A Comprehensive Study on Processing Ti–6Al–4V ELI with High Power EDM

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

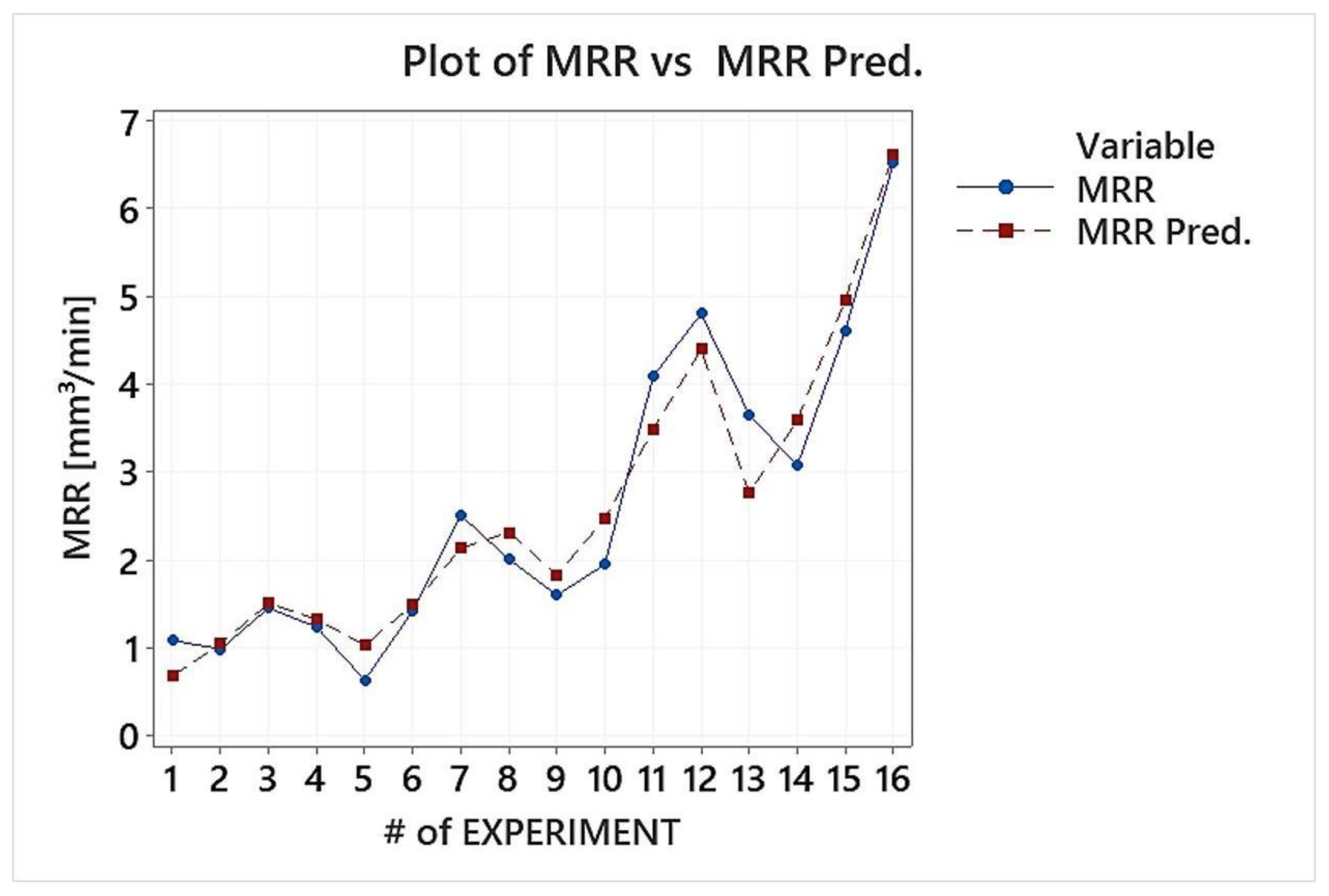

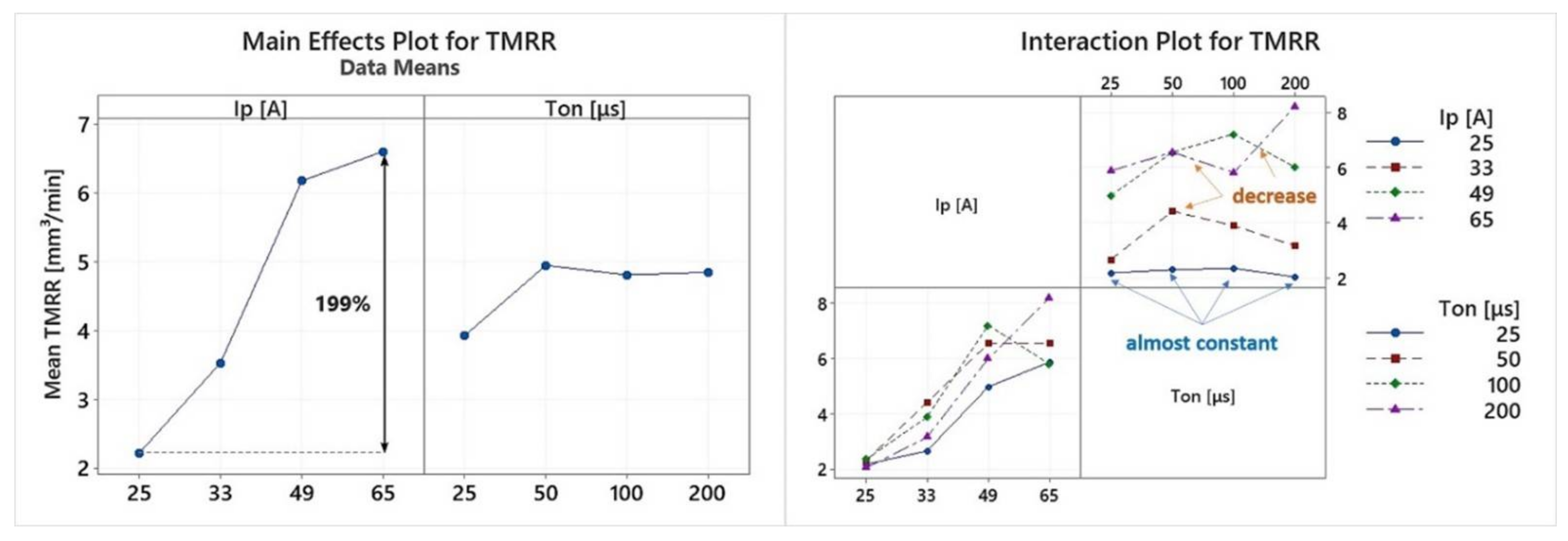

3.1. Material Removal Rate, Tool Material Removal Rate and Tool Wear Ratio

3.2. Surface Roughness and Surface Quality

4. Conclusions

- The MRR is affected by both, the pulse-on current and time, although the pulse-on current has a greater impact on it. This conclusion is not entailed only by the ANOVA analysis, but from the RSM model as well, in which the contribution of Ip is significantly higher than that of Ton.

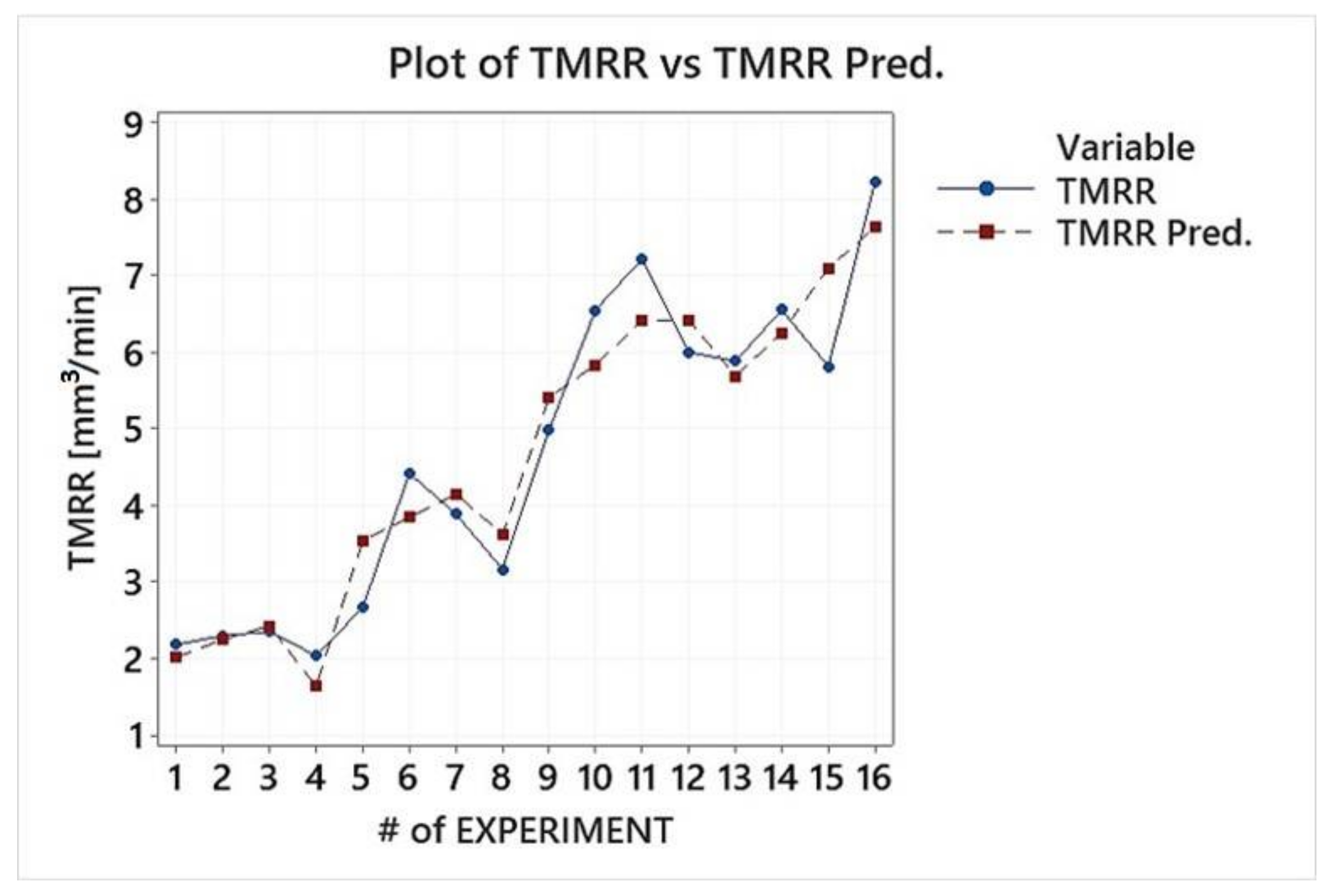

- The TMRR mainly depends on the pulse-on current, while the pulse-on time has a minor and a vague effect on it. Moreover, in the RSM model, the Ip term is an order of magnitude of higher significance that Ton.

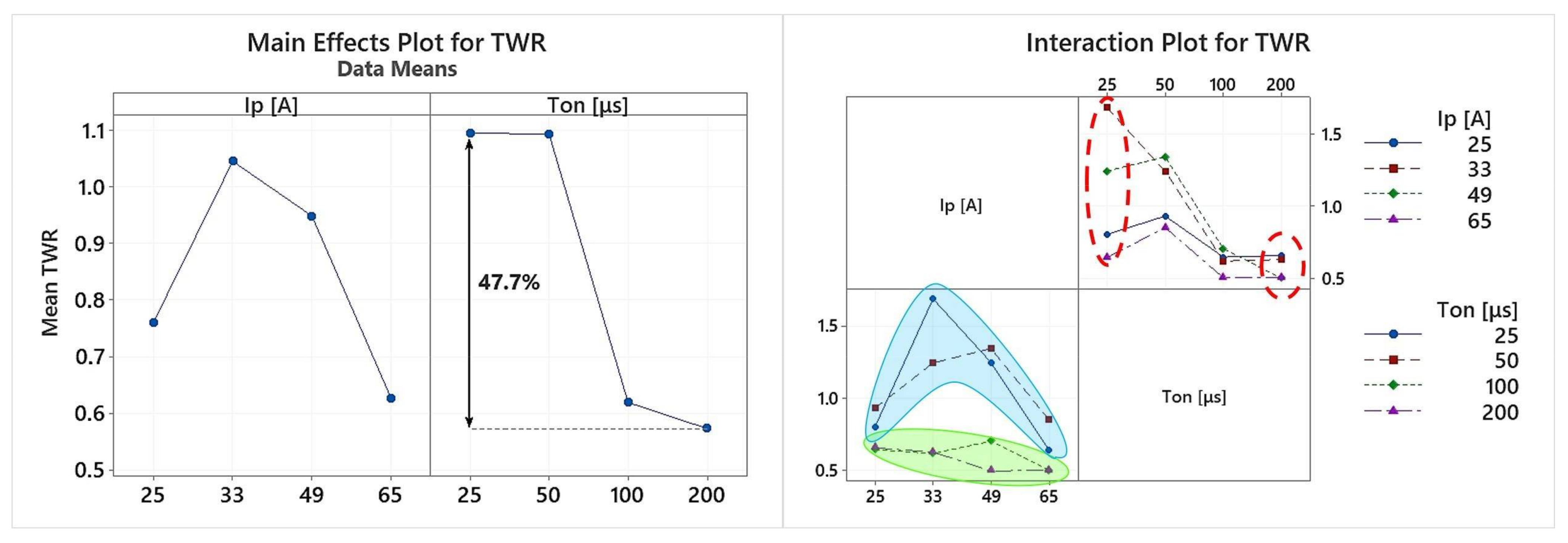

- The TWR strongly depends on the machining parameters combination, with some to be, in terms of TWR, far more preferable than others.

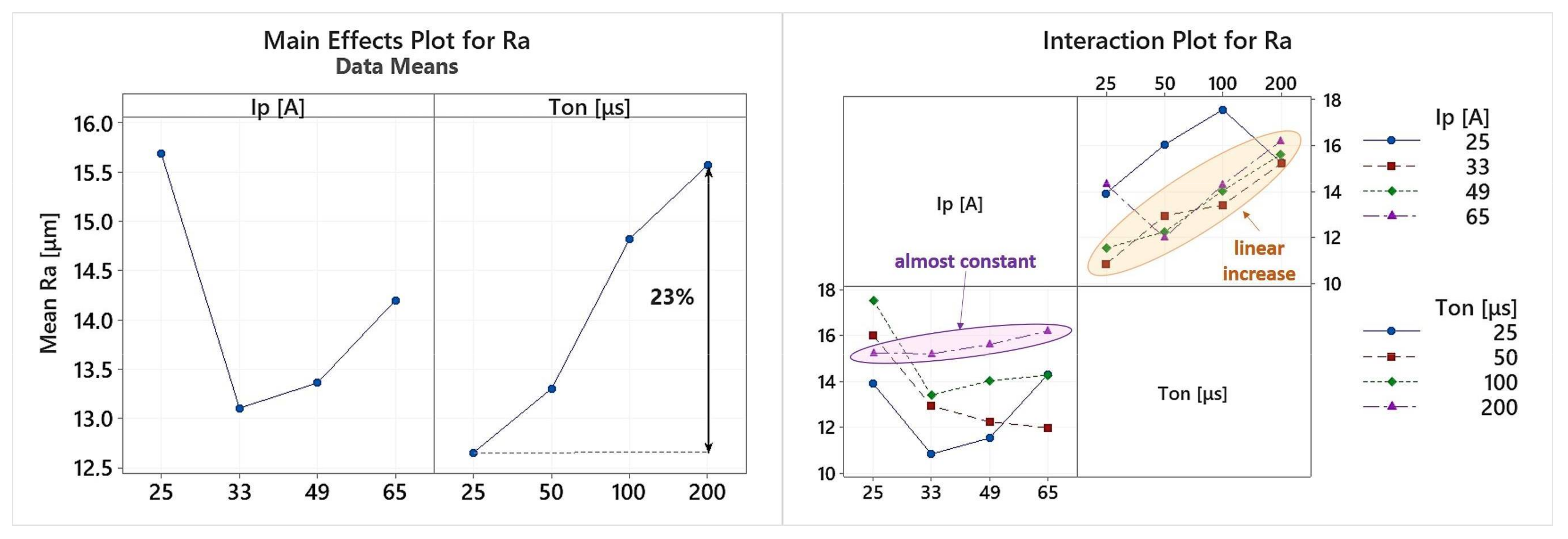

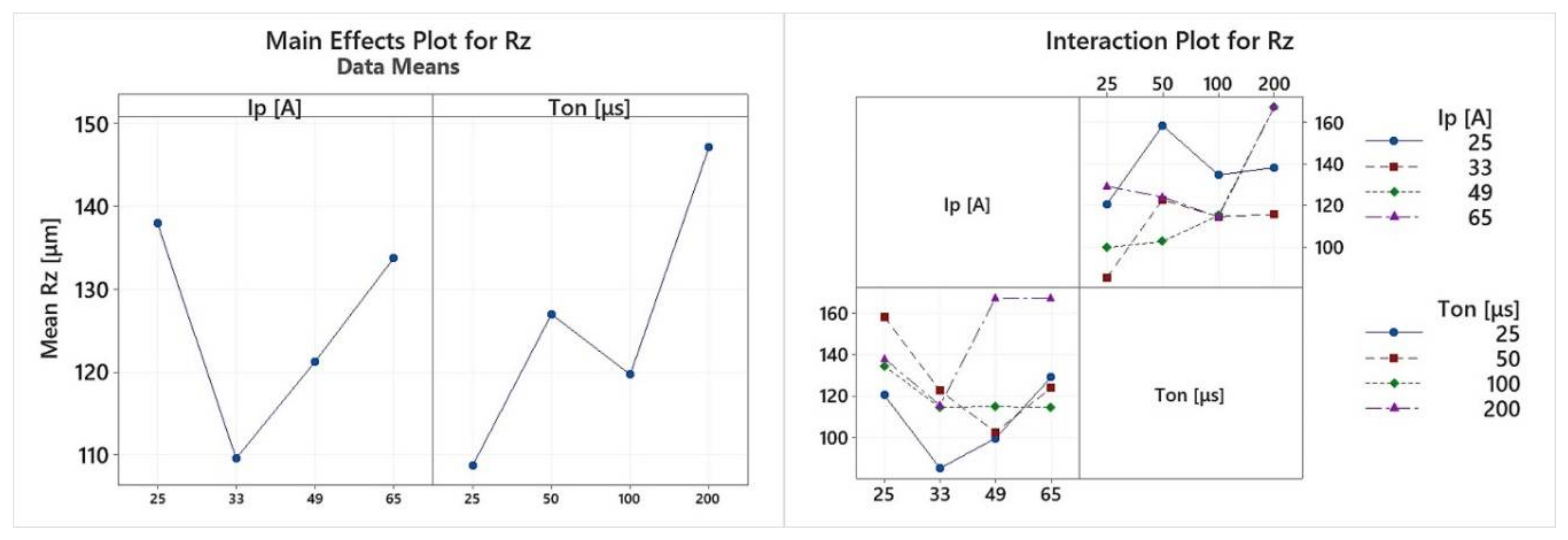

- The mean Ra is increased in respect of the pulse-on time, while the pulse-on current affects it in a more fuzzy and ambiguous way. On the other hand, for the Rz, any strict correlation with Ip and Ton would be precarious, at least for those machining conditions, since a clear trend or pattern cannot be deduced.

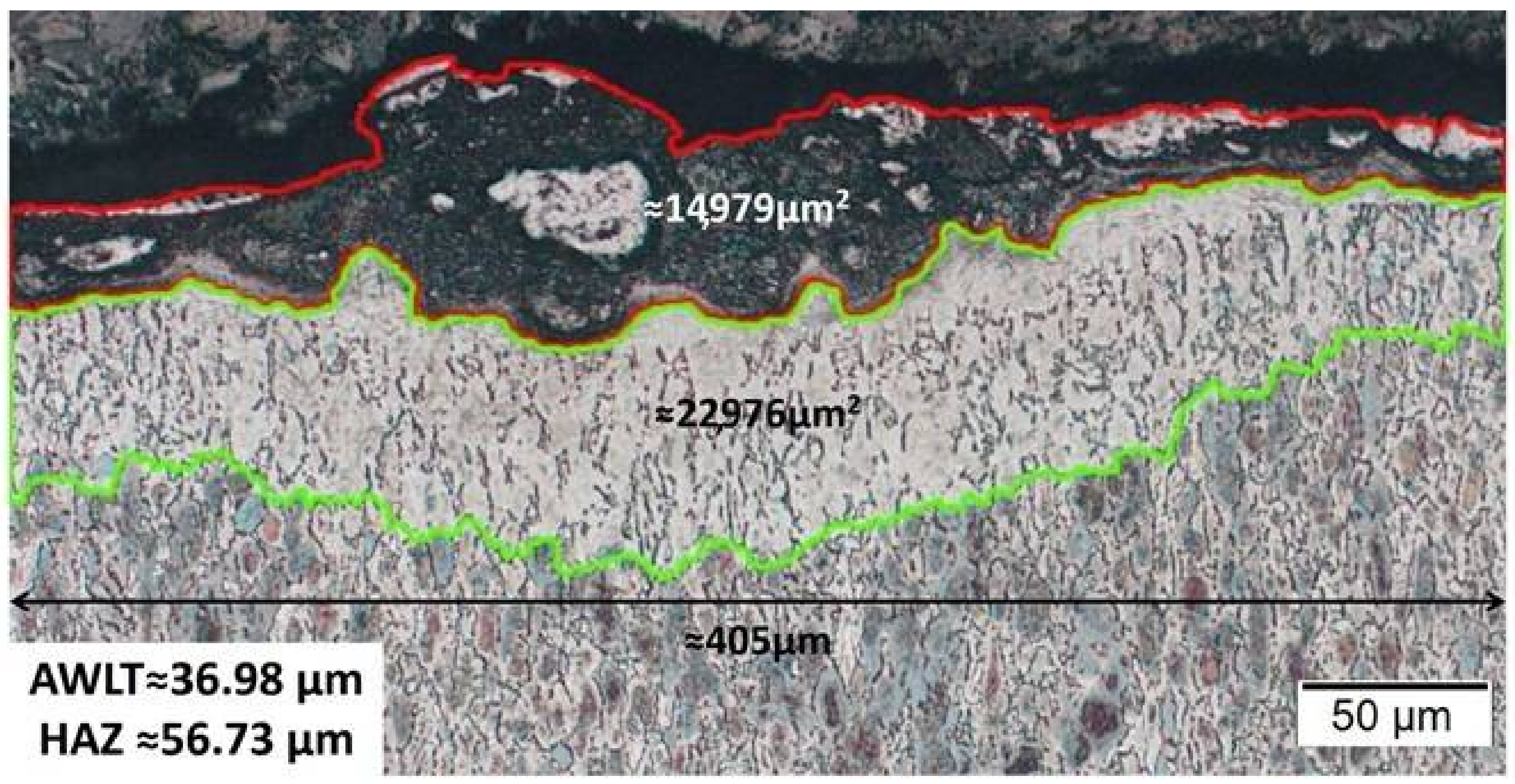

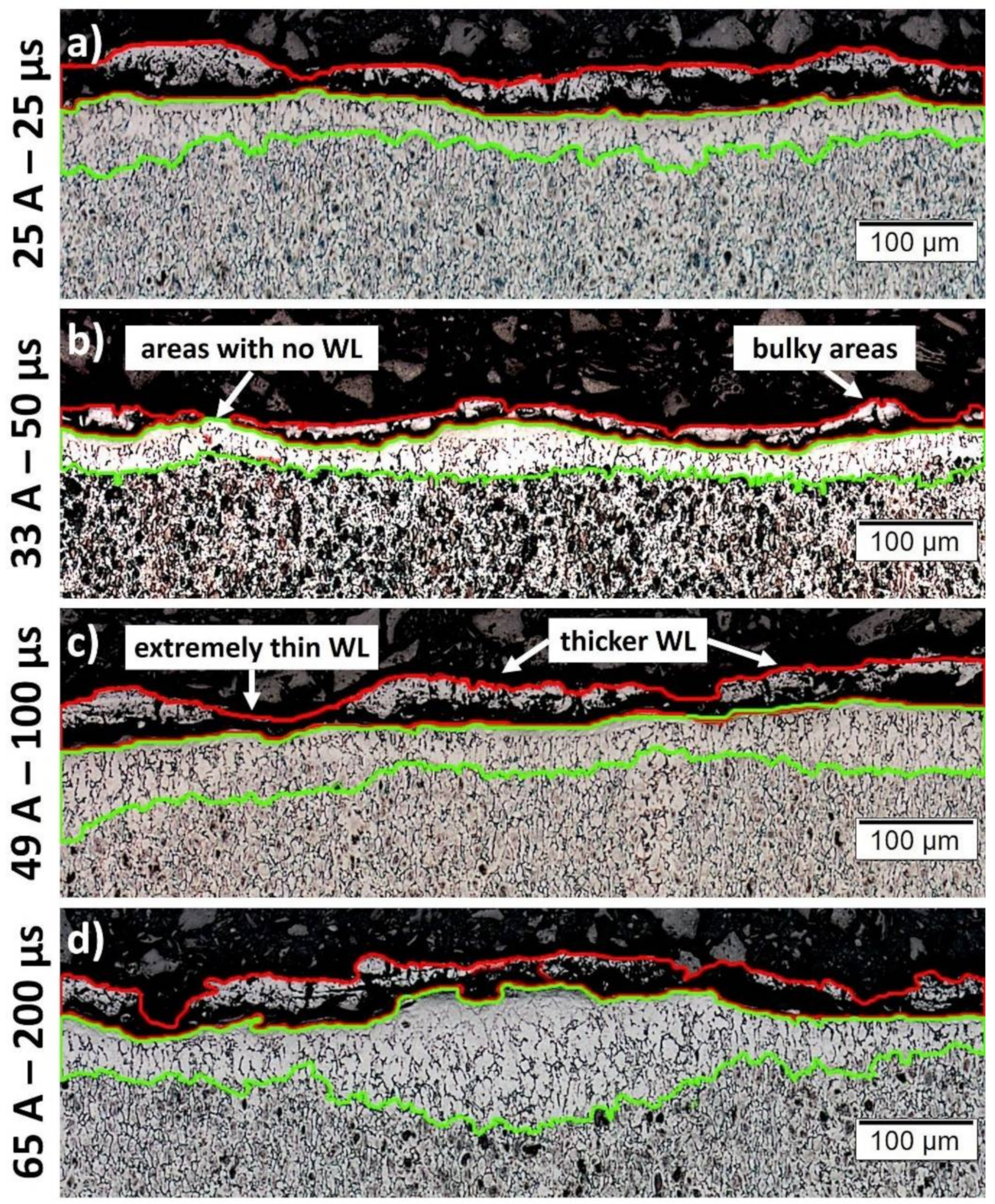

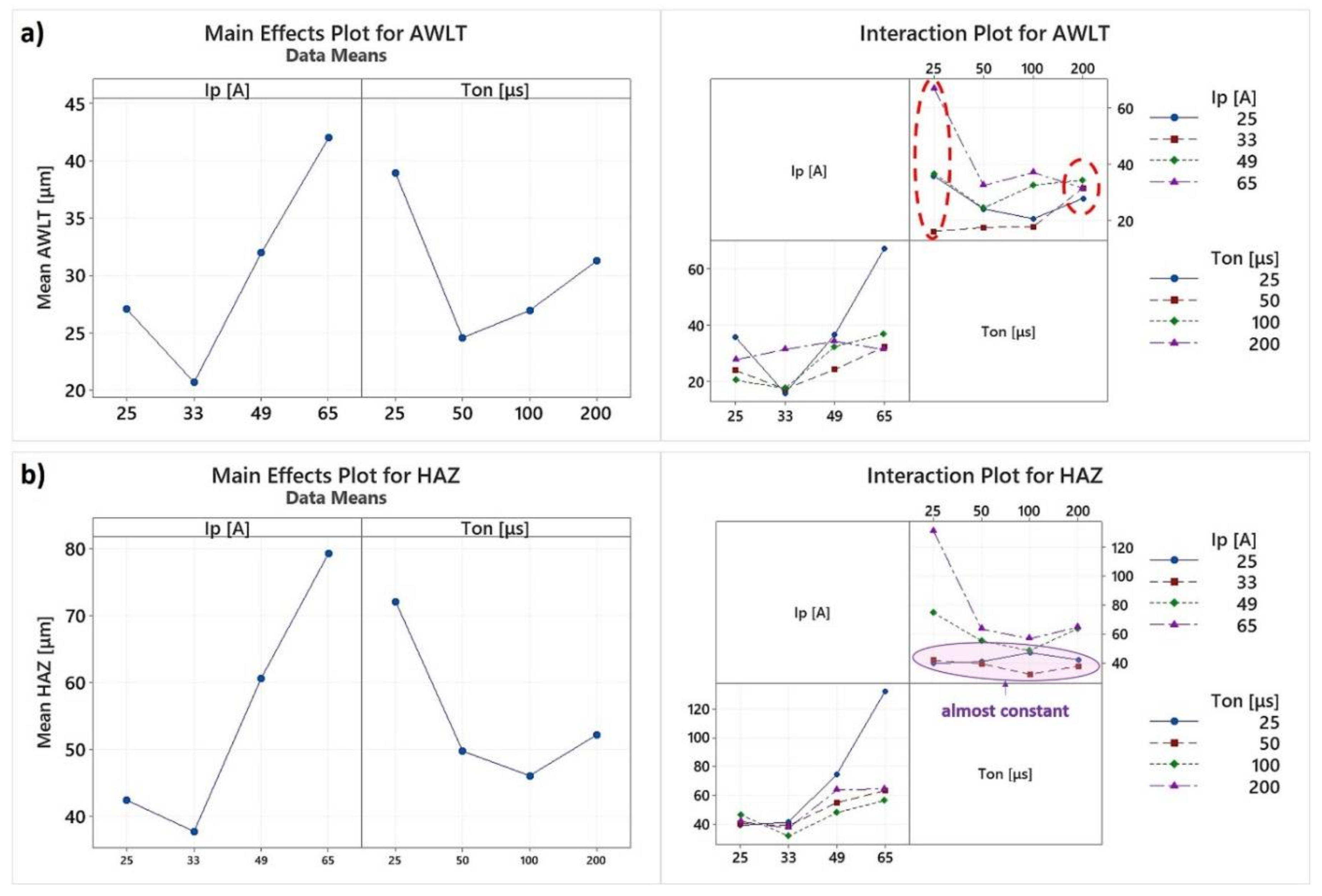

- The WL characteristics significantly change depending on the machining conditions. The WL thickness and its homogeneity are altered according to the machining power and the per-pulse energy that is utilized. On the contrary, the HAZ seems to be less sensitive in changes in the machining parameters.

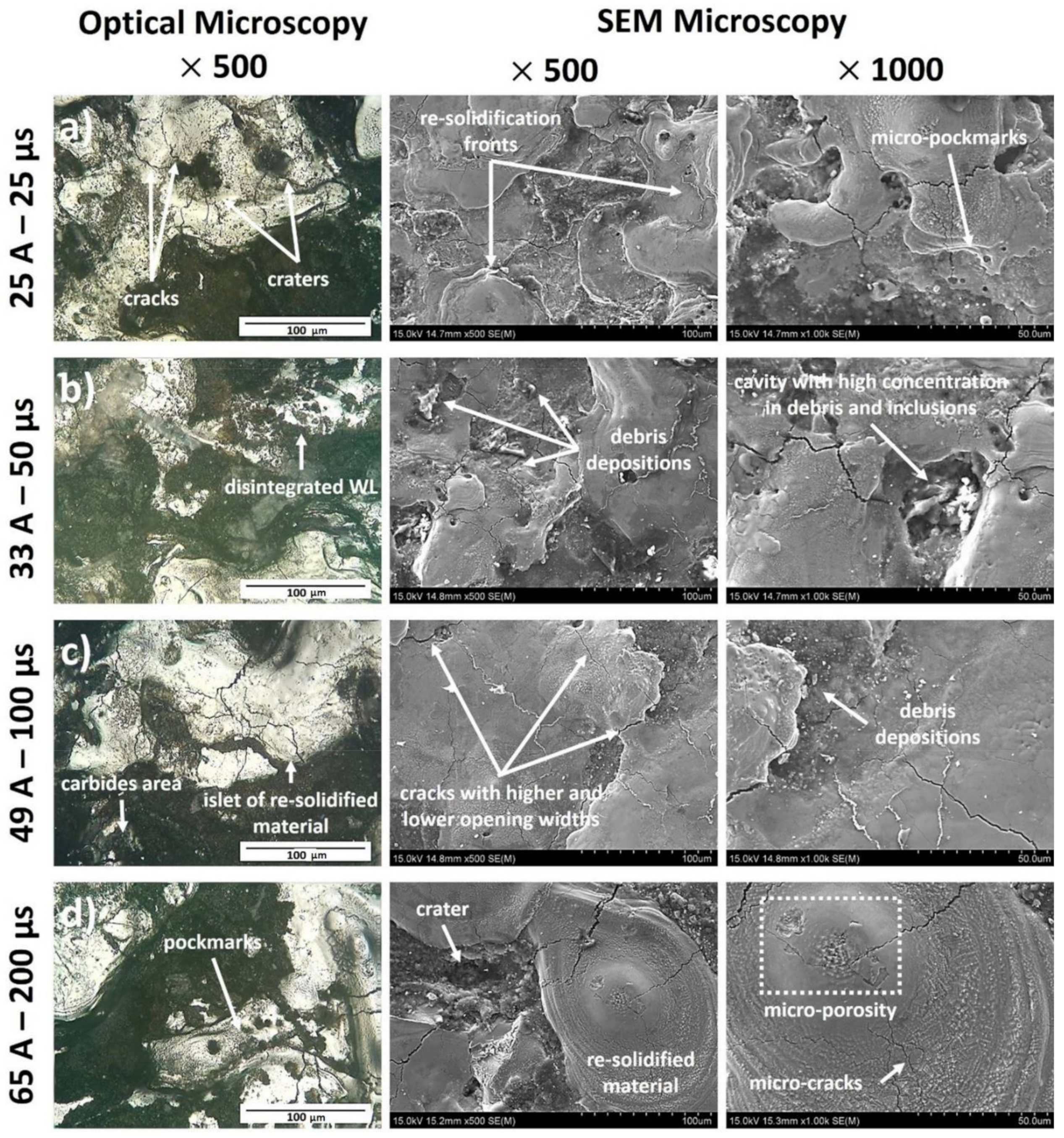

- Through the microscopy (optical and SEM), typical formations of the EDMed surfaces were depicted. Namely, cracks with different opening widths and depths, craters, re-solidified material that forms islets, debris and carbides depositions, pockmarks, as well areas with developed micro-porosity, were observed. These surface characteristics are varied according to the machining conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| EDM | Electrical Discharge Machining | |

| AWLT | Average White Layer Thickness | μm |

| Efin | Electrode weight after machining | gr |

| Est | Electrode weight before machining | gr |

| HAZ | Heat Affected Zone | μm |

| Ip | Pulse-on current | A |

| MRR | Material Removal Rate | mm3/min |

| Ra | Mean Roughness | μm |

| Rz | Maximum peak to valley height | μm |

| SCD | Surface Crack Density | m/mm2 |

| SQ | Surface Quality | |

| ST | Surface Topography | |

| TMRR | Tool Material Removal Rate | mm3/min |

| Ton | Pulse-on time | μs |

| TWR | Tool Wear Ratio | % |

| tmach | Mahining time | min |

| Wfin | Workpiece weight after machining | gr |

| Wst | Workpiece weight before machining | gr |

| WL | White Layer | |

| ρel | Electrode density | gr/mm3 |

| ρw | Workpiece density | gr/mm3 |

| DF | Degrees of freedom | |

| Seq SS | Sequential sums of squares | |

| Adj SS | Adjusted sums of squares | |

| Adj MS | Adjusted mean squares |

References

- Raju, L.; Hiremath, S.S. A State-of-the-art Review on Micro Electro-discharge Machining. Procedia Technol. 2016, 25, 1281–1288. [Google Scholar] [CrossRef]

- Jahan, M.P. (Ed.) Electrical Discharge Machining (EDM): Types, Technologies and Applications; Nova Science Publishers: New York, NY, USA, 2015. [Google Scholar]

- Fonda, P.; Wang, Z.; Yamazaki, K.; Akutsu, Y. A fundamental study on Ti–6Al–4V’s thermal and electrical properties and their relation to EDM productivity. J. Mater. Process. Technol. 2008, 202, 583–589. [Google Scholar] [CrossRef]

- Gostimirović, M.; Kovac, P.; Sekulic, M.; Skoric, B. Influence of discharge energy on machining characteristics in EDM. J. Mech. Sci. Technol. 2012, 26, 173–179. [Google Scholar] [CrossRef]

- Gao, C.; Liu, Z. A study of ultrasonically aided micro-electrical-discharge machining by the application of workpiece vibration. J. Mater. Process. Technol. 2003, 139, 226–228. [Google Scholar] [CrossRef]

- Marafona, J.D.; Chousal, J. A finite element model of EDM based on the Joule effect. Int. J. Mach. Tools Manuf. 2006, 46, 595–602. [Google Scholar] [CrossRef]

- Faisal, N.; Kumar, K. Optimization of Machine Process Parameters in EDM for EN 31 Using Evolutionary Optimization Techniques. Technologies 2018, 6, 54. [Google Scholar] [CrossRef]

- Jameson, E.C. Electrical Discharge Machining; Society of Manufacturing Engineers: Michigan, IN, USA, 2001. [Google Scholar]

- Lin, Y.-C.; Chen, Y.-F.; Wang, D.-A.; Lee, H.-S. Optimization of machining parameters in magnetic force assisted EDM based on Taguchi method. J. Mater. Process. Technol. 2009, 209, 3374–3383. [Google Scholar] [CrossRef]

- Ho, S.; Aspinwall, D.; Voice, W. Use of powder metallurgy (PM) compacted electrodes for electrical discharge surface alloying/modification of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2007, 191, 123–126. [Google Scholar] [CrossRef]

- Nikalje, A.M.; Kumar, A.; Srinadh, K.V.S. Influence of parameters and optimization of EDM performance measures on MDN 300 steel using Taguchi method. Int. J. Adv. Manuf. Technol. 2013, 69, 41–49. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Soni, J.; Chakraverti, G. Experimental investigation on migration of material during EDM of die steel (T215 Cr12). J. Mater. Process. Technol. 1996, 56, 439–451. [Google Scholar] [CrossRef]

- Erden, A. Effect of Materials on the Mechanism of Electric Discharge Machining (E.D.M.). J. Eng. Mater. Technol. 1983, 105, 132–138. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Stevens, L.; Froyen, L.; Lauwers, B. Study of the White Layer of a Surface Machined by Die-Sinking Electro-Discharge Machining. CIRP Ann. 1995, 44, 169–172. [Google Scholar] [CrossRef]

- Kaneko, T.; Tsuchiya, M. Three-dimensional numerically controlled contouring by electric discharge machining with compensation for the deformation of cylindrical tool electrodes. Precis. Eng. 1988, 10, 157–163. [Google Scholar] [CrossRef]

- Abu Qudeiri, J.; Mourad, A.-H.I.; Ziout, A.; Abidi, M.H.; Elkaseer, A. Electric discharge machining of titanium and its alloys: Review. Int. J. Adv. Manuf. Technol. 2018, 96, 1319–1339. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. A review on machining of titanium based alloys using EDM and WEDM. Rev. Adv. Mater. Sci. 2014, 36, 89–111. [Google Scholar]

- Davim, J.P. (Ed.) Machining of Titanium Alloys, 1st ed.; Springer-Verlag Berlin Heidelberg: Berlin, Germany, 2014. [Google Scholar]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and Economical Comparison of Roughing Strategies via Milling, EDM and ECM for Titanium- and Nickel-based Blisks. Procedia CIRP 2012, 2, 98–101. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yan, B.H.; Chang, Y.S. Machining characteristics of titanium alloy (Ti–6Al–4V) using a combination process of EDM with USM. J. Mater. Process. Technol. 2000, 104, 171–177. [Google Scholar] [CrossRef]

- Hasçalık, A.; Çaydaş, U. Electrical discharge machining of titanium alloy (Ti–6Al–4V). Appl. Surf. Sci. 2007, 253, 9007–9016. [Google Scholar] [CrossRef]

- Hasçalık, A.; Çaydaş, U. A comparative study of surface integrity of Ti–6Al–4V alloy machined by EDM and AECG. J. Mater. Process. Technol. 2007, 190, 173–180. [Google Scholar] [CrossRef]

- Kumar, S.; Batish, A.; Singh, R.; Singh, T.P. A hybrid Taguchi-artificial neural network approach to predict surface roughness during electric discharge machining of titanium alloys. J. Mech. Sci. Technol. 2014, 28, 2831–2844. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Xue, R.; Tian, Z.; Huang, Y. Research on the influence of dielectric characteristics on the EDM of titanium alloy. Int. J. Adv. Manuf. Technol. 2014, 72, 979–987. [Google Scholar] [CrossRef]

- Mower, T.M. Degradation of titanium 6Al–4V fatigue strength due to electrical discharge machining. Int. J. Fatigue 2014, 64, 84–96. [Google Scholar] [CrossRef]

- Khan, A.R.; Rahman, M.; Salehina, Z.U.; Rahman, S. Optimal set-up and surface finish characteristics in electrical discharge machining on Ti-5Al-2.5Sn using graphite. Perspect. Sci. 2016, 8, 440–443. [Google Scholar] [CrossRef]

- Khan, A.R.; Rahman, M. Surface characteristics of Ti-5Al-2.5Sn in electrical discharge machining using negative polarity of electrode. Int. J. Adv. Manuf. Technol. 2017, 92, 1–13. [Google Scholar] [CrossRef]

- Nair, S.; Dutta, A.; Giridharan, A. Investigation on EDM machining of Ti6Al4V with negative polarity brass electrode. Mater. Manuf. Process. 2019, 34, 1824–1831. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Experimental investigations in powder mixed electric discharge machining of Ti–35Nb–7Ta–5Zrβ-titanium alloy. Mater. Manuf. Process. 2017, 32, 274–285. [Google Scholar] [CrossRef]

- Ahmed, N.; Ishfaq, K.; Moiduddin, K.; Ali, R.; Al-Shammary, N. Machinability of titanium alloy through electric discharge machining. Mater. Manuf. Process. 2018, 34, 93–102. [Google Scholar] [CrossRef]

- Ahmed, N.; Anwar, S.; Ishfaq, K.; Rafaqat, M.; Saleh, M.; Ahmad, S. The potentiality of sinking EDM for micro-impressions on Ti-6Al-4V: Keeping the geometrical errors (axial and radial) and other machining measures (tool erosion and work roughness) at minimum. Sci. Rep. 2019, 9, 1–18. [Google Scholar] [CrossRef]

- Farooq, M.U.; Mughal, M.P.; Ahmed, N.; Mufti, N.A.; Al-Ahmari, A.; He, Y. On the Investigation of Surface Integrity of Ti6Al4V ELI Using Si-Mixed Electric Discharge Machining. Materials 2020, 13, 1549. [Google Scholar] [CrossRef]

- Bui, V.D.; Mwangi, J.W.; Schubert, A. Powder mixed electrical discharge machining for antibacterial coating on titanium implant surfaces. J. Manuf. Process. 2019, 44, 261–270. [Google Scholar] [CrossRef]

- Sen, I.; Karthikeyan, G.; Ramkumar, J.; Balasubramaniam, R. A Study on Machinability of B-Modified Ti-6Al-4V Alloys by EDM. Mater. Manuf. Process. 2012, 27, 348–354. [Google Scholar] [CrossRef]

- Lee, H.T.; Yur, J.P. Characteristic Analysis of EDMed Surfaces Using the Taguchi Approach. Mater. Manuf. Process. 2000, 15, 781–806. [Google Scholar] [CrossRef]

- Jabbaripour, B.; Sadeghi, M.H.; Faridvand, S.; Shabgard, M.R. Investigating the Effects of Edm Parameters on Surface Integrity, Mrr and Twr in Machining of Ti–6Al–4V. Mach. Sci. Technol. 2012, 16, 419–444. [Google Scholar] [CrossRef]

- Kushwaha, A.; Jadam, T.; Datta, S.; Masanta, M. Assessment of Surface Integrity During Electrical Discharge Machining of Titanium Grade 5 Alloys (Ti-6Al-4V). Mater. Today Proc. 2019, 18, 2477–2485. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Zagórski, K.; Cieślik, J.; Papazoglou, E.L.; Markopoulos, A. Surface Topography of Ti 6Al 4V ELI after High Power EDM. Procedia Manuf. 2020, 47, 788–794. [Google Scholar] [CrossRef]

- Shabgard, M.; Ahmadi, R.; Seyedzavvar, M.; Oliaei, S.N.B. Mathematical and numerical modeling of the effect of input-parameters on the flushing efficiency of plasma channel in EDM process. Int. J. Mach. Tools Manuf. 2013, 65, 79–87. [Google Scholar] [CrossRef]

- Papazoglou, E.L.; Markopoulos, A.; Papaefthymiou, S.; Manolakos, D.E. Electrical discharge machining modeling by coupling thermal analysis with deformed geometry feature. Int. J. Adv. Manuf. Technol. 2019, 103, 4481–4493. [Google Scholar] [CrossRef]

- Verma, V.; Sahu, R. Process parameter optimization of die-sinking EDM on Titanium grade–V alloy (Ti6Al4V) using full factorial design approach. Mater. Today Proc. 2017, 4, 1893–1899. [Google Scholar] [CrossRef]

- Verma, V.; Sajeevan, R. Multi Process Parameter Optimization of Diesinking EDM on Titanium Alloy (Ti6Al4V) Using Taguchi Approach. Mater. Today Proc. 2015, 2, 2581–2587. [Google Scholar] [CrossRef]

- Holsten, M.; Koshy, P.; Klink, A.; Schwedt, A. Anomalous influence of polarity in sink EDM of titanium alloys. CIRP Ann. 2018, 67, 221–224. [Google Scholar] [CrossRef]

- Aich, U. Investigation for the presence of chaos in surface topography generated by EDM. Tribol. Int. 2018, 120, 411–433. [Google Scholar] [CrossRef]

- Kolli, M.; Kumar, A. Effect of dielectric fluid with surfactant and graphite powder on Electrical Discharge Machining of titanium alloy using Taguchi method. Eng. Sci. Technol. Int. J. 2015, 18, 524–535. [Google Scholar] [CrossRef]

| Ti | C max (%) | Fe max (%) | H max (%) | N max (%) | O max (%) | V (%) | Al (%) |

|---|---|---|---|---|---|---|---|

| Bal. | 0.08 | 0.25 | 0.0125 | 0.03 | 0.13 | 3.5–4.5 | 5.5–6.5 |

| Material | Graphite | Ti Grade 23 ELI |

|---|---|---|

| Density (g/cm3) | 1.77 | 4.43 |

| Melting Point (°C) | 3300 | 1600 |

| Electrical Resistively (μΩ cm−1) | 1400 | 53.3 |

| Hardness (HB) | 7 | 326 |

| Thermal Conductivity (W/mK) | 168 | 16.70 |

| Machining Conditions | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Pulse-on Current (A) | 25 | 33 | 49 | 65 |

| Pulse-on Time (μs) | 25 | 50 | 100 | 200 |

| Duty Factor | 0.5 | |||

| Polarity | Straight | |||

| Waveform | Square pulses | |||

| Open Circuit Voltage (V) | 120 | |||

| Close Circuit Voltage (V) | 30 | |||

| Dielectric | Synthetic Hydrocarbon Fluid | |||

| Dielectric Flushing | Side Flushing with pressure | |||

| Dielectric Flushing Pressure (MPa) | 0.7 (Constant) | |||

| Recoil | 0.2 μs per 0.6 μs with speed of 1000 mm/min | |||

| # | Ip (A) | Ton (μs) | MRR (mm3/min) | TMRR (mm3/min) | TWR | Ra (μm) | Rz (μm) | AWLT (μm) | HAZ (μm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 25 | 1.08 | 2.18 | 0.80 | 13.9 | 120.6 | 35.79 | 39.60 |

| 2 | 25 | 50 | 0.98 | 2.29 | 0.93 | 16.0 | 158.4 | 24.05 | 40.86 |

| 3 | 25 | 100 | 1.45 | 2.35 | 0.65 | 17.6 | 134.6 | 20.57 | 47.00 |

| 4 | 25 | 200 | 1.23 | 2.03 | 0.66 | 15.2 | 138.2 | 27.80 | 42.16 |

| 5 | 33 | 25 | 0.63 | 2.66 | 1.69 | 10.8 | 85.3 | 16.00 | 41.81 |

| 6 | 33 | 50 | 1.42 | 4.41 | 1.24 | 12.9 | 122.8 | 17.44 | 39.34 |

| 7 | 33 | 100 | 2.51 | 3.88 | 0.62 | 13.4 | 114.6 | 17.75 | 32.07 |

| 8 | 33 | 200 | 2.00 | 3.16 | 0.63 | 15.2 | 115.7 | 31.49 | 37.70 |

| 9 | 49 | 25 | 1.60 | 4.98 | 1.25 | 11.5 | 99.7 | 36.63 | 74.93 |

| 10 | 49 | 50 | 1.95 | 6.54 | 1.34 | 12.2 | 102.8 | 24.37 | 55.27 |

| 11 | 49 | 100 | 4.09 | 7.21 | 0.70 | 14.0 | 115.1 | 32.46 | 48.47 |

| 12 | 49 | 200 | 4.80 | 6.00 | 0.50 | 15.6 | 167.4 | 34.35 | 63.93 |

| 13 | 65 | 25 | 3.65 | 5.87 | 0.64 | 14.3 | 129.2 | 67.14 | 132.00 |

| 14 | 65 | 50 | 3.07 | 6.55 | 0.85 | 12.0 | 124.1 | 32.36 | 63.49 |

| 15 | 65 | 100 | 4.61 | 5.81 | 0.50 | 14.3 | 114.4 | 36.99 | 56.73 |

| 16 | 65 | 200 | 6.51 | 8.21 | 0.50 | 16.2 | 167.4 | 31.41 | 64.85 |

| Analysis of Variance | |||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

| Model | 5 | 40.2865 | 93.88% | 40.2865 | 8.0573 | 30.69 | 0 |

| Linear | 2 | 35.8677 | 83.58% | 39.9774 | 19.9887 | 76.13 | 0 |

| Ip(A) | 1 | 26.4539 | 61.65% | 29.7724 | 29.7724 | 113.4 | 0 |

| Ton(A) | 1 | 9.4138 | 21.94% | 11.4278 | 11.4278 | 43.53 | 0 |

| Square | 2 | 0.8489 | 1.98% | 0.8489 | 0.4244 | 1.62 | 0.246 |

| Ip (A)·Ip (A) | 1 | 0.0302 | 0.07% | 0.0302 | 0.0302 | 0.11 | 0.742 |

| Ton (μs) Ton (μs) | 1 | 0.8187 | 1.91% | 0.8187 | 0.8187 | 3.12 | 0.108 |

| 2-Way Interaction | 1 | 3.5699 | 8.32% | 3.5699 | 3.5699 | 13.6 | 0.004 |

| Ip (A) ·Ton (μs) | 1 | 3.5699 | 8.32% | 3.5699 | 3.5699 | 13.6 | 0.004 |

| Error | 10 | 2.6255 | 6.12% | 2.6255 | 0.2626 | - | - |

| Total | 15 | 42.912 | 100.00% | - | - | - | - |

| Analysis of Variance | |||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

| Model | 5 | 56.6081 | 91.60% | 56.6081 | 11.3216 | 21.81 | 0 |

| Linear | 2 | 49.6418 | 80.33% | 51.9521 | 25.9761 | 50.04 | 0 |

| Ip(A) | 1 | 48.8631 | 79.07% | 51.0921 | 51.0921 | 98.42 | 0 |

| Ton(A) | 1 | 0.7786 | 1.26% | 1.3757 | 1.3757 | 2.65 | 0.135 |

| Square | 2 | 5.0933 | 8.24% | 5.0933 | 2.5467 | 4.91 | 0.033 |

| Ip (A)·Ip (A) | 1 | 4.2039 | 6.80% | 4.2039 | 4.2039 | 8.1 | 0.017 |

| Ton (μs) ·Ton (μs) | 1 | 0.8894 | 1.44% | 0.8894 | 0.8894 | 1.71 | 0.22 |

| 2-Way Interaction | 1 | 1.873 | 3.03% | 1.873 | 1.873 | 3.61 | 0.087 |

| Ip (A) ·Ton (μs) | 1 | 1.873 | 3.03% | 1.873 | 1.873 | 3.61 | 0.087 |

| Error | 10 | 5.191 | 8.40% | 5.191 | 0.5191 | - | - |

| Total | 15 | 61.7991 | 100.00% | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karmiris-Obratański, P.; Papazoglou, E.L.; Leszczyńska-Madej, B.; Zagórski, K.; Markopoulos, A.P. A Comprehensive Study on Processing Ti–6Al–4V ELI with High Power EDM. Materials 2021, 14, 303. https://doi.org/10.3390/ma14020303

Karmiris-Obratański P, Papazoglou EL, Leszczyńska-Madej B, Zagórski K, Markopoulos AP. A Comprehensive Study on Processing Ti–6Al–4V ELI with High Power EDM. Materials. 2021; 14(2):303. https://doi.org/10.3390/ma14020303

Chicago/Turabian StyleKarmiris-Obratański, Panagiotis, Emmanouil L. Papazoglou, Beata Leszczyńska-Madej, Krzysztof Zagórski, and Angelos P. Markopoulos. 2021. "A Comprehensive Study on Processing Ti–6Al–4V ELI with High Power EDM" Materials 14, no. 2: 303. https://doi.org/10.3390/ma14020303

APA StyleKarmiris-Obratański, P., Papazoglou, E. L., Leszczyńska-Madej, B., Zagórski, K., & Markopoulos, A. P. (2021). A Comprehensive Study on Processing Ti–6Al–4V ELI with High Power EDM. Materials, 14(2), 303. https://doi.org/10.3390/ma14020303