Investigation on Microstructure, Nanohardness and Corrosion Response of Laser Cladded Colmonoy-6 Particles on 316L Steel Substrate

Abstract

:1. Introduction

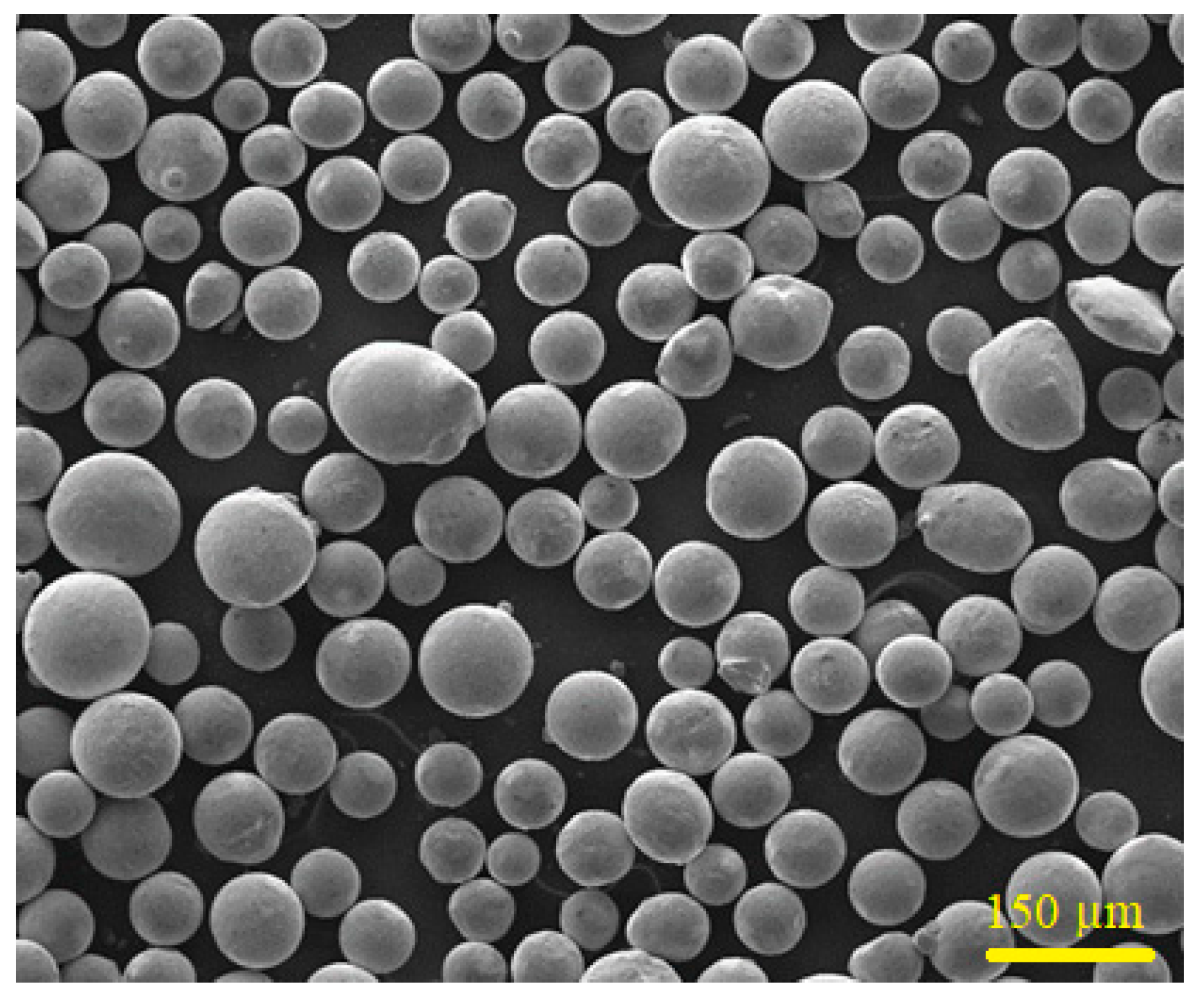

2. Materials and Methods

2.1. Materials

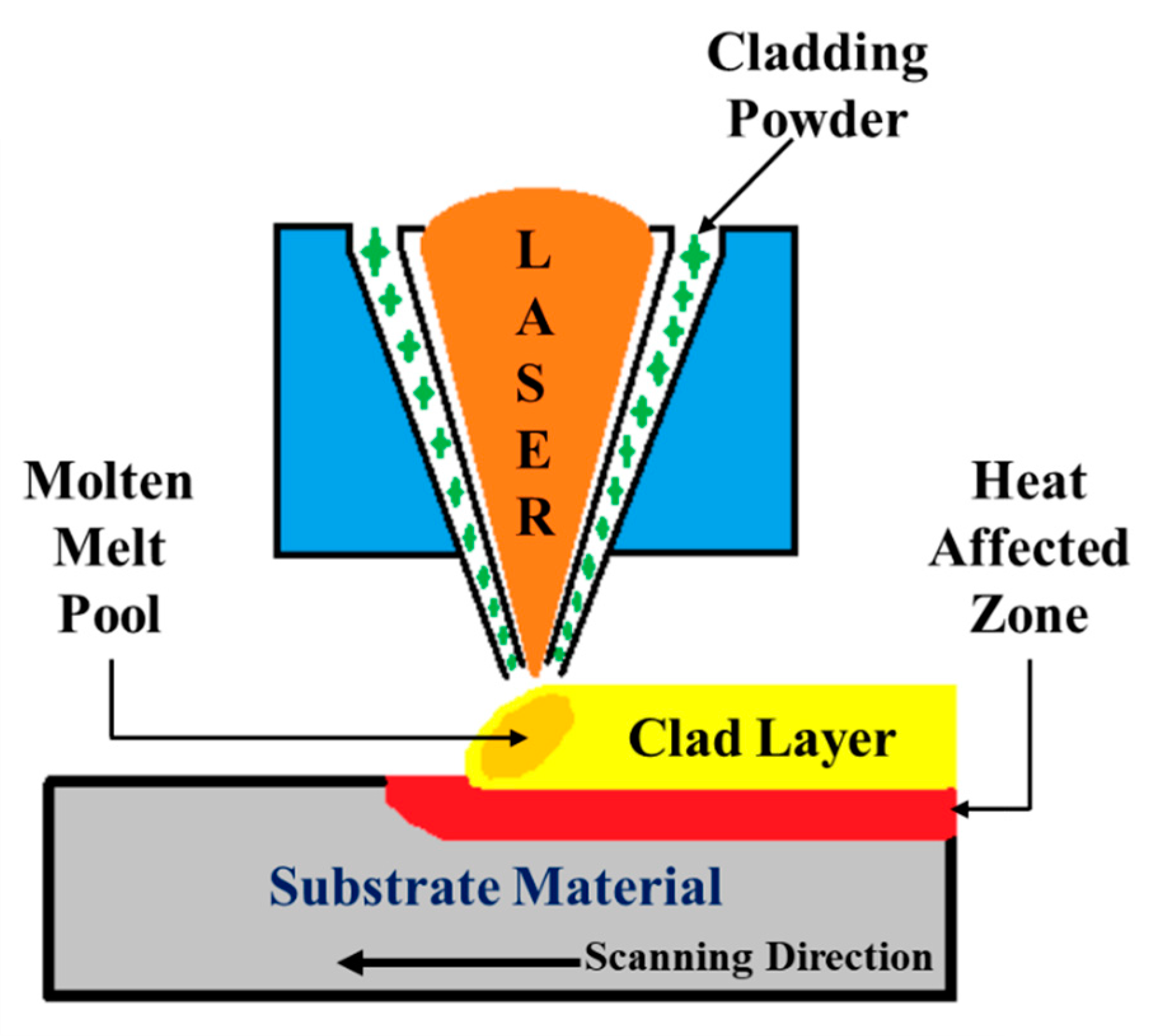

2.2. Laser Cladding Method

2.3. Corrosion Analysis

3. Results and Discussion

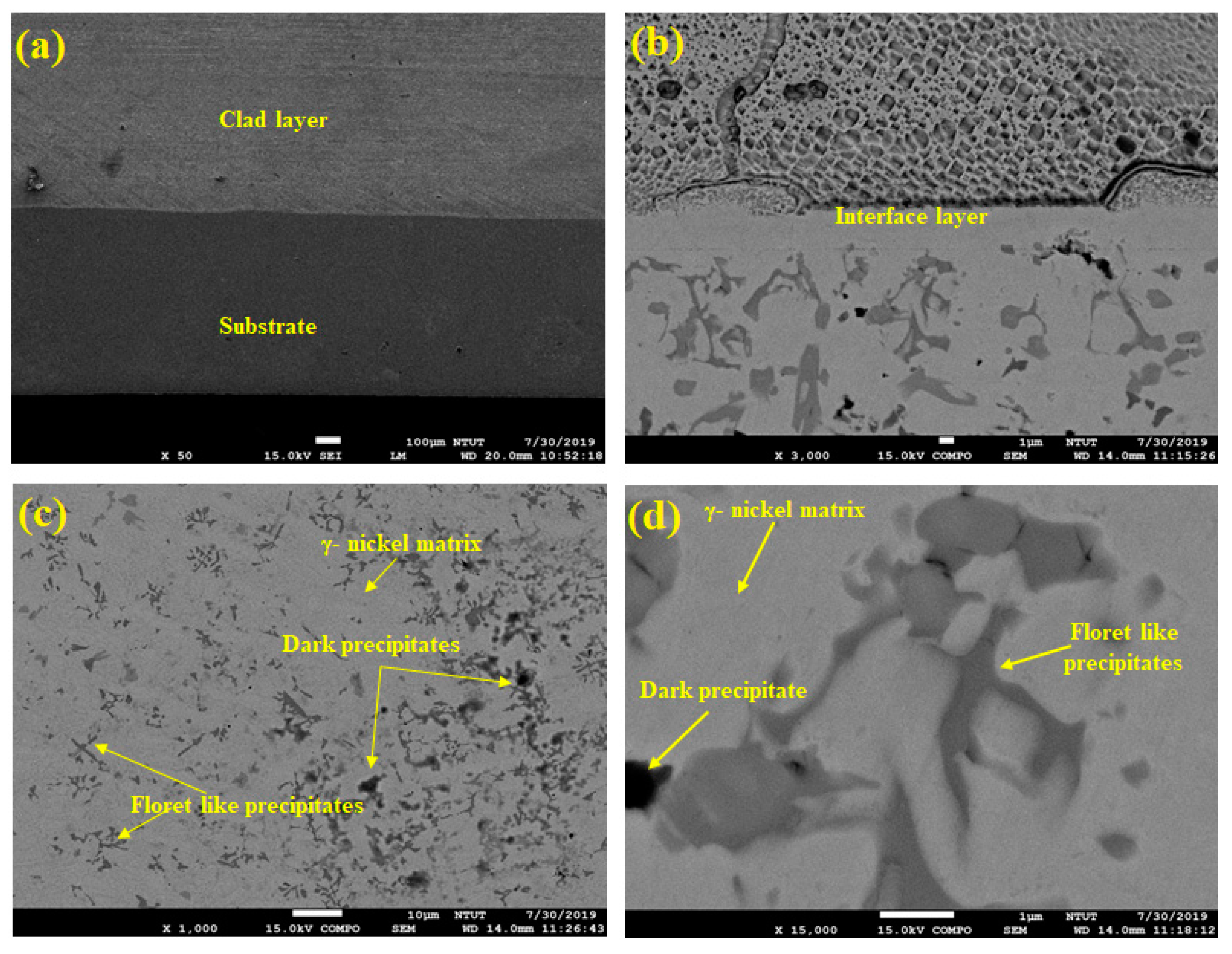

3.1. Microstructure Examination

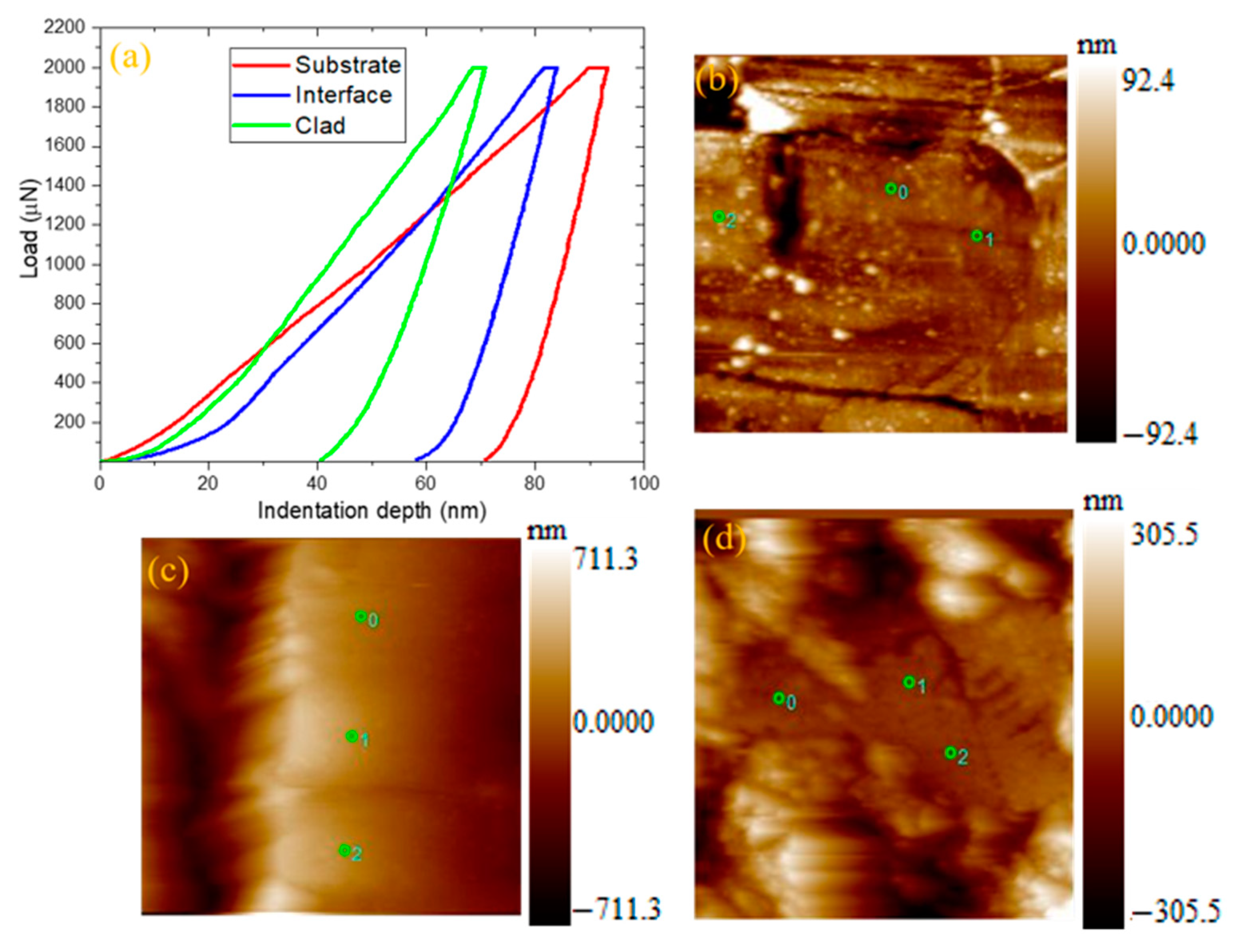

3.2. Hardness Evaluation

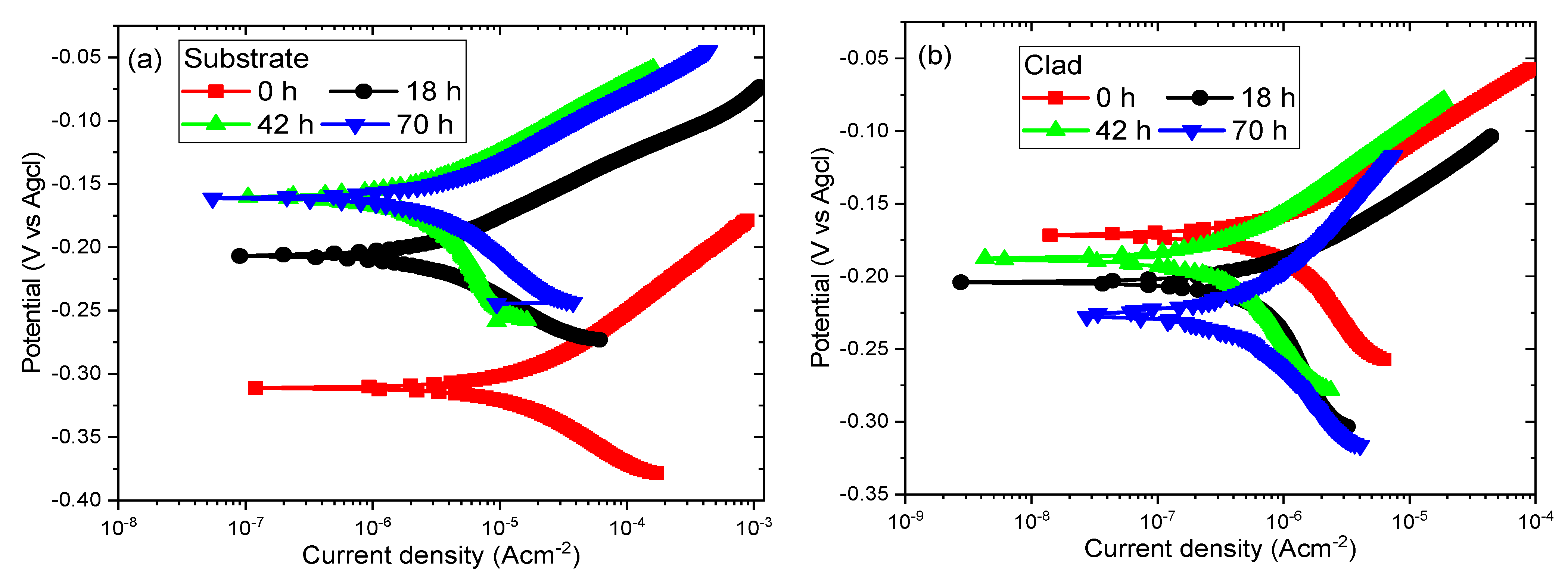

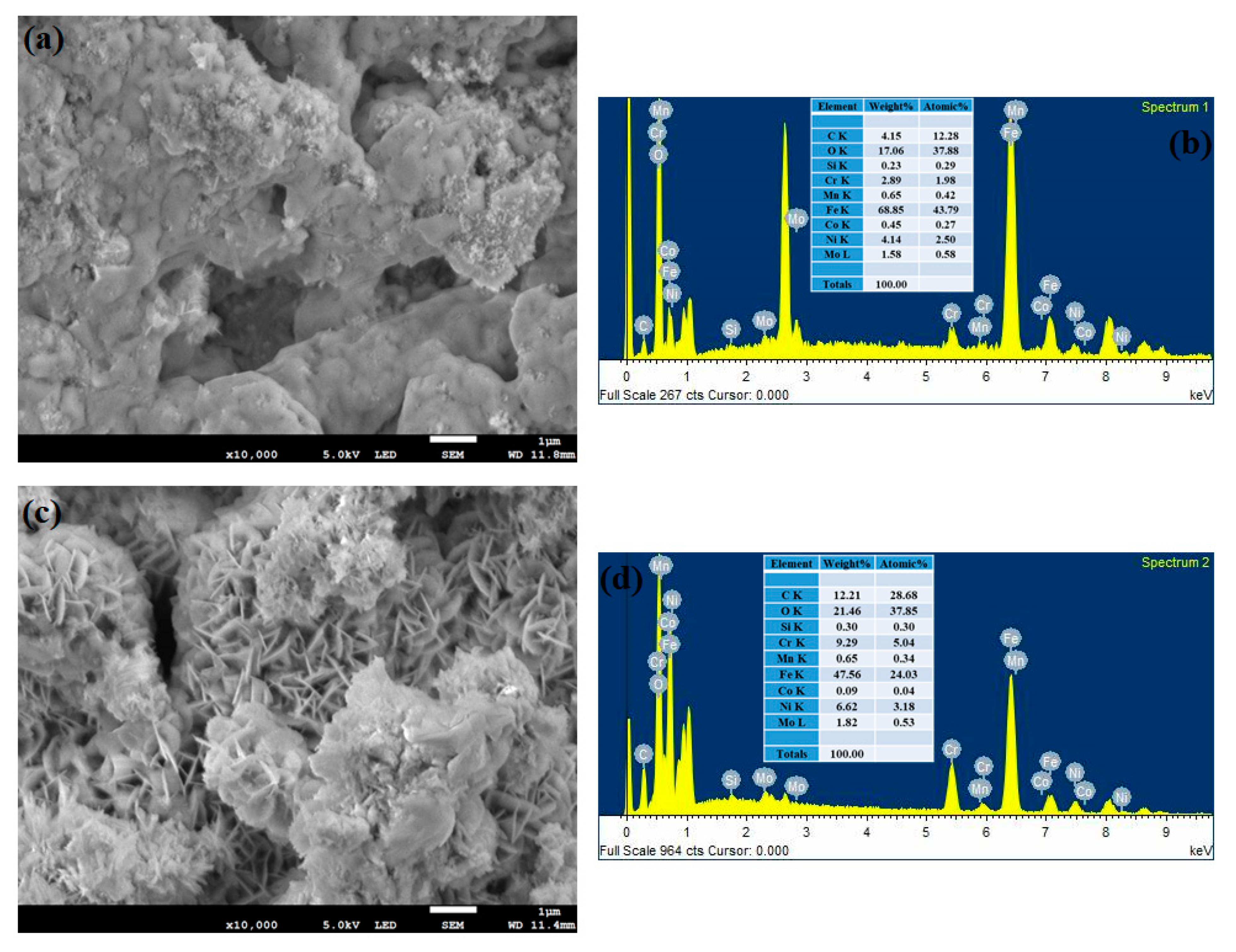

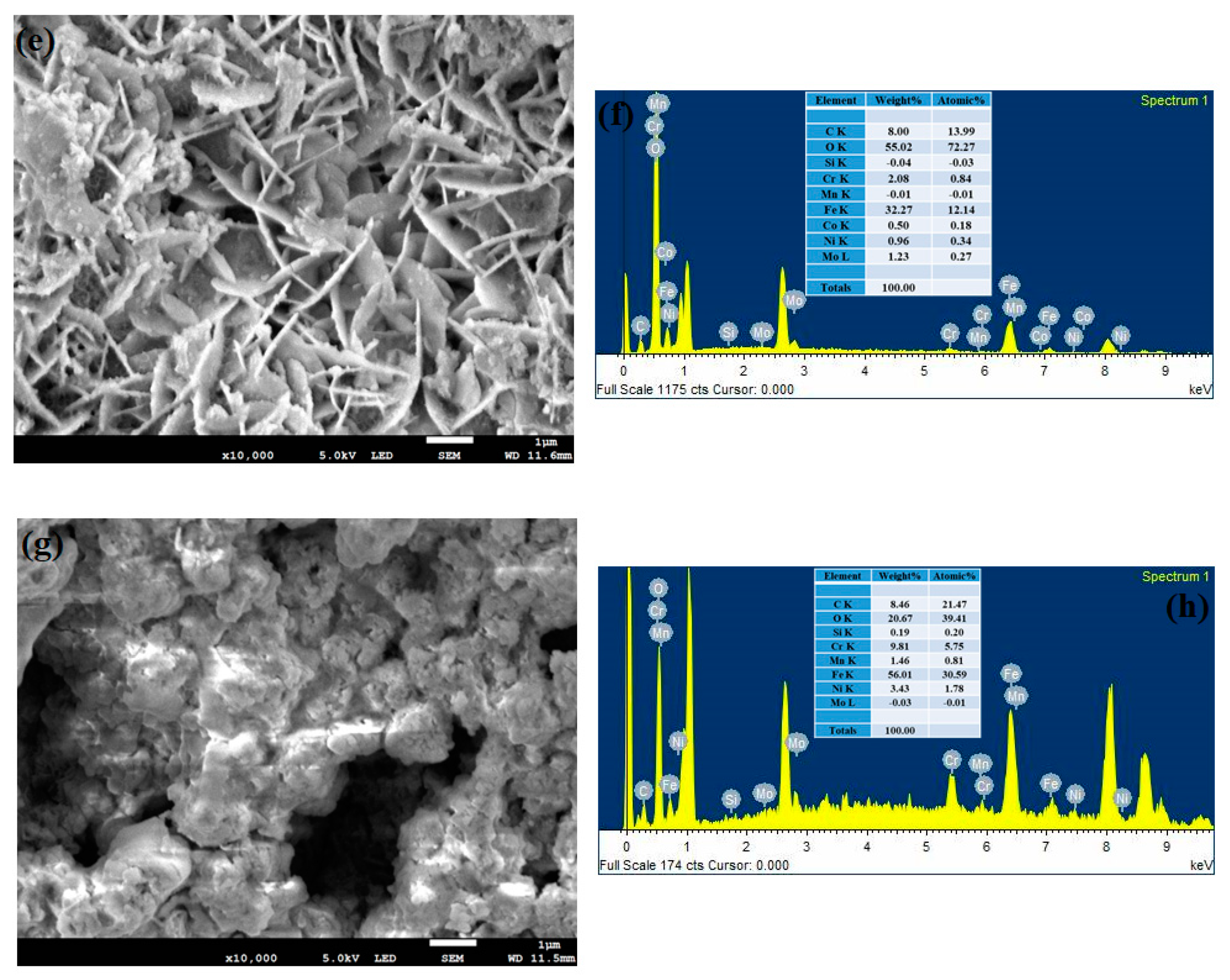

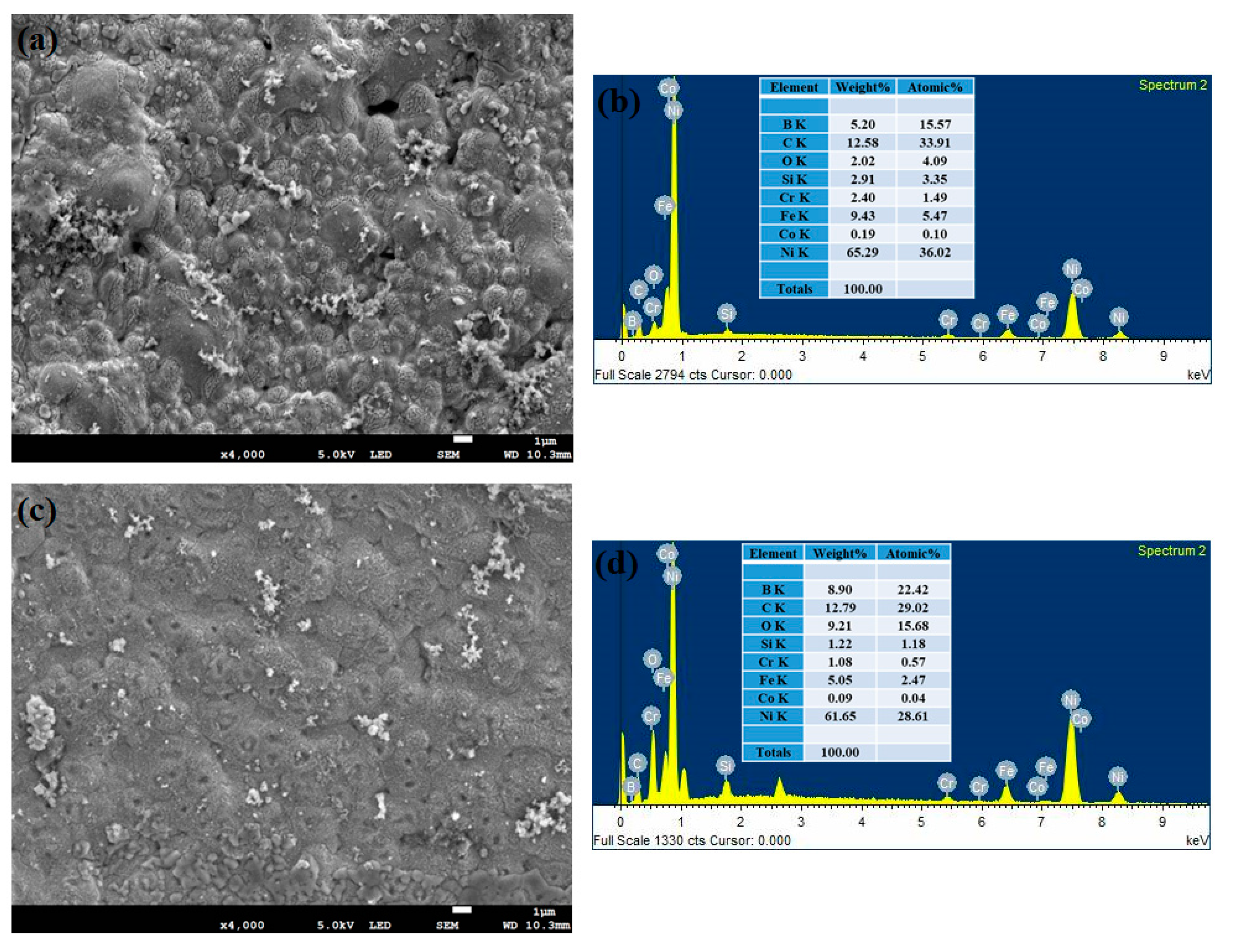

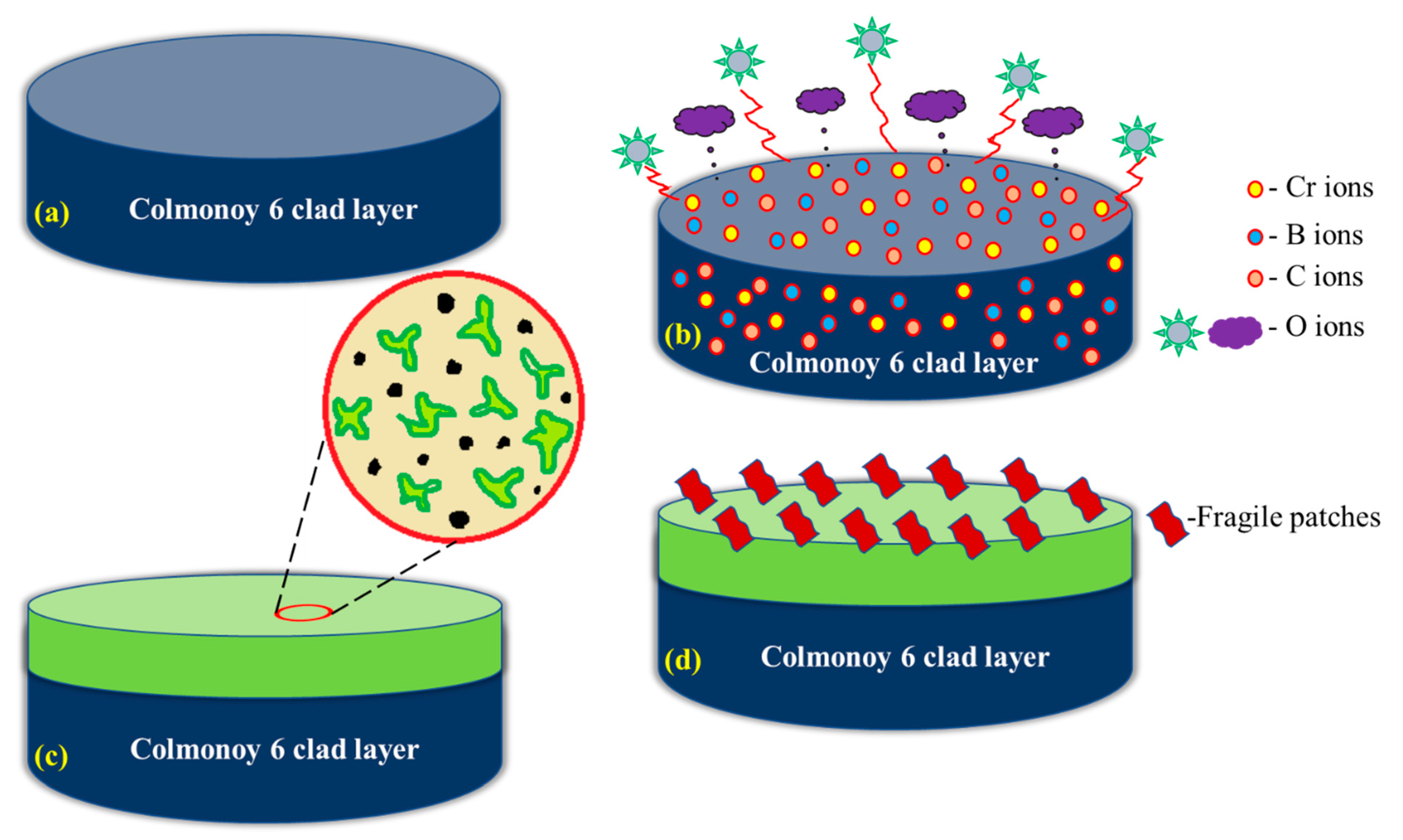

3.3. Corrosion Behavior Analysis

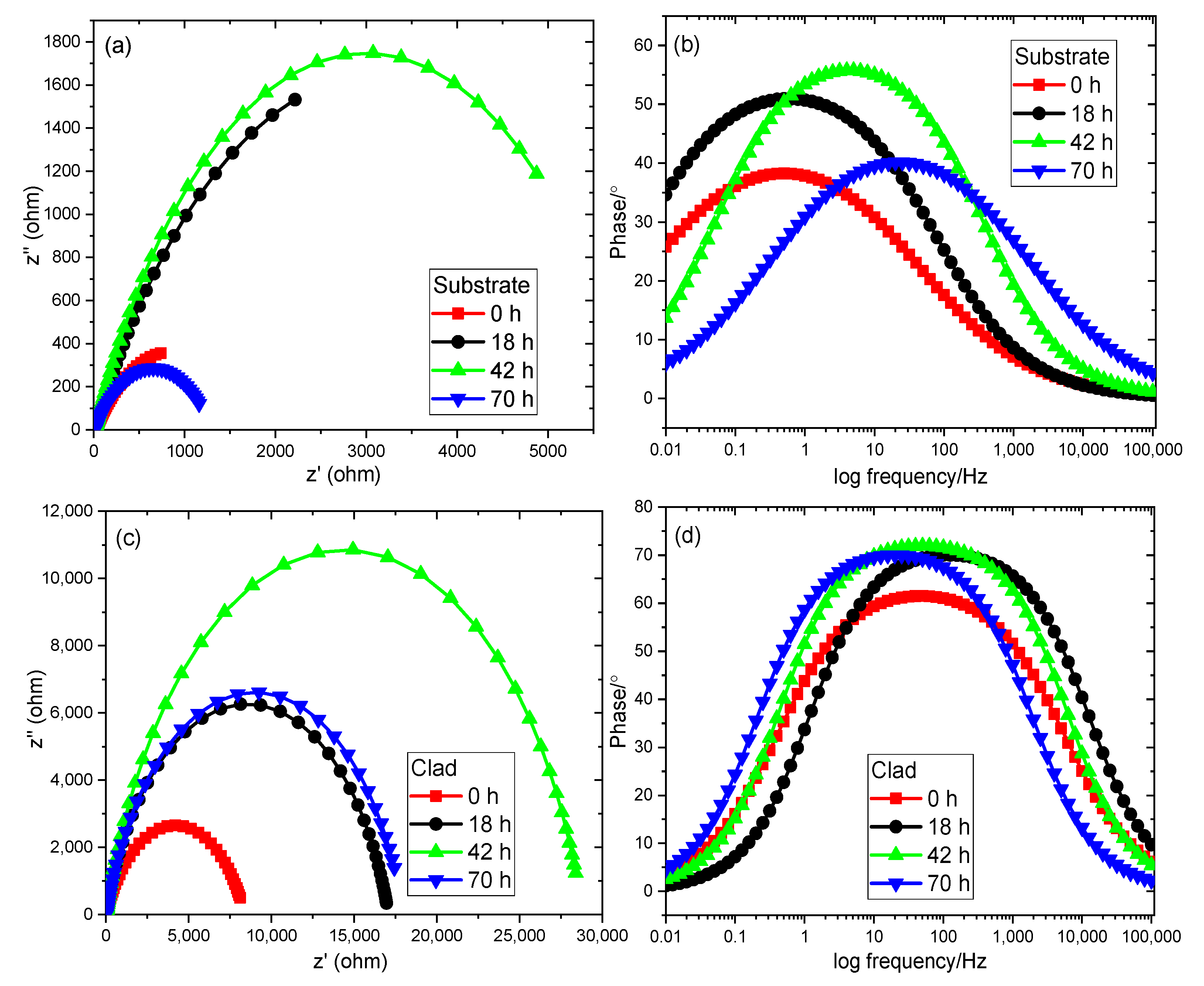

3.4. Electrochemical Impedance Spectroscopy (EIS) Evaluation

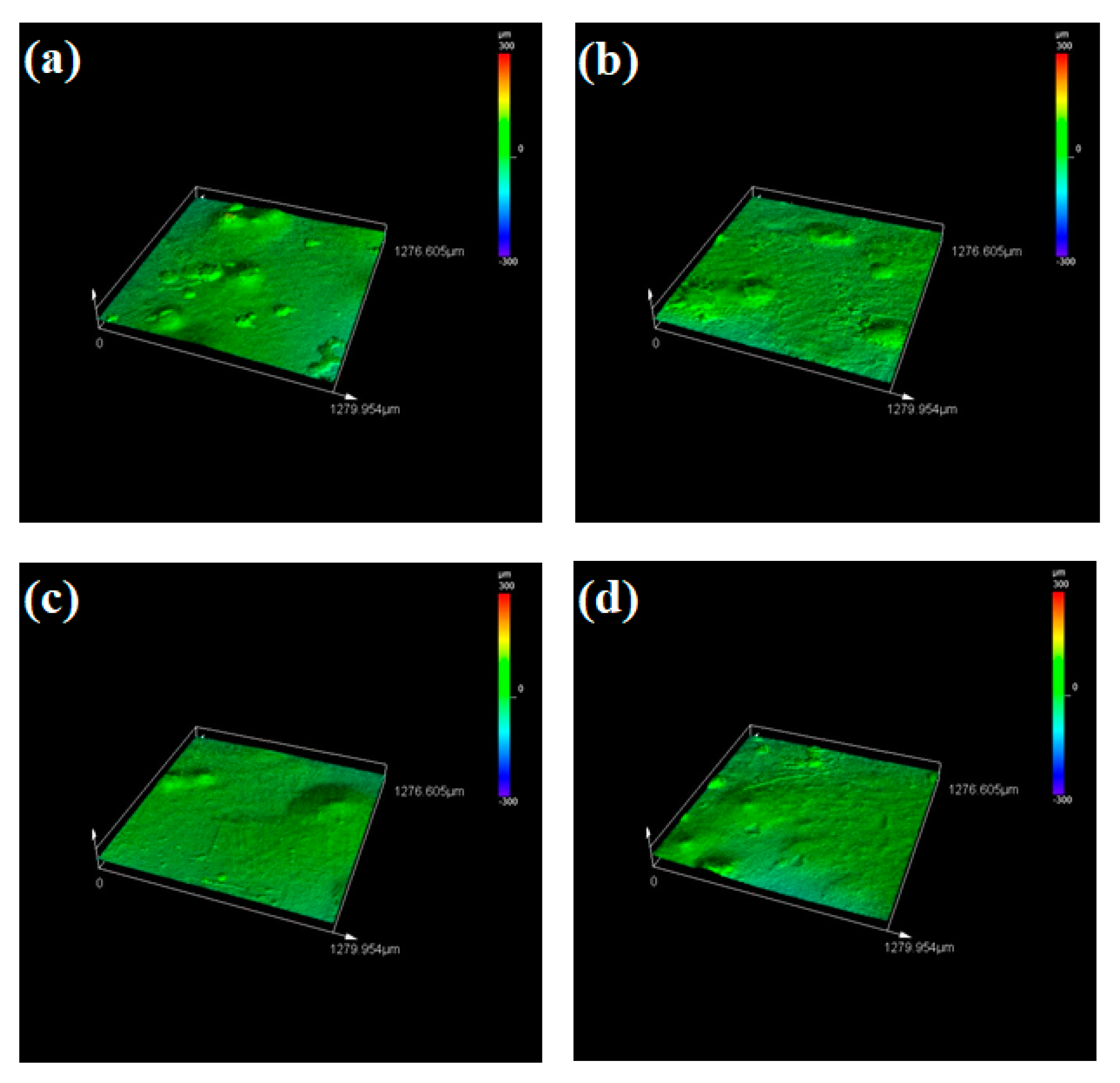

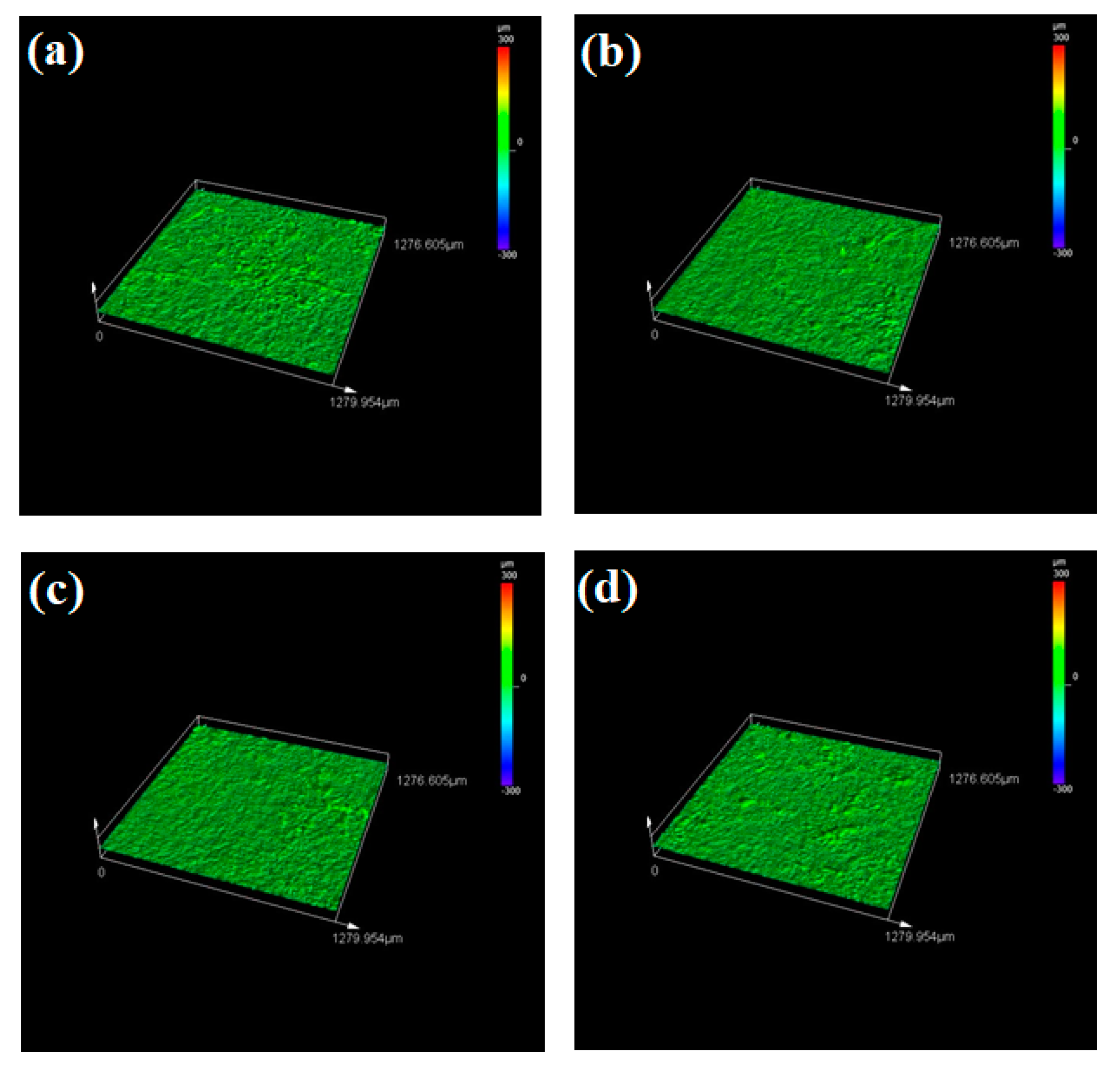

3.5. Corroded Surface Roughness Characteristics

4. Conclusions

- The microstructural examination reveals that the clad region consists of the hard laves phase of dendritic and interdendritic structures in the γ-nickel matrix. These structures are due to the existence of dark and floret-like precipitates of chromium-rich carbides and borides which aids in enhancing the properties at the clad region.

- From the nanoindentation study, it is evident that the cladded region experiences a higher hardness value due to lower indentation depth than the substrate and interface region. Moreover, the higher hardness at the cladded surface is because of the chromium boride precipitates thereby enhances the wear resistance.

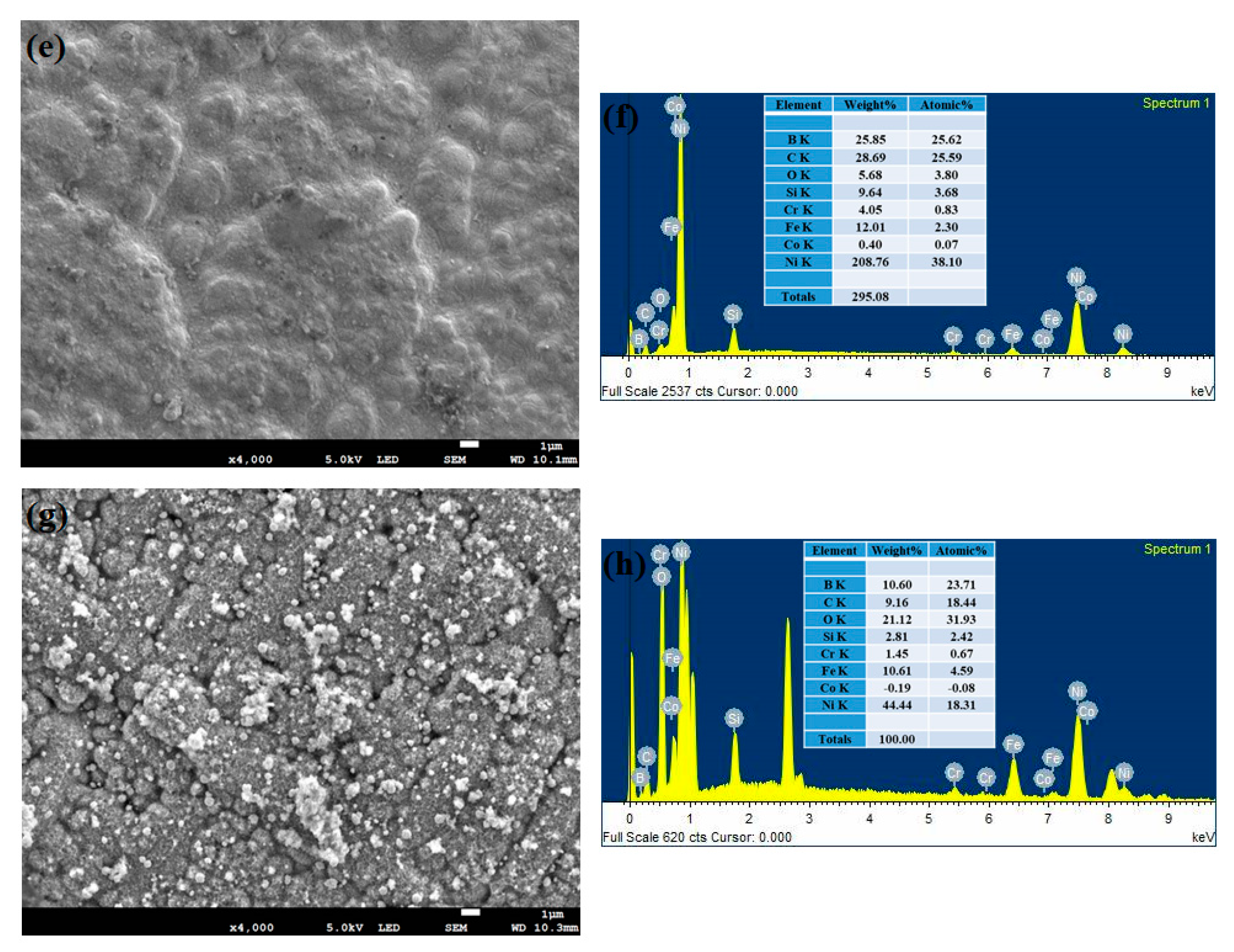

- The results of the Tafel plots for both substrate and clad samples show that the cladded samples have lower current density values than the substrate samples. The 42 h clad sample has the lowest current density and offers excellent resistance towards corrosion compared with other clad and substrate samples. In addition, in the 42 h clad sample, a stable passive film is formed that resists corrosion compared to the other passive films observed by FESEM with the EDS technique.

- The EIS analysis also proves that the cladded samples have a larger arc radius (Nyquist plot) and greater area-covered curves (bode plot) than the substrate samples. Further, the polarization resistance has been calculated for both samples. Thus, the Nyquist, bode and RP values are higher for cladded samples and in particular, the 42 h clad sample provides greater corrosion resistance due to the maximum value of RP (28,798).

- The surface roughness measurement also confirms that the laser cladded Colmonoy-6 samples have a minimum value of surface roughness. Also, the 42 h clad sample has a lower value of roughness (Ra = 3.795 µm) thereby offering maximum corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sproul, W.D. Physical vapor deposition tool coatings. Surf. Coat. Technol. 1996, 81, 1–7. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Sabarison, P.; Liu, Z.C.; Liao, A.H.; Muthusankar, G.; Huang, S.T.; Lee, C.T.; Chuang, H.C. High-performance anti-corrosion behavior of graphene oxide decorated nickel coating by novel ultrasonic-assisted supercritical-CO2 electrodeposition approach. Electrochim. Acta 2021, 387, 138543. [Google Scholar]

- Berndt, M.L.; Berndt, C.C. Thermal spray coatings. Corros. Fundam. Test. Prot. 2003, 13, 803–813. [Google Scholar]

- Espallargas, N. (Ed.) Future Development of Thermal Spray Coatings: Types, Designs, Manufacture and Applications; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; William Andrew: Norwich, NY, USA, 2010. [Google Scholar]

- Liu, Y.; Ding, Y.; Yang, L.; Sun, R.; Zhang, T.; Yang, X. Research and progress of laser cladding on engineering alloys: A review. J. Manuf. Process. 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Staicu, A.R. Review of the laser cladding technology. Metalurgia 2012, 64, 36. [Google Scholar]

- Birger, E.M.; Moskvitin, G.V.; Polyakov, A.N.; Arkhipov, V.E. Industrial laser cladding: Current state and future. Weld. Int. 2011, 25, 234–243. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Ramkumar, K.R.; Sui, G.Z. Comparison of microstructure, mechanical and wear behaviour of laser cladded stainless steel 410 substrate using stainless steel 420 and Colmonoy 5 particles. J. Iron Steel Res. Int. 2020, 27, 1446–1455. [Google Scholar] [CrossRef]

- Eshkabilov, S.; Ara, I.; Sevostianov, I.; Azarmi, F.; Tangpong, X. Mechanical and thermal properties of stainless steel parts, manufactured by various technologies, in relation to their microstructure. Int. J. Eng. Sci. 2021, 159, 103398. [Google Scholar] [CrossRef]

- Baddoo, N. 100 years of stainless steel: A review of structural applications and the development of design rules. SESOC J. 2013, 26, 17–27. [Google Scholar]

- Gardner, L. Stability and design of stainless steel structures–Review and outlook. Thin-Walled Struct. 2019, 141, 208–216. [Google Scholar] [CrossRef]

- Kaladhar, M.; Subbaiah, K.V.; Rao, C.S. Machining of austenitic stainless steels—A review. Int. J. Mach. Mach. Mater. 2012, 12, 178–192. [Google Scholar] [CrossRef]

- Singh, A. Hardness, Wear and Corrosion Improvement techniques for Austenitic Stainless Steel SS316L-A Review. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 955. [Google Scholar]

- Plaut, R.L.; Herrera, C.; Escriba, D.M.; Rios, P.R.; Padilha, A.F. A short review on wrought austenitic stainless steels at high temperatures: Processing, microstructure, properties and performance. Mater. Res. 2007, 10, 453–460. [Google Scholar] [CrossRef]

- Bhosale, D.G.; Rathod, W.S. Investigation on wear behaviour of SS 316L, atmospheric plasma and high velocity oxy-fuel sprayed WC-Cr3C2-Ni coatings for fracturing tools. Surf. Coat. Technol. 2020, 390, 125679. [Google Scholar] [CrossRef]

- Feng, K.; Wu, G.; Li, Z.; Cai, X.; Chu, P.K. Corrosion behavior of SS316L in simulated and accelerated PEMFC environments. Int. J. Hydrogen Energy 2011, 36, 13032–13042. [Google Scholar] [CrossRef]

- Rao, M.A.; Babu, R.S.; Kumar, M.P. Stress corrosion cracking failure of a SS 316L high pressure heater tube. Eng. Fail. Anal. 2018, 90, 14–22. [Google Scholar]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Balaguru, S.; Gupta, M. Hardfacing studies of Ni alloys: A critical review. J. Mater. Res. Technol. 2020, 10, 1210–1242. [Google Scholar] [CrossRef]

- Das, C.R.; Albert, S.K.; Bhaduri, A.K.; Sudha, C.; Terrance, A.L. Characterisation of nickel based hardfacing deposits on austenitic stainless steel. Surf. Eng. 2005, 21, 290–296. [Google Scholar] [CrossRef]

- Ramasubbu, V.; Chakraborty, G.; Albert, S.K.; Bhaduri, A.K. Effect of dilution on GTAW Colmonoy 6 (AWS NiCr–C) hardface deposit made on 316LN stainless steel. Mater. Sci. Technol. 2011, 27, 573–580. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, H.; Xu, C.Y. Research on the Structure and Wear Resistance of Colmonoy 6 Alloy Coating Cladded on Austenitic Stainless Steel by Laser. Acta Armamentarii 2010, 31, 927–932. [Google Scholar]

- Kumar, H.; Ramakrishnan, V.; Albert, S.K.; Bhaduri, A.K.; Ray, K.K. Friction and wear behaviour of Ni-Cr-B hardface coating on 316LN stainless steel in liquid sodium at elevated temperature. J. Nucl. Mater. 2017, 495, 431–437. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Tseng, S.P. Wear Tribo-performances of laser cladding Colmonoy-6 and Stellite-6 Micron layers on stainless steel 304 using Yb: YAG disk laser. Met. Mater. Int. 2021, 27, 1540–1553. [Google Scholar] [CrossRef]

- Mele, C.; Lionetto, F.; Bozzini, B. An erosion-corrosion investigation of coated steel for applications in the oil and gas field, based on bipolar electrochemistry. Coatings 2020, 10, 92. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Geng, Y.; Konovalov, S.V.; Chen, X. Research status and application of the high-entropy and traditional alloys fabricated via the laser cladding. Usp. Fiz. Met. 2020, 21, 26–45. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Kumar, N.; Fusco, M.; Komarasamy, M.; Mishra, R.S.; Bourham, M.; Murty, K.L. Understanding effect of 3.5 wt.% NaCl on the corrosion of Al0. 1CoCrFeNi high-entropy alloy. J. Nucl. Mater. 2017, 495, 154–163. [Google Scholar] [CrossRef]

- Kwok, C.T.; Cheng, F.T.; Man, H.C. Synergistic effect of cavitation erosion and corrosion of various engineering alloys in 3.5% NaCl solution. Mater. Sci. Eng. A 2000, 290, 145–154. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Sivasankaran, S. Laser cladding process of Cobalt and Nickel based hard-micron-layers on 316L-stainless-steel-substrate. Mater. Manuf. Process. 2020, 35, 142–151. [Google Scholar] [CrossRef]

- Ming, Q.; Lim, L.C.; Chen, Z.D. Laser cladding of nickel-based hardfacing alloys. Surf. Coat. Technol. 1998, 106, 174–182. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, Y.; Kutsuna, M.; Xu, G.J. Laser cladding of Colmonoy 6 powder on AISI316L austenitic stainless steel. Nucl. Eng. Des. 2010, 240, 2691–2696. [Google Scholar] [CrossRef]

- Lim, L.C.; Ming, Q.; Chen, Z.D. Microstructures of laser-clad nickel-based hardfacing alloys. Surf. Coat. Technol. 1998, 106, 183–192. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Ramkumar, K.R. Microstructure and wear resistance of laser cladded Inconel 625 and Colmonoy 6 depositions on Inconel 625 substrate. Appl. Phys. A 2020, 126, 1–11. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T. Effects of the alloy composition on phase constitution and properties of laser deposited Ni-Cr-B-Si coatings. Phys. Procedia 2013, 41, 302–311. [Google Scholar] [CrossRef] [Green Version]

- Ballarre, J.; López, D.A.; Cavalieri, A.L. Nano-indentation of hybrid silica coatings on surgical grade stainless steel. Thin Solid Film. 2008, 516, 1082–1087. [Google Scholar] [CrossRef]

- Hu, H.X.; Guo, X.M.; Zheng, Y.G. Comparison of the cavitation erosion and slurry erosion behavior of cobalt-based and nickel-based coatings. Wear 2019, 428, 246–257. [Google Scholar]

- Chen, L.; Bai, S.L. The anti-corrosion behavior under multi-factor impingement of Hastelloy C22 coating prepared by multilayer laser cladding. Appl. Surf. Sci. 2018, 437, 1–12. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural characteristics and tribological behavior of HVOF-sprayed novel Fe-based alloy coatings. Coatings 2014, 4, 98–120. [Google Scholar] [CrossRef]

- Krawczyk, J.; Bembenek, M.; Frocisz, Ł.; Śleboda, T.; Paćko, M. The Effect of Sandblasting on Properties and Structures of the DC03/1.0347, DC04/1.0338, DC05/1.0312, and DD14/1.0389 Steels for Deep Drawing. Materials 2021, 14, 3540. [Google Scholar] [CrossRef]

- Iqbal, M.; Prasetya, D.; Mahardika, M.; Suyitno, S.; Arifvianto, B.; Prihandana, G.S.; Dewo, P. The effect of sandblasting on AISI 316L stainless steels. In Proceedings of the Prosiding Industrial Research Workshop and National Seminar, Bandung, Indonesia, 17 November 2011; Volume 2, pp. 58–61. [Google Scholar]

- Reinaldo, P.R.; D’Oliveira, A.S. NiCrSiB coatings deposited by plasma transferred arc on different steel substrates. J. Mater. Eng. Perform. 2013, 22, 590–597. [Google Scholar] [CrossRef]

- Kosaka, T.; Suzuki, S.; Inoue, H.; Saito, M.; Waseda, Y.; Matsubara, E. XPS/GIXS studies of thin oxide films formed on Fe-Cr alloys. Appl. Surf. Sci. 1996, 103, 55–61. [Google Scholar] [CrossRef]

- Luo, X.; Tang, R.; Long, C.; Miao, Z.; Peng, Q.; Li, C. Corrosion behavior of austenitic and ferritic steels in supercritical water. Nucl. Eng. Technol. 2008, 40, 147–154. [Google Scholar] [CrossRef]

- Loto, R.T. Study of the corrosion behaviour of S32101 duplex and 410 martensitic stainless steel for application in oil refinery distillation systems. J. Mater. Res. Technol. 2017, 6, 203–212. [Google Scholar] [CrossRef]

- Marcus, P.; Maurice, V.; Strehblow, H.H. Localized corrosion (pitting): A model of passivity breakdown including the role of the oxide layer nanostructure. Corros. Sci. 2008, 50, 2698–2704. [Google Scholar] [CrossRef]

- Zhou, C.; Hu, S.; Shi, Q.; Tao, H.; Song, Y.; Zheng, J.; Xu, P.; Zhang, L. Improvement of corrosion resistance of SS316L manufactured by selective laser melting through subcritical annealing. Corros. Sci. 2020, 164, 108353. [Google Scholar] [CrossRef]

- Torbati-Sarraf, H.; Ghamarian, I.; Poorganji, B.; Torbati-Sarraf, S.A. An Investigation on the role of crystallographic texture on anisotropic electrochemical behavior of a commercially pure nickel manufactured by laser powder bed fusion (L-PBF) additive manufacturing. Electrochim. Acta 2020, 354, 136694. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, A.; Wang, Y.; Xiong, D.; Tang, H. Diode laser cladding of Fe-based alloy on ductile cast iron and related interfacial behavior. Surf. Coat. Technol. 2016, 286, 64–71. [Google Scholar] [CrossRef]

- Chandran, S.; Vinayak, S.N.; Subramanian, V.; Rangarajan, S.; Velmurugan, S.; Narasimhan, S.V.; Ramasubbu, V.; Albert, S.K. Effect of substrate dilution on corrosion of colmonoy-6 weld overlays in nitric acid. Int. J. Nucl. Energy Sci. Technol. 2011, 6, 199–212. [Google Scholar] [CrossRef]

- Mei, B.A.; Munteshari, O.; Lau, J.; Dunn, B.; Pilon, L. Physical interpretations of Nyquist plots for EDLC electrodes and devices. J. Phys. Chem. C 2018, 122, 194–206. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Gharbi, O.; Vivier, V.; Gao, M.; Orazem, M.E. Electrochemical impedance spectroscopy. Nat. Rev. Methods Primers 2021, 1, 1–21. [Google Scholar] [CrossRef]

- Selvam Kevin, P.; Tiwari, A.; Seman, S.; Beer Mohamed, S.A.; Jayaganthan, R. Erosion-Corrosion Protection Due to Cr3C2-NiCr Cermet Coating on Stainless Steel. Coatings 2020, 10, 1042. [Google Scholar] [CrossRef]

- Moghaddasi, M.; Bozorg, M.; Aghaie, E.; Bakhtiyari, H.; Torbati-Sarraf, H. Corrosion and Wear Analysis of High-Velocity Oxy-Fuel Sprayed WC-10Co-4Cr and Colmonoy-6 Coatings on Nickel-Aluminum Bronze Alloy Substrate. J. Mater. Eng. Perform. 2021, 30, 7564–7576. [Google Scholar] [CrossRef]

- Ahn, S.H.; Choi, Y.S.; Kim, J.G.; Han, J.G. A study on corrosion resistance characteristics of PVD Cr-N coated steels by electrochemical method. Surf. Coat. Technol. 2002, 150, 319–326. [Google Scholar] [CrossRef]

- Hong, M.S.; Park, Y.; Kim, J.G.; Kim, K. Effect of incorporating MoS2 in organic coatings on the corrosion resistance of 316L stainless steel in a 3.5% NaCl solution. Coatings 2019, 9, 45. [Google Scholar] [CrossRef] [Green Version]

- Chira, M.; Hegyi, A.; Vermeşan, H.; Szilagyi, H.; Lăzărescu, A. Corrosion Resistance of Electrodeposited Layers using a Zn-Ni Electrolyte Impregnated with Tri-, Tetra-, and Pentavalent Elements. Procedia Manuf. 2020, 46, 4–11. [Google Scholar] [CrossRef]

- Toloei, A.; Stoilov, V.; Northwood, D. The relationship between surface roughness and corrosion. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 56192, p. V02BT02A054. [Google Scholar]

- Budke, E.; Krempel-Hesse, J.; Maidhof, H.; Schüssler, H. Decorative hard coatings with improved corrosion resistance. Surf. Coat. Technol. 1999, 112, 108–113. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P.P. Understanding the role of surface roughness on the tribological performance and corrosion resistance of WC-Co coating. Surf. Coat. Technol. 2019, 378, 125080. [Google Scholar] [CrossRef]

- Walter, R.; Kannan, M.B. Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater. Des. 2011, 32, 2350–2354. [Google Scholar] [CrossRef]

| Material | Ni (%) | P (%) | Cr (%) | Fe (%) | B (%) | Si (%) | C (%) | Mn (%) | S (%) | Mo (%) | N (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 316L steel substrate | 13.00 | 0.045 | 18.00 | BAL | - | 1.00 | 0.03 | 2.00 | 0.015 | 2.5 | 0.10 |

| Colmomoy-6 | BAL | - | 14.3 | 4.00 | 3.00 | 4.25 | 0.70 | - | - | - | - |

| Power | Feed Rate | Scanning Speed | Preheat Temperature | Shielding Gas Flow | Carrier Gas Flow |

|---|---|---|---|---|---|

| 1400 W | 9 g/min | 600 mm/min | 50 °C | 25 L/min | 6 SD @ 100,000/Pa |

| Duration | E-Current (V) | I-Current (A/cm2) |

|---|---|---|

| Substrate 0 h | −0.311714771 | 1.69288259 × 10−5 |

| Substrate 18 h | −0.162945671 | 3.70289779 × 10−6 |

| Substrate 42 h | −0.20528438 | 3.31057838 × 10−6 |

| Substrate 70 h | −0.161990662 | 4.43903655 × 10−6 |

| Clad 0 h | −0.171866157 | 1.00896469 × 10−6 |

| Clad 18 h | −0.203961517 | 7.21036311 × 10−7 |

| Clad 42 h | −0.188327674 | 2.70147248 × 10−7 |

| Clad 70 h | −0.226584607 | 5.16628422 × 10−7 |

| Specimens | Element | C K | O K | Si K | Cr K | Mn K | Fe K | Co K | Ni K | B K | Mo L | Totals | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substrate 0 h | Weight% | 4.15 | 17.06 | 0.23 | 2.89 | 0.65 | 68.85 | 0.45 | 4.14 | - | 1.58 | 100.00 | |

| Atomic% | 12.28 | 37.88 | 0.29 | 1.98 | 0.42 | 43.79 | 0.27 | 2.50 | - | 0.58 | |||

| Substrate 18 h | Weight% | 12.21 | 21.46 | 0.30 | 9.29 | 0.65 | 47.56 | 0.09 | 6.62 | - | 1.82 | 100.00 | |

| Atomic% | 28.68 | 37.85 | 0.30 | 5.04 | 0.34 | 24.03 | 0.04 | 3.18 | - | 0.53 | |||

| Substrate 42 h | Weight% | 8.00 | 55.02 | −0.04 | 2.08 | −0.01 | 32.27 | 0.50 | 0.96 | - | 1.23 | 100.00 | |

| Atomic% | 13.99 | 72.27 | −0.03 | 0.84 | −0.01 | 12.14 | 0.18 | 0.34 | - | 0.27 | |||

| Substrate 70 h | Weight% | 8.46 | 20.67 | 0.19 | 9.81 | 1.46 | 56.01 | - | 3.43 | - | −0.03 | 100.00 | |

| Atomic% | 21.47 | 39.41 | 0.20 | 5.75 | 0.81 | 30.59 | - | 1.78 | - | −0.01 | |||

| Clad 0 h | Weight% | 12.58 | 2.02 | 2.91 | 2.40 | - | 9.43 | 0.19 | 65.29 | 5.20 | - | 100.00 | |

| Atomic% | 33.91 | 4.09 | 3.35 | 1.49 | - | 5.47 | 0.10 | 36.02 | 15.57 | - | |||

| Clad 18 h | Weight% | 12.79 | 9.21 | 1.22 | 1.08 | - | 5.05 | 0.09 | 61.65 | 8.90 | - | 100.00 | |

| Atomic% | 29.02 | 15.68 | 1.18 | 0.57 | - | 2.47 | 0.04 | 28.61 | 22.42 | - | |||

| Clad 42 h | Weight% | 28.69 | 5.68 | 9.64 | 4.05 | - | 12.01 | 0.40 | 208.76 | 25.85 | - | 295.08 | |

| Atomic% | 25.59 | 3.80 | 3.68 | 0.83 | - | 2.30 | 0.07 | 38.10 | 25.62 | - | |||

| Clad 70 h | Weight% | 9.16 | 21.12 | 2.81 | 1.45 | - | 10.61 | −0.19 | 44.44 | 10.60 | - | 100.00 | |

| Atomic% | 18.44 | 31.93 | 2.42 | 0.67 | - | 4.59 | −0.08 | 18.31 | 23.71 | - | |||

| Duration | Element | Rs | RP | CPE | |

|---|---|---|---|---|---|

| Parameter | R | R | Y0 | N | |

| Substrate 0 h (χ2 = 0.83517) | Value | 13.259 | 1279.4 | 0.00053777 | 0.53608 |

| Estimated Error (%) | 4.061 | 4.323 | 5.601 | 1.865 | |

| Substrate 18 h (χ2 = 0.92959) | Value | 15.576 | 5968.7 | 0.00035181 | 0.67476 |

| Estimated Error (%) | 2.839 | 5.864 | 3.757 | 1.246 | |

| Substrate 42 h (χ2 = 0.49617) | Value | 15.531 | 6264.1 | 0.0014249 | 0.6167 |

| Estimated Error (%) | 1.867 | 12.253 | 2.329 | 1.123 | |

| Substrate 70 h (χ2 = 0.6928) | Value | 18.121 | 1708.5 | 0.003173 | 0.51266 |

| Estimated Error (%) | 2.408 | 14.564 | 3.687 | 2.199 | |

| Clad 0 h (χ2 =0.86605) | Value | 8.5646 | 8373 | 0.000061818 | 0.71986 |

| Estimated Error (%) | 4.105 | 3.429 | 4.309 | 0.928 | |

| Clad 18 h (χ2 =0.97353) | Value | 9.4141 | 17069 | 0.000011745 | 0.80688 |

| Estimated Error (%) | 4.901 | 2.922 | 4.996 | 0.850 | |

| Clad 42 h (χ2 = 0.8678) | Value | 10.683 | 28798 | 0.00001558 | 0.82306 |

| Estimated Error (%) | 3.826 | 3.048 | 4.028 | 0.740 | |

| Clad 70 h (χ2 = 1.2022) | Value | 11.18 | 17984 | 0.000044658 | 0.80815 |

| Estimated Error (%) | 3.678 | 4.086 | 4.491 | 0.958 |

| Specimens | Roughness Value—Ra (µm) |

|---|---|

| Substrate—0 h | 15.475 |

| Substrate—18 h | 13.133 |

| Substrate—42 h | 10.745 |

| Substrate—70 h | 14.239 |

| Clad—0 h | 5.359 |

| Clad—18 h | 4.954 |

| Clad—42 h | 3.795 |

| Clad—70 h | 4.273 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natarajan, J.; Yang, C.-H.; Karuppasamy, S.S. Investigation on Microstructure, Nanohardness and Corrosion Response of Laser Cladded Colmonoy-6 Particles on 316L Steel Substrate. Materials 2021, 14, 6183. https://doi.org/10.3390/ma14206183

Natarajan J, Yang C-H, Karuppasamy SS. Investigation on Microstructure, Nanohardness and Corrosion Response of Laser Cladded Colmonoy-6 Particles on 316L Steel Substrate. Materials. 2021; 14(20):6183. https://doi.org/10.3390/ma14206183

Chicago/Turabian StyleNatarajan, Jeyaprakash, Che-Hua Yang, and Sundara Subramanian Karuppasamy. 2021. "Investigation on Microstructure, Nanohardness and Corrosion Response of Laser Cladded Colmonoy-6 Particles on 316L Steel Substrate" Materials 14, no. 20: 6183. https://doi.org/10.3390/ma14206183

APA StyleNatarajan, J., Yang, C.-H., & Karuppasamy, S. S. (2021). Investigation on Microstructure, Nanohardness and Corrosion Response of Laser Cladded Colmonoy-6 Particles on 316L Steel Substrate. Materials, 14(20), 6183. https://doi.org/10.3390/ma14206183