The Effects of Various Conditions of Short-Term Rejuvenation Heat Treatment on Room-Temperature Mechanical Properties of Thermally Aged P92 Boiler Steel

Abstract

:1. Introduction

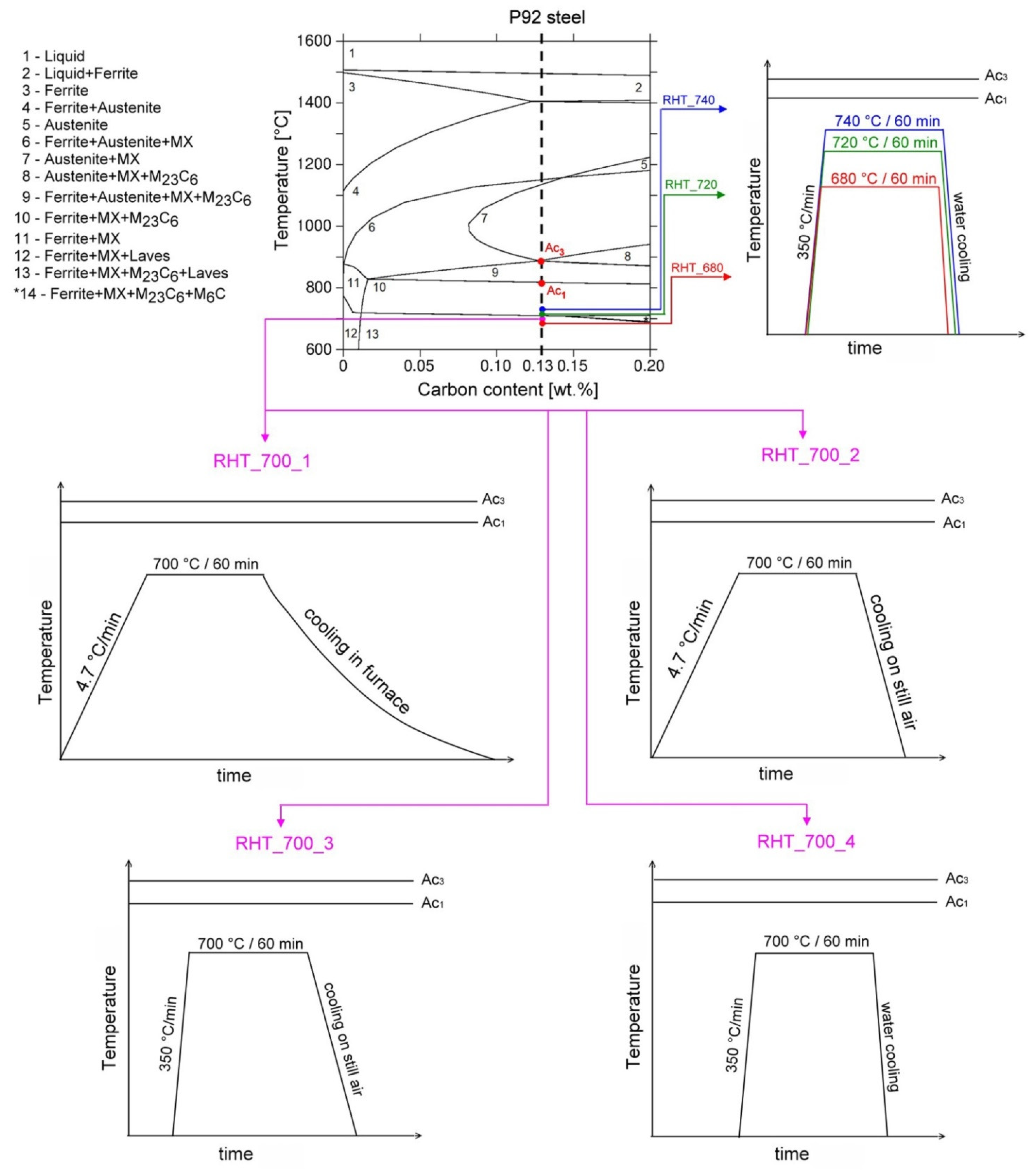

2. Experimental Materials and Methods

3. Results and Discussion

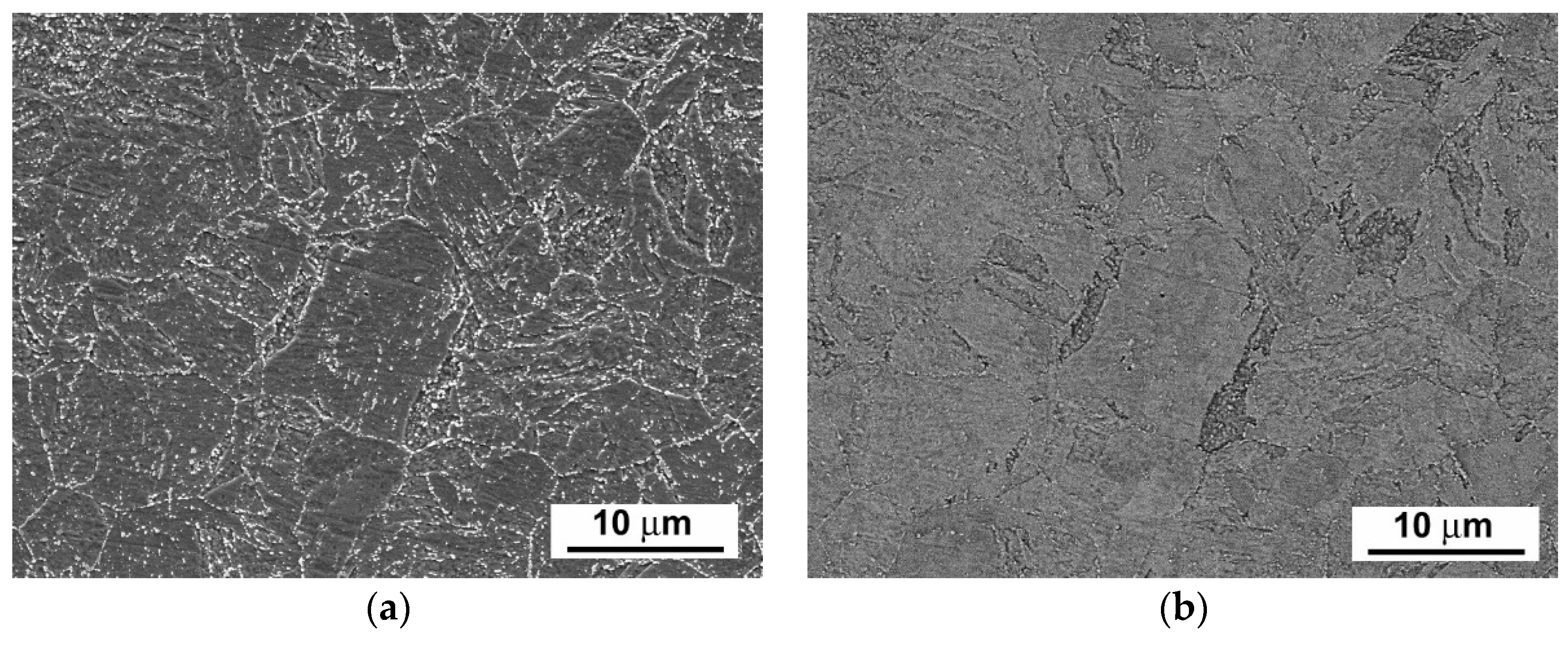

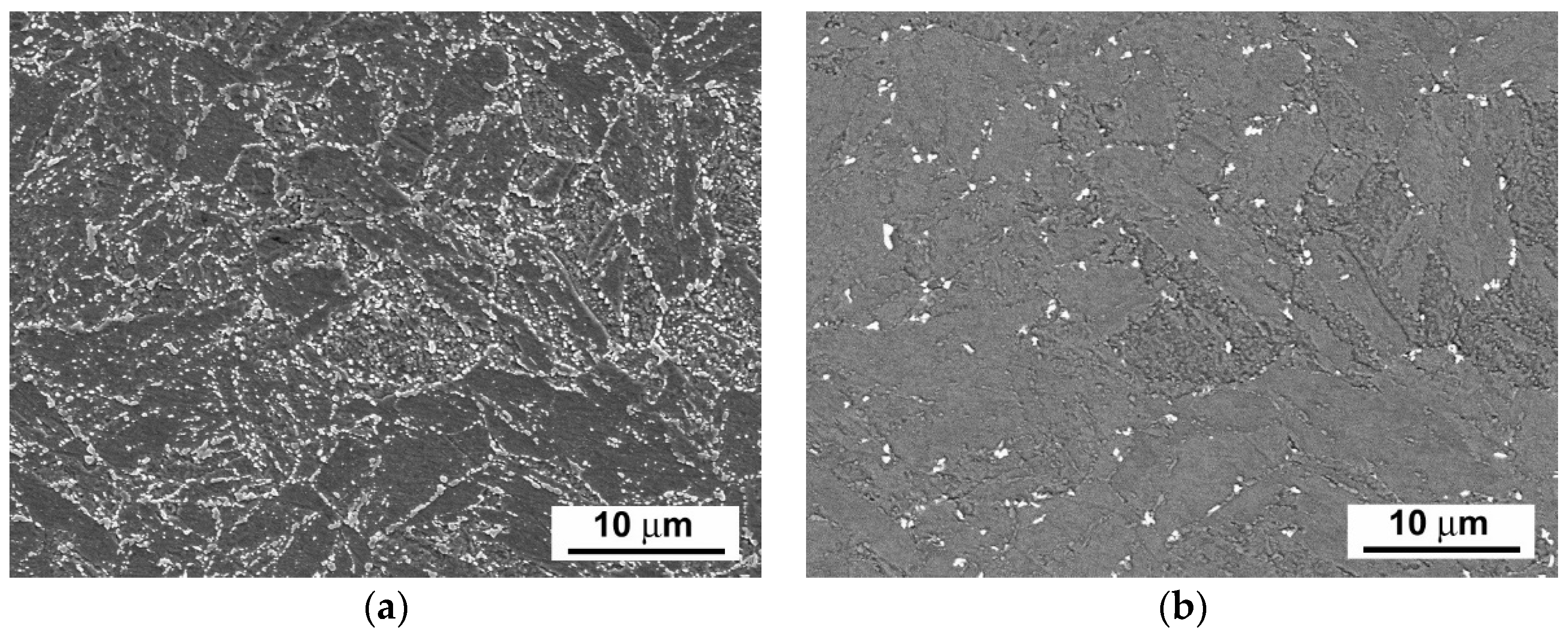

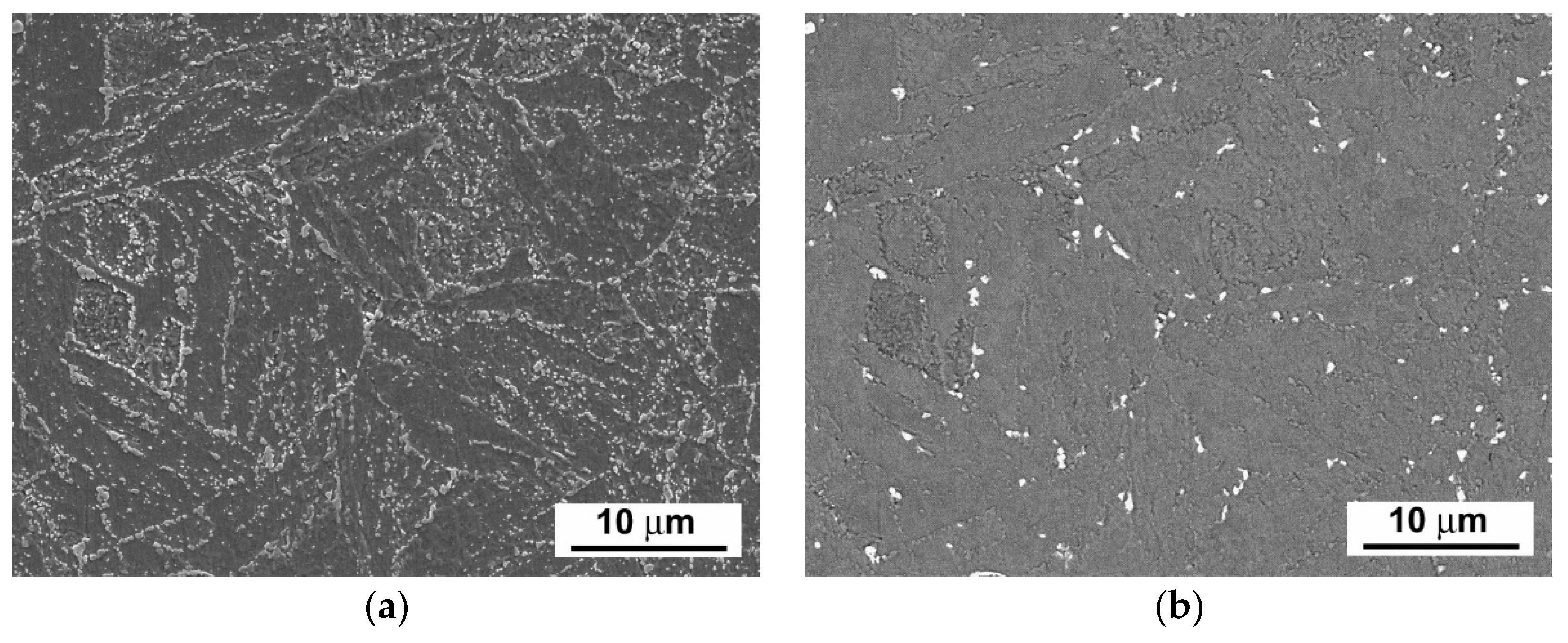

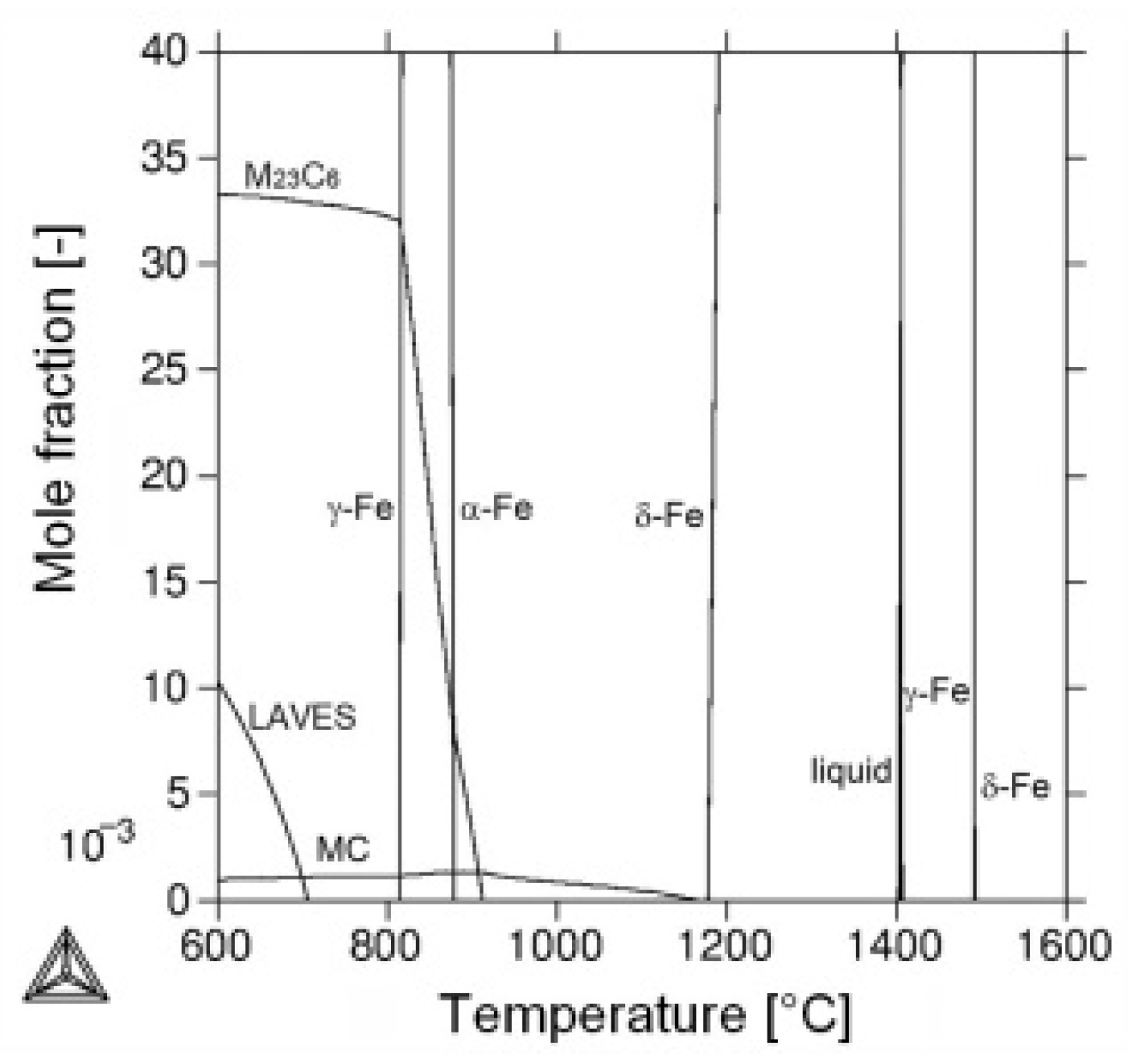

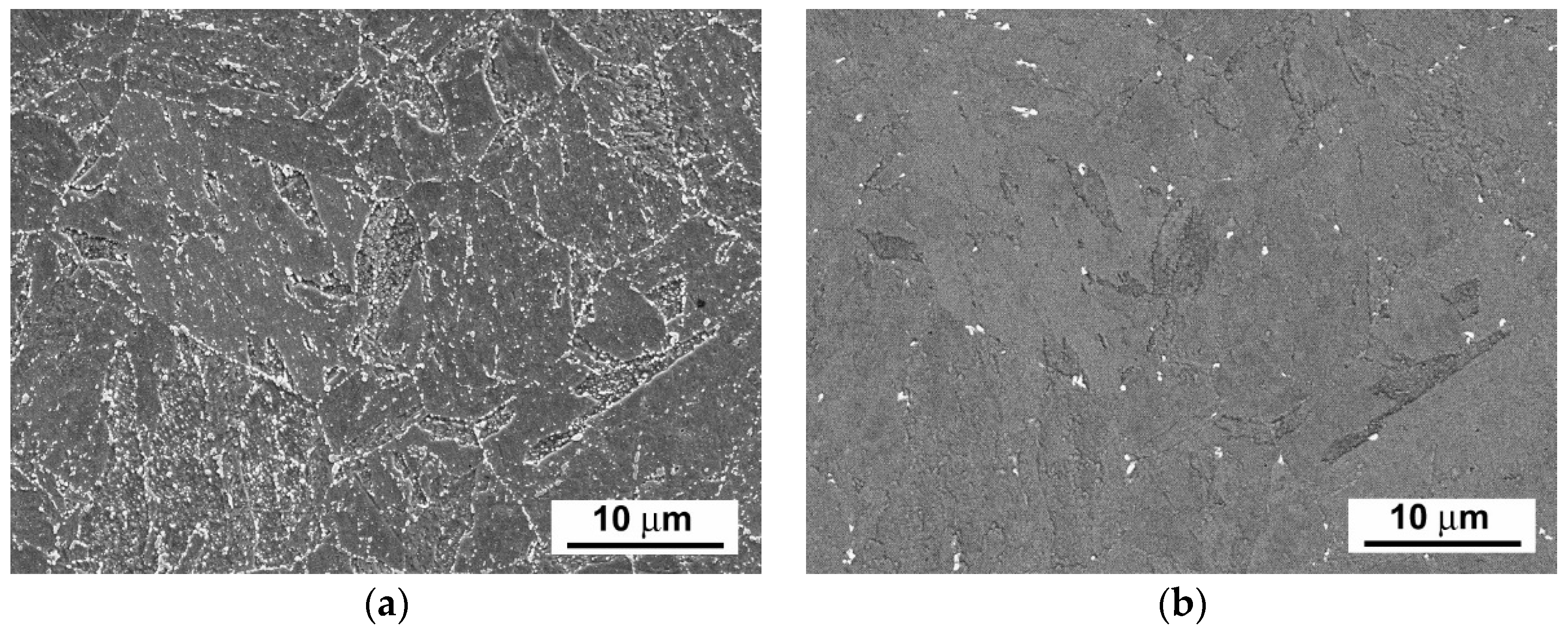

3.1. Microstructure Evolution during Thermal Ageing

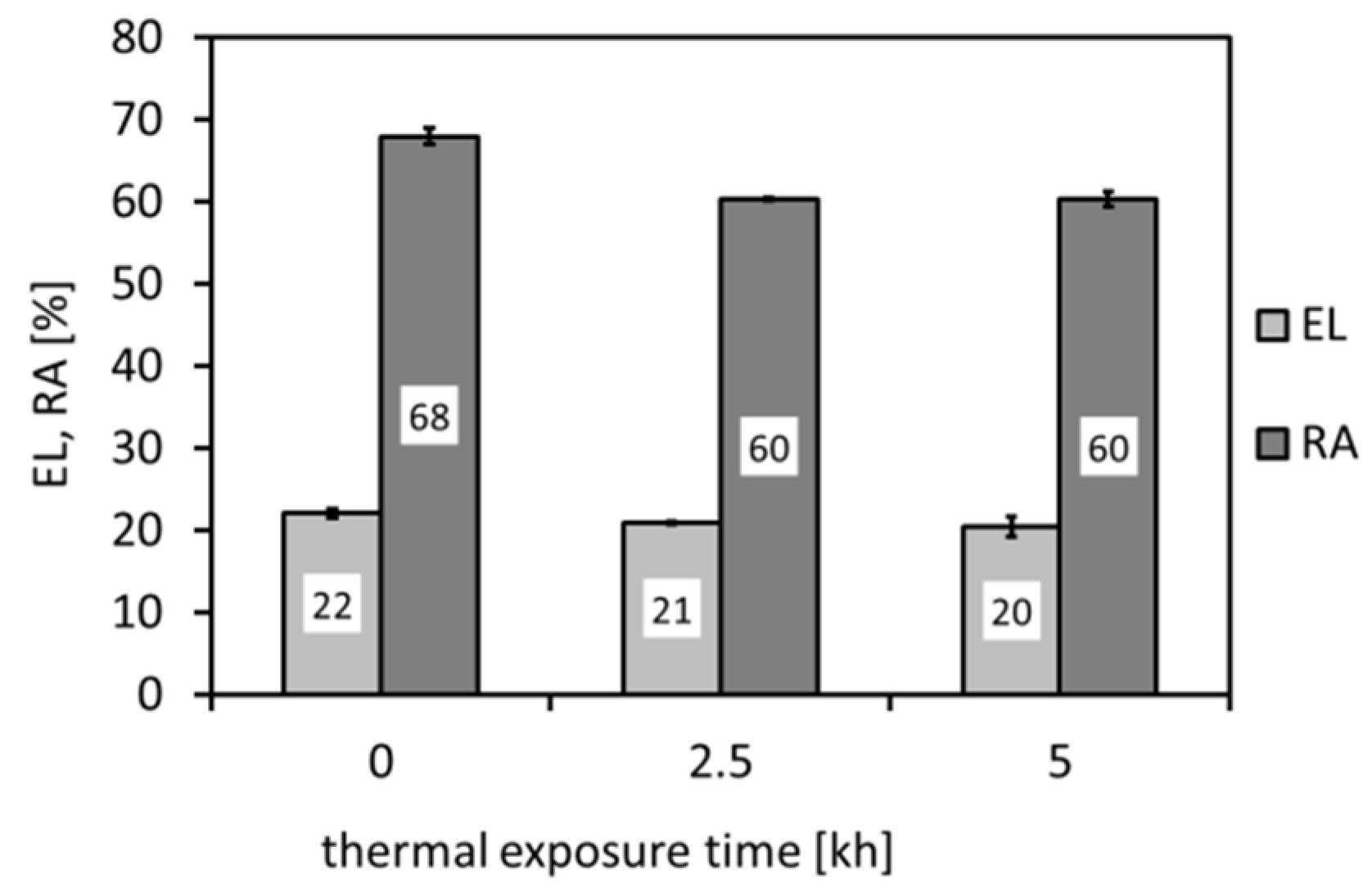

3.2. Effect of Thermal Ageing on Mechanical Properties

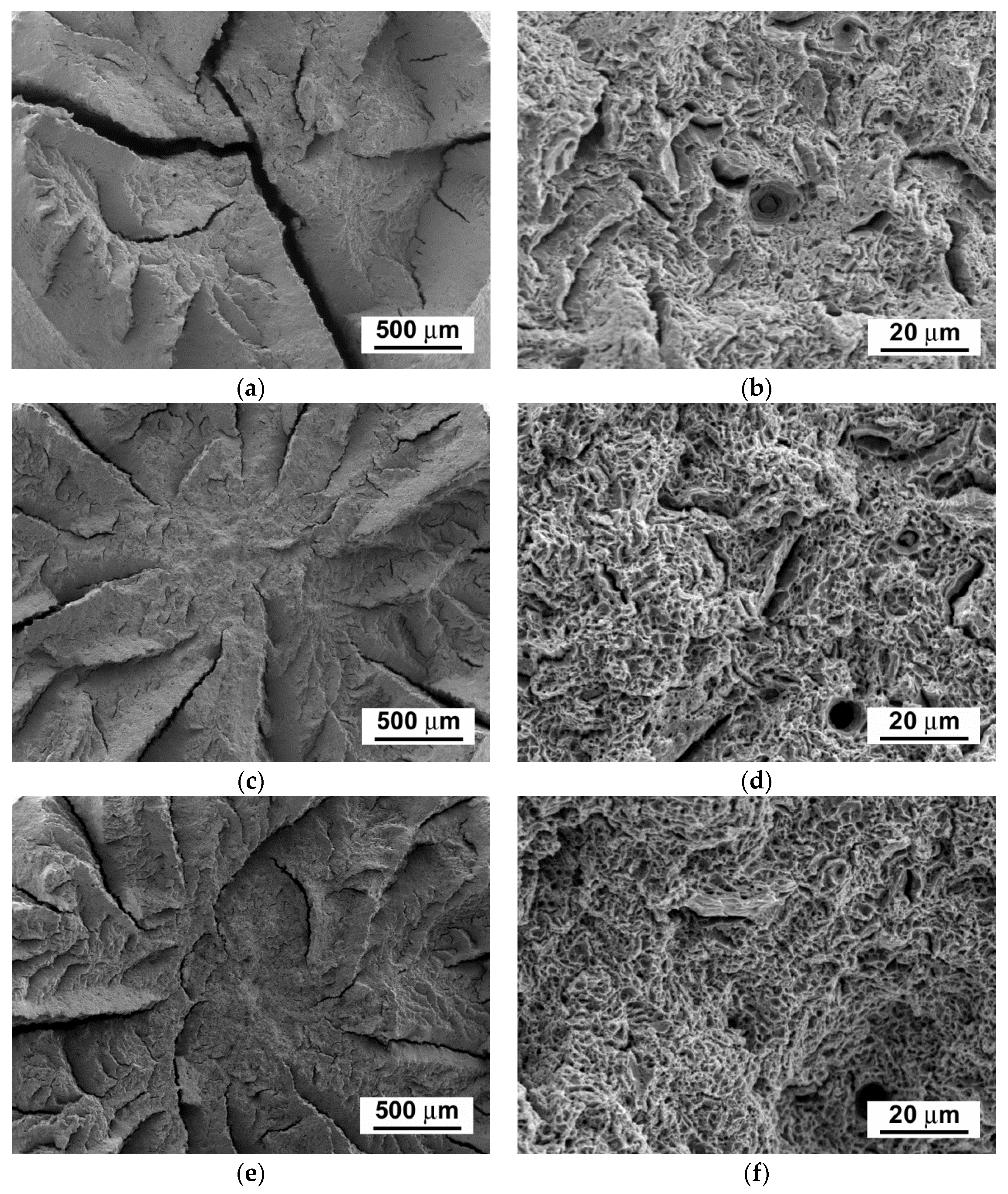

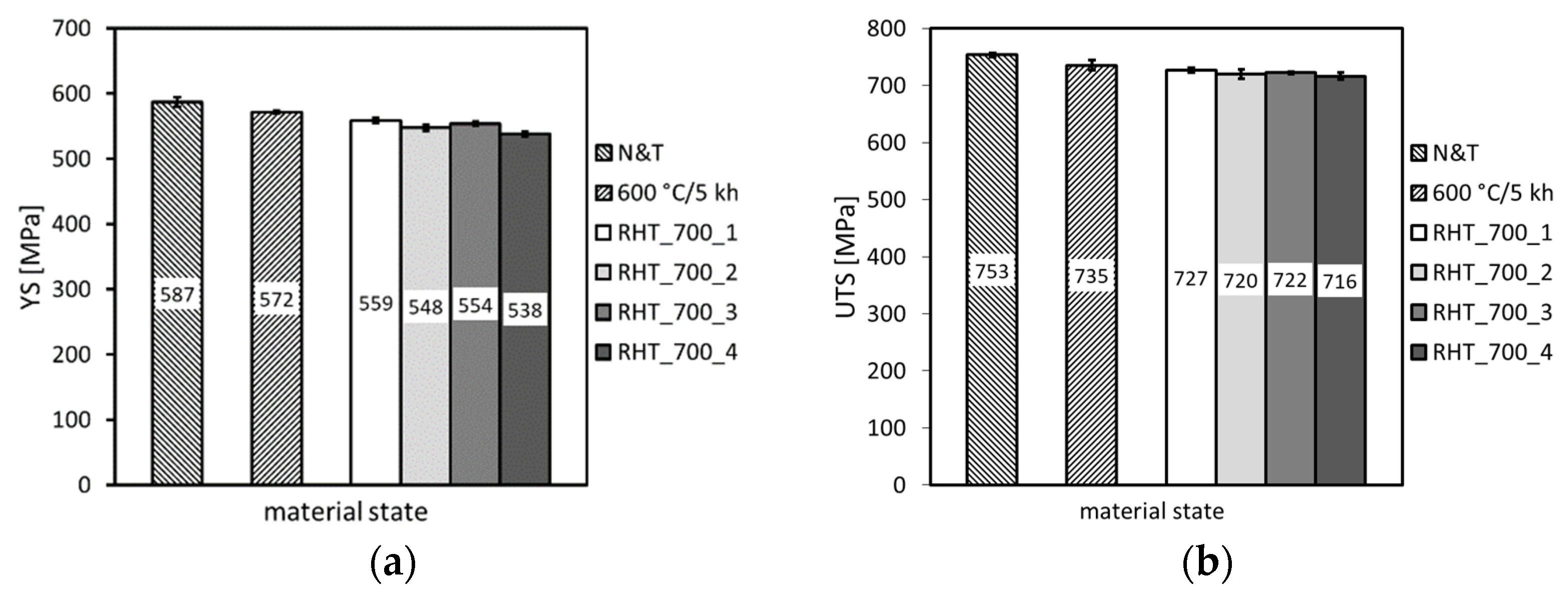

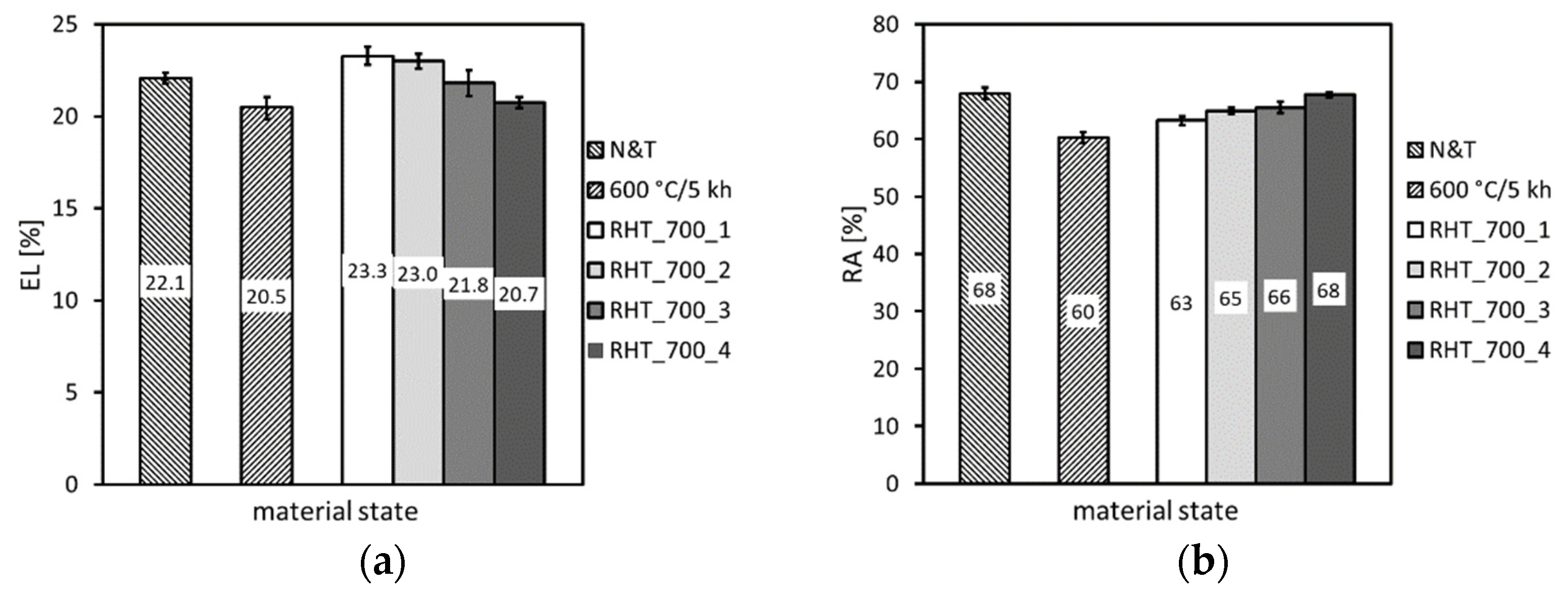

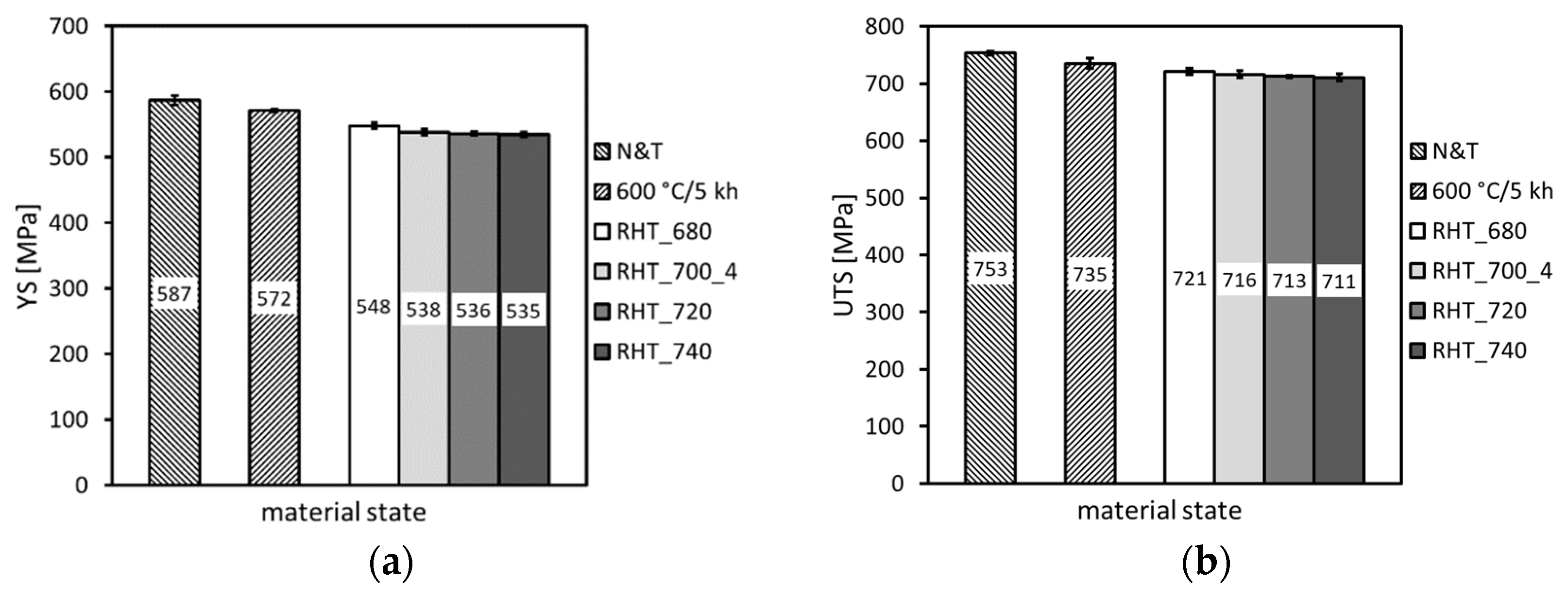

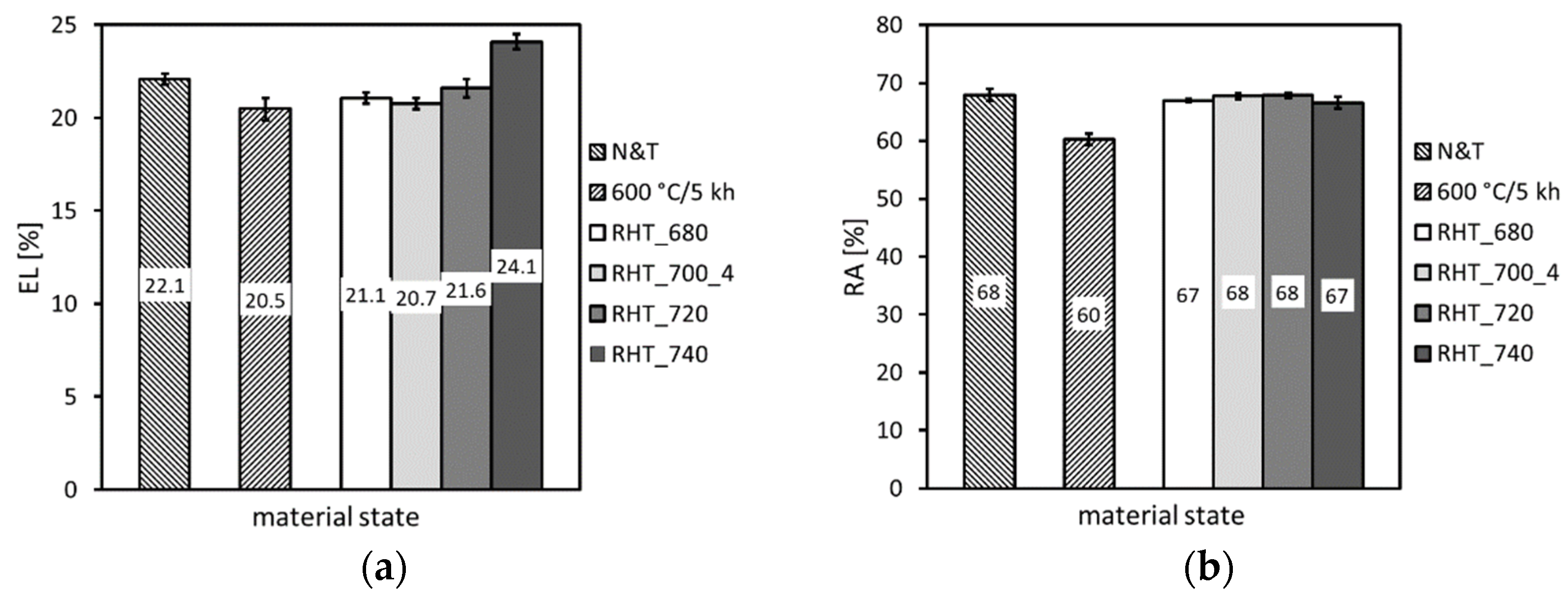

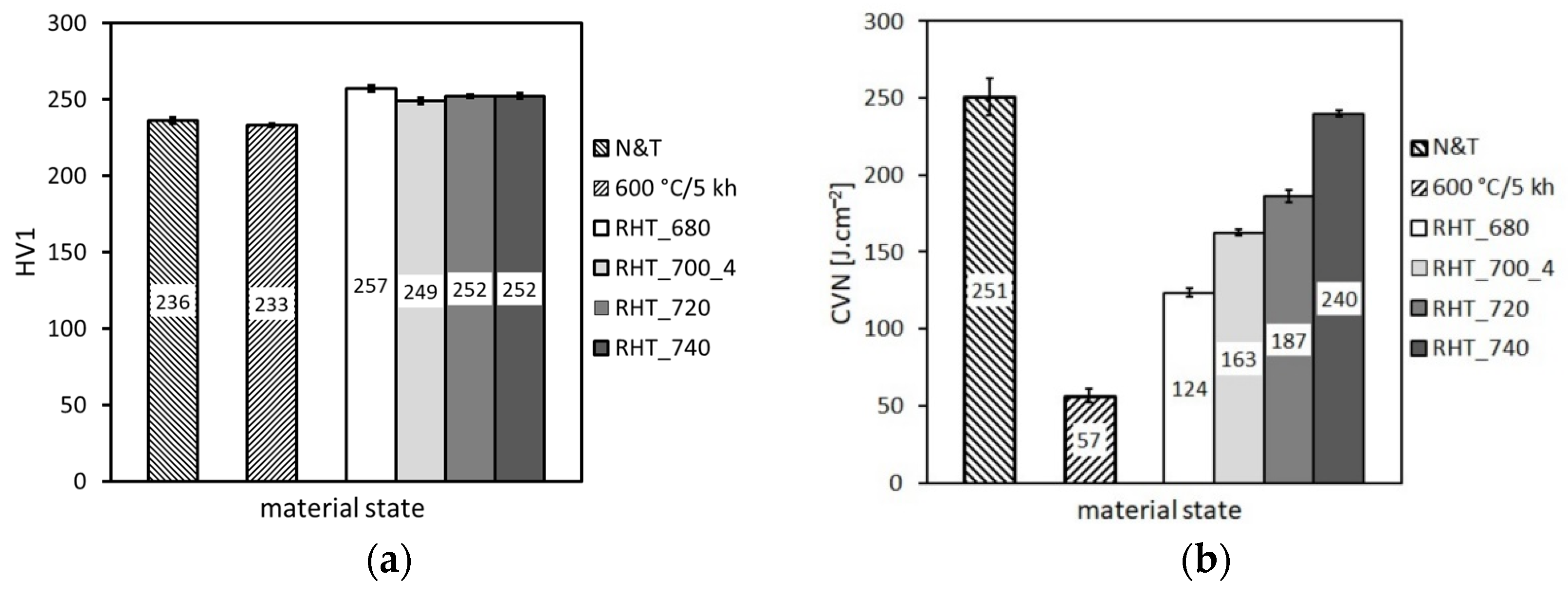

3.3. Effect of Various Rejuvenation Heat Treatments on Mechanical Properties

4. Summary and Conclusions

- Long-term ageing of investigated P92 steel at 600 °C up to 5000 h led only to small changes in its room-temperature tensile properties and hardness, whereas its Charpy impact toughness was significantly deteriorated. The sharp drop in impact toughness occurred already after 2500 h ageing at 600 °C and, afterwards, i.e., following the increase in the ageing time, it did not experience any further notable decrease. The main reason for the impact toughness deterioration was ascribed to thermal embrittlement caused by coarsening of secondary phase precipitates, especially the Fe2W-based Laves phase.

- By investigating the effects of various heating up and cooling down conditions of the rejuvenation heat treatments at 700 °C for 1 h, it was found that the rapid heating up by directly inserting examined specimens into the heated furnace and quick cooling down of the specimens in water represent the most efficient conditions for the maximization of the rejuvenation effect for the restoration of impact toughness. This result indicates that, for obtaining the maximal rejuvenation effect at the considered rejuvenation annealing temperature, rapid cooling of the material from the annealing temperature is needed in order to preserve the high temperature material state, and thus avoid reversible diffusion-controlled microstructural changes that might reduce the rejuvenation effect by slower cooling.

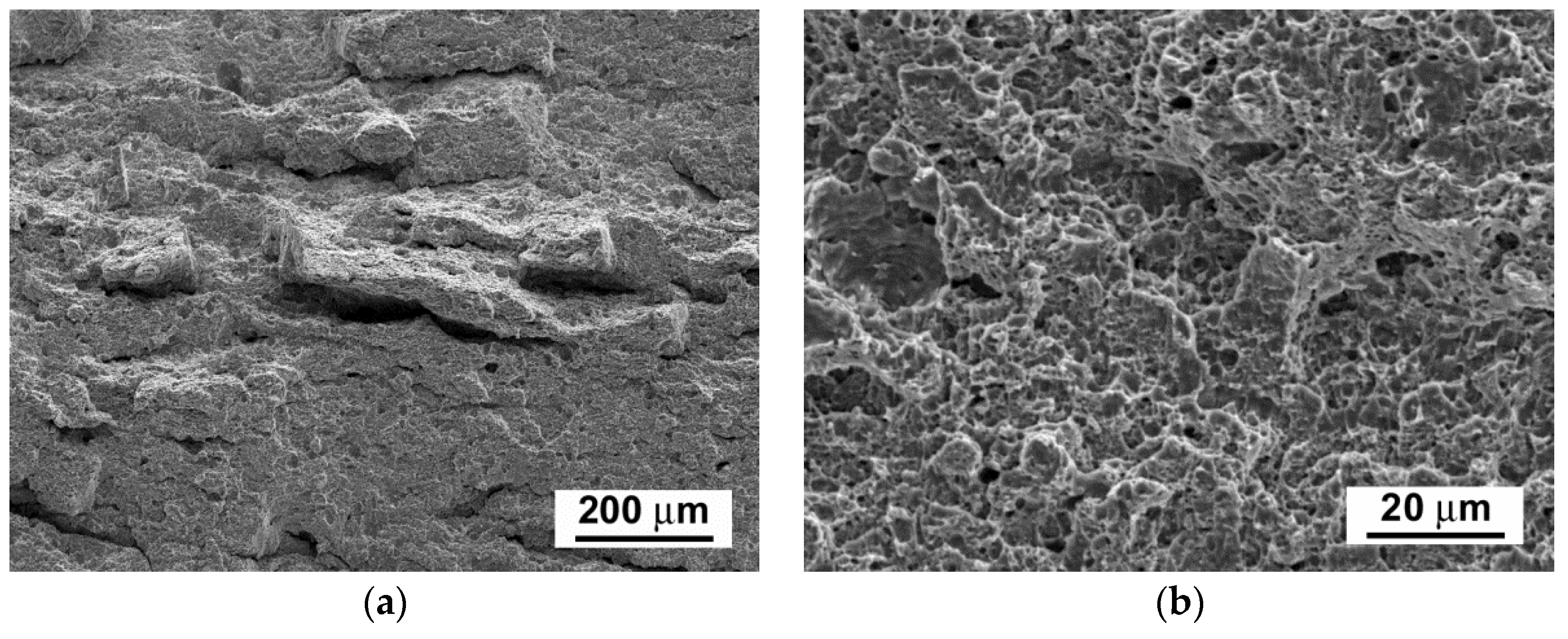

- By investigating the effects of various rejuvenation annealing temperatures in the range from 680 °C to 740 °C, it was revealed that the maximal rejuvenation effect for CVN impact toughness restoration of long-term thermally aged P92 steel (i.e., obtaining the CVN values closely approaching the original values corresponding to normalized and tempered material condition) was obtained at 740 °C using the most efficient, i.e., rapid heating up and fast cooling down, conditions. From the performed microstructural observations, it can be concluded that the rejuvenation effect can be ascribed to partial dissolution of the Laves phase precipitates, i.e., around 60% of their original area fraction. The rejuvenation effect was also correlated with fractographic observations, indicating full restoration of the ductile dimple fracture micro-mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Kumar, P.; Saini, N.; Thakare, J.G.; Kumar, S. Study on effect of double austenitization treatment on fracture morphology tensile tested nuclear grade P92 steel. Eng. Fail. Anal. 2019, 96, 158–167. [Google Scholar] [CrossRef]

- Seo, W.-G.; Suh, J.-Y.; Shim, J.-H.; Lee, H.; Yoo, K.; Choi, S.-H. Effect of post-weld heat treatment on the microstructure and hardness of P92 steel in IN740H/P92 dissimilar weld joints. Mater. Charact. 2020, 160, 110083. [Google Scholar] [CrossRef]

- Peng, Y.-Q.; Chen, T.-C.; Chung, T.-J.; Jeng, S.-L.; Huang, R.-T.; Tsay, L.-W. Creep Rupture of the Simulated HAZ of T92 Steel Compared to that of a T91 Steel. Materials 2017, 10, 139. [Google Scholar] [CrossRef] [Green Version]

- Wu, T.-J.; Liao, C.-C.; Chen, T.-C.; Shiue, R.-K.; Tsay, L.-W. Microstructural Evolution and Short-Term Creep Rupture of the Simulated HAZ in T92 Steel Normalized at Different Temperatures. Metals 2019, 9, 1310. [Google Scholar] [CrossRef] [Green Version]

- Sklenička, V.; Kuchařová, K.; Svoboda, M. Creep behaviour and microstructure evolution of advanced creep-resistant 9%Cr martensitic steels under cyclic thermal loading. Kovove Mater. 2018, 56, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D.; Zhang, S.; Zhang, H.; Li, S.; Xiao, H.; Wang, Y.; Wang, X. Effects of Tempering Temperature on the Microstructure and Mechanical Properties of T92 Heat-Resistant Steel. Metals 2019, 9, 194. [Google Scholar] [CrossRef] [Green Version]

- Abe, F. Effect of fine precipitation and subsequent coarsening of Fe2W Laves phase on the creep deformation behaviour of tempered martensitic 9Cr-W steels. Metal. Mater. Trans. A 2005, 36, 321–332. [Google Scholar] [CrossRef]

- Xia, X.; Zhu, B.; Jin, X.; Tang, M.; Yang, L.; Xue, F.; Shi, J.; Zhang, G. Analysis on microstructure and properties evolution and life prediction of P92 steel in high temperature service. Int. J. Press. Vessels Pip. 2021, 194, 104482. [Google Scholar] [CrossRef]

- Král, P.; Dvořák, J.; Sklenička, V.; Masuda, T.; Tang, Y.; Horita, Z.; Kunčická, L.; Kuchařová, K.; Kvapilová, M.; Svobodová, M. Effect of severe plastic deformation on creep behavior and microstructure changes of P92 at 923K. Kovove Mater. 2021, 59, 141–148. [Google Scholar] [CrossRef]

- Jin, X.; Zhu, B.; Li, Y.; Zhao, Y.; Xue, F.; Zhang, G. Effect of the microstructure evolution on the high-temperature strength of P92 heat-resistant steel for different service times. Int. J. Press. Vessels Pip. 2020, 186, 104131. [Google Scholar] [CrossRef]

- Falat, L.; Výrostková, A.; Svoboda, M.; Milkovic, O. The influence of PWHT regime on microstructure and creep rupture behaviour of dissimilar T92/TP316H ferritic/austenitic welded joints with Ni-based filler metal. Kovove Mater. 2011, 49, 417–426. [Google Scholar] [CrossRef]

- Saini, N.; Mulik, R.S.; Mahapatra, M.M. Study on the effect of ageing on laves phase evolution and their effect on mechanical properties of P92 steel. Mater. Sci. Eng. A 2018, 716, 179–188. [Google Scholar] [CrossRef]

- Xue, W.; Pan, Q.-G.; Ren, Y.-Y.; Shang, W.; Zeng, H.-Q.; Liu, H. Microstructure and type IV cracking behavior of HAZ in P92 steel weldment. Mater. Sci. Eng. A 2012, 552, 493–501. [Google Scholar] [CrossRef]

- Výrostková, A.; Homolová, V.; Pecha, J.; Svoboda, M. Phase evolution in P92 and E911 weld metals during ageing. Mater. Sci. Eng. A 2008, 480, 289–298. [Google Scholar] [CrossRef]

- Zhao, L.; Jing, H.; Xu, L.; Han, Y.; Xiu, J. Experimental study on creep damage evolution process of Type IV cracking in 9Cr–0.5Mo–1.8W–VNb steel welded joint. Eng. Fail. Anal. 2012, 19, 22–31. [Google Scholar] [CrossRef]

- Junek, M.; Svobodova, M.; Horvath, J.; Mara, V. The Effect of Long-Term Ageing on Microstructural Properties and Laves Phase Precipitation of Welded P91and P92 Steels. Steel Res. Int. 2021, 2100311. [Google Scholar] [CrossRef]

- Maddi, L.; Deshmukh, G.S.; Ballal, A.R.; Peshwe, D.R.; Paretkar, R.K.; Laha, K.; Mathew, M.D. Effect of Laves phase on the creep rupture properties of P92 steel. Mater. Sci. Eng. A 2016, 668, 215–223. [Google Scholar] [CrossRef]

- Guo, X.; Gong, J.; Jiang, Y.; Rong, D. The influence of long-term aging on microstructures and static mechanical properties of P92 steel at room temperature. Mater. Sci. Eng. A 2013, 564, 199–205. [Google Scholar] [CrossRef]

- Fedorova, I.; Belyakov, A.; Kozlov, P.; Skorobogatykh, V.; Shenkova, I.; Kaibyshev, R. Laves-phase precipitates in a low-carbon 9% Cr martensitic steel during aging and creep at 923 K. Mater. Sci. Eng. A 2014, 615, 153–163. [Google Scholar] [CrossRef]

- Stein, F.; Leineweber, A. Laves phases: A review of their functional and structural applications and an improved fundamental understanding of stability and properties. J. Mater. Sci. 2021, 56, 5321–5427. [Google Scholar] [CrossRef]

- Yamamoto, K.; Kimura, Y.; Mishima, Y. Effect of Matrix Substructures on Precipitation of the Laves Phase in Fe-Cr-Nb-Ni System. ISIJ Int. 2003, 43, 1253–1259. [Google Scholar] [CrossRef] [Green Version]

- Li, Q. Precipitation of Fe2W laves phase and modeling of its direct influence on the strength of a 12Cr-2W steel. Metall. Mater. Trans. A 2006, 37, 89–97. [Google Scholar] [CrossRef]

- Komazaki, S.; Kishi, S.; Shoji, T.; Chiba, H.; Suzuki, K. Thermal aging embrittlement of tungsten-alloyed 9%Cr ferritic steels and electrochemical evaluation. Mater. Sci. Res. Int. 2003, 9, 42–49. [Google Scholar] [CrossRef]

- Sello, M.P.; Stumpf, W.E. Laves phase embrittlement of the ferritic stainless steel type AISI 441. Mater. Sci. Eng. A 2010, 527, 5194–5202. [Google Scholar] [CrossRef] [Green Version]

- Sawada, K.; Kubo, K.; Abe, F. Creep behavior and stability of MX precipitates at high temperature in 9Cr–0.5Mo–1.8W–VNb steel. Mater. Sci. Eng. A 2001, 319, 784–787. [Google Scholar] [CrossRef]

- Zhong, W.; Wang, W.; Yang, X.; Li, W.; Yan, W.; Sha, W.; Wang, W.; Shan, Y.; Yang, K. Relationship between Laves phase and the impact brittleness of P92 steel reevaluated. Mater. Sci. Eng. A 2015, 639, 252–258. [Google Scholar] [CrossRef] [Green Version]

- ISO 6892-1:2019 Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Available online: https://www.iso.org/standard/78322.html (accessed on 17 September 2021).

- ISO 148-1:2016 Metallic materials—Charpy Pendulum Impact Test—Part 1: Test Method. Available online: https://www.iso.org/standard/63802.html (accessed on 17 September 2021).

- Walton, W. Feret‘s Statistical Diameter as a Measure of Particle Size. Nature 1948, 162, 329–330. [Google Scholar] [CrossRef]

- Abe, F. Heat-to-heat variation in long-term creep strength of some ferritic steels. Int. J. Press. Vessels Pip. 2010, 87, 310–318. [Google Scholar] [CrossRef]

- Mohyla, P.; Kubon, Z.; Cep, R.; Janasek, A.; Samardzic, I. Secondary hardening of low-alloyed creep-resistant steel welds. Metalurgija 2014, 53, 25–28. [Google Scholar]

- Sawada, K.; Kushima, H.; Hara, T.; Tabuchi, M.; Kimura, K. Heat-to-heat variation of creep strength and long-term stability of microstructure in Grade 91 steels. Mater. Sci. Eng. A 2014, 597, 164–170. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Q.; Yu, S.-M.; Hu, L.; Liu, H.; Ren, Y.-Y. Laves-phase evolution during aging in 9Cr-1.8W-0.5Mo-VNb steel for USC power plants. Mater. Chem. Phys. 2015, 163, 219–228. [Google Scholar] [CrossRef]

- Sun, N.; Jiang, Y.; Weng, X.X.; Gong, J.M. Microstructural Evolution of P92 Steel during Long-Term Aging. J. Fail. Anal. Preven. 2017, 17, 882–889. [Google Scholar] [CrossRef]

- Zieliński, A.; Sroka, M.; Miczka, M.; Śliwa, A. Forecasting the particle diameter size distribution in P92 (X10CrWMoVNb9-2) steel after long-term ageing at 600 and 650 °C. Arch. Metall. Mater. 2016, 61, 753–760. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Assessment of microstructure stability and mechanical properties of X10CrWMoVNb9-2 (P92) steel after long-term thermal ageing for high-temperature applications. Kovove Mater. 2016, 54, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Duan, P.; Liu, Z.; Li, B.; Li, J.; Tao, X. Study on microstructure and mechanical properties of P92 steel after high-temperature long-term aging at 650 °C. High Temp. Mater. Process. 2020, 39, 545–555. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | Cr | Mo | W | Al | Ni | Cu | V | Nb | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P92 | 0.13 | 0.37 | 0.42 | 9.39 | 0.28 | 1.54 | 0.006 | 0.29 | 0.09 | 0.23 | 0.07 | 0.01 | balance |

| RHT Denotation | Annealing Temperature/Time | Heating Up (Approx. Rate) | Cooling Down (Approx. Rate) |

|---|---|---|---|

| RHT_700_1 | 700 °C/1 h | with furnace (4.7 °C/min) | with furnace (0.7 °C/min) |

| RHT_700_2 | 700 °C/1 h | with furnace (4.7 °C/min) | on still air (100 °C/min) |

| RHT_700_3 | 700 °C/1 h | inserting at 700 °C (350 °C/min) | on still air (100 °C/min) |

| RHT_700_4 | 700 °C/1 h | inserting at 700 °C (350 °C/min) | into water (700 °C/min) |

| RHT_680 | 680 °C/1 h | inserting at 680 °C (350 °C/min) | into water (700 °C/min) |

| RHT_720 | 720 °C/1 h | inserting at 720 °C (350 °C/min) | into water (700 °C/min) |

| RHT_740 | 740 °C/1 h | inserting at 740 °C (350 °C/min) | into water (700 °C/min) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Falat, L.; Čiripová, L.; Homolová, V.; Džupon, M.; Džunda, R.; Kovaľ, K. The Effects of Various Conditions of Short-Term Rejuvenation Heat Treatment on Room-Temperature Mechanical Properties of Thermally Aged P92 Boiler Steel. Materials 2021, 14, 6076. https://doi.org/10.3390/ma14206076

Falat L, Čiripová L, Homolová V, Džupon M, Džunda R, Kovaľ K. The Effects of Various Conditions of Short-Term Rejuvenation Heat Treatment on Room-Temperature Mechanical Properties of Thermally Aged P92 Boiler Steel. Materials. 2021; 14(20):6076. https://doi.org/10.3390/ma14206076

Chicago/Turabian StyleFalat, Ladislav, Lucia Čiripová, Viera Homolová, Miroslav Džupon, Róbert Džunda, and Karol Kovaľ. 2021. "The Effects of Various Conditions of Short-Term Rejuvenation Heat Treatment on Room-Temperature Mechanical Properties of Thermally Aged P92 Boiler Steel" Materials 14, no. 20: 6076. https://doi.org/10.3390/ma14206076

APA StyleFalat, L., Čiripová, L., Homolová, V., Džupon, M., Džunda, R., & Kovaľ, K. (2021). The Effects of Various Conditions of Short-Term Rejuvenation Heat Treatment on Room-Temperature Mechanical Properties of Thermally Aged P92 Boiler Steel. Materials, 14(20), 6076. https://doi.org/10.3390/ma14206076