Wear Analysis of Materials Used for a Track Steering System in Abrasive Soil Mass

Abstract

1. Introduction

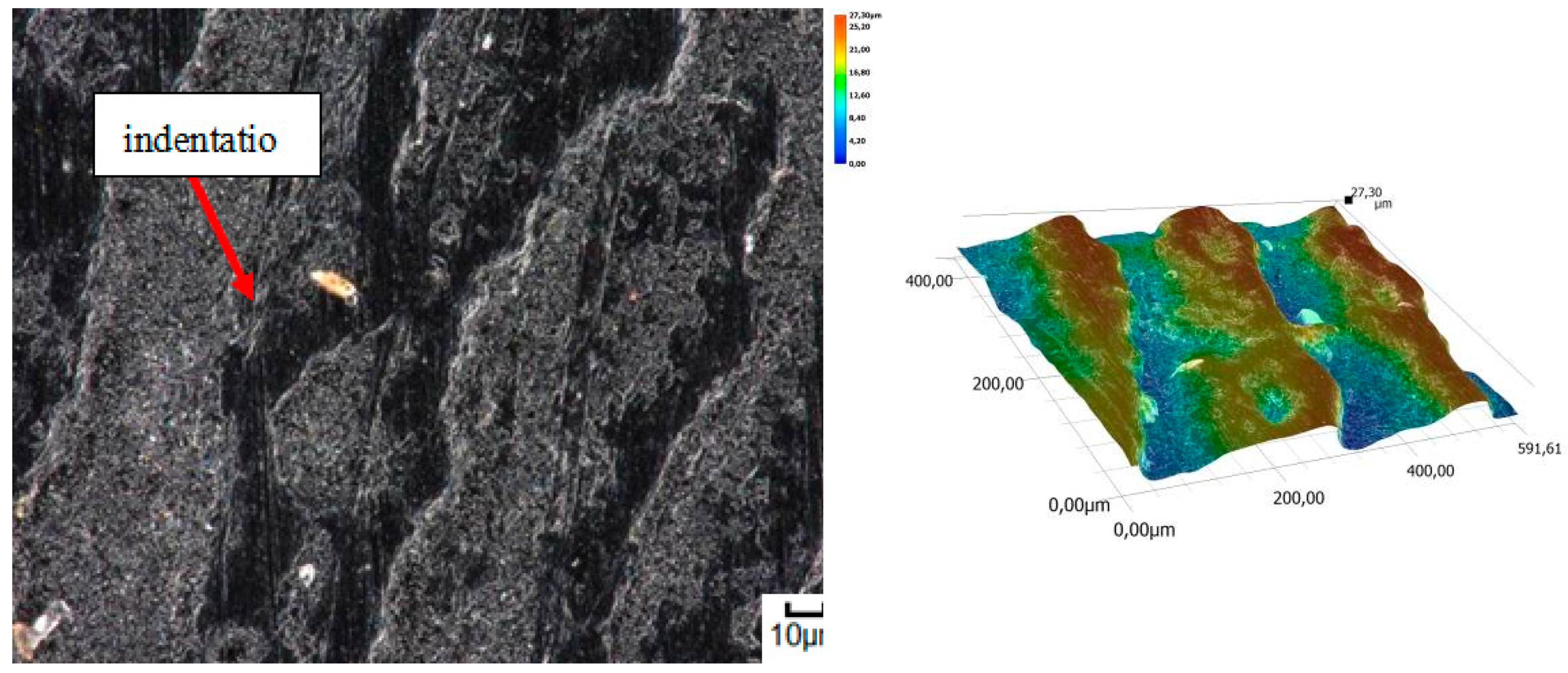

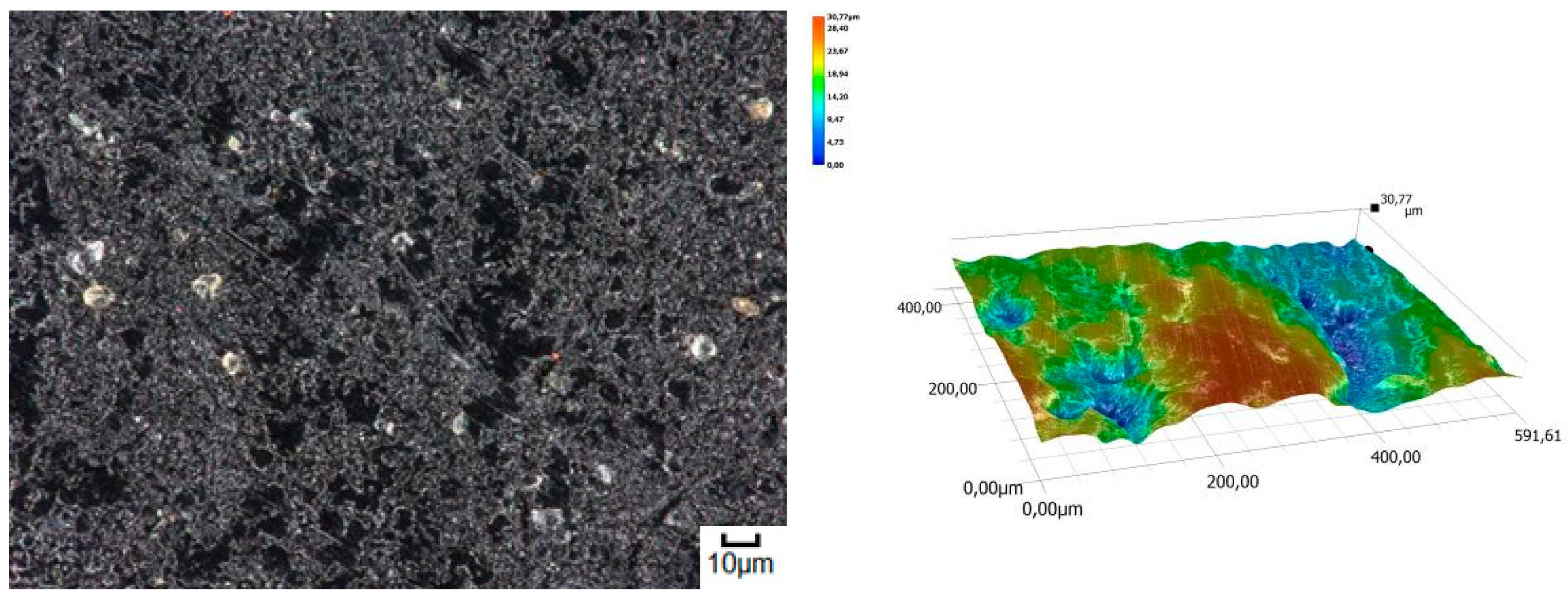

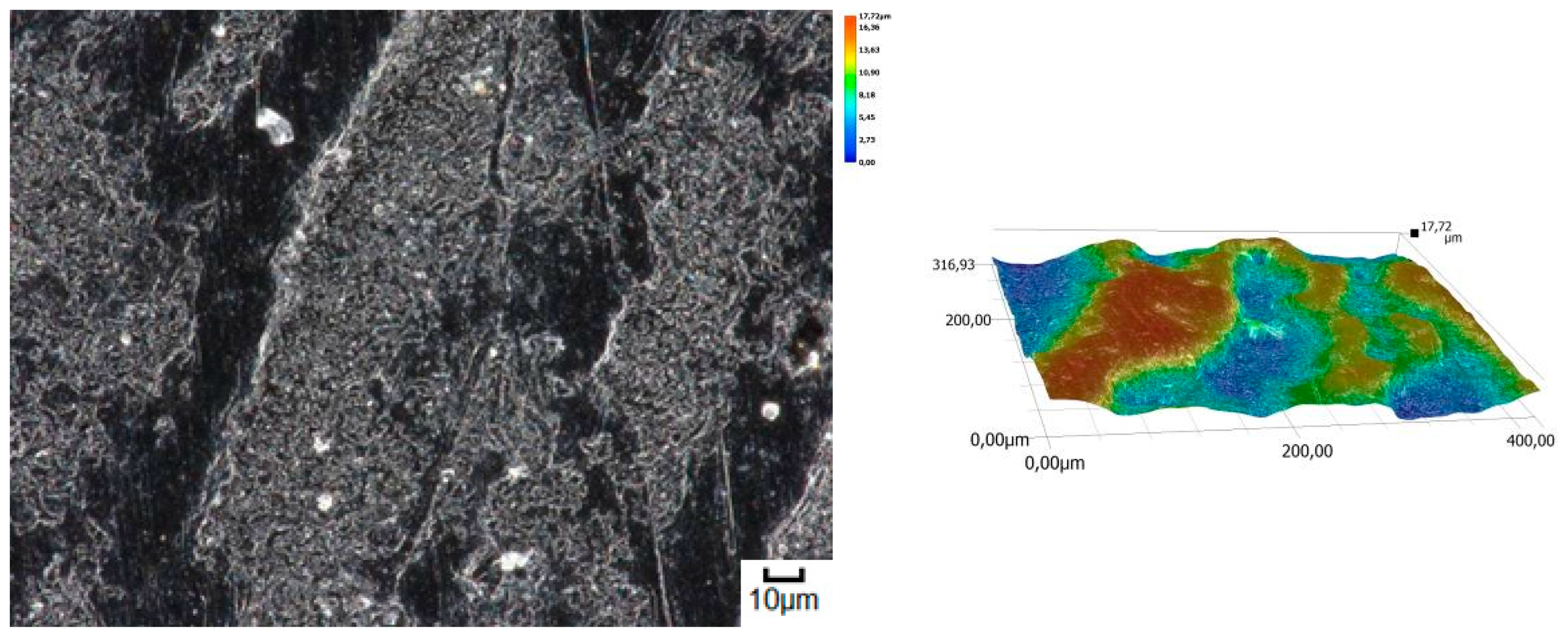

2. Research Methodology

2.1. The Test Procedure

- mw—input sample mass before friction [g],

- mi—sample mass after travelling the friction path S [g],

- —mass wear intensity;

- S—friction path [km].

- ZVw—volumetric wear of the reference material;

- ZVb—volumetric wear of the tested material;

- ZWw—mass wear of the reference material;

- ZWb—mass wear of the tested material;

- STw—friction path of reference material;

- STb—friction path of tested material;

- ρw—density of the reference material;

- ρb—density of the tested material.

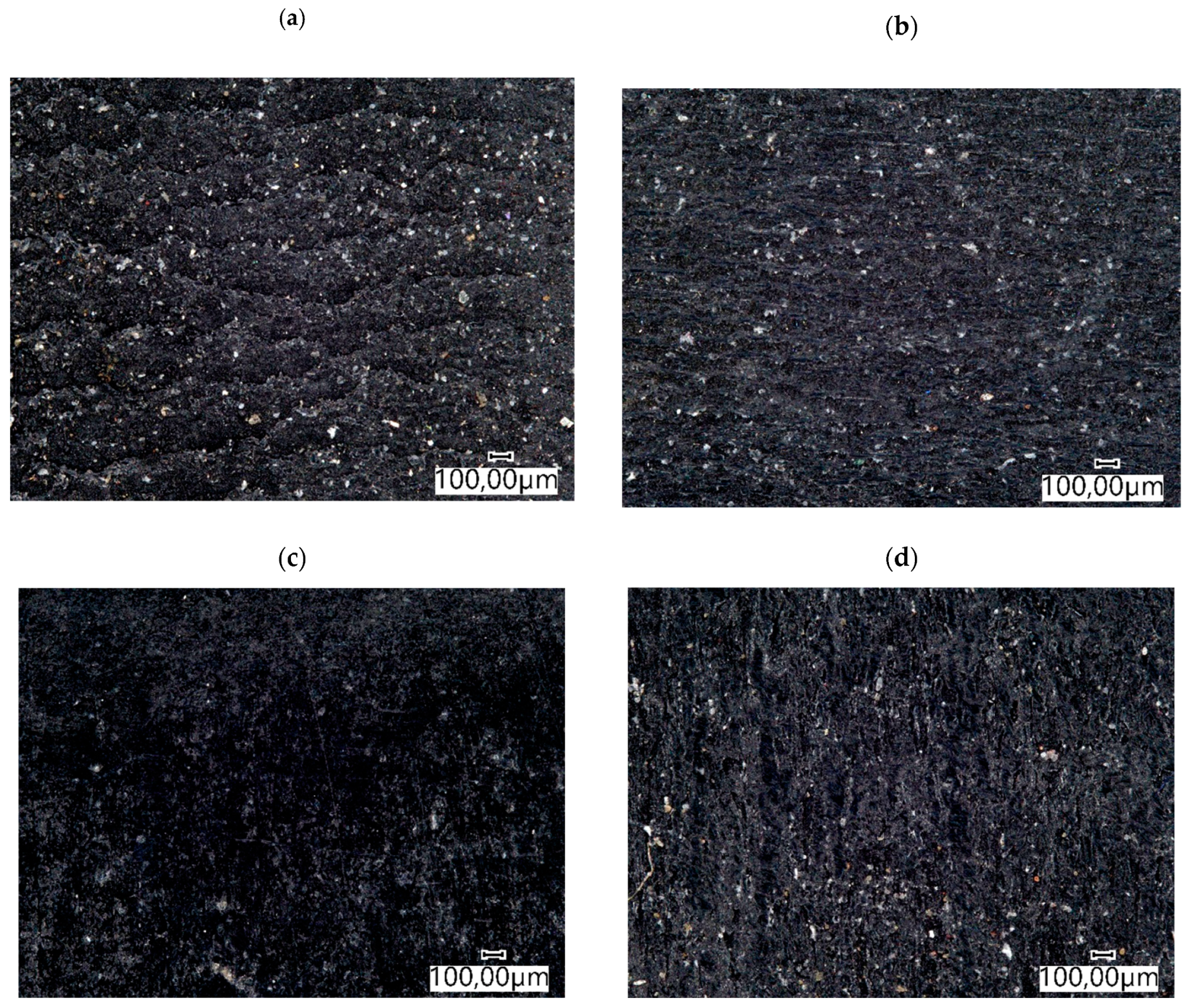

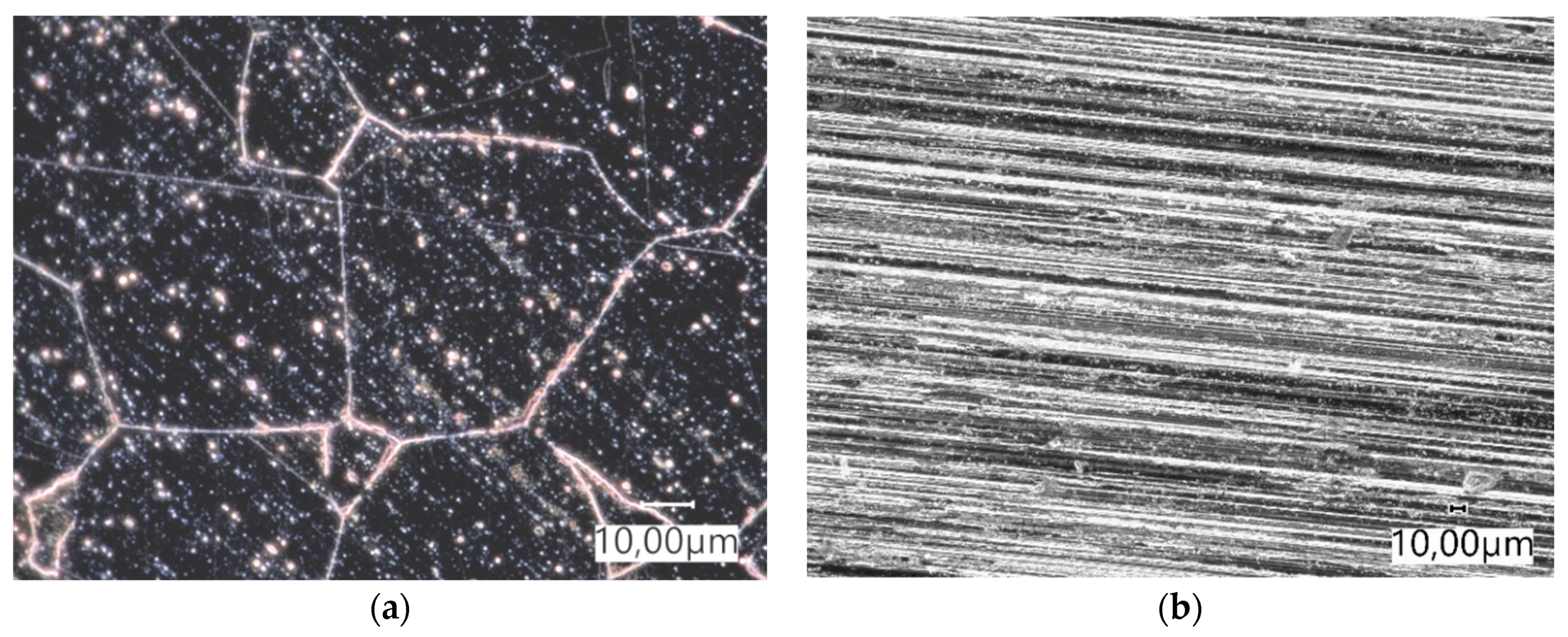

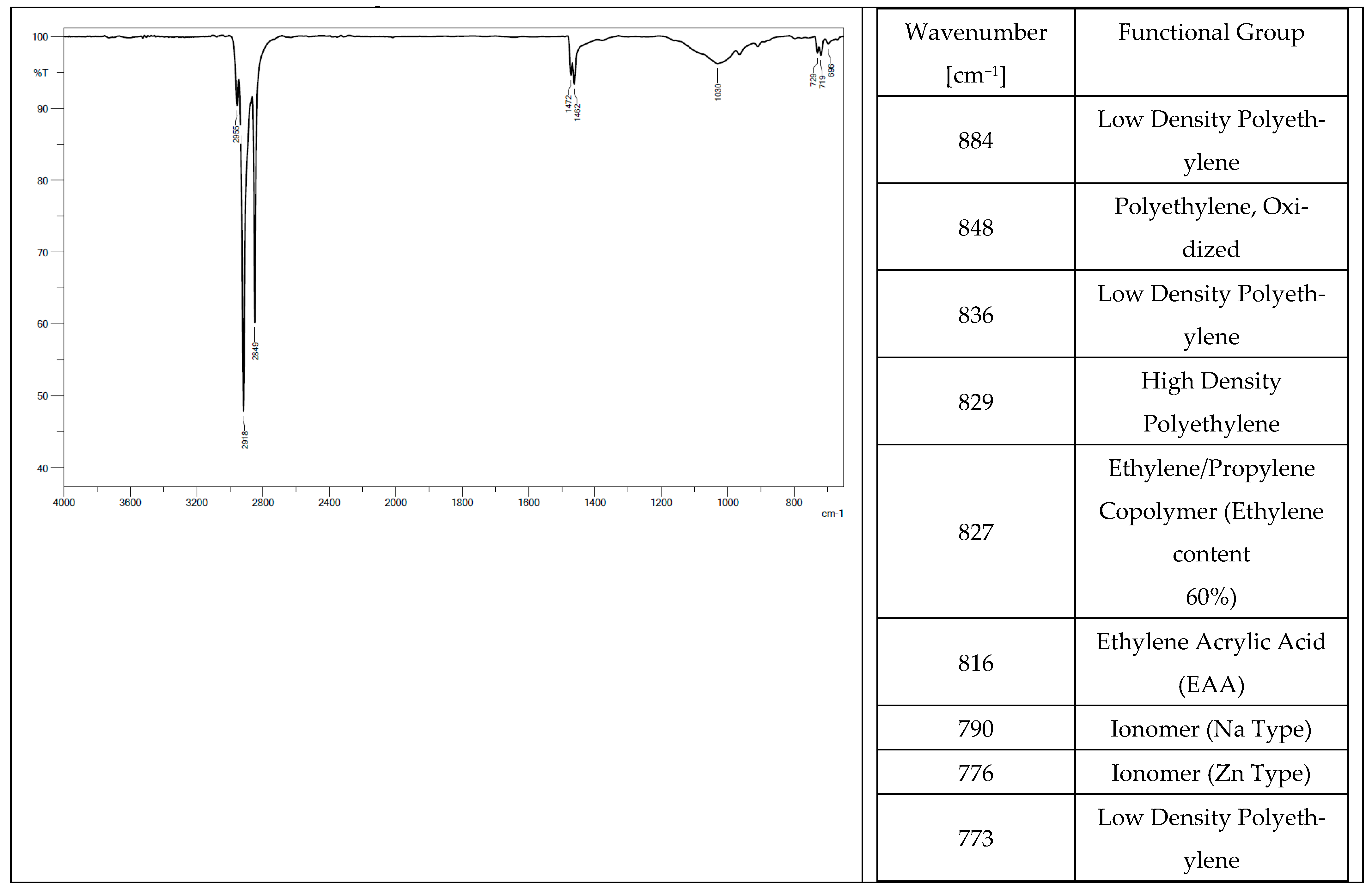

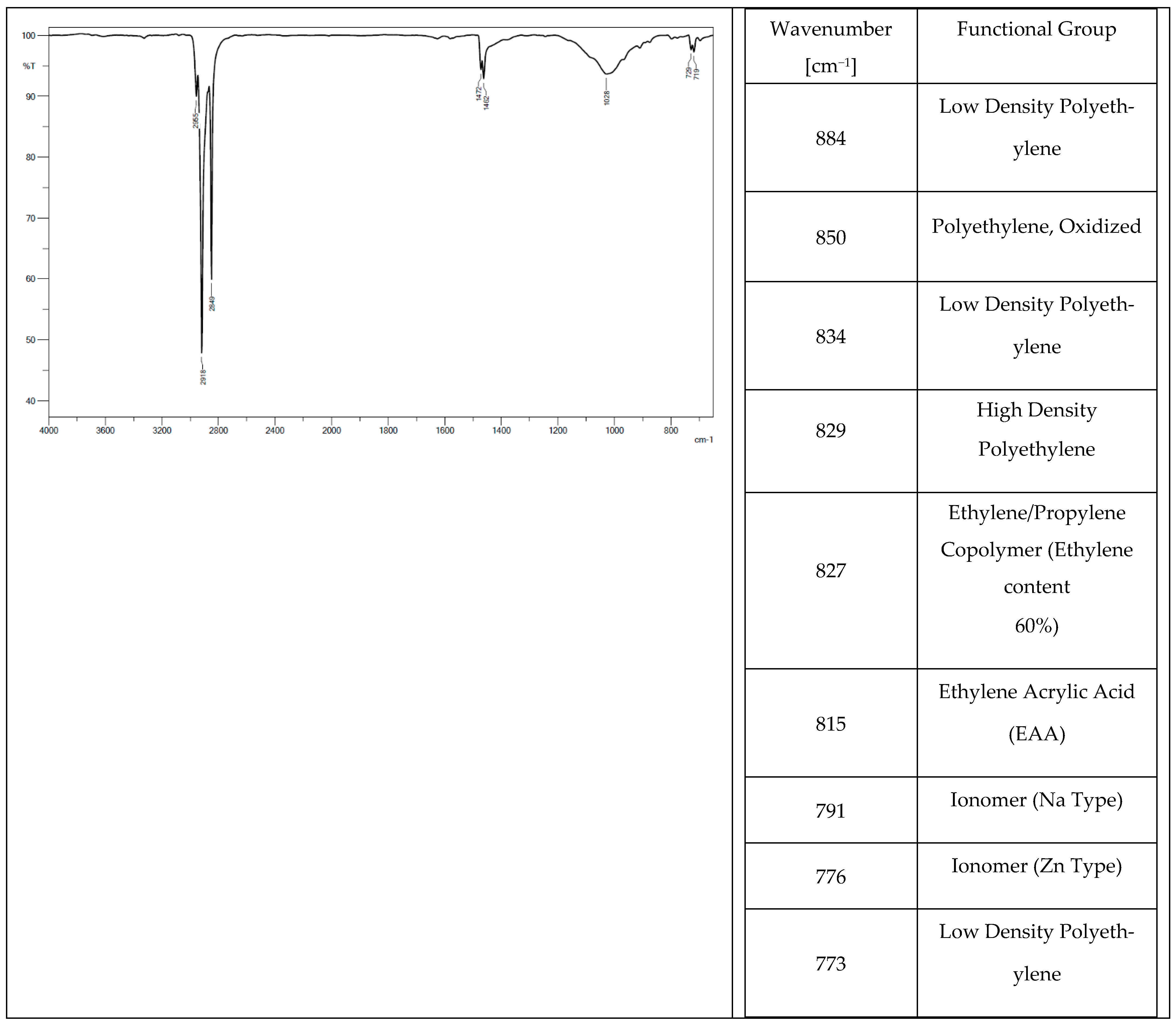

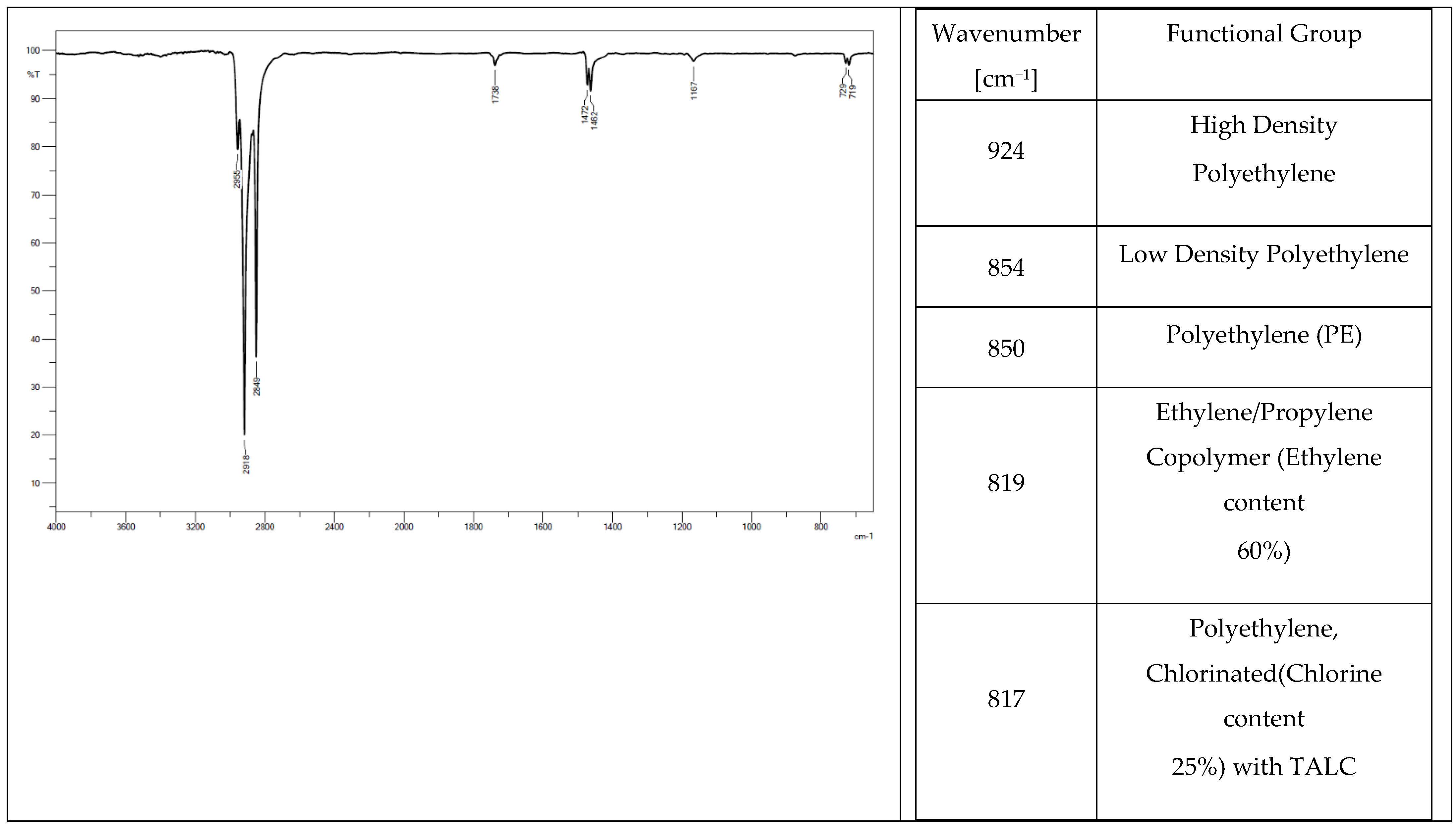

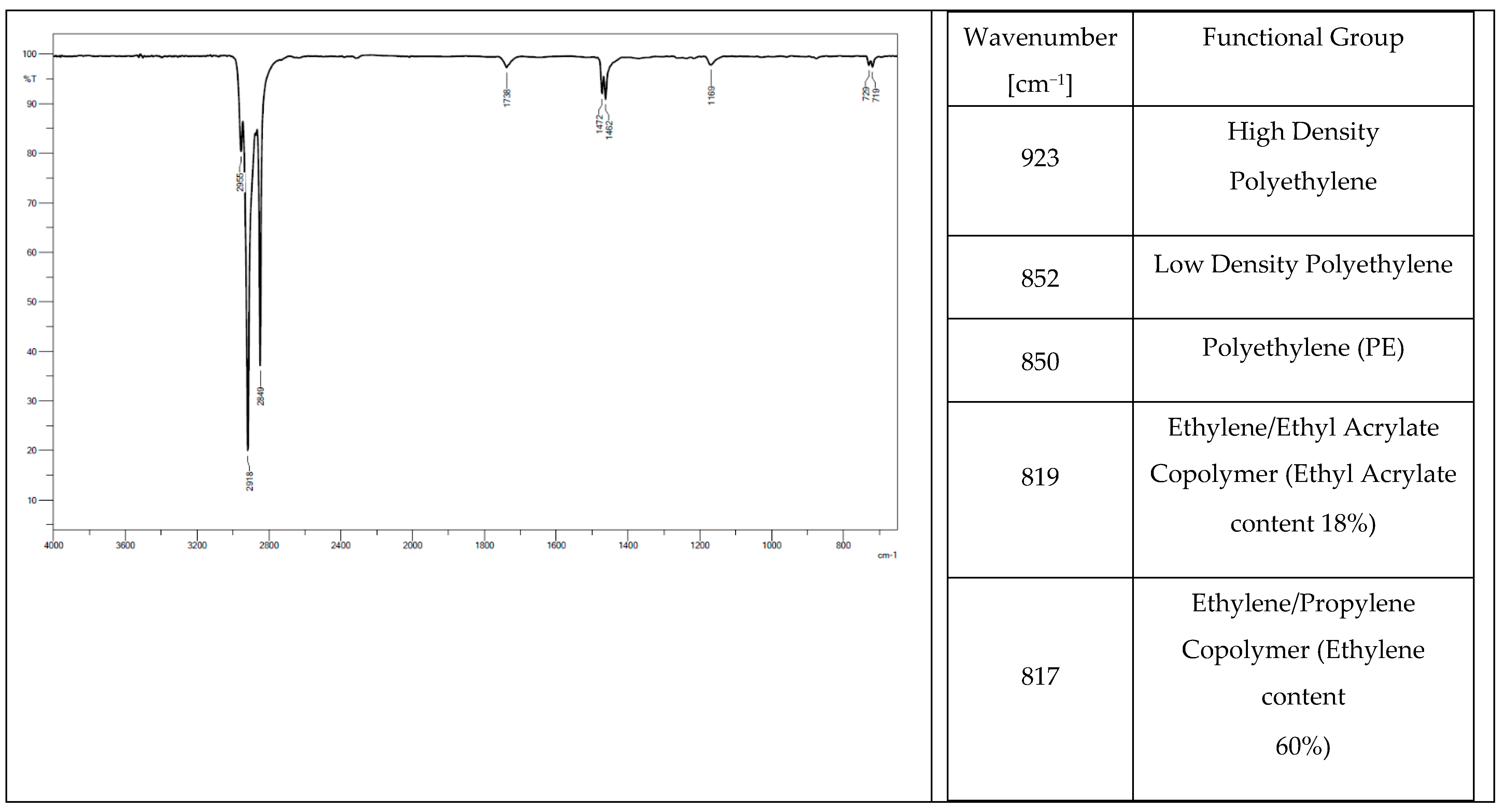

2.2. Test Subject

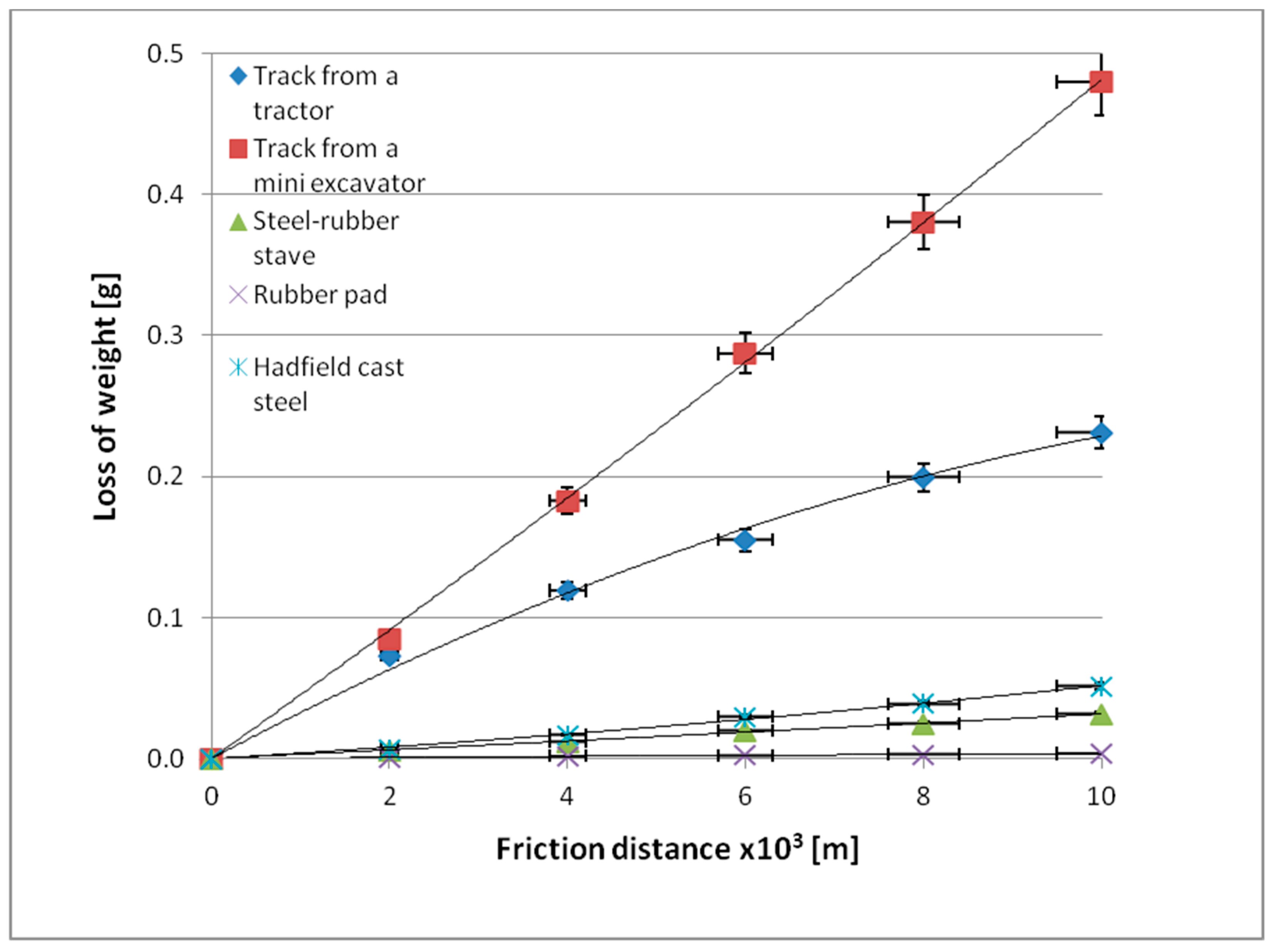

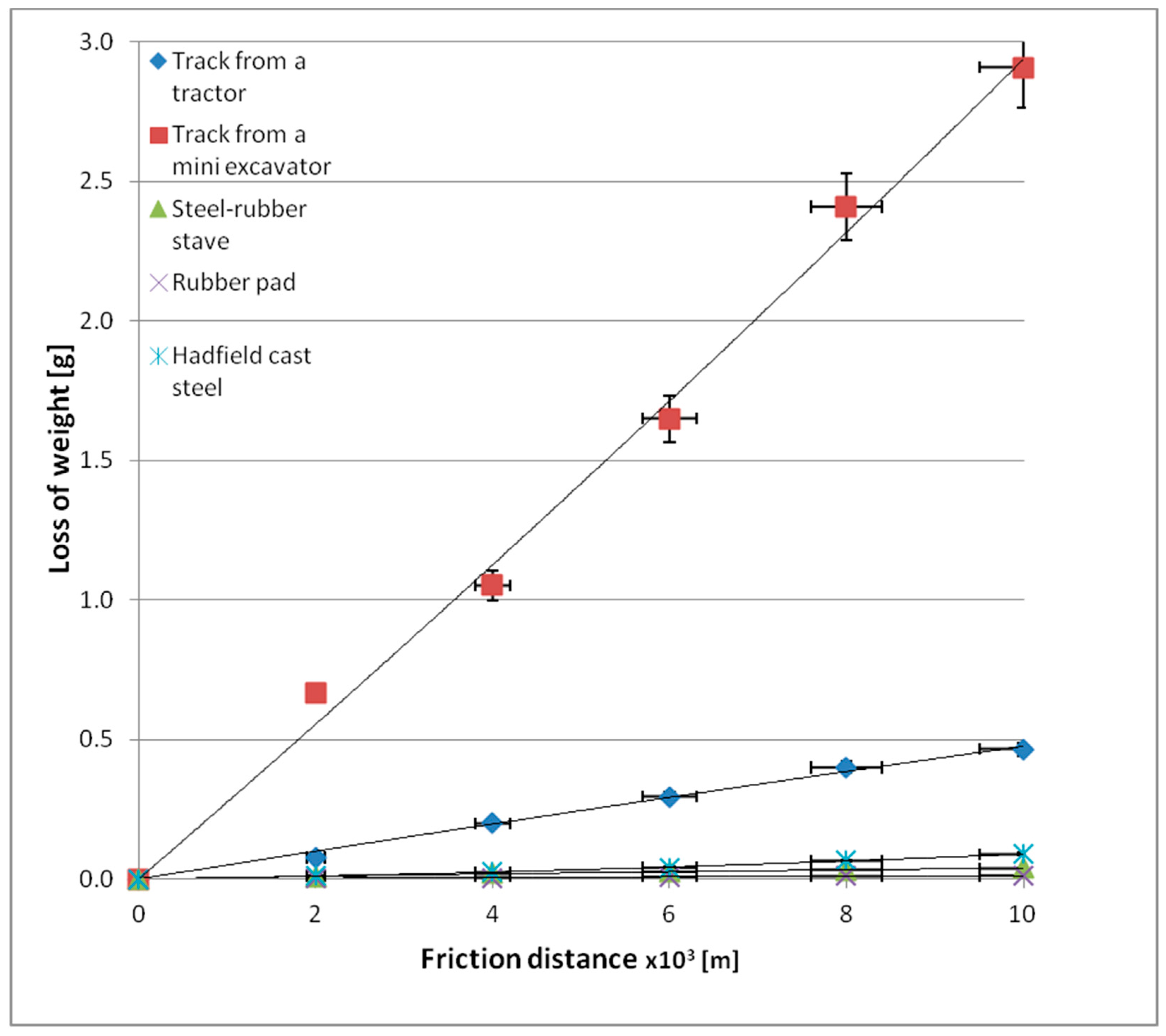

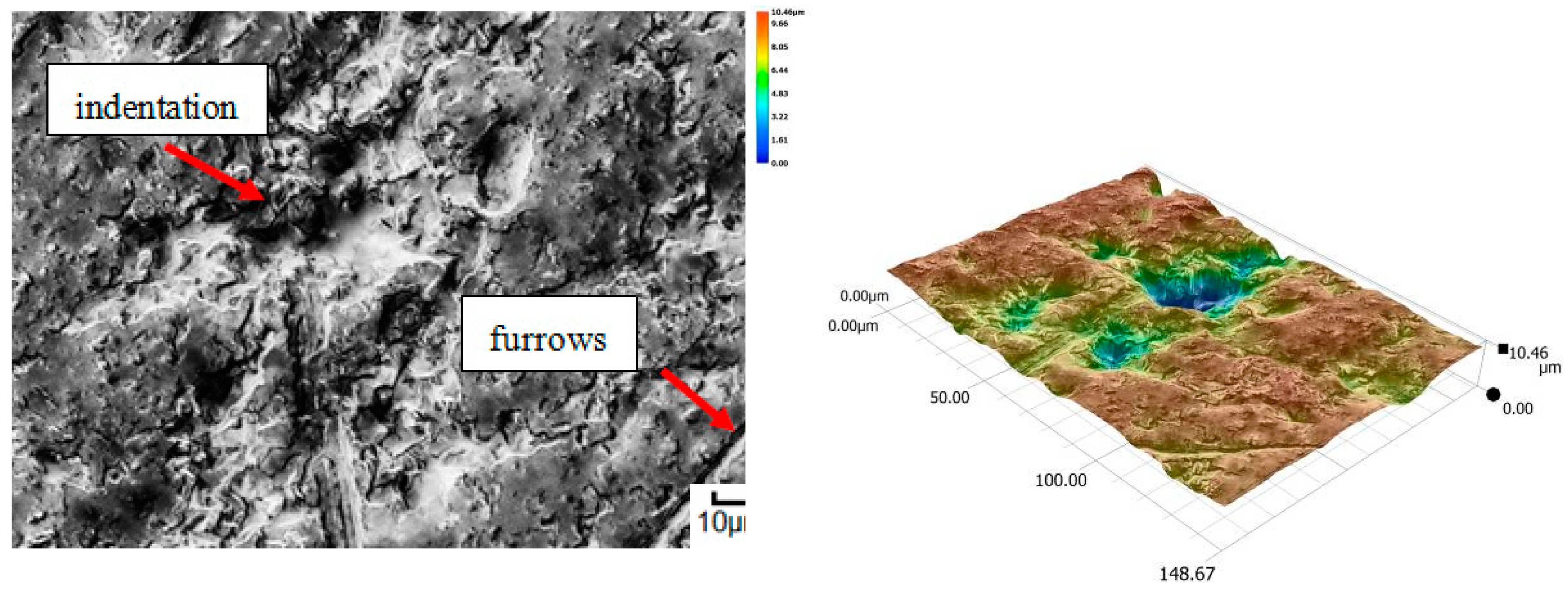

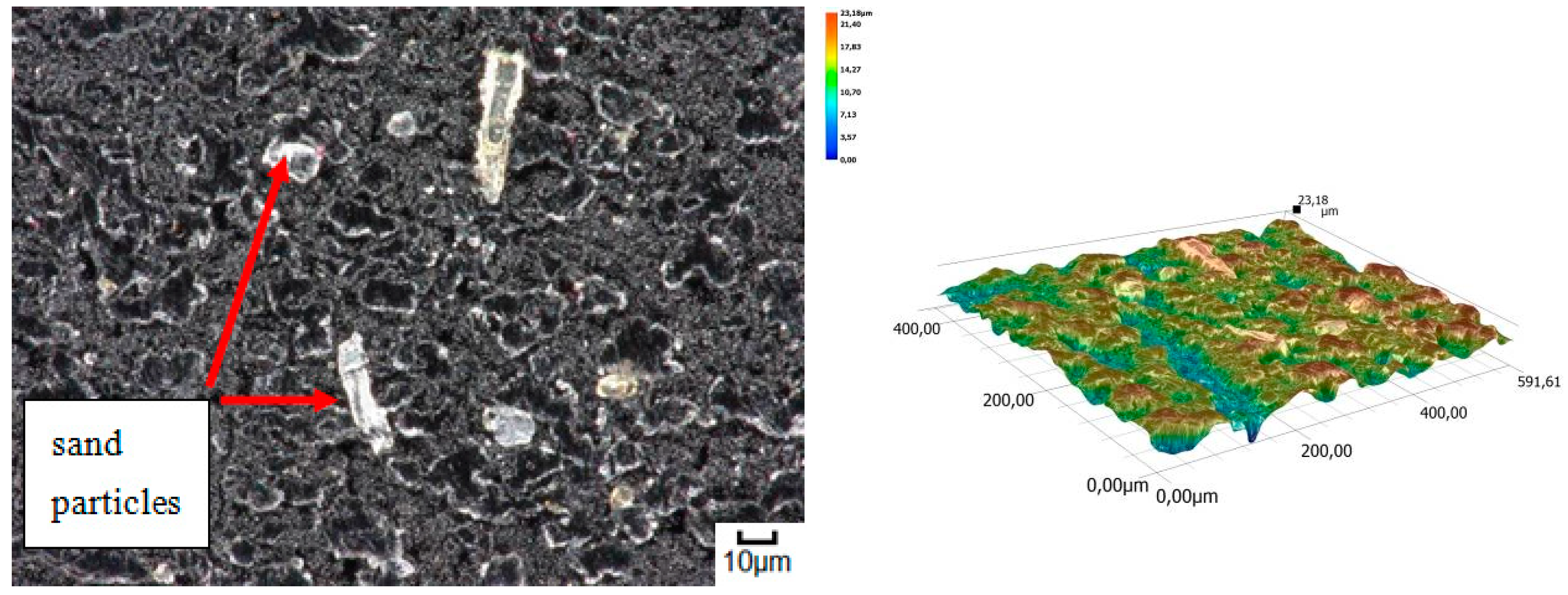

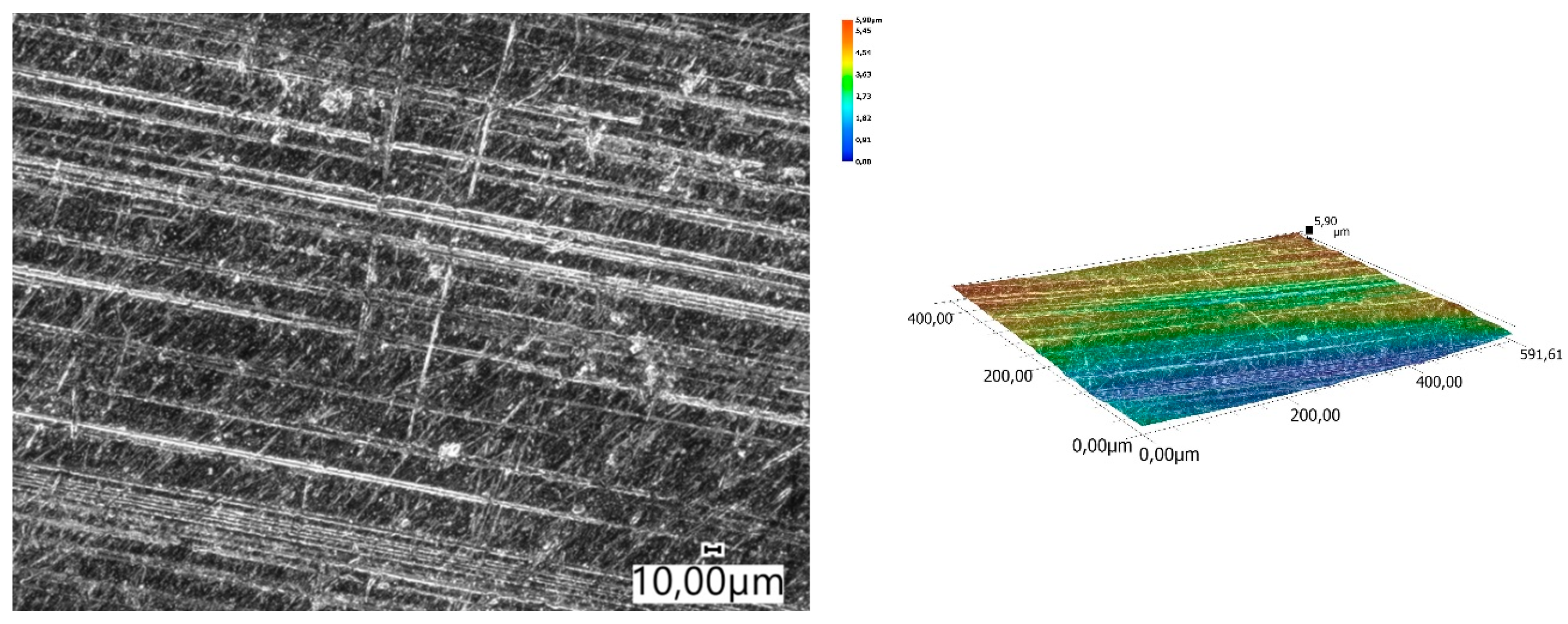

3. Analysis of the Results

4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bęben, A. Maszyny i Urządzenia do Wydobywania Kopalin Pospolitych bez Użycia Materiałów Wybuchowych; Wydawnictwo AGH: Kraków, Poland, 2008. [Google Scholar]

- Grygier, D. The impact of operation of elastomeric track chains on the selected properties of the steel cordwires. Maint. Reliab. 2017, 19, 95–101. [Google Scholar]

- Napiórkowski, J.; Olejniczak, K. Effect of PE–LD and PE–HD as modifiers of elastomers used in mobile tracks on their tribological wear. Tribologia 2019, 285, 89–95. [Google Scholar] [CrossRef]

- Bodziony, P.; Kasztelewicz, Z.; Patyk, M. Characteristic of the dozer chassis and track-type undercarriage used in surface mining. Przegląd Górniczy 2016, 72, 9–14. [Google Scholar]

- Berns, H. Einfluß von Korngröße und Korngrenzencarbid auf die mechanischen Eigenschaften von Manganhartstahlguß. Giesserei 1977, 64, 323–328. [Google Scholar]

- Berns, H.; Fischer, A. New Abrasion Resistant Alloys. In Proceedings of the International Conference. Tribology–Friction, Lubrication and Wear, Fifty Years On, London, UK, 1–3 July 1987; IMechE Publ. Ltd.: London, UK, 1–3 July 1987; pp. 603–608. [Google Scholar]

- PN H–83156: Constructional Alloy Cast Steel–Grades. 1997. Available online: https://infostore.saiglobal.com/en-us/standards/pn-h-83156-1997-944913_saig_pkn_pkn_2222823/ (accessed on 6 October 2021).

- Bogucki, R. Badania prototypów nakładek elastomerowych na człony taśm gąsienicowych. Szybkobieżna Pojazdy Gąsienicowe 2013, 32, 1–10. [Google Scholar]

- Wieleba, W. The mechanism of tribological wear of thermoplastic materials. Arch. Civ. Mech. Eng. 2007, 7, 185–199. [Google Scholar] [CrossRef]

- Capanidis, D.; Tański, A. Investigations of resistance to abrasive wear of selected engineering polymers. Tribologia 2012, 4, 25–32. [Google Scholar]

- Capanidis, D.; Kowalewski, P.; Krauze, M. Study of resistance to abrasive wear of multicomponent polyoxymethylene composites. Tribologia 2016, 265, 7–19. [Google Scholar] [CrossRef][Green Version]

- Hooke, C.J.; Kukureka, S.N.; Liao, P.; Chen, Y.K. The friction and wear of polymers in non-conformal contacts. Wear 1996, 200, 83–94. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Petrokovets, M.I.; Kovalev, A.V. Tribology of polymers: Adhesion, friction, wear, and mass-transfer. Tribol. Int. 2005, 38, 910–921. [Google Scholar] [CrossRef]

- Lancaster, K.L. Relationships between the Wear of Polymers and their Mechanical Properties. SAGE J. 1968, 183, 98–106. [Google Scholar] [CrossRef]

- Laux, K.A.; Jean-Fulcrand, A.; Sue, H.J.; Bremner, T.; Wong, J.S.S. The influence of surface properties on slipping contact temperature and friction polyetheretherketone (PEEK). Polymer 2016, 103, 397–404. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Takashima, T. Fraction and wear of water-lubricated PEEK and PPS slipping contacts. Wear 2002, 253, 820–826. [Google Scholar] [CrossRef]

- Quaglini, V.; Dubini, P. Friction of polymers slipping on a smooth surface. Adv. Tribol. 2011, 8, 178943. [Google Scholar]

- Werner, P.; Altstadtädt, V.; Jaskulka, R.; Jacobs, O.; Sandler, J.K.W.; Shaffler, M.S.P.; Windle, A.H. Tribological behaviour of carbon-nanofibre-reinforced poly(ether ether ketone). Wear 2004, 257, 1006–1014. [Google Scholar] [CrossRef]

- Napiórkowski, J.; Lemecha, M.; Konat, Ł. Forecasting the Wear of Operating Parts in an Abrasive Soil Mass Using the Holm-Archard Model. Materials 2019, 12, 2180. [Google Scholar] [CrossRef]

- Napiórkowski, J.; Olejniczak, K.; Konat, Ł. Wear Properties of Nitride-Bonded Silicon Carbide under the Action of an Abrasive Soil Mass. Materials 2021, 14, 2043. [Google Scholar] [CrossRef]

- Kostencki, P.; Stawicki, T.; Białobrzeska, B. Durability and wear geometry of subsoiler shanks provided with sintered carbide plates. Tribol. Int. 2016, 104, 19–35. [Google Scholar] [CrossRef]

- Konstencki, P.; Królicka, A. The Evaluation of the Effectiveness of Reinforcement by Cemented-Carbide Plates in Two Design Variants of the Chisels Intended for Cultivation-Sowing Aggregates. Materials 2021, 14, 1020. [Google Scholar] [CrossRef] [PubMed]

- Napiórkowski, J.; Ligier, K. Investigation of wear resistance of polyurethanes in abrasive soil mass. In Proceedings of the International Symposium on Material Science and Engineering (ISMSE 2018), Seoul, Korea, 19–21 January 2018. [Google Scholar]

- Napiórkowski, J.; Ligier, K. Tribological properties of polyurethanes in abrasive soll mass. Tribologia 2017, 6, 65–70. [Google Scholar] [CrossRef]

- Zawadiak, J.; Marek, A.; Stec, Z.; Orlińska, B. Oxidized polyethylene. Methods for production and applications. Przemysł Chem. 2009, 88, 1006–1010. [Google Scholar]

- Pikosz, P.; Iwko, J.; Mrzygłód, R. Wpływ zawartości talku w LDPE na właściwości kompozytu. Tworzywa Sztuczne W Przemyśle 2016, 3, 52–58. [Google Scholar]

- Chaudhry, A.U.; Mittal, V. High-density polyethylene nanocomposites using masterbatches of chlorinated polyethylene/graphene oxide. Polym. Eng. Sci. 2013, 53, 78–88. [Google Scholar] [CrossRef]

| Granulometric Groups | Fraction Diameter (mm) | Fraction Content (%) | |

|---|---|---|---|

| Sand | 2.0–0.05 | 67.17 | 16.20 |

| Fines | 0.05–0.002 | 31.03 | 77.30 |

| Silt | <0.002 | 1.80 | 6.50 |

| Determined as per PN–EN ISO 14688–2(2006) | Loamy sand–light soil | Ordinary soil–heavy soil | |

| C | Mn | Cr | Ni | S | D | Si |

|---|---|---|---|---|---|---|

| (% mass) | ||||||

| 1.27 | 13.15 | 0.67 | 0.42 | 0.03 | 0.07 | 0.44 |

| Hardness | Density (g/cm3) | |

|---|---|---|

| Track from a tractor | 72 Shore scale A | 1.1 |

| Track from a mini excavator | 66 Shore scale A | 1.1 |

| Steel-rubber stave | 73 Shore scale A | 2.3 |

| Rubber pad | 70 Shore scale A | 1.2 |

| Hadfield cast steel | HV 281 | 7.2 |

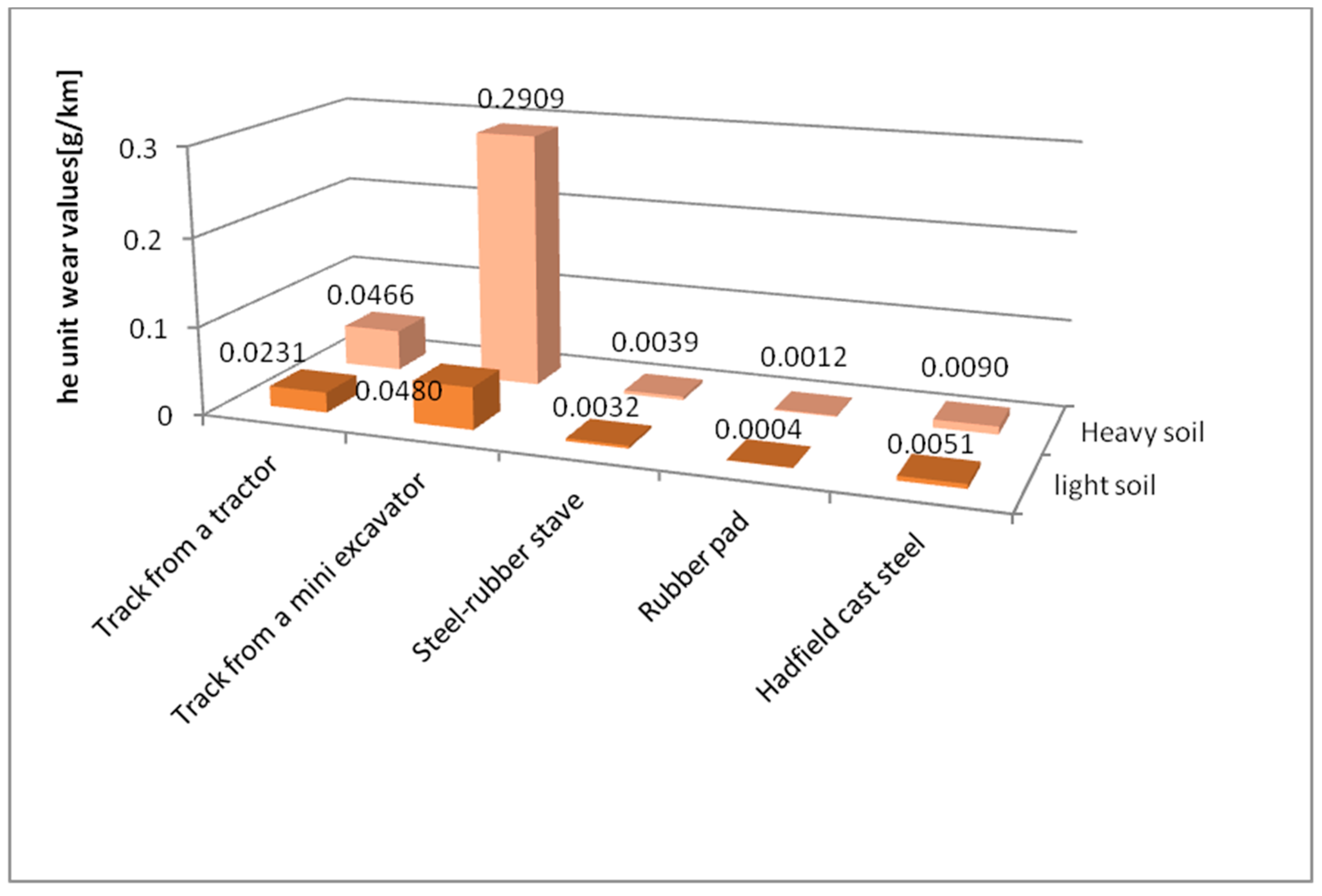

| Mass Wear [g] | ||||

|---|---|---|---|---|

| Material | Light Soil | Standard Deviation | Heavy Soil | Standard Deviation |

| Track from a tractor | 0.2313 | 0.0847 | 0.4661 | 0.1821 |

| Track from a mini excavator | 0.4797 | 0.1812 | 2.9085 | 1.0919 |

| Steel-rubber stave | 0.0315 | 0.0119 | 0.0391 | 0.0145 |

| Rubber pad | 0.0035 | 0.0013 | 0.0122 | 0.0047 |

| Hadfield cast steel | 0.0514 | 0.0197 | 0.0897 | 0.0339 |

| Light Soil | Heavy Soil | |||

|---|---|---|---|---|

| Kb | Confidence Interval | Kb | Confidence Interval | |

| Track from a tractor | 0.0339 | 0.0211 | 0.0294 | 0.0110 |

| Track from a mini excavator | 0.0163 | 0.0218 | 0.0047 | 0.3273 |

| Steel-rubber stave | 0.5212 | 0.0047 | 0.7328 | 0.0020 |

| Rubber pad | 2.4476 | 0.0010 | 1.2254 | 0.0018 |

| Hadfield cast steel | 1.0000 | 0.0086 | 1.0000 | 0.0148 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejniczak, K.; Napiórkowski, J. Wear Analysis of Materials Used for a Track Steering System in Abrasive Soil Mass. Materials 2021, 14, 6164. https://doi.org/10.3390/ma14206164

Olejniczak K, Napiórkowski J. Wear Analysis of Materials Used for a Track Steering System in Abrasive Soil Mass. Materials. 2021; 14(20):6164. https://doi.org/10.3390/ma14206164

Chicago/Turabian StyleOlejniczak, Klaudia, and Jerzy Napiórkowski. 2021. "Wear Analysis of Materials Used for a Track Steering System in Abrasive Soil Mass" Materials 14, no. 20: 6164. https://doi.org/10.3390/ma14206164

APA StyleOlejniczak, K., & Napiórkowski, J. (2021). Wear Analysis of Materials Used for a Track Steering System in Abrasive Soil Mass. Materials, 14(20), 6164. https://doi.org/10.3390/ma14206164