Release of Bisphenol A from Milled and 3D-Printed Dental Polycarbonate Materials

Abstract

1. Introduction

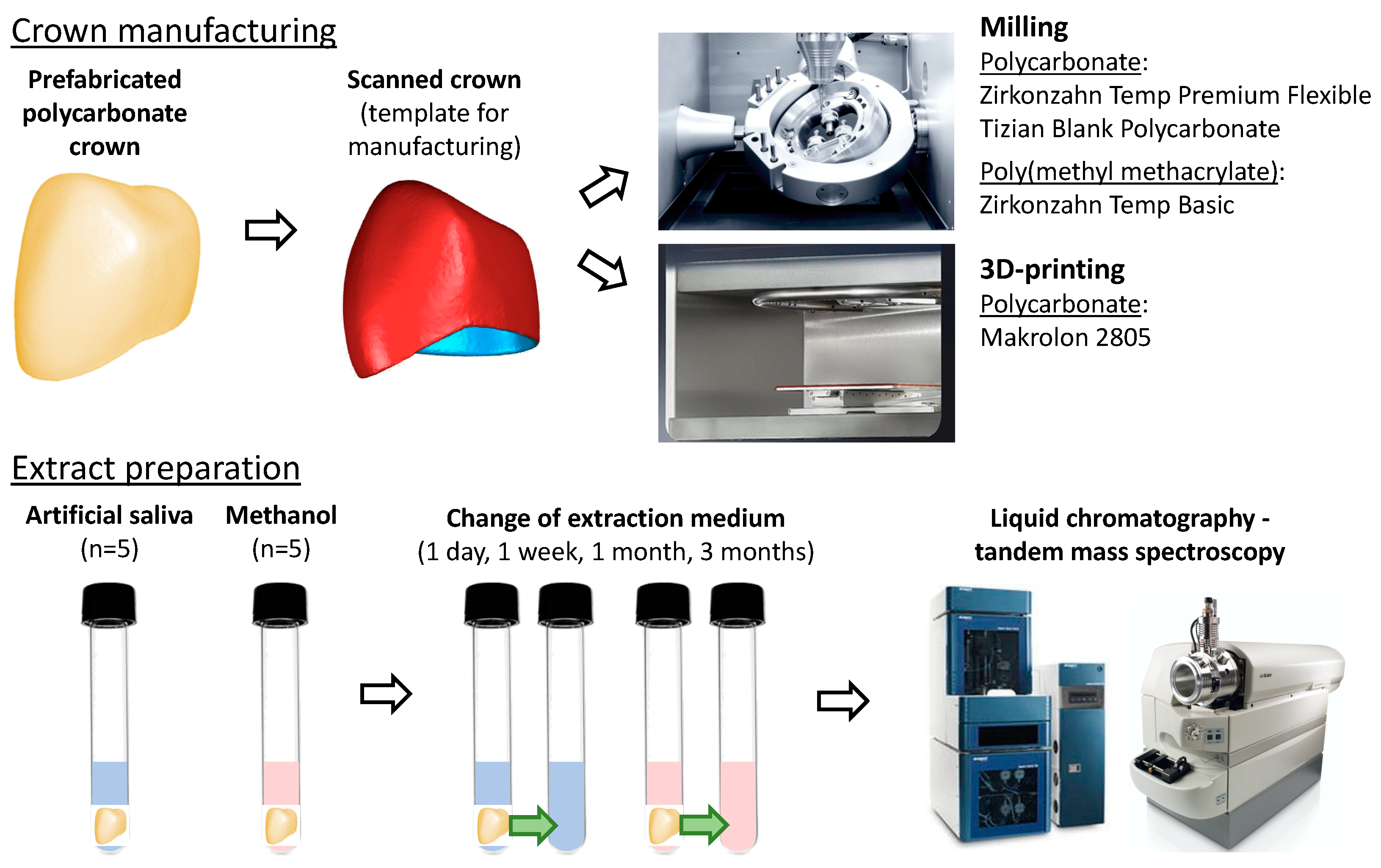

2. Materials and Methods

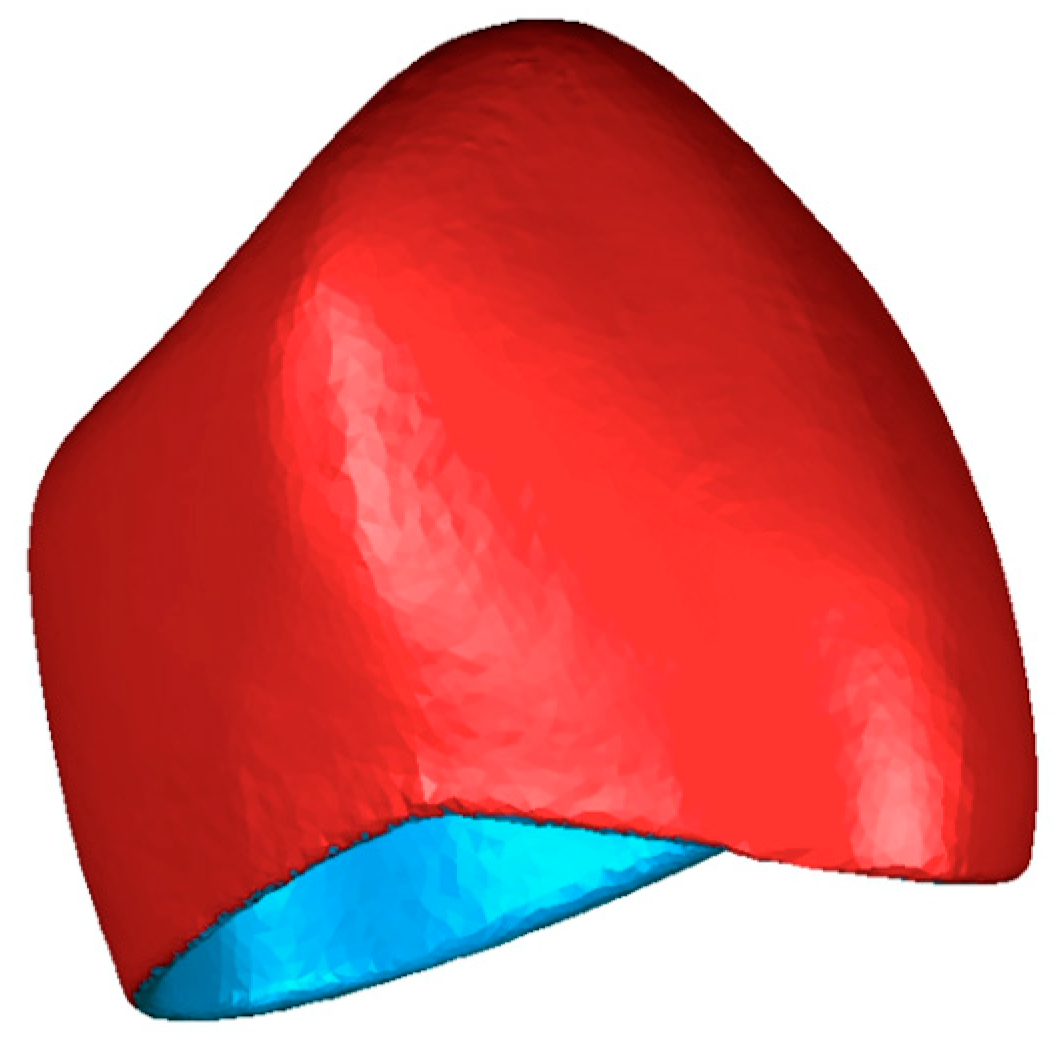

2.1. Crown Preparation

2.2. Extract Preparation

2.3. Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS)

2.4. Sorption and Amount of Extractable Matter in the Artificial Saliva

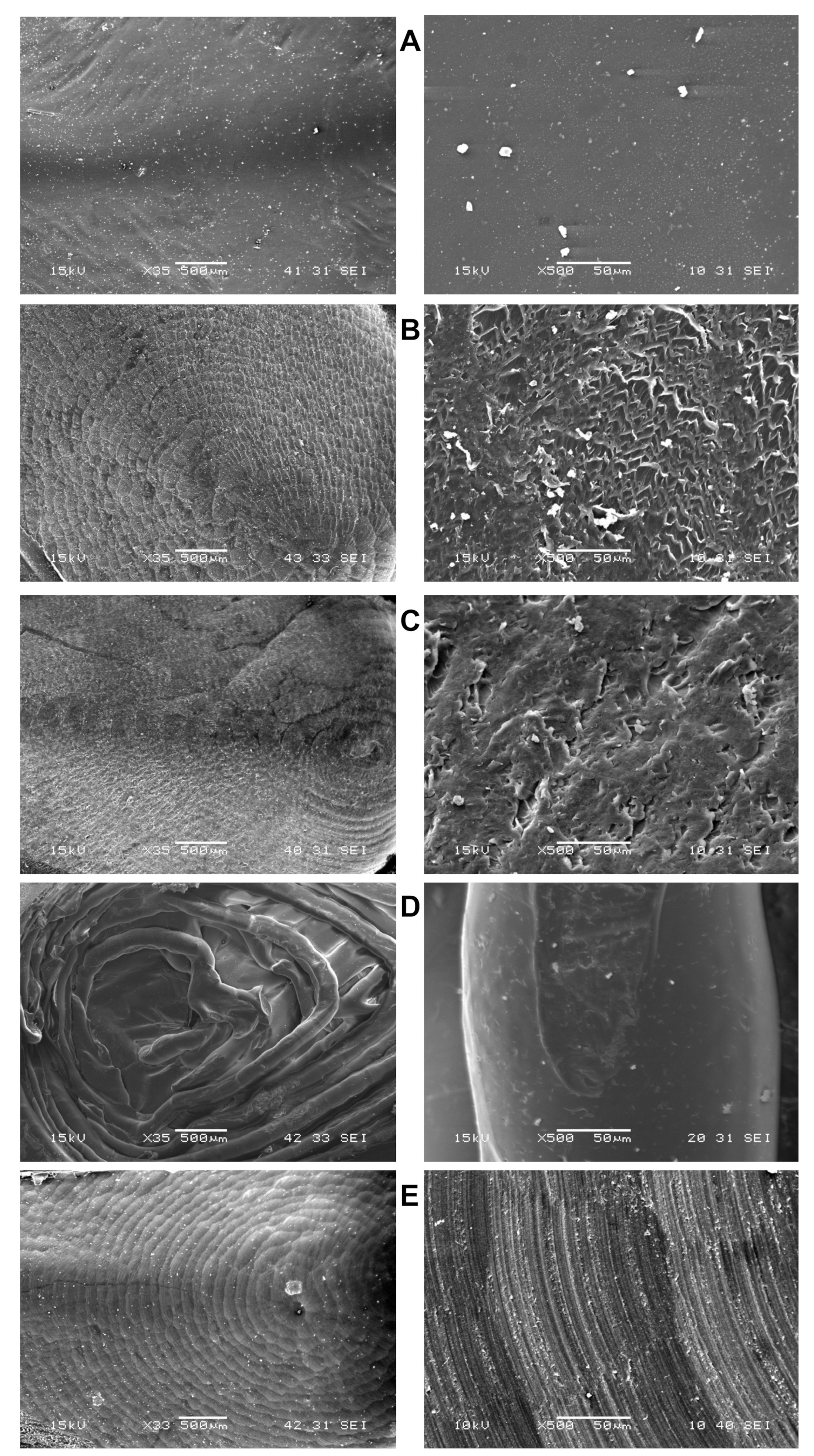

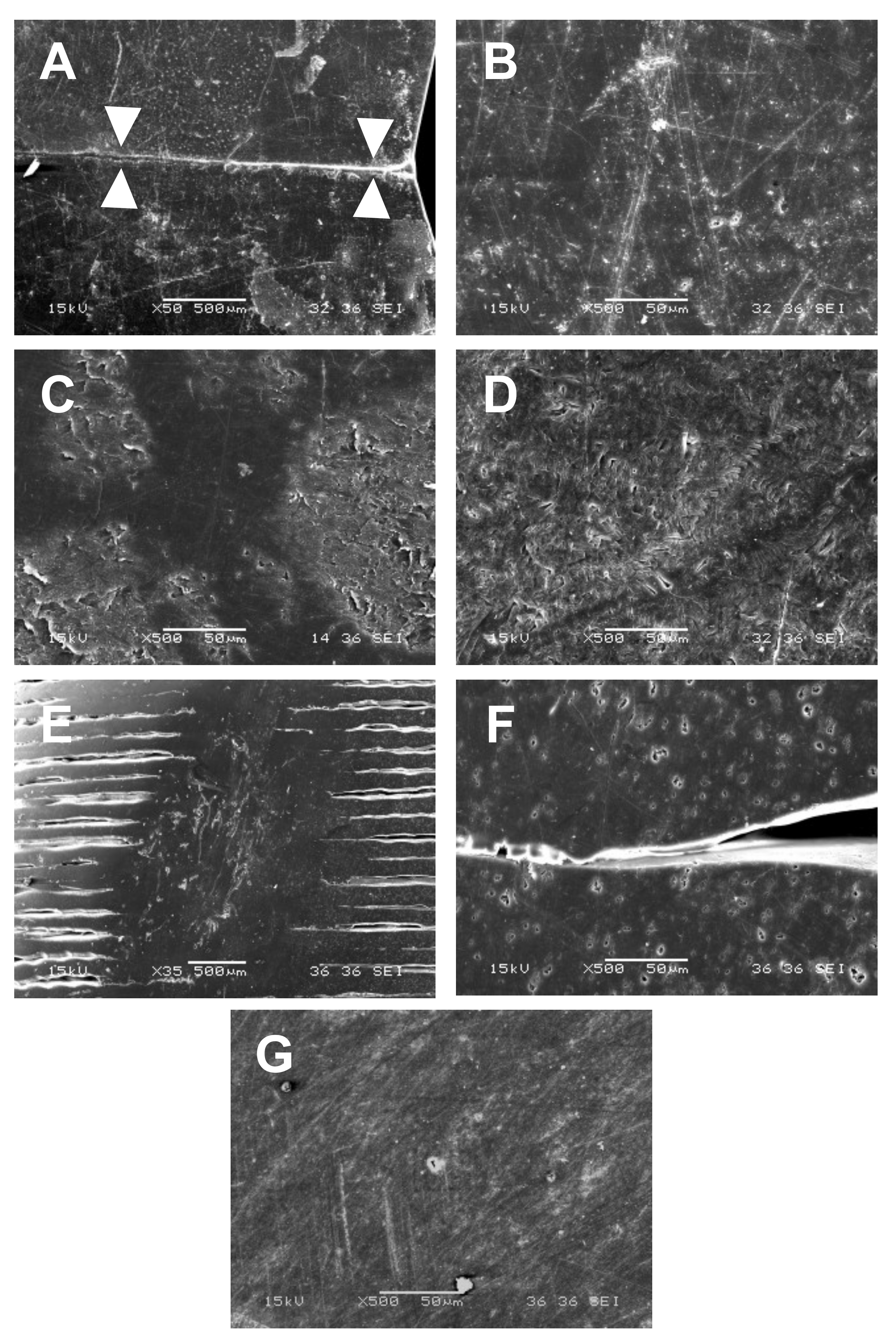

2.5. Morphological Analysis

2.6. Statistical Analysis

3. Results

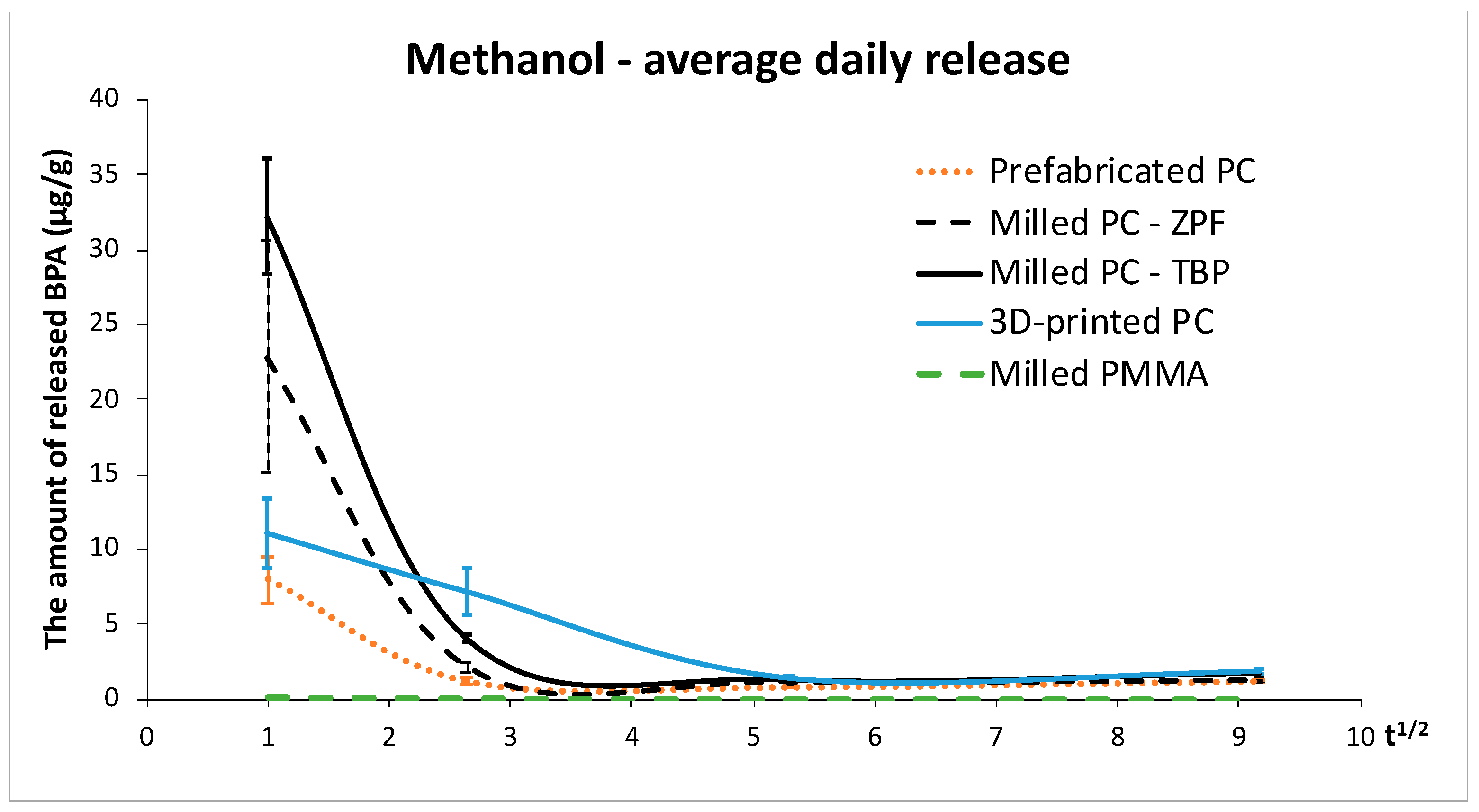

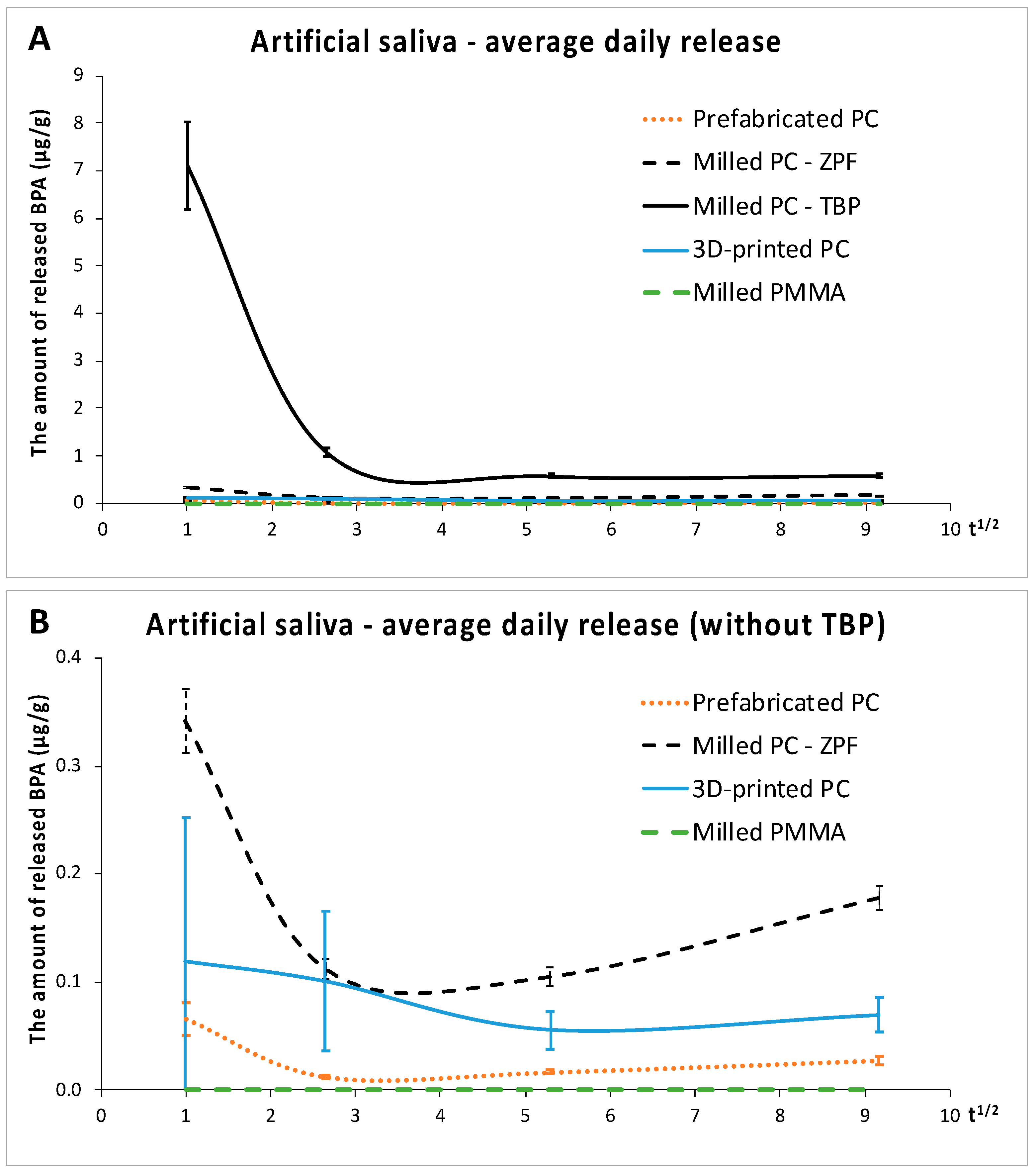

3.1. BPA Release

3.2. Sorption and Amount of Extractable Matter

3.3. Morphological Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Diamanti-Kandarakis, E.; Bourguignon, J.-P.; Giudice, L.C.; Hauser, R.; Prins, G.S.; Soto, A.M.; Zoeller, R.T.; Gore, A.C. Endocrine-Disrupting Chemicals: An Endocrine Society Scientific Statement. Endocr. Rev. 2009, 30, 293–342. [Google Scholar] [CrossRef] [PubMed]

- Vandenberg, L.N.; Maffini, M.V.; Sonnenschein, C.; Rubin, B.S.; Soto, A.M. Bisphenol-A and the great divide: A review of controversies in the field of endocrine disruption. Endocr. Rev. 2009, 30, 75–95. [Google Scholar] [CrossRef] [PubMed]

- Rochester, J.R. Bisphenol A and human health: A review of the literature. Reprod. Toxicol. 2013, 42, 132–155. [Google Scholar] [CrossRef] [PubMed]

- Vandenberg, L.N.; Colborn, T.; Hayes, T.B.; Heindel, J.J.; Jacobs, D.R., Jr.; Lee, D.H.; Shioda, T.; Soto, A.M.; vom Saal, F.S.; Welshons, W.V.; et al. Hormones and endocrine-disrupting chemicals: Low-dose effects and nonmonotonic dose responses. Endocr. Rev. 2012, 33, 378–455. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids. Scientific opinion on the risks to public health related to the presence of bisphenol A (BPA) in foodstuffs. EFSA J. 2015, 13, 3978. [Google Scholar] [CrossRef]

- Olea, N.; Pulgar, R.; Pérez, P.; Olea-Serrano, F.; Rivas, A.; Novillo-Fertrell, A.; Pedraza, V.; Soto, A.M.; Sonnenschein, C. Estrogenicity of resin-based composites and sealants used in dentistry. Environ. Health Perspect. 1996, 104, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Habib, C.M.; Kugel, G. Estrogenicity of resin-based composites and sealants in dentistry. Environ. Health Perspect. 1996, 104, 808. [Google Scholar] [CrossRef]

- Imai, Y. Comments on “Determination of bisphenol A and related aromatic compounds released from bis-GMA-based composites and sealants by high performance liquid chromatography”. Environ. Health Perspect. 2000, 108, A545–A546. [Google Scholar] [CrossRef]

- Löfroth, M.; Ghasemimehr, M.; Falk, A.; Vult von Steyern, P. Bisphenol A in dental materials—Existence, leakage and biological effects. Heliyon 2019, 5, e01711. [Google Scholar] [CrossRef]

- Kechagias, K.; Anastasaki, P.; Kyriakidou, M.; Dedi, K.D. Bisphenol A in Dentistry. Eur. J. Prosthodont. Restor. Dent. 2020, 28, 3–9. [Google Scholar] [CrossRef]

- Testai, E.; Epstein, M.; Emri, I.; Hartemann, P.; Hoet, P.; Leitgeb, N.; Martínez Martinez, L.; Proykova, A.; Rizzo, L.; Rodriguez-Farré, E.; et al. The safety of the use of bisphenol A in medical devices. Regul. Toxicol. Pharmacol. 2016, 79, 106–107. [Google Scholar] [CrossRef]

- Van Landuyt, K.L.; Nawrot, T.; Geebelen, B.; De Munck, J.; Snauwaert, J.; Yoshihara, K.; Scheers, H.; Godderis, L.; Hoet, P.; Van Meerbeek, B. How much do resin-based dental materials release? A meta-analytical approach. Dent. Mater. 2011, 27, 723–747. [Google Scholar] [CrossRef]

- Soderholm, K.J.; Mariotti, A. BIS-GMA--based resins in dentistry: Are they safe? J. Am. Dent. Assoc. 1999, 130, 201–209. [Google Scholar] [CrossRef]

- De Nys, S.; Duca, R.C.; Vervliet, P.; Covaci, A.; Boonen, I.; Elskens, M.; Vanoirbeek, J.; Godderis, L.; Van Meerbeek, B.; Van Landuyt, K.L. Bisphenol A as degradation product of monomers used in resin-based dental materials. Dent. Mater. 2021, 37, 1020–1029. [Google Scholar] [CrossRef]

- Suzuki, K.; Ishikawa, K.; Sugiyama, K.; Furuta, H.; Nishimura, F. Content and Release of Bisphenol A from Polycarbonate Dental Products. Dent. Mater. J. 2000, 19, 389–395. [Google Scholar] [CrossRef]

- Watanabe, M.; Hase, T.; Imai, Y. Change in the Bisphenol A Content in a Polycarbonate Orthodontic Bracket and Its Leaching Characteristics in Water. Dent. Mater. J. 2001, 20, 353–358. [Google Scholar] [CrossRef]

- Watanabe, M. Degradation and formation of bisphenol A in polycarbonate used in dentistry. J. Med. Dent. Sci. 2004, 51, 1–6. [Google Scholar] [CrossRef]

- Edelhoff, D.; Schweiger, J.; Prandtner, O.; Trimpl, J.; Stimmelmayr, M.; Güth, J.F. CAD/CAM splints for the functional and esthetic evaluation of newly defined occlusal dimensions. Quintessence Int. 2017, 48, 181–191. [Google Scholar] [CrossRef]

- Bradna, P.; Vrbova, R.; Fialova, V.; Housova, D.; Gojisova, E. Formation of protective deposits by anti-erosive toothpastes—A microscopic study on enamel with artificial defects. Scanning 2016, 38, 380–388. [Google Scholar] [CrossRef][Green Version]

- Vitku, J.; Chlupacova, T.; Sosvorova, L.; Hampl, R.; Hill, M.; Heracek, J.; Bicikova, M.; Starka, L. Development and validation of LC-MS/MS method for quantification of bisphenol A and estrogens in human plasma and seminal fluid. Talanta 2015, 140, 62–67. [Google Scholar] [CrossRef]

- Kolatorova Sosvorova, L.; Chlupacova, T.; Vitku, J.; Vlk, M.; Heracek, J.; Starka, L.; Saman, D.; Simkova, M.; Hampl, R. Determination of selected bisphenols, parabens and estrogens in human plasma using LC-MS/MS. Talanta 2017, 174, 21–28. [Google Scholar] [CrossRef]

- Simkova, M.; Tichy, A.; Duskova, M.; Bradna, P. Dental composites—A low-dose source of bisphenol A? Phys. Res. 2020, 69, S295–S304. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021; Available online: http://www.r-project.org/ (accessed on 7 May 2021).

- De Nys, S.; Putzeys, E.; Vervliet, P.; Covaci, A.; Boonen, I.; Elskens, M.; Vanoirbeek, J.; Godderis, L.; Van Meerbeek, B.; Van Landuyt, K.L.; et al. A novel high sensitivity UPLC-MS/MS method for the evaluation of bisphenol A leaching from dental materials. Sci. Rep. 2018, 8, 6981. [Google Scholar] [CrossRef]

- Polydorou, O.; König, A.; Hellwig, E.; Kümmerer, K. Long-term release of monomers from modern dental-composite materials. Eur. J. Oral Sci. 2009, 117, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Imai, Y.; Komabayashi, T. Elution of Bisphenol A from Composite Resin: A Model Experiment. Dent. Mater. J. 2000, 19, 133–138. [Google Scholar] [CrossRef] [PubMed]

- Becher, R.; Wellendorf, H.; Sakhi, A.K.; Samuelsen, J.T.; Thomsen, C.; Bølling, A.K.; Kopperud, H.M. Presence and leaching of bisphenol a (BPA) from dental materials. Acta Biomater. Odontol. Scand. 2018, 4, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Bair, H.E.; Falcone, D.R.; Hellman, M.Y.; Johnson, G.E.; Kelleher, P.G. Hydrolysis of polycarbonate to yield BPA. J. Appl. Polym. Sci. 1981, 26, 1777–1786. [Google Scholar] [CrossRef]

- Golovoy, A.; Zinbo, M. Water sorption and hydrolytic stability of polycarbonates. Polym. Eng. Sci. 1989, 29, 1733–1737. [Google Scholar] [CrossRef]

- Brunelle, D.J. Polycarbonates. In Encyclopedia of Polymer Science and Technology, 4th ed.; Mark, H.F., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Yoo, Y.-E.; Woo, S.-W.; Kim, S.K. Injection molding without prior drying process by the gas counter pressure. Polym. Eng. Sci. 2012, 52, 2417–2423. [Google Scholar] [CrossRef]

- Lin, R.; Yu, C.-H.; Sun, J. Mechanical properties and cytotoxicity of three-dimensional printing polycarbonate for occlusal splints. Shanghai Kou Qiang Yi Xue 2019, 28, 467–471. [Google Scholar]

- Hamanaka, I.; Iwamoto, M.; Lassila, L.; Vallittu, P.; Shimizu, H.; Takahashi, Y. Influence of water sorption on mechanical properties of injection-molded thermoplastic denture base resins. Acta Odontol. Scand. 2014, 72, 859–865. [Google Scholar] [CrossRef]

| Material | 1 Day (Day 1) | 1 Week (Days 2–7) | 1 Month (Days 8–28) | 3 Months (Days 29–84) |

|---|---|---|---|---|

| Methanol | ||||

| Prefabricated polycarbonate crowns | 8.0 ± 1.6 bA * | 1.2 ± 0.2 bB * | 0.80 ± 0.11 bC * | 1.2 ± 0.1 bB * |

| Milled Zirkonzahn Temp Premium Flexible (ZPF) | 22.8 ± 7.7 cA * | 2.1 ± 0.3 cB * | 1.1 ± 0.2 bcC * | 1.2 ± 0.06 bC * |

| Milled Tizian Blank Polycarbonate (TBP) | 32.2 ± 3.8 dA * | 4.0 ± 0.3 dB * | 1.3 ± 0.2 cC * | 1.7 ± 0.3 cD * |

| 3D-printed crowns | 11.1 ± 2.3 bA * | 7.2 ± 1.6 eB * | 1.4 ± 0.2 cC * | 1.9 ± 0.2 cD * |

| Milled Zirkonzahn Temp Basic (PMMA) | 0.04 ± 0.03 aA * | 0.02 ± 0.01 aA * | 0.00 ± 0.00 aB | 0.00 ± 0.00 aB |

| Artificial Saliva | ||||

| Prefabricated polycarbonate crowns | 0.07 ± 0.02 bA * | 0.01 ± 0.00 bB * | 0.02 ± 0.00 bBC * | 0.03 ± 0.00 bC * |

| Milled Zirkonzahn Temp Premium Flexible (ZPF) | 0.34 ± 0.03 cA * | 0.11 ± 0.01 cB * | 0.11 ± 0.01 dB * | 0.18 ± 0.01 dC * |

| Milled Tizian Blank Polycarbonate (TBP) | 7.1 ± 0.9 dA * | 1.1 ± 0.1 dB * | 0.58 ± 0.04 eC * | 0.59 ± 0.05 eC * |

| 3D-printed crowns | 0.12 ± 0.13 bA * | 0.10 ± 0.07 cA * | 0.06 ± 0.02 cA * | 0.07 ± 0.02 cA * |

| Milled Zirkonzahn Temp Basic (PMMA) | 0.00 ± 0.00 aA * | 0.00 ± 0.00 aA * | 0.00 ± 0.00 aA | 0.00 ± 0.00 aA |

| Material | Sorption | Amount of Extractable Matter |

|---|---|---|

| Prefabricated polycarbonate crowns | 3.9 ± 0.8 b | 1.7 ± 1.0 ab |

| Milled Zirkonzahn Temp Premium Flexible (ZPF) | 2.7 ± 0.5 a | 3.2 ± 0.5 b |

| Milled Tizian Blank Polycarbonate (TBP) | 2.8 ± 1.0 ab | 2.9 ± 1.2 ab |

| 3D-printed crowns | 15.5 ± 1.8 c | 1.3 ± 1.0 a |

| Milled Zirkonzahn Temp Basic (PMMA) | 17.2 ± 0.8 c | 2.7 ± 0.9 ab |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tichy, A.; Simkova, M.; Schweiger, J.; Bradna, P.; Güth, J.-F. Release of Bisphenol A from Milled and 3D-Printed Dental Polycarbonate Materials. Materials 2021, 14, 5868. https://doi.org/10.3390/ma14195868

Tichy A, Simkova M, Schweiger J, Bradna P, Güth J-F. Release of Bisphenol A from Milled and 3D-Printed Dental Polycarbonate Materials. Materials. 2021; 14(19):5868. https://doi.org/10.3390/ma14195868

Chicago/Turabian StyleTichy, Antonin, Marketa Simkova, Josef Schweiger, Pavel Bradna, and Jan-Frederik Güth. 2021. "Release of Bisphenol A from Milled and 3D-Printed Dental Polycarbonate Materials" Materials 14, no. 19: 5868. https://doi.org/10.3390/ma14195868

APA StyleTichy, A., Simkova, M., Schweiger, J., Bradna, P., & Güth, J.-F. (2021). Release of Bisphenol A from Milled and 3D-Printed Dental Polycarbonate Materials. Materials, 14(19), 5868. https://doi.org/10.3390/ma14195868