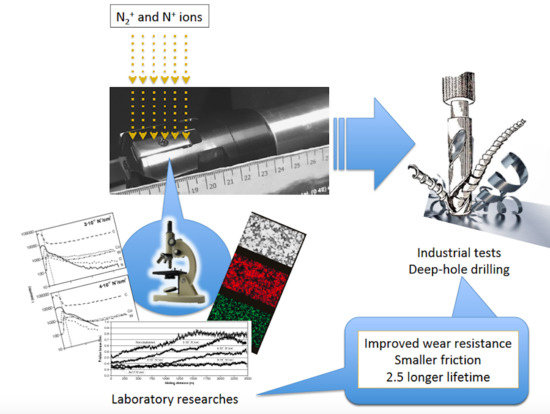

Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation

Abstract

1. Introduction

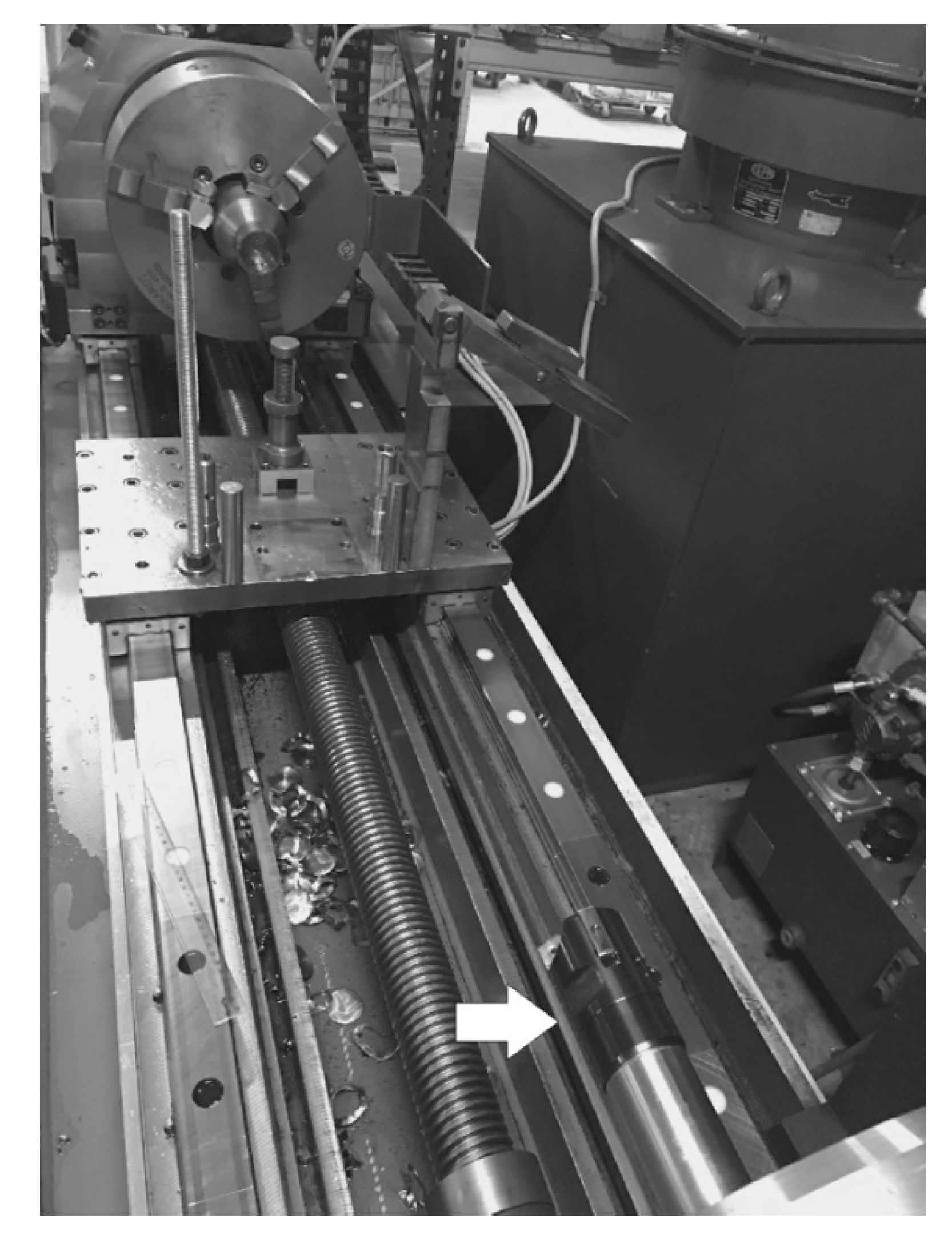

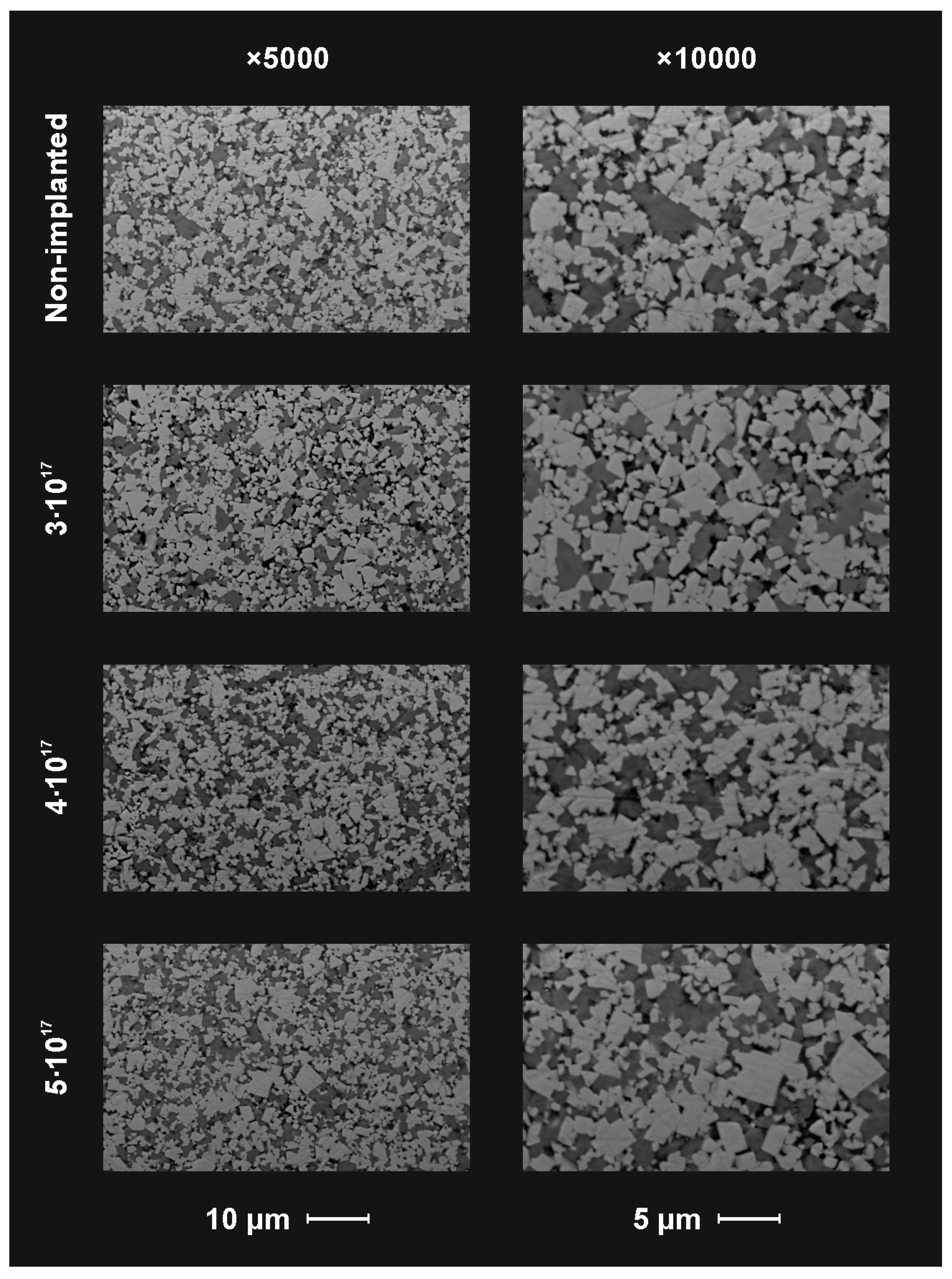

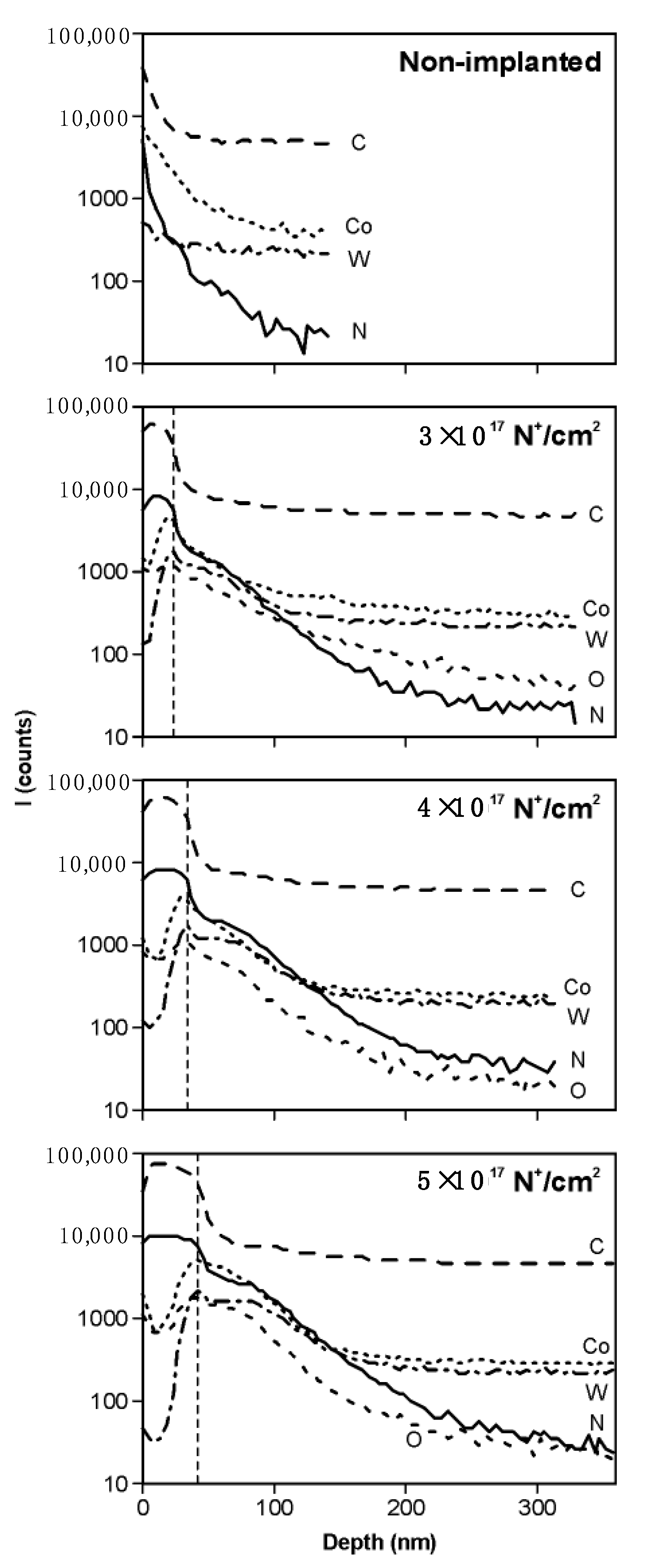

2. Materials and Methods

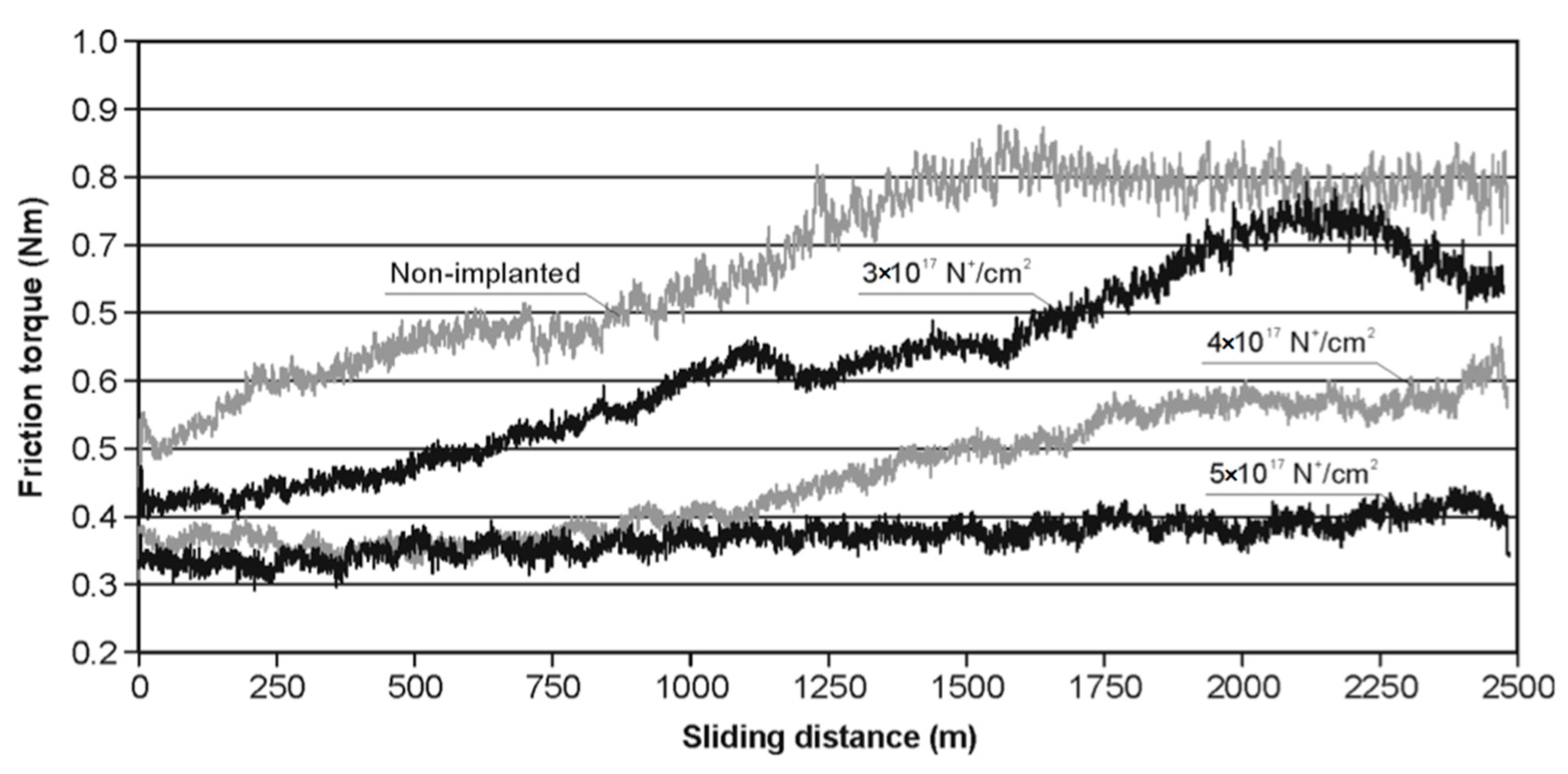

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanner, L.A.; Pittari, J.J.; Swab, J.J. Dynamic hardness of cemented tungsten carbides. Int. J. Refract. Met. Hard Mater. 2018, 75, 294–298. [Google Scholar] [CrossRef]

- Dearnaley, G.; Hartley, N.E.W. Ion implantation into metals and cabrides. Thin Solid Film. 1978, 54, 215–232. [Google Scholar] [CrossRef]

- Dearnaley, G. The effects of ion implantation upon the mechanical properties of metals and cemented carbides. Radiat. Eff. 1982, 63, 1–15. [Google Scholar] [CrossRef]

- Inspektor, A.; Salvador, P.A. Architecture of PVD coatings for metal cutting applications: A review. Surf. Coat. Technol. 2014, 257, 138–153. [Google Scholar] [CrossRef]

- Beste, U.; Hartzell, T.; Engqvist, H.; Axén, N. Surface damage on cemented carbide rock-drill buttons. Wear 2001, 249, 324–329. [Google Scholar] [CrossRef]

- Beste, U.; Jacobson, S. A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 2008, 264, 1129–1141. [Google Scholar] [CrossRef]

- Nahak, S.; Dewangan, S.; Chattopadhyaya, S. Discussion on wear phenomena in cemented carbide. Procedia Earth Planet. Sci. 2015, 11, 284–293. [Google Scholar] [CrossRef]

- Nahak, S.; Dewangan, S.; Chattopadhyaya, S.; Królczyk, G.; Hloch, S. Discussion on importance of tungsten carbide-cobalt (WC-Co) cemented carbide and its critical characterization for wear mechanisms based on mining applications. Arch. Min. Sci. 2018, 63, 229–246. [Google Scholar] [CrossRef]

- Potgieter, J.H.; Olubambi, P.; Potgieter-Vermaak, S.S. The corrosion behaviour of WC-Co-Ru alloys in aggressive chloride media. Int. J. Electrochem. 2014, 2014, 594871. [Google Scholar] [CrossRef][Green Version]

- Tarragó, J.M.; Fargas, G.; Jimenez-Piqué, E.; Felip, A.; Isern, L.; Coureaux, D.; Roa, J.J.; Al-Dawery, I.; Fair, J.; Llanes, L. Corrosion damage in WC-Co cemented carbides: Residual strength assessment and 3D FIB-FESEM tomography characterization. Powder Metall. 2014, 57, 324–330. [Google Scholar] [CrossRef]

- Emanuelli, L.; Pellizzari, M.; Molinari, A.; Castellani, F.; Zinutti, E. Thermal fatigue behaviour of WC-20Co and WC-30(CoNiCrFe) cemented carbide. Int. J. Refract. Met. Hard Mater. 2016, 60, 118–124. [Google Scholar] [CrossRef]

- Chen, L.; Yi, D.; Wang, B.; Liu, H.; Wu, C. Mechanism of the early stages of oxidation of WC–Co cemented carbides. Corros. Sci. 2016, 103, 75–87. [Google Scholar] [CrossRef]

- Kindermann, P.; Sockel, H.G. Mechanisms of fatigue in cemented carbides at elevated temperatures. Adv. Eng. Mater. 2000, 2, 356–358. [Google Scholar] [CrossRef]

- Walter, J.L.; Skelly, D.W.; Minnear, W.P. Ion implantation of cobalt-tungsten carbide tools for machining titanium. Wear 1993, 170, 79–92. [Google Scholar] [CrossRef]

- Bricín, D.; Průcha, V.; Kříž, A. Texturing of WC-Co substrate surface to improve the resistance of deposited PVD film to wear and dynamic loads. Procedia Manuf. 2017, 13, 702–709. [Google Scholar] [CrossRef]

- Linnik, S.A.; Gaydaychuk, A.V.; Okhotnikov, V.V. Improvement to the adhesion of polycrystalline diamond films on WC-Co cemented carbides through ion etching of loosely bound growth centers. Surf. Coat. Technol. 2018, 334, 227–232. [Google Scholar] [CrossRef]

- Wang, J.; Fang, F.; Yan, G.; Guo, Y. Study on diamond cutting of ion implanted tungsten carbide with and without ultrasonic vibration. Nanomanuf. Metrol. 2019, 2, 177–185. [Google Scholar] [CrossRef]

- Belbah, A.; Mkaddem, A.; Ladaci, N.; Mebarki, N.; Mansori, M.E. Low energy implantation to inhibit wear in N+ ions implanted WC-Co composite. Mater. Des. 2014, 53, 202–208. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Morozow, D.; Rucki, M.; Siemiatkowski, Z.; Gutsalenko, Y. Tribological tests of the ceramic cutting tools after yttrium (Y+) and rhenium (Re+) ion implantation. Tribologia 2019, 285, 71–77. [Google Scholar] [CrossRef]

- Werner, Z.; Barlak, M.; Grądzka-Dahlke, M.; Diduszko, R.; Szymczyk, W.; Dąbrowski, J.; Piekoszewski, J.; Borkowska, K. The effect of ion implantation on the wear of Co-Cr-Mo alloy. Vacuum 2007, 81, 1191–1194. [Google Scholar] [CrossRef]

- García, J.A.; Rodríguez, R.J. Ion implantation techniques for non-electronic applications. Vacuum 2011, 85, 1125–1129. [Google Scholar] [CrossRef]

- Shi, W.D.; Wen, X.Y.; Liu, J.H.; Ren, C.S.; Long, Z.H.; Zhang, G.B.; Gong, Z.X.; Wang, Y.N.; Zhang, T. Study of surface modification of WC-Co alloy by nitrogen implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1993, 80, 229–232. [Google Scholar] [CrossRef]

- Narojczyk, J.; Morozow, D.; Narojczyk, J.W.; Rucki, M. Ion implantation of the tool’s rake face for machining of the Ti-6Al-4V alloy. J. Manuf. Process. 2018, 34, 274–280. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M.; Werner, Z.; Böttger, R.; Konarski, P.; Pisarek, M. The effect of nitrogen ion implantation on the properties of WC-Co composites used in wood-based materials machining. In Proceedings of the “Yucomat” Conference, Herceg Novi, Montenegro, 3–7 September 2018. [Google Scholar]

- Barlak, M.; Wilkowski, J.; Werner, Z. Modelling of the ion implantation modification of WC-Co indexable knives for wood machining. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 106, 57–61. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wei, X.T.; Guo, Y.B.; Sealy, M.P. State-Of-Art, Challenges, and Outlook on Manufacturing of Cooling Holes for Turbine Blades. Mach. Sci. Technol. 2015, 19, 361–399. [Google Scholar] [CrossRef]

- Kumar, R.; Saho, A.K.; Mishra, P.C.; Das, R.K. Comparative investigation towards machinability improvement in hard turning using coated and uncoated carbide inserts: Part I experimental investigation. Adv. Manuf. 2018, 6, 52–70. [Google Scholar] [CrossRef]

- Kong, L.; Cao, S.; Chin, J.H.; Si, Y.; Mao, F.; Li, Y. Vibration suppression of drilling tool system during deep-hole drilling process using independence mode space control. Int. J. Mach. Tools Manuf. 2020, 151, 103525. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, X.; Bo, A.; Li, Y.; Zhan, H.; Gu, Y. A multiscale evaluation of the surface integrity in boring trepanning association deep hole drilling. Int. J. Mach. Tools Manuf. 2017, 123, 48–56. [Google Scholar] [CrossRef]

- Heinemann, R.; Hinduja, S. A new strategy for tool condition monitoring of small diameter twist drills in deep-hole drilling. Int. J. Mach. Tools Manuf. 2012, 52, 69–76. [Google Scholar] [CrossRef]

- Diniz, A.E.; Machado, Á.R.; Corrêa, J.G. Tool wear mechanisms in the machining of steels and stainless steels. Int. J. Adv. Manuf. Technol. 2016, 87, 3157–3168. [Google Scholar] [CrossRef]

- Kuczmaszewski, J.; Pieśko, P.; Zawada-Michałowska, M. Carbide milling cutter blades durability during machining of Al-Si casting alloy. Multidiscip. Asp. Prod. Eng. 2018, 1, 169–175. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Glowacz, A.; Tjahjowidodo, T. Modelling of material removal in abrasive belt grinding process: A regression approach. Symmetry 2020, 12, 99. [Google Scholar] [CrossRef]

- Szala, M.; Latka, L.; Walczak, M.; Winnicki, M. Comparative study on the cavitation erosion and sliding wear of cold-sprayed Al/Al2O3 and Cu/Al2O3 coatings, and stainless steel, aluminium alloy, copper and brass. Metals 2020, 10, 856. [Google Scholar] [CrossRef]

- Świć, A.; Wołos, D.; Gola, A.; Kłosowski, G. The Use of Neural Networks and Genetic Algorithms to Control Low Rigidity Shafts Machining. Sensors 2020, 20, 4683. [Google Scholar] [CrossRef] [PubMed]

- Tapp, M. Cutting Tool Coatings and Edge Preparation; FRAISA: Bellach, Switzerland, 2011; pp. 1–37. [Google Scholar]

- Zawada-Michałowska, M.; Pieśko, P.; Józwik, J. Tribological aspects of cutting tool wear during the turning of stainless steels. Materials 2020, 13, 123. [Google Scholar] [CrossRef] [PubMed]

- Chu, N.H.; Nguyen, V.D.; Ngo, Q.H. Machinability enhancements of ultrasonic-assisted deep drilling of aluminum alloys. Mach. Sci. Technol. 2020, 24, 112–135. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J.; Werner, Z. Modelling of nitrogen implantation processes into WC-Co indexable knives for wood-based material machining using ion implanters with or without direct ion beam. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 108, 68–78. [Google Scholar] [CrossRef]

- Zhang, W.; He, F.; Xiong, D. Gundrill life improvement for deep-hole drilling on manganese steel. Int. J. Mach. Tools Manuf. 2004, 44, 327–331. [Google Scholar] [CrossRef]

- Wu, W.; Kuzu, A.; Stephenson, D.; Hong, J.; Bakkal, M.; Shih, A. Dry and minimum quantity lubrication high-throughput drilling of compacted graphite iron. Mach. Sci. Technol. 2018, 22, 652–670. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J.; Werner, Z. The selected problems of the modelling of the depth profiles of the elements implanted to the tools used in wood material machining. Biul. Inf. Ob Rppd 2019, 3–4, 118–134. (In Polish) [Google Scholar] [CrossRef]

- Konarski, P.; Mierzejewska, A. B4C/Mo/Si and Ta2O5/Ta nanostructures analysed by ultra-low energy argon ion beams. Appl. Surf. Sci. 2003, 203, 354–358. [Google Scholar] [CrossRef]

- Qiu, W.; Liua, Y.; Ye, J.; Fan, H.; Qiu, Y. Effects of (Ti,Ta,Nb,W)(C,N) on the microstructure, mechanicalproperties and corrosionbehaviors of WC-Co cementedcarbides. Ceram. Int. 2017, 43, 2918–2926. [Google Scholar] [CrossRef]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-ray Photoelectron Spectroscopy; Chastain, J., King, R.C., Jr., Eds.; Physical Electronics, Inc.: Eden Prairie, MN, USA, 1995. [Google Scholar]

- Srinivasan, N.B.; Thiede, T.B.; de los Arcos, T.; Gwildies, V.; Krasnopolski, M.; Becker, H.W.; Rogalla, D.; Devi, A.; Fischer, R.A. Transition metal nitride thin films grown by MOCVD using amidinato based complexes [M(NtBu)2{(iPrN)2CMe}2] (M = Mo, W) as precursors. Surf. Coat. Technol. 2013, 230, 130–136. [Google Scholar] [CrossRef]

- Rodella, C.B.; Barrett, D.H.; Moya, S.F.; Figueroa, S.J.A.; Pimenta, M.T.B.; Curvelo, A.A.S.; da Silva, V.T. Physical and chemical studies of tungsten carbide catalysts: Effects of Ni promotion and sulphonated carbon. RSC Adv. 2015, 5, 23874–23885. [Google Scholar] [CrossRef]

- Shen, Y.G.; Mai, Y.W. Effect of deposition conditions on internal stresses and microstructure of reactively sputtered tungsten nitride films. Surf. Coat. Technol. 2000, 127, 239–246. [Google Scholar] [CrossRef]

- Dezelah, C.L.; El-Kadri, O.M.; Kukli, K.; Arstila, K.; Baird, R.J.; Lu, J.; Niinisto, L.; Winter, C.H. A low valent metalorganic precursor for the growth of tungsten nitride thin films by atomic layer deposition. J. Mater. Chem. 2007, 17, 1109–1116. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Krolczyk, G. Material ratio curve as information on the state of surface topography—A review. Precis. Eng. 2020, 65, 240–258. [Google Scholar] [CrossRef]

- Sansom, D.; Viviente, J.L.; Alonso, F.; Ugarte, J.J.; Oñate, J.I. Ion implantation of TiN films with carbon or nitrogen for improved tribomechanical properties. Surf. Coat. Technol. 1996, 84, 519–523. [Google Scholar] [CrossRef]

- Alegre, D.; Acsente, T.; Martin-Rojo, A.B.; Oyarzabal, E.; Tabarés, F.L.; Dinescu, G.; de Temmerman, G.; Birjega, R.; Logofatu, C.; Kovac, J.; et al. Characterisation of tungsten nitride layers and their erosion under plasma exposure in NANO-PSI. Rom. Rep. Phys. 2015, 67, 532–546. [Google Scholar]

- Chou, Y.K.; Liu, J. Ion implantation of superhard ceramic cutting tools. J. Mater. Eng. Perform. 2004, 13, 398–405. [Google Scholar] [CrossRef]

- Pauleau, Y. Materials Surface Processing by Directed Energy Techniques; European Materials Research Society; Elsevier Science: Amsterdam, The Netherlands, 2006. [Google Scholar] [CrossRef]

| Materials | Binding Energy (eV) High-Resolution Spectra | Chemical State | ||||

|---|---|---|---|---|---|---|

| WC-Co nonimplanted | W4f7/2 | Co2p3/2 | N1s | O1s | C1s | |

| 31.1 | 282.9 | W0, W-C (WCx) | ||||

| 32.2 | 282.9 | W in WC | ||||

| 778.5 | Co0 | |||||

| 32.8 | 779.7 | 530.6 | W4+, Co2+-Co3+ | |||

| WC-Co 3 × 1017 | W4f7/2 | Co2p3/2 | N1s | O1s | C1s | |

| 31.6 | 282.8 | W0, W-C (WCx), W-N (WNx) | ||||

| 398.0 | C-NHx | |||||

| 400.2 | Co0 | |||||

| 32.8 | 778.5 | W4+, Co2+-Co3+ | ||||

| 33.7 | 779.7 | 530.5 | W-O (WOx) | |||

| WC-Co 4 × 1017 | W4f7/2 | Co2p3/2 | N1s | O1s | C1s | |

| 31.8 | W0, W-N (WNx) | |||||

| 398.3 | C-NHx | |||||

| 400.1 | N-H (NHx) | |||||

| 402.6 | Co0 | |||||

| 33.0 | 778.7 | W4+, Co2+-Co3+ | ||||

| 34.0 | 779.8 | 530.6 | W-O (WOx) | |||

| WC-Co 5 × 1017 | W4f7/2 | Co2p3/2 | N1s | O1s | C1s | |

| 31.4 | 282.7 | W0, W-C (WCx), W-N (WNx) | ||||

| 397.9 | C-NHx | |||||

| 400.1 | Co0 | |||||

| 32.5 | 778.6 | W4+, Co2+-Co3+ | ||||

| 33.4 | 780.0 | 530.3 | W-O (WOx) | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morozow, D.; Barlak, M.; Werner, Z.; Pisarek, M.; Konarski, P.; Zagórski, J.; Rucki, M.; Chałko, L.; Łagodziński, M.; Narojczyk, J.; et al. Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation. Materials 2021, 14, 239. https://doi.org/10.3390/ma14020239

Morozow D, Barlak M, Werner Z, Pisarek M, Konarski P, Zagórski J, Rucki M, Chałko L, Łagodziński M, Narojczyk J, et al. Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation. Materials. 2021; 14(2):239. https://doi.org/10.3390/ma14020239

Chicago/Turabian StyleMorozow, Dmitrij, Marek Barlak, Zbigniew Werner, Marcin Pisarek, Piotr Konarski, Jerzy Zagórski, Mirosław Rucki, Leszek Chałko, Marek Łagodziński, Jakub Narojczyk, and et al. 2021. "Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation" Materials 14, no. 2: 239. https://doi.org/10.3390/ma14020239

APA StyleMorozow, D., Barlak, M., Werner, Z., Pisarek, M., Konarski, P., Zagórski, J., Rucki, M., Chałko, L., Łagodziński, M., Narojczyk, J., Krzysiak, Z., & Caban, J. (2021). Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation. Materials, 14(2), 239. https://doi.org/10.3390/ma14020239