Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact

Abstract

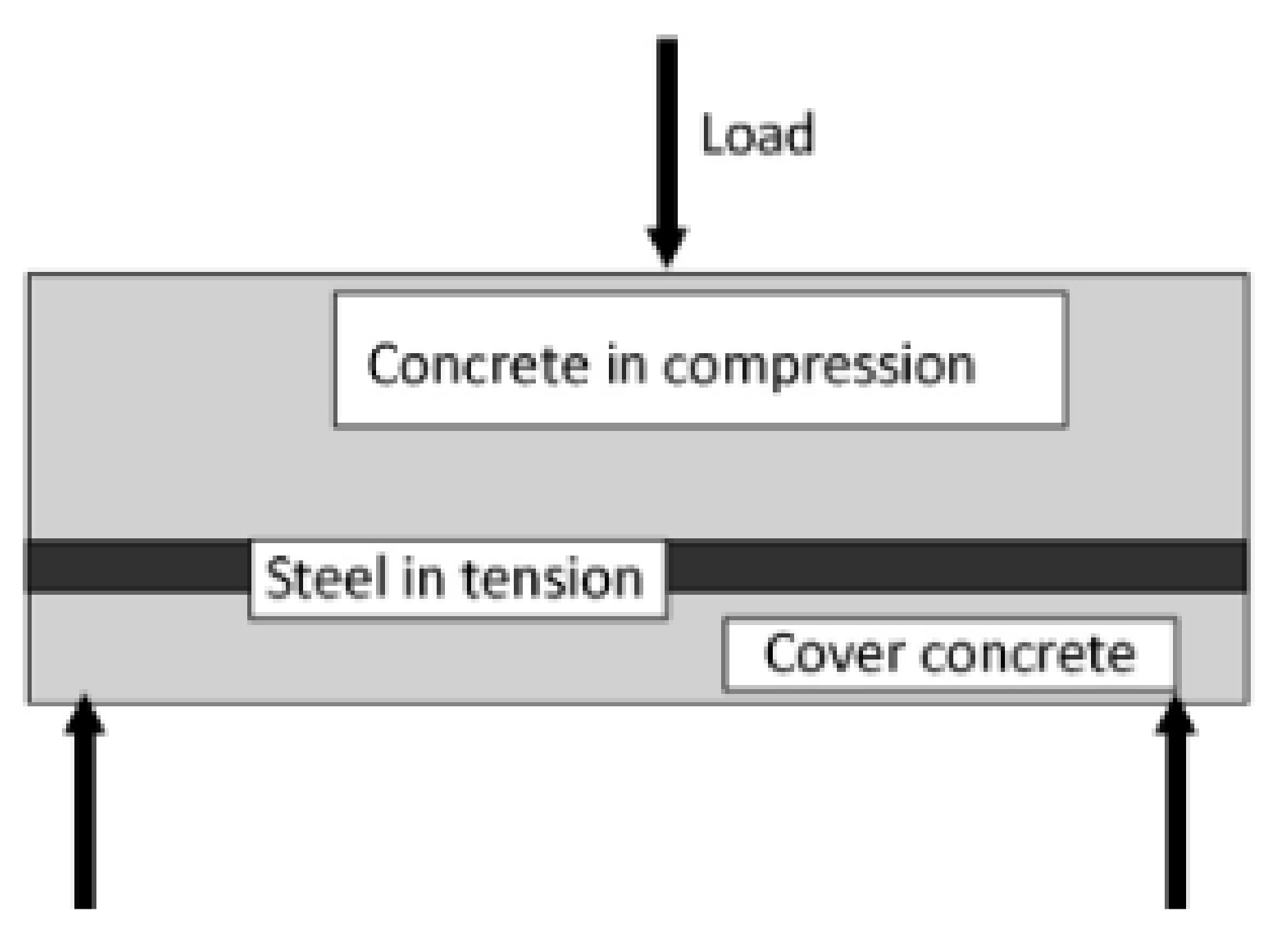

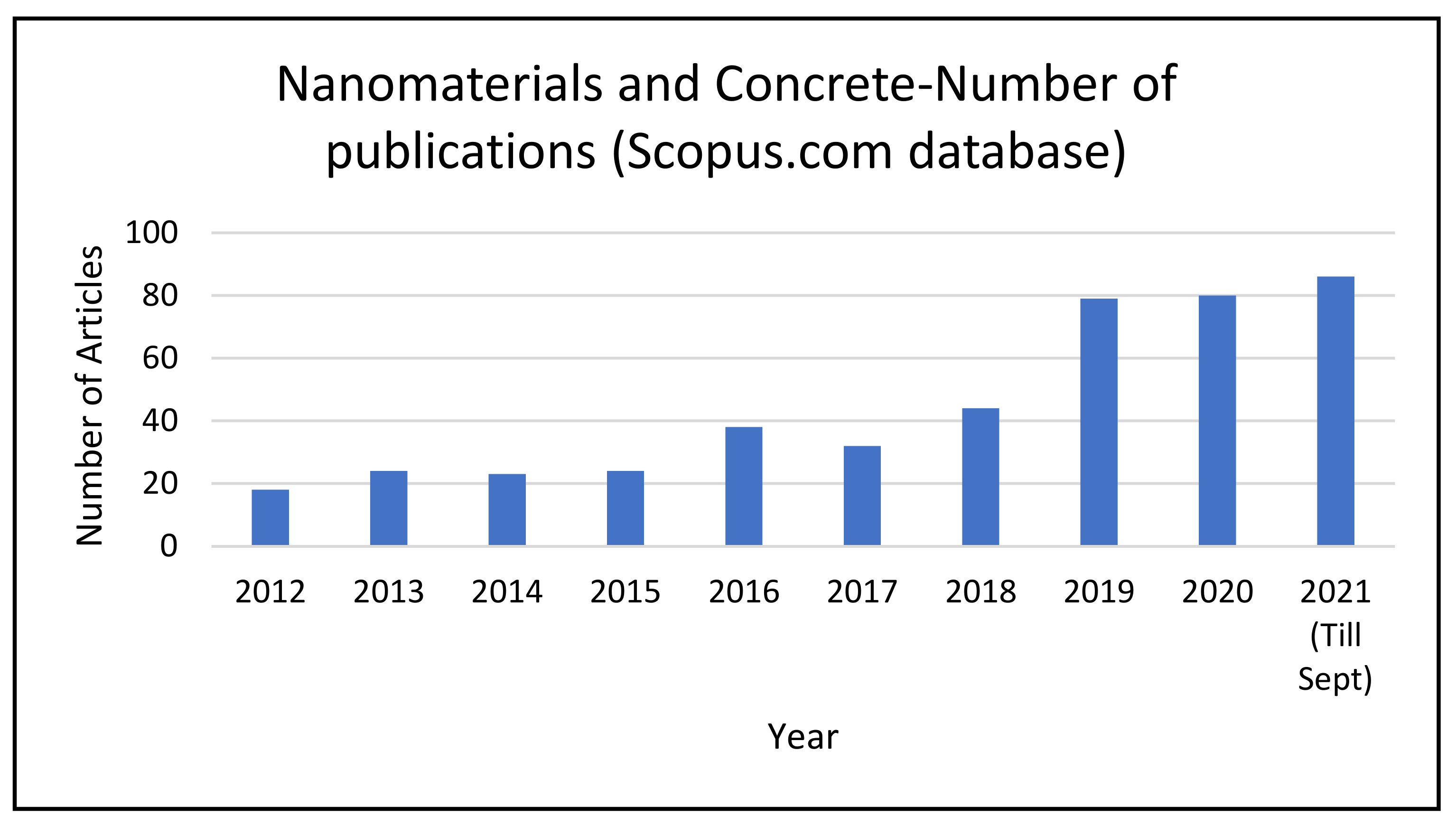

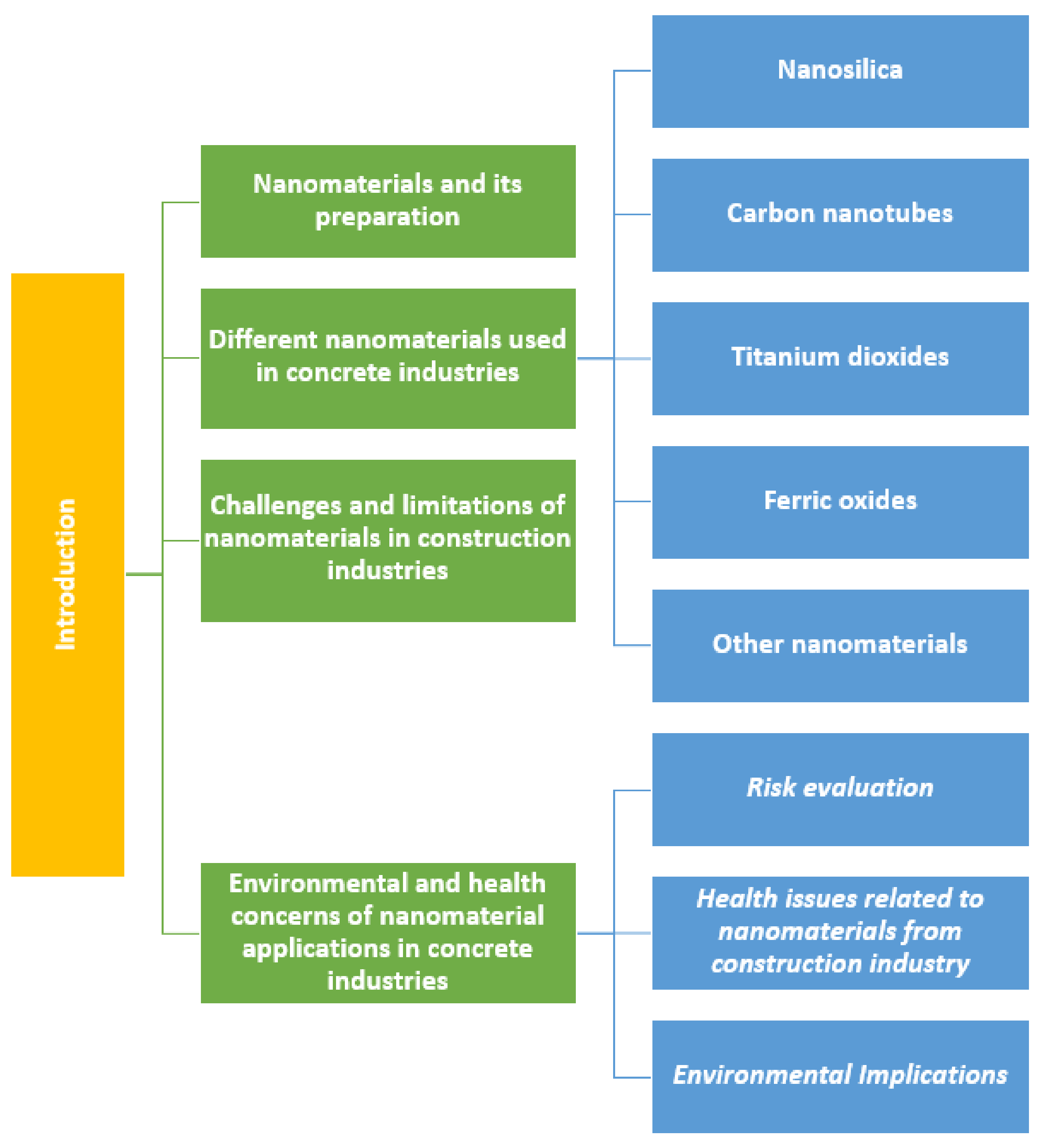

:1. Introduction

2. Nanomaterials and Their Preparation

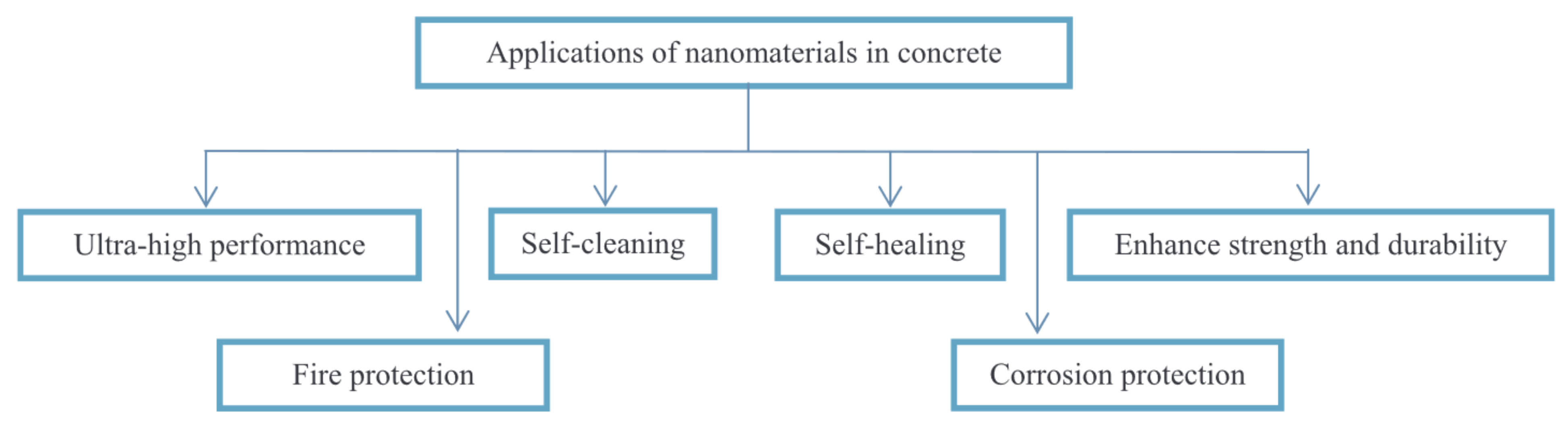

3. Nanomaterial Application in Concrete Industries

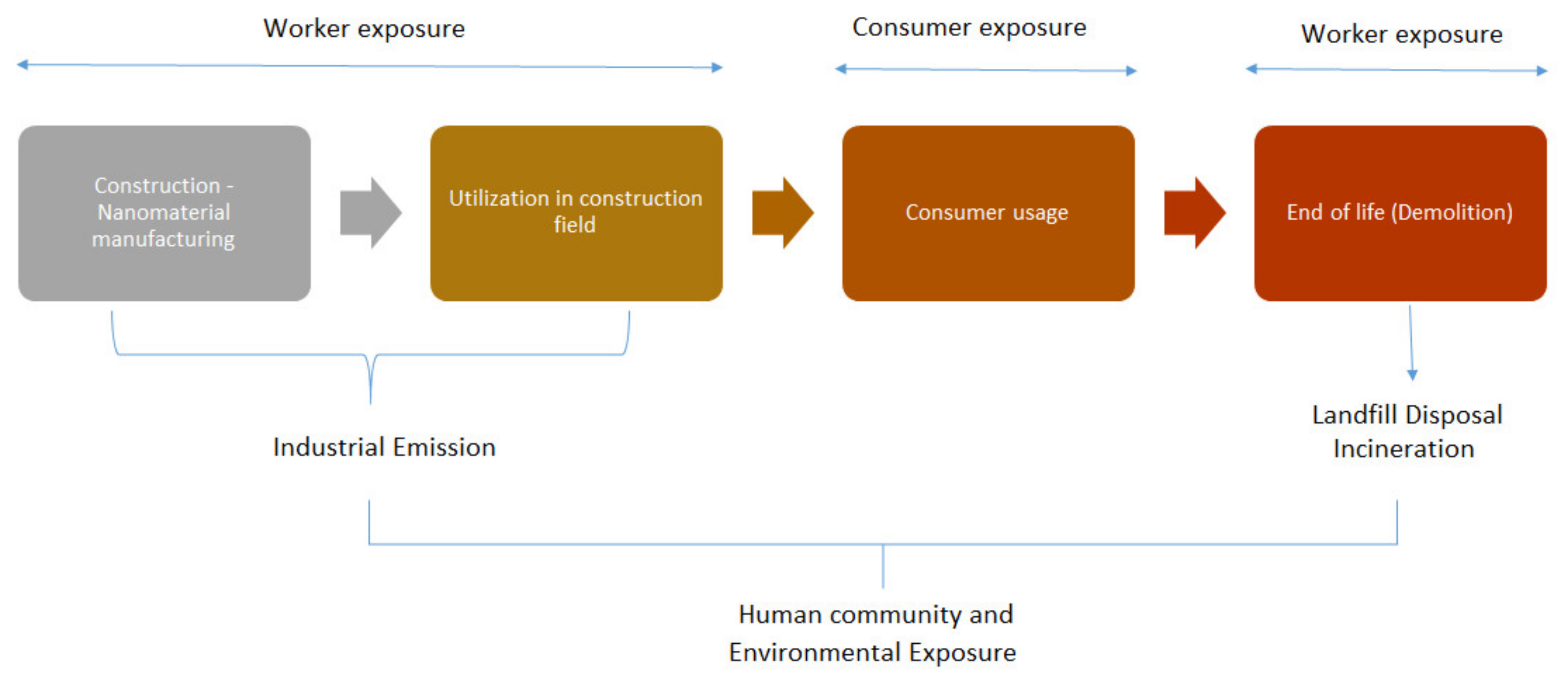

3.1. Nanosilica

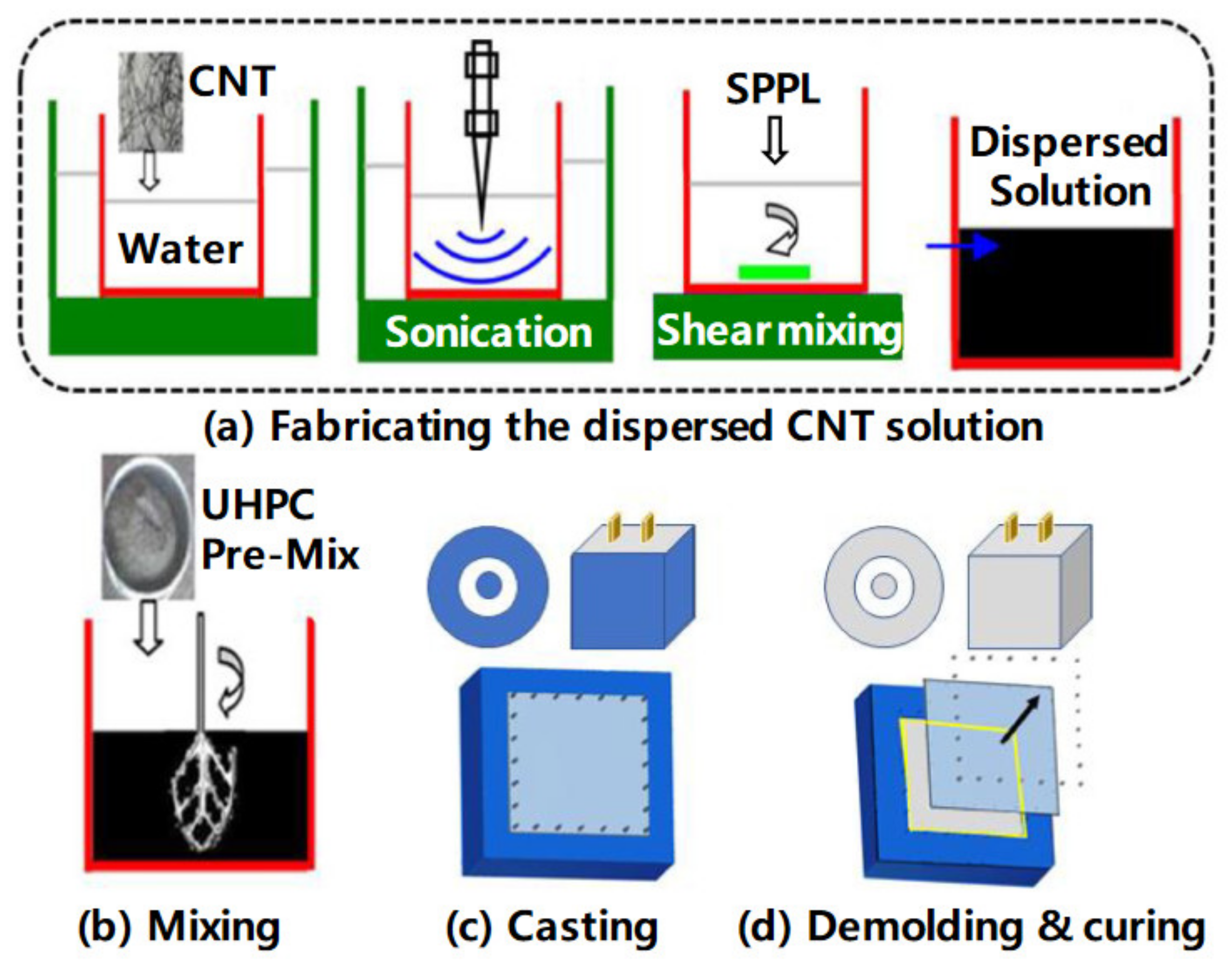

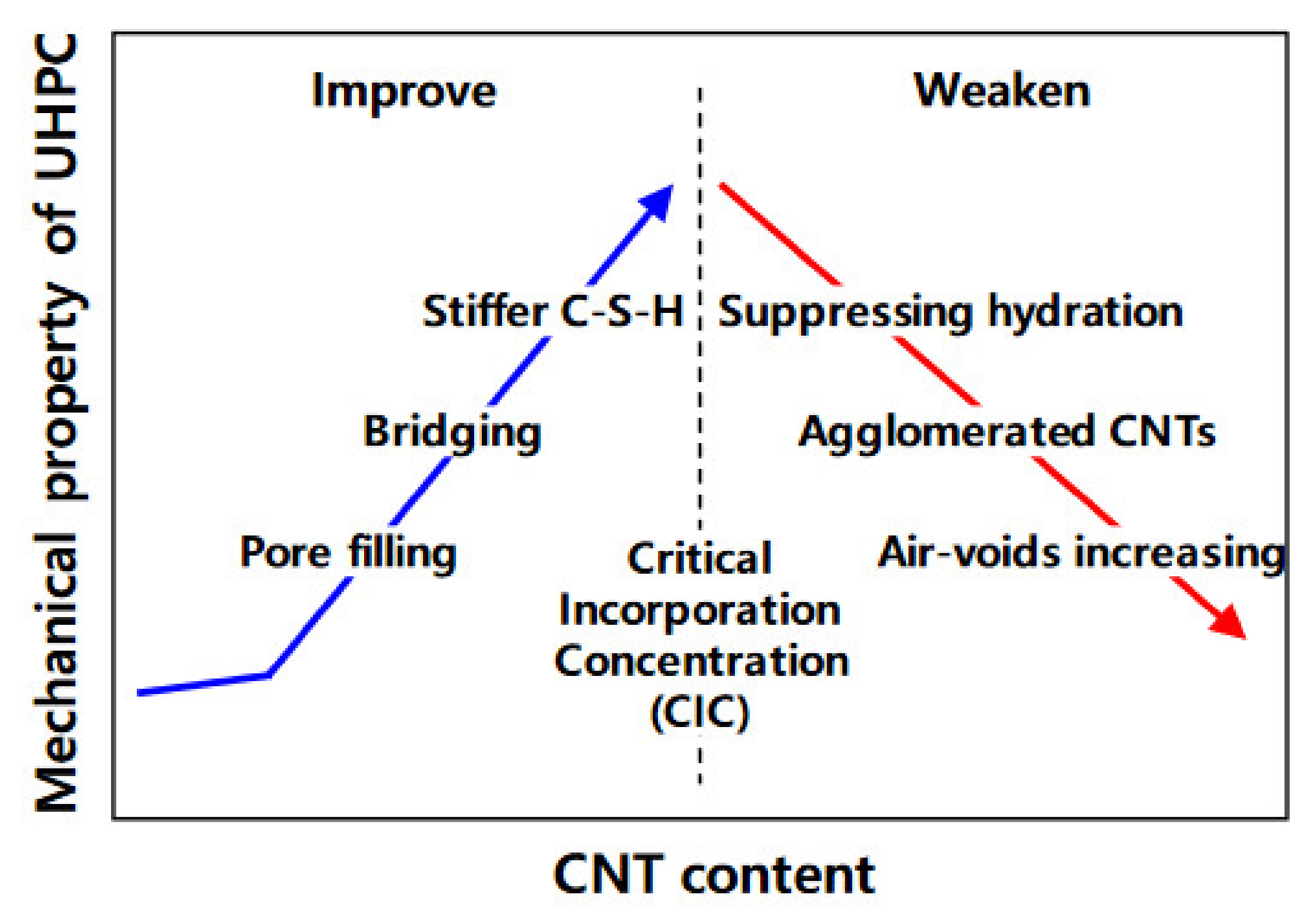

3.2. Carbon Nanotubes (CNTs)

3.3. Titanium Dioxide (TiO2)

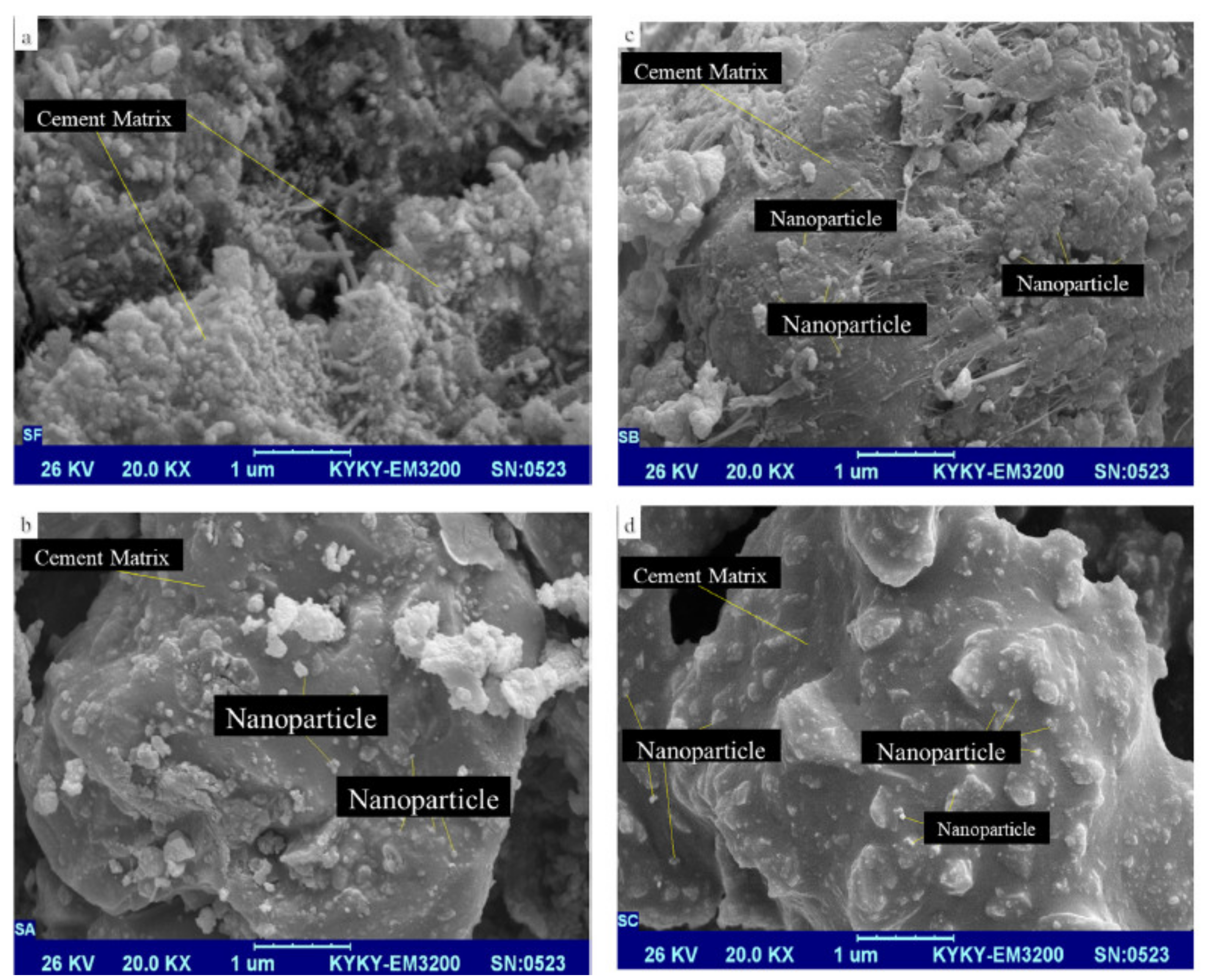

3.4. Ferric Oxide (Fe2O3)

3.5. Other Nanomaterials

4. Challenges and Limitations of Nanomaterials in Construction Industries

5. Environmental and Health Concerns of Nanomaterial Applications in Construction Industries

5.1. Risk Assessment

5.2. Health Issues Related to Nanomaterials from Construction Industry

5.3. Environmental Implications

6. Concrete Recycling

7. Future Research

8. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, X.; Deng, H.; Hwang, H.M. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Svendsen, C.; Walker, L.A.; Matzke, M.; Lahive, E.; Harrison, S.; Crossley, A.A.; Park, B.; Lofts, S.; Lynch, I.; Vázquez-Campos, S.; et al. Key principles and operational practices for improved nanotechnology environmental exposure assessment. Nat. Nanotechnol. 2020, 15, 731–742. [Google Scholar] [CrossRef] [PubMed]

- Sanzari, I.; Leone, A.; Ambrosone, A. Nanotechnology in plant science: To make a long story short. Front. Bioeng. Biotechnol. 2019, 7, 120. [Google Scholar] [CrossRef] [Green Version]

- Saleem, H.; Trabzon, L.; Kilic, A.; Zaidi, S.J. Recent advances in nanofibrous membranes: Production and applications in water treatment and desalination. Desalination 2020, 478, 114178. [Google Scholar] [CrossRef]

- Yadav, S.; Saleem, H.; Ibrar, I.; Naji, O.; Hawari, A.A.; Alanezi, A.A.; Zaidi, S.J.; Altaee, A.; Zhou, J. Recent developments in forward osmosis membranes using carbon-based nanomaterials. Desalination 2020, 482, 114375. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Nanoparticles in reverse osmosis membranes for desalination: A state of the art review. Desalination 2020, 475, 114171. [Google Scholar] [CrossRef]

- Guisbiers, G.; Mejía-Rosales, S.; Deepak, F.L. Nanomaterial properties: Size and shape dependencies. J. Nanomater. 2012, 2012, 180976. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Mohamad Ibrahim, M.N. Role of nanomaterials in the treatment of wastewater: A review. Water 2020, 12, 495. [Google Scholar] [CrossRef] [Green Version]

- Saleem, H.; Zaidi, S.J. Sustainable Use of Nanomaterials in Textiles and Their Environmental Impact. Materials 2020, 13, 5134. [Google Scholar] [CrossRef]

- Malhotra, B.D.; Ali, M.A. Nanomaterials in Biosensors. Nanomater. Biosens. 2018, 1–74. [Google Scholar] [CrossRef]

- Zaidi, S.J.; Fadhillah, F.; Saleem, H.; Hawari, A.; Benamor, A. Organically modified nanoclay filled thin-film nanocomposite membranes for reverse osmosis application. Materials 2019, 12, 3803. [Google Scholar] [CrossRef] [Green Version]

- Saleem, H.; Zaidi, S.J. Recent Developments in the Application of Nanomaterials in Agroecosystems. Nanomaterials 2020, 10, 2411. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Developments in the Application of Nanomaterials for Water Treatment and Their Impact on the Environment. Nanomaterials 2020, 10, 1764. [Google Scholar] [CrossRef] [PubMed]

- Saleem, H.; Javaid Zaidi, S. Innovative Nanostructured Membranes for Reverse Osmosis Water Desalination, Qatar University Annual Research Forum Exhibition, QUARFE 2020 Theme 1: Energy. 2020. Available online: https://qspace.qu.edu.qa/handle/10576/16558 (accessed on 5 October 2021).

- Khare, S.; Williams, K.; Gokulan, K. Nanotechnology. In Encyclopedia of Food Microbiology; Academic Press: Cambridge, MA, USA, 2014; pp. 893–900. Available online: https://www.sciencedirect.com/topics/neuroscience/nanotechnology (accessed on 5 October 2021).

- Almeida, L.; Felzenszwalb, I.; Marques, M.; Cruz, C. Nanotechnology activities: Environmental protection regulatory issues data. Heliyon 2020, 6, e05303. [Google Scholar] [CrossRef]

- Kamarulzaman, N.A.; Lee, K.E.; Siow, K.S.; Mokhtar, M. Public benefit and risk perceptions of nanotechnology development: Psychological and sociological aspects. Technol. Soc. 2020, 62, 101329. [Google Scholar] [CrossRef]

- Anandharamakrishnan, C. Trends and Impact of Nanotechnology in Agro-Food Sector. Ref. Modul. Food Sci. 2020. [Google Scholar] [CrossRef]

- Rodriguez-Narvaez, O.M.; Peralta-Hernandez, J.M.; Goonetilleke, A.; Bandala, E.R. Biochar-supported nanomaterials for environmental applications. J. Ind. Eng. Chem. 2019, 78, 21–33. [Google Scholar] [CrossRef]

- Gong, C.; Sun, S.; Zhang, Y.; Sun, L.; Su, Z.; Wu, A.; Wei, G. Hierarchical nanomaterials via biomolecular self-assembly and bioinspiration for energy and environmental applications. Nanoscale 2019, 11, 4147–4182. [Google Scholar] [CrossRef]

- Singh, B.; Na, J.; Konarova, M.; Wakihara, T.; Yamauchi, Y.; Salomon, C.; Gawande, M.B. Functional Mesoporous Silica Nanomaterials for Catalysis and Environmental Applications. Bull. Chem. Soc. Jpn. 2020, 93, 1459–1496. [Google Scholar] [CrossRef]

- Yang, L.; Yang, L.; Ding, L.; Deng, F.; Luo, X.B.; Luo, S.L. Principles for the Application of Nanomaterials in Environmental Pollution Control and Resource Reutilization. In Nanomaterials for the Removal of Pollutants and Resource Reutilization; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–23. [Google Scholar]

- Zhang, H.; Zhu, C.; Wei, C.; Duan, H.; Yu, J. Application of functionalized nanomaterials in asphalt road construction materials. In Handbook of Functionalized Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 865–907. [Google Scholar]

- Díaz-Soler, B.; López-Alonso, M.; Martínez-Aires, M.D. Nanoenabled Products Applied on Construction Sector. New Risks for Workers. In International Congress on Engineering and Sustainability in the XXI Century; Springer: Cham, Switzerland, 2019; pp. 1000–1007. [Google Scholar]

- Díaz-Soler, B.M.; Martínez-Aires, M.D.; López-Alonso, M. Potential risks posed by the use of nano-enabled construction products: A perspective from coordinators for safety and health matters. J. Clean. Prod. 2019, 220, 33–44. [Google Scholar] [CrossRef]

- Tanzadeh, J. Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 2020, 232, 117211. [Google Scholar]

- Ram, V.V.; Singhal, R.; Parameshwaran, R. Energy efficient pumpable cement concrete with nanomaterials embedded PCM for passive cooling application in buildings. Mater. Today Proc. 2020, 28, 1054–1063. [Google Scholar]

- Singh, N.B. Properties of cement and concrete in presence of nanomaterials. In Smart Nanoconcretes and Cement-Based Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 9–39. [Google Scholar]

- Pacheco-Torgal, F. Introduction to nanotechnology in eco-efficient construction. In Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Sawston, UK, 2019; pp. 1–9. [Google Scholar]

- Shah, K.W.; Li, W. A review on catalytic nanomaterials for volatile organic compounds VOC removal and their applications for healthy buildings. Nanomaterials 2019, 9, 910. [Google Scholar] [CrossRef] [Green Version]

- Dahlan, A.S. Smart and Functional Materials Based Nanomaterials in Construction Styles in Nano-Architecture. Silicon 2019, 11, 1949–1953. [Google Scholar] [CrossRef]

- Aljenbaz, A.Z.; Çağnan, Ç. Evaluation of Nanomaterials for Building Production within the Context of Sustainability. Eur. J. Sustain. Dev. 2020, 9, 53. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef] [Green Version]

- Solano, R.; Patiño-Ruiz, D.; Herrera, A. Preparation of modified paints with nano-structured additives and its potential applications. Nanomater. Nanotechnol. 2020, 10, 1847980420909188. [Google Scholar] [CrossRef]

- Zheng, L.; Xiong, T.; Shah, K.W. Transparent nanomaterial-based solar cool coatings: Synthesis, morphologies and applications. Sol. Energy 2019, 193, 837–858. [Google Scholar] [CrossRef]

- Vidales-Herrera, J.; López, I. Nanomaterials in coatings: An industrial point of view. In Handbook of Nanomaterials for Manufacturing Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 51–77. [Google Scholar]

- Saleem, H.; Zaidi, S.J.; Ismail, A.F.; Goh, P.S. Advances of nanomaterials for air pollution remediation and their impacts on the environment. Chemosphere 2022, 287, 132083. [Google Scholar] [CrossRef]

- Ali, S.I.A.; Amiruddin, I.; Nur, I.M.Y.; Norhidayah, A.H.; Ahmad, N.H.I. Characterization of the performance of aluminum oxide nanoparticles modified asphalt binder. J. Teknol. 2016, 78, 78. [Google Scholar]

- Hassan, A.; Hala, E.; Ibrahim, G.S. Effect of Adding Carbon Nanotubes on Corrosion Rates and Steel-Concrete Bond. Sci. Rep. 2019, 9, 6285. [Google Scholar] [CrossRef]

- Yu, X.; Shaobo, K.; Xu, L. Compressive strength of concrete reinforced by TiO2 nanoparticles. AIP Conf. Proc. 2018, 2036, 030006. [Google Scholar]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High strength sustainable concrete using silica nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Kurmus, H.; Milas, J.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A.A. Nanoparticles in construction materials and other applications, and implications of nanoparticle use. Materials 2019, 12, 3052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horszczaruk, E. Properties of cement-based composites modified with magnetite nanoparticles: A review. Materials 2019, 12, 326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karozou, A.; Eleni, P.; Stefanidou, M. Enhancing Properties of Clay Mortars Using Nano-Additives. Solid State Phenom. 2019, 286, 145–155. [Google Scholar] [CrossRef]

- Brooks, J. Elasticity, shrinkage, creep and thermal movement. In Advanced Concrete Technology; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Aïtcin, P.C. Portland cement. In Science and Technology of Concrete Admixtures; Elsevier: Amsterdam, The Netherlands, 2016; pp. 27–51. [Google Scholar]

- Leone, M.F. Nanotechnology for architecture. Innovation and eco-efficiency of nanostructured cement-based materials. J. Arch. Eng. Technol. 2012, 1, 1–9. [Google Scholar] [CrossRef]

- How Cement is Made? Portland Cement Association. Available online: https://www.cement.org/cement-concrete/how-cement-is-made (accessed on 6 May 2021).

- Ghasemzadeh, F.; Manafpour, A.; Sajedi, S.; Shekarchi, M.; Hatami, M. Predicting long-term compressive creep of concrete using inverse analysis method. Constr. Build. Mater. 2016, 124, 496–507. [Google Scholar] [CrossRef]

- Aili, A.; Vandamme, M.; Torrenti, J.M.; Masson, B. Is long-term autogenous shrinkage a creep phenomenon induced by capillary effects due to self-desiccation? Cem. Concr. Res. 2018, 108, 186–200. [Google Scholar] [CrossRef] [Green Version]

- Claisse, P. Introduction to cement and concrete. In Civil Engineering Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 155–162. [Google Scholar]

- Wang, Y.L.; Lee, Y.H.; Chiu, I.J.; Lin, Y.F.; Chiu, H.W. Potent impact of plastic nanomaterials and micromaterials on the food chain and human health. Int. J. Mol. Sci. 2020, 21, 1727. [Google Scholar] [CrossRef] [Green Version]

- Hochella, M.F.; Mogk, D.W.; Ranville, J.; Allen, I.C.; Luther, G.W.; Marr, L.C.; Sahai, N.; McGrail, B.P.; Murayama, M.; Qafoku, N.P.; et al. Natural, incidental, and engineered nanomaterials and their impacts on the Earth system. Science 2019, 363, 6434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miernicki, M.; Hofmann, T.; Eisenberger, I.; von der Kammer, F.; Praetorius, A. Legal and practical challenges in classifying nanomaterials according to regulatory definitions. Nat. Nanotechnol. 2019, 14, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Demir, E. A review on nanotoxicity and nanogenotoxicity of different shapes of nanomaterials. J. Appl. Toxicol. 2020, 41, 118–147. [Google Scholar] [CrossRef] [PubMed]

- Yuvaraj, M.; Yuvaraj, V.; Arunkumar, V.; Pandiyan, M.; Subramanian, K.S. Nanosafety. In Biochemical Toxicology-Heavy Metals and Nanomaterials; IntechOpen: London, UK, 2020. [Google Scholar]

- Riediker, M. Nano-safety research lessons for dealing with aerosol transmissions of COVID-19. Nanotoxicology 2020, 14, 866–868. [Google Scholar] [CrossRef] [PubMed]

- Cronin, J.G.; Jones, N.; Thornton, C.A.; Jenkins, G.J.; Doak, S.H.; Clift, M.J. Nanomaterials and innate immunity: A perspective of the current status in nanosafety. Chem. Res. Toxicol. 2020, 33, 1061–1073. [Google Scholar] [CrossRef]

- Winkler, D.A. Role of Artificial Intelligence and Machine Learning in Nanosafety. Small 2020, 16, 2001883. [Google Scholar] [CrossRef]

- Trybula, W.; Newberry, D. Progress and Upcoming Challenges of Nano-Safety: Education, Manufacture, and Long-Term Impacts. IEEE Nanotechnol. Mag. 2020, 14, 23–27. [Google Scholar] [CrossRef]

- Valdiglesias, V.; Laffon, B. The impact of nanotechnology in the current universal COVID-19 crisis. Let’s not forget nanosafety! Nanotoxicology 2020, 14, 1013–1016. [Google Scholar] [CrossRef]

- Wigger, H.; Nowack, B. Material-specific properties applied to an environmental risk assessment of engineered nanomaterials—Implications on grouping and read-across concepts. Nanotoxicology 2019, 13, 623–643. [Google Scholar] [CrossRef] [PubMed]

- Isigonis, P.; Afantitis, A.; Antunes, D.; Bartonova, A.; Beitollahi, A.; Bohmer, N.; Doak, S.; Bouman, E.; Chaudhry, Q.; Cimpan, M.R.; et al. Risk Governance of Emerging Technologies Demonstrated in Terms of its Applicability to Nanomaterials. Small 2020, 16, 2003303. [Google Scholar] [CrossRef]

- Kühnel, D.; Nickel, C.; Hellack, B.; van der Zalm, E.; Kussatz, C.; Herrchen, M.; Meisterjahn, B.; Hund-Rinke, K. Closing gaps for environmental risk screening of engineered nanomaterials. NanoImpact 2019, 15, 100173. [Google Scholar] [CrossRef]

- Auffan, M.; Masion, A.; Mouneyrac, C.; de Garidel-Thoron, C.; Hendren, C.O.; Thiery, A.; Santaella, C.; Giamberini, L.; Bottero, J.Y.; Wiesner, M.R.; et al. Contribution of mesocosm testing to a single-step and exposure-driven environmental risk assessment of engineered nanomaterials. NanoImpact 2019, 13, 66–69. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; das Neves, J.M.C.; Capitão, S.D.; de Picado-Santos, L.G. Evaluation of the durability of asphalt concrete modified with nanomaterials using the TEAGE aging method. Constr. Build. Mater. 2019, 214, 178–186. [Google Scholar] [CrossRef]

- Singh, N.B.; Saxena, S.K.; Kumar, M. Effect of nanomaterials on the properties of geopolymer mortars and concrete. Mater. Today Proc. 2018, 5, 9035–9040. [Google Scholar] [CrossRef]

- Huguet-Casquero, A.; Gainza, E.; Pedraz, J.L. Towards green nanoscience: From extraction to nanoformulation. Biotechnol. Adv. 2020, 46, 107657. [Google Scholar] [CrossRef] [PubMed]

- Yoonus, J.; Resmi, R.; Beena, B. Greener nanoscience: Piper betel leaf extract mediated synthesis of CaO nanoparticles and evaluation of its antibacterial and anticancer activity. Mater. Today Proc. 2020, 41, 535–540. [Google Scholar] [CrossRef]

- Zhuang, C.; Chen, Y. The effect of nano-SiO2 on concrete properties: A review. Nanotechnol. Rev. 2019, 8, 562–572. [Google Scholar] [CrossRef]

- Cai, X.; Hong, R.Y.; Wang, L.S.; Wang, X.Y.; Li, H.Z.; Zheng, Y.; Wei, D.G. Synthesis of silica powders by pressured carbonation. Chem. Eng. J. 2009, 151, 380–386. [Google Scholar] [CrossRef]

- Hong, R.Y.; Feng, B.; Ren, Z.Q.; Xu, B.; Li, H.Z.; Zheng, Y.; Ding, J.; Wei, D.G. Thermodynamic, hydrodynamic, particle dynamic, and experimental analyses of silica nanoparticles synthesis in diffusion flame. Can. J. Chem. Eng. 2009, 87, 143–156. [Google Scholar] [CrossRef]

- Hong, R.; Ding, J.; Li, H. Thermodynamic analysis and experimental verification for synthesizing silicon nitride nanoparticles using RF plasma CVD. China Particuology 2003, 1, 162–167. [Google Scholar] [CrossRef]

- Al-Abboodi, S.M.T.; Al-Shaibani, E.J.A.; Alrubai, E.A. Preparation and Characterization of Nano silica Prepared by Different Precipitation Methods. IOP Conf. Ser. Mater. Sci. Eng. 2020, 978, 012031. [Google Scholar] [CrossRef]

- Che, J.; Cagin, T.; Goddard, W.A., III. Thermal conductivity of carbon nanotubes. Nanotechnology 2000, 11, 65. [Google Scholar] [CrossRef]

- Pandey, P.; Dahiya, M. Carbon nanotubes: Types, methods of preparation and applications. Carbon 2016, 1, 15–21. [Google Scholar]

- Macak, J. Growth of Anodic Self-Organized Titanium Dioxide Nanotube Layers. 2008. Available online: https://opus4.kobv.de/opus4-fau/frontdoor/index/index/docId/634 (accessed on 9 October 2021).

- Pratsinis, S.E. History of Manufacture of Fine Particles in High-Temperature Aerosol Reactors. In Aerosol Science and Technology: History and Reviews; Ensor, D.S., Ed.; RTI International: Research Triangle Park, NC, USA, 2011; pp. 475–507. [Google Scholar]

- Chen, X.; Mao, S.S. Titanium dioxide nanomaterials: Synthesis, properties, modifications, and applications. Chem. Rev. 2007, 107, 2891–2959. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar] [CrossRef]

- Piqué, T.M.; Balzamo, H.; Vázquez, A. Evaluation of the hydration of portland cement modified with polyvinyl alcohol and nano clay. Key Eng. Mater. 2011, 466, 47–56. [Google Scholar] [CrossRef]

- Norhasri, M.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- AlZainati, N.; Saleem, H.; Altaee, A.; Zaidi, S.J.; Mohsen, M.; Hawari, A.; Millar, G.J. Pressure retarded osmosis: Advancement, challenges and potential. J. Water Process. Eng. 2021, 40, 101950. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef] [Green Version]

- Rollins, A.B.; Collet, P.E.P.; Andres, V. Concrete Porosity Reduction by Colloidal Silica Nano Technology, Part 2: One Year Results from Djeno Wharf. Available online: https://www.pci.org/PCI_Docs/Papers/2018/10001_Final_Paper.pdf (accessed on 9 October 2021).

- Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; El-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Elrahman, M.A. Influence of nanoparticles from waste materials on mechanical properties, durability and microstructure of UHPC. Materials 2020, 13, 4530. [Google Scholar] [CrossRef] [PubMed]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Najigivi, A.; Khaloo, A.; Rashid, S.A. Investigating the effects of using different types of SiO2 nanoparticles on the mechanical properties of binary blended concrete. Compos. Part B Eng. 2013, 54, 52–58. [Google Scholar] [CrossRef]

- Barbhuiya, G.H.; Moiz, M.A.; Hasan, S.D.; Zaheer, M.M. Effects of the nanosilica addition on cement concrete: A review. Mater. Today Proc. 2020, 32, 560–566. [Google Scholar] [CrossRef]

- Sobolev, K.; Gutiérrez, M.F. How nanotechnology can change the concrete world: Part two of a two-part series. Am. Ceram. Soc. Bull. 2005, 84, 16–19. [Google Scholar]

- Kim, G.M.; Yang, B.J.; Ryu, G.U.; Lee, H.K. The electrically conductive carbon nanotube (CNT)/cement composites for accelerated curing and thermal cracking reduction. Compos. Struct. 2016, 158, 20–29. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Al Ansari, M.S.; Taha, R.; Al Nuaimi, N.; Taqa, A.A. Carbon nanotube effect on the ductility, flexural strength, and permeability of concrete. J. Nanomater. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Yıldırım, G.; Sarwary, M.H.; Al-Dahawi, A.; Öztürk, O.; Anıl, Ö.; Şahmaran, M. Piezoresistive behavior of CF- and CNT-based reinforced concrete beams subjected to static flexural loading: Shear failure investigation. Constr. Build. Mater. 2018, 168, 266–279. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudzionis, Z.; Ghosh, R. Influence of CNT, graphene nanoplate and CNT-graphene nanoplate hybrid on the properties of lightweight concrete. Mater. Today Proc. 2021, 44, 1979–1982. [Google Scholar] [CrossRef]

- Lushnikova, A.; Zaoui, A. Improving mechanical properties of CSH from inserted carbon nanotubes. J. Phys. Chem. Solids 2017, 105, 72–80. [Google Scholar] [CrossRef]

- Chandran, R.B. Macroscopic CNTs as promising reinforcements for concrete structures. In Smart Nanoconcretes and Cement-Based Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 637–648. [Google Scholar]

- Yu, Z.; Lau, D. Evaluation on mechanical enhancement and fire resistance of carbon nanotube (CNT) reinforced concrete. Coupled Syst. Mech. 2017, 6, 335–349. [Google Scholar]

- Jung, M.; Lee, Y.S.; Hong, S.G.; Moon, J. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 2020, 131, 106017. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Zanfir, A.V.; Voicu, G.; Bădănoiu, A.I.; Gogan, D.; Oprea, O.; Vasile, E. Synthesis and characterization of titania-silica fume composites and their influence on the strength of self-cleaning mortar. Compos. Part B Eng. 2018, 140, 157–163. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Mehdipour, S.; Dezhampanah, S.; Mohammadi, R.; Mohebbi, R.; Moghadam, H.H.; Sadrmomtazi, A. Effect of high temperature on mechanical and gamma ray shielding properties of concrete containing nano-TiO2. Radiat. Phys. Chem. 2020, 174, 108967. [Google Scholar] [CrossRef]

- Cardellicchio, L. On conservation issues of contemporary architecture: The technical design development and the ageing process of the Jubilee Church in Rome by Richard Meier. Front. Arch. Res. 2018, 7, 107–121. [Google Scholar] [CrossRef]

- Kani, E.N.; Rafiean, A.H.; Alishah, A.; Astani, S.H.; Ghaffar, S.H. The effects of Nano-Fe2O3 on the mechanical, physical and microstructure of cementitious composites. Constr. Build. Mater. 2021, 266, 121137. [Google Scholar] [CrossRef]

- Heikal, M.; Zaki, M.E.; Ibrahim, S.M. Characterization, hydration, durability of nano-Fe2O3-composite cements subjected to sulphates and chlorides media. Constr. Build. Mater. 2021, 269, 121310. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Szymańska-Chargot, M.; Jarosz-Hadam, M.; Łagód, G. Effect of cellulose nanofibrils and nanocrystals on physical properties of concrete. Constr. Build. Mater. 2019, 223, 1–11. [Google Scholar] [CrossRef]

- Gao, Y.; He, B.; Li, Y.; Tang, J.; Qu, L. Effects of nano-particles on improvement in wear resistance and drying shrinkage of road fly ash concrete. Constr. Build. Mater. 2017, 151, 228–235. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Gonzalez, M.; Tighe, S.L.; Hui, K.; Rahman, S.; Lima, A.D.O. Evaluation of freeze/thaw and scaling response of nanoconcrete for Portland Cement Concrete (PCC) pavements. Constr. Build. Mater. 2016, 120, 465–472. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, J. Effects of amorphous nano-silica additions on mechanical and durability performance of SCC mixtures. In Proceedings of the International Congress on Durability of Concrete (ICDC 2012), Trondhelm, Norway, 18–21 June 2012; Norsk Betongforening: Oslo, Norway, 2012; pp. 18–21. [Google Scholar]

- Li, H.; Zhang, M.H.; Ou, J.P. Abrasion resistance of concrete containing nano-particles for pavement. Wear 2006, 260, 1262–1266. [Google Scholar] [CrossRef]

- Ghafoori, N.; Najimi, M. Sulfate resistance of nanosilica and microsilica contained mortars. ACI Mater. J. 2016, 113, 113. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The effect of elevated temperature on the properties of cement mortars containing nanosilica and heavyweight aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Zaheer, M.M.; Hasan, S.D. Mechanical and durability performance of carbon nanotubes (CNTs) and nanosilica (NS) admixed cement mortar. Mater. Today Proc. 2021, 42, 1422–1431. [Google Scholar]

- Narasimman, K.; Jassam, T.M.; Velayutham, T.S.; Yaseer, M.M.M.; Ruzaimah, R. The synergic influence of carbon nanotube and nanosilica on the compressive strength of lightweight concrete. J. Build. Eng. 2020, 32, 101719. [Google Scholar] [CrossRef]

- De Volder, M.F.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World’s First Super-Growth Carbon Nanotube Mass Production PlantOpens, ZEON, Press Releases. Available online: https://www.zeon.co.jp/en/news/assets/pdf/151104.pdf (accessed on 6 May 2021).

- Zhao, W.; Yu, X.; Peng, S.; Luo, Y.; Li, J.; Lu, L. Construction of nanomaterials as contrast agents or probes for glioma imaging. J. Nanobiotechnol. 2021, 19, 1–31. [Google Scholar] [CrossRef] [PubMed]

- Vinodhini, C.; Rajeshkumar, V.; Anandraj, S.; Kavitha, R.; Logsehwaran, S.; Kapildev, C. Review of Nanomaterials in Construction. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1145, 012016. [Google Scholar] [CrossRef]

- Nawar, A.H. Nano-technologies and nano-materials for civil engineering construction works applications. Mater. Today Proc. 2021, 497. [Google Scholar] [CrossRef]

- Ou, C.; Wang, D. Structural Performance Characteristics of Nanomaterials and Its Application in Traditional Architectural Cultural Design and Landscape Planning. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Verma, A.; Yadav, M. Application of nanomaterials in architecture—An overview. Mater. Today Proc. 2021, 43, 2921–2925. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. Use of nanomaterial for asphalt binder and mixtures: A comprehensive review on development, prospect, and challenges. Road Mater. Pavement Des. 2021, 22, 492–538. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Colangiuli, D.; Calia, A.; Bianco, N. Novel multifunctional coatings with photocatalytic and hydrophobic properties for the preservation of the stone building heritage. Constr. Build. Mater. 2015, 93, 189–196. [Google Scholar] [CrossRef]

- Papanikolaou, I.; de Souza, L.R.; Litina, C.; Al-Tabbaa, A. Investigation of the dispersion of multi-layer graphene nanoplatelets in cement composites using different superplasticiser treatments. Constr. Build. Mater. 2021, 293, 123543. [Google Scholar] [CrossRef]

- Chanda, S.; Bajwa, D.S. A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices. Rev. Adv. Mater. Sci. 2021, 60, 325–341. [Google Scholar] [CrossRef]

- Mudimela, P.R.; Nasibulina, L.I.; Nasibulin, A.G.; Cwirzen, A.; Valkeapää, M.; Habermehl-Cwirzen, K.; Malm, J.E.; Karppinen, M.J.; Penttala, V.; Koltsova, T.S.; et al. Synthesis of carbon nanotubes and nanofibers on silica and cement matrix materials. J. Nanomater. 2009, 2009. [Google Scholar] [CrossRef]

- Wu, S.; Tahri, O. State-of-art carbon and graphene family nanomaterials for asphalt modification. Road Mater. Pavement Des. 2021, 22, 735–756. [Google Scholar] [CrossRef]

- Ali, R.A.; Kharofa, O.H. The impact of nanomaterials on sustainable architectural applications smart concrete as a model. Mater. Today Proc. 2021, 42, 3010–3017. [Google Scholar] [CrossRef]

- Feng, H.; Zhao, X.; Li, L.; Zhao, X.; Gao, D. Water stability of bonding properties between nano-Fe2O3-modified magnesium-phosphate-cement mortar and steel fibre. Constr. Build. Mater. 2021, 291, 123316. [Google Scholar] [CrossRef]

- Hou, L.; Li, J.; Lu, Z.; Niu, Y. Influence of foaming agent on cement and foam concrete. Constr. Build. Mater. 2021, 280, 122399. [Google Scholar] [CrossRef]

- Srinivas, K. Nanomaterials for concrete technology. Int. J. Civ. Struct. Environ. Infrastruct. Eng. Res. Dev. 2014, 1, 79–90. [Google Scholar]

- Gamal, H.A.; El-Feky, M.S.; Alharbi, Y.R.; Abadel, A.A.; Kohail, M. Enhancement of the concrete durability with hybrid nano materials. Sustainability 2021, 13, 1373. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Huseien, G.F.; Lim, N.H.A.S.; Amran, M.; Samadi, M. Effect of nanomaterials inclusion on sustainability of cement-based concretes: A comprehensive review. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar] [CrossRef]

- Rana, A.K.; Rana, S.B.; Kumari, A.; Kiran, V. Significance of nanotechnology in construction engineering. Int. J. Recent Trends Eng. 2009, 1, 46. [Google Scholar]

- Mallakpour, S.; Hussain, C.M.; Ajith, S.; Arumugaprabu, V. Environmental and Occupational Health Hazards of Nanomaterials in Construction Sites. Handb. Consum. Nanoproducts 2021, 1–12. [Google Scholar] [CrossRef]

- Onyango, J. Health Impacts of Building Materials on Construction Workers. In Ecological and Health Effects of Building Materials; Springer: Cham, Switzerland, 2022; pp. 543–566. [Google Scholar]

- Santhosh, G.; Nayaka, G.P. Nanoparticles in Construction Industry and Their Toxicity. In Ecological and Health Effects of Building Materials; Springer: Cham, Switzerland, 2022; pp. 133–146. [Google Scholar]

- Thakur, M.; Sharma, A.; Chandel, M.; Pathania, D. Modern applications and current status of green nanotechnology in environmental industry. In Green Functionalized Nanomaterials for Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 259–281. [Google Scholar]

- Karnena, M.K.; Konni, M.; Saritha, V. Occupational Health Problems of Construction Workers. In Ecological and Health Effects of Building Materials; Springer: Cham, Switzerland, 2022; pp. 405–426. [Google Scholar]

- Gupta, A.D.; Patil, S.Z. Potential Environmental Impacts of Nanoparticles Used in Construction Industry. In Ecological and Health Effects of Building Materials; Springer: Cham, Switzerland, 2022; pp. 159–183. [Google Scholar]

- Joglekar, S.; Gajaralwar, R. Potential risk and safety concerns of industrial nanomaterials in environmental management. In Handbook of Nanomaterials for Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1057–1079. [Google Scholar]

- Cook, L.; Wantenaar, C.; Wise, B. An Exploratory Study of the Cutting-Edge Development of Nanotechnology Pertaining to the Construction Industry. Mater. Sci. Forum 2021, 1046, 95–103. [Google Scholar] [CrossRef]

- Singh, D.; Marrocco, A.; Wohlleben, W.; Park, H.R.; Diwadkar, A.R.; Himes, B.E.; Lu, Q.; Christiani, D.C.; Demokritou, P. Release of particulate matter from nano-enabled building materials (NEBMs) across their lifecycle: Potential occupational health and safety implications. J. Hazard. Mater. 2022, 422, 126771. [Google Scholar] [CrossRef]

- Augustyniak, A.; Jablonska, J.; Cendrowski, K.; Głowacka, A.; Stephan, D.; Mijowska, E.; Sikora, P. Investigating the release of ZnO nanoparticles from cement mortars on microbiological models. Appl. Nanosci. 2021, 1–14. [Google Scholar] [CrossRef]

- Allujami, H.M.; Jassam, T.M.; Al-Mansob, R.A. Nanomaterials characteristics and current utilization status in rigid pavements: Mechanical features and Sustainability. A review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement Matrix Materials: How Nanofiller Can Help a Sustainability Approach for Smart Construction Applications—A Review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef]

- García-Quintero, A.; Palencia, M. A critical analysis of environmental sustainability metrics applied to green synthesis of nanomaterials and the assessment of environmental risks associated with the nanotechnology. Sci. Total Environ. 2021, 793, 148524. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, L.; Jenifer, M.A.; Mukherjee, A. Eco-Corona Formation on the Nanomaterials in the aquatic systems lessens their toxic impact: A comprehensive review. Environ. Res. 2020, 194, 110669. [Google Scholar] [CrossRef]

- Jin, M.; Li, N.; Sheng, W.; Ji, X.; Liang, X.; Kong, B.; Yin, P.; Li, Y.; Zhang, X.; Liu, K. Toxicity of different zinc oxide nanomaterials and dose-dependent onset and development of Parkinson’s disease-like symptoms induced by zinc oxide nanorods. Environ. Int. 2020, 146, 106179. [Google Scholar] [CrossRef]

- Wu, D.; Ma, Y.; Cao, Y.; Zhang, T. Mitochondrial toxicity of nanomaterials. Sci. Total Environ. 2020, 702, 134994. [Google Scholar] [CrossRef]

- Samadi, S.; Lajayer, B.A.; Moghiseh, E.; Rodríguez-Couto, S. Effect of carbon nanomaterials on cell toxicity, biomass production, nutritional and active compound accumulation in plants. Environ. Technol. Innov. 2020, 21, 101323. [Google Scholar] [CrossRef]

- Caixeta, M.B.; Araújo, P.S.; Gonçalves, B.B.; Silva, L.D.; Grano-Maldonado, M.I.; Rocha, T.L. Toxicity of engineered nanomaterials to aquatic and land snails: A scientometric and systematic review. Chemosphere 2020, 260, 127654. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Verma, H.K.; Mohnot, J.K. Recycling of dimensional stone waste in concrete: A review. J. Clean. Prod. 2016, 135, 312–331. [Google Scholar] [CrossRef]

- Ji, Z.; Guo, W.; Sakkiah, S.; Liu, J.; Patterson, T.A.; Hong, H. Nanomaterial Databases: Data Sources for Promoting Design and Risk Assessment of Nanomaterials. Nanomaterials 2021, 11, 1599. [Google Scholar] [CrossRef]

- Radnik, J.; Kersting, R.; Hagenhoff, B.; Bennet, F.; Ciornii, D.; Nymark, P.; Grafstrom, R.; Hodoroaba, V.D. Reliable Surface Analysis Data of Nanomaterials in Support of Risk Assessment Based on Minimum Information Requirements. Nanomaterials 2021, 11, 639. [Google Scholar] [CrossRef]

- Ha, J. Novel Applications of Nanoparticles in Nature and Building Materials. In Novel Nanomaterials; IntechOpen: London, UK, 2021; p. 331. Available online: https://www.intechopen.com/chapters/76700 (accessed on 5 October 2021). [CrossRef]

- Vera-Agullo, J.; Chozas-Ligero, V.; Portillo-Rico, D.; García-Casas, M.J.; Gutiérrez-Martínez, A.; Mieres-Royo, J.M.; Grávalos-Moreno, J. Mortar and concrete reinforced with nanomaterials. Nanotechnol. Constr. 2009, 383–388. [Google Scholar] [CrossRef]

- He, X.; Shi, X. Chloride permeability and microstructure of Portland cement mortars incorporating nanomaterials. Transp. Res. Rec. 2008, 2070, 13–21. [Google Scholar] [CrossRef]

- Karthick, S.; Park, D.J.; Lee, Y.S.; Saraswathy, V.; Lee, H.S.; Jang, H.O.; Choi, H.J. Development of water-repellent cement mortar using silane enriched with nanomaterials. Prog. Org. Coat. 2018, 125, 48–60. [Google Scholar] [CrossRef]

- Lee, J.; Mahendra, S.; Alvarez, P.J. Nanomaterials in the construction industry: A review of their applications and environmental health and safety considerations. ACS Nano 2010, 4, 3580–3590. [Google Scholar] [CrossRef]

- Jones, W.; Gibb, A.; Goodier, C.; Bust, P.; Jin, J.; Song, M. Nanomaterials in construction and demolition-how can we assess the risk if we don’t know where they are? J. Phys. Conf. Ser. 2015, 617, 012031. [Google Scholar] [CrossRef] [Green Version]

- Al-Bayati, A.J.; Al-Zubaidi, H.A. Inventory of Nanomaterials in Construction Products for Safety and Health. J. Constr. Eng. Manag. 2018, 144, 06018004. [Google Scholar] [CrossRef]

- Jones, W.; Gibb, A.; Goodier, C.; Bust, P.; Song, M.; Jin, J. Nanomaterials in construction—What is being used, and where? Proc. Inst. Civ. Eng. Constr. Mater. 2019, 172, 49–62. [Google Scholar] [CrossRef] [Green Version]

- Kamali, S.; Sanajou, S.; Tazehzadeh, M.N. Nanomaterials in Construction and their Potential Impacts on Human Health and the Environment. Environ. Eng. Manag. J. (EEMJ) 2019, 18, 2305–2318. [Google Scholar] [CrossRef]

- Lee, J.; Mahendra, S.; Alvarez, P.J.J. Potential environmental and human health impacts of nanomaterials used in the construction industry. Nanotechnol. Constr. 2009, 3, 1–14. [Google Scholar]

- Sofranko, A.; Wahle, T.; Heusinkveld, H.J.; Stahlmecke, B.; Dronov, M.; Pijnenburg, D.; Hilhorst, R.; Lamann, K.; Albrecht, C.; Schins, R.P. Evaluation of the neurotoxic effects of engineered nanomaterials in C57BL/6J mice in 28-day oral exposure studies. NeuroToxicology 2021, 84, 155–171. [Google Scholar] [CrossRef] [PubMed]

- Ndika, J.; Karisola, P.; Kinaret, P.; Ilves, M.; Alenius, H. Profiling Non-Coding RNA Changes Associated with 16 Different Engineered Nanomaterials in a Mouse Airway Exposure Model. Cells 2021, 10, 1085. [Google Scholar] [CrossRef] [PubMed]

- Wils, R.S.; Jacobsen, N.R.; Di Ianni, E.; Roursgaard, M.; Møller, P. Reactive oxygen species production, genotoxicity and telomere length in FE1-Muta™ Mouse lung epithelial cells exposed to carbon nanotubes. Nanotoxicology 2021, 15, 661–672. [Google Scholar] [CrossRef] [PubMed]

- Adedara, I.A.; Anao, O.O.; Forcados, G.E.; Awogbindin, I.O.; Agbowo, A.; Ola-Davies, O.E.; Patlolla, A.K.; Tchounwou, P.B.; Farombi, E.O. Low doses of multi-walled carbon nanotubes elicit hepatotoxicity in rats with markers of oxidative stress and induction of pro-inflammatory cytokines. Biochem. Biophys. Res. Commun. 2018, 503, 3167–3173. [Google Scholar] [CrossRef]

- Migliore, L.; Uboldi, C.; Di Bucchianico, S.; Coppedè, F. Nanomaterials and Neurodegeneration. Environ. Mol. Mutagenesis 2015, 56, 149–170. [Google Scholar] [CrossRef] [Green Version]

- Grande, F.; Tucci, P. Titanium dioxide nanoparticles: A risk for human health? Mini Rev. Med. Chem. 2016, 16, 762–769. [Google Scholar] [CrossRef] [PubMed]

- Wiemann, M.; Vennemann, A.; Blaske, F.; Sperling, M.; Karst, U. Silver nanoparticles in the lung: Toxic effects and focal accumulation of silver in remote organs. Nanomaterials 2017, 7, 441. [Google Scholar] [CrossRef] [Green Version]

- Gaharwar, U.S.; Meena, R.; Rajamani, P. Iron oxide nanoparticles induced cytotoxicity, oxidative stress and DNA damage in lymphocytes. J. Appl. Toxicol. 2017, 37, 1232–1244. [Google Scholar] [CrossRef] [PubMed]

- Ickrath, P.; Wagner, M.; Scherzad, A.; Gehrke, T.; Burghartz, M.; Hagen, R.; Radeloff, K.; Kleinsasser, N.; Hackenberg, S. Time-dependent toxic and genotoxic effects of zinc oxide nanoparticles after long-term and repetitive exposure to human mesenchymal stem cells. Int. J. Environ. Res. Public Health 2017, 12, 1590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hansen, S.F.; Hjorth, R.; Skjolding, L.M.; Bowman, D.M.; Maynard, A.; Baun, A. A critical analysis of the environmental dossiers from the OECD sponsorship programme for the testing of manufactured nanomaterials. Environ. Sci. Nano 2017, 4, 282–291. [Google Scholar] [CrossRef] [Green Version]

- NIOSH. Current Intelligence Bulletin 63, Occupational Exposure to Titanium Dioxide; NIOSH: Cincinnati, OH, USA, 2011. [Google Scholar]

- NIOSH. NIOSH Current Intelligence Bulletin Occupational Exposure to Carbon Nanotubes and Nanofibers; NIOSH: Cincinnati, OH, USA, 2010. [Google Scholar]

- Raftis, J.B.; Miller, M.R. Nanoparticle translocation and multi-organ toxicity: A particularly small problem. Nano Today 2019, 26, 8–12. [Google Scholar] [CrossRef]

- Spitzmiller, M.; Mahendra, S.; Damoiseaux, R. Safety issues relating to nanomaterials for construction applications. In Nanotechnology in Eco-Efficient Construction; Elsevier: Amsterdam, The Netherlands, 2013; pp. 127–158. [Google Scholar]

- Díaz-Soler, B.M.; Martínez-Aires, M.D.; López-Alonso, M. Emerging risk in the construction industry: Recommendations for managing exposure to nanomaterials. Dyna 2016, 83, 48–54. [Google Scholar] [CrossRef]

- Yin, Y.; Yu, S.; Shen, M.; Liu, J.; Jiang, G. Fate and transport of silver nanoparticles in the environment. In Silver Nanoparticles in the Environment; Springer: Berlin/Heidelberg, Germany, 2015; pp. 73–108. [Google Scholar]

- Part, F.; Berge, N.; Baran, P.; Stringfellow, A.; Sun, W.; Bartelt-Hunt, S.; Mitrano, D.; Li, L.; Hennebert, P.; Quicker, P.; et al. A review of the fate of engineered nanomaterials in municipal solid waste streams. Waste Manag. 2018, 75, 427–449. [Google Scholar] [CrossRef] [Green Version]

- Holder, A.L.; Vejerano, E.P.; Zhou, X.; Marr, L.C. Nanomaterial disposal by incineration. Environ. Sci. Process. Impacts 2013, 15, 1652–1664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Zhu, X. Measurement of formaldehyde and VOCs emissions from wood-based panels with nanomaterial-added melamine-impregnated paper. Constr. Build. Mater. 2014, 66, 132–137. [Google Scholar] [CrossRef]

- Zheng, S.; Zhou, Q.; Chen, C.; Yang, F.; Cai, Z.; Li, D.; Geng, Q.; Feng, Y.; Wang, H. Role of extracellular polymeric substances on the behavior and toxicity of silver nanoparticles and ions to green algae Chlorella vulgaris. Sci. Total Environ. 2019, 660, 1182–1190. [Google Scholar] [CrossRef] [PubMed]

- Oh, D.; Noguchi, T.; Kitagaki, R.; Choi, H. Proposal of demolished concrete recycling system based on performance evaluation of inorganic building materials manufactured from waste concrete powder. Renew. Sustain. Energy Rev. 2021, 135, 110147. [Google Scholar] [CrossRef]

- Tsydenova, N.; Becker, T.; Walther, G. Optimised design of concrete recycling networks: The case of North Rhine-Westphalia. Waste Manag. 2021, 135, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Kasal, B.; Li, W.; Jin, R.; Wang, Y.; Li, Y.; Deng, P. Compressive performance of fiber reinforced polymer encased recycled concrete with nanoparticles. J. Mater. Res. Technol. 2021, 14, 2727–2738. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of steel slag aggregate in portland cement concrete: An overview. J. Clean. Prod. 2021, 282, 124447. [Google Scholar] [CrossRef]

- Guo, F.; Li, H. Influence of Nanomaterials on Physical Mechanics and Durability of Concrete Composite Piers. Integr. Ferroelectr. 2021, 216, 108–121. [Google Scholar] [CrossRef]

- Li, W.; Luo, Z.; Long, C.; Wu, C.; Duan, W.H.; Shah, S.P. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater. Des. 2016, 112, 58–66. [Google Scholar] [CrossRef]

- Agarwal, A.; Bhusnur, S.; Priya, T.S. Experimental Investigation on Recycled Aggregate with Laboratory Concrete Waste and Nano-Silica. Mater. Today Proc. 2020, 22, 1433–1442. [Google Scholar] [CrossRef]

- Hosseini, P.; Booshehrian, A.; Madari, A. Developing concrete recycling strategies by utilization of nano-SiO 2 particles. Waste Biomass Valorization 2011, 2, 347–355. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, F.; Wang, Y.; Zhang, X.; Niu, H. Impact Properties of Recycled Aggregate Concrete with Nanosilica Modification. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Mukharjee, B.B.; Barai, S.V. Development of construction materials using nano-silica and aggregates recycled from construction and demolition waste. Waste Manag. Res. 2015, 33, 515–523. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhuo, J.; Zhang, P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete. Constr. Build. Mater. 2021, 304, 124659. [Google Scholar] [CrossRef]

- Bang, S.S.; Lippert, J.J.; Yerra, U.; Mulukutla, S.; Ramakrishnan, V. Microbial calcite, a bio-based smart nanomaterial in concrete remediation. Int. J. Smart Nano Mater. 2010, 1, 28–39. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Omiotek, Z.; Szafraniec, M.; Dzierżak, R. An integrated texture analysis and machine learning approach for durability assessment of lightweight cement composites with hydrophobic coatings modified by nanocellulose. Measurement 2021, 179, 109538. [Google Scholar] [CrossRef]

- Teizer, J.; Venugopal, M.; Teizer, W.; Felkl, J. Nanotechnology and its impact on construction: Bridging the gap between researchers and industry professionals. J. Constr. Eng. Manag. 2012, 138, 594–604. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Panesar, D.K. Nano reinforced cement paste composite with functionalized graphene and pristine graphene nanoplatelets. Compos. Part B Eng. 2020, 197, 108063. [Google Scholar] [CrossRef]

| Sl. No. | Nanomaterial Used | Application Area in Construction | Properties | Reference |

|---|---|---|---|---|

| 1 | Aluminium oxide nanoparticles | Asphalt concrete, timber | Increased serviceability | [39] |

| 2 | Carbon nanotubes | Concrete | Crack prevention, mechanical durability | [40] |

| 3 | Titania nanoparticles | Concrete | Self-cleaning, increased degree of hydration | [41] |

| 4 | Silica nanoparticles | Concrete | Rapid hydration, reinforcement of mechanical strength | [42] |

| 5 | Copper nanoparticles | Steel | Formability, corrosion resistance | [43] |

| 6 | Iron oxide nanoparticles | Concrete | Abrasion-resistant, increased compressive strength | [44] |

| 7 | Clay nanoparticles | Bricks and mortar | Increased surface roughness and compressive strength | [45] |

| Sl. No. | Nanomaterial Used | Function | Details | Reference |

|---|---|---|---|---|

| 1 | Nanosilica | Overcome physical deteriorations—shrinkage | Nanosilica aggravated the drying shrinkage when admixed in cement composites | [109] |

| 2 | Carbon nanotubes | Overcome physical deteriorations—shrinkage | The admixed CNT decreased the porosity of the cementitious matrix | [110] |

| 3 | Nanosilica | Overcome physical deteriorations—freeze–thaw damage | Nanosilica reduced the frost damage | [111] |

| 4 | Nanosilica | Overcome physical deteriorations—freeze–thaw damage | Nanosilica improved the freeze–thaw resistance | [112] |

| 5 | Nanosilica | Overcome physical deteriorations—freeze–abrasion/erosion | Nanosilica increased the abrasion resistance | [109] |

| 6 | Nano-TiO2 | Overcome physical deteriorations—freeze–abrasion/erosion | Nano-TiO2 increased the abrasion resistance | [113] |

| 7 | Nanosilica | Overcome chemical deteriorations—sulfate attack | Nanosilica decreased the mortar expansion | [114] |

| 8 | Nanosilica | Overcome chemical deteriorations—thermal degradation | Nanosilica increased the thermal resistance of the cement mortar | [115] |

| 9 | Carbon nanotubes and nanosilica | Improvement of mechanical properties | Compressive and flexural strength were enhanced for the nano-admixed mortar | [116] |

| 10 | Carbon nanotubes and nanosilica | Improvement of mechanical properties | Nanomaterials improved the compressive strength | [117] |

| Sl. No. | Nanomaterials Used | Property Improvements in Concrete |

|---|---|---|

| 1 | Nanosilica |

|

| 2 | Carbon nanotubes |

|

| 3 | Nano-TiO2 |

|

| 4 | Nano-Fe2O3 |

|

| Sl. No. | Nanomaterial | Construction Industry Application | Affected System/Organ/Cell | References |

|---|---|---|---|---|

| 1 | Carbon nanotubes | Concrete, ceramics | Inflammation, oxidative stress | [173] |

| 2 | SiO2 nanoparticles | Windows, ceramics, concrete | Bronchoalveolar carcinoma-derived cells | [174] |

| 3 | TiO2 nanoparticles | Windows, cement | Cell death, carcinogenesis, metabolic changes | [175] |

| 4 | Silver nanoparticles | Biocidal activity | Fibroblast, reproductive organs, vascular system, carcinogenesis, brain, liver, lungs, immune system | [176] |

| 5 | Iron oxide nanoparticles | Concrete | Oxidative DNA damage | [177] |

| 6 | Zinc oxide Nanoparticles | Sensors | Cell proliferation | [178] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleem, H.; Zaidi, S.J.; Alnuaimi, N.A. Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials 2021, 14, 6387. https://doi.org/10.3390/ma14216387

Saleem H, Zaidi SJ, Alnuaimi NA. Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials. 2021; 14(21):6387. https://doi.org/10.3390/ma14216387

Chicago/Turabian StyleSaleem, Haleema, Syed Javaid Zaidi, and Nasser Abdullah Alnuaimi. 2021. "Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact" Materials 14, no. 21: 6387. https://doi.org/10.3390/ma14216387

APA StyleSaleem, H., Zaidi, S. J., & Alnuaimi, N. A. (2021). Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials, 14(21), 6387. https://doi.org/10.3390/ma14216387