Fabrication of (SiC-AlN)/ZrB2 Composite with Nano-Micron Hybrid Microstructure via PCS-Derived Ceramics Route

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Processing

2.2.1. Crosslink

2.2.2. Preparation of Composite Materials

2.3. Characterization

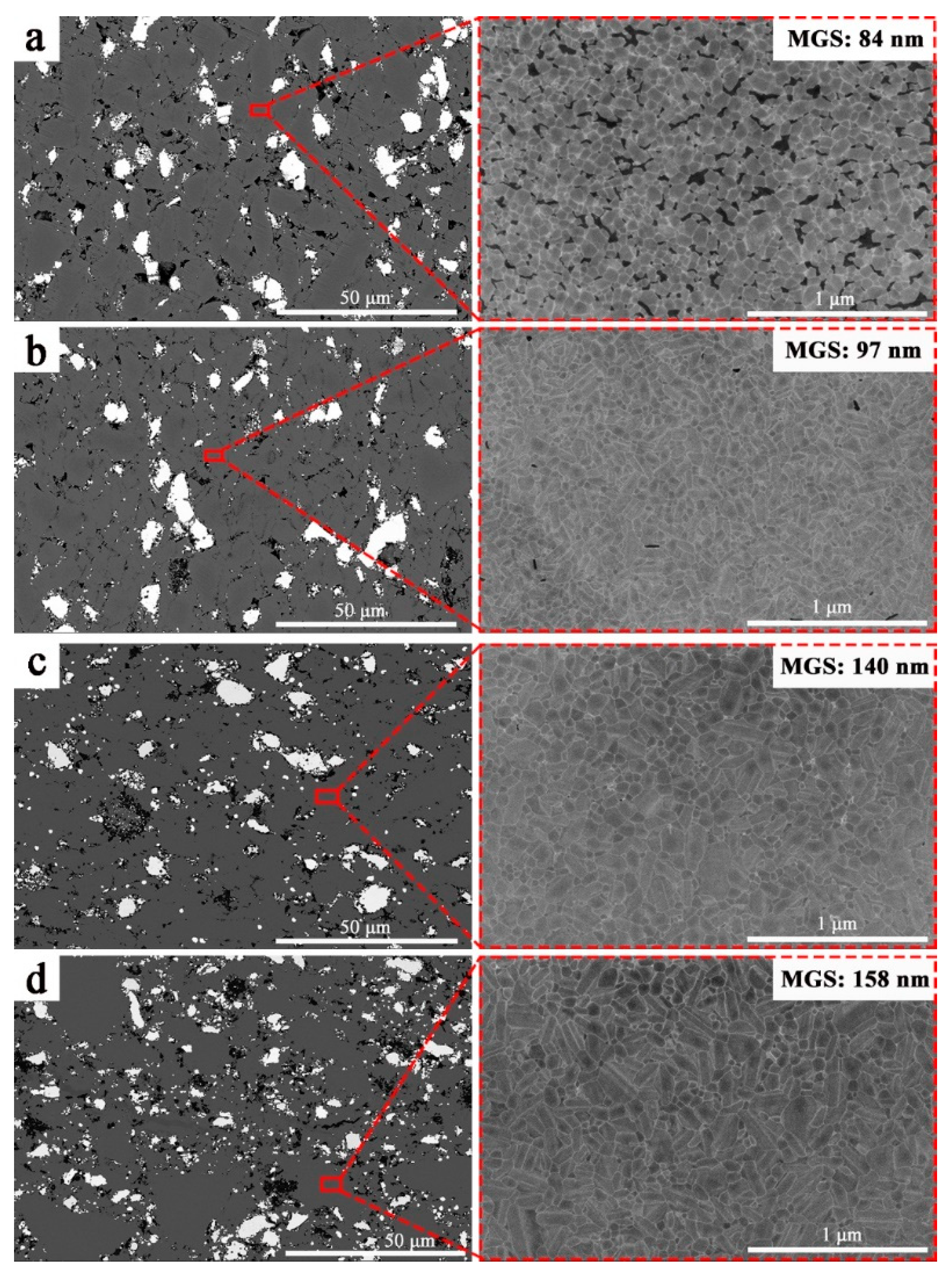

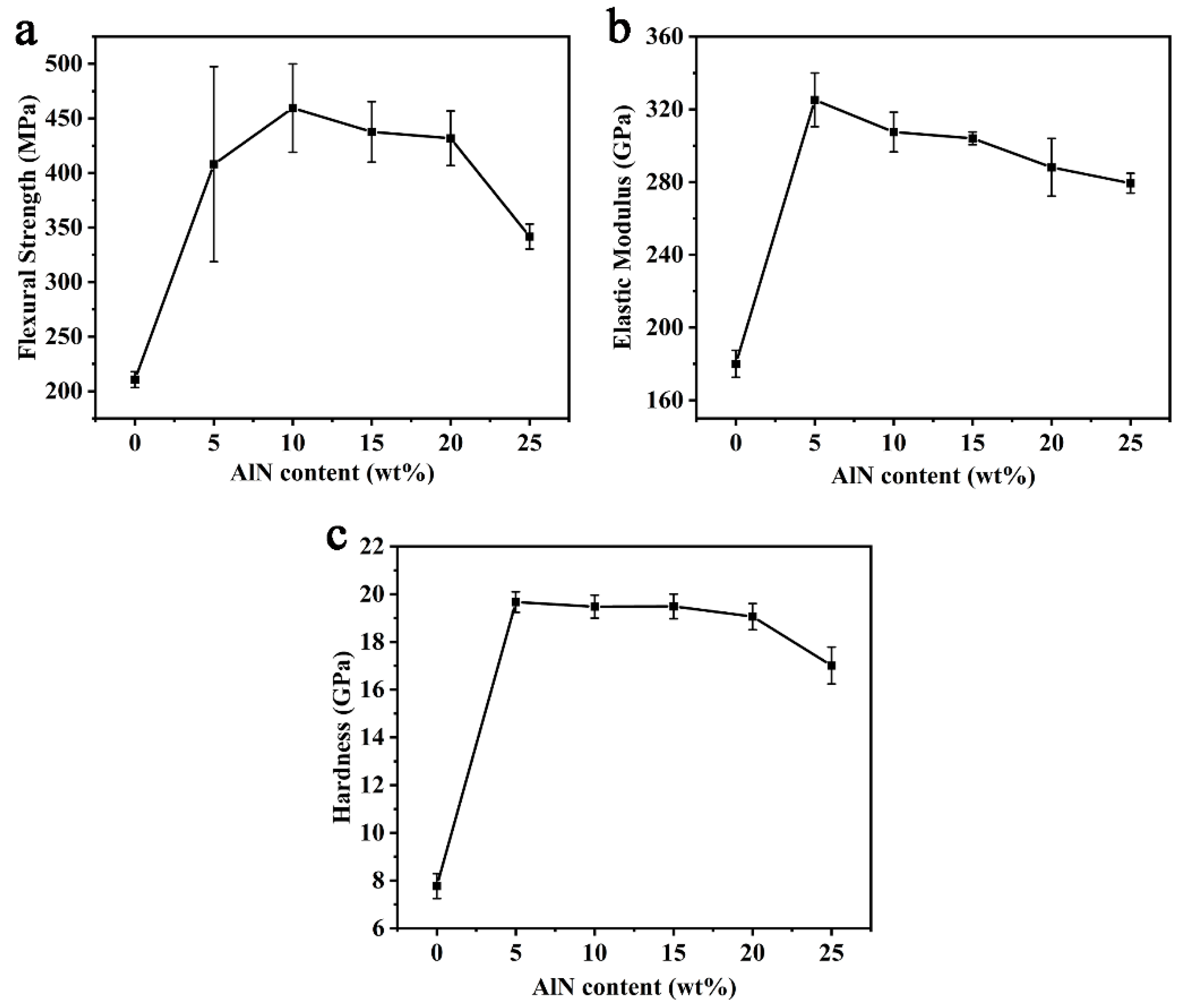

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, Q.; Yu, Z.; Riedel, R. The Fate and Role of in situ Formed Carbon in Polymer-Derived Ceramics. Prog. Mater. Sci. 2020, 109, 100623. [Google Scholar] [CrossRef]

- Mohammadzadeh, B.; Jung, S.; Lee, T.H.; Le, Q.V.; Cha, J.H.; Jang, H.W.; Lee, S.H.; Kang, J.; Shokouhimehr, M. Manufacturing ZrB2-SiC-TaC Composite: Potential Application for Aircraft Wing Assessed by Frequency Analysis through Finite Element Model. Materials 2020, 13, 2213. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.; Zhu, M.; Zhu, Y. Organosilicon Polymer-Derived Ceramics: An Overview. J. Adv. Ceram. 2019, 8, 457–478. [Google Scholar] [CrossRef]

- Ionescu, E.; Bernard, S.; Lucas, R.; Kroll, P.; Ushakov, S.; Navrotsky, A.; Riedel, R. Polymer-Derived Ultra-High Temperature Ceramics (UHTCs) and Related Materials. Adv. Eng. Mater. 2019, 21, 1900269. [Google Scholar] [CrossRef]

- Xia, A.; Yin, J.; Chen, X.; Liu, X.; Huang, Z. Polymer-Derived Si-Based Ceramics: Recent Developments and Perspectives. Crystals 2020, 10, 824. [Google Scholar] [CrossRef]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. 3D Printing Additive Manufacturing of Polymer-Derived Ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef]

- Viard, A.; Fonblanc, D.; Lopez, F.D.; Schmidt, M.; Lale, A.; Durif, C.; Balestrat, M.; Rossignol, F.; Weinmann, M.; Riedel, R.; et al. Polymer Derived Si-B-C-N Ceramics: 30 Years of Research. Adv. Eng. Mater. 2018, 20, 1800360. [Google Scholar] [CrossRef]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Saha, A.; Raj, R.; Williamson, D.L. A Model for the Nanodomains in Polymer-Derived SiCO. J. Am. Ceram. Soc. 2006, 89, 2188–2195. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, Y.; Mao, K.; Feng, Y.; Wen, Q.; Riedel, R. Single-Source-Precursor Synthesis and Phase Evolution of SiC-TaC-C Ceramic Nanocomposites Containing Core-Shell Structured TaC@C Nanoparticles. J. Adv. Ceram. 2020, 9, 320–328. [Google Scholar] [CrossRef]

- Schelm, K.; Abreu, M.E.; Scheffler, M. Mechanical and Surface-Chemical Properties of Polymer Derived Ceramic Replica Foams. Materials 2019, 12, 1870. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Ajayi, T.D.; Morales, J.; Chowdhury, M.A.R.; Sauti, G.; Chu, S.H.; Park, C.; Xu, C. Thermal Properties of Polymer-Derived Ceramic Reinforced with Boron Nitride Nanotubes. J. Am. Ceram. Soc. 2019, 102, 7584–7593. [Google Scholar] [CrossRef]

- Balestrat, M.; Diz, A.E.; Hanzel, O.; Tessier, D.N.; Machado, R.; Šajgalík, P.; Lenčéš, Z.; Bernard, S. Additive-Free Low Temperature Sintering of Amorphous Si-B-C Powders Derived from Boron-Modified Polycarbosilanes: Toward the Design of SiC with Tunable Mechanical, Electrical and Thermal Properties. J. Eur. Ceram. Soc. 2020, 40, 2604–2612. [Google Scholar] [CrossRef]

- Santhosh, B.; Vakifahmetoglu, C.; Ionescu, E.; Reitz, A.; Albert, B.; Sorarù, G.D. Processing and Thermal Characterization of Polymer Derived SiCN(O) and SiOC Reticulated Foams. Ceram. Int. 2020, 46, 5594–5601. [Google Scholar] [CrossRef]

- Mazo, M.A.; Tamayo, A.; Caballero, A.C.; Rubio, J. Electrical and Thermal Response of Silicon Oxycarbide Materials Obtained by Spark Plasma Sintering. J. Eur. Ceram. Soc. 2017, 37, 2011–2020. [Google Scholar] [CrossRef]

- Niu, J.; Meng, S.; Jin, H.; Yi, F.; Li, J.; Zhang, G.; Zhou, Y. Electrical Conductivity Change Induced by Porosity within Polymer-Derived SiCN Ceramics. J. Alloys Compd. 2019, 777, 1010–1016. [Google Scholar] [CrossRef]

- Sorarù, G.D.; Kacha, G.; Campostrini, R.; Ponzoni, A.; Donarelli, M.; Kumar, A.; Mariotto, G. The Effect of B-Doping on the Electrical Conductivity of Polymer-Derived Si(B)OC Ceramics. J. Am. Ceram. Soc. 2017, 100, 4611–4621. [Google Scholar] [CrossRef]

- Shen, C.; Calderon, J.E.; Barrios, E.; Soliman, M.; Khater, A.; Jeyaranjan, A.; Tetard, L.; Gordon, A.; Seal, S.; Zhai, L. Anisotropic Electrical Conductivity in Polymer Derived Ceramics Induced by Graphene Aerogels. J. Mater. Chem. C 2017, 5, 11708–11716. [Google Scholar] [CrossRef]

- Stabler, C.; Ionescu, E.; Graczyk, Z.M.; Gonzalo, J.I.; Riedel, R. Silicon Oxycarbide Glasses and Glass-Ceramics: “All-Rounder” Materials for Advanced Structural and Functional Applications. J. Am. Ceram. Soc. 2018, 101, 4817–4856. [Google Scholar] [CrossRef]

- Graczyk, Z.M.; Vrankovic, D.; Waleska, P.; Hess, C.; Sasikumar, P.V.; Lauterbach, S.; Kleebe, H.J.; Sorarù, G.D. The Li-Storage Capacity of SiOC Glasses with and without Mixed Silicon Oxycarbide Bonds. J. Mater. Chem. A 2018, 6, 93–103. [Google Scholar] [CrossRef]

- Du, B.; He, C.; Qian, J.; Cai, M.; Wang, X.; Shui, A. Electromagnetic Wave Absorbing Properties of Glucose-Derived Carbon-Rich Ceramics Annealed at Different Temperatures. J. Am. Ceram. Soc. 2019, 102, 7015–7025. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, X.; Gong, H.; Zhang, Y.; Feng, Y.; Mao, J.; Xie, B. Electromagnetic Properties and Microwave Absorption Performances of Nickel-Doped SiCN Ceramics Pyrolyzed at Different Temperatures. J. Alloys Compd. 2019, 771, 356–363. [Google Scholar] [CrossRef]

- Wang, S.; Lin, X.; Ashfaq, M.Z.; Zhang, X.; Zhao, C.; Sheng, M.; Yang, R.; Pei, Y.; Gong, H.; Zhang, Y. Microwave Absorption Properties of SiCN Ceramics Doped with Cobalt Nanoparticles. J. Mater. Sci. Mater. Electron. 2020, 31, 3803–3816. [Google Scholar] [CrossRef]

- Ren, F.; Yin, X.; Mo, R.; Ye, F.; Zhang, L.; Cheng, L. Hierarchical Carbon Nanowires Network Modified PDCs-SiCN with Improved Microwave Absorption Performance. Ceram. Int. 2019, 45, 14238–14248. [Google Scholar] [CrossRef]

- Yu, Z.; Lv, X.; Mao, K.; Yang, Y.; Liu, A. Role of in-situ Formed Free Carbon on Electromagnetic Absorption Properties of Polymer-Derived SiC Ceramics. J. Adv. Ceram. 2020, 9, 617–628. [Google Scholar] [CrossRef]

- Huang, Y.; Xiong, H.; Zou, J.; Zhou, K.; Zhang, D. Ultralight Porous SiC with Attracting Strength: Freeze Casting of Polycarbosilane/SiCp/Camphene-Based Suspensions. Ceram. Int. 2020, 46, 9582–9589. [Google Scholar] [CrossRef]

- Durif, C.; Wynn, M.; Balestrat, M.; Franchin, G.; Kim, Y.W.; Leriche, A.; Miele, P.; Colombo, P.; Bernard, S. Open-Celled Silicon Carbide Foams with High Porosity from Boron-Modified Polycarbosilanes. J. Eur. Ceram. Soc. 2019, 39, 5114–5122. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, C.; Zhang, Y.; Zhao, D.; Hu, H.; Xiong, X. Effects of Polymer Derived SiC Interphase on the Properties of C/ZrC Composites. Mater. Des. 2014, 58, 102–107. [Google Scholar] [CrossRef]

- Laadoua, H.; Pradeilles, N.; Lucas, R.; Foucaud, S.; Clegg, W.J. Preparation of ZrC/SiC Composites by Using Polymer-Derived Ceramics and Spark Plasma Sintering. J. Eur. Ceram. Soc. 2020, 40, 1811–1819. [Google Scholar] [CrossRef]

- He, R.; Ding, G.; Zhang, K.; Li, Y.; Fang, D. Fabrication of SiC Ceramic Architectures Using Stereolithography Combined with Precursor Infiltration and Pyrolysis. Ceram. Int. 2019, 45, 14006–14014. [Google Scholar] [CrossRef]

- Xiong, H.; Chen, H.; Chen, Z.; Xiong, X.; Zhang, D.; Zhou, K. 3D-SiC Decorated with SiC Whiskers: Chemical Vapor Infiltration on the Porous 3D-SiC Lattices Derived from Polycarbosilane-Based Suspensions. Ceram. Int. 2020, 46, 6234–6242. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, J.; Ran, N.; Zheng, J.; Huang, Z.; Liu, X.; Chen, Z. High Infrared Emissivity of SiC-AlN Ceramics at Room Temperature. J. Eur. Ceram. Soc. 2020, 40, 3528–3534. [Google Scholar] [CrossRef]

- Hu, J.; Gu, H.; Chen, Z.; Tan, S.; Jiang, D.; Rühle, M. Core–Shell Structure from the Solution–Reprecipitation Process in Hot-Pressed AlN-Doped SiC Ceramics. Acta Mater. 2007, 55, 5666–5673. [Google Scholar] [CrossRef]

- Feng, L.; Fahrenholtz, W.G.; Hilmas, G.E. Effect of ZrB2 Content on the Densification, Microstructure, and Mechanical Properties of ZrC-SiC Ceramics. J. Eur. Ceram. Soc. 2020, 40, 220–225. [Google Scholar] [CrossRef]

- Lian, X.; Hua, X.; Wang, X.; Deng, L. In situ Growth Behavior of SiC Whiskers with High Aspect Ratio in the Synthesis of ZrB2-SiC Composite Powders. Materials 2020, 13, 3502. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, Y.W.; Lim, K.Y.; Nishimura, T.; Narimatsu, E. Electrical and Thermal Properties of SiC-AlN Ceramics without Sintering Additives. J. Eur. Ceram. Soc. 2015, 35, 2715–2721. [Google Scholar] [CrossRef]

- Su, B.; Liu, G.; Huang, Z.; Liang, H.; Liu, X.; Chen, Z. The Effect of in situ Synthesized AlN on Densification of SiC Ceramics by Pressureless Sintering. Ceram. Int. 2015, 41, 14172–14178. [Google Scholar] [CrossRef]

- Zangvil, A.; Ruh, R. Phase Relationships in the Silicon Carbide-Aluminum Nitride System. J. Am. Ceram. Soc. 1988, 71, 884–890. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Huang, J.; Wang, L.; Low, K.W.Q.; Feng, Q.; Yin, Y.; Setchi, R. Selective Laser Melting of Hastelloy X Nanocomposite: Effects of TiC Reinforcement on Crack Elimination and Strength Improvement. Compos. B Eng. 2020, 202, 108442. [Google Scholar] [CrossRef]

- Takeo, K.; Aoki, Y.; Osada, T.; Nakao, W.; Ozaki, S. Finite Element Analysis of the Size Effect on Ceramic Strength. Materials 2019, 12, 2885. [Google Scholar] [CrossRef]

- Chen, K.; Jin, H.; Zhou, H.; Jose´, M.F.F. Combustion Synthesis of AlN-SiC Solid Solution Particles. J. Eur. Ceram. Soc. 2000, 20, 2601–2606. [Google Scholar] [CrossRef]

- Ruh, R.; Zangvil, A. Composition and Properties of Hot-Pressed SiC-AlN Solid Solutions. J. Am. Ceram. Soc. 1982, 65, 260–265. [Google Scholar] [CrossRef]

| Label | PCS (wt%) | ZrB2 (wt%) | AlN (wt%) |

|---|---|---|---|

| P85Z15A0 | 85 | 15 | 0 |

| P80Z15A5 | 80 | 15 | 5 |

| P75Z15A10 | 75 | 15 | 10 |

| P70Z15A15 | 70 | 15 | 15 |

| P65Z15A20 | 65 | 15 | 20 |

| P60Z15A25 | 60 | 15 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, A.; Yin, J.; Chen, X.; Huang, Z.; Liu, X.; Liu, W. Fabrication of (SiC-AlN)/ZrB2 Composite with Nano-Micron Hybrid Microstructure via PCS-Derived Ceramics Route. Materials 2021, 14, 334. https://doi.org/10.3390/ma14020334

Xia A, Yin J, Chen X, Huang Z, Liu X, Liu W. Fabrication of (SiC-AlN)/ZrB2 Composite with Nano-Micron Hybrid Microstructure via PCS-Derived Ceramics Route. Materials. 2021; 14(2):334. https://doi.org/10.3390/ma14020334

Chicago/Turabian StyleXia, Aidong, Jie Yin, Xiao Chen, Zhengren Huang, Xuejian Liu, and Wei Liu. 2021. "Fabrication of (SiC-AlN)/ZrB2 Composite with Nano-Micron Hybrid Microstructure via PCS-Derived Ceramics Route" Materials 14, no. 2: 334. https://doi.org/10.3390/ma14020334

APA StyleXia, A., Yin, J., Chen, X., Huang, Z., Liu, X., & Liu, W. (2021). Fabrication of (SiC-AlN)/ZrB2 Composite with Nano-Micron Hybrid Microstructure via PCS-Derived Ceramics Route. Materials, 14(2), 334. https://doi.org/10.3390/ma14020334