1. Introduction

The management of waste has drawn the concern of industrialists and researchers in recent years to decrease environmental hazards and problems. The globe is observing a constant growth in the generation of waste products from the evolution of industrial projects consumed by man. Numerous efforts have been made to invent and use scientific and economic approaches to maximize the advantages of these wastes [

1]. Despite the works and studies, several gases and solids drain into the environment without any treatment, leading to severe risks for water and air. The issue is how the wastes can be utilized to avoid environmental damage that is reflected in climate change.

The remains of the petroleum industry are one of the most crucial industrial by-products in the world, especially in countries that are exporting oil such as Malaysia. In Malaysia, one typical refinery with the capacity to manufacture 105,000 barrels/day can produce another 50 tons of oily sludge (petroleum sludge) per year. The tremendous amount of wastes generated is alarmingly increasing as the production of crude oil becomes more important in time because crude oil is the sole source of energy and acts as feedstock in refineries [

2]. Oily sludge is the result of several processes of the oil industry (wells drilling, crude oil pools, refining, transporting, and storage tanks) [

3]. Oily sludge is a hazardous waste containing a complex mixture of different emulsified petroleum hydrocarbons, water, heavy metals, and solid particles. Oily sludge contains large amounts of crude oil, heavy metal ions, inorganic salts, polycyclic aromatic hydrocarbons (PAHs), and other toxic substances that contaminate the soil, surface, and groundwater [

4,

5]. According to the Resources Conservation and Recovery Act (RCRA), oily sludge is a hazardous waste that affects the environment and the living things if it is disposed of improperly [

6]. Effective management of the oily sludge waste is urgently required, where its resulting reuse and recycling represent ideal opportunities for sustainable development [

7].

There are different techniques for the treatment of oily sludge, and the choice depends on the desired aim to be achieved [

8]. Various oily sludge treatment methods include centrifugation, froth flotation, solidification/stabilization, solvent extraction, surfactant EOR (enhanced oil recovery), landfarming, pyrolysis, biodegradation, photocatalysis, ultrasonic treatment, and incineration [

9,

10,

11,

12,

13]. Researchers have concluded that it is ineffective to implement a typical method to fully remove the dangers of the oily sludge without any side-effects, and these methods may either partially or fully decrease the harmful substances in petroleum sludge to a minimum acceptable level [

14].

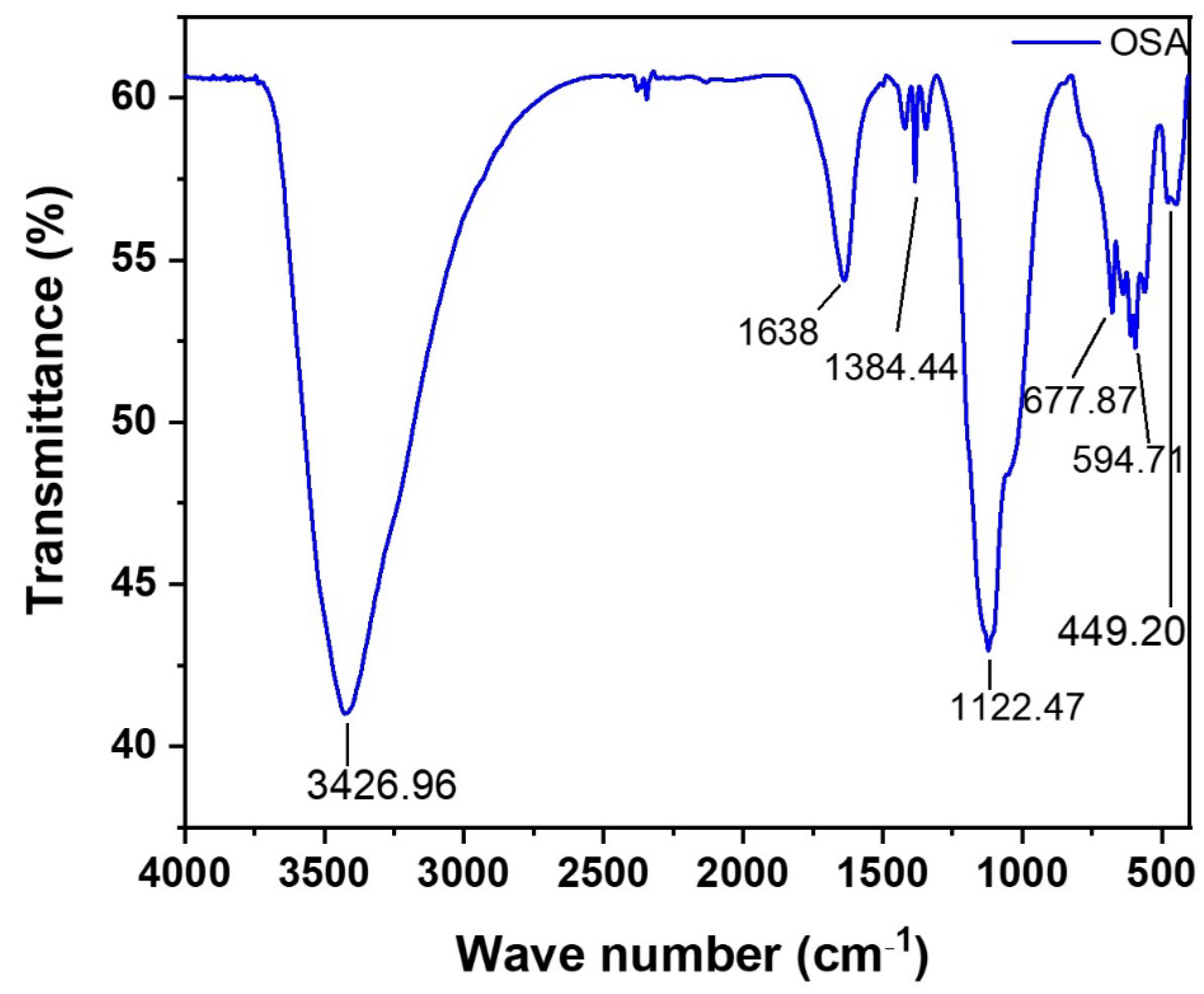

Thermal incineration is among the available techniques for the treatment of oily sludge [

15]. The thermal method helps to remove grease and oil that could retard the setting time and the development of strength, which affect the encapsulation of heavy metals in the solidified matrix. The method can also decrease all significant PAHs, but it is associated with a high temperature of operation [

16]. Besides, the generated solid residue (oily sludge ash, OSA) from the thermal technique poses some issues, challenges, and problems concerning environmental safety and public health protection. The encapsulation of heavy metals is one of the major concerns that decrease their migration into the environment. The stabilization and solidification (SS) method is a successful and efficient process of disposal commonly employed to deactivate or decrease the harmful effects of heavy metals’ migration into the environment [

17]. SS is a quick and cheap treatment strategy of OSA, fulfilling the need to immobilize hazardous wastes by converting them into a less harmful or dissolvable matrix (i.e., stabilization) and confining the deactivated wastes into a durable matrix form, i.e., solidification [

4]. The SS technique involves the use of cement as a binder to seal or encapsulate the hazardous waste in a closed and inactive space through the physicochemical process. The SS method offers a good performance of mechanical properties, and pozzolanic materials are commonly added to increase the SS performances.

In construction industries, mortar is commonly used as a construction material, and the ingredients include water, cement, and fine aggregates. These three basic components are proportioned appropriately and mixed homogeneously to produce mortar with the aid of an admixture to enhance the chosen performance of specific physical and mechanical characteristics such as density, hardness, corrosion resistance, durability, compressive strength, and flexural strength of mortar [

18]. These properties mainly depend upon the appropriate selection of water/cement ratio, properties of the cement, and fine aggregate. These ingredients offer significant benefits either to replace them partially or fully to produce mortar with the desired properties. Numerous waste materials such as agricultural by-products and industrial wastes that contain amorphous silica have been used as partial replacement materials of cement in the construction industries, and they are known as cement replacement materials (CRM). Cement has been replaced with, in some cases, fly ash, silica fume, slag, coconut shell ash, stainless steel waste, and palm kernel shell ash [

19,

20,

21]. Similarly, the fine aggregate was substituted with the waste materials to produce lightweight mortar/concrete [

22]. Studies revealed that up to 40% of cement was replaced and showed a significant enhancement of compressive strength compared to the control made with 100% cement [

16].

Pinheiro and Holanda [

23] partially substituted kaolin material with oily sludge up to 5 wt.% in the manufacture of porcelain stoneware tile. It was revealed that the optimum replacement of kaolin is 2.5 wt.% of oily sludge, producing the porcelain stoneware tiles with safe leaching limits. Moreover, the results indicated that incorporating more oily sludge into tile preparations led to a declination in apparent density, linear shrinkage, and flexural strength, while the water absorption increased. In addition, Sengupta et al. [

24] used oily sludge in manufacturing acceptable masonry bricks. The oily sludge addition in the mixture reduced the needed water and fuel in the manufacturing process. The cured bricks achieved all the Indian Standard requirements. Souza et al. [

25] added oily sludge in the manufacture of clay-based ceramics (roofing tiles and hollow bricks) up to 30 wt.% of waste as a substitute for natural clay, and the result revealed that the heavy metals were within allowable leaching limits. Usman et al. [

5] incorporated OSA in fly ash-based geopolymer mortar and found that the 28 day compressive strength for the mixture made with 10 wt.% OSA was highest (31 MPa).

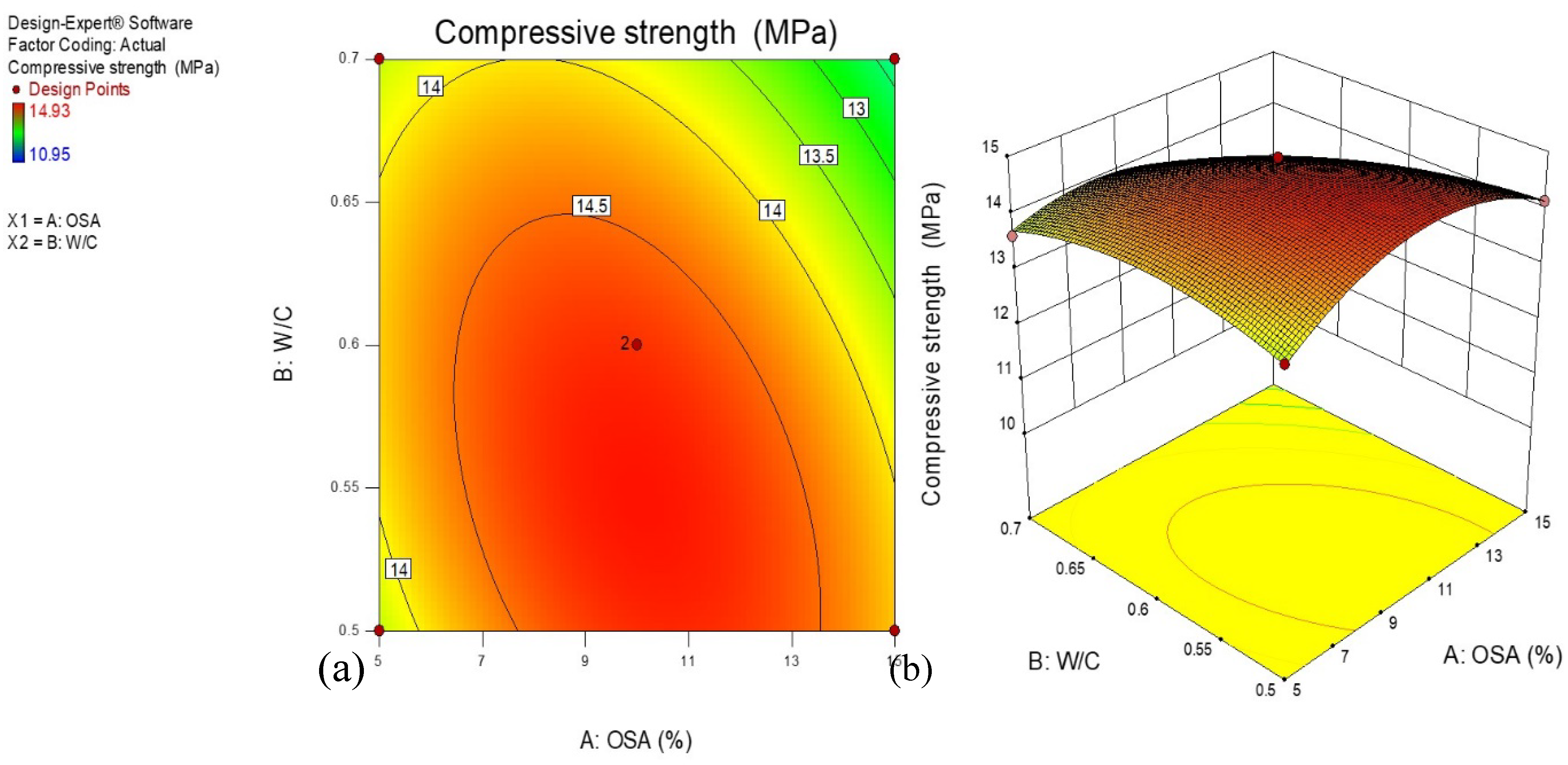

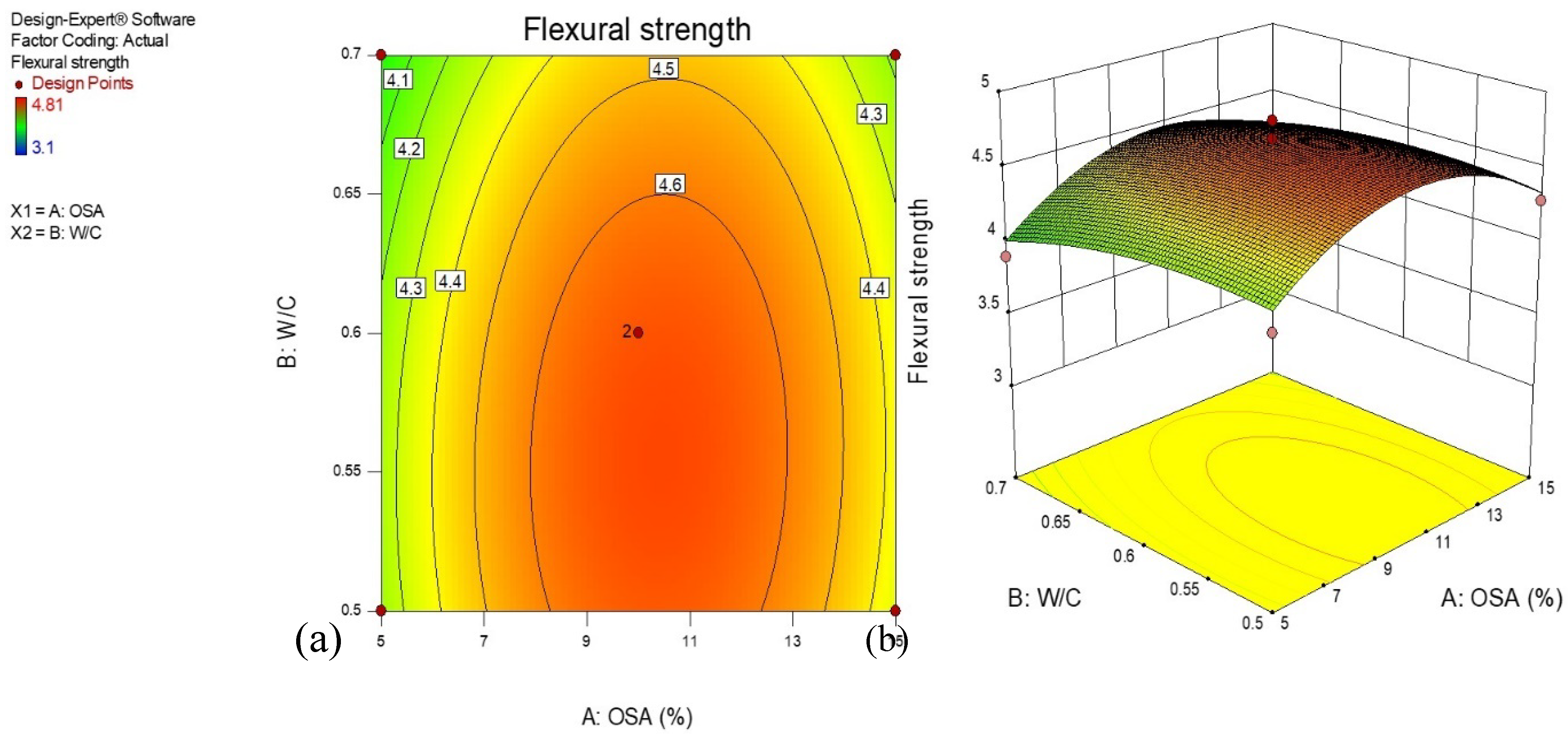

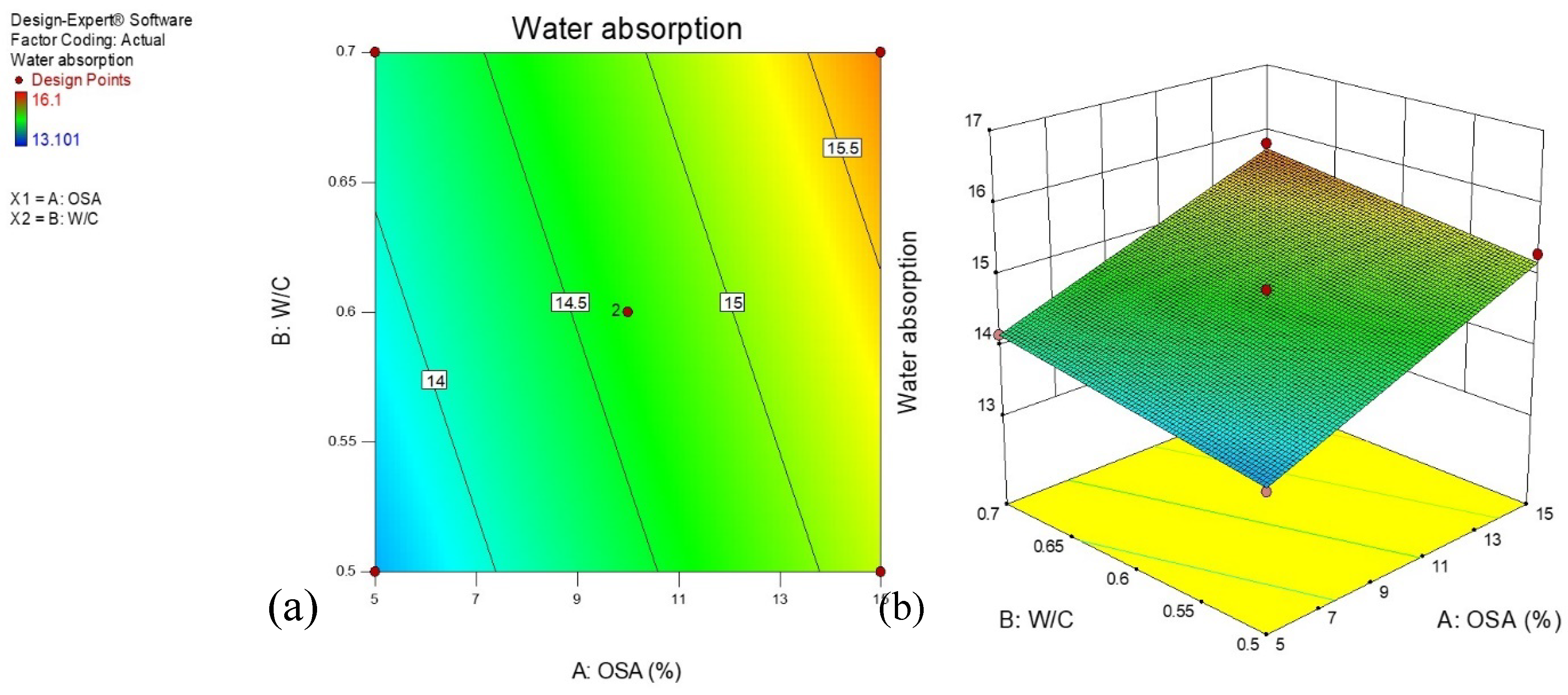

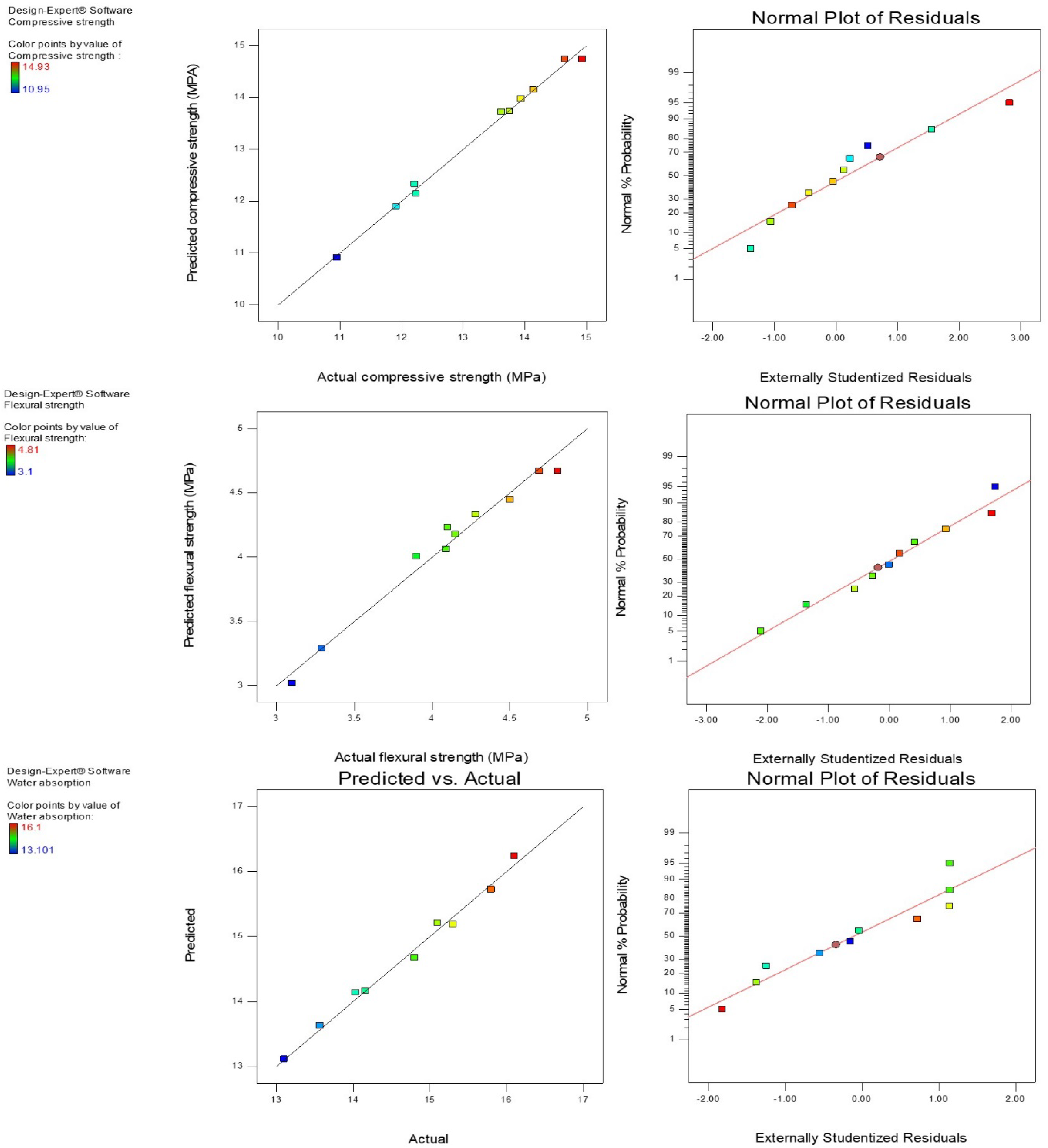

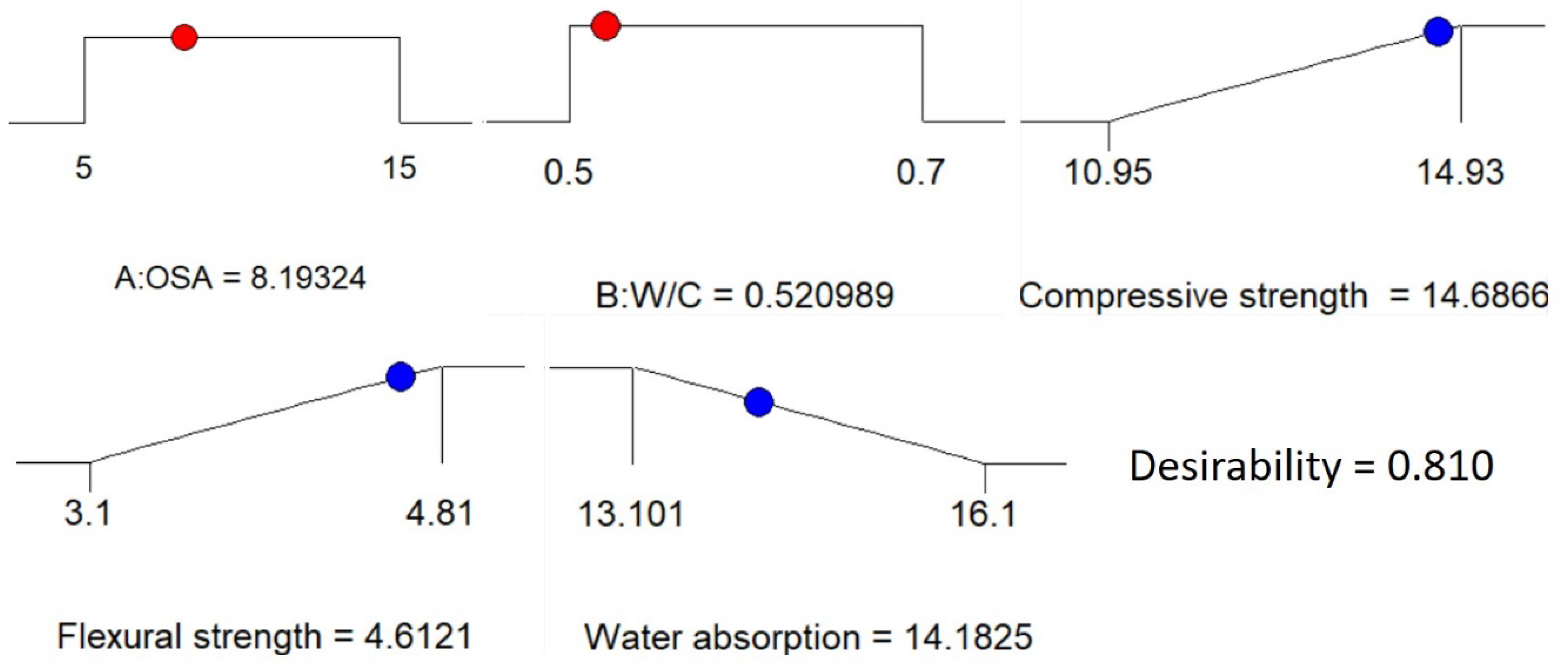

The techniques for the efficient reuse of oily sludge and effective and safe oily sludge disposal are very important to reduce the problems associated with oily sludge. The present study aimed to thermally treat petroleum sludge to remove oil and grease that affect the hydration reaction of cement and strength development and reduce the level of PAHs and heavy metals in the oily sludge. The response surface methodology was employed to optimize the mortar proportions where the amount of OSA and the ratio of water to cement were used as independent variables. Furthermore, the performance of the OSA in the mortar mixture was assessed through compressive strength, flexural strength, and water absorption.