The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars

Abstract

:1. Introduction

2. Materials and Methods

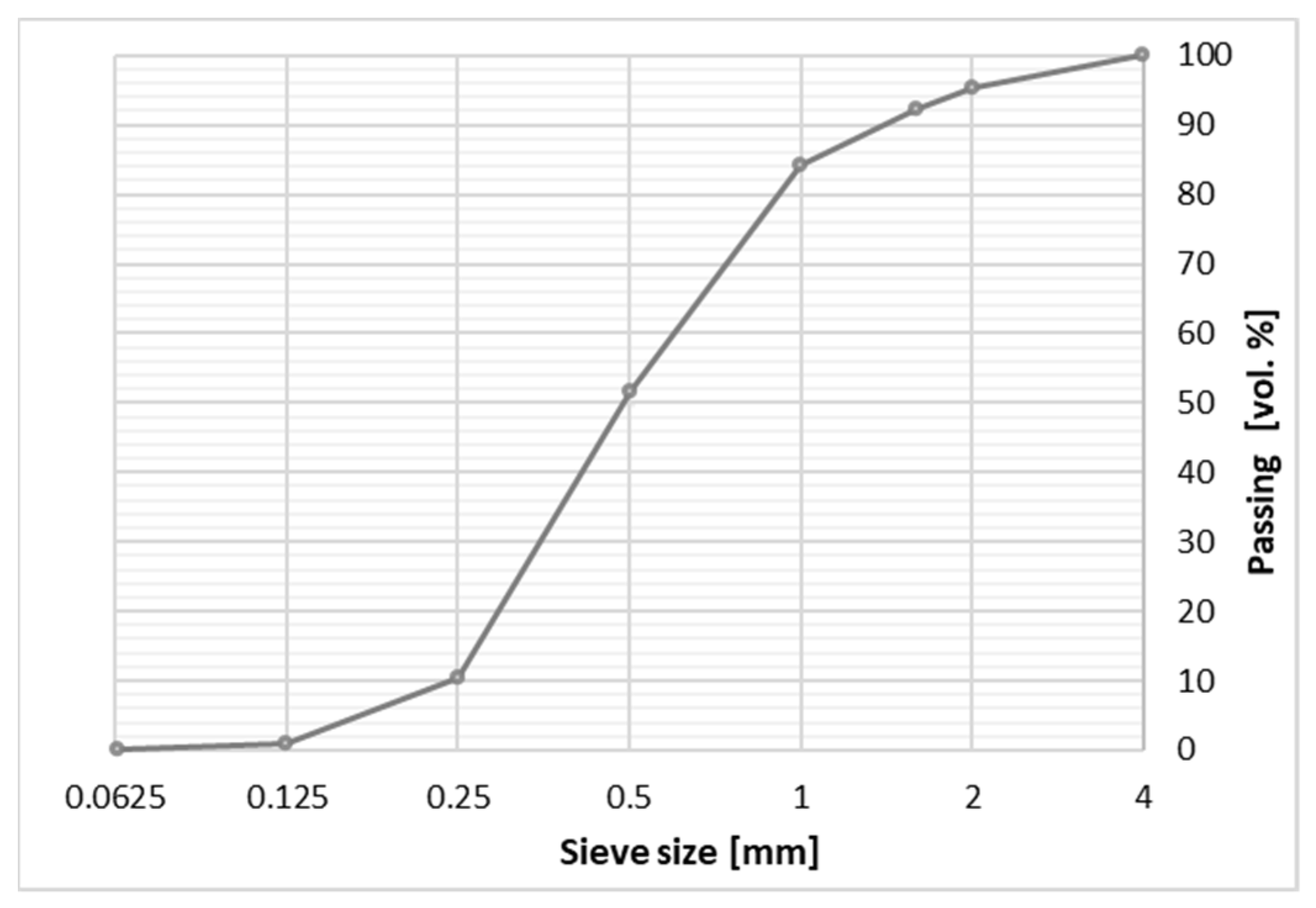

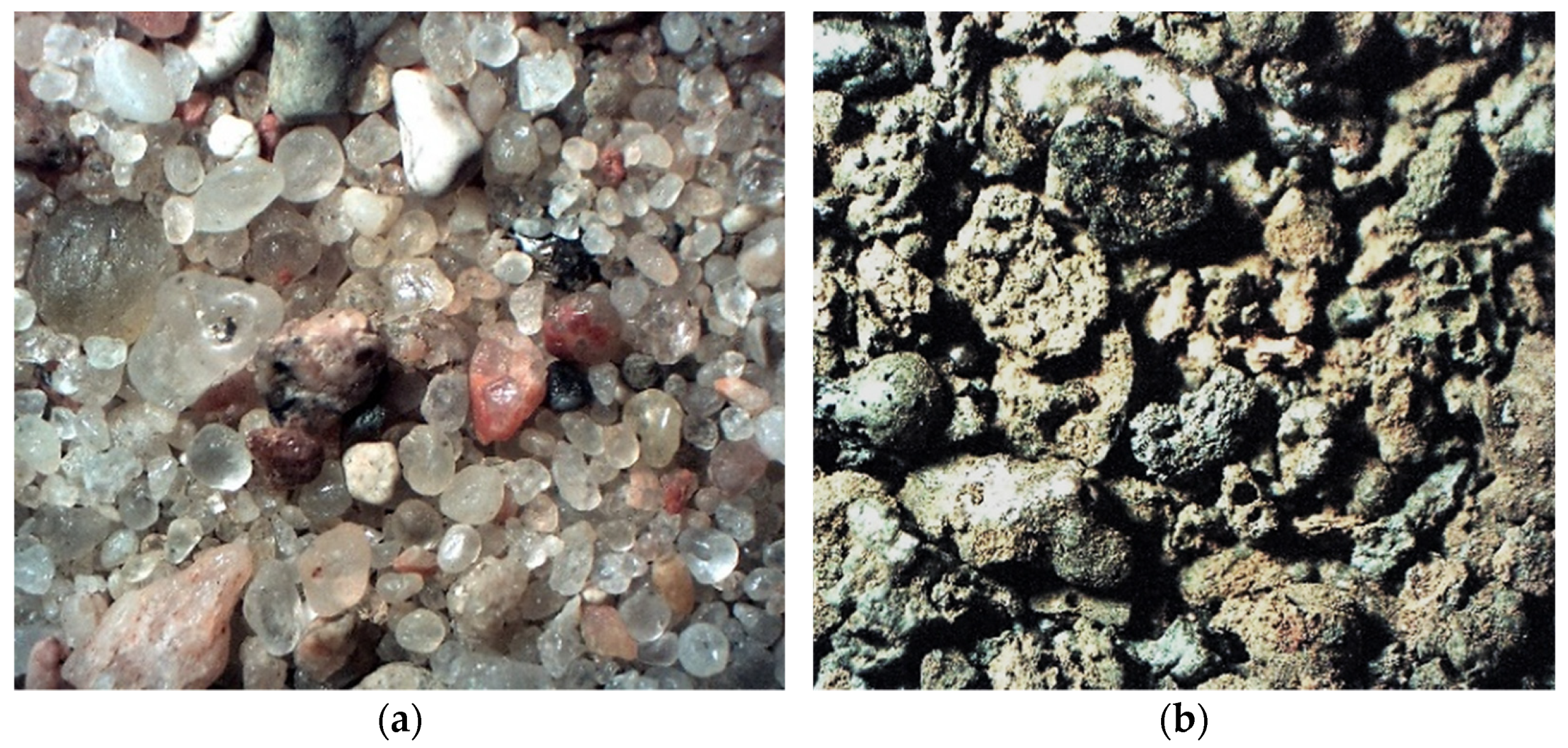

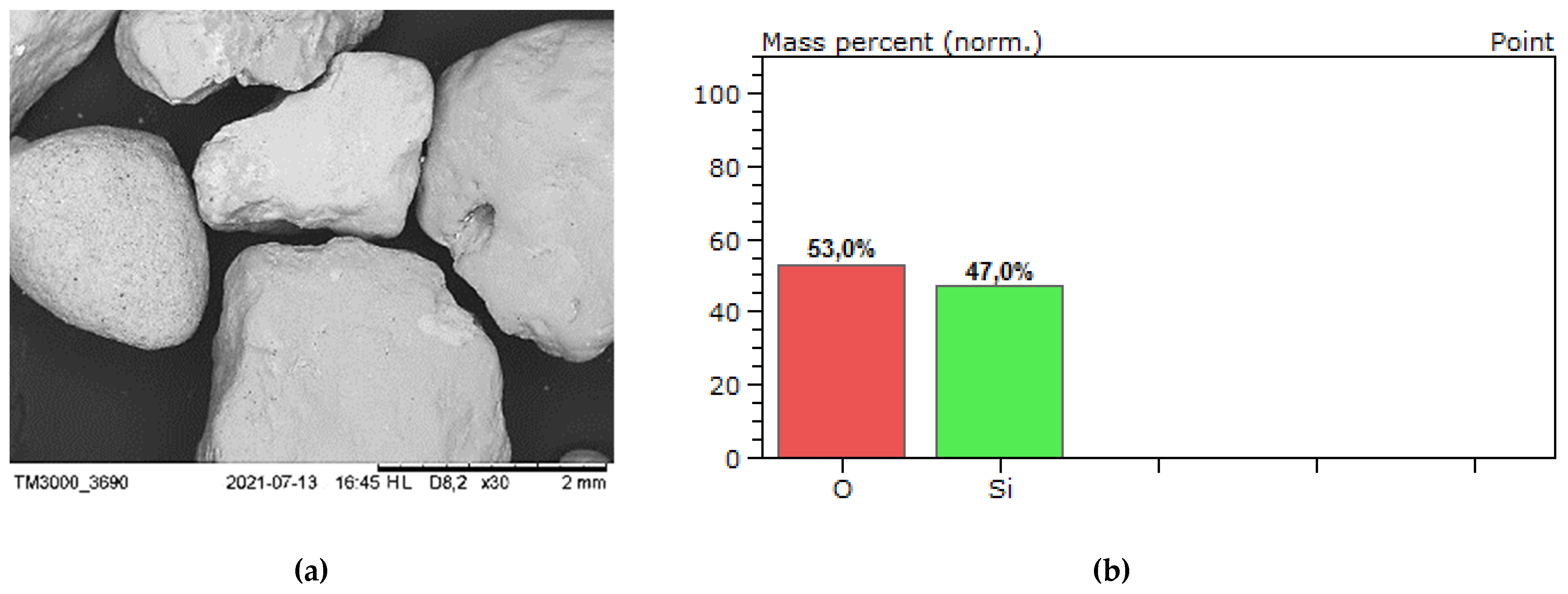

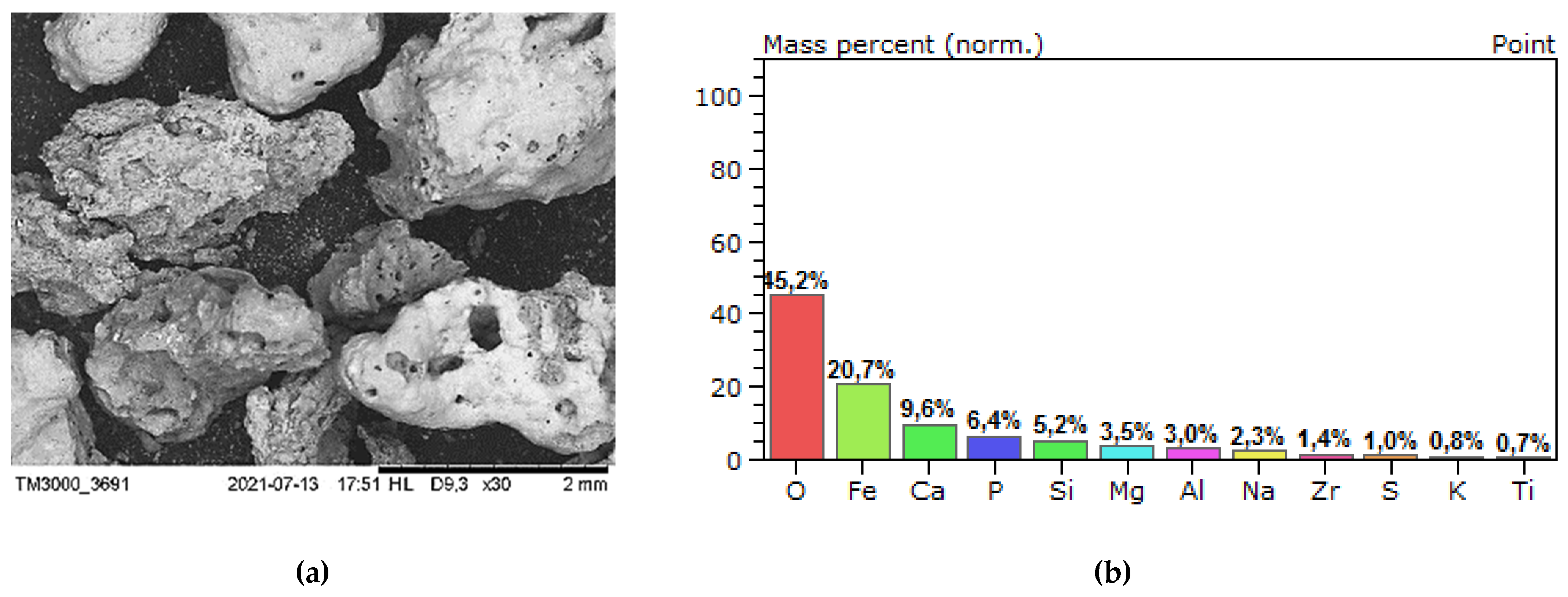

2.1. Materials

2.2. Mix Preparation

3. Results and Discussion

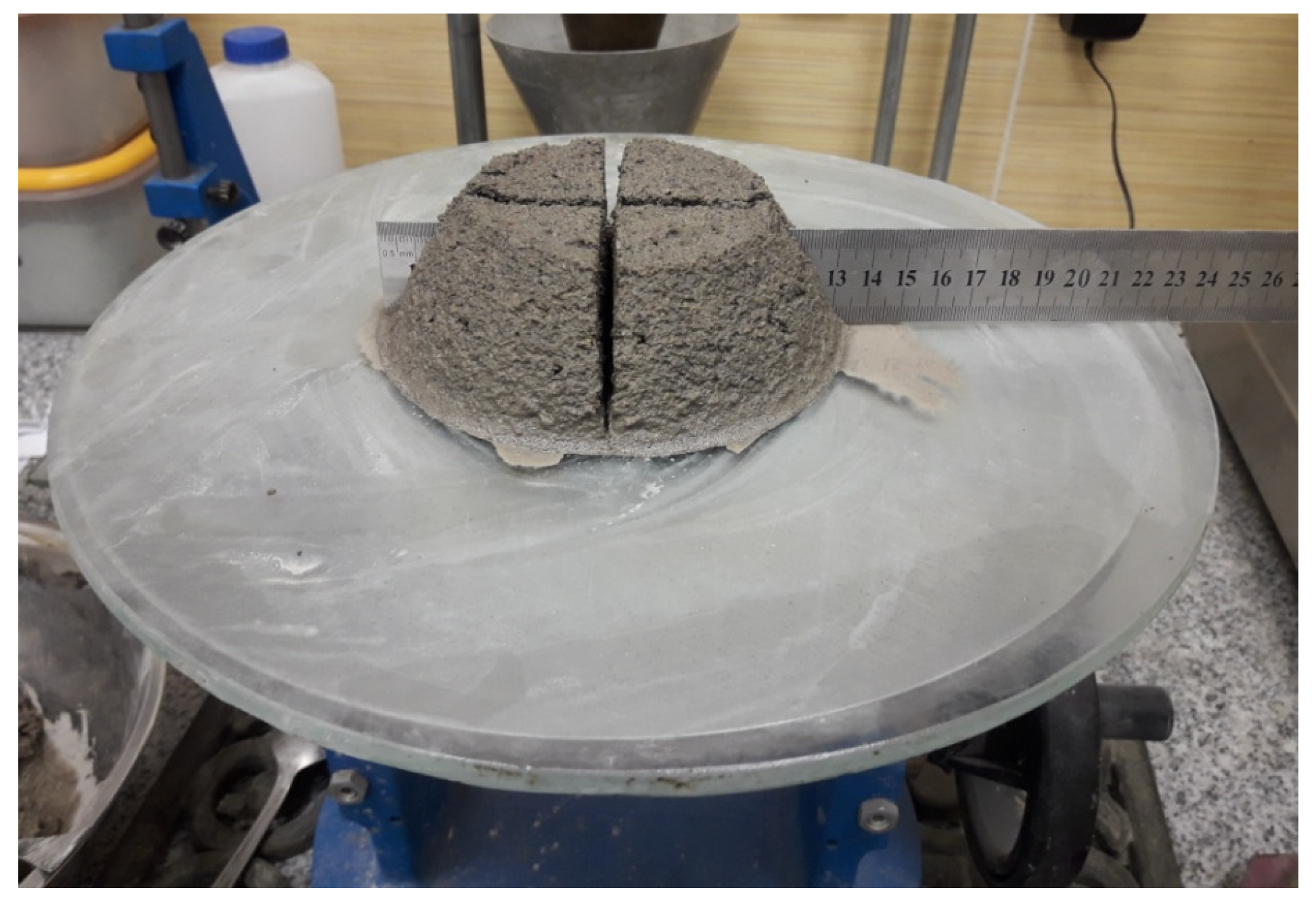

3.1. Fresh Mortar Consistency

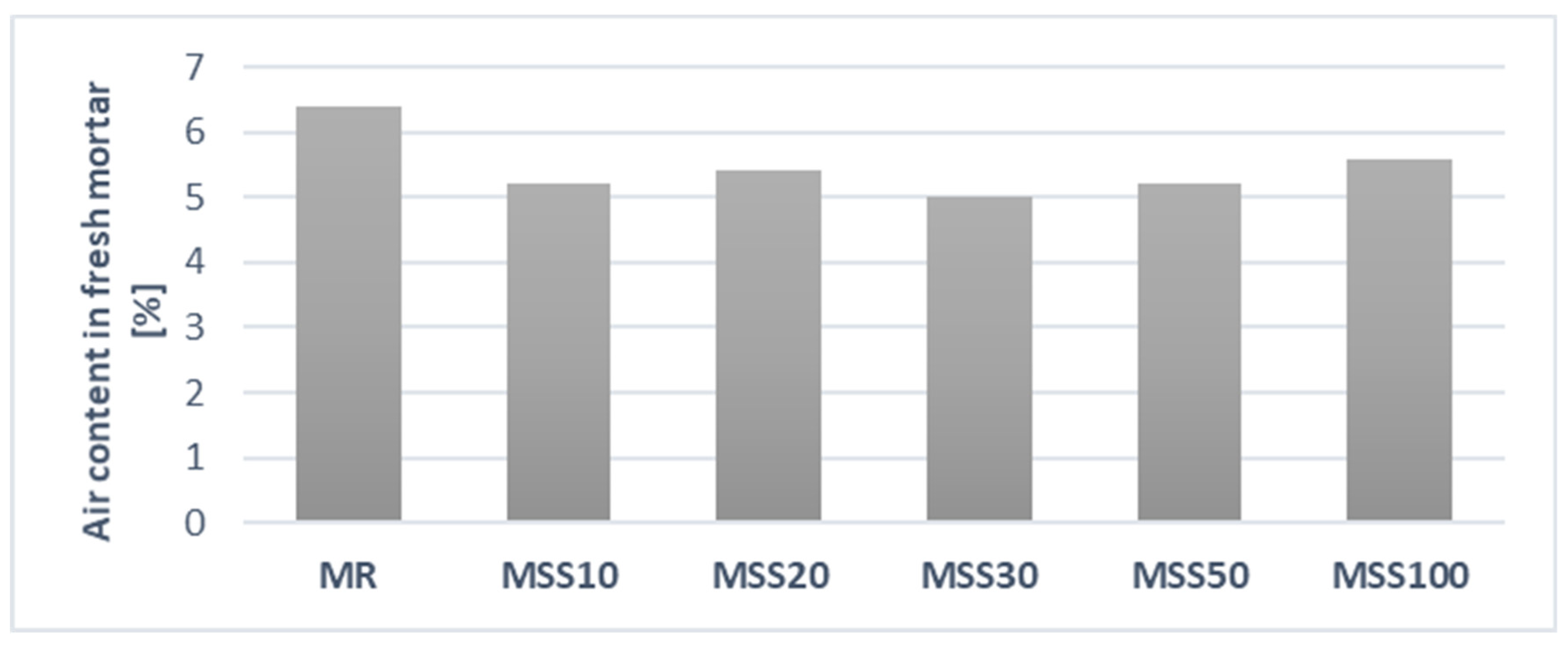

3.2. Air Content in Fresh Mortar

3.3. Sample Molding

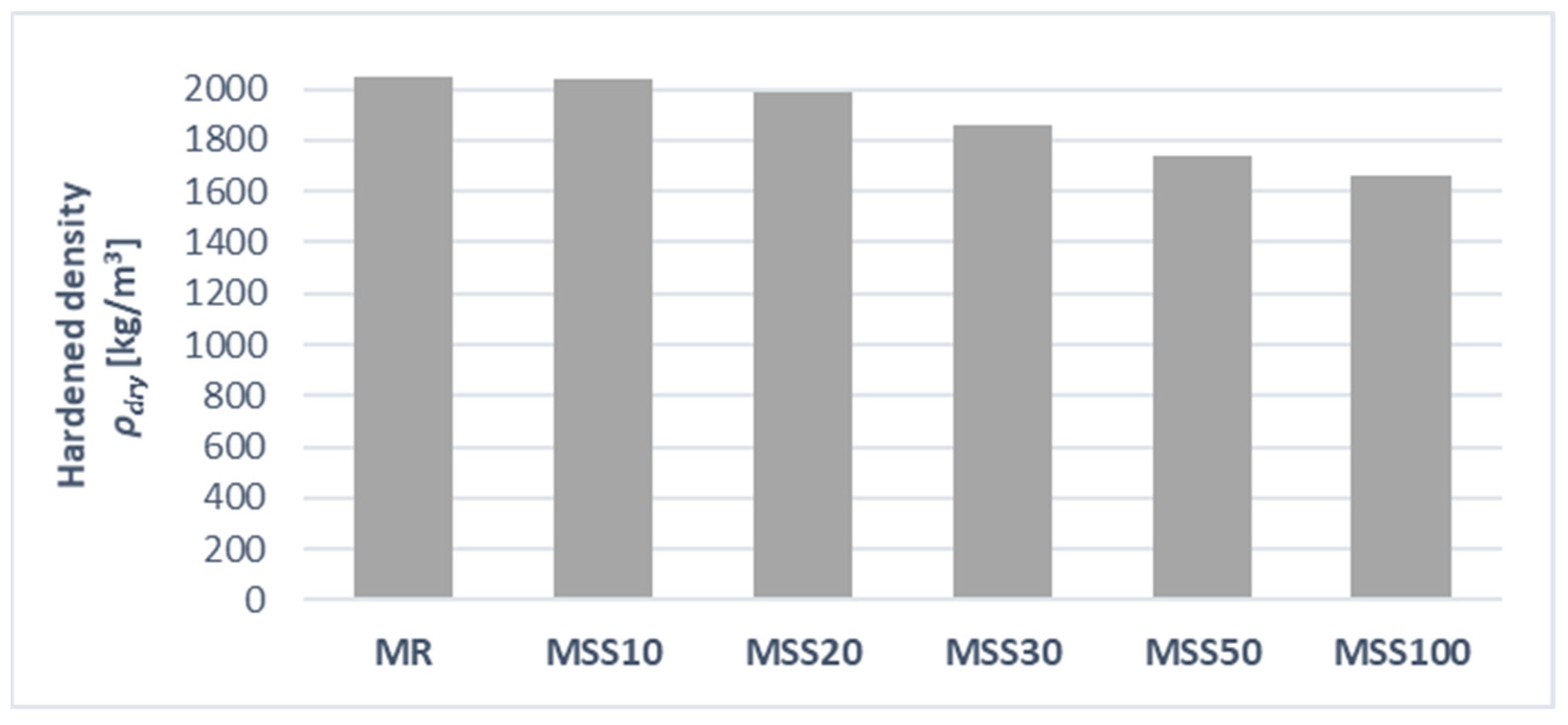

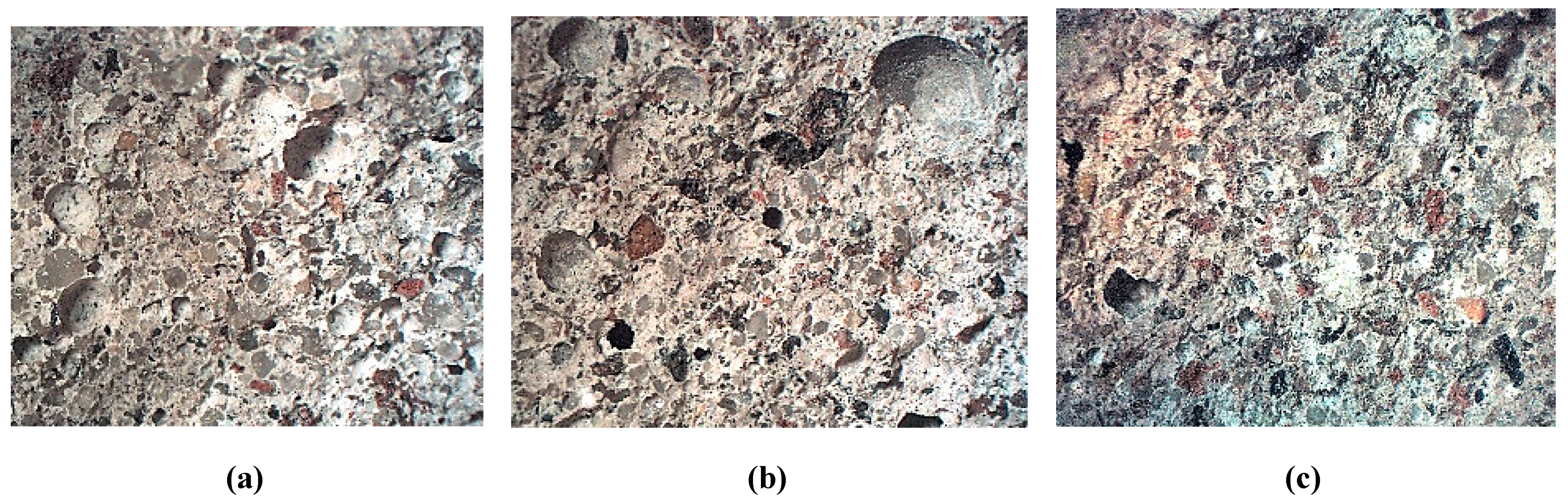

3.4. Dry-Hardened Density

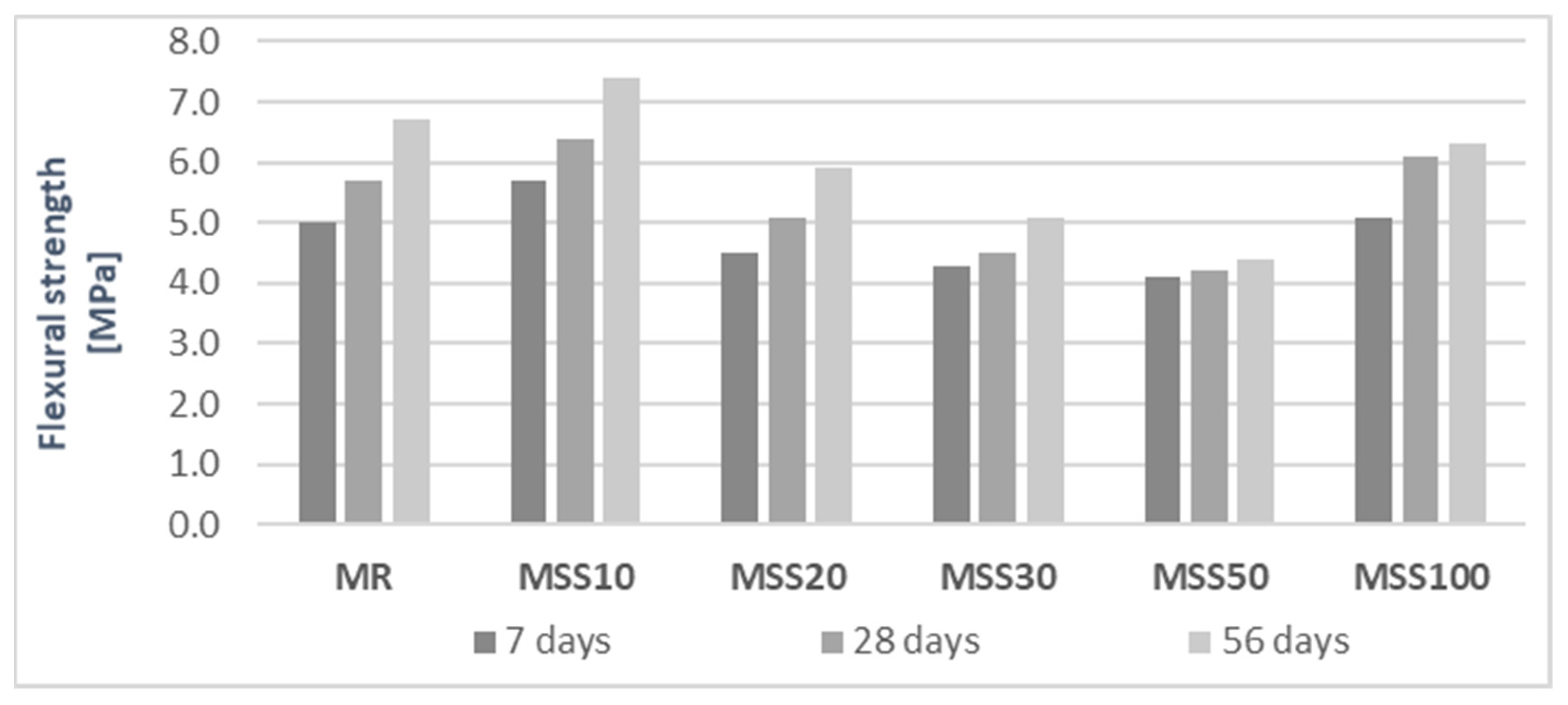

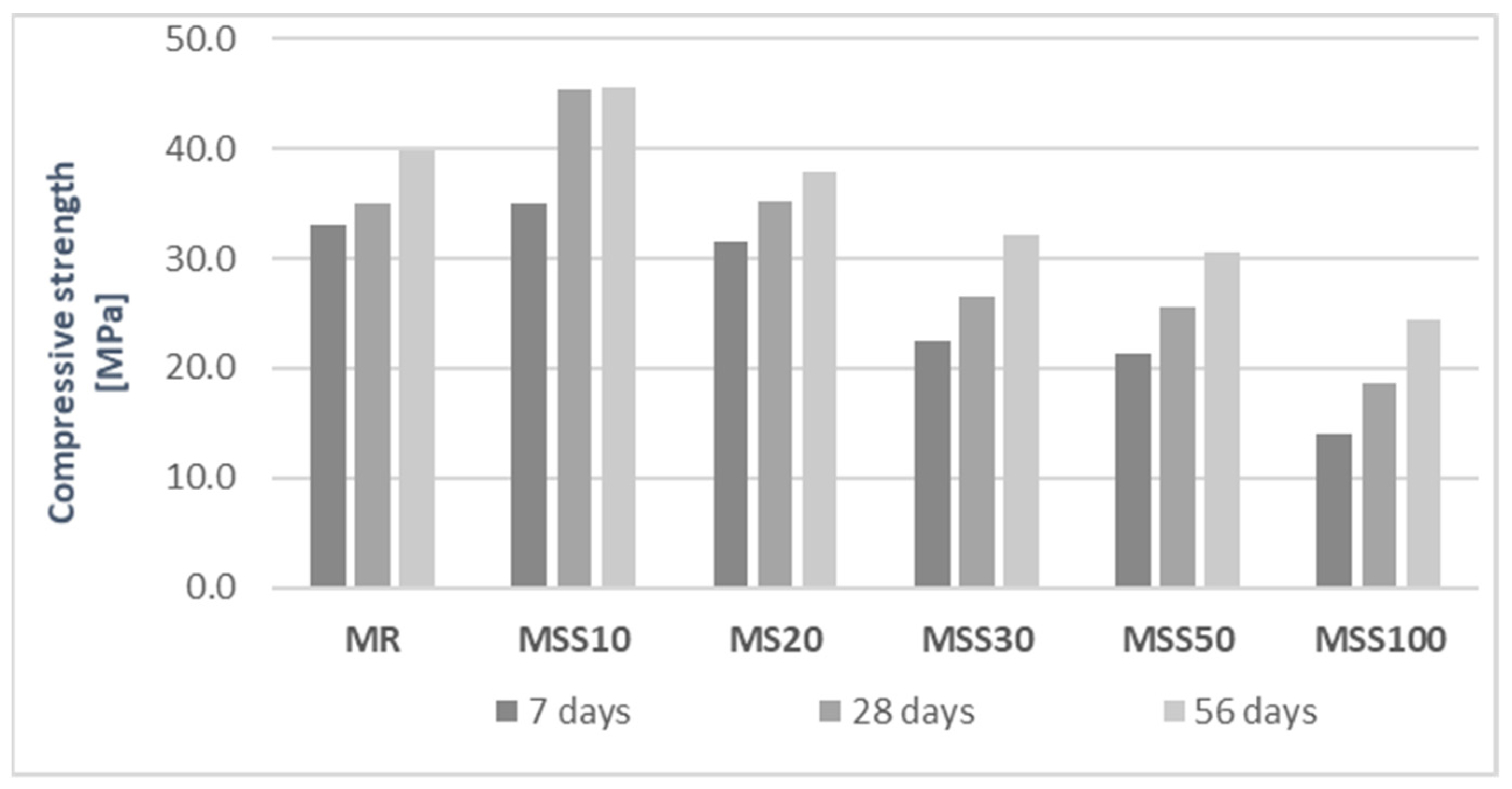

3.5. Mortar Strength

3.6. Thermal Conductivity Coefficient

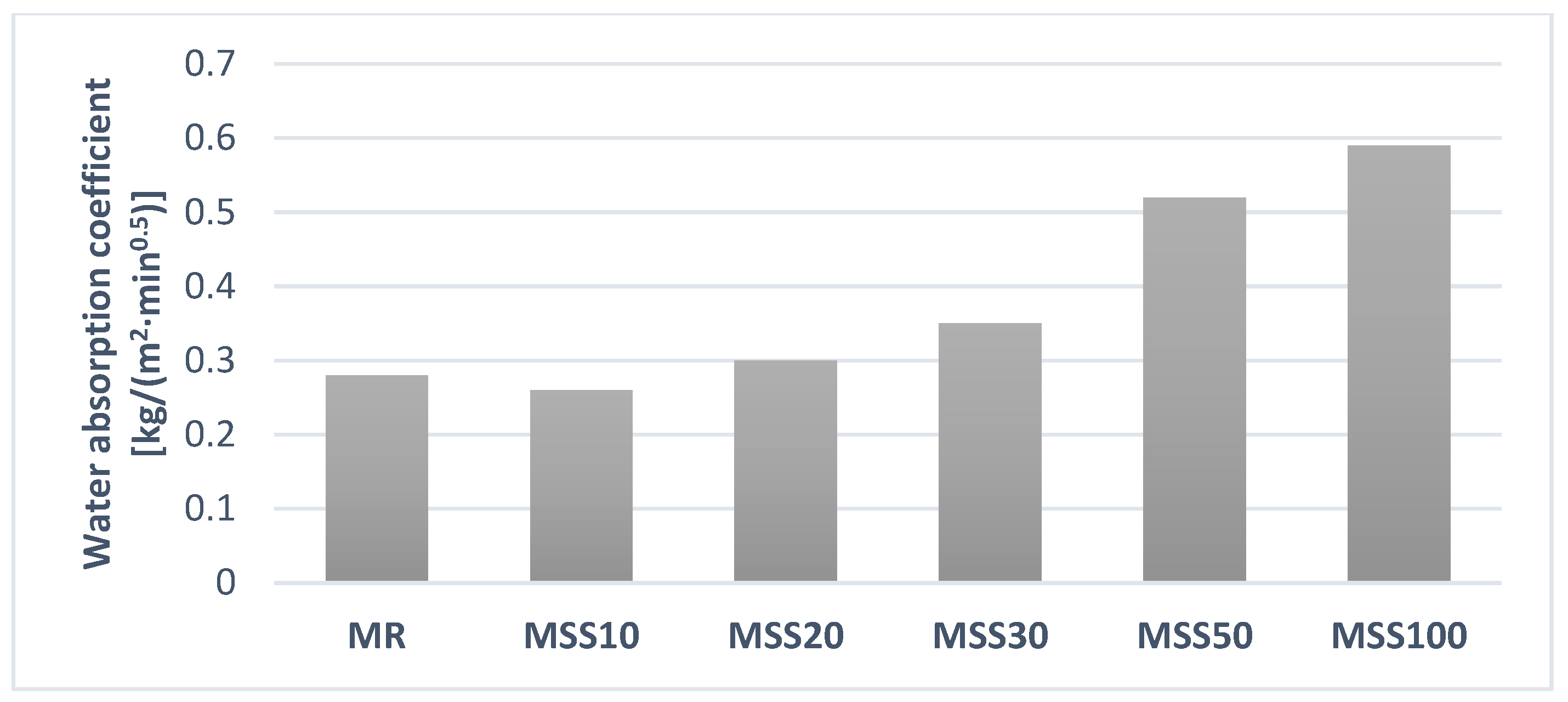

3.7. Water Absorpion Due to Capillary Action

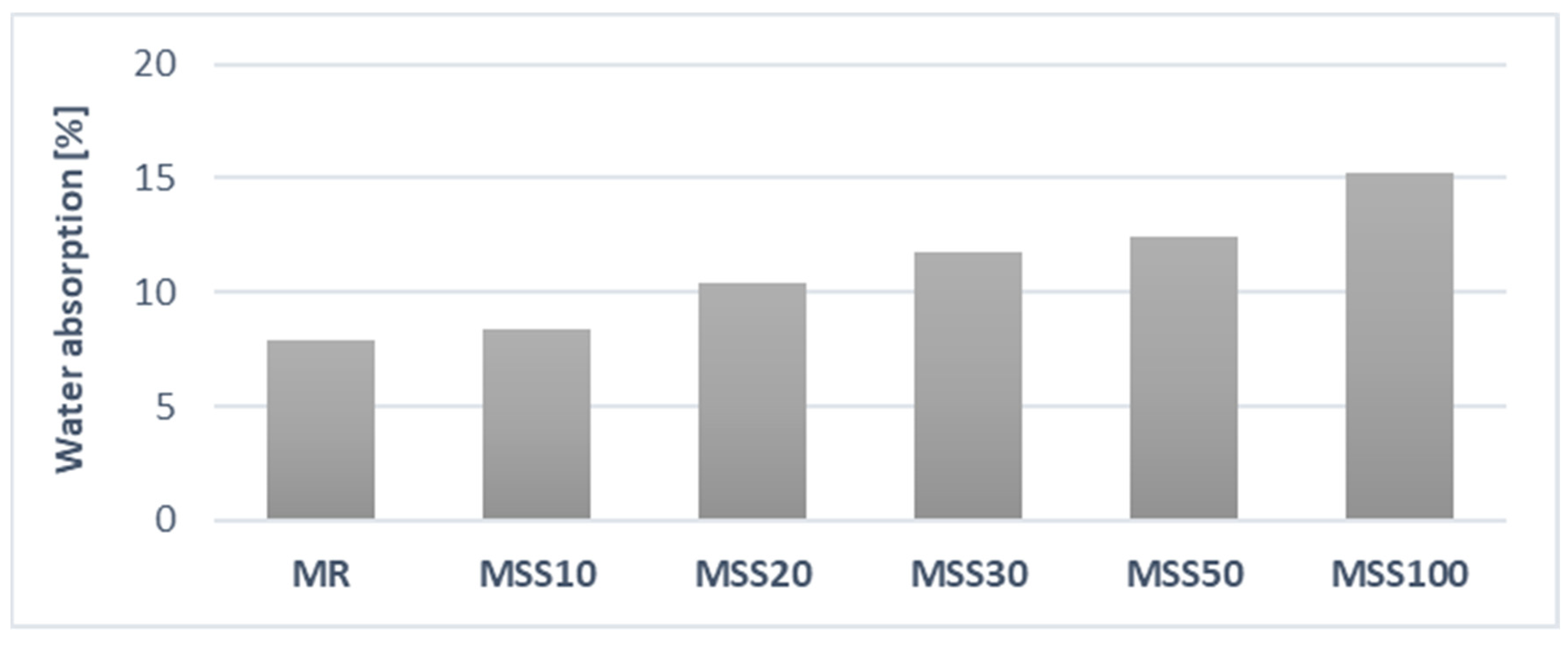

3.8. Water Absorption

4. Conclusion

- Waste aggregate obtained from incineration of municipal sewage sludge, can be a valuable component of mortars. All analyzed mortars showed suitability for construction purposes.

- The porous structure and open pores of the waste aggregate results in significant absorption of batch water during mortar mixing, which requires adding additional water experimentally to obtain the desired consistency. This was not observed for 10% of aggregate replacement.

- In mortars with waste aggregate, a favorable relation between flexural and compressive strengths was observed, which translates into increased strength of the interfacial transition zone.

- The strength of the mortars allows them to be categorize in accordance with EN 998-1 and EN-998-2. As the proportion of waste aggregate increases, the compressive strength of MSS20-MSS100 mortars decreases rapidly.

- Water absorption coefficient of mortars increases with the increase of the porous waste aggregate.

- A significant increase in water absorption was observed for mortars containing high amounts of waste aggregate, which is directly related to its porous structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Kropyvnytska, T.; Sanytsky, M.; Rucińska, T.; Rykhlitska, O. Development of nanomodified rapid hardening clinker-efficient concretes based on composite Portland cements. EEJET 2019, 6, 38–48. [Google Scholar] [CrossRef]

- Rucińska, T. Sustainable cement mortars. E3S Web Conf. 2018, 49, 90. [Google Scholar] [CrossRef]

- Rucińska, T. Use of Sustainable Fine-Grain Aggregates in Cement Composites. J. Ecol. Eng. 2019, 20, 102–109. [Google Scholar] [CrossRef]

- Donatello, S.; Cheeseman, C.R. Recycling and recovery routes for incinerated sewage sludge ash (ISSA): A review. Waste Manag. 2013, 33, 2328–2340. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal Properties of Cement Mortars Containing Waste Glass Aggregate and Nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Skoczylas, K.; Rucińska, T. Influence of Grain Shape of Waste Glass Aggregate on the Properties of Cement Mortar. J. Ecol. Eng. 2020, 21, 148–159. [Google Scholar] [CrossRef]

- Salihoglu, G.; Mardani-Aghabaglou, A. Characterization of sewage sludge incineration ashes from multi-cyclones and baghouse dust filters as possible cement substitutes. Environ. Sci. Pollut. Res. Int. 2021, 28, 645–663. [Google Scholar] [CrossRef] [PubMed]

- Sänger, M.; Werther, J.; Ogada, T. NOx and N2O emission characteristics from fluidised bed combustion of semi-dried municipal sewage sludge. Fuel 2001, 80, 167–177. [Google Scholar] [CrossRef]

- Sanytsky, M.; Kropyvnytska, T.; Ivashchyshyn, H.; Rykhlitska, O. Eco-efficient blended cements with high volume supplementary cementitious materials. Bud-Architektura 2020, 18, 5–14. [Google Scholar] [CrossRef]

- Chin, S.C.; Shu Ing, D.; Kusbiantoro, A.; Wan Ahmad, S. Characterization of sewage sludge ASH (SSA) in cement mortar. J. Eng. Appl. Sci. 2016, 11, 2242–2247. [Google Scholar]

- Chang, F.C.; Lin, J.D.; Tsai, C.C.; Wang, K.S. Study on cement mortar and concrete made with sewage sludge ash. Water Sci. Technol. 2010, 62, 1689–1693. [Google Scholar] [CrossRef] [PubMed]

- Cyr, M.; Coutand, M.; Clastres, P. Technological and environmental behavior of sewage sludge ash (SSA) in cement-based materials. Cem. Concr. Res. 2007, 37, 1278–1289. [Google Scholar] [CrossRef]

- Pan, S.-C.; Tseng, D.-H.; Lee, C.-C.; Lee, C. Influence of the fineness of sewage sludge ash on the mortar properties. Cem. Concr. Res. 2003, 33, 1749–1754. [Google Scholar] [CrossRef]

- Garcés, P.; Pérez Carrión, M.; García-Alcocel, E.; Payá, J.; Monzó, J.; Borrachero, M.V. Mechanical and physical properties of cement blended with sewage sludge ash. Waste Manag. 2008, 28, 2495–2502. [Google Scholar] [CrossRef]

- Krejcirikova, B.; Ottosen, L.M.; Kirkelund, G.M.; Rode, R.; Peuhkuri, R. Characterization of sewage sludge ash and its effect on moisture physics of mortar. J. Build. Eng. 2019, 21, 396–403. [Google Scholar] [CrossRef]

- Lin, Y.; Zhou, S.; Li, F.; Lin, Y. Utilization of municipal sewage sludge as additives for the production of eco-cement. J. Hazard. Mater. 2012, 213–214, 457–465. [Google Scholar] [CrossRef] [PubMed]

- Głowacka, A.; Rucińska, T.; Kiper, J. The slag original from the process of sewage sludge incineration selected properties characteristic. E3S Web Conf. 2017, 22, 54. [Google Scholar] [CrossRef] [Green Version]

- Głowacka, A.; Tarnowski, K.; Bering, S.; Mazur, J.; Kiper, J.; Wołoszyk, C. Energy crops cultivated on the slag from incineration of the sewage sludge energy value assessment. E3S Web Conf. 2017, 22, 55. [Google Scholar] [CrossRef] [Green Version]

- Rutkowska, G.; Wichowski, P.; Franus, M.; Mendryk, M.; Fronczyk, J. Modification of Ordinary Concrete Using Fly Ash from Combustion of Municipal Sewage Sludge. Materials 2020, 13, 487. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Zhang, Y.; Liu, L.; Seetharaman, S.; Wang, X.; Zhang, Z. Integrated Utilization of Sewage Sludge and Coal Gangue for Cement Clinker Products: Promoting Tricalcium Silicate Formation and Trace Elements Immobilization. Materials 2016, 9, 275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mejdi, M.; Saillio, M.; Chaussadent, T.; Divet, L.; Tagnit-Hamou, A. Hydration mechanisms of sewage sludge ashes used as cement replacement. Cem. Concr. Res. 2020, 135, 106115. [Google Scholar] [CrossRef]

- Tkaczewska, E.; Kłosek-Wawrzyn, E. Effect of phosphate PO43− ions on cement hydration. Cem. Lime Concr. 2012, 6, 401–408. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Cement Producers Association: Paddington Station, UK, 2012. [Google Scholar]

- Garbalińska, H.; Strzałkowski, J. Thermal and Strength Properties of Lightweight Concretes with Variable Porosity Structures. J. Mater. Civ. Eng. 2018, 30, 4018326. [Google Scholar] [CrossRef] [Green Version]

- Stolarska, A.; Strzałkowski, J. The Thermal Parameters of Mortars Based on Different Cement Type and W/C Ratios. Materials 2020, 13, 4258. [Google Scholar] [CrossRef] [PubMed]

| Mix | MR | MSS10 | MSS20 | MSS30 | MSS50 | MSS100 |

|---|---|---|---|---|---|---|

| Total W/C Batch water + added water | 0.5 | 0.5 | 0.65 | 0.72 | 0.95 | 1.16 |

| Natural Sand 0–2 mm | Waste Aggregate 0–2 mm | CEM I 42.5 R | Water | MasterGlenium ACE 430 |

|---|---|---|---|---|

| 2.65 | 2.86 | 3.11 | 1.0 | 1.06 |

| Mix | MR | MSS10 | MSS20 | MSS30 | MSS50 | MSS100 |

|---|---|---|---|---|---|---|

| Mean slump [mm] | 135 | 133 | 133 | 133 | 134 | 133 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rucińska, T.; Głowacka, A.; Sidełko, R. The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars. Materials 2021, 14, 5846. https://doi.org/10.3390/ma14195846

Rucińska T, Głowacka A, Sidełko R. The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars. Materials. 2021; 14(19):5846. https://doi.org/10.3390/ma14195846

Chicago/Turabian StyleRucińska, Teresa, Anna Głowacka, and Robert Sidełko. 2021. "The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars" Materials 14, no. 19: 5846. https://doi.org/10.3390/ma14195846

APA StyleRucińska, T., Głowacka, A., & Sidełko, R. (2021). The Influence of Incinerated Sewage Sludge as an Aggregate on the Selected Properties of Cement Mortars. Materials, 14(19), 5846. https://doi.org/10.3390/ma14195846