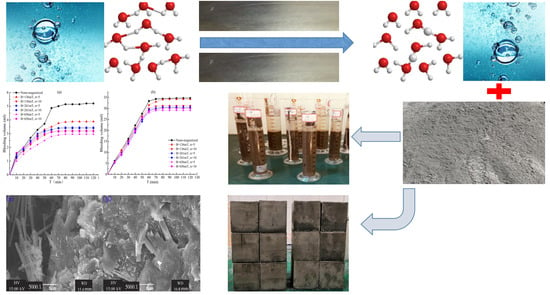

Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout

Abstract

:1. Introduction

2. Experimental Design

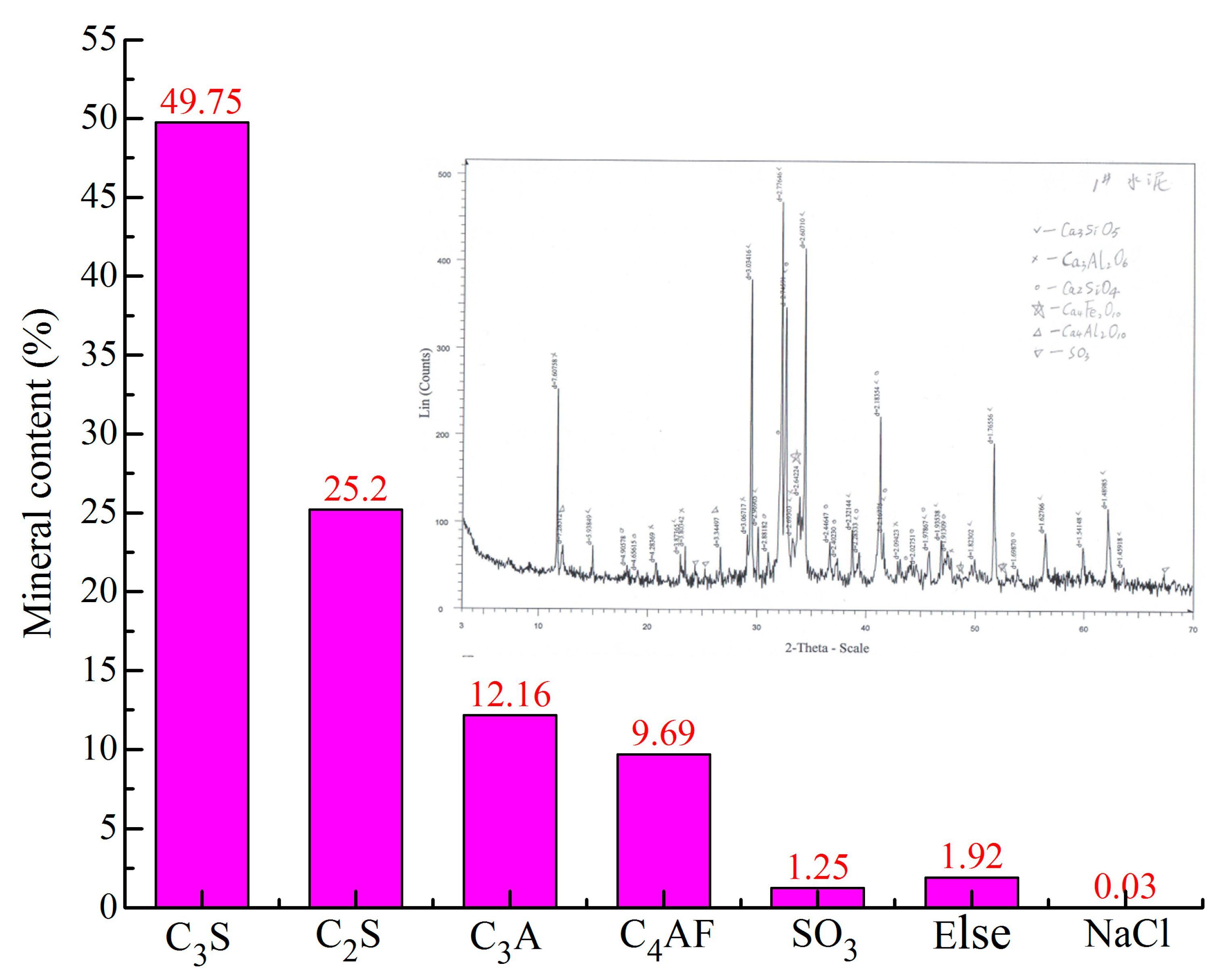

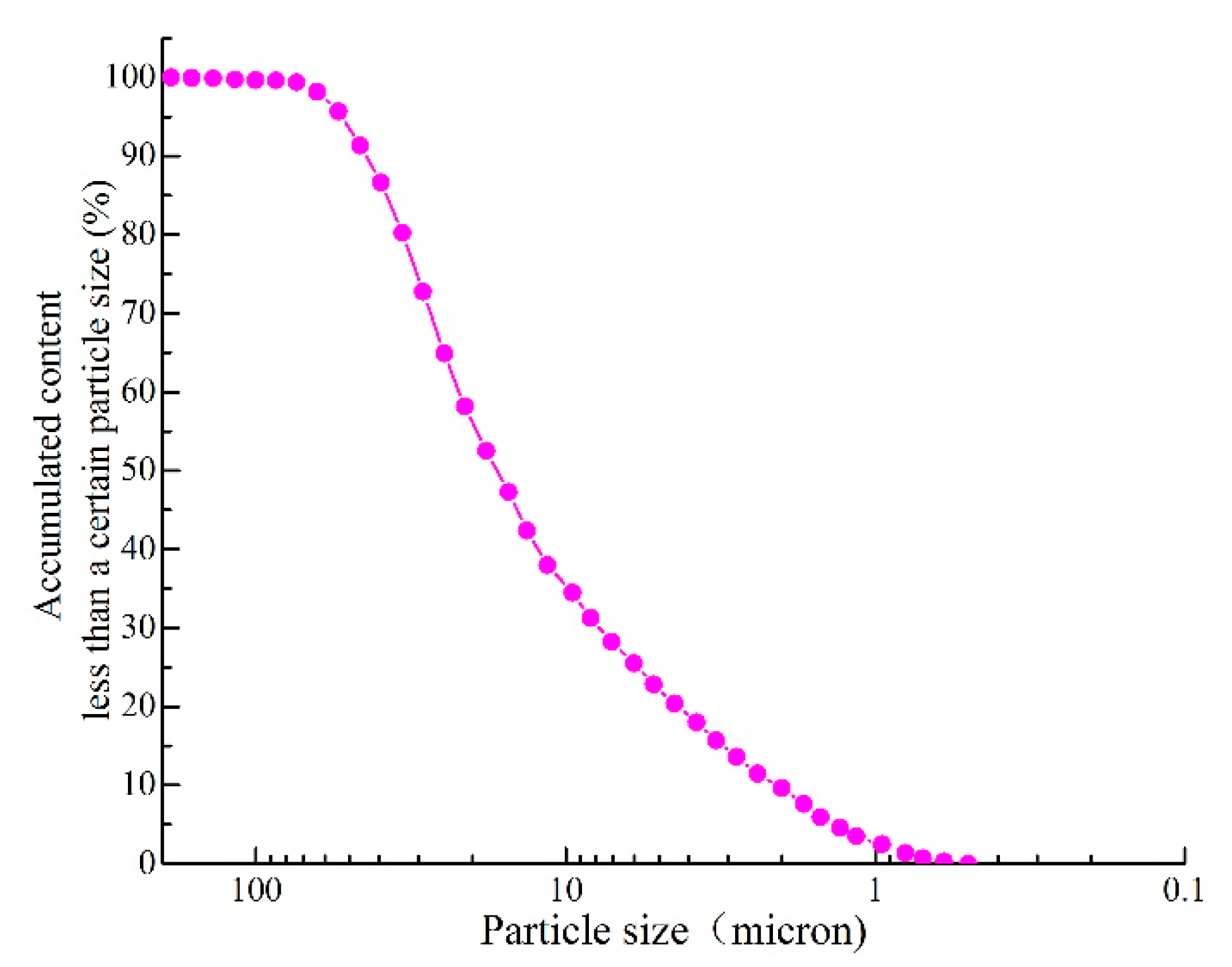

2.1. Materials

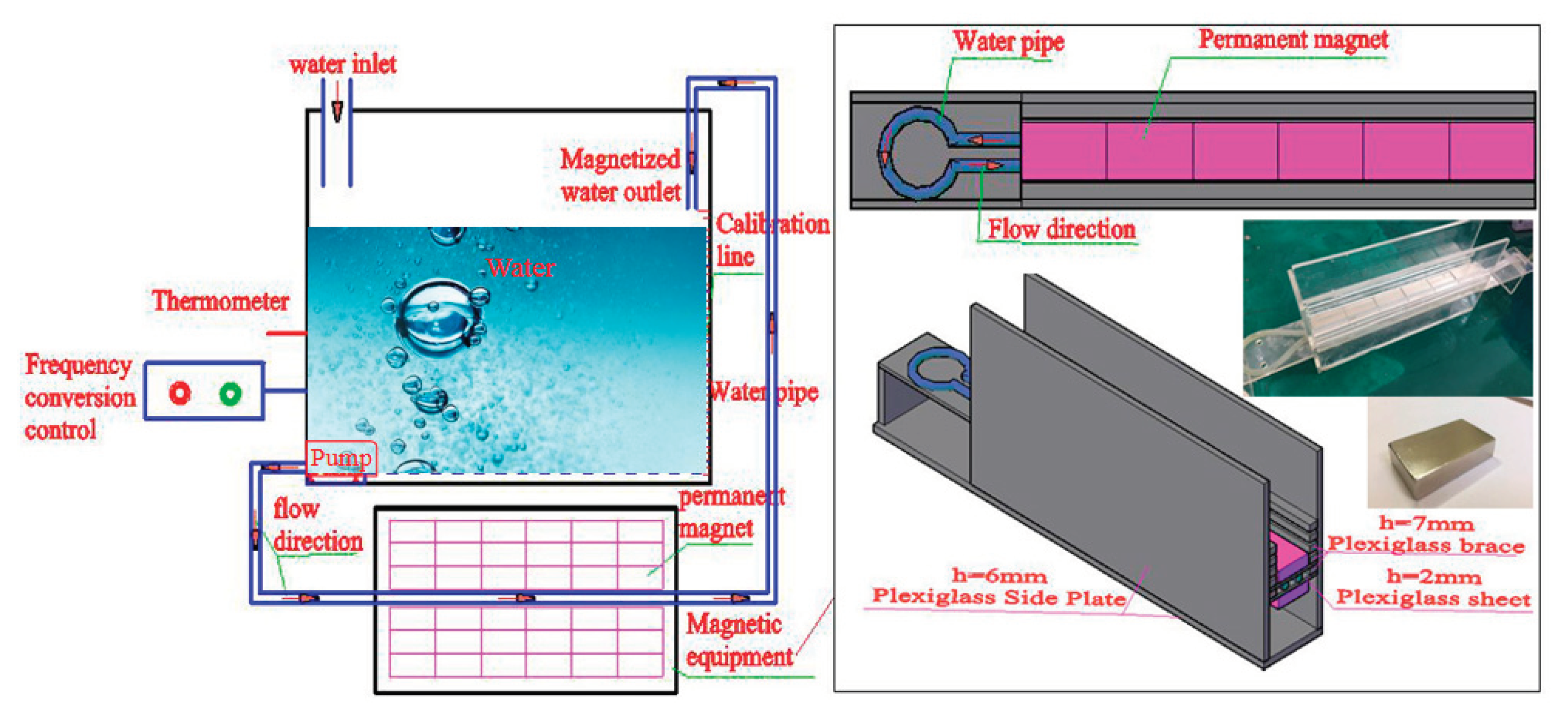

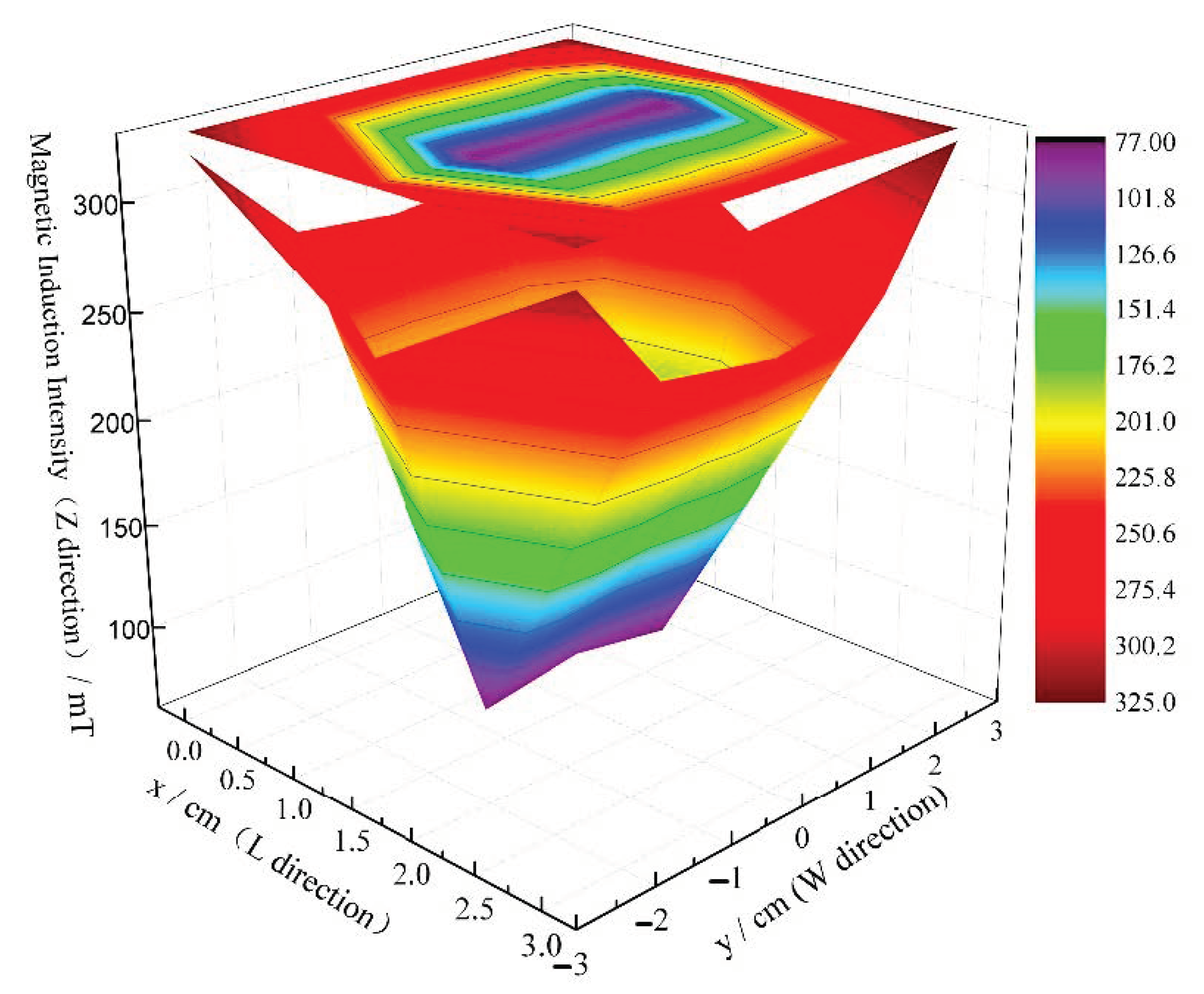

2.2. Magnetization System

2.3. Magnetization Parameters Design

2.4. Magnetized Water Performance Test

2.5. Test Procedures and Methods for Cement Grout

3. Test Results and Discussion

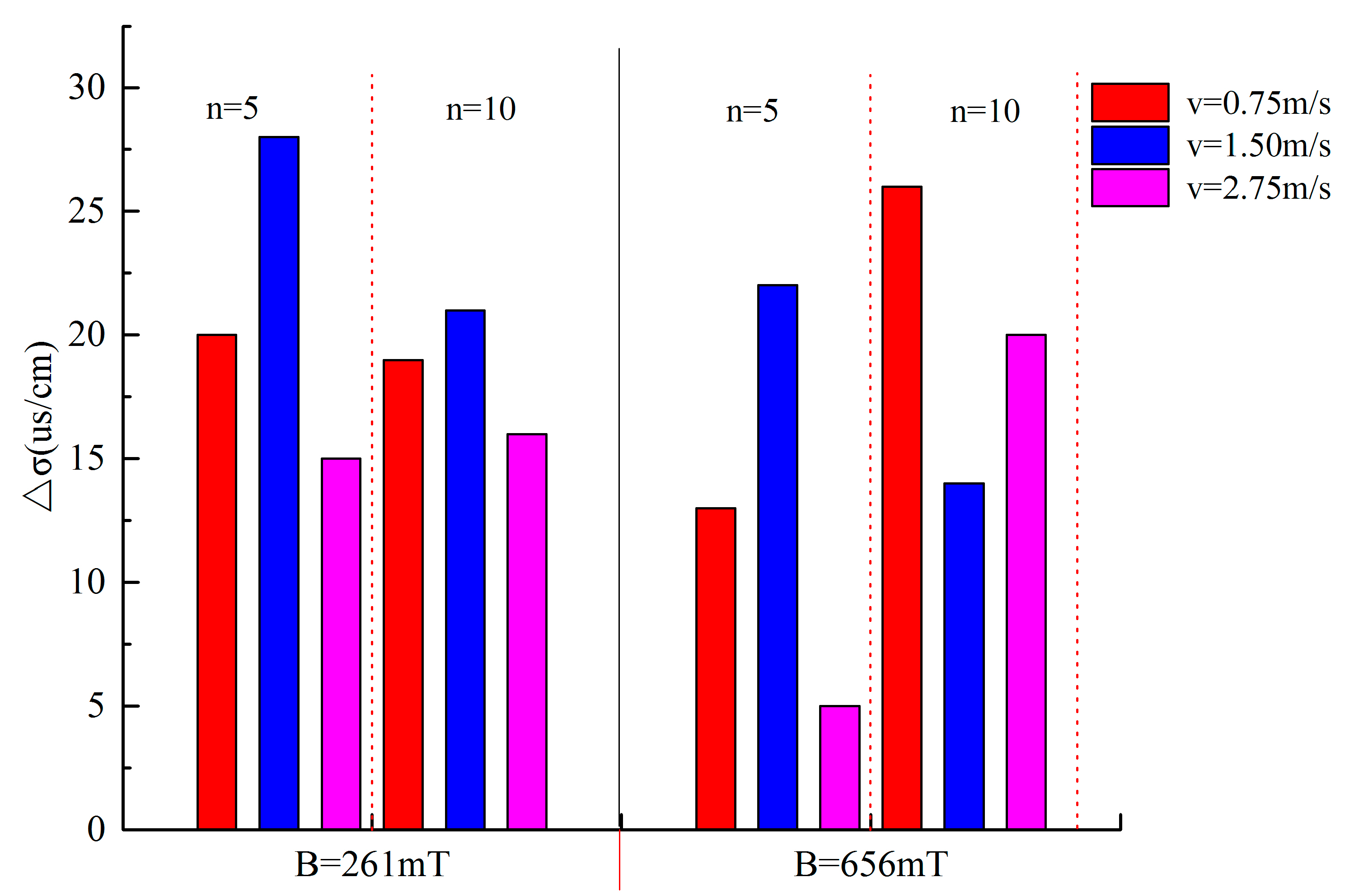

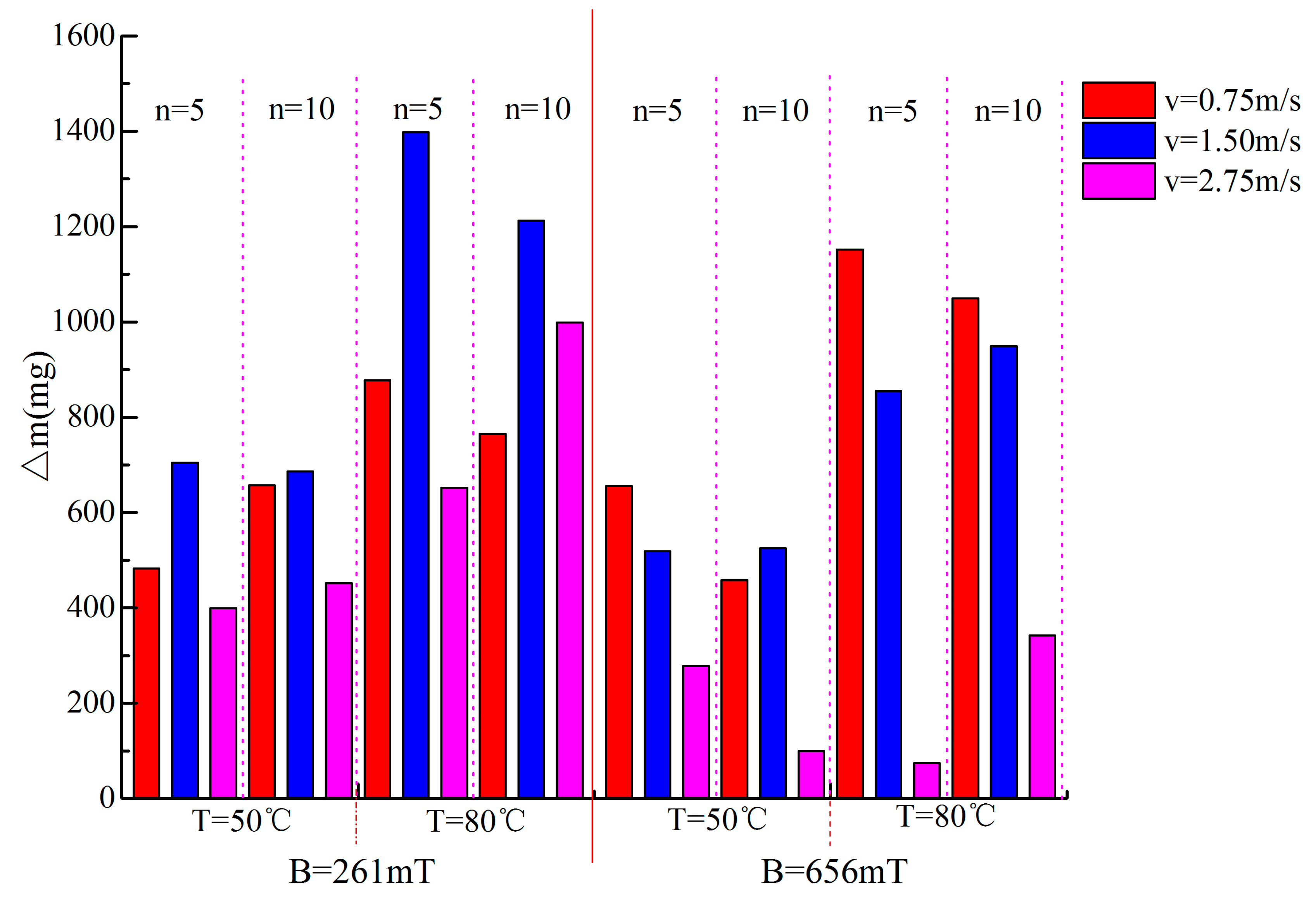

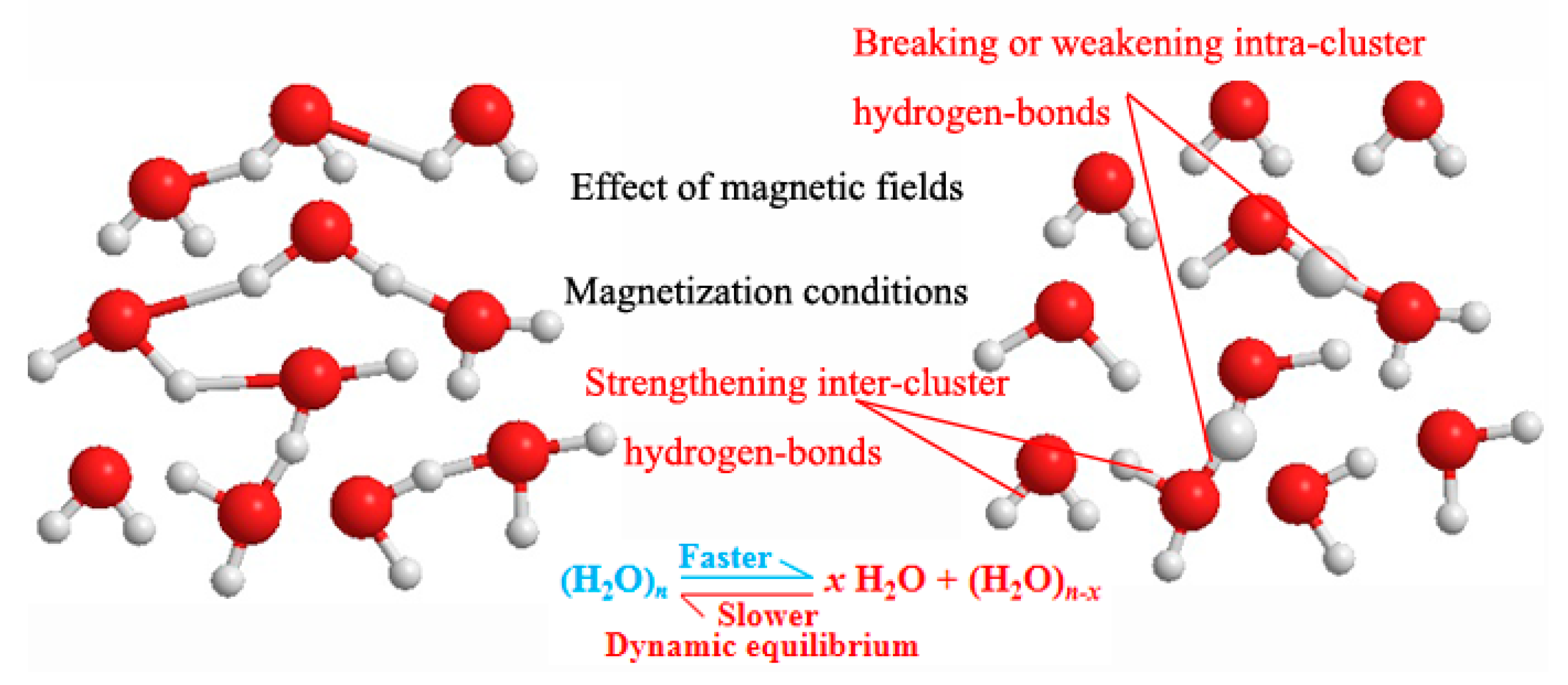

3.1. The Effects of the Magnetic Field on the Water

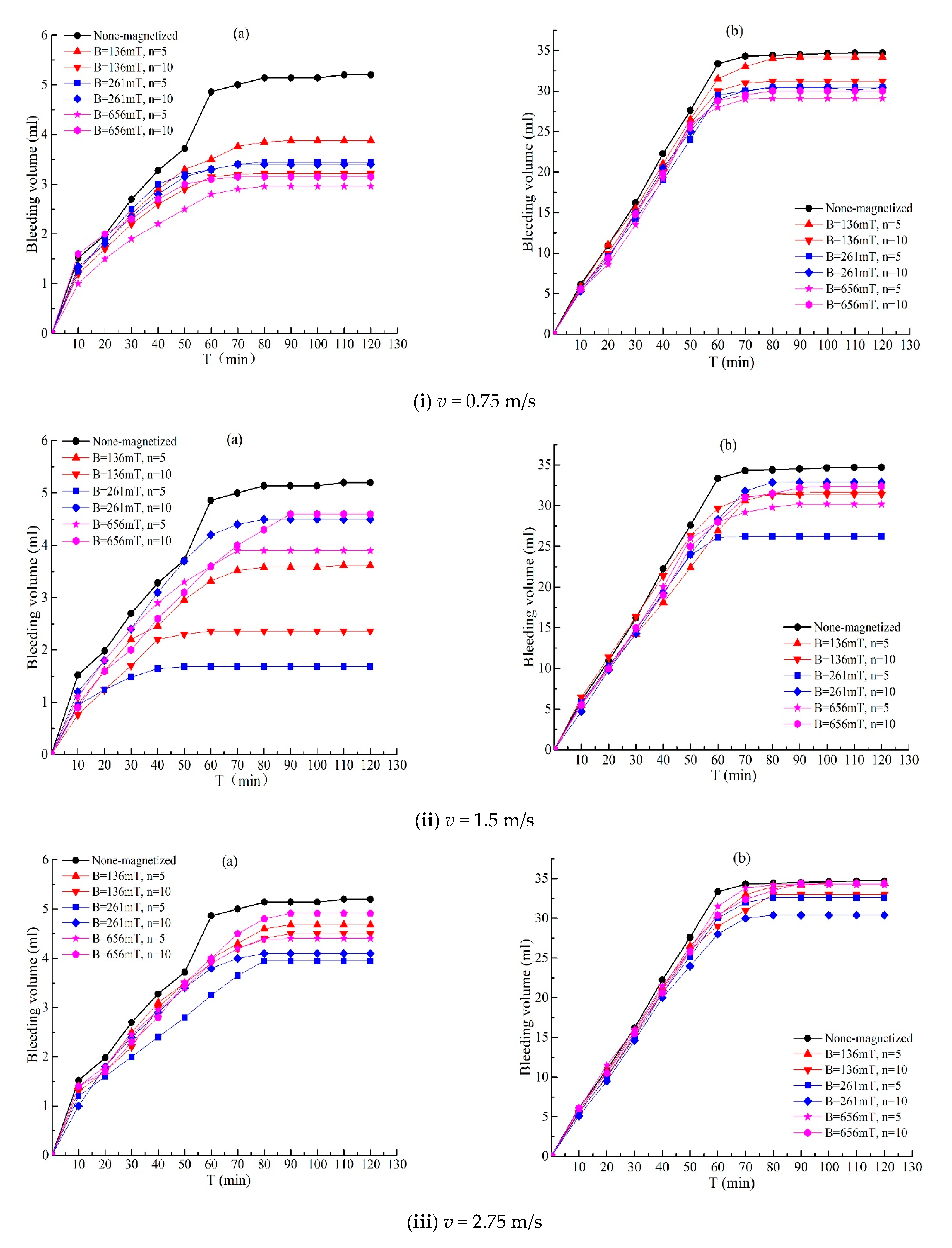

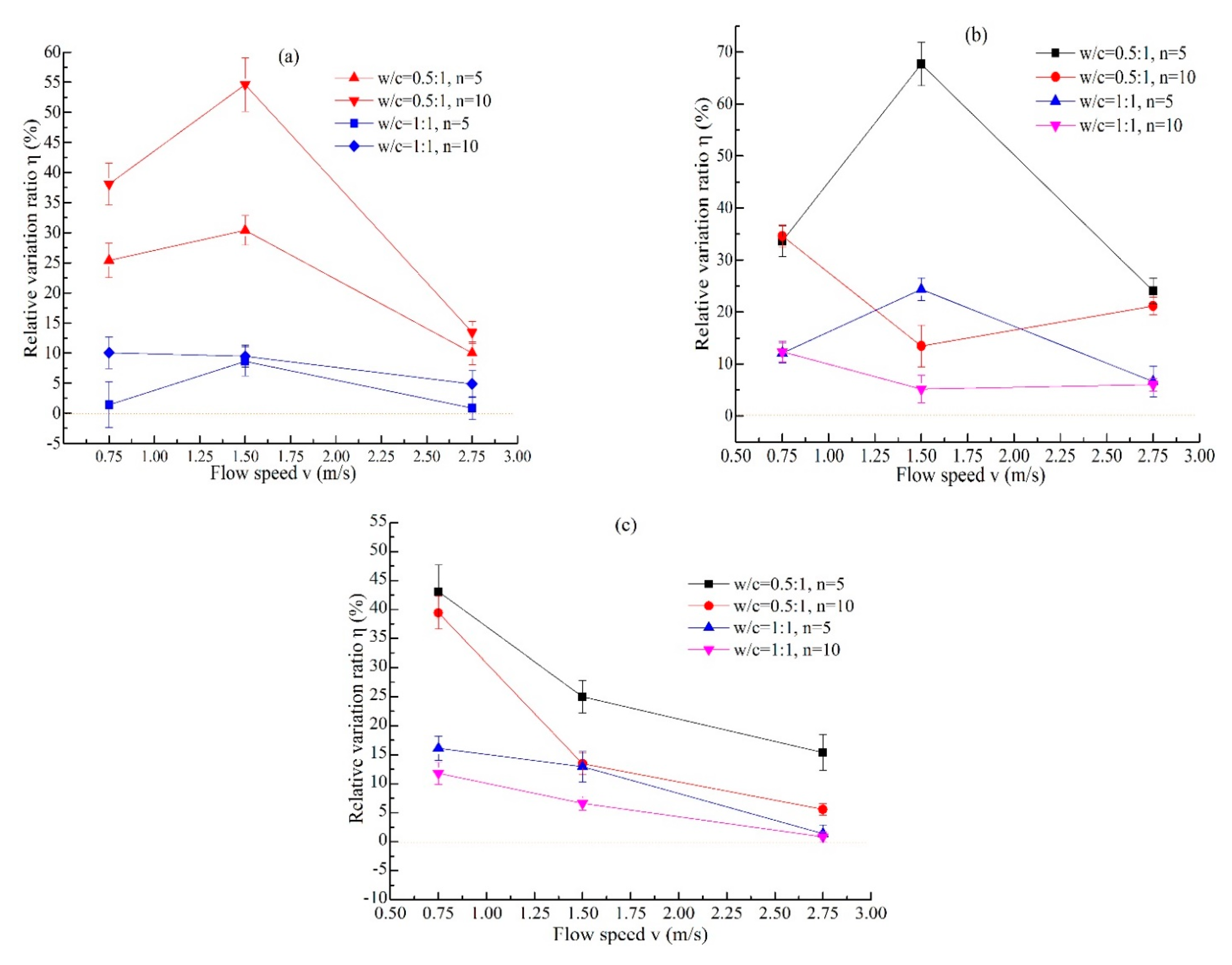

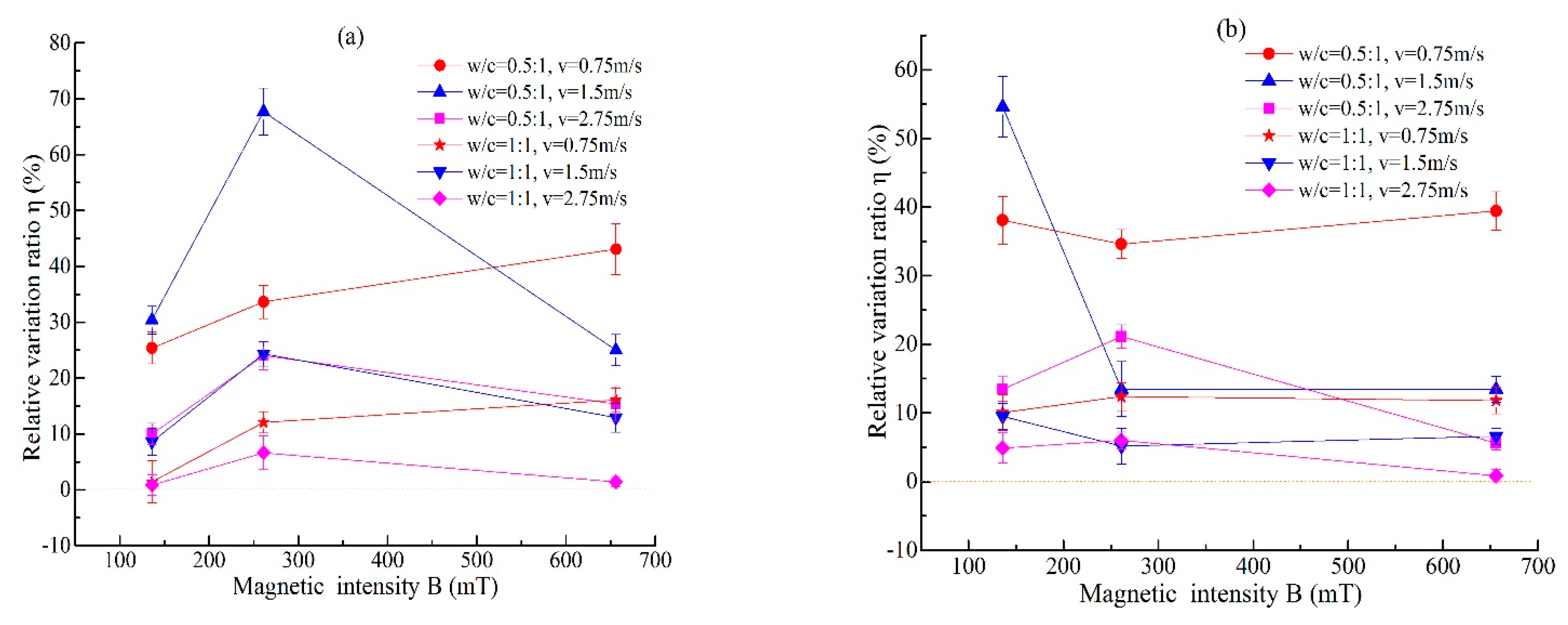

3.2. Effect of Magnetized Water on the Stability of Cement Grout

3.3. The Consolidation Compressive Strength and SEM Images of Cement Grout

4. Conclusions

- The magnetic field can change the physical and electrical properties of tap water, and the evaporation and conductivity of magnetized tap water are increased. At ambient temperatures of 50 and 80 °C, the maximum increase in the accumulated evaporation at 2 h was 25.6% and 16.7%, respectively, and the maximum increase in conductivity was 10.6%;

- Compared with the cement grout with regular tap water, the cement grout mixed with magnetized water had a slower bleeding speed and smaller bleeding volume;

- The magnetic intensity, water flow speed, and cycle times are important factors in the stability of cement grout. In the application of magnetized water, over-magnetization should be avoided, and the best magnetization conditions should be determined to obtain the best results;

- The cement grout mixed with magnetized water under the condition of B = 261 mT, v = 1.5 m/s, and n = 5 obtained the most beneficial stability of the cement grout, and the stability of the cement grout with w/c ratios of 0.5 and 1 increased by approximately 67.69% and 24.36% relative to the control specimens, respectively;

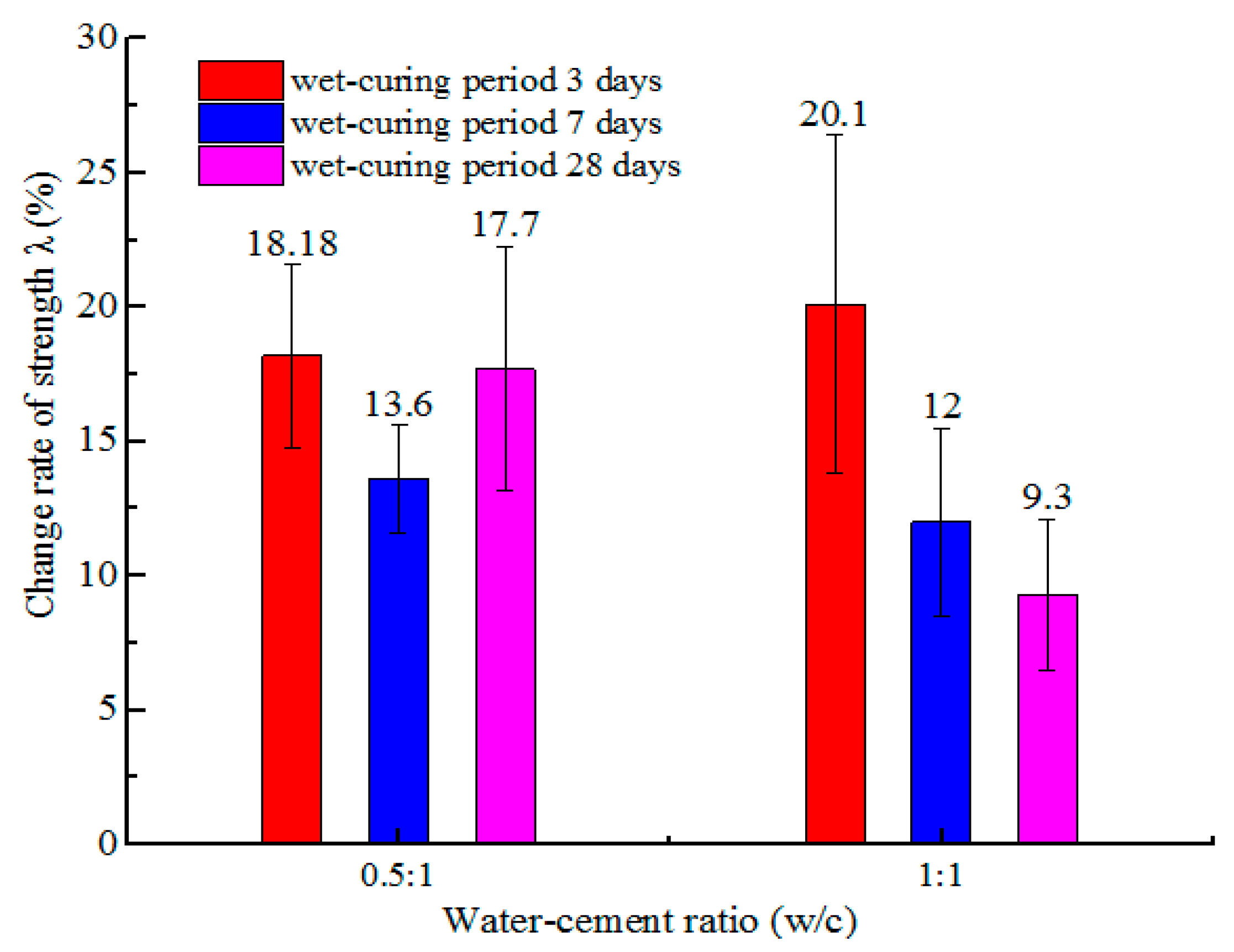

- Magnetized water has a positive effect on the consolidation compressive strength of cement grout, which is beneficial for improving the early consolidation compressive strength of cement grout. The consolidation compressive strength of cement grout with w/c ratios of 0.5 and 1 increased by about 18.8% and 20.1% under the best magnetization conditions, respectively;

- The SEM images showed that there are more hydrate crystals in hardened cement grout mixed with MW, the filling of the space between the cement particles is denser, the gap is increasingly smaller, which led to a significant improvement in the microstructure compared with that of the control specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luzar, J.; Padovnik, A.; Štukovnik, P.; Marinšek, M.; Jagličić, Z.; Bosiljkov, V.B.; Dolinšek, J. NMR spectroscopy-supported design and properties of air lime-white cement injection grouts for strengthening of historical masonry buildings. Constr. Build. Mater. 2020, 250, 118937. [Google Scholar] [CrossRef]

- Li, S.; Liu, R.; Zhang, Q.; Zhang, X. Protection against water or mud inrush in tunnels by grouting: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 753–766. [Google Scholar] [CrossRef] [Green Version]

- Çınar, M.; Karpuzcu, M.; Çanakçı, H. The measurement of fresh properties of cement-based grout containing waste marble powder. Measurement 2019, 150, 106833. [Google Scholar] [CrossRef]

- Bohloli, B.; Skjølsvold, O.; Justnes, H.; Olssona, R.; Grøv, E.; Aarset, A. Cements for tunnel grouting -Rheology and flow properties tested at different temperatures. Tunn. Undergr. Space Technol. 2019, 91, 103011. [Google Scholar] [CrossRef]

- Li, S.; Sha, F.; Liu, R.; Zhang, Q.; Li, Z. Investigation on fundamental properties of microfine cement and cement-slag grouts. Constr. Build. Mater. 2017, 153, 965–974. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Remond, S.; Gallias, J.-L. Influence of cement grouts composition on the rheological behaviour. Cem. Concr. Res. 2011, 41, 292–300. [Google Scholar] [CrossRef]

- Eriksson, M.; Friedrich, M.; Vorschulze, C. Variations in the rheology and penetrability of cement-based grouts—An experimental study. Cem. Concr. Res. 2004, 34, 1111–1119. [Google Scholar] [CrossRef]

- Assaad, J.J.; Daou, Y. Cementitious grouts with adapted rheological properties for injection by vacuum techniques. Cem. Concr. Res. 2014, 59, 43–54. [Google Scholar] [CrossRef]

- Tafadzwa John Shamu, U.H. Rheology of cement grouts: On the critical shear rate and no-slip regime in the Couette geometry. Cem. Concr. Res. 2019, 123, 105769. [Google Scholar] [CrossRef]

- Rahman, M.; Wiklund, J.; Kotzé, R.; Håkansson, U. Yield stress of cement grouts. Tunn. Undergr. Space Technol. 2017, 61, 50–60. [Google Scholar] [CrossRef]

- Esmaeilnezhad, E.; Choi, H.J.; Kamyabi, A.; Gholizadeh, M.; Ranjbar, M. Characteristics and applications of magnetized water as a green technology. J. Clean. Prod. 2017, 161, 908–921. [Google Scholar] [CrossRef]

- Yousry, O.M.M.; Abd-Elaty, M.A.; Ghazy, M.F.; Taman, M.; Kaloop, M.R. A Study for Improving Compressive Strength of Cementitious Mortar Utilizing Magnetic Water. Materials 2020, 13, 1971. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiaofeng, P.; Bo, D. The changes of macroscopic features and microscopic structures of water under influence of magnetic field. Phys. B Phys. Condens. Matter 2008, 403, 3571–3577. [Google Scholar]

- Coey, J.M.D. Magnetic water treatment-how might it work? Philos. Mag. 2012, 92, 3857–3865. [Google Scholar] [CrossRef]

- Chibowski, E.; Szcześ, A. Magnetic water treatment-a review of the latest approaches. Chemosphere 2018, 203, 54–67. [Google Scholar] [CrossRef]

- Cai, R.; Yang, H.; He, J.; Zhu, W. The effects of magnetic fields on water molecular hydrogen bonds. J. Mol. Struct. 2009, 938, 15–19. [Google Scholar] [CrossRef]

- Ghorbani, S.; Tavakkolizadeh, M.; De Brito, J.; Ghorbani, S.; Jalayer, M.A.; Tavakkolizadeh, M. Using statistical analysis and laboratory testing to evaluate the effect of magnetized water on the stability of foaming agents and foam concrete. Constr. Build. Mater. 2019, 207, 28–40. [Google Scholar] [CrossRef]

- Ghorbani, S.; Ghorbani, S.; Tao, Z.; De Brito, J.; Tavakkolizadeh, M. Effect of magnetized water on foam stability and compressive strength of foam concrete. Constr. Build. Mater. 2019, 197, 280–290. [Google Scholar] [CrossRef]

- Gholhaki, M.; Kheyroddin, A.; Hajforoush, M.; Kazemi, M. An investigation on the fresh and hardened properties of self-compacting concrete incorporating magnetic water with various pozzolanic materials. Constr. Build. Mater. 2018, 158, 173–180. [Google Scholar] [CrossRef]

- Salehi, H.; Mazloom, M. An experimental investigation on fracture parameters and brittleness of self-compacting lightweight concrete containing magnetic field treated water. Arch. Civ. Mech. Eng. 2019, 19, 803–819. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Y.; Luo, J. Influence of magnetic water on early-age shrinkage cracking of concrete. Constr. Build. Mater. 2017, 147, 91–100. [Google Scholar] [CrossRef]

- Abdel-Magid, T.I.M.; Hamdan, R.M.; Abdelgader, A.A.B.; Omer, M.E.A.; Ahmed, N.M.R.-A. Effect of Magnetized Water on Workability and Compressive Strength of Concrete. Procedia Eng. 2017, 193, 494–500. [Google Scholar] [CrossRef]

- Soto-Bernal, J.J.; Rosario, G.M.; Iliana, R.C.; Ortiz-Lozano, J.A. Effects of static magnetic fields on the physical, mechanical, and microstructural properties of cement pastes. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Abavisani, I.; Rezaifar, O.; Kheyroddin, A. Alternating Magnetic Field Effect on Fine-aggregate Concrete Compressive Strength. Constr. Build. Mater. 2017, 134, 83–90. [Google Scholar] [CrossRef]

- Zeng, X.; Ren, Z.; Wang, X. Experimental investigations on reducing the dust density and the rebound rate of shotcrete by using magnetized water. J. China Coal Soc. 2014, 39, 705–712. [Google Scholar]

- Szcześ, A.; Chibowski, E.; Hołysz, L.; Rafalski, P. Effects of static magnetic field on water at kinetic condition. Chem. Eng. Process. Process. Intensif. 2011, 50, 124–127. [Google Scholar] [CrossRef]

- Seyfi, A.; Afzalzadeh, R.; Hajnorouzi, A. Increase in water evaporation rate with increase in static magnetic field perpendicular to water-air interface. Chem. Eng. Process. Process. Intensif. 2017, 120, 195–200. [Google Scholar] [CrossRef]

- Holysz, L.; Szczes, A.; Chibowski, E. Effects of a static magnetic field on water and electrolyte solutions. J. Colloid Interface Sci. 2007, 316, 996–1002. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, H.; Li, Z. Effect of magnetic field on the physical properties of water. Results Phys. 2018, 8, 262–267. [Google Scholar] [CrossRef]

- Lee, S.H.; Jeon, S.I.; Kim, Y.S.; Lee, S.K. Changes in the electrical conductivity, infrared absorption, and surface tension of partially-degassed and magnetically-treated water. J. Mol. Liq. 2013, 187, 230–237. [Google Scholar] [CrossRef]

- Al-Qahtani, H. Effect of magnetic treatment on Gulf seawater. Desalination 1996, 107, 75–81. [Google Scholar] [CrossRef]

- Guo, Y.-Z.; Yin, D.-C.; Cao, H.-L.; Shi, J.-Y.; Zhang, C.-Y.; Liu, Y.-M.; Huang, H.-H.; Liu, Y.; Wang, Y.; Guo, W.-H.; et al. Evaporation Rate of Water as a Function of a Magnetic Field and Field Gradient. Int. J. Mol. Sci. 2012, 13, 16916–16928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pang, X.-F.; Shen, G.-F. The changes of physical properties of water arising from the magnetic field and its mechanism. Mod. Phys. Lett. B 2013, 27, 1350228. [Google Scholar] [CrossRef]

- Toledo, E.J.; Ramalho, T.C.; Magriotis, Z.M. Influence of magnetic field on physical–chemical properties of the liquid water: Insights from experimental and theoretical models. J. Mol. Struct. 2008, 888, 409–415. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, B.; Gong, Z.; Gao, K.; Ou, Y.; Zhangab, J. The effect of a static magnetic field on the hydrogen bonding in water using frictional experiments. J. Mol. Struct. 2013, 1052, 102–104. [Google Scholar] [CrossRef]

- Afshin, H.; Gholizadeh, M.; Khorshidi, N. Improving mechanical properties of high strength concrete by magnetic water technology. Sci. Iran. 2010, 17, 74–79. [Google Scholar]

| Item | Specific Surface Area (m2/Kg) | Loss on Ignition (%) | Slag Content (%) | Alcoholamine Grinding Aids (%) | Initial Setting Time (min) | Final Setting Time (min) | Alkali Content (%) | Soundness |

|---|---|---|---|---|---|---|---|---|

| P.O 42.5 | 356 | 2.76 | 9.5 | 0.1 | 176 | 335 | 0.4 | Qualified |

| Standard | ≥300 | ≤5.0 | 5.0~20.0 | ≤0.5 | ≥45 | ≤600 | 0.6 | Qualified |

| Item | Turbidity (NTU) | Free Residual Chlorine (mg/L) | Total Hardness (CaCO3) | Oxygen Consumption (mg/L) | PH | Iron Content (mg/L) | Manganese Content (mg/L) | Aluminum Content (mg/L) | Colority |

|---|---|---|---|---|---|---|---|---|---|

| Test value | 0.16 | 0.18 | 107 | 0.99 | 7.14 | <0.05 | <0.05 | 0.035 | <5 |

| Standard | <3 | 0.3~4 | <450 | <5 | 6.5~8.5 | <0.3 | <0.1 | <0.2 | <15 |

| Magnetic Intensity B (mT) | Water Flow Speed v (m/s) | Cycle Times n | Water/Cement Ratio (w/c) | Water Performance Test/Sample Quantity | Grout Performance Test/Sample Quantity |

|---|---|---|---|---|---|

| 0 | 0 | 0 | 0.5/1.0 | Yes/5 | Yes/10 |

| 136 | 0.75 | 5/10 | No | ||

| 1.5 | No | ||||

| 2.75 | No | ||||

| 261 | 0.75 | Yes/5 | |||

| 1.5 | Yes/5 | ||||

| 2.75 | Yes/5 | ||||

| 656 | 0.75 | Yes/5 | |||

| 1.5 | Yes/5 | ||||

| 2.75 | Yes/5 |

| Width of Mixing Blade (mm) | Size of Mixing Pot (mm) | Revolution Speed (r/min) | Rotation Speed (r/min) | Automatic Control Time (s) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inner Diameter | Depth | Wall Thickness | High Speed | Low Speed | High Speed | Low Speed | High Speed | Stop | Low Speed | |

| 111 | 160 | 140 | 1 | 125 ± 10 | 62 ± 5 | 285 ± 10 | 140 ± 5 | 120 ± 5 | 15 | 120 ± 3 |

| Magnetic Intensity (mT) | w/c | Flow Speed (m/s) | Cycle Times | Bleeding Ratio β (%) | Standard Deviation | Relative Variation Ratio η (%) | Increment of η by Cycle Times ∆η (%) |

|---|---|---|---|---|---|---|---|

| 0 | 0.5 | 0 | 0 | 5.20 | 0.5099 | 0.00 | |

| 1 | 34.69 | 0.7392 | 0.00 | ||||

| 136 | 0.5 | 0.75 | 5 | 3.88 | 0.6632 | 25.38 | +12.7 |

| 10 | 3.22 | 0.4952 | 38.08 | ||||

| 1.5 | 5 | 3.62 | 0.4578 | 30.38 | +24.23 | ||

| 10 | 2.36 | 0.4454 | 54.61 | ||||

| 2.75 | 5 | 4.68 | 0.3889 | 10.00 | +3.46 | ||

| 10 | 4.50 | 0.8112 | 13.46 | ||||

| 1 | 0.75 | 5 | 34.20 | 0.7785 | 1.41 | +8.65 | |

| 10 | 31.21 | 0.5999 | 10.06 | ||||

| 1.5 | 5 | 31.70 | 1.4236 | 8.62 | +0.86 | ||

| 10 | 31.41 | 0.8602 | 9.48 | ||||

| 2.75 | 5 | 34.40 | 0.8788 | 0.84 | +4.03 | ||

| 10 | 33.00 | 0.4232 | 4.87 | ||||

| 261 | 0.5 | 0.75 | 5 | 3.45 | 0.3631 | 33.65 | +0.95 |

| 10 | 3.40 | 0.8784 | 34.62 | ||||

| 1.5 | 5 | 1.68 | 0.4833 | 67.69 | −54.23 | ||

| 10 | 4.50 | 0.1833 | 13.46 | ||||

| 2.75 | 5 | 3.95 | 0.4950 | 24.04 | −2.89 | ||

| 10 | 4.10 | 0.1561 | 21.15 | ||||

| 1 | 0.75 | 5 | 30.50 | 0.3890 | 12.08 | +0.28 | |

| 10 | 30.41 | 0.7411 | 12.36 | ||||

| 1.5 | 5 | 26.24 | 0.7419 | 24.36 | −19.20 | ||

| 10 | 32.90 | 0.4899 | 5.16 | ||||

| 2.75 | 5 | 32.40 | 0.5680 | 6.60 | −0.60 | ||

| 10 | 32.61 | 0.2986 | 6.00 | ||||

| 656 | 0.5 | 0.75 | 5 | 2.96 | 0.6662 | 43.08 | −3.66 |

| 10 | 3.15 | 0.3232 | 39.42 | ||||

| 1.5 | 5 | 3.90 | 0.6777 | 25.00 | −11.54 | ||

| 10 | 4.50 | 0.4511 | 13.46 | ||||

| 2.75 | 5 | 4.40 | 0.7996 | 15.38 | −9.81 | ||

| 10 | 4.91 | 0.3665 | 5.57 | ||||

| 1 | 0.75 | 5 | 29.10 | 0.3222 | 16.11 | −4.32 | |

| 10 | 30.60 | 0.3692 | 11.79 | ||||

| 1.5 | 5 | 30.20 | 0.4560 | 12.94 | −6.34 | ||

| 10 | 32.40 | 0.7996 | 6.60 | ||||

| 2.75 | 5 | 34.20 | 0.8798 | 1.41 | −0.57 | ||

| 10 | 34.40 | 0.4848 | 0.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.-X.; Deng, C. Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout. Materials 2021, 14, 275. https://doi.org/10.3390/ma14020275

Hu H-X, Deng C. Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout. Materials. 2021; 14(2):275. https://doi.org/10.3390/ma14020275

Chicago/Turabian StyleHu, Huan-Xiao, and Chao Deng. 2021. "Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout" Materials 14, no. 2: 275. https://doi.org/10.3390/ma14020275

APA StyleHu, H.-X., & Deng, C. (2021). Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout. Materials, 14(2), 275. https://doi.org/10.3390/ma14020275