Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments

(This article belongs to the Section Manufacturing Processes and Systems)

Abstract

:1. Introduction

2. The Influence of Tooth Spalling Fault on TMS

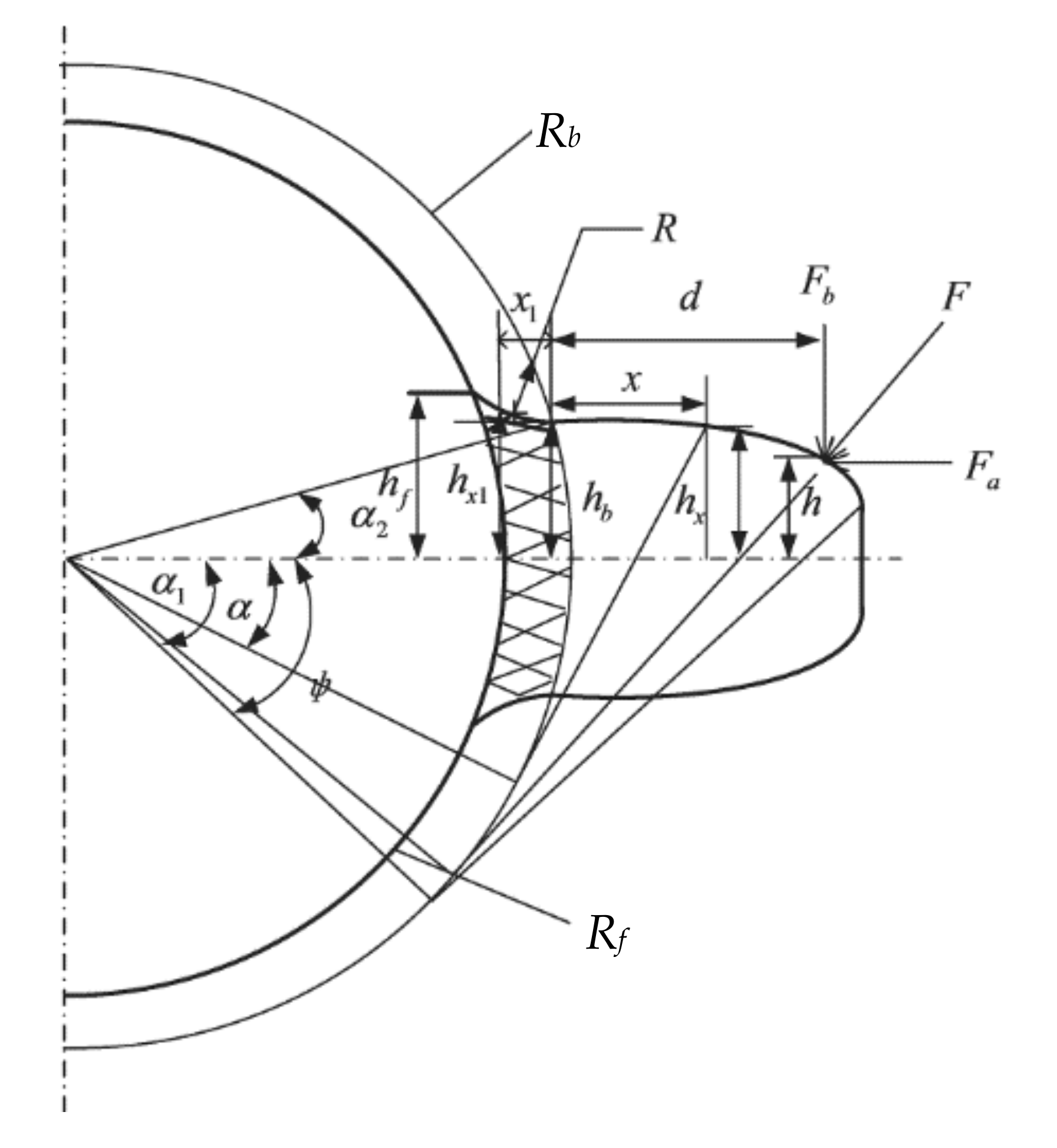

2.1. The Basic Principle of Calculating the TMS by the PEM

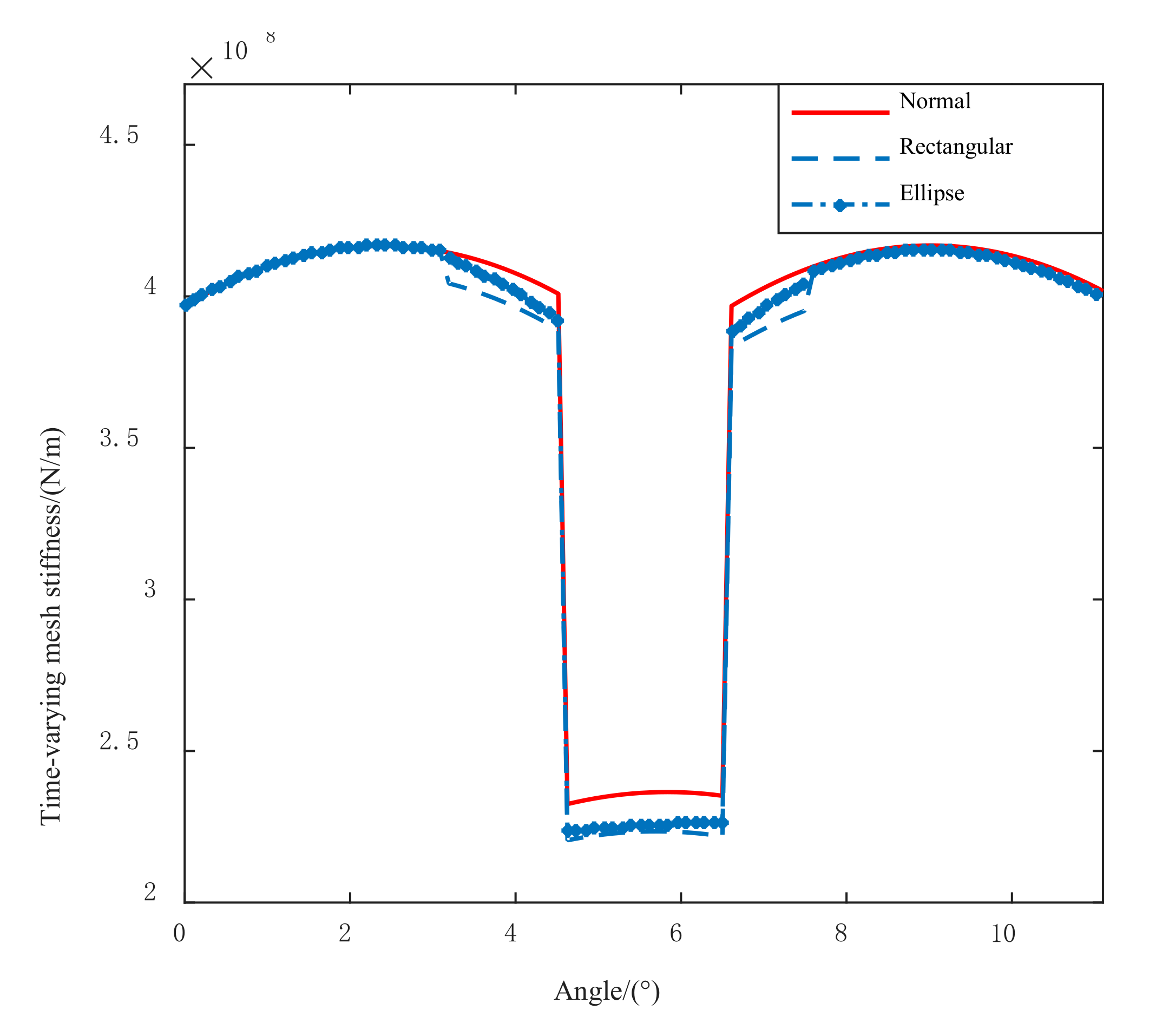

2.2. The Influence of Tooth Spalling Fault on TMS

3. The Nonlinear Dynamic Model of Gear System

3.1. The Dynamic Model of Gear Shaft

3.2. Nonlinear Bearing Model

3.3. Nonlinear Dynamic Model of Gear Pair

3.4. The Dynamic Model of Gear System

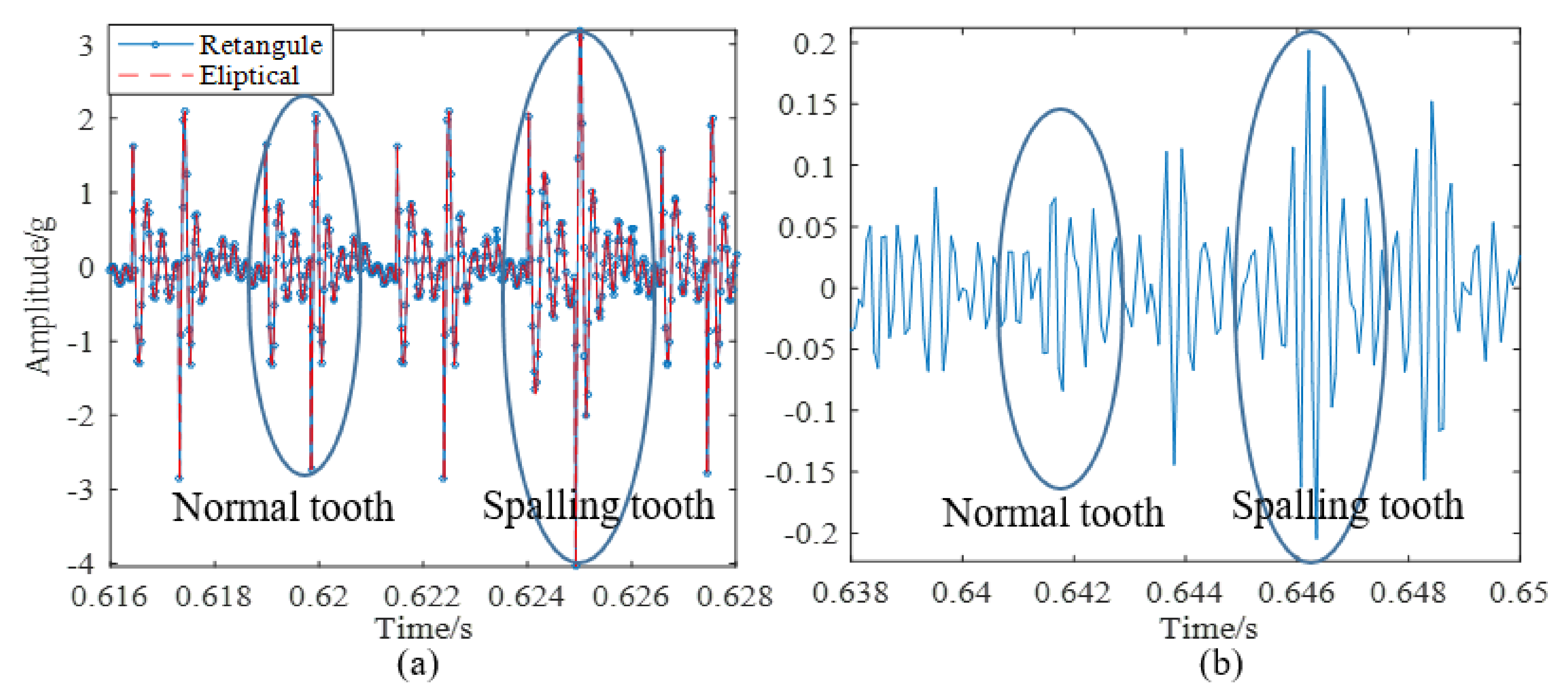

4. Fault Feature Analysis of Tooth Spalling Based on Dynamic Simulation and Experiments

Dynamic Simulation and Experiment Verification of Gear System without Defect

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Shao, Y. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth. Eng. Fail. Anal. 2011, 18, 2149–2164. [Google Scholar] [CrossRef]

- Pandya, Y.; Parey, A. Failure path based modified gear mesh stiffness for spur gear pair with tooth root crack. Eng. Fail. Anal. 2013, 27, 286–296. [Google Scholar] [CrossRef]

- Shao, R.; Huang, X.; Li, Y. Influence of Crack on Structure Vibration of Gear Tooth. J. Fail. Anal. Prev. 2009, 9, 563–571. [Google Scholar] [CrossRef]

- Ma, R.; Chen, Y. Research on the dynamic mechanism of the gear system with local crack and spalling failure. Eng. Fail. Anal. 2012, 26, 12–20. [Google Scholar] [CrossRef]

- Wan, Z.; Cao, H.; Zi, Y.; He, W.; He, Z. An improved time-varying mesh stiffness algorithm and dynamic modeling of gear-rotor system with tooth root crack. Eng. Fail. Anal. 2014, 42, 157–177. [Google Scholar] [CrossRef]

- Wan, Z.; Cao, H.; Zi, Y.; He, W.; Chen, Y. Mesh stiffness calculation using an accumulated integral potential energy method and dynamic analysis of helical gears. Mech. Mach. Theory 2015, 92, 447–463. [Google Scholar] [CrossRef]

- Ma, H.; Pang, X.; Feng, R.; Song, R.; Wen, B. Fault features analysis of cracked gear considering the effects of the extended tooth contact. Eng. Fail. Anal. 2015, 48, 105–120. [Google Scholar] [CrossRef]

- Ma, J.; Liu, T.; Zha, C.; Song, L. Simulation Research on the Time-Varying Meshing Stiffness and Vibration Response of Micro-Cracks in Gears under Variable Tooth Shape Parameters. Appl. Sci. 2019, 9, 1512. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, O.D.; Rantatalo, M.; Aidanpää, J.-O. Dynamic modelling of a one-stage spur gear system and vibration-based tooth crack detection analysis. Mech. Syst. Signal Process. 2015, 54, 293–305. [Google Scholar] [CrossRef]

- Brethee, K.; Zhen, D.; Gu, F.; Ball, A.D. Helical gear wear monitoring: Modelling and experimental validation. Mech. Mach. Theory 2017, 117, 210–229. [Google Scholar] [CrossRef]

- Lei, Y.; Liu, Z.; Wang, D.; Yang, X.; Liu, H.; Lin, J. A probability distribution model of tooth pits for evaluating time-varying mesh stiffness of pitting gears. Mech. Syst. Signal Process. 2018, 106, 355–366. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.; Chen, Z. A novel distribution model of multiple teeth pits for evaluating time-varying mesh stiffness of external spur gears. Mech. Syst. Signal Process. 2019, 129, 479–501. [Google Scholar] [CrossRef]

- Jiang, H.; Shao, Y.; Mechefske, C.K. Dynamic characteristics of helical gears under sliding friction with spalling defect. Eng. Fail. Anal. 2014, 39, 92–107. [Google Scholar] [CrossRef]

- Zhe, C.; Niaoqing, H.; Fengshou, G.; Guojun, Q. Pitting damage levels estimation for planetary gear sets based on model simulation and grey relational analysis. Trans. Can. Soc. Mech. Eng. 2011, 35, 403–417. [Google Scholar] [CrossRef]

- Abouel-seoud, S.A.; Dyab, E.S.; Elmorsy, M.S. Influence of tooth pitting and cracking on gear meshing stiffness and dynamic response of wind turbine gearbox. Int. J. Sci. Adv. Technol. 2012, 2, 151–165. [Google Scholar]

- Saxena, A.; Parey, A.; Chouksey, M. Time varying mesh stiffness calculation of spur gear pair considering sliding friction and spalling defects. Eng. Fail. Anal. 2016, 70, 200–211. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, H.; Liu, L.; Zuo, M.J. The influence of tooth pitting on the mesh stiffness of a pair of external spur gears. Mech. Mach. Theory 2016, 106, 1–15. [Google Scholar] [CrossRef]

- El Yousfi, B.; Soualhi, A.; Medjaher, K.; Guillet, F. New approach for gear mesh stiffness evaluation of spur gears with surface defects. Eng. Fail. Anal. 2020, 116, 104740. [Google Scholar] [CrossRef]

- Huangfu, Y.; Chen, K.; Ma, H.; Li, X.; Han, H.; Zhao, Z. Meshing and dynamic characteristics analysis of spalled gear systems: A theoretical and experimental study. Mech. Syst. Signal Process. 2020, 139, 106640. [Google Scholar] [CrossRef]

- Chaari, F.; Fakhfakh, T.; Haddar, M. Analytical modelling of spur gear tooth crack and influence on gearmesh stiffness. Eur. J. Mech. - A/Solids 2009, 28, 461–468. [Google Scholar] [CrossRef]

- Cao, H.; Niu, L.; He, Z. Method for Vibration Response Simulation and Sensor Placement Optimization of a Machine Tool Spindle System with a Bearing Defect. Sensors 2012, 12, 8732–8754. [Google Scholar] [CrossRef] [Green Version]

- Zhen, L.; Zhengjia, H.; Yanyang, Z.; Xuefeng, C. Bearing condition monitoring based on shock pulse method and improved redundant lifting scheme. Math. Comput. Simul. 2008, 79, 318–338. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Liang, M. Dynamical modeling and experimental validation for tooth pitting and spalling in spur gears. Mech. Syst. Signal Process. 2019, 119, 155–181. [Google Scholar] [CrossRef]

| Parameters | Pinion | Gear | |

|---|---|---|---|

| Gear | Teeth number | 55 | 75 |

| Module (mm) | 2 | 2 | |

| Pressure angle (°) | 20 | 20 | |

| Tooth width (mm) | 20 | 20 | |

| Moment of inertia (kg.m2) | 0.003 | 0.01 | |

| Eccentricity (um) | 20 | 20 | |

| Shaft | Radius (mm) | 15 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Z.; Zheng, J.; Li, J.; Man, Z. Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments. Materials 2021, 14, 6053. https://doi.org/10.3390/ma14206053

Wan Z, Zheng J, Li J, Man Z. Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments. Materials. 2021; 14(20):6053. https://doi.org/10.3390/ma14206053

Chicago/Turabian StyleWan, Zhiguo, Jie Zheng, Jie Li, and Zhenfeng Man. 2021. "Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments" Materials 14, no. 20: 6053. https://doi.org/10.3390/ma14206053

APA StyleWan, Z., Zheng, J., Li, J., & Man, Z. (2021). Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments. Materials, 14(20), 6053. https://doi.org/10.3390/ma14206053