Mechanical Properties and Constitutive Model Applied to the High-Speed Impact of Aluminum Foam That Considers Its Meso-Structural Parameters

Abstract

:1. Introduction

2. Materials and Methods

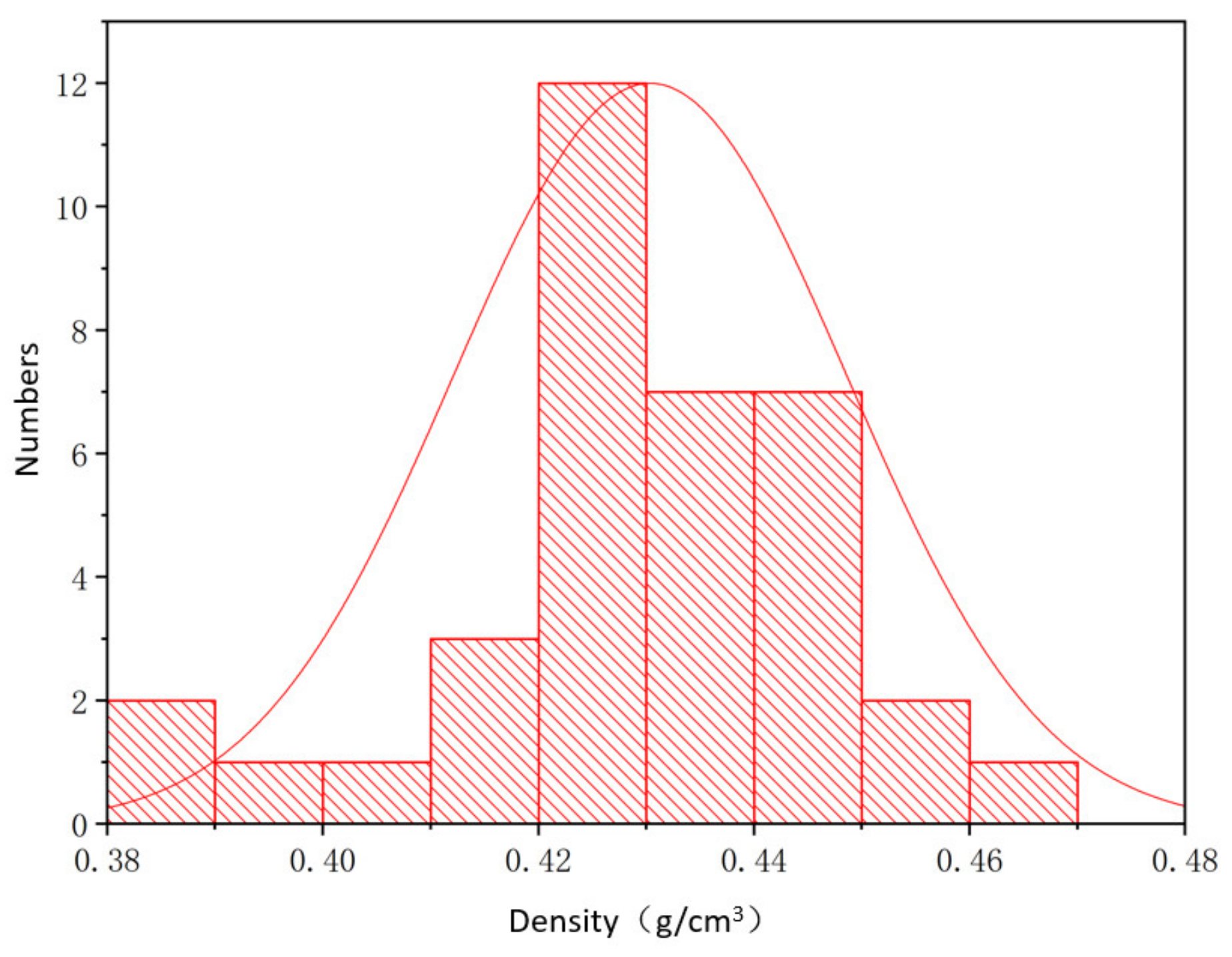

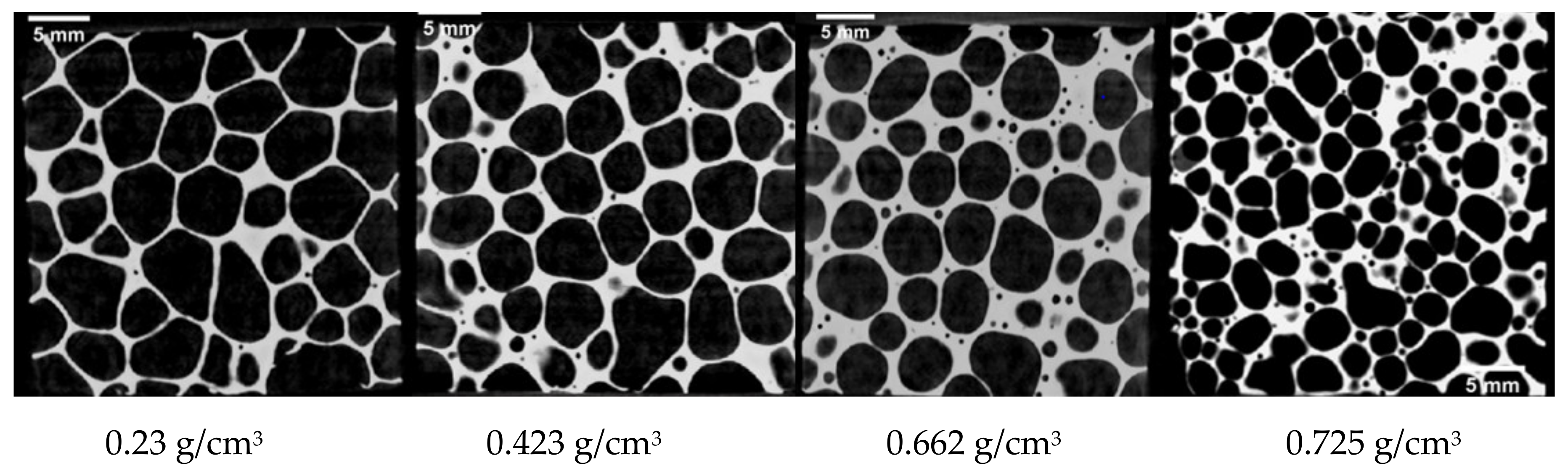

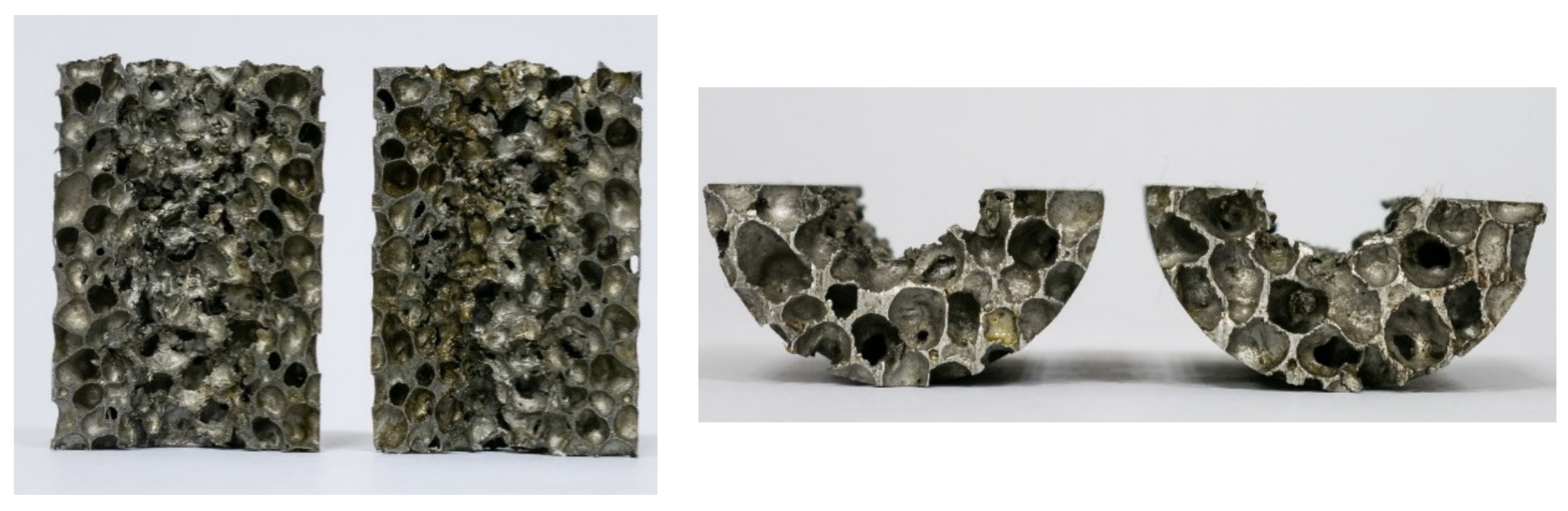

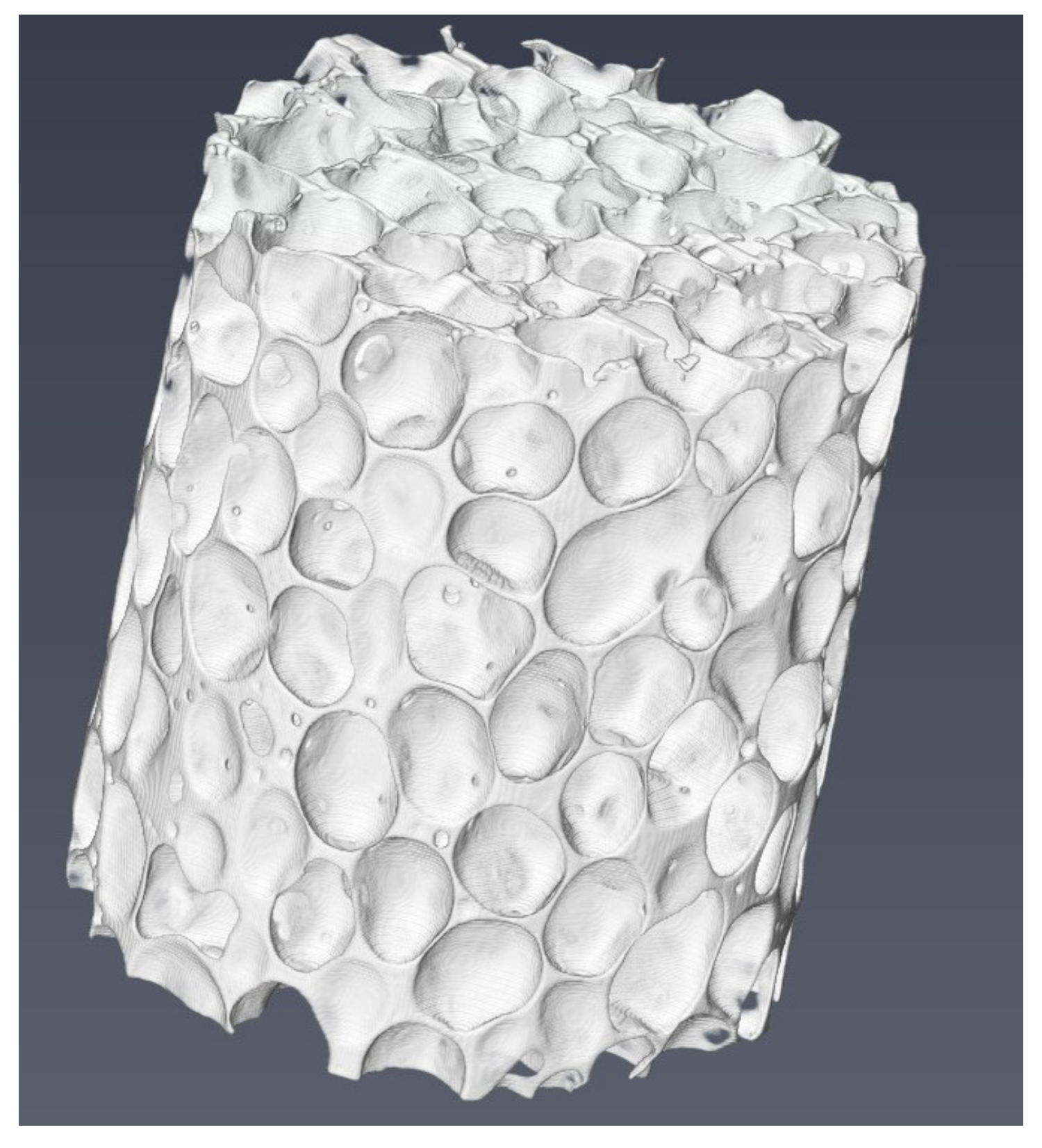

2.1. Materials

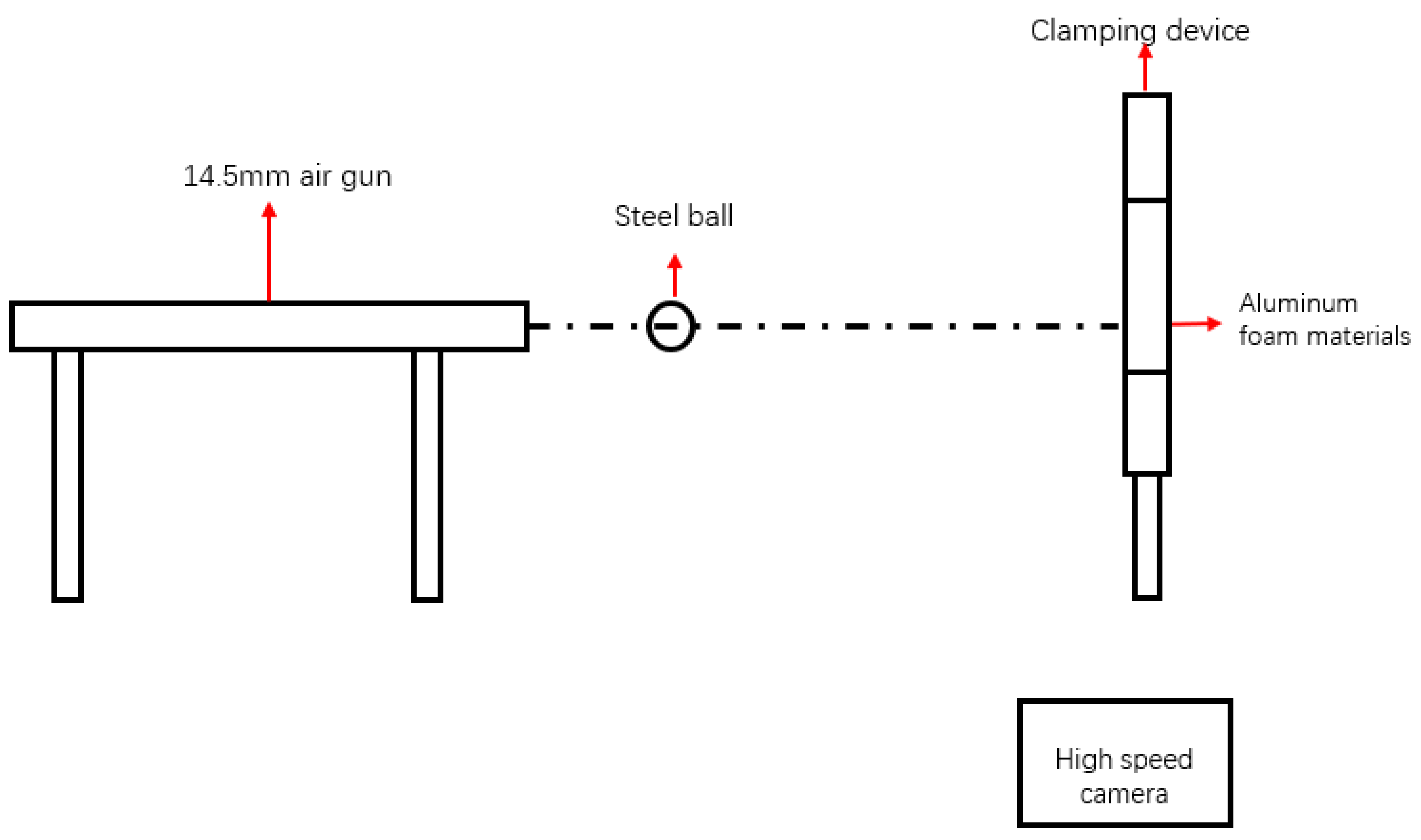

2.2. Experimental Scheme

3. Results and Discussion

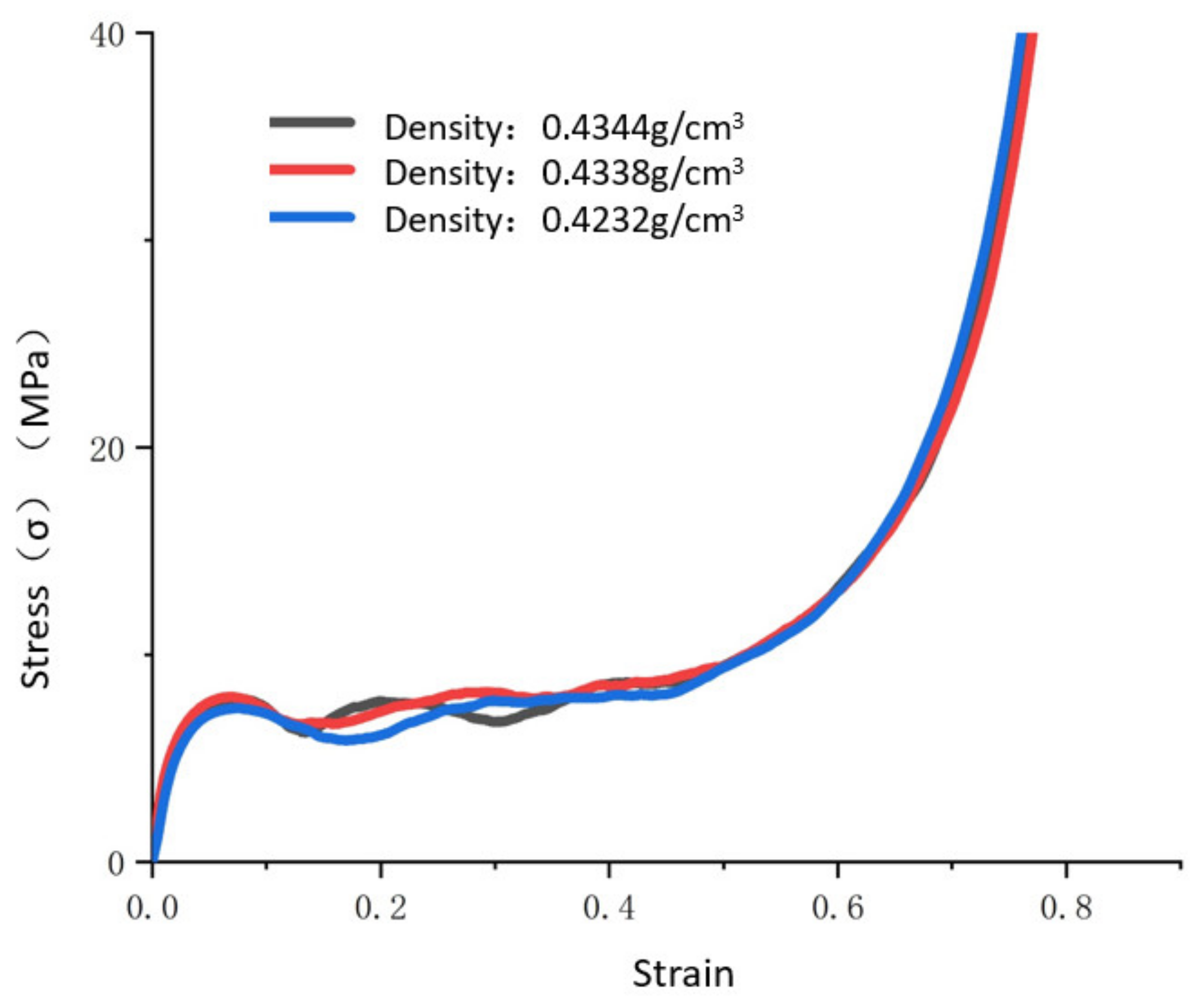

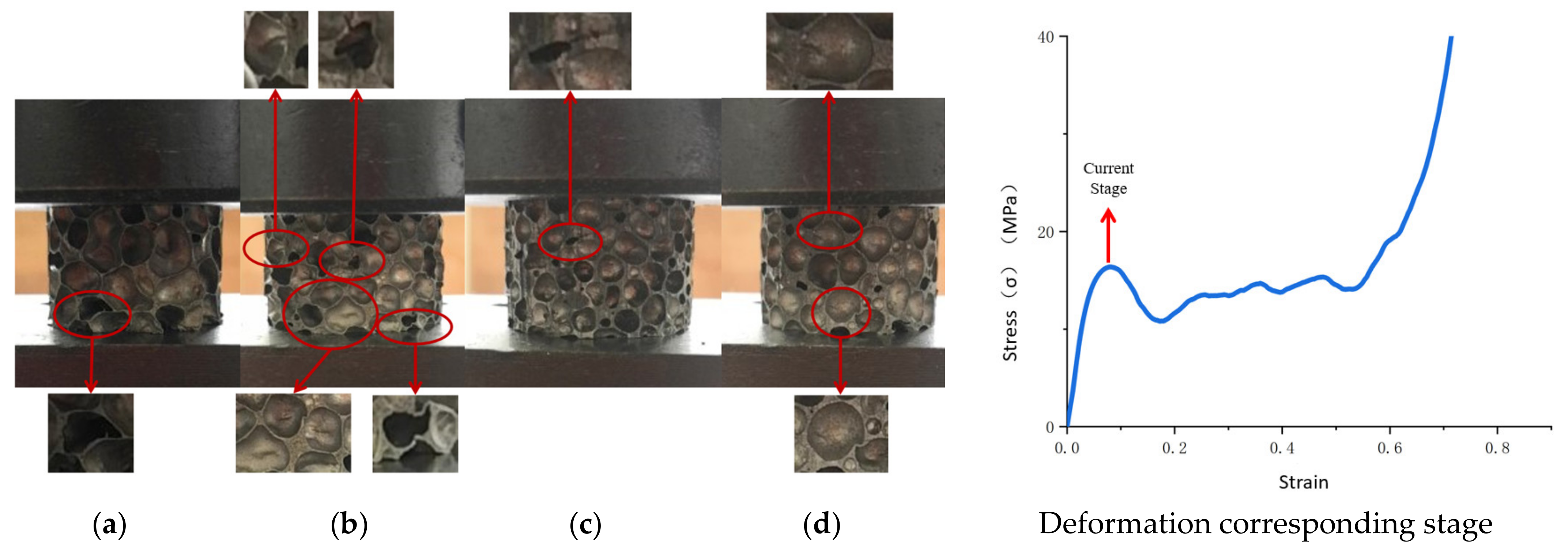

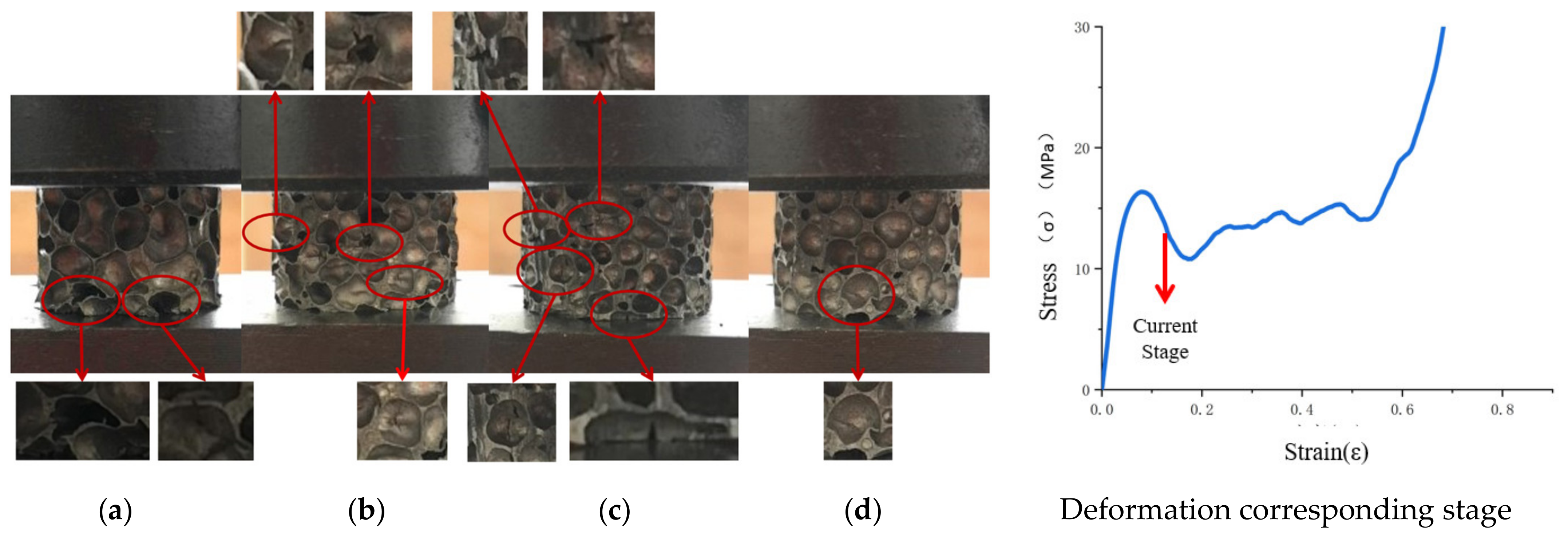

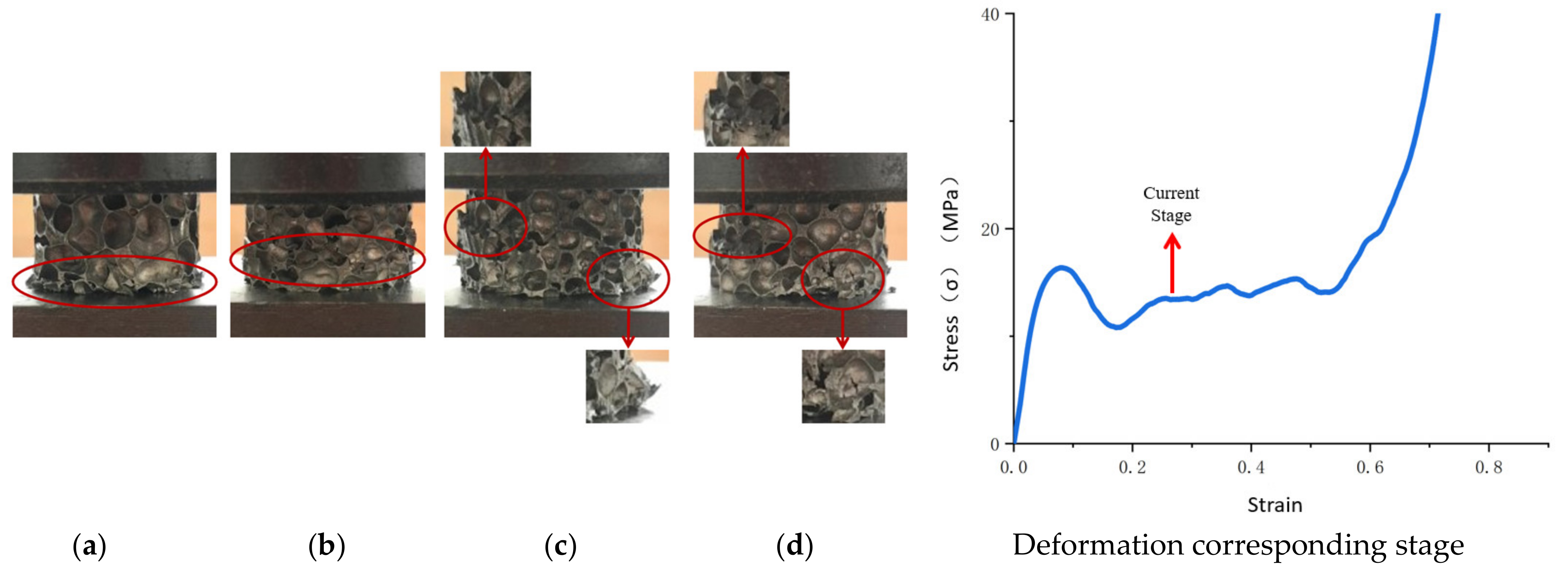

3.1. The Quasistatic Compressive Deformation Characteristics of the Aluminum Foam Materials under Macroscopic Conditions

3.2. Mechanism of Aluminum Foam Deformation at the Mesoscopic Scale

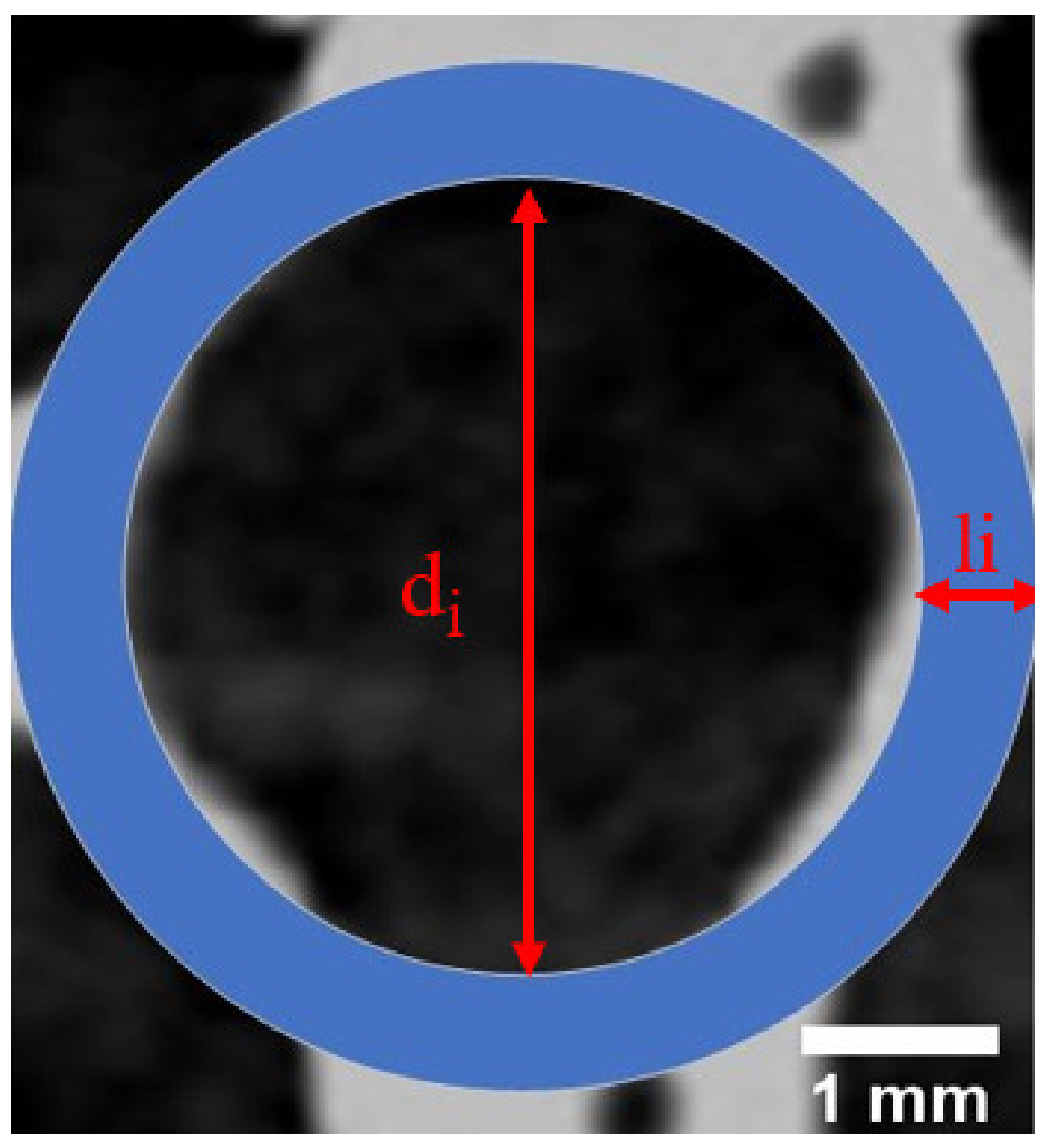

3.2.1. Definition of Structural Parameters

3.2.2. Definitions of Structural Parameters

3.2.3. Impacts of Structural Parameters at Each Stage of Compression

3.3. Establishment of a Constitutive Model

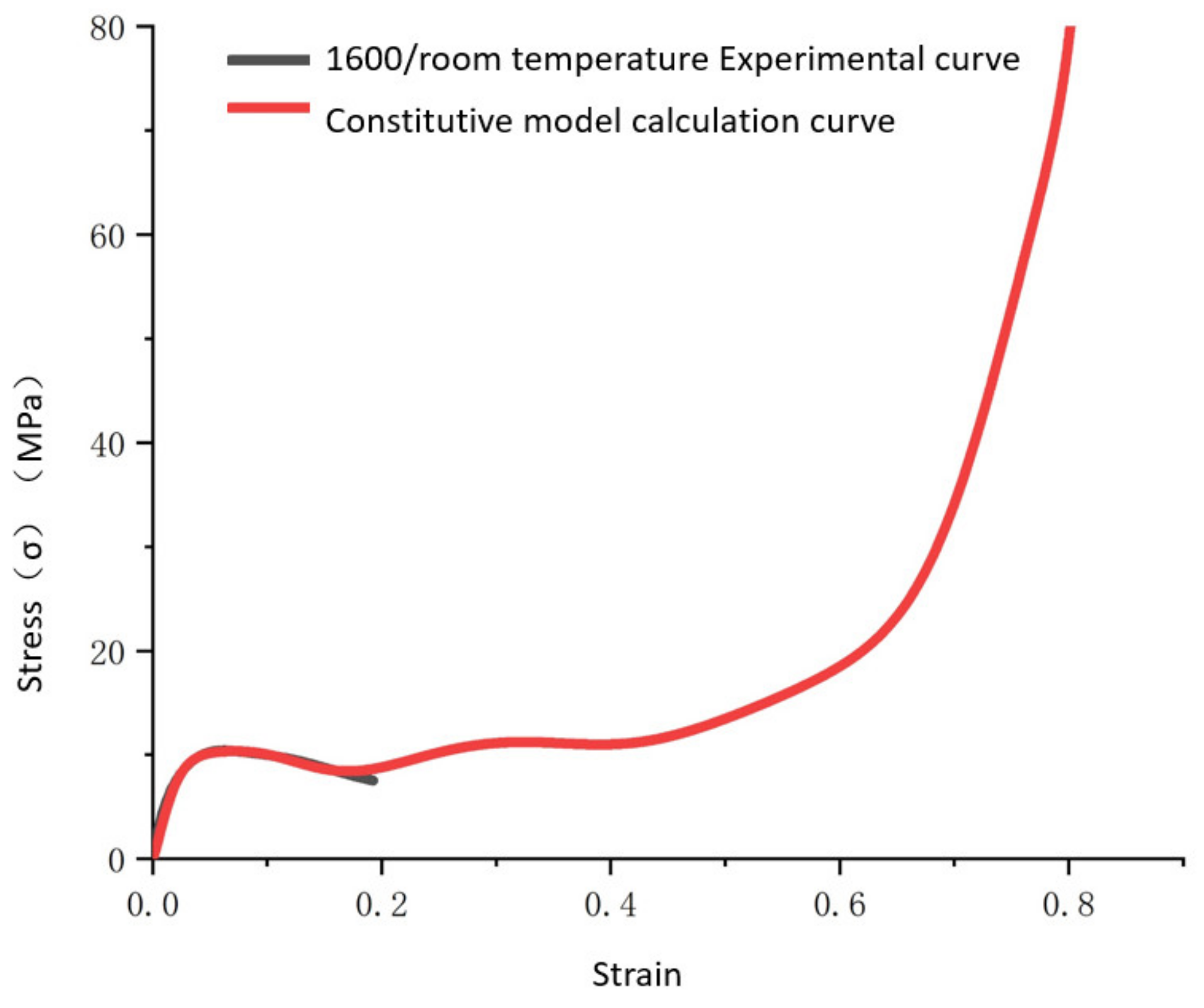

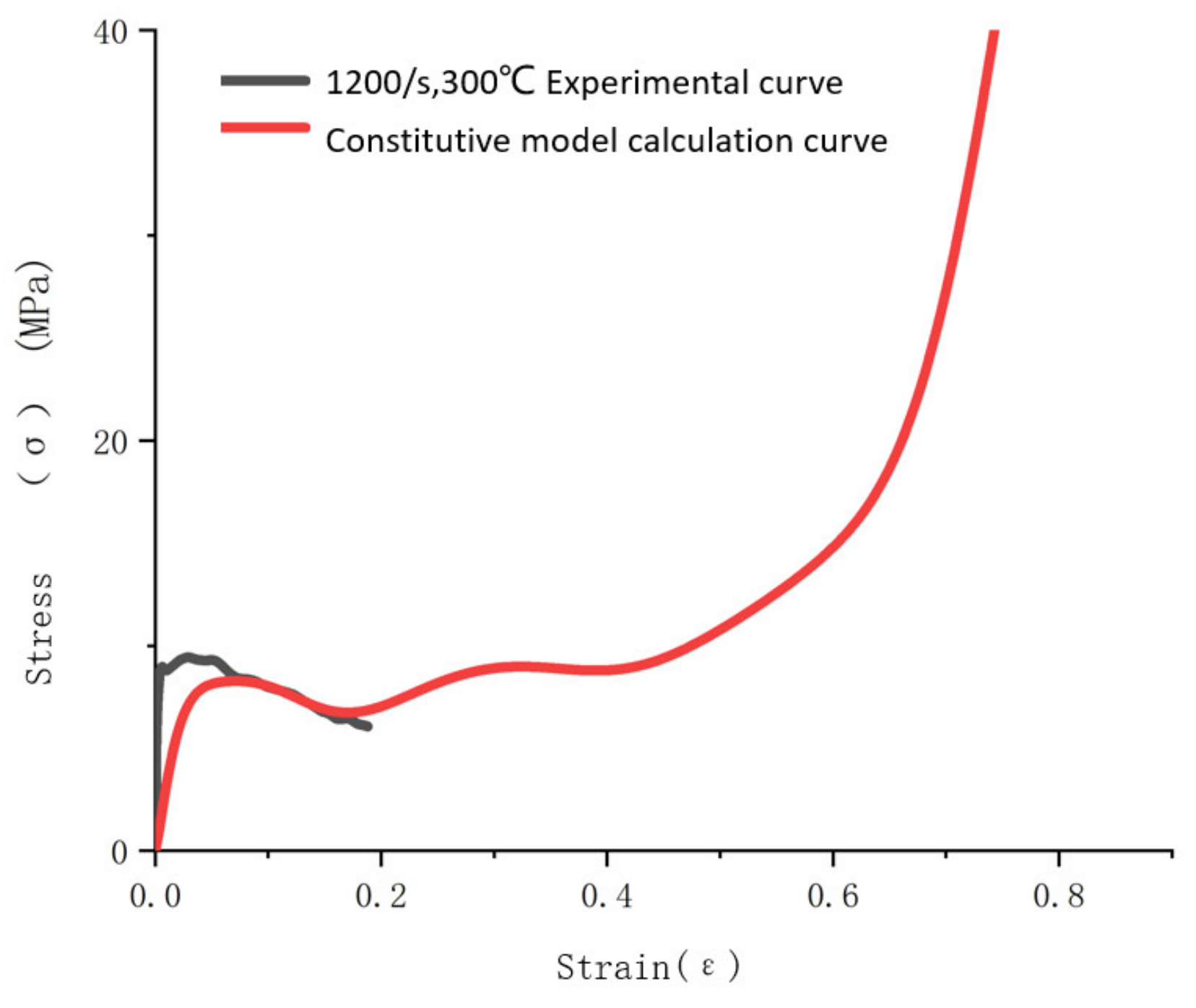

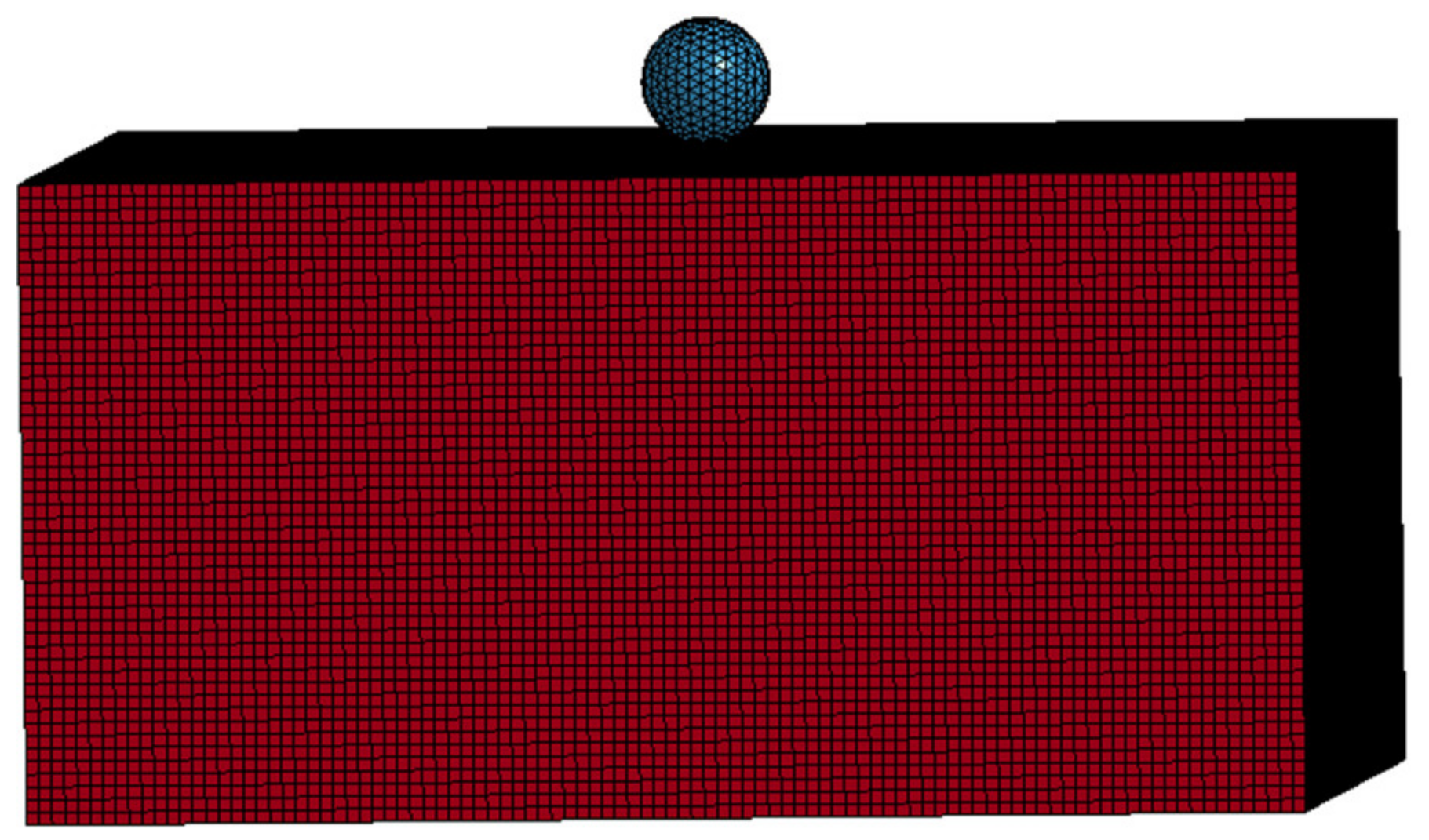

3.4. Validation of the Constitutive Model

4. Conclusions

- (1)

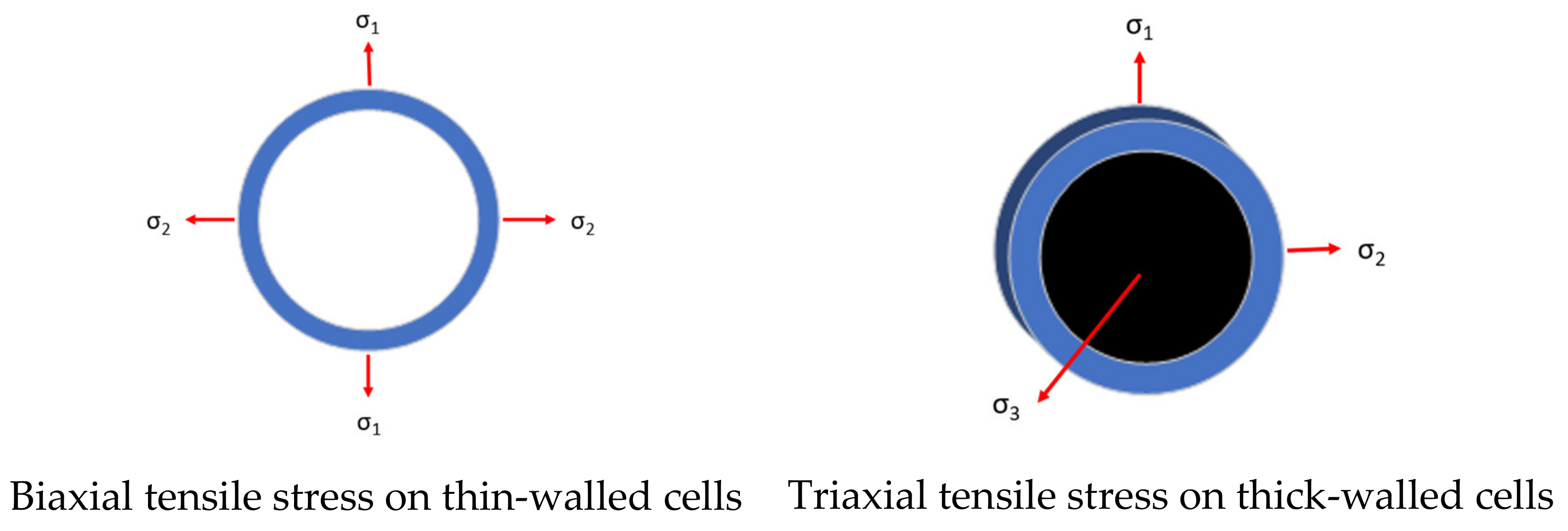

- In this paper, aluminum foam was modeled as a hollow ring in a two-dimensional plane. The cell structural parameters of the aluminum foam material in the two-dimensional plane were defined. The quasistatic compressive deformation process of the aluminum foam was divided into five stages, namely, the initial state, elastic stage, “stress drop” stage, yield plateau stage, and densification stage. Meanwhile, the microscopic deformation mechanisms of the cells of aluminum foam materials with different cellular structural parameters at different stages were analyzed sequentially.

- (2)

- The structural parameters mainly affected the magnitude of strain of the aluminum foam in each stage and the width of the plateau stage of the aluminum foam. In terms of the microscopic deformation of the material, with increasing cell wall thickness, the stress state of a cell changed from biaxial tensile stress to triaxial tensile stress. The tensile stress state affected the changes in the direction of cell cracks of the aluminum foam.

- (3)

- Based on the Sherwood–Frost constitutive framework model, a constitutive model was established, which aimed to simulate the shape function, the coupling function of density and cellular structural parameters, and the coupling function of strain rate and temperature. The influence of density and cellular structure was considered when establishing the model, and the results were obtained by curve fitting. High-speed impact tests and numerical simulations were used to validate the accuracy of the constitutive model in practical applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, Y.-A.; Zhang, J. Review of mechanical properties of metallic foams. J. Foshan Univ. Nat. Sci. Ed. 2005, 23, 11–16. [Google Scholar]

- Jing, L.; Wang, Z.; Zhao, L. Advances in studies of the mechanical performance of cellular metals and related sandwich structures. Mech. Eng. 2015, 37, 1–24. [Google Scholar]

- Sun, Y.; Li, Q. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int. J. Impact Eng. 2018, 112, 74–115. [Google Scholar] [CrossRef] [Green Version]

- Lan, F.; Zeng, F.; Zhou, Y.; Chen, J. Progress on Research of Mechanical Properties of Closed-cell Aluminum Foams and Its Applications in Automobile Crashworthiness. J. Mech. Eng. 2015, 50, 97–112. [Google Scholar] [CrossRef]

- Lu, Z.; Guo, Y. Brief review of studies on the mechanical behavior of metallic foams. J. Beijing Univ. Aeronaut. Astronaut. 2003, 29, 978–983. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Lehmhus, D.; Vesenjak, M.; De Schampheleire, S.; Fiedler, T. From Stochastic Foam to Designed Structure: Balancing Cost and Performance of Cellular Metals. Materials 2017, 10, 922. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marx, J.; Rabiei, A. Overview of Composite Metal Foams and Their Properties and Performance. Adv. Eng. Mater. 2017, 19, 1–13. [Google Scholar] [CrossRef]

- Garcia-Avila, M.; Portanova, M.; Rabiei, A. Ballistic performance of composite metal foams. Compos. Struct. 2015, 125, 202–211. [Google Scholar] [CrossRef]

- Marx, J.; Portanova, M.; Rabiei, A. Ballistic performance of composite metal foam against large caliber threats. Compos. Struct. 2019, 225, 111032. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Bobor, K.; Májlinger, K.; Orbulov, I.N. Compressive behaviour of aluminium matrix syntactic foams reinforced by iron hollow spheres. Mater. Des. 2015, 83, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Cao, G.; Wang, F.; Wang, L. The Mechanical Property and Progress of metal foams. Res. Stud. Foundry Equip. 2008, 2, 52–54. [Google Scholar]

- Lu, T.J.; Ong, J.M. Characterization of close-celled cellular aluminum alloys. J. Mater. Sci. 2001, 36, 2773–2786. [Google Scholar] [CrossRef]

- Andrews, E.; Sanders, W.; Gibson, L.J. Compressive and tensile behaviour of aluminum foams E. Mater. Sci. Eng. A 1999, 270, 113–124. [Google Scholar] [CrossRef]

- Alvandi-Tabrizi, Y.; Whisler, D.; Kim, H.; Rabiei, A. High strain rate behavior of composite metal foams. Mater. Sci. Eng. A 2015, 631, 248–257. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L. Compressive behaviour of unconstrained and constrained integral-skin closed-cell aluminium foam. Compos. Struct. 2016, 154, 231–238. [Google Scholar] [CrossRef]

- Vesenjak, M.; Veyhl, C.; Fiedler, T. Analysis of anisotropy and strain rate sensitivity of open-cell metal foam. Mater. Sci. Eng. A 2012, 541, 105–109. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Májlinger, K. Microstructural aspects of ceramic hollow microspheres reinforced metal matrix composites. Int. J. Mater. Res. 2013, 104, 903–911. [Google Scholar] [CrossRef]

- Baumgärtner, F.; Duarte, I.; Banhart, J. Industrialization of Powder Compact Toaming Process. Adv. Eng. Mater. 2002, 2, 168–174. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Gupta, N.; Lehmhus, D.; Weise, J.; Baumeister, J. Quasi-static and high strain rates compressive response of iron and Invar matrix syntactic foams. Mater. Des. 2015, 66, 516–531. [Google Scholar] [CrossRef]

- Weise, J.; Lehmhus, D.; Sandfuchs, J.; Steinbacher, M.; Fechte-Heinen, R.; Busse, M. Syntactic Iron Foams’ Properties Tailored by Means of Case Hardening via Carburizing or Carbonitriding. Materials 2021, 14, 4358. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.; Kader, M.; Hazell, P.; Brown, A.; Saadatfar, M.; Quadir, M.; Escobedo, J. Investigation of microstructural and mechanical properties of cell walls of closed-cell aluminium alloy foams. Mater. Sci. Eng. A 2016, 666, 245–256. [Google Scholar] [CrossRef]

- Islam, A.; Brown, A.; Hazell, P.; Kader, M.; Escobedo-Diaz, J.; Saadatfar, M.; Xu, S.; Ruan, D.; Turner, M. Mechanical response and dynamic deformation mechanisms of closed-cell aluminium alloy foams under dynamic loading. Int. J. Impact Eng. 2018, 114, 111–122. [Google Scholar] [CrossRef]

- Islam, M.; Kader, M.; Hazell, P.; Escobedo, J.; Brown, A.; Saadatfar, M. Effects of impactor shape on the deformation and energy absorption of closed cell aluminium foams under low velocity impact. Mater. Des. 2020, 191, 108599. [Google Scholar] [CrossRef]

- Kader, M.; Islam, A.; Saadatfar, M.; Hazell, P.; Brown, A.; Ahmed, S.; Escobedo, J. Macro and micro collapse mechanisms of closed-cell aluminium foams during quasi-static compression. Mater. Des. 2017, 118, 11–21. [Google Scholar] [CrossRef]

- Simone, A.; Gibson, L. The effects of cell face curvature and corrugations on the stiffness and strength of metallic foams. Acta Mater. 1998, 46, 3929–3935. [Google Scholar] [CrossRef]

- Simone, A.; Gibson, L. Effects of solid distribution on the stiffness and strength of metallic foams. Acta Mater. 1998, 46, 2139–2150. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Fang, Q.; Wu, H.; Zhang, Y. Response of closed-cell aluminum foams under static and impact loading: Experimental and mesoscopic numerical analysis. Int. J. Impact Eng. 2017, 110, 382–394. [Google Scholar] [CrossRef]

- He, Q.; Song, H.; Huang, C. A Fractal Study on Meso Structures and Size Effect of Metallic Foams. Chin. J. Theor. Appl. Mech. 2009, 41, 370–375. [Google Scholar]

- Yang, D.; Wang, H.; Guo, S.; Chen, J.; Xu, Y.; Lei, D.; Sun, J.; Wang, L.; Jiang, J.; Ma, A. Coupling Effect of Porosity and Cell Size on the Deformation Behavior of Al Alloy Foam under Quasi-Static Compression. Materials 2019, 12, 951. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Huang, J.; Xia, X.; Chen, X.; Zhang, Z.; Zhao, W.; Liao, B. Finite element analysis for the influence of the closed-cell aluminum foams compression performance with internal defects. J. Hebei Univ. Technol. 2015, 44, 55–59. [Google Scholar]

- Nammi, S.; Edwards, G.; Shirvani, H. Effect of cell-size on the energy absorption features of closed-cell aluminium foams. Acta Astronaut. 2016, 128, 243–250. [Google Scholar] [CrossRef]

- Hassanli, F.; Paydar, M.H. Improvement in energy absorption properties of aluminum foams by designing pore-density distribution. J. Mater. Res. Technol. 2021, 14, 609–619. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloy. Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Hakamada, M.; Nomura, T.; Yamada, Y.; Chino, Y.; Chen, Y.; Kusuda, H.; Mabuchi, M. Compressive Deformation Behavior at Elevated Temperatures in a Closed-Cell Aluminum Foam. Mater. Trans. 2005, 46, 1677–1680. [Google Scholar] [CrossRef] [Green Version]

- Orbulov, I.N.; Májlinger, K. Description of the compressive response of metal matrix syntactic foams. Mater. Des. 2013, 49, 1–9. [Google Scholar] [CrossRef]

- Jia, R.; Zhao, G. Progress in constitutive behavior of aluminum foam. Chin. J. Theor. Appl. Mech. 2020, 52, 603–622. [Google Scholar]

- Hu, L.; Huang, X.; Zhang, H.; Tang, L. One-dimension Viscous-plastic Constitution of Aluminum Foam. J. China Univ. Technol. Nat. Sci. Ed. 2004, 32, 87–91. [Google Scholar]

- Chen, C.; Lu, T. A phenomenological framework of constitutive modelling for incompressible and compressible elasto-plastic solids. Int. J. Solids Struct. 2000, 37, 7769–7786. [Google Scholar] [CrossRef]

- Wang, E.; Yu, J.; Wang, F.; Sun, L. A theoretical and experimental study on the quasi—Static constitutive model of aluminum foams. Acta Mech. Sin. 2004, 36, 673–679. [Google Scholar]

- Miller, R.E. A continuum plasticity model for the constitutive and indentation behaviour of foamed metals. Int. J. Mech. Sci. 2000, 42, 729–754. [Google Scholar] [CrossRef]

- Jacques, N.; Barthelemy, R. An analytical expression for the Hugoniot stress–strain curve of elastic-plastic cellular materials. Int. J. Impact Eng. 2018, 115, 76–80. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.; Wang, L. Experimental determination of dynamic constitutive parameters for aluminum foams. Explos. Shock. Waves 2015, 35, 1–8. [Google Scholar]

- Deshpande, V.; Fleck, N. Isotropic constitutive models for metallic foams. J. Mech. Phys. Solids 2000, 48, 1253–1283. [Google Scholar] [CrossRef] [Green Version]

- Reyes, A.; Hopperstad, O.; Berstad, T.; Hanssen, A.; Langseth, M. Constitutive modeling of aluminum foam including fracture and statistical variation of density. Eur. J. Mech. A Solids 2003, 22, 815–835. [Google Scholar] [CrossRef]

- Liu, Q.; Subhash, G. A phenomenological constitutive model for foams under large deformations. Polym. Eng. Sci. 2004, 44, 463–473. [Google Scholar] [CrossRef]

- Sherwood, J.A.; Frost, C.C. Constitutive modeling and simulation of energy absorbing polyurethane foam under impact loading. Polym. Eng. Sci. 1992, 32, 1138–1146. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, F.; Hu, S. An Empirical Dynamic Constitutive Model for Aluminum Foams and Its Implemention in LS-DYNA. Acta Armamentar II 2014, 35, 46–50. [Google Scholar]

- Wang, P.; Xu, S.; Li, Z.; Yang, J.; Zheng, H.; Hu, S. Temperature effects on the mechanical behavior of aluminum foam under dynamic loading. Mater. Sci. Eng. A 2014, 599, 174–179. [Google Scholar] [CrossRef]

- Qi, M.-S.; Zhang, W.; Wang, J.-Y.; Ren, G.-M.; Yin, Y.-P.; Lu, C.-X. A three dimensional modeling method for spherical open cell aluminum foams based on spherical core stratification algorithm. China Foundry 2019, 16, 248–255. [Google Scholar] [CrossRef] [Green Version]

- Gao, H.; Xiong, C.; Yin, J. Experimental and Constitutive Model on Dynamic Compressive Mechanical Properties of Aluminum Foams under Repeated Impacts. Acta Armamentar II 2018, 39, 2410–2419. [Google Scholar]

- Banhart, J. Metal Foams: Production and Stability. Adv. Eng. Mater. 2006, 8, 781–794. [Google Scholar] [CrossRef]

- Pengfei, W. Research on Dynamic Mechanical Response of Cellular Metals and Temperature Dependency. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2012. [Google Scholar]

| No. | Pressure State | Density Range |

|---|---|---|

| 1 | Quasi-static experiment | 0.23–0.25 g/cm3 |

| 2 | 0.41–0.45 g/cm3 | |

| 3 | 0.62–0.68 g/cm3 | |

| 4 | 0.73–0.79 g/cm3 |

| Structural Parameter Ω | Density (g/cm3) | Plastic Yield Strain | Elastic Modulus (MPa) | Yield Stress (MPa) | Initial Strain of Yield Plateau Stage | Yield Plateau Stress (MPa) | Densification Strain |

|---|---|---|---|---|---|---|---|

| 0.138 | 0.237 | 0.0351 | 78.57 | 2.043 | 0.0914 | 2.07 | 0.738 |

| 0.1519 | 0.423 | 0.0654 | 252.78 | 7.41 | 0.1695 | 7.89 | 0.687 |

| 0.1735 | 0.725 | 0.0685 | 491.47 | 19.779 | 0.1727 | 14.5 | 0.673 |

| 0.2011 | 0.662 | 0.0787 | 401.11 | 16.356 | 0.1764 | 14.23 | 0.637 |

| Parameter | A1 | A2 | A3 | A4 | A5 | A6 |

|---|---|---|---|---|---|---|

| Value | 126.71 | −3017.97 | 32,720.82 | −191,926.73 | 669,897.0082 | −1,455,540 |

| Parameter | A7 | A8 | A9 | A10 | a | |

| Value | 1,986,420 | −1,653,940 | 766,307.24 | −150,868.865 | 1.82 | 0.05 |

| Parameter | m | k | ||||

| Value | 1.08 | 1.754 | 0.0266 |

| Initial Velocities (m/s) | Residual Velocity of Experiments (m/s) | Residual Velocity of Numerical Simulation (m/s) | Result Error (%) |

|---|---|---|---|

| 216 | 48 | 45.2 | −5.833 |

| 247 | 122 | 125.3 | 2.70 |

| 632 | 495 | 518.3 | 4.71 |

| 855 | 725 | 704 | −2.9 |

| 971 | 859 | 799 | −6.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Q.; Li, W.; Yao, W.; Wang, X.; Huang, C. Mechanical Properties and Constitutive Model Applied to the High-Speed Impact of Aluminum Foam That Considers Its Meso-Structural Parameters. Materials 2021, 14, 6206. https://doi.org/10.3390/ma14206206

Guo Q, Li W, Yao W, Wang X, Huang C. Mechanical Properties and Constitutive Model Applied to the High-Speed Impact of Aluminum Foam That Considers Its Meso-Structural Parameters. Materials. 2021; 14(20):6206. https://doi.org/10.3390/ma14206206

Chicago/Turabian StyleGuo, Qian, Wenbin Li, Wenjin Yao, Xiaoming Wang, and Changqiang Huang. 2021. "Mechanical Properties and Constitutive Model Applied to the High-Speed Impact of Aluminum Foam That Considers Its Meso-Structural Parameters" Materials 14, no. 20: 6206. https://doi.org/10.3390/ma14206206

APA StyleGuo, Q., Li, W., Yao, W., Wang, X., & Huang, C. (2021). Mechanical Properties and Constitutive Model Applied to the High-Speed Impact of Aluminum Foam That Considers Its Meso-Structural Parameters. Materials, 14(20), 6206. https://doi.org/10.3390/ma14206206