3.1. Dilatometric Tests

The main goal of the present study was to evaluate mechanical properties of samples with various, specifically prepared during the thermomechanical processing microstructures, deformed with high strain-rates. In order to precisely determine the critical temperatures for the austenitic range, the experiments began with dilatometric tests. Information was obtained on the starting temperature of the austenite–ferrite transformation for different reheating rates of the samples to the temperatures at which the rolling processes were carried out. The results obtained from the conducted tests are presented in

Table 1. The key heating transformation temperatures were established by dilatometric testing at different reheating rates: 1, 10, 30, 50, 70 and 100 K/s. The approximate temperature of the end of the austenitic transformation of A

c1 was taken as 880 °C. The differences in the duration of phase transitions resulting from the reheating rate turned out to be negligible from the technological point of view.

The austenite grain size is essential for the production of a specific final microstructure, strength and toughness of microalloyed steels after thermomechanical processing. Qualitatively and quantitatively, the austenite microstructure is already formed at the stage of reheating to the austenitizing temperature. Therefore, information from the dilatometric tests, which allowed for an assessment of the role of reheating rate, were investigated at the beginning of the present study.

Subsequent samples were tested in order to assess the influence of austenite deformation and austenitization temperature on phase transformations during cooling. Four austenitization temperatures were selected. After annealing (reheating rate 1 K/s) and austenitization (withstanding for 180 s), one sample was cooled and the other was deformed with a strain of 0.34, and then cooled. The cooling medium was nitrogen gas. Recorded dilatometric curves with assigned critical temperatures are presented in

Figure 3, where the final microstructures after the tests are also presented.

A temperature of 890 °C has been chosen as the nearest temperature at which stable austenite exist. However, dilatometric tests do not correspond with real rolling processes because of the temperature drop during the transfer of the billet from the furnace to the rolls. This temperature drop is estimated as 10 °C. For this reason, an austenitization temperature of 900 °C was applied in order to achieve an 890 °C billet temperature during deformation.

During the laboratory rolling process, the billet size is relatively small compared to industrial processes, so the correct choice of temperatures may be disturbed due to the temperature fluctuations and non-uniform distribution that occur. Moreover, in order to assess the impact of the intensity of these changes on the kinetics of austenite transformation and the morphology of its products, an austenitization temperature of 920 °C was included in the adopted thermomechanical processing schemes. The influence of the austenite deformations at temperatures higher than austenite recrystallization (estimated as 980 °C, based on chemical composition) require higher austenitization temperature, so 1000 °C was chosen as the last test temperature. Two different kinds of cooling strategies were applied: in air and in water.

In the first stage of the conducted research, the images of microstructures and the resulting mechanical properties of samples deformed under different conditions of thermomechanical processing with the same total deformation were analyzed. Thus, for the same thickness of rolled flat bars, several structural materials of different properties were obtained. The thermomechanical treatment schemes used in the present study are presented in

Figure 1. However, for the following investigations, we decided to study, more particularly, only selected schemes. On the basis of dilatometric tests, samples for thermomechanical rolling were prepared. Samples 1A, 1B, 3A, 3B, 4A, 4B, 6A and 6B were selected (rolling schedules—see

Figure 1). The criterion for selecting samples for further tests resulted from the degree of differentiation of microstructures at room temperature and the process parameters used in the completed thermomechanical rolling tests.

3.2. Microstructural Studies

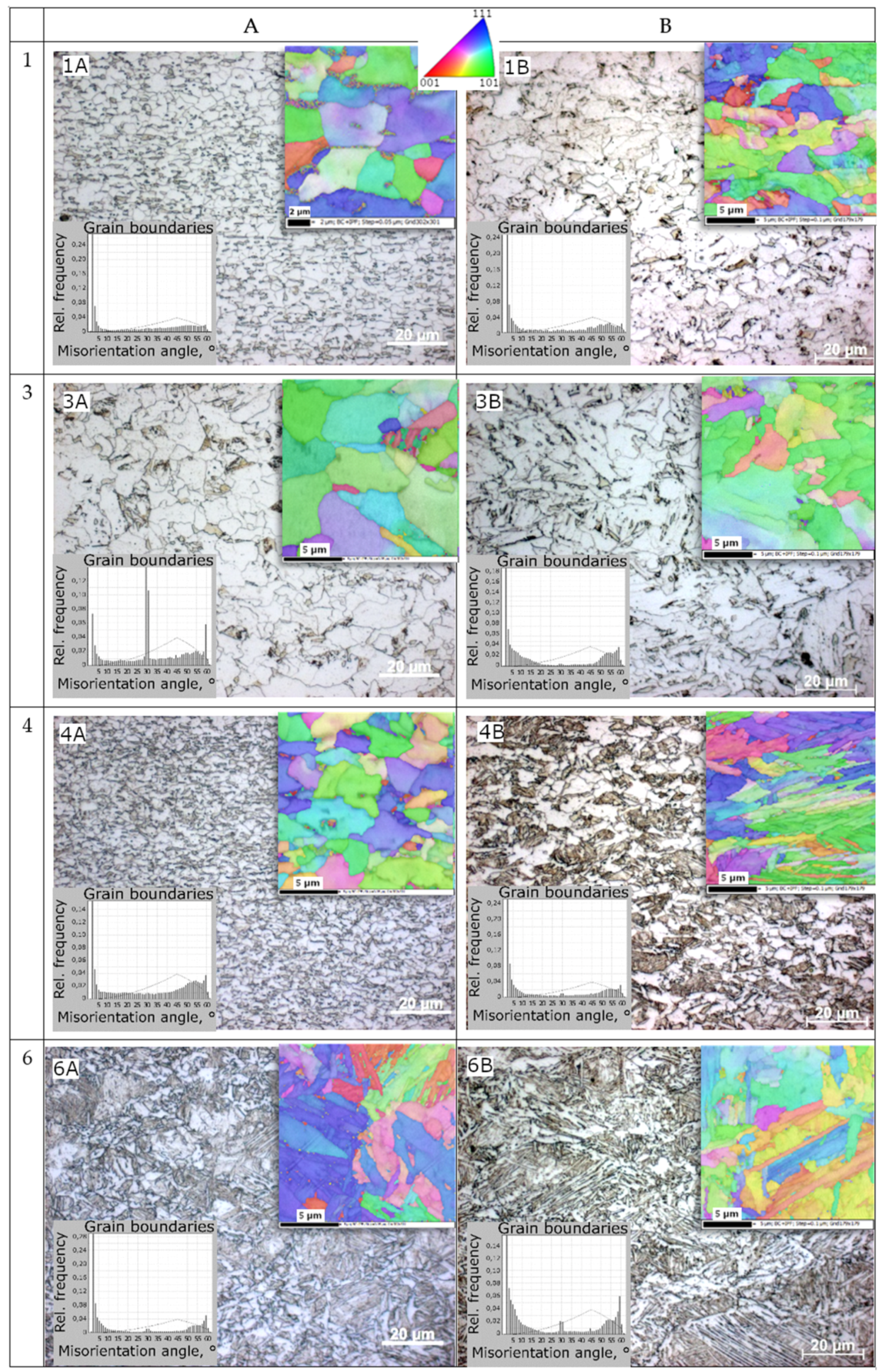

Microstructural investigations of the specimens produced by the TMP were performed. Both the phase composition and the morphology of individual components of the studied microstructures were assessed. Examples of the results of the obtained images of microstructures are shown in

Figure 4. The microstructural analysis was performed using samples cut, in a plane parallel to the rolling direction, from (i) the near surface (1 mm slice for prior austenite grain revealing due to low ability of that steel for martensitic transformation) and (ii) mid-thickness location of a 5 mm thick final flat bar. The microstructural characterization was carried out by optical and scanning electron microscopy (SEM) with EBSD technique. High mechanical properties, including impact toughness, require not only higher strength of the microstructure components, such as non-polygonal ferrite, acicular ferrite, bainites or martensite achieved due to dedicated chemical composition and high cooling rates, but also a controlled degree of their refinement and finally, in the case of many phases, of their proper arrangement in the micro-regions. Microstructural studies have revealed that bainite is the dominant microstructural component for the produced materials. Nevertheless, from the point of view of mechanical properties, an important factor characterizing the obtained microstructures is their heterogeneity and the morphology of individual components. It can be noticed (

Figure 4) that in the case of samples 1A and 1B, the obtained microstructure is characterized by the highest proportion of ferrite with a fairly uniform degree of refinement, especially in the case of sample 1A. The greatest microstructural inhomogeneity can be seen in the images of samples 4A, especially 4B (

Figure 4). The latter is dominated by a characteristic image of areas marked with granular ferrite, corresponding to the primary austenite structure, filled with a mixture of bainite, martensite and acicular ferrite. The microstructure revealed in sample 3A (

Figure 4) shows a distinct bimodal character, i.e., there are uniformly distributed grains of very fine and much larger diameters. Such a microstructure, as already mentioned in [

6,

7,

8,

9], is very advantageous from the point of view of the optimal combination of ductility and high strength.

It should be expected that the observed characteristics of the microstructures, i.e., significant differences in morphology, phase composition and structure refinement, will have a significant impact on the mechanical responses of the tested samples under both quasi-static and dynamic loading conditions.

The quantitative assessment of the retained austenite was also the result of the per-formed analysis. The thermomechanically rolled specimens were examined using X-ray diffraction analysis (XRD). Based on the diffractograms, the volume fraction of retained austenite in the tested samples was calculated. Based on the evaluation of the microstructures, the volume fraction and the morphology of individual structural components and histograms showing the degree of disorientation within the grain boundaries, the dominant phases occurring in each of the microstructures were identified. The grain sizes presented in

Table 2 were determined on the basis of maps from the EBSD analysis, where 0.2 µm

2 was assumed as the minimum grain area.

3.3. Plastometric Tests

On the basis of the microstructural tests performed and the aforementioned criterion of the selection of the research material, samples were selected for plastometric tests. In the first stage of the study, the quasi-static tensile tests were carried out. In addition to the obtained stress–strain curves, images of strain distributions were also produced using the DIC system. These tests allowed us to determine the mechanical characteristics of all tested samples under quasi-static loads. The examples of results of the tensile tests and measurements with the DIC system are shown in

Figure 5. The representation of the initial microstructures in the samples before test is also shown.

As it was mentioned earlier, the microstructures obtained after thermomechanical rolling were formed mainly by ferrite–pearlite (specimens 1A, 1B) or bainite–martensite and acicular ferrite reaching (specimens 4A, 4B). The results presented in

Figure 4 clearly show that hard microstructural components (perlite, bainite, martensite) exerted a significant influence on the mechanical response of the tested samples. These observations are consistent with literature [

23,

24] where it was shown that the ferrite was the soft microstructure component with high elongation, whereas bainite was the hard microstructure component with high strength. We can expect that in the high strain rate regime, the retained austenite (specimens 1A, 1B) can be considered as independent of strain rate in comparison to the ferrite and bainite, which usually show positive strain rate sensitivity.

An important feature of structural materials, especially those intended for applications in various load conditions due to the mechanical state, is their susceptibility to work hardening. For this reason, also in the case of the materials produced in this study after thermomechanical rolling, tests were carried out that allowed us to compare the mechanical response of individual samples in the function of deformation distribution and as a result of work hardening. First, the samples with a special shape (

Figure 6) were subjected to the tension tests with this same range of the total elongations. During loading, the measurements of strain distributions were made using the DIC system [

25], to determine the degree of the localizations of deformation. Then, the deformed samples were subjected to hardness measurements in order to assess the characterization of work hardening of the various microstructures. The results of the performed quasi-static tensile tests indicate significant differences in the ability of work hardening between the tested samples. Comparing samples 1A and 1B with 4A and 4B, it can be seen that in the case of the former, there is a stronger tendency for localization of the deformation. In the case of sample 6, in general, higher hardness values and weaker tendency for strain localization were observed.

It should be mentioned here that, as it is generally known, the formation of a local stress state at the micro level on various types of stress concentrators, e.g., hard phase and soft ferrite interfaces, facilitates the dissipation of deformation energy on a macro scale. The possibility of evaluating the characteristics of work hardening, which is presented in

Figure 5 as an effect in the form of localization of both deformation and strengthening (hardness), is of key importance in this case. Therefore, it is reasonable to follow the relationships between the local inhomogeneous states of the microstructure, hard and soft components, and the resulting macro-scale consequences of the mechanical response. This dependence is of particular importance in dynamic load conditions, where the wave pattern of stress spreading is observed.

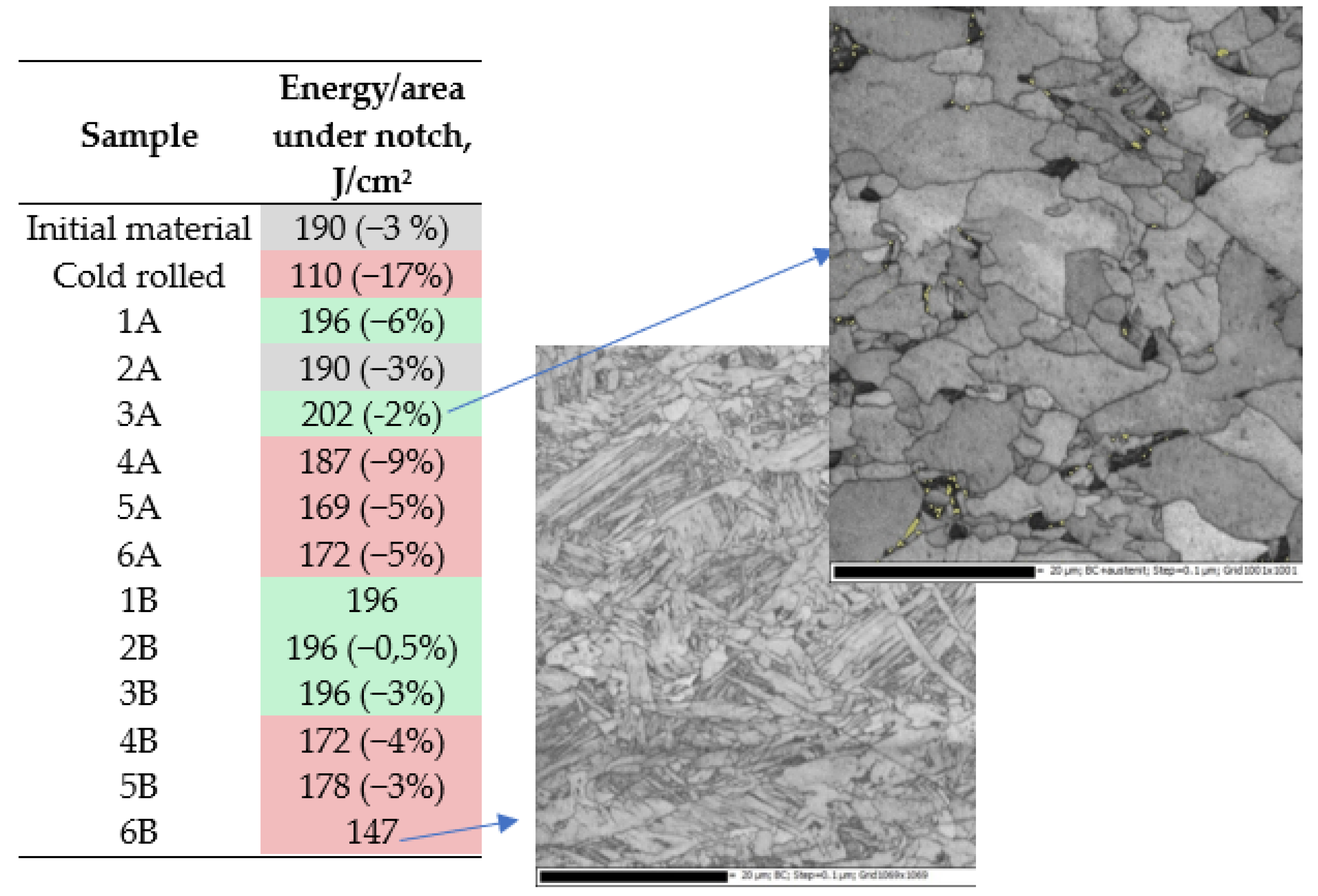

The next stage of the research included the measurements of impact toughness and the interpretation of the obtained results. It can be noticed (

Figure 7) that in relation to the material in the initial state, based on the analysis of the fracture energy, the produced materials show a clear, dominant division in terms of cooling conditions. The samples cooled after rolling in air have a fracture energy slightly higher than or equal to that of the sample in the input state, while for samples cooled in water, this energy is much lower.

When analyzing the obtained results in more detail, it can be seen that in the case of thermomechanical rolling according to scheme A, samples 1A and 2A almost do not differ in the breaking energy from the input material. The increase in impact toughness was observed in the case of the sample rolled according to the scheme 3A and it should be noted that this increase is the greatest among all tested samples. Observing the image of the microstructure for this sample 3A, it should be assumed that high toughness value in this case is a direct result of the bimodal distribution of significantly refined and large grains [

6,

7,

8,

9,

13]. The rolling pattern B (two hot passes), in turn, in each case shows an increase in the fracture energy for air-cooled samples, and the obtained results are very similar to each other. Thermomechanically rolled samples according to schemes 1B and 2B are characterized by high impact toughness, and this can be related to the morphology of their structure. The observed SEM fractures and the microstructures indicate a relatively uniform distribution of both larger and finely comminuted grains, which on the one hand ensures an increase in strength resulting from the refinement of the structure, and at the same time does not generate privileged places (as in the case of very fine grain conglomerates) for initiation and crack propagation.

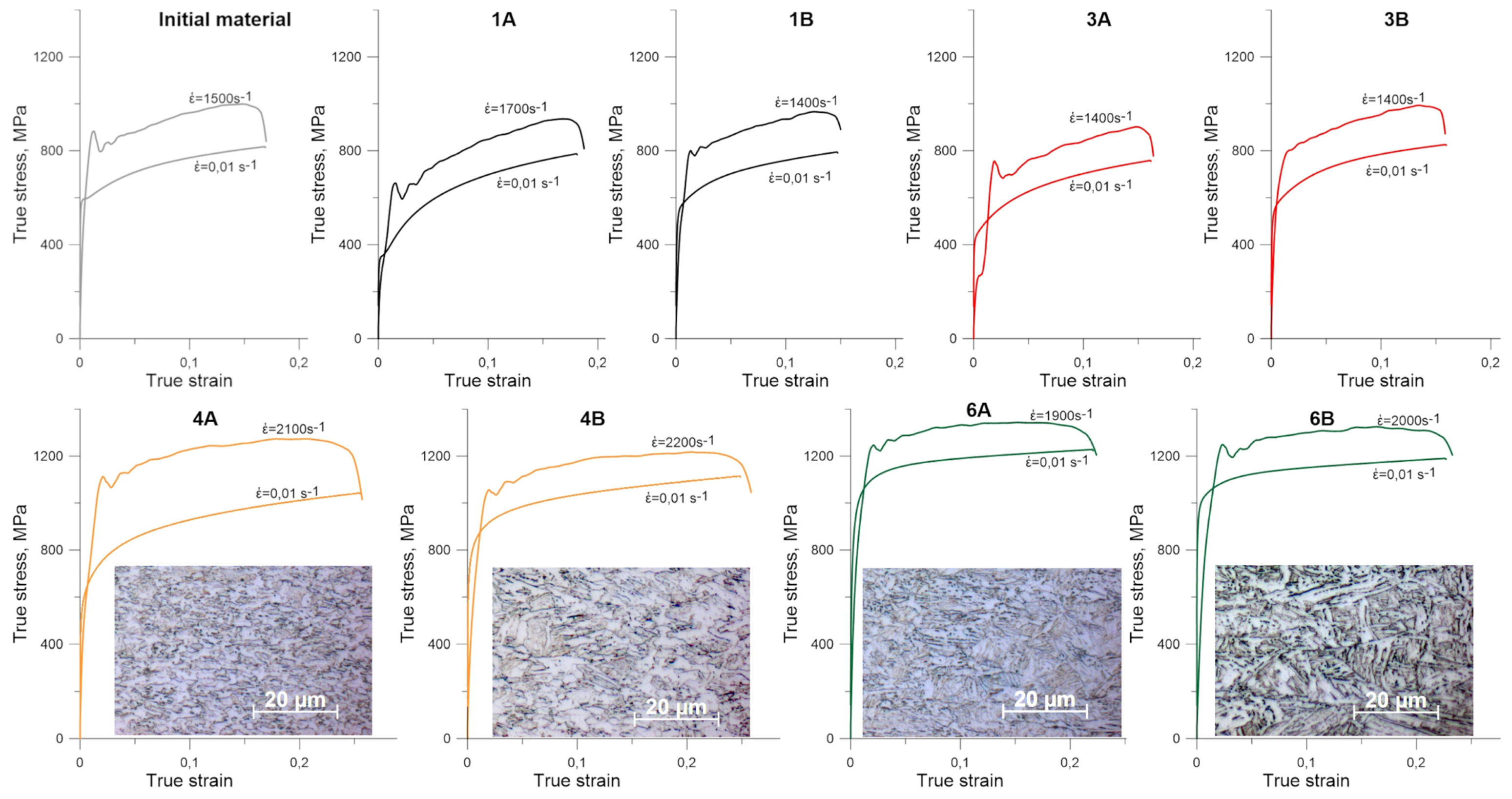

The influence of the strain rate on the mechanical properties of the tested samples was presented in

Figure 8, in which the quasi-static and dynamic stress–strain curves obtained for samples subjected to different histories of thermomechanical treatment were collected.

Comparisons of the obtained results for samples subjected to different histories of thermomechanical treatment and subsequent compression in quasi-static conditions and SHPB are shown in

Figure 8. The representation of the final microstructures in dynamically deformed samples is also shown. The microstructure analysis performed with the use of optical microscopy showed a uniform image of the microstructure on the sample cross-sections after dynamic deformation. This is consistent with the expectation that in the SHPB tests, the distribution of the effective strain on the sample cross-section should be as uniform as possible [

26,

27,

28]. Using the comparisons of the obtained stress–strain curves for different strain rates, the increments of flow stress of the tested samples were determined as an effect of their strain rate sensitivity (

Table 3). This seems to be the result of the finest refinement of the microstructure obtained with scheme 4A.

The selected stress–strain curves clearly show the possibility of obtaining significant changes in the mechanical properties of the tested microalloyed steels subjected to thermomechanical processing. It results directly from the fact that the HSLA steels are characterized by the highest number of strengthening mechanisms, i.e., deformation, solid solution, precipitation, complex phase and grain refinement strengthening. In turn, these strengthening mechanisms are activated in different ways in different microstructural compositions produced by a thermomechanical processing. Multiple microalloying additions also have a clear synergistic effect on hardenability. A favorable combination of high strength and ductility at high strain rates was obtained due to the developed multi-phase microstructure and its dedicated inhomogeneity in the micro and meso scales.

The results of plastometric tests presented in

Figure 8 allow for the formulation of some general conclusions. The differences in the behavior of materials heated to 900 °C and 1000 °C (

Figure 1) can be explained by the presence of more precipitates in the steel heated to a lower temperature, because the vanadium micro-additions did not dissolve sufficiently when reheated to the rolling temperature at 900 °C. In steel reheated to 1000 °C, the vanadium present in the solution did not have enough time to form carbides and the austenite with dissolved vanadium underwent a bainite transformation.

Sample 4A is characterized by the highest work hardening among water-cooled specimens. It contains the smallest share in the structure of upper bainite, and due to the lowest reheating temperature, it contains the highest number of carbides in the structure. At the given reheating temperatures, samples rolled in two passes (

Figure 1) are characterized by higher strength in the quasi-static compressions than those rolled in one pass when cooled in the air. When cooled in water, single pass rolled specimens represent higher strength. The exception is sample 4A, for which the yield stress is lower than for sample 4B.

In the case of air-cooled samples, for high strain rate regime, the differences between samples rolled according to schemes A and B are the same as for quasi-static compression.

This is not the case with water-cooled samples. The increase in plastic flow stress of samples reheated before rolling to 1000 °C is the same, regardless of whether the rolling was carried out in one or two passes. In samples reheated before rolling to 900 °C, the increase in the yield stress of a sample rolled in one pass is much greater than in a sample rolled in two passes. The compression yield stress of the sample 4A at a strain rate of 2100 s−1 is higher than that of the sample 4B compressed at a strain rate of 2200 s−1.

Significant differences in the strain rate sensitivity were observed in case of samples 1A, 1B and 4A, 4B. The compression curves shown in

Figure 8 also show that the sample 4A, characterized by a fine-grained structure of granular bainite strengthened with particles of foreign phases, shows the highest sensitivity to the strain rate while maintaining a high strain hardening ability. Hence, it can be concluded that for given strain rate and strain level, the microalloyed steel with heterogeneous, multiphase microstructure exhibits higher strain rate sensitivity than fully ferritic/pearlitic microstructure.

The analysis of the obtained results of compression tests clearly shows that material of sample 1A represents the highest work hardening rate, which may be due to the low yield stress associated with the presence of a relatively large amount of retained austenite. Additionally, the presence of a substantially high volume of retained austenite makes the sample material highly susceptible to work hardening.

Summarizing the results of compression tests presented in

Figure 8, it should be stated that samples 1A, 1B and 4A, 4B exhibit an exceptionally attractive combination of mechanical properties under dynamic loading conditions. Sample 4A shows a higher sensitivity to strain rate even though the structure morphology is relatively similar to 1A, although sample 4A has a finer microstructure and sample 1A contains a significant amount of retained austenite. It follows that under dynamic load conditions, the grain refinement has a stronger positive effect on toughness than increasing the amount of retained austenite.

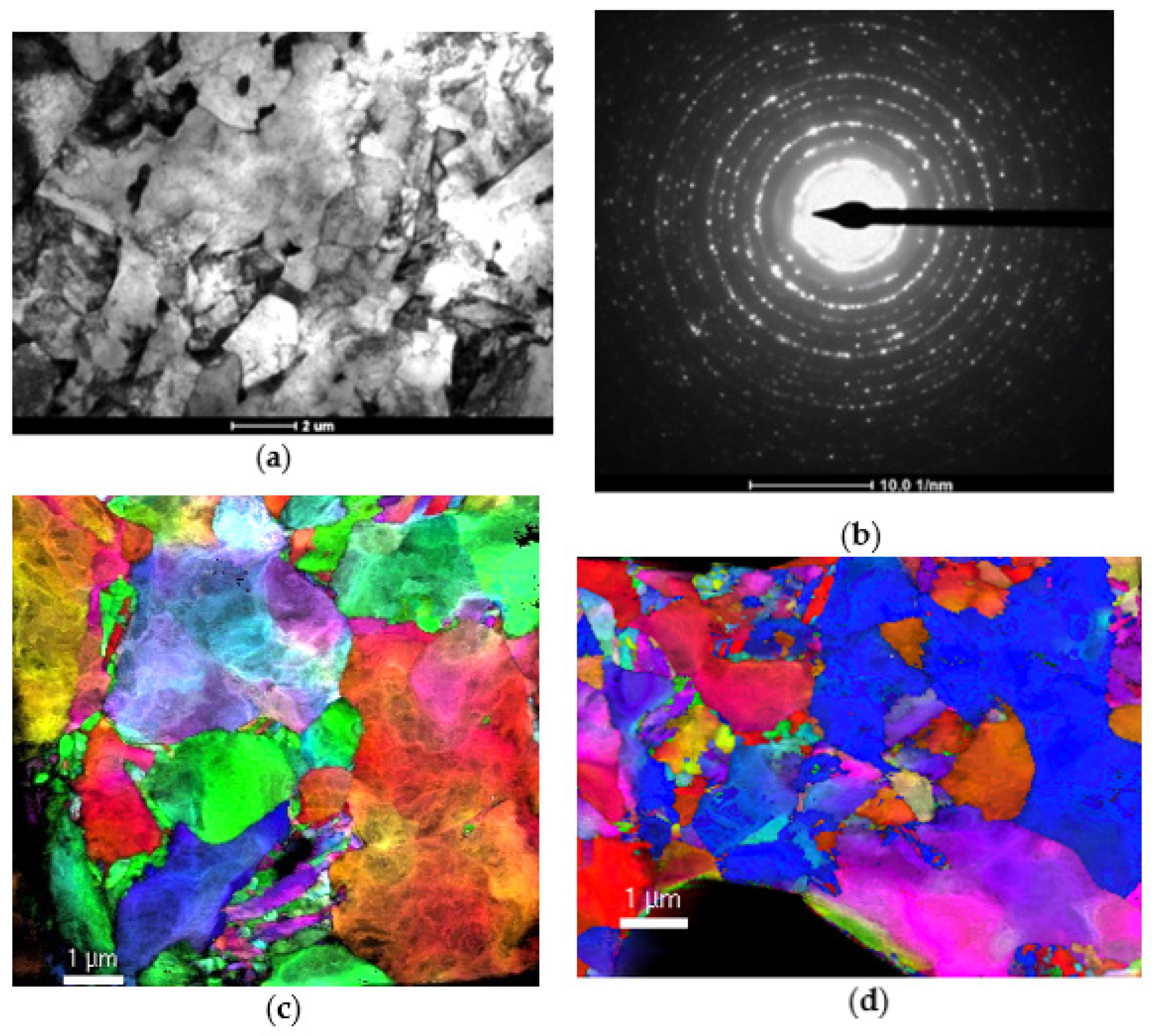

At the end of the study, a more detailed analysis of the relationship between the history of thermomechanical rolling, the resulting microstructure and the mechanical properties, especially at high strain rates, was carried out. TEM microscopy and diffraction analysis were used in these studies. Sample images of the microstructures are shown in

Figure 9.

Due to the very large differentiation of microstructural effects, selected cases were analyzed in detail. The microstructure analysis was carried out on samples made of rolled steel according to variant 4A (cold deformation, heating to 900 °C, rolling in one pass, cooling in water). The samples were analyzed at the condition after rolling and after deformation with the value of ε = 0.25 with two strain rates: 0.01 s−1 and 2100 s−1. TEM analysis showed that the original structure of sample 4A was composed of finely divided components with no visible signs of deformation. The diffraction pattern shows over 15 rings, formed out of numerous spots, the evidence of the large number of small grains. Such a complex diffraction pattern corresponds to a more complex microstructural features, than ferrite structure only. These rings are probably derived from numerous carbides. The dots on the diffraction pattern are clear and not stretched, which shows that the accumulated strain energy is not high and the material is relatively free from microstructural strain effects. The structure also includes bainite grains and numerous precipitates of various sizes, from a few to several hundred nm. The sample after deformation with a strain rate of 0.01 s−1 shows a strong development of the dislocation substructure and a large change in the crystallographic orientation within one grain. The presence of the precipitates facilitates the accumulation of microstructural effects of deformation. The dislocation substructure tends to be orderly. It is visible on the diffraction map, where the outlines of the subgrains can be seen. Dislocations are arranged in tangles, which transform into subgrain boundaries with further deformation.

The deformation effects can be observed much more significantly in the sample deformed with the strain rate of 2000 s−1. Optical microscope images of microstructures show that the microstructure is clearly finer than in the sample deformed at a lower strain rate. The change in the crystallographic orientation within the grains is smooth and does not form a distinct substructure. The photos of the dislocation substructure show the significant accumulation of dislocations blocked on numerous highly dispersive precipitates. This effect is characteristic for steels with Nb, Ti and V microalloying additions, and also for the microalloyed steel tested in this study.

The presented research has shown that it is possible to form the microstructure in the finished product in such a way as to achieve the expected mechanical responses at high strain rates without the need to change the chemical composition of the microalloyed steel. For this reason, further study on the problem discussed in this paper should be directed towards the creation of appropriate models that can be used directly for designing an online control of more and more complex thermomechanical processing of the microalloyed steels. The results of the present study are important not only for the automotive, defense and mining industries, but also for the further development of processes under dynamic forming conditions.