundary | 4.0 |

| AZ91–SiC | Load transfer | 6.0 |

| AZ91–SiC | Orowan | 0.1 |

| AZ91–SiC | Solid solution | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, C.; Chang, H.-H. Al0.5CoCrFeNi2 High Entropy Alloy Particle Reinforced AZ91 Magnesium Alloy-Based Composite Processed by Spark Plasma Sintering. Materials 2021, 14, 6520. https://doi.org/10.3390/ma14216520

Chiu C, Chang H-H. Al0.5CoCrFeNi2 High Entropy Alloy Particle Reinforced AZ91 Magnesium Alloy-Based Composite Processed by Spark Plasma Sintering. Materials. 2021; 14(21):6520. https://doi.org/10.3390/ma14216520

Chicago/Turabian StyleChiu, Chun, and Hsun-Hsiang Chang. 2021. "Al0.5CoCrFeNi2 High Entropy Alloy Particle Reinforced AZ91 Magnesium Alloy-Based Composite Processed by Spark Plasma Sintering" Materials 14, no. 21: 6520. https://doi.org/10.3390/ma14216520

APA StyleChiu, C., & Chang, H.-H. (2021). Al0.5CoCrFeNi2 High Entropy Alloy Particle Reinforced AZ91 Magnesium Alloy-Based Composite Processed by Spark Plasma Sintering. Materials, 14(21), 6520. https://doi.org/10.3390/ma14216520