Effect of Different Tool Probe Profiles on Material Flow of Al–Mg–Cu Alloy Joined by Friction Stir Welding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Base Metal

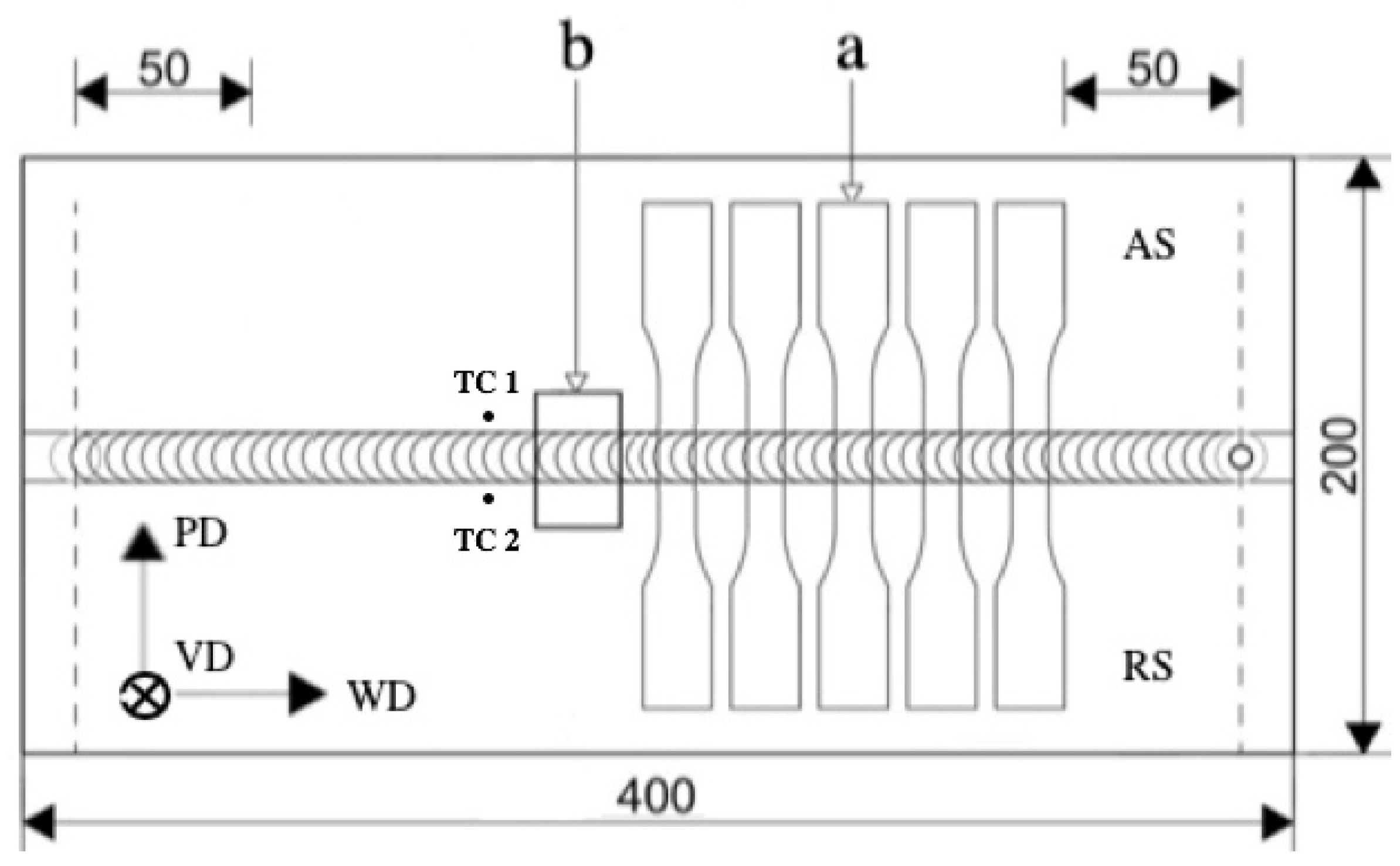

2.2. Friction Stir Welding Procedure

2.3. Macrostructural and Mechanical Properties Analysis

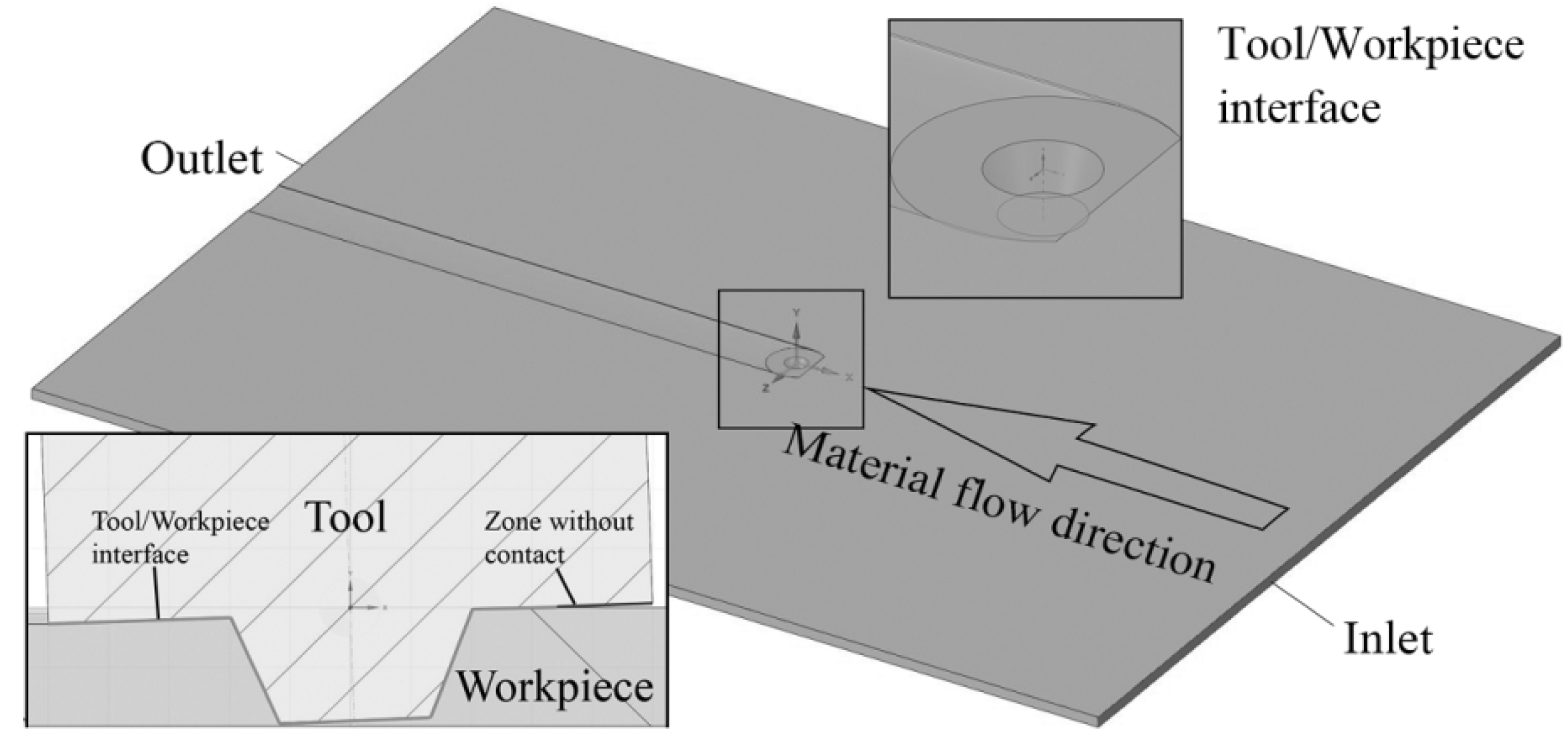

2.4. Numerical Simulation

3. Results and Discussion

3.1. Macrostructural Characteristics

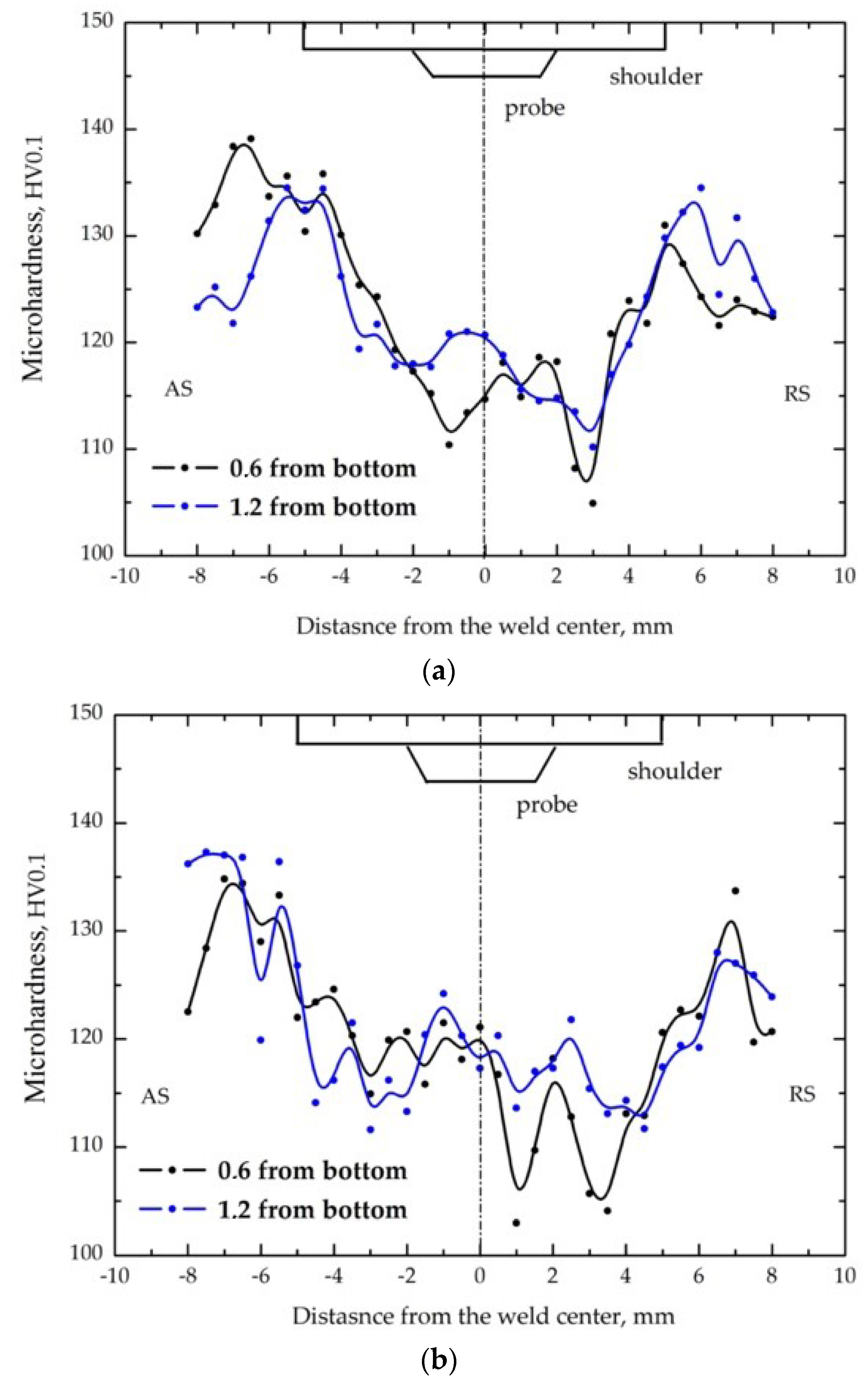

3.2. Microhardness and Tensile Behaviour

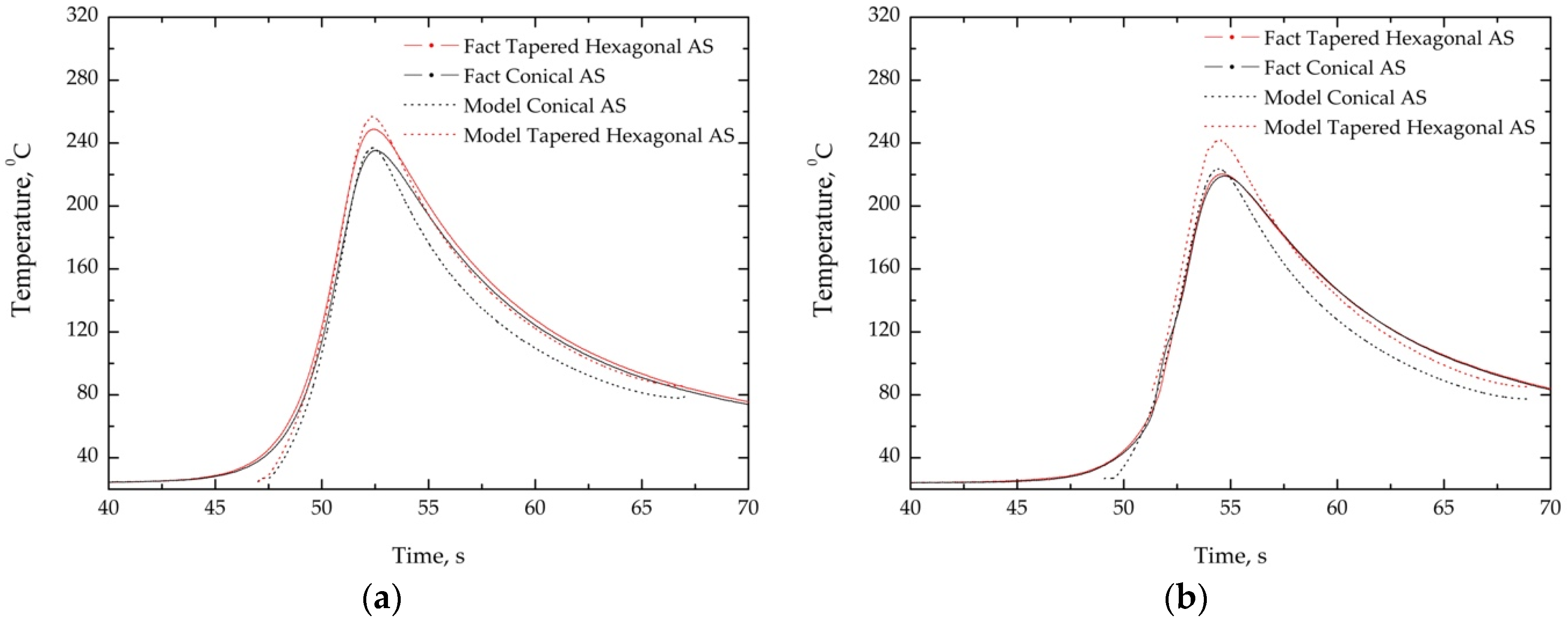

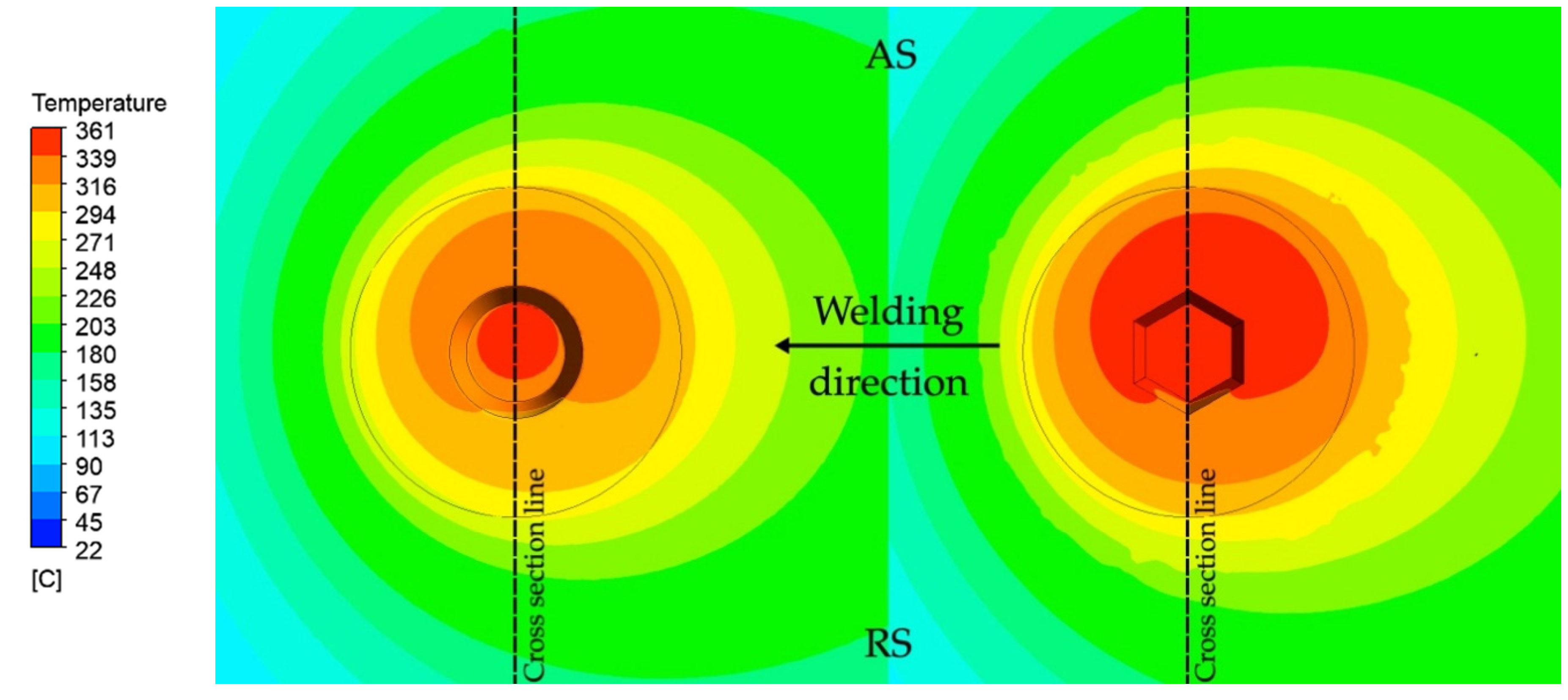

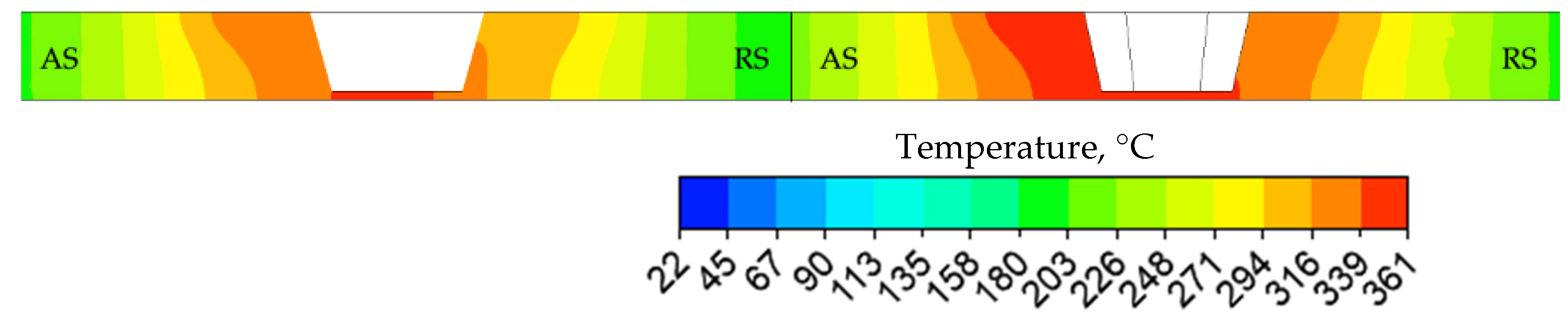

3.3. Temperature Fields

4. Conclusions

- (1)

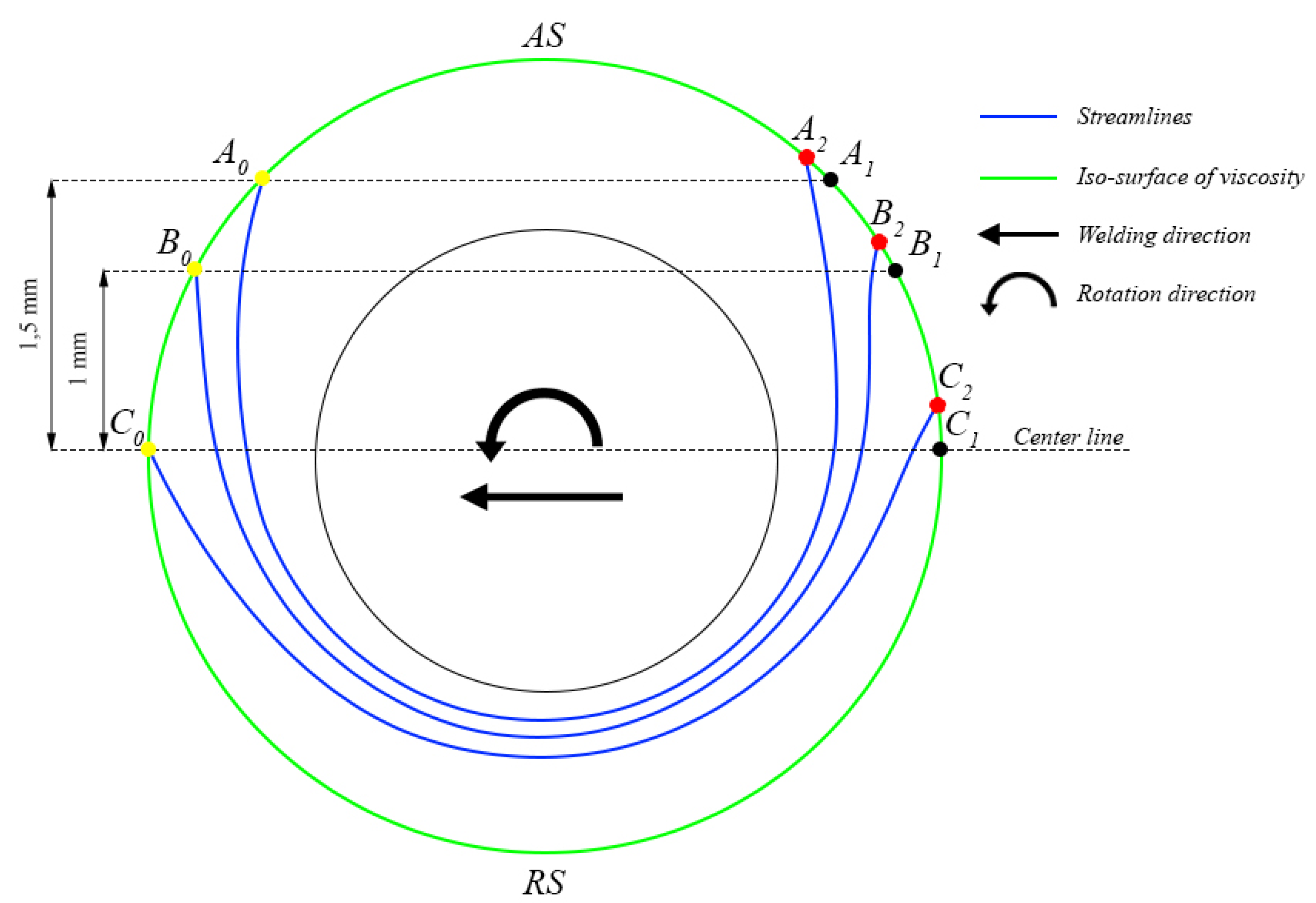

- In the case of the conical probe, ROL passes through the top to the bottom of the entire nugget zone, and reveals a curved, long loop toward the retreating side (RS) in the lower part of the joint. While in the case of the tapered hexagonal probe, ROL passes through the top to the bottom of the nugget zone, without revealing a curved loop. The conical and tapered hexagonal probes obviously resulted in different material flows.

- (2)

- A narrower SZ closer to the bottom of the joint is a feature of the macrostructure of the weld produced by the tapered hexagonal probe. The SZ of the weld produced by the tapered hexagonal probe reveals a narrower width than that of the conical probe, while the weld of the tapered hexagonal probe reveals a wider HAZ than that of the conical probe. This macroscopic observation was supported by calculation results.

- (3)

- The average ultimate tensile strength of the welds of FSW−H specimens reached a higher value of 354 MPa compared with that achieved by the FSW−C probe, of 288 MPa. This could be attributed to the more intensive material flow around the probe. Yielding strength is almost the same for both probe types.

- (4)

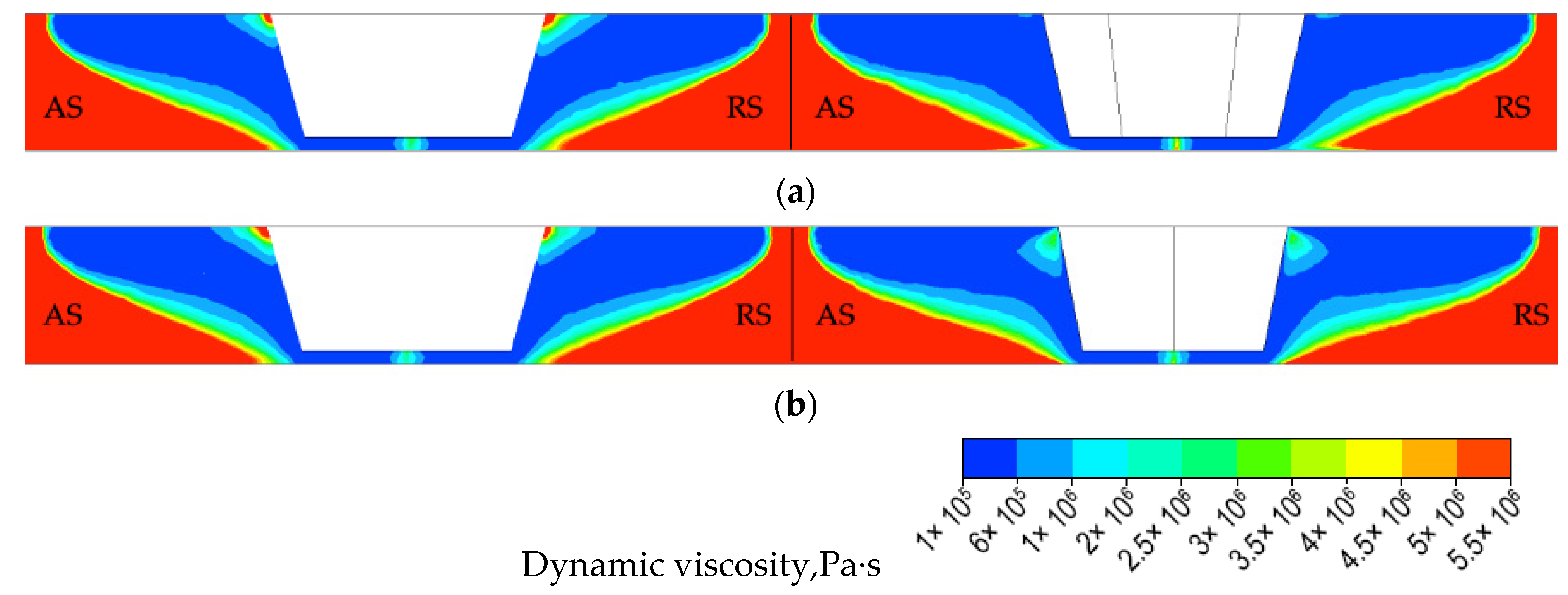

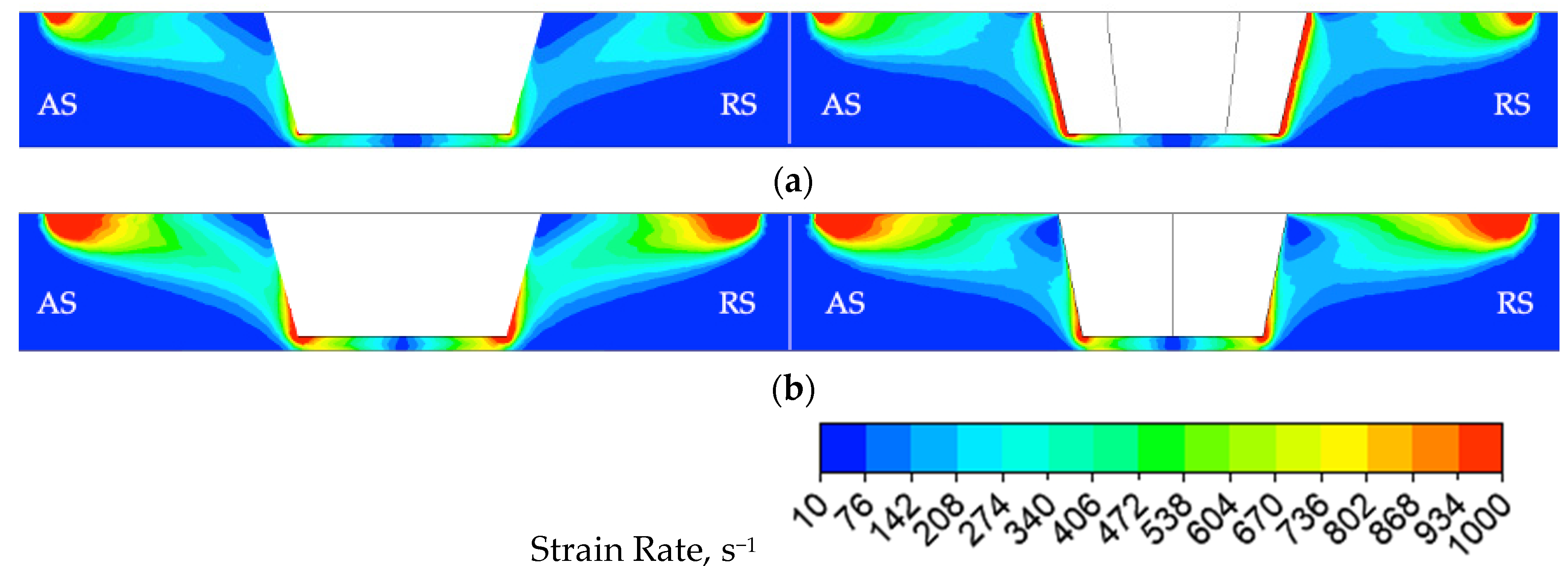

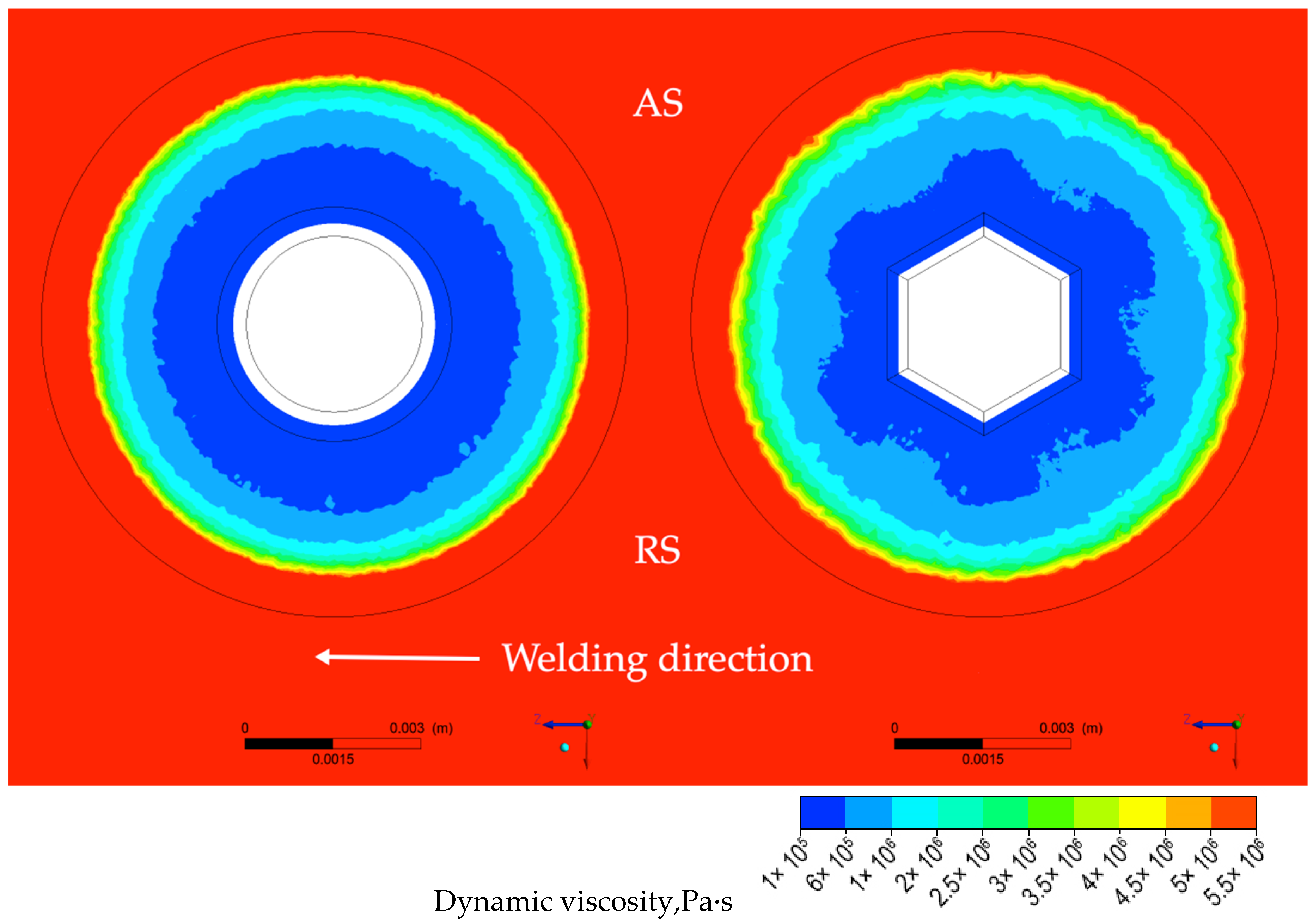

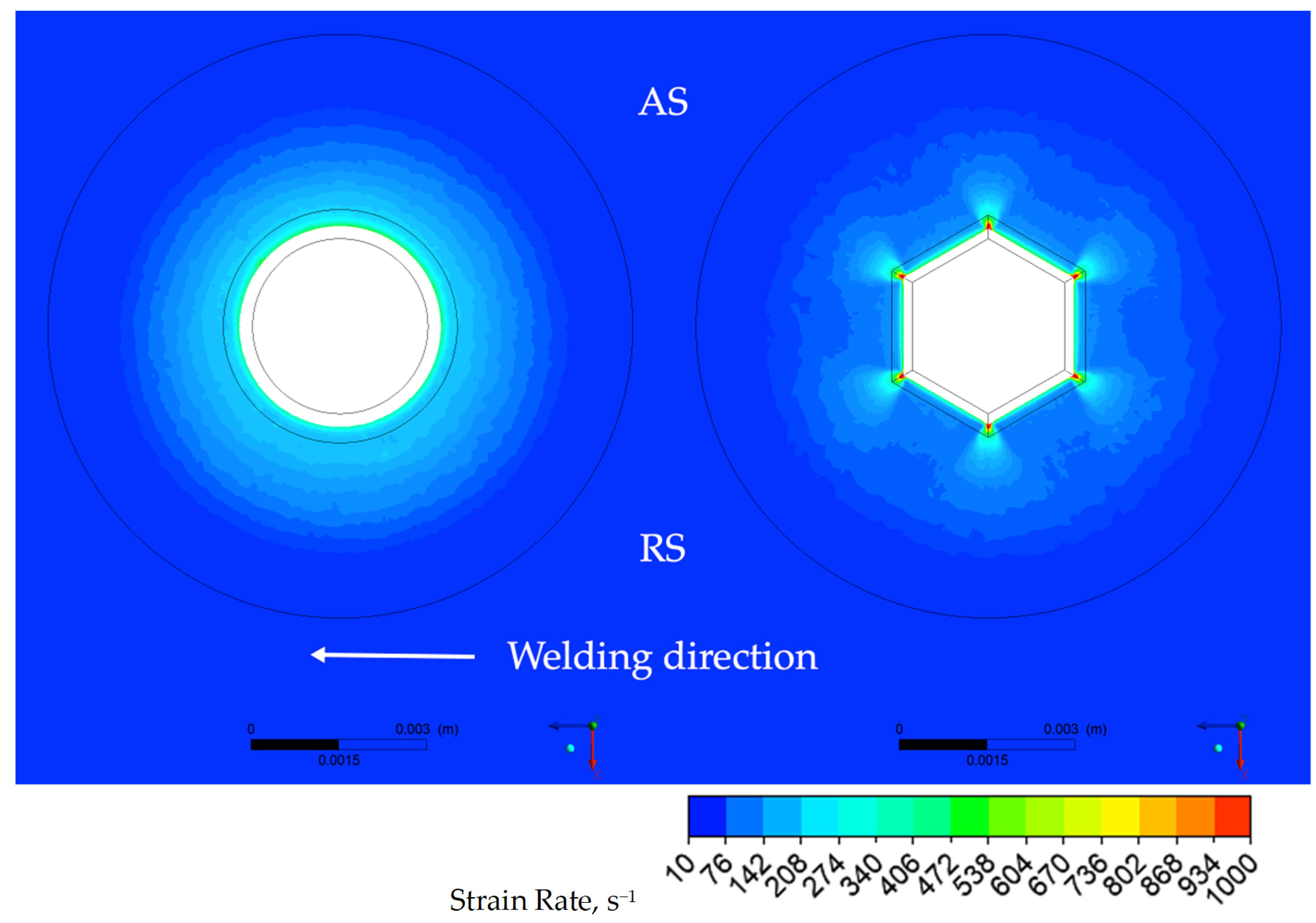

- In the case of the FSW−C sample, the dynamic viscosity and strain rate are homogeneously distributed around the probe, while in the case of the FSW−H sample, maximum strain rate and minimum dynamic viscosity are located along the six tapered edges.

- (5)

- The temperature distribution of the FSW−C sample exhibits a region of maximum temperature located beneath the probe end, whereas the temperature distribution of the FSW−H sample reveals a larger region of maximum temperature which extends from the probe tip to the adjacent area towards the advancing side.

- (6)

- The probe profile has a relevant effect on the stirring and breaking of the remnant oxide layer. The microstructure evolution in the SZ was dominated by dynamic recrystallization.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fridlyander, I.N. Aluminum alloys in aviation, rocket and nuclear power engineering. Vest. Ross. Akad. Nauk. 2004, 74, 1076–1081. [Google Scholar]

- Naumov, A.A.; Isupov, F.Y.; Golubev, Y.A.; Morozova, Y.N. Effect of the Temperature of Friction Stir Welding on the Microstructure and Mechanical Properties of Welded Joints of an Al-Cu-Mg Alloy. Met. Sci. Heat Treat. 2019, 60, 695–700. [Google Scholar] [CrossRef]

- Kondrat’ev, S.Y.; Zotov, O.G.; Shvetsov, O.V. Structural stability and variation of properties of aluminum alloys D16 and 1953 in production and operation of drill pipes. Met. Sci. Heat Treat. 2014, 55, 526–532. [Google Scholar] [CrossRef]

- Muratov, V.S.; Morozova, E.A.; Zakopets, O.I. Control of the structure and hardness of aluminum alloys of the Al-Cu-Mg system in cast condition. Int. Zh. Prikl. Fund. Issled. 2012, 3, 77–78. [Google Scholar]

- John, E.H. Metallurgy of Heat Treatment and General Principles of Precipitation Hardening. Alum. Prop. Phys. Metall. 1984, 134–199. [Google Scholar]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Elsevier: Amsterdam, The Netherlands, 1979; 986p. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C. Friction Stir Butt Welding. International Patent Application No. PCTGGB92G02203. GB Patent Application No. 9125978.8, 6 December 1991. [Google Scholar]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998 297 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef] [Green Version]

- Karlsen, M.; Frigaard, Ø.; Hjelen, J.; Grong, Ø.; Norum, H. SEM-EBSD Characterisation of the Deformation Microstructure in Friction Stir Welded 2024 T351 Aluminium Alloy. Mater. Sci. Forum 2003, 426–432, 2861–2866. [Google Scholar] [CrossRef]

- Heurtier, P.; Jones, M.J.; Desrayaud, C.; Driver, J.H.; Montheillet, F. Thermomechanical Conditions and Resultant Microstructures in Friction Stir Welded 2024 Aluminum. Mater. Sci. Forum 2003, 426–432, 2927–2932. [Google Scholar] [CrossRef]

- Dimopoulos, A.; Vairis, A.; Vidakis, N.; Petousis, M. On the friction stir welding of al 7075 thin sheets. Metals 2021, 11, 57. [Google Scholar] [CrossRef]

- Liu, F.; Fu, L.; Chen, H. Microstructure Evolution and Mechanical Properties of High-Speed Friction Stir Welded Aluminum Alloy Thin Plate Joints. J. Mater. Eng. Perform. 2018, 27, 3590–3599. [Google Scholar] [CrossRef]

- Golubev, I.A.; Chernikov, E.V.; Naumov, A.A.; Michailov, V.G. Temperature distribution and welding distortion measurements after FSW of Al 6082-T6 sheets. In Friction Stir Welding and Processing VIII; Springer: Cham, Switzerland, 2016; pp. 289–295. [Google Scholar] [CrossRef]

- Su, H.; Wu, C. Numerical Simulation for the Optimization of Polygonal Pin Profiles in Friction Stir Welding of Aluminum. Acta Metall. Sin. 2021, 34, 1065–1078. [Google Scholar] [CrossRef]

- Khodaverdizadeh, H.; Heidarzadeh, A.; Saeid, T. Effect of tool pin profile on microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Des. 2013, 45, 265–270. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N.; Dinaharan, I. Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater. Des. 2012, 40, 7–16. [Google Scholar] [CrossRef]

- Anand, R.V.; Prakash, P.; Jha, S.K.; Singh, A.K. Numerical investigations of effect of input process parameters on heat generation in friction stir welding. Mater. Today 2021, 33, 5354–5361. [Google Scholar] [CrossRef]

- Vijay, S.J.; Murugan, N. Influence of tool pin profile on the metallurgical and mechanical properties of friction stir welded Al-10 wt.% TiB2 metal matrix composite. Mater. Des. 2010, 31, 3585–3589. [Google Scholar] [CrossRef]

- Padmanaban, G.; Balasubramanian, V. Selection of FSW tool pin profile, shoulder diameter and material for joining AZ31B magnesium alloy—An experimental approach. Mater. Des. 2009, 30, 2647–2656. [Google Scholar] [CrossRef]

- Gadakh, V.S.; Kumar, A. Friction stir welding window for AA6061-T6 aluminium alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1172–1181. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y.; Domblesky, J.P.; Li, W.; Han, J. Development of a heat source model for friction stir welding tools considering probe geometry and tool/workpiece interface conditions. Int. J. Adv. Manuf. Technol. 2021, 114, 1767–1802. [Google Scholar] [CrossRef]

- Suresha, C.N.; Rajaprakash, B.M.; Upadhya, S. A study of the effect of tool pin profiles on tensile strength of welded joints produced using friction stir welding process. Mater. Manuf. Process. 2011, 26, 1111–1116. [Google Scholar] [CrossRef]

- Ramanjaneyulu, K.; Madhusudhan Reddy, G.; Venugopal Rao, A.; Markandeya, R. Structure-property correlation of AA2014 friction stir welds: Role of tool pin profile. J. Mater. Eng. Perform. 2013, 22, 2224–2240. [Google Scholar] [CrossRef]

- Moghadam, D.G.; Farhangdoost, K.; Nejad, R.M. Microstructure and Residual Stress Distributions Under the Influence of Welding Speed in Friction Stir Welded 2024 Aluminum Alloy. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2016, 47, 2048–2062. [Google Scholar] [CrossRef]

- Hu, Z.L.; Wang, X.S.; Yuan, S.J. Quantitative investigation of the tensile plastic deformation characteristic and microstructure for friction stir welded 2024 aluminum alloy. Mater. Charact. 2012, 73, 114–123. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kurihara, S.; Kokawa, H. Systematic examination of precipitation phenomena associated with hardness and corrosion properties in friction stir welded aluminium alloy 2024. Weld. World 2011, 55, 39–47. [Google Scholar] [CrossRef]

- Panchenko, O.V.; Ivanov, S.Y.; Naumov, A.A.; Isupov, F.Y.; Popovich, A.A. Local mechanical properties estimation of friction stir welded Al-Mg-Si joints. In Proceedings of the 28th International Offshore and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018; pp. 172–174. [Google Scholar]

- Zhang, X.X.; Xiao, B.L.; Ma, Z.Y. A transient thermal model for friction stir weld. Part I: The model. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3218–3228. [Google Scholar] [CrossRef]

- Chen, G.; Feng, Z.; Zhu, Y.; Shi, Q. An Alternative Frictional Boundary Condition for Computational Fluid Dynamics Simulation of Friction Stir Welding. J. Mater. Eng. Perform. 2016, 25, 4016–4023. [Google Scholar] [CrossRef]

- Al-Badour, F.; Merah, N.; Shuaib, A.; Bazoune, A. Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J. Mater. Process. Technol. 2013, 213, 1433–1439. [Google Scholar] [CrossRef]

- Rylkov, E.N.; Naumov, A.A.; Isupov, F.Y.; Panchenko, O.V.; Popovich, A.A. Numerical simulation of temperature distribution and material flow during friction stir welding of magnesium alloy. In Proceedings of the MS and T 2019—Materials Science and Technology 2019, Portland, OR, USA, 29 September–3 October 2019; pp. 1034–1040. [Google Scholar]

- Naumov, A.; Morozova, I.; Rylkov, E.; Obrosov, A.; Isupov, F.; Michailov, V.; Rudskoy, A. Metallurgical and mechanical characterization of high-speed friction stir welded AA 6082-T6 aluminum alloy. Materials 2019, 12, 4211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naumov, A.; Isupov, F.; Rylkov, E.; Polyakov, P.; Panteleev, M.; Skupov, A.; Amancio-Filho, S.T.; Panchenko, O. Microstructural evolution and mechanical performance of Al-Cu-Li alloy joined by friction stir welding. J. Mater. Res. Technol. 2020, 9, 14454–14466. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Niu, P.; Li, W.; Zhang, Z.; Wang, F.; Feng, Y.; Fu, M. Significant effect of oxide on mechanical properties of friction-stir-welded AA2024 joints. Sci. Technol. Weld. Join. 2017, 22, 66–70. [Google Scholar] [CrossRef]

- Sato, Y.S.; Takauchi, H.; Park, S.H.C.; Kokawa, H. Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Mater. Sci. Eng. A 2005, 405, 333–338. [Google Scholar] [CrossRef]

- Cerri, E.; Leo, P.; Wang, X.; Embury, J.D. Mechanical properties and microstructural evolution of friction-stir-welded thin sheet aluminum alloys. Metall. Mater. Trans. A 2011, 42, 1283–1295. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; Deschamps, A.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2020, 117, 100752. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.G.; Debroy, T. Numerical simulation of three dimensional heat transfer and plastic flow during friction stir welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 1247–1259. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, F.; Zhang, W.; Li, X. Kinetics of dynamic recrystallization in AA2024 aluminum alloy. Mod. Appl. Sci. 2014, 8, 47–52. [Google Scholar] [CrossRef]

| Fe | Si | Cu | Mn | Mg | Zn | Al |

|---|---|---|---|---|---|---|

| 0.25 | 0.11 | 3.80 | 0.41 | 1.30 | 0.22 | Bal. |

| Weld ID | Probe Form | N, rpm | υ, mm/min | WP, mm/rpm | Qtotal, Watt | l, J/mm |

|---|---|---|---|---|---|---|

| FSW−C | Conical | 1200 | 300 | 0.250 | 728 | 146 |

| FSW−H | Tapered Hexagonal | 1200 | 300 | 0.250 | 754 | 151 |

| Specimen | UTS (MPa) | YS (MPa) |

|---|---|---|

| FSW−C | 288.3 | 275.9 |

| FSW−H | 354.8 | 279.2 |

| Start Point Position | FSW−C | FSW−H |

|---|---|---|

| 0 mm | 0.385 | 0.366 |

| 1 mm | 0.892 | 0.814 |

| 1.5 mm | 2.493 | 2.269 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naumov, A.; Rylkov, E.; Polyakov, P.; Isupov, F.; Rudskoy, A.; Aoh, J.-N.; Popovich, A.; Panchenko, O. Effect of Different Tool Probe Profiles on Material Flow of Al–Mg–Cu Alloy Joined by Friction Stir Welding. Materials 2021, 14, 6296. https://doi.org/10.3390/ma14216296

Naumov A, Rylkov E, Polyakov P, Isupov F, Rudskoy A, Aoh J-N, Popovich A, Panchenko O. Effect of Different Tool Probe Profiles on Material Flow of Al–Mg–Cu Alloy Joined by Friction Stir Welding. Materials. 2021; 14(21):6296. https://doi.org/10.3390/ma14216296

Chicago/Turabian StyleNaumov, Anton, Evgenii Rylkov, Pavel Polyakov, Fedor Isupov, Andrey Rudskoy, Jong-Ning Aoh, Anatoly Popovich, and Oleg Panchenko. 2021. "Effect of Different Tool Probe Profiles on Material Flow of Al–Mg–Cu Alloy Joined by Friction Stir Welding" Materials 14, no. 21: 6296. https://doi.org/10.3390/ma14216296

APA StyleNaumov, A., Rylkov, E., Polyakov, P., Isupov, F., Rudskoy, A., Aoh, J.-N., Popovich, A., & Panchenko, O. (2021). Effect of Different Tool Probe Profiles on Material Flow of Al–Mg–Cu Alloy Joined by Friction Stir Welding. Materials, 14(21), 6296. https://doi.org/10.3390/ma14216296